Abstract

Urban rail transport has advantages that determine its particular usefulness. However, despite decades of technical development, it is still difficult to speak about satisfactory solutions. Safe, independent access to this transport and public infrastructure for passengers with reduced mobility (PRM) is an essential element of civil rights and an interesting subject of scientific research. In relation to that, the interface between rail vehicle and platform, despite multiple efforts aiming at improving this situation, is one of the hardest problems to overcome. This paper presents a summary and analyses of distinctive features of selected transit systems that are interesting from the viewpoint of finding various solutions to improve the safety of passengers on platforms. This analysis led to preparation of a new, improved standard of the vehicle–platform interface, illustrated with an example of the city of Wrocław, as discussed further in this paper. Some of the main conclusions of this paper are that insufficient progress has been made with developing the vehicle–platform interface, there are a multitude of systems and ways of (more or less effectively) ensuring independent access for PRM, and further research and development work is needed to optimize engineering solutions in this domain so they are both sustainable and economical.

1. Introduction

Public transit, especially by rail, has unrivaled positive qualities, which give it an advantage over other means of transport [1]. Foremost among these are safety, a low pollution level, low spending, avoidance of road congestion, and high reliability [2,3]. However, it is possible for rail transport to effectively compete with car transport only with continuous improvements in infrastructure and rolling stock, as well as by perfecting the organization of transportation and transfers [4]. It sometimes seems that impressive results can be achieved by relatively inexpensive means, resulting in better safety, comfort, and convenience of travel [5]. Still, public transport users are continuously exposed to more negative experiences than the users of cars or bikes, or pedestrians [6]. All the mentioned advantages are more expected than achieved, and drawbacks are more visible in cities, where transport systems are subject to various limitations due to historical or political reasons, for instance, former underinvestment.

In Wrocław, where about one million people travel each day, it is predicted, like in many other cities, that congestion problems will become increasingly severe. Due to dense car traffic, travel times vary widely and are becoming longer, and despite that, the number of cars per 1000 inhabitants is rising [7]. Public transport, despite using an Intelligent Transport System (ITS), struggles to improve its attractiveness significantly, mainly due to its of lack priority at crossroads, the insufficient number of dedicated bus lanes, and the blockages caused by transverse traffic flows at crossings [8]. These issues result in adverse phenomena and consequences, such as excessive travel times for intra-city journeys, excessive emissions of pollutants, and reduction in safety for traffic participants [9].

Using the railway structure for transport within the city and so-called “small agglomeration” may be a practical and effective solution for the above problems. The existing system of 11 radial lines and remaining peripheral and cross-city railway lines, if appropriately adopted, could provide effective, fast transport over longer distances for many passengers. This assumption is based on many domestic and foreign implementations; some selected cases from among these were described in previous papers, like [10,11,12,13]. Because many studies have been already been published on the possible development directions and plans for transforming the track systems in Wrocław and other cities, herein, we instead address an issue that it seems has not yet been given due consideration. Starting with transport known as Commuter Rail (CR), we consider the safety standard of matching the existing and newly designed platform edges throughout the city area and in the close surroundings, which involves matching both the infrastructure and vehicles. This is worthy of investigation because the railway, as a system, can operate effectively only when equipped with efficient, strong, and sustainable infrastructure, and it uses rolling stock adapted to its specific tasks.

Section 2 of this manuscript analyzes selected transport systems that are attractive from the points of view of various solutions that improve the safety of passenger exchanges on the platforms; conclusions are drawn from the analysis. Section 3 outlines the evolution of the approaches to tackling the problem of vertical and horizontal gaps between vehicle and platform. Section 4 includes a summary of movable and fixed equipment used to reduce the platform gaps and our proposal to resolve this problem by introducing a new shape of platform edge combined with an insignificant adaptation of the rolling stock, with no moving parts. Section 5 describes the existing condition of platforms in railway stations in Wrocław with reference to their compatibility with the trainsets in use. Section 6 includes guidelines for constructing a future Wrocław fleet, based on closely matching the vehicle dimensions to an unified infrastructure. A summary of this paper and our final conclusions are included in Section 7.

2. Analysis of Selected Transport Systems

The systems of CR have been operated in many cities and agglomerations for decades, which leads them to have high variability, but it seems justified to present the characteristic features of several selected systems, concentrating on the vehicle–platform interface. Then, using a comparative analysis, we identify solutions that have a chance of being implemented in Polish conditions, to operate within the existing infrastructure. It seems useful to describe diverse systems to obtain a wide context for the applications of particular technical solutions and networks, which have been developed in stages over several dozens of years, as this highlights the need to adapt older solutions to modern requirements [14]. While collecting data on a particular network, special attention was paid to the safety of passengers during boarding and alighting, with reference to matching the platforms and rolling stock.

An analysis of the statistical data shows that CR systems and urban and agglomeration railway transport in Western Europe are used for many more railway journeys per passenger than in Poland. Selected data for 2018 (based on [15]) are summarized in Table 1. Poland was compared with selected European countries where intra-city, suburban, and agglomeration transit has a greater share of rail transport [16].

Table 1.

Statistical data for selected parameters of railway travel in EU28 [15].

Our comparison of the numerical values in Table 1 leads to the following conclusions: an individual in Poland makes 2.5-times fewer railway journeys than the average European, about 4 times less than a German or Austrian, and over 7 times less than someone in Switzerland. The average rail travel distance in Poland is one and a half of the average in Europe overall and about twice that in Switzerland or Germany. As Austria, Germany, and Switzerland all have intense CR transit use, this suggests that the reason for the lower use level in Poland is not related to the average rail travel distance.

2.1. CR in Berlin

The system commonly known as S-Bahn was first designed in the 1870s and then the name was passed on to later systems. It originally referred to one railway cross-city line in the latitudinal direction, on a viaduct 11.2 km long. This was put into operation in 1882 and provided with two pairs of tracks: local and long-distance ones. At first, the trains were powered by steam, but at an early date, the line was subjected to electrification. This allowed for the introduction of new cars with much better performance and capacity, as well as a north–south railway tunnel under the center of the city. This tunnel limits the height of Berlin’s S-Bahn trains to just 3.6 m above the floor in a car 1.0 m above the top of the rail (TOR). During electrification, it was decided to use a third-rail power system, as introduced in Berlin’s subway in 1902 [17].

The platforms in use and adapted to the current requirements, which differ from those in long-distance railway infrastructure, are 960 mm high above the TOR, and the platform edge is 1625 mm from the track axis [18]. The newly bought (series BR 481/482) rail cars in use have a floor height of 1000 mm and a car width of 3140 mm [19], meaning the vertical and horizontal gaps between the sill of the car and the platform do not exceed 40 and 55 mm, respectively. This ensures a high level of safety for all passengers and free access for PRM without the need to use any ramps, elevators, or movable steps or platforms. Such a tight fit is possible due to the application of a sliding plug door that moves above the sill, which strongly protrudes beyond the car body (Figure 1).

Figure 1.

View of entrance zone of Berlin S-Bahn train series BR482.

The essential features of CR and other modes of public transport in Berlin were described in detail in paper [20]. High usage and ease of intermodal travel result from the essential features of the system for passengers. These include connection reliability, short waiting time during transfers, safety, passenger information, and protection against atmospheric factors. These findings coincide with trends observed globally [21,22]. What is interesting is that an essential role is played by the factors that help with travel for PRM; in a survey, respondents rated as very important or important the factors of barrier-free access (31% of respondents) and availability of an elevator (29%) or escalator (32%) [20], and these results are reflected in more general papers like [23].

2.2. CR in Ruhr Area (Rhein-Ruhr)

The first regional connections with a regular timetable ran in the Ruhr area as early as before World War II. The construction of CR in its present meaning began at the time of electrification in 1967. Since then, the connection network has spread gradually, reaching in succession Duisburg and Bochum in 1974, Köln and Düsseldorf in 1975, Solingen in 1980, and Dortmund in 1983 [24]. In the following decades, the system was regularly expanded and complemented, until 2014, when the S19 line to Hennef was opened, and the RB23 line reaching Bonn was renamed S23. Unlike in Berlin, the management of CR in the Ruhr area is subject to tenders for parts of the work to service the routes, which are then carried out various carriers so there is no monopoly, i.e., DB. The lines are currently divided between the companies Abellio Rail, Keolis, and DB Regio, and tenders for service work on several routes will be settled in late 2023 [25].

Since series BR 420 trains were introduced in 1969, the cars used in this network have had a floor height of about 1000 mm above the TOR level. Up to 2016, the DB Station & Service Company adapted the platform edges to a height of 960 mm. However, when the tender for the service work on the S8 and S5 lines was launched, the decision was taken that the new standard would be 760 mm (Figure 2). This resulted from the fact that despite the long-term adaptation work, of the total 45 platforms along these two lines, only 21 were raised, while 24 still had a height of 760 mm.

Figure 2.

Trains BR 422 and Stadler Flirt at the newly modernized platform (April 2019), which is 760 mm high, at Castrop—Rauxel Hbf Station; different fits of entrance height are visible.

According to the plan in place since 2014 [26], rolling stock with a 760 mm high floor should replace the existing stock by 2033, while the reconstruction of platform edges is to conclude by 2059. The most numerous EMU series, BR 422, has a body 3020 mm wide, without protruding sills, which makes the vertical gap 40 mm for 960 mm high platforms and 240 mm for 760 mm platforms, and there is a horizontal gap of at least 140 mm when the platform is at a nominal distance of 1650 mm from the track axis [27]. In the best case, this exceeds the value required for independent access for PRM by about twice, as described in Section 3.

2.3. CR in Dresden

The Dresden system differs from the remaining ones described in Section 2 as it consists of only three lines (for comparison: Berlin—15, Rhein-Ruhr—11, Zurich—30 lines), which jointly serve only four outlet directions. Furthermore, the lines transfer about 15 million passengers yearly (in comparison, Berlin 478 M, Zurich 206 M). At the same time, the lines have considerable lengths, namely 77, 32, and 40 km. This is not a system serving Dresden alone, but rather one that connects the city to subregions in the medium distance and further in selected directions [28]. Given the quite sparsely arranged stops, the Dresden CR rolling stock is not composed of the EMUs or DMUs most commonly used for CR applications, but of push–pull trainsets including low-entry double-decker cars with Vmax = 160 km/h, paired with series BR 182, 146, and 143 locomotives. Due to the relatively high power of the locomotives, the traction features of these trains match the standard of modern vehicles. Furthermore, another feature of the routes in Dresden is that there is a relatively low number of stations where mass exchange of passengers takes place. This means it is sufficient to use four-car trains on the S1 line and two-car trains on the S2 and S3 lines, and it is suitable for the sum of door widths to be less than 10% of the trainset length, which contrasts with the examples of Berlin or Rhein-Ruhr.

As no individual standard of platform–car configuration has been adopted for the Dresden CR, the system is based on standard platforms from German regulations, that is, 550 mm high over TOR and 1650 mm from the track axis [27]. The width of the series DBpza 780.4 used for the S-Bahn Dresden is 2784 mm; hence, the distance from the side of the vehicle to the platform edge on the straight track is a minimum of 258 mm, while fixed sills made of perforated metal have a reach of 91 mm, which reduces the gap to 167 mm (Figure 3). Meanwhile, the sill height above the TOR is 600 mm, so the vertical gap amounts to 50 mm, according to information obtained from Deutsche Bahn AG by email.

Figure 3.

Door area of a double-decker car of Dresden CR at the platform, which is 550 mm high, at the Dresden Bischofsplatz stop.

2.4. CR in Zurich

Commuter Rail in Zurich consists of 30 lines with a total length of 380 km and 171 stations and stops. The system has operated under the current name since 1990 when a ZVV transport association was formed [29]. In the 20th century, progressive extension and unification of the railway routes within the region began under “Projekt 1954”. However, while most lines in the network are integrated in terms of tariffs and timetables, others are not. Furthermore, they cannot be considered as one in technical terms, for example, due to different power supply systems using asymmetrically located catenary (S10, Uetlibergbahn) or a narrow gauge track and street running (S18, Forchbahn). Another feature of this case is that conservation of the original layout of the main Zurich station despite progressive expansion led to a situation where tunneling under the city center was necessary to increase capacity in the main sections where the traffic load was highest. So, the Stadelhofen station became interconnected with the main station through the 1300 m long Hirschbergtunnel, which opened in 1990; then, more recently, the 4800 m Weinbergtunnel was constructed in 2014 [30,31,32]. Despite creating an interesting situation where three parallel connections with independent routes were constructed between the Zurich stations Hauptbahnhof and Oerlikon, via Hardturm, Wipkingen, and Weinberg, and although there has been intense development of the infrastructure, it does not keep up with traffic needs. Now, the system bottleneck is at the three-track Stadelhofen station where nine lines overlap, meaning 36–40 trains per hour pass through in peak traffic times. The planned expansion, under the STEP2035 Programme, will cost as much as 900 M CHF, mainly due to need to construct a separate single-track tunnel deep behind the anchoring of the retaining wall of the current station [32,33].

Despite the many tunnel sections, the CR rolling stock is mainly double-decker in Zurich and includes DPZ + Re450 trains (115 three-car trainsets, Figure 4), RABe 514 trains (61 four-car sets), and RABe 511 trains (50 six-car sets). With these trains, the arrangement and number of doors is similar to those in Dresden and amounts to about 10% of the set length. It is estimated, in the S-Bahn 2G program currently in preparation, that the final capacity of the system must be doubled. For this purpose, it will be divided into an external subsystem serviced by double-decker cars, and an internal subsystem with a smaller reach, but which will be shuttling more frequently, using single-decker cars with a larger number of doors, thus accelerating passenger exchange [34].

Figure 4.

Train of S6 line (DPZ + Re450 in double traction) with fold-out steps opening to a horizontal position, about 200 mm wide, in Stadelhofen station (2006).

In Switzerland, the distances between the track axis and the platform edge, as well as the heights of platforms, are subject to indirect regulations. As a general act of law, BehiG [35] was implemented in 2004, which is aimed at the prevention, limitation, or elimination of inconveniences experienced by PRM. Elaborations supplementing the law are in force as executive acts for both railway transport and urban public transit. It was established that the maximum gap that can be overcome by people with disabilities by themselves amounts to 50 mm vertically and horizontally; alternatively, it can be 70 mm horizontally and 30 mm vertically [36]. It seems there are two ways to solve the problem of how to stay within these limits: using the current equipment but with improvements, such as clearly defined sills of vehicles brought significantly closer to platform edges, or using equipment, either fixed or movable, examples of which are outlined in Section 4. At present, the solution to reduce the horizontal gap for trams and older S-Bahn trains in Zurich consists of a folding step, about 200 mm wide, which is movable and opens to a horizontal position (Figure 4); in newer trains, a horizontal sliding sill is instead used, which reduces the maximum size of the horizontal gap to 50 mm.

2.5. Observations and Intermediate Conclusions

The CR cases outlined in Section 2.1, Section 2.2, Section 2.3, Section 2.4 are diverse, both in typical features and capacities, which in this article are understood as the shared traffic structure and system load. Selected features, which we emphasize as essential for safety during the exchange of passengers, are summarized and highlighted below. This summary allows us to draw conclusions about which interventions may be helpful in order to reach the highest safety standards for boarding and alighting, under the assumption that they may be transferrable to the CR system in Wrocław. The following findings were identified as important:

- Berlin CR is the most similar to a stereotypically understood underground: it mainly serves the capital city center, uses rolling stock powered by third rail, and has a special vehicle gauge in a separate infrastructure. However, thanks to its unique features, it is the sole system out of those mentioned in Section 2.1, Section 2.2, Section 2.3, Section 2.4 that ensures safe independent access for PRM with no special equipment in its vehicles or on platforms.

- The system operated in Rhein-Ruhr interconnects distant urban centers with similar numbers of inhabitants (polycentric conurbation), while the number of stops within a single city is relatively low. An excessively longwinded process of adapting to new technical standards has caused obsolescence and created a need for new solutions. Hence, the safety of independent boarding and alighting is considerably reduced when compared to Berlin.

- The S-Bahn in Dresden has a small total number of passengers, which results from the few stops within the city area, the sparse populations in suburban areas, and the strong, modern, and intensely exploited tram network. The application of the general railway standard, consistent with the TSI INF [37], means PRM are essentially denied independent access to the system.

- The CR in Zurich breaks attendance records and develops dynamically because it offers, in six trunk routes, trains at intervals of just several minutes (resulting from joint provision of services for most lines, along with frequent services for each line despite the common use of their tracks by long-distance trains), high travel comfort, and unbeatable travel times. Safe independent access for PRM will soon be the standard and will be delivered at a high level, but achieved at the cost of incorporating expensive and hard-to-maintain movable elements, such as fold-out steps and sliding sills.

- The rolling stock used in the CR system that can be exchanged with those in general railway transport, i.e., with a body width of approximately 2.80 m or less, does not ensure independent access for PRM on railway platforms consistent with the TSI INF [37] or with the reference standard EN 15273 [38], and using this stock extends the passenger exchange time. That lengthening of passenger exchange is especially severe when double-decker cars with few doors are used.

- To ensure efficient passenger exchange, it is necessary to use cars and platforms with unified dimensions [39,40,41]. Berlin is a positive example, as this criterion is almost satisfied. The negative example would be Rhein-Ruhr, where long-standing modernization efforts, aimed at raising the platforms, were not completed on even half of the platforms and will be reversed in the coming decades.

- In CR systems that use a mixed-traffic track infrastructure with long-distance railway and regional railway, it is essential to meet interoperational requirements. This is key to consider because almost every large railway junction in Poland and in the whole European Union with the potential to run urban and agglomeration transport has at least one line belonging to the trans-European transport network [42]. The TSI INF [37] requirements limit the number of possible versions of platform height to two: 550 and 760 mm. Since it is desirable to unify the heights of the platforms accessed from the same junctions, this requirement covers all platforms, including those that are not on lines covered by international agreements.

- In Central Europe, the universal height of platforms is 760 mm for three reasons: the infrastructure may cooperate with long-distance trains, which usually have high-deck wagons; urban railway trains are adapted to 760 mm platforms and may have a better interior arrangement than trains adapted to lower platforms (e.g., 550 mm), which may have entrances at the level of the platform but uneven floors throughout the full length of train set and narrow passages over bogies; and sets adapted for platforms higher than 760 mm may find effective uses in closed systems, separate from the remaining railway traffic. Furthermore, the value of 760 mm follows regulations and standards—for example, [37,38,43]—and its appropriateness is supported by the results of research [44].

- For systems that are not burdened with historical issues (e.g., low north–south tunnel in Berlin, or other historical engineering objects), it is often convenient to use a vehicle gauge and system electrification compatible with the remaining part of the railway network. Even when faced with many tunnels, this does not necessarily form an obstacle to using double-decker wagons, as in Zurich.

- Difficulties may arise when there is a full separation of the infrastructure, both in the case of CR and for trams. CR trains often share tracks and platforms with other types of railway transport, in particular, with long-distance transport. Similarly, trams in legacy systems share platform edges with low-floor urban buses or trolleybuses.

It has already been proven that simply copying existing solutions from one location does not guarantee success in other places. Therefore, it is not enough to emulate the most beneficial features of those mentioned above; instead, a creative analysis and adaptation to the specific situation and local conditions in Wrocław and the surroundings is necessary. Corresponding studies and analyses are presented in Section 3, Section 4 and Section 5.

3. Distances in CR Vehicle–Platform Interface

Because two corridors of the Trans-European Transport Network [42] intersect at the Wrocław Railway Junction (WRJ), a new system must be adapted with interoperability in mind, which can present a challenge [37]. However, for many related issues that may arise, the TSI and the bodies enforcing all other relevant standards allow the regulations to be overrode if a solution will improve the security and comfort of passengers. For example, a car body width measured at the sill height as larger than that of the TSI may be used if this helps to reduce the horizontal gap between the vehicle and platform. Important and interesting work on this subject is available in papers [45,46,47,48]; report [49] also gives a summary of the previous research. Reliably useful and especially interesting are the Swiss guidelines, such as the AB-EBV [36,50,51], which provide answers for how to meet the statutory requirement BehiG [35] that we adapt the whole public transport to allow unaided access for PRM, which must be implemented before the end of 2023. Furthermore, based on previous French research, summarized in [47], and German studies in the book [14], researchers from those countries have concluded that independent access to public transport vehicles for PRM can be ensured only by a narrow range of vertical and horizontal gaps, in close relationship with each other. The Swiss guidelines are more suitable for the Wrocław case than, for example, the values assumed in French projects for trams because the project at hand is more the reconstruction of the existing platform infrastructure rather than the construction of new infrastructure.

It should be stated that there are various classes and categories of disability, and only some of them are related to human motor function restrictions. In this respect, PRM can be divided into four main groups:

- People with a limited step length and limited ability to overcome level differences, but moving on their own;

- People moving with the help of devices without wheels (walking sticks, canes, elbow crutches, crutches, walkers);

- People supported when walking with wheeled devices (rollators);

- People moving in a sitting position only (hand wheelchair, electric wheelchair, mobility scooter) [45,46].

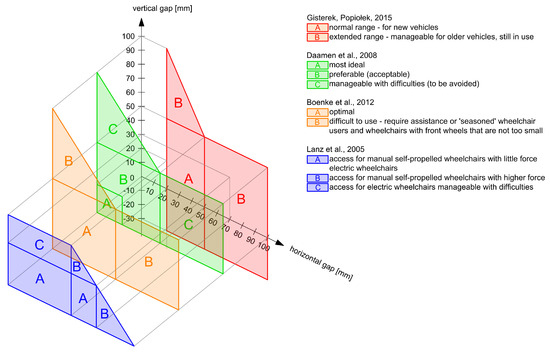

After reviewing previous examinations and regulations, based on practical tests with PRM in simulated conditions of the platform–vehicle interface, for example [36,45,46,50,52], the original diagram (Figure 5) was developed of the dimensions of admissible horizontal and vertical gaps [53]. The authors of the paper in question also participated in practical tests and measurements carried out in 2016 by MPK Wrocław (Wrocław Transit Authority) for trams and buses, coordinated by P. Szyszka. Based on the above work combined, the admissible combination of horizontal and vertical gaps for independent access constitutes maximum gaps of 70 and 30 mm, respectively, while the ideal values are no higher than 50 and 30 mm. These are values similar to those used in Berlin and in all French tram systems. However, the TSI INF [37] states that a relatively large gap should be left between the vehicle and infrastructure because this distance directly affects the capacity for travel at medium and high speeds. Only if the CR stops at each platform along a route (meaning its speed never rises above a low speed), or if in unusual situations it moves at a reduced speed (e.g., up to 40 km/h), is there no need to increase the horizontal distance.

Figure 5.

Sizes of vertical and horizontal gaps between platform and vehicle for independent access of PRM, by various researchers [14,36,45,53].

4. Fixed and Movable Devices Improving Passenger Safety during Boarding

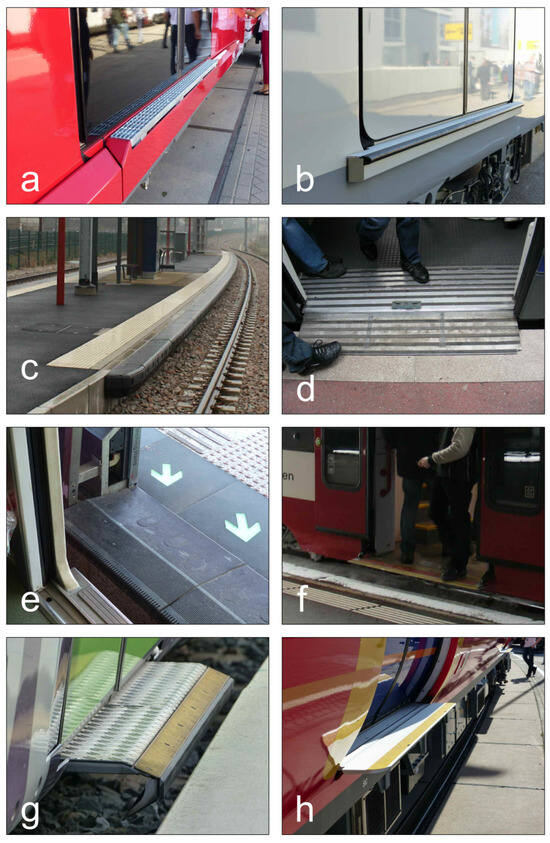

As mentioned in earlier sections, a combination of a standard platform and typical straight-sided rolling stock is not enough to ensure independent use of railway transport by PRM [44]. Furthermore, many examples in this paper show that only a small portion of this rolling stock can ensure free access to disabled people, and only under the condition that some movable elements are used. The usage of moving parts is related to both additional purchase and operation costs, and considerable problems can arise even in the case of a trivial failure, while extends the time needed for passenger exchange in the station. Likewise, sliding doors and raised gates have similar influences on passenger movement [54,55], and they cannot completely eliminate the chance of serious accidents during boarding and alighting [56].

Adapting rail transport to meet the improved safety standards for passengers should be treated as a task of mutual matching within the platform–vehicle system. Accordingly, pairs of solutions used to meet this target of adaptation include the following:

- Classic form of platforms and protruding fixed sills installed within the doors of cars;

- Platforms equipped with fixed edge covers, most often made of plastic, metal, or wood, and protruding fixed sills installed within the doors of cars;

- Classic form of platforms and fold-out steps or sliding sills mounted on cars.

The remaining systems and accessories helping with boarding of PRM, such as manual or electric ramps installed in cars, elevators or hoists installed at car steps or adapted for moving over the platform, or movable stages permanently installed on the platform, are omitted from this list as they do not ensure the self-reliance of PRM. Instead, they require operation by the vehicle driver or by other trained personnel and thus considerably extend the car’s stoppage time at the platform. Exemplary solutions for vehicle–platform interfaces are shown in Figure 6a–h.

Figure 6.

Mutual compatibility of vehicles and platforms meeting the needs of PRM: (a) S-Bahn Berlin (Germany), permanent metal sill along the full length of the car and classic platform, (b) subway in Riyadh (Saudi Arabia), permanent sill with rubber profile in the door zone and typical platform, (c) Tram-train Mulhouse (France), sliding sills in a vehicle and permanent rubber covers on the platform edge, (d) Metrobus in Rouen (France), short ramp sliding from the vehicle over a typical platform, (e) Chongqing Monorail (China), small permanent sill and door opened in vehicle wall thickness, plastic cover and doors on platform, (f) Trogner Bahn (Switzerland), step folding out to horizontal position and typical platform, (g) Tram-train Lyon (France), sliding sill with J-shaped cross-section and typical platform, (h) BR Class 707 (Great Britain), permanent flat sill with considerable cantilever to compensate car wall rounding, the door open in vehicle wall thickness, cooperates with a classic platform.

The above solutions in Figure 6 were selected due to the primary and justified concern that over time the distance between the vehicle door sill and the platform edge will become uncontrolled. Factors that reduce this distance over time include, but are not limited to, vertical and side wear of wheels, vertical and side wear of rails, track settling, track twist, loss of platform geometry, vehicle load from passengers and resulting suspension deflection, and retention of a layer of snow and ice on the platform surface [57]. Alternatively, the “hard and heavy” structures, i.e., the concrete platform edge and vehicle body, moving away from each other is a serious issue as it raises the risk of collision. To fill an excessive gap generated this way, various types of covers and movable elements are used, such as those shown in Figure 6c,d,f,g.

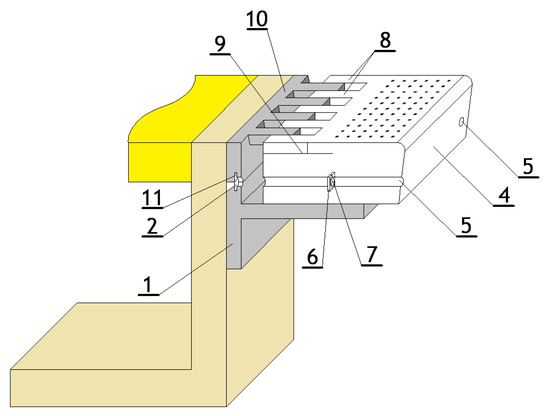

The device described in the PL 224,580 B1 patent [58], shown in Figure 7, is a different and unique solution to this problem. The device to prevent enlargement or closing of the platform–vehicle gap is mounted using a supporting strap with sockets and secured to the platform wall. In the sockets, there are embedded heads of partially screwed distant bars, which run through tunnels created in a support strap of the edge plate, to be made of hard rubber. In a rear part of the edge plate, the embedded teeth of the adjacent comb strap engage with the strap secured to the platform wall in a similar way to that for a bridge expansion joint. Cooperating teeth of the edge plate have a trapezoidal shape in a cross-section. The design of the device ensures there can be no widening of the distance between the edge plate and platform wall as it maintains a constant horizontal distance of the device from the track axis.

Figure 7.

Idea of adjustable platform edge according to the patent [56]. Parts: 1—supporting strap, 2—socket, 4—step, 5—clearance hole, 6—square nut, 7—thread, 8—comb strap (rubber), 9—cut, 10—comb strap (steel), 11—embedded head.

Such a device allows us to keep the platform edge straight or matching the track geometry, despite displacements—e.g., particular elements of the platform wall constituting its foundation or horizontal displacements of the track—which can occur in long-term service. This innovative device design could offer the best solution in several respects:

- It ensures independent access to vehicles for all groups of passengers;

- It places no specific requirements on the rolling stock, except a uniform width of cars, a uniform height of the entrance, and optional use of a fixed sill;

- There is no need to use moving parts in the rolling stock or on the platform, which are expensive in terms of construction and maintenance;

- It enables the position of the platform edge to be adjusted quickly during operation of the railway line and using basic tools;

- It enables the cost-free adaptation of the infrastructure to a new standard of rolling stock, for example, with a wider car body.

5. The Existing State of Compatibility and Standardization Proposal for Platforms in WRJ

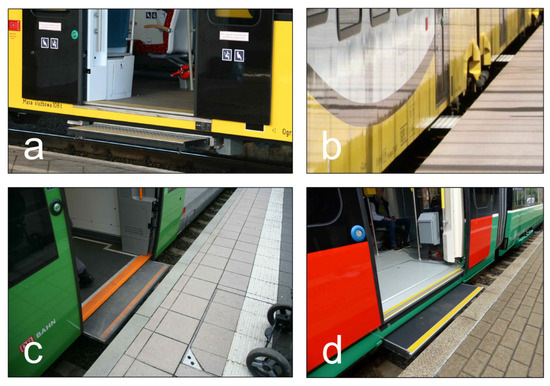

In the case of CR planning for railway junctions with no separate urban rail infrastructure, such as in Wrocław, an extensive assessment of platform uniformity and the compatibility of platforms with the rolling stock is important for safety, comfort, and efficiency reasons. Furthermore, this assessment is important in vast urban railway junctions with a long history, which present different levels of technical development of particular elements, and which are served by a diverse urban, regional, and long-distance rolling stock originating from different eras. As stated in Section 2.5, a universal rolling stock intended for regional and long-distance transportation rarely meets the requirements of typical CR in terms of the train–platform interface. When there are few stops, it is not a key issue to provide independent access for PRM or a large number of vehicle doors. However, challenges arise in terms of provision for PRM since providers seek to maximize the number of passenger seats while also providing zones for storing large luggage and for a passenger catering service, which puts pressure on the interior space, and they seek to allow high-speed passage by platforms without stopping, though this requires that there is a relatively large distance between the train body and the platform structure. Meanwhile, the optimal adjustment of the vehicle entrances to the platforms is important for vehicles that serve shorter journeys with many stops and intensive passenger exchange. An analysis of the compatibility of long-distance rolling stock with platforms is beyond this paper; however, approaches centered on using typical universal regional rolling stock in CR are typical for Poland, as stated in Section 2. They often result in a poor fit at the train–platform interface, and the differences in the height of the edge of the train doors and the edge of the platform are most often bridged with sliding sills.

An example with relevance to these considerations is that of the Newag Impuls trains, which are EMUs designed and made in Poland. Four batches of these have been delivered since 2012 to Koleje Dolnośląskie, the regional carrier serving the WRJ, with a floor height of 760 mm at all doors, raised with ramps over Jacobs bogies. These trainsets are well-matched in height to the standard platform edges of 760 mm above the TOR, while a difference of 210 mm plus train suspension tolerance of +/40 mm exists for 550 mm platforms. All the doors have sliding sills. They are at a level that corresponds to the standard of the 550 mm platform (Figure 8a), and they eliminate the horizontal gap for such platforms almost completely, though they leave a large difference in height. When the sills are hidden, the car body remains at a distance of at least 227 mm from the platform edge [59]. Despite the sills, we cannot say about the provision to reduce the horizontal gap in the case of standard platforms of 760 mm, for which these trains are specially designed, as the sills are located considerably below the edge of the platform (Figure 8b). Such trains, to span the platform gap for both platform standards, should have two sliding sills, including one directly under the car floor plate. It is structurally possible for sills that extend directly from under the floor to be used, as in the example of Bombardier Talent 2 trains made for Deutsche Bahn (Figure 8c). Double sills are operational in Newag Impuls trains produced for CR in the cities of Gdańsk, Gdynia, and Sopot, so called Tricity (floor level of 960 mm, as the core of the system has 960 mm high platforms; sills at levels of 530 and 760 mm, designed for serving standard platforms in outer areas). The problems described show that the key parameter for the compatibility of the train–platform interface is the height of the floor of the vehicle door in relation to the height of the platform, which are both typically measured in relation to the TOR.

Figure 8.

Sliding sills in trains: (a) Newag Impuls belonging to Koleje Dolnośląskie—visible floor level at the entrance of 760 mm, extended sill of 550 mm, and platform of 190 mm, (b) Newag Impuls—extended sill at the platform of 750 mm at Wrocław Główny station (Poland), (c) Bombardier Talent 2 belonging to S-Bahn Mitteldeuschland—extended sill at 550 mm platform at Leipzig MDR (Germany) stop, (d) Stadler Citylink Chemnitz—example of tram-train with two sliding sills, where one is extended, while the other is visible as the yellow edge below the floor at the entrance.

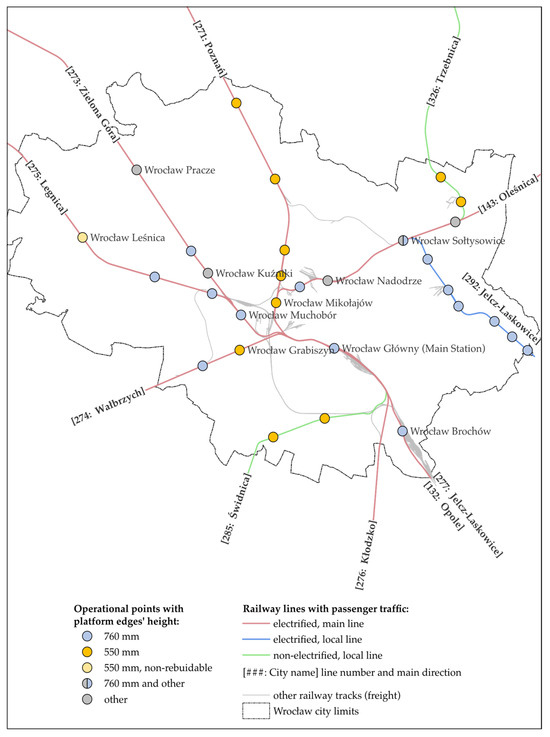

Meanwhile, when we started our analysis in 2020, according to the regulations [60,61,62], there were 11 different heights of rail platform in the Wrocław city limits: 280, 300, 310, 320, 350, 380 (low); 550 (medium); 680, 750, 760, and 780 mm above the top of the rail (high). Now (in 2023) [63], there are 8 left (without 310, 750, and 780 mm) (Figure 9). The Wrocław Railway Junction, like many other railway junctions in European cities, includes both historical infrastructure elements and others that have recently been modernized. The most essential renovated objects in WRJ include Wrocław Główny—Main Railway Station (2012), Wrocław Mikołajów station (2012), Grabiszyn branch post (2015), the main lines towards Poznań (2012), Legnica (2010, 2013—Wrocław Leśnica station), Opole (2011), and Wałbrzych (in stages in 2012–2019), and the local lines to Świdnica and Jelcz-Laskowice (2022). In the context of recently upgraded platforms, it should be underlined that according to national guidelines [60], from 1998 to 2014, the platform height standard of 550 mm was the basic one for almost the entire rail network, with an exceptionally allowed height of 760 mm for lines with “suburban traffic”; however, this condition was vague due to the lack of a strict definition of “suburban traffic”. With the law amendment in 2014 [61], both standards were equalized in terms of importance, but this time without any indication of the scope of their application. The design of low platforms (550 mm) on non-electrified lines and high platforms (760 mm) on electrified lines became an unwritten rule, which befitted the parameters of new types of rolling stock that appeared on the Polish railway network in the 21st century. Trains intended for local non-electrified lines had to comply both with the applicable guidelines, according to which platforms should be built and modernized to meet the 550 mm standard, and be adapted to serve many old low platforms with a height of approx. 350 mm or less. This rolling stock was even called low-floor. But a significant number of high-floor trains of classic types still operated on electrified lines, so the 760 mm standard was adopted for the new ones. At the end of the second decade of the 21st century, the internal technical guidelines of the largest national railway infrastructure manager were established for good [43], according to which the nominal height of platforms in all cases is to be 760 mm, with other cases only exceptionally allowed. According to the guidelines, 760 mm is the height of the universal platform. The guidelines even require that when designing platforms in the 550 mm standard, the documentation should indicate the technical solution for adapting to a height of 760 mm.

Figure 9.

Summary of passenger platform heights for operational points of Wrocław Railway Junctions in 2023, according to data from [63], on the basis of OpenStreetMap data.

In the authors’ opinion, the Wrocław CR system should be, as far as possible, compatible with the remaining Polish railway network, as in the foreseeable future, this system cannot count on remaining separate. This compatibility should extend even to independent infrastructure in current railway areas. This means that standard features need to become accepted, like the track width, structural clearance, voltage and position of the catenary above the track, and dimensions of the platform. A 760 mm high CR platform should be recognized as properly designed from the viewpoint of passenger safety and comfort and of compatibility with the rail system.

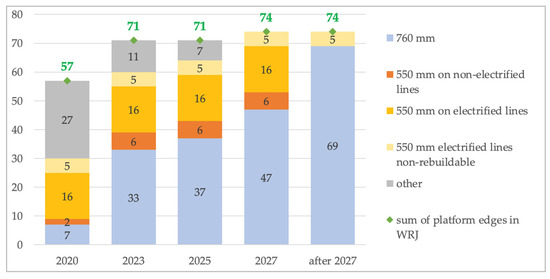

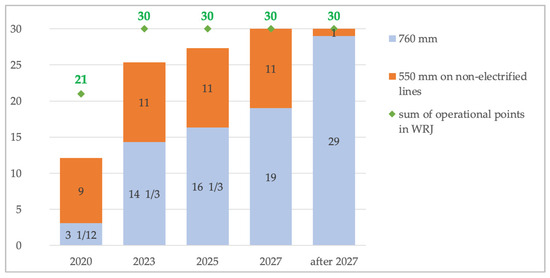

However, when we started our research in 2020, out of the 57 active platform edges at 20 operation points (stations and stops), only 7 (12.3%) strictly met the 760 mm standard; meanwhile, 23 edges (40%) were 550 mm high, and the remaining 27 did not meet any standard (Figure 11) [62]. This means that only 3.5 out of 20 stops and stations had standard 760 mm edges and only 9 met the 550 mm standard (Figure 12; the fraction mark denotes the number of 760 mm edges per total number of edges in a particular operation point). We expect that in the next few years, the number of standard edges (both 760 and 550 mm) will go up significantly, first, due to change in existing edges and, second, due to work to increase the number of active edges per junction and the number of operation points, which is in progress.

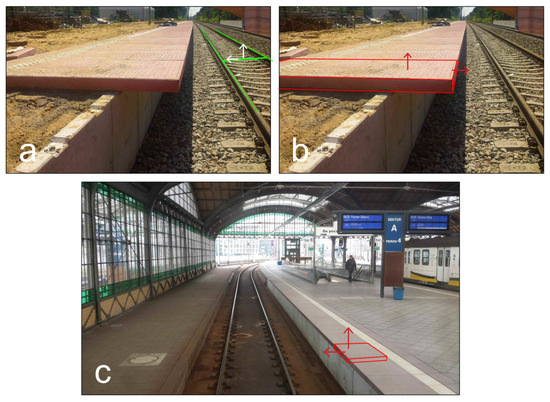

Completed work to adapt 14 edges in WRJ to the 760 mm standard appeared relatively easy and was possible to implement in a few years, as the platform height was close to the required 760 mm (750 or 780 mm). There are two ways to make the change in these cases, as shown in Figure 10: raising the track in its regular profile by 2 cm in the case of 780 mm platforms (Figure 10a); or raising the edge plate, as typical Polish platforms are built with a prefabricated retaining wall and edge plate in the L + P system (Figure 10b) or some variation on it (Figure 10c), customized to local construction or architectural conditions.

Figure 10.

Possible change in platform edge position: (a) typical in L + P system—by adjusting the position of the track, vertically and horizontally (green lines—rails, white arrows—adjustment direction), (b) typical in L + P system—by adjusting the position of the platform plate (red box), vertically and horizontally (red arrows), (c) non-typical in the example of Wrocław Główny station—shifting the edge plate (red box) upwards and towards (red arrows) the track (slab track, not adjustable in the range required).

The next 16 platform edges were completed in 2020 under the scope of ongoing or contracted construction works, 12 of which were 760 mm and 4 more 550 mm high. Only 5 (reconstructed from low edges of 280, 350, and 350–760 mm) were previously in operation: Wrocław Muchobór with 3 edges (a very important rail stop within the business district) and Wrocław Brochów with 2 edges. A further 2 brand-new 760 mm single-edge platforms were built in Wrocław Szczepin for the newly created train-tram junction. The rest (9) were built on line 292 to Jelcz-Laskowice (760 mm) and on line 285 to Świdnica (550 mm). Both were revitalized lines that had received no passenger traffic for many years, so we did not include their platforms in the total number of 57 active platforms in 2020. Now, after completion of all mentioned changes and construction works, the total number of 760 mm edges is 33 out of a total 71 (46.5%) and for those at 550 mm it is 27 (38%) (Figure 11). Regarding the number of stops and stations, today 14 + 1/3 out of 30 meet the 760 mm standard and 11 have 550 mm high platforms (Figure 12).

Figure 11.

Changes in the number of platform edges with specific heights.

Figure 12.

Changes in the number of operational points (stations and stops) with standard edges.

In 2023, 4 + 2/3 operational points (11 edges) still do not meet the standard for the height of the platform edges [63]. A common feature of these stations (Wrocław Psie Pole, Wrocław Sołtysowice—2 out of 3 edges, Wrocław Nadodrze, Wrocław Kuźniki, Wrocław Pracze) is that they are on railway lines 143 and 273, which have not been covered by comprehensive modernization projects in the 21st century, with only ongoing maintenance works carried out. So, not only do these platforms not meet the height standards but also the structure of their surface, accesses, equipment, and markings (including tactile markings for the blind) additionally fails to meet modern requirements. They are not in the best technical condition. In contrast, lines 143 and 273 uphold the highest standards for a running commuter rail [11]. To bring them up to speed, the modernization of the platforms mentioned should be carried out as soon as possible.

When assessing the time horizon for the modernization of a platform, it must be determined whether it is possible without rebuilding the station in terms of the track layout and traffic control system. In that scenario, according to the authors’ experience of designing and conducting investment processes related to railway platforms, the commissioning time is approximately 2 years from the moment of making the decision. This time includes the period of preparing the tender for the public investment process, selecting a contractor, design works and arrangements, obtaining a building permit, and then carrying out construction works in stages while maintaining the station in a state where regular train traffic can pass through. In the authors’ opinion, it is possible to rebuild the platforms of line 273 in this way, so in 2025, WRJ could obtain 4 more edges in the 760 mm standard at two operational points (37 of 71 edges—52%).

It is slightly more difficult to forecast the dates of the potential modernization of platforms on line 143, because adopting an assumption similar to that for line 273, i.e., reconstruction of platforms in their current locations without changes in the track layout, would block the possibility of adding one or two more tracks on the line. However, many analyses [64] indicate that this addition is vital in order to launch a high-standard urban railway in Wrocław on line 143.

Because reconstruction of the Wrocław Nadodrze station (extension by the fourth platform edge) and Wrocław Psie Pole station (moving the platforms to improve accessibility, adding more tracks and platform edges) requires special attention, it is necessary to consider the time needed for a feasibility study, analysis of variants, and a more complicated design and construction process. Therefore, it should not be expected that the remaining platform edges in WRJ will be brought up to the necessary standard earlier than 2027. The problem is also that the consensus about rebuilding operational points on line 143 seems to be that we should wait for a comprehensive modernization of this line, the time horizon of which is not yet clearly defined.

However, assuming that, by 2027, it will be possible to adapt all substandard platform edges in the WRJ to the 760 mm standard, then within 4–5 years, their share in the number of edges will go up to approximately 64%, located at 18 of 28 operational points (the number of edges due to adding more tracks on line 143 will go up by 2 or 3). The remaining 36% of the edges will then be 550 mm high, and although they will meet the second European standard, they will be poorly adapted to the CR requirements. So, in the next step of the modernization of the WRJ, plans should be made to raise these platforms, to unify the height standard throughout the junction to 760 mm. The weakness of this proposal is that all these 550 mm platforms are relatively new; they were built between 2005 and 2022 and their reconstruction seems economically unjustified. However, a closer analysis of the locations of these platforms gives other strong arguments for their reconstruction. First, more than half of them (14 of 27) are on the main line 271 that runs towards Poznań. This line was modernized in three sections (separate design and construction contracts) between 2010 and 2022. Only the first section within the Dolnośląskie Voivodeship (approx. one-third of the line’s length), modernized in 2010–2012, was built according to law in force before 2014 and thus with 550 mm high platforms (compared to 760 mm on the entire remaining part of the line). Today, the platforms on this line in the WRJ should, therefore, be considered substandard, especially since the line is electrified and served only by typical modern electric rolling stock. In addition, on line 271, there is one of the most important points, the WRJ—Wrocław Mikołajów stop, where the second largest (after Main Station) passenger exchange in the WRJ is regularly recorded [65]. Unifying the standard of its two double-edged platforms is important from the point of view of passenger exchange efficiency related to the train stoppage time, which affects the capacity of this heavily loaded section of the track layout at the center of the entire WRJ. It should be expected that the reconstruction of the platforms of Wrocław Mikołajów, although not very complicated technically, may be difficult due to the need to maintain heavy train traffic during construction works with the lowest possible reduction in its intensity. Doing it quickly is also an argument for rebuilding this point before the CR becomes well-developed and trains serving this passenger load will be difficult to temporarily replace with substitute transport.

A special case of a station with platforms with a height of 550 mm within the WRJ is the Wrocław Leśnica station. It is the only operational point equipped with low platforms along the main line 275 running towards Legnica, while all others meet the 760 mm standard. The reason is that the entire complex of the railway station is registered as a monument, which influences and limits the adjustments that can be made for accessibility. The consequences are lower platforms, uneven platform surfaces, and a lack of elevators—PRM can access island platforms via a tunnel with ramps, but at the opposite ends of the platforms to the main station building and forecourt with public transport stops, which lengthens the access distance to platforms by up to 700 m as compared to the access for other passengers via a historic tunnel with stairs. The authors are concerned that architectural considerations will in this case block for a long time the possibility of bringing in uniform platform edges in this important area for CR in Wrocław (potentially a terminus for some CR trains), so in Figure 11, these 5 edges are marked as non-rebuildable, even in the outcome after 2027.

Other cases of platforms with a height of 550 mm, not discussed here (2 single-edge platforms on the electrified line 274 toward Wałbrzych and 6 single-edge platforms on two nonelectrified lines 285 and 326), require uniformization, but these are cases of typical platforms that are easy to reconstruct. After their reconstruction, the WRJ will have a 93% share of 760 mm platforms in terms of the number of edges and a 97% share in terms of operational points. We assume here that the Wrocław Leśnica station will remain an unresolved problem. The predictions presented in this paper are based on the number of edges and platforms that exist in the WRJ in the first half of 2023, and we presume that the number of platform edges will increase in the time horizon taken into account. However, neither construction works nor design processes are underway in the WRJ that could increase the number of railway platforms, although many planning documents, scientific analyses, and published public opinions attest that such investments are important for bringing in sustainable transport in the city and agglomeration. It is also worth noting that the range of the potential CR system for the WRJ will not be demarked by the city limits. Accordingly, an analysis, like the one carried out in this paper, should be conducted of sections of railway lines for the planned CR beyond the administrative borders of Wrocław.

In summarizing the aforementioned considerations on the position of platform edges in relation to the track, it is worth briefly noting the horizontal distance of the platform edge to the track axis. For many years in Poland, 550 and 760 mm high platforms were constructed at a distance of 1725 mm based on the already withdrawn gauge standard, and this value was reduced a few years ago to 1675 mm [66] (the value concerns straight platform edges, not considering gauge widenings in curves). Thus, older platforms may require reconstruction not only due to the height of their edges but also due to the distance from the track. As most of the contemporary platforms in the WRJ and across the entire Polish rail network are made of prefabricated L + P system elements, this can be easily achieved by correcting the position of the platform plates (Figure 10b). Adjusting the position of the track horizontally by applying methods already in regular service is another way to change this distance (Figure 10a). Horizontal inaccuracies of the train–track interface can be easily reduced by well-designed sliding sills on the rolling stock; however, properly built platform edges should not require the use of sliding sills to save time during the train stop.

6. Resulting Design Features Proposed for Wrocław Rolling Stock

Based on the examples and data outlined in the earlier sections, key dimensions are specified to ensure the desired results for free access by PRM when assuming a standard platform height of 760 mm compatible with the remaining parts of the railway system in Poland. Here, the logic is that the infrastructure standard provides guidelines for future rolling stock purchases. The vehicle width should be 3240 mm with door sills and about 3080 mm for the body of the car. Concerning its floor height, to ensure ideal cooperation with standard platforms, it should be within 760–780 mm above the railhead level with load and wear compensation. Other desired features of the vehicle include high reliability, a system of external and internal cameras controlled from the driver’s cab or through an external link, a modern and easy-to-maintain interior, a pneumatic suspension with carload and wheel wear compensation, air conditioning, an advanced passenger information system, large entrance zones, multi-functioning areas, glass enclosures embracing the door side edges, free access for disabled people, a seat layout arranged with ‘two facing two’, as well as interior space that is easy to maintain and use due to cantilever seat fittings. It is desirable not to use movable elements in the entrance zone, such as folding steps or sliding sills, as these are expensive and troublesome solutions in construction and maintenance. Their bearing capacity is also limited, which could affect the access of passengers in common heavy electric wheelchairs, which can weigh over 300 kg with the user. Furthermore, cars must be adapted to new anthropometric standards considering a steady increase in the average height and other body dimensions of a passenger. This last observation leads to the conclusion that the height of the passenger compartment should not be less than 220 or even 230 cm, and the space between the seats facing each other should not be less than 60 cm [67].

7. Conclusions and Summary

Safe independent access to public transport and other types of public infrastructure for passengers with reduced mobility is an important part of civil rights and an interesting subject of scientific research. In this regard, the interface between the rail vehicle and the platform is one of the most challenging problems to overcome [37]. Then, further difficulties arise from various standards of infrastructure and vehicle dimensions, as well as many expensive movable devices that require more even spending during operation. Furthermore, some officials and decision makers hold the opinion that adapting public transport to the needs of PRM provides a specific social benefit that is not related to the optimization of services for all groups of passengers [57].

There is almost universal confidence that the observed climate changes are strongly affected by industrial production and transport. Accordingly, the extension and improvement of the standards of the public transport system, since it consumes significantly less energy per passenger than individual transport and especially car transport, is an important element of policy in developed and developing countries. Forcing residents to give up their cars is met with social resistance, so a better course of action is to improve the attractiveness of public transport, leading people to choose it voluntarily. In this sense, ensuring high safety and comfort during boarding and alighting over the vehicle–platform interface becomes a key issue [20].

The future Wrocław CR system should use the latest technical achievements to improve the safety and comfort of passengers, to ensure efficient, reliable shuttling, and, finally, to take over sizeable shares of the total traffic. Urban rail has been operating for about 150 years and has been continuously improved, for instance, by making use of technical innovations such as platform doors and independent driving. Looking ahead, it is advisable that we further introduce new solutions (like a proprietary solution for the platform edge) and verify how they work in practice, which is not known as of yet. With the development of suburbanization, the number of passenger cars travelling within the city and crossing city borders continues to increase. The numbers of cars measured on the Wrocław border in the years 2011 and 2018 were 190,000 and 240,000, respectively. Therefore, the increase amounts to about 25%. In the same period, public transport, i.e., buses and trams, recorded significant decreases in their traffic shares for the years 2011 to 2018 of 35% and 28%, respectively [7]. These statistics should be classified as adverse and difficult to reverse with the means and methods available to date. Introducing new effective rail transport, almost fully based on the existing railway lines, which can shorten journeys by several times, especially between more distant points of the city, will result in a decrease in passenger car use in Wrocław not due to penalties and prohibitions but instead by proposing a more favorable option. It is almost certain that if Wrocław CR combines the advantages of some existing railway systems, as mentioned above, while avoiding some of their pitfalls and threats, for which conclusions have already been drawn in Western countries, then CR will become a system of key importance for residents.

The analyses described in this article and the partial conclusions drawn from them in the context of existing CR networks, together with consideration of plans for the WRJ, may be extended to many other potential CR systems. As such, and according to prevailing transport trends, these suggestions could be put into operation elsewhere in the future, especially in Central and Eastern European cities. According to the observed patterns, these systems will use infrastructure partially shared with other rail traffic, an important matter that requires clarification in the context of the vehicle–platform interface. This is factored into the requirements of general railway standards, in particular the EU’s TSI INF, concerning the design patterns of CR systems considered as very well organized, i.e., those using primarily their own dedicated corridors. First and foremost, this concerns the sole choice of a specific standard for platform height, from among the two currently permitted by the TSI INF, and the platform gap. Also related to this issue is the contradiction between the safety requirements for, among others, long-distance trains to pass by platforms without stopping, often at higher speeds, which requires a corresponding increase in clearance, and the needs of CR (meaning the desire to minimize clearance as much as possible). According to the authors’ conclusions, the action here should be parallel. The standard of the platform edge position should meet the requirements of mixed traffic, but it should be a common uniform standard (which, from the economic and construction point of view, is not easy to achieve due to the historical legacy, as is clear to see in the context of the WRJ). Also, the design of the CR rolling stock should fill the gap as much as possible, taking advantage of the fact that CR trains stop at each or most platforms or pass by them at relatively low speeds. Lastly, we recommend that in the process of achieving a certain standard at the junction scale, temporary solutions should not be used, since in their existing state, the platforms provide a sub-optimal level of safety and comfort.

Author Contributions

Conceptualization, I.G. and A.H.; methodology, I.G. and A.H.; validation, I.G. and A.H.; formal analysis, I.G. and A.H.; investigation, I.G. and A.H.; resources, I.G. and A.H.; data curation, I.G. and A.H.; writing—original draft preparation, I.G. and A.H.; writing—review and editing, I.G. and A.H.; visualization, A.H.; supervision, I.G.; project administration, I.G. and A.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Oliveira, L.; Bruen, C.; Birrell, S.; Cain, R. What passengers really want: Assessing the value of rail innovation to improve experiences. Transp. Res. Interdiscip. Perspect. 2019, 1, 100014. [Google Scholar] [CrossRef]

- Litman, T. Rail Transit in America: A Comprehensive Evaluation of Benefits; Victoria Transport Policy Institute: Victoria, BC, Canada, 2012. [Google Scholar]

- Wener, R.E.; Evans, G.W. Comparing stress of car and train commuters. Transp. Res. Part F Traffic Psychol. Behav. 2011, 14, 111–116. [Google Scholar] [CrossRef]

- Oliveira, L.; Fox, C.; Birrell, S.; Cain, R. Analysing passengers’ behaviours when boarding trains to improve rail infrastructure and technology. Robot. Comput. Integr. Manuf. 2019, 57, 282–291. [Google Scholar] [CrossRef]

- Litman, T. Valuing transit service quality improvements. J. Public Transp. 2008, 11, 43–63. [Google Scholar] [CrossRef]

- Morris, E.; Guerra, E. Mood and mode: Does how we travel affect how we feel? Transportation 2015, 42, 25–43. [Google Scholar] [CrossRef]

- Kompleksowe Badania Ruchu We Wrocławiu I Otoczeniu. Urząd Miasta Wrocławia, 2018.

- Molecki, A. Wdrażanie Inteligentnych Systemów Transportowych (ITS) w kontekście polityki transportowej aglomeracji miejskiej na przykładzie Wrocławia. Maz. Stud. Reg. 2017, 20, 111–121. [Google Scholar] [CrossRef][Green Version]

- Bratzel, S. Conditions of success in sustainable urban transport policy. Policy change in ‘relatively successful’ European cities. Transp. Rev. 1999, 19, 177–190. [Google Scholar] [CrossRef]

- Korzeń, M.; Gisterek, I. Create of the Agglomeration Railway in Wrocław with the use of new cross-city sections. Przegląd Komun. 2021, 76, 8–13. Available online: https://transportation.overview.pwr.edu.pl/UPLOAD/CALE-NUMERY/NUMERY-PL/2021/N_PK_06_07_21.pdf (accessed on 15 April 2023). [CrossRef]

- Kruszyna, M.; Makuch, J. Mobility nodes as an extension of the idea of transfer nodes—Solutions for smaller rail stations with an example from Poland. Sustainability 2023, 15, 2106. [Google Scholar] [CrossRef]

- Asensio, J. The success story of Spanish suburban railways: Determinants of demand and policy implications. Transp. Policy 2000, 7, 295–302. [Google Scholar] [CrossRef]

- Sohoni, A.; Thomas, M.; Krishna Rao, K.V. Mode shift behaviour of commuters due to the introduction of new rail transit mode. Transp. Res. Procedia 2017, 25, 2603–2618. [Google Scholar] [CrossRef]

- Boenke, D.; Girnau, G.; Grossmann, H.; Mallikat, J.; Pütz, R.; Thienert Ch Höger, U.; Monninger, D.; Wiesenhütter, M. Barrier-Free Public Transport in Germany, 2nd ed.; Verband Deutscher Verkehrsunternehmen: Berlin, Germany, 2012. [Google Scholar]

- Eurostat. Railway Passenger Transport Statistics—Quarterly and Annual Data. 2019. Available online: https://ec.europa.eu/eurostat/statistics-explained/pdfscache/7066.pdf (accessed on 15 April 2023).

- Stoilova, S. Study of railway passenger transport in the European Union. Teh. Vjesn. 2018, 25, 587–595. [Google Scholar] [CrossRef]

- Kiebert, W. Die Berliner Stadtbahn. Bau und Geschichte der Ersten Viaduktbahn Europas; VBN Verlag Bernd Neddermeyer GmbH: Berlin, Germany, 2011. [Google Scholar]

- Hering Bau GmbH & Co. KG. Design Documentation “S-Bf Hoppegarten. Grunderneuerung Bahnsteiganlagen”. 2010. Available online: https://www.heringinternational.com/fileadmin/media/archive1/downloads/bahnsteigdach_bodenheim/uebersichtsplan_bodenheim_light.pdf (accessed on 21 March 2023).

- Konsortium Siemens; Stadler. Neue S-Bahnzüge Für Berlin. 2018. Available online: https://press.siemens.com/global/de/feature/neue-zuege-fuer-die-berliner-s-bahn (accessed on 12 April 2023).

- Oostendorp, R.; Gebhardt, L. Combining means of transport as a users’ strategy to optimise traveling in an urban context: Empirical results on intermodal travel behaviour from a survey in Berlin. J. Transp. Geogr. 2018, 71, 72–83. [Google Scholar] [CrossRef]

- Lois, D.; Monzon, A.; Hernandez, S. Analysis of satisfaction factors at urban transport interchanges: Measuring travellers’ attitudes to information, security and waiting. Transp. Policy 2018, 67, 49–56. [Google Scholar] [CrossRef]

- Vuchic, V. Urban Transit Systems and Technology; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2007. [Google Scholar]

- Ingvardson, J.B.; Nielsen, O.A. Effects of new bus and rail rapid transit systems—An international review. Transp. Rev. 2018, 38, 96–116. [Google Scholar] [CrossRef]

- Achenbach, H.; Fry, V.; Norgall, T. Die Vergabe der S-Bahn Rhein-Main. Der Nahverk. 2013, 1–2, 42–49. [Google Scholar]

- Verkehrsverbund Rhein–Ruhr VRR: Company History. Available online: https://www.s-bahn-rhein-ruhr.de/de/historie/ (accessed on 16 April 2023).

- Verkehrsverbund Rhein–Ruhr VRR. Beschlussvorlage Migrationskonzept S-Bahn Bahnsteige S/IX/2018/0504. 2018. Available online: https://zvis.vrr.de/bi/vo0050.asp?__kvonr=4980 (accessed on 11 April 2023).

- DB Station&Service, AG. Ausführungsbestimmungen der DB Station&Service AG zur Anwendung der TSI PRM 2008 bei Stationsbauprojekten (AB-PRM). 2017. Available online: https://www1.deutschebahn.com/resource/blob/1786090/3800d65c3f98cdfabf77177340b0def6/152_Ausfuehrungsbestimmungen-zur-TSI-PRM-2015-data.pdf (accessed on 11 April 2023).

- Hütter, K.; Heimann, D.; Schurig, R. Der komplexe Umbau des Eisenbahnknotes Dresden. Eisenbahningenieur 2005, 6, 30–38. [Google Scholar]

- Buehler, R.; Pucher, J.; Duemmler, O. Verkehrsverbund: The evolution and spread of fully integrated regional public transport in Germany, Austria, and Switzerland. Int. J. Sustain. Transp. 2019, 13, 36–50. [Google Scholar] [CrossRef]

- Hagmann, A. Station Museumstrasse and crossing of the River Limmat. Struct. Eng. Int. 1991, 1, 7–11. [Google Scholar] [CrossRef]

- Heierli, W.; Kleiner, P.; Schindler, J. Zurichberg Tunnel. Struct. Eng. Int. 1991, 1, 17–21. [Google Scholar] [CrossRef]

- Schweizerische Bundesbahnen, SBB. Projektwettbewerb Erweiterung Bahnhof Zürich Stadelhofen. 2019. Available online: https://company.sbb.ch/content/dam/internet/corporate/de/ueber-die-sbb/projekte/projekte-zuerich-ostschweiz/Zuerich-Stadelhofen-Jurybericht.pdf.sbbdownload.pdf (accessed on 21 April 2023).

- Schweizerische Bundesbahnen, SBB. STEP Ausbauschritt 2035: Ein Takt Für die Ganze Schweiz. 2018. Available online: https://company.sbb.ch/content/dam/internet/corporate/de/ueber-die-sbb/projekte/nationale-programme/Broschuere-STEP-Ausbauschritt-2035.pdf.sbbdownload.pdf (accessed on 21 April 2023).

- Böhler, A.; Bürgi, D. Kürzere Fahrgastwechselzeiten Für die «Zürcher S-Bahn 2G». Master’s Thesis, Zürcher Hochschule für Angewandte Wissenschaften, Winterthur, Switzerland, 2014. [Google Scholar]

- Die Bundesversammlung der Schweizerischen Eidgenossenschaft (2004, Current Version 01.2020) Das Bundesgesetz Über die Beseitigung von Benachteiligungen von Menschen mit Behinderungen (Behindertengleichstellungsgesetz, BehiG; SR 151.3). Available online: https://www.admin.ch/opc/de/classified-compilation/20002658/index.html (accessed on 2 May 2023).

- Lanz, R.; Renard, A.; Ebinger, L. Dimensionierung der Fussgängerflächen von Haltestellen des Strassengebundenen Öffentlichen Verkehrs; B+S Ingenieur AG: Bern, Switzerland, 2005. [Google Scholar]

- European Commission. Technical Specifications for Interoperability: Commission Regulation (EU) No 1299/2014 of 18 November 2014 on the Technical Specifications for Interoperability Relating to the ‘Infrastructure’ Subsystem of the Rail System in the European Union. (Current Consolidated Version 16 June 2019). 2014. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:02014R1299-20190616 (accessed on 25 February 2023).

- EN 15273; European Norm EN 15273 Railway Applications–Gauges–Part 1–3. European Committee for Standardization: Brussels, Belgium, 2017.

- Harris, N. Train boarding and alighting rates at high passenger loads. J. Adv. Transp. 2006, 40, 249–263. [Google Scholar] [CrossRef]

- Harris, N.; Graham, D.; Anderson, R.; Li, H. The impact of urban boarding and alighting factors. In Proceedings of the Transport Research Board 93rd Annual Meeting, Washington, DC, USA, 12–16 January 2014; Available online: https://www.semanticscholar.org/paper/The-Impact-of-Urban-Rail-Boarding-and-Alighting-Harris-Graham/d571705c9d3da39c7ee84cd8c05b932236c1db8e (accessed on 18 April 2023).

- Karekla, X.; Tyler, N. Reduced dwell times resulting from train—Platform improvements: The costs and benefits of improving passenger accessibility to metro trains. Transp. Plan. Technol. 2012, 35, 525–543. [Google Scholar] [CrossRef]

- European Parliament and the Council, Regulation (EU) No 1315/2013 of the European Parliament and of the Council of 11 December 2013 on Union Guidelines for the Development of the Trans-European Transport Network and Repealing Decision No 661/2010/EU Text with Eea Relevance. (Current Consolidated Version 9 July 2023). 2013. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A02013R1315-20230709 (accessed on 7 April 2023).

- PKP Polskie Linie Kolejowe S.A. Szczegółowe Warunki Techniczne Dla Modernizacji Lub Budowy Linii Kolejowych Do Prędkości Vmax ≤ 250 km/h–Tom XI–Budowle. 2022. Available online: https://www.plk-sa.pl/files/public/user_upload/pdf/Akty_prawne_i_przepisy/Standardy_techniczne/11.04.2022/10_TOM_XI.pdf (accessed on 28 March 2023).

- Frączek, R.; Pałyga, J. Czynniki warunkujące wybór standardowej wysokości modernizowanych peronów osobowych na sieci PKP oraz zakupy i modernizacje taboru. Probl. Kolejnictwa 2006, 141, 5–46. [Google Scholar]

- Daamen, W.; de Boer, E.; de Kloe, R. Assessing the Gap between Public Transport Vehicles and Platforms as a Barrier for the Disabled: Use of Laboratory Experiments. Transp. Res. Rec. J. Transp. Res. Board 2008, 2072, 131–138. [Google Scholar] [CrossRef]

- Daamen, W.; Lee, Y.; Wiggenraad, P. Boarding and alighting experiments. Overview of setup and performance and some preliminary results. Transp. Res. Rec. J. Transp. Res. Board 2008, 2042, 71–81. [Google Scholar] [CrossRef]

- Grange-Faivre, C.; Marin-Lamellet, C.; Alauzet, A. Maximum acceptable gap between urban-guided transport vehicles and platforms for persons with disabilities: The findings of an experimental study conducted to inform policy decisions. Transp. Plan. Technol. 2017, 40, 167–181. [Google Scholar] [CrossRef]

- Sze, N.; Christensen, K. Access to urban transportation system for individuals with disabilities. IATSS Res. 2017, 41, 66–73. [Google Scholar] [CrossRef]

- COST European Cooperation in Science & Technology. COST 335: Passengers’ Accessibility of Heavy Rail Systems—Final Report of the Action; EC Directorate General Transport: Brussels, Belgium, 1999. [Google Scholar]

- Bundesamt Für Verkehr Der Schweizerischen Eidgenossenschaft. Ausführungsbestimmungen Zur Eisenbahnsverordnung (AB-EBV) 2016. Available online: https://www.bav.admin.ch/bav/de/home/rechtliches/rechtsgrundlagen-vorschriften/ab-ebv/ab-ebv-aenderungsinfos-2016.html (accessed on 25 February 2023).

- BVB 2018: Projektierungsrichtlinie Für Infrastrukturanlagen; Basler Verkehrsbetriebe: Basel, Switzerland, 2018.

- Grange-Faivre, C.; Alauzet, A.; Marin-Lamellet, C. Etude Portant Sur Les Difficultés de Franchissement Des Lacunes Quai-Seuil Par Les Usagers de Fauteuil Roulant Lors de L’Accès Aux Transports Guidés—Rapport Final 2009. Available online: http://v2.handi-social.fr/wa_files/INRETS_10_etudeportantsurdifficulteesfranchisstlacunesquai-seuilparUFRlorsaccestransportsguides.pdf (accessed on 13 April 2023).

- Gisterek, I.; Popiołek, A. Propozycja nowelizacji tramwajowych przepisów budowlanych. Przegląd Komun. 2015, 9, 115–125. [Google Scholar]

- Sasamoto, K.; Momomoto, A. Safety equipment for passengers on railway platforms. Saf. Sci. 1995, 18, 301–307. [Google Scholar] [CrossRef]

- de Ana Rodriguez, G.; Seriani, S.; Holloway, C. Impact of platform edge doors on passengers’ boarding and alighting time and platform behaviour. Transp. Res. Rec. J. Transp. Res. Board 2016, 2540, 102–110. [Google Scholar] [CrossRef]

- Barron, A.; Canavan, S.; Anderson, R.; Cohen, J. Operational impacts of platform doors in metros. Transp. Res. Rec. J. Transp. Res. Board 2018, 2672, 266–274. [Google Scholar] [CrossRef]

- Gisterek, I. Propozycje unowocześnień w infrastrukturze tramwajowej we Wrocławiu. In Proceedings of the Conference Nowoczesne Technologie i Systemy Zarządzania w Kolejnictwie, Zakopane, Poland, 30 November–2 December 2016; pp. 51–61. [Google Scholar]

- Gisterek, I. Device for Reducing the Gap at the Platform. Patent PL 224580 B1, 31 January 2017. [Google Scholar]

- Newag Impuls. Available online: https://www.newag.pl/en/wp-content/uploads/sites/3/2018/08/EZT-Impuls.pdf (accessed on 24 March 2023).

- Kancelaria Sejmu Rzeczypospolitej Polskiej. Rozporządzenie Ministra Transportu I Gospodarki Morskiej Z Dnia 10 Września 1998 R. W Sprawie Warunków Technicznych, Jakim Powinny Odpowiadać Budowle Kolejowe I Ich Usytuowanie. 1998. Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU19981510987 (accessed on 29 June 2022).

- Kancelaria Sejmu Rzeczypospolitej Polskiej. Rozporządzenie Ministra Infrastruktury I Rozwoju Z Dnia 5 Czerwca 2014 R. Zmieniające Rozporządzenie W Sprawie Warunków Technicznych, Jakim Powinny Odpowiadać Budowle Kolejowe I Ich Usytuowanie. 2014. Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20140000867 (accessed on 29 June 2022).

- PKP Polskie Linie Kolejowe, S.A. Regulamin Sieci 2020/2021. Wykaz Peronów Przy Liniach Kolejowych Zarządzanych Przez PKP Polskie Linie Kolejowe S.A. Available online: https://www.plk-sa.pl/dla-klientow-i-kontrahentow/warunki-udostepniania-infrastruktury-i-regulaminy/regulamin-sieci/regulamin-sieci-20202021/ (accessed on 20 March 2020).

- PKP Polskie Linie Kolejowe, S.A. Regulamin Sieci 2022/2023. Wykaz Peronów Przy Liniach Kolejowych Zarządzanych Przez PKP Polskie Linie Kolejowe S.A. Available online: https://www.plk-sa.pl/klienci-i-kontrahenci/warunki-udostepniania-infrastruktury-i-regulaminy/regulamin-sieci/regulamin-sieci-2022/2023 (accessed on 28 March 2023).

- Kruszyna, M. NOAH as an Innovative Tool for Modeling the Use of Suburban Railways. Sustainability 2023, 15, 193. [Google Scholar] [CrossRef]

- Urząd Transportu Kolejowego. Wymiana Pasażerska Na Stacjach. Available online: https://dane.utk.gov.pl/sts/przewozy-pasazerskie/wymiana-pasazerska-na-s/20230,Przewozy-pasazerskie.html (accessed on 28 March 2023).

- PKP Polskie Linie Kolejowe S.A. Szczegółowe Warunki Techniczne Dla Modernizacji Lub Budowy Linii Kolejowych Do Prędkości Vmax ≤ 250 km/h–Tom II–Skrajnia Budowlana Linii Kolejowych. 2022. Available online: https://www.plk-sa.pl/files/public/user_upload/pdf/Akty_prawne_i_przepisy/Standardy_techniczne/11.04.2022/1_TOM_II_.pdf (accessed on 28 March 2023).

- Kyrieleis, S. Interieurs als Zeichen der Wertschätzung für den Fahrgast. Stadtverkehr 2017, 6, 40–45. [Google Scholar]