Analysis of the Stressed State of Sand-Soil Using Ultrasound

Abstract

1. Introduction

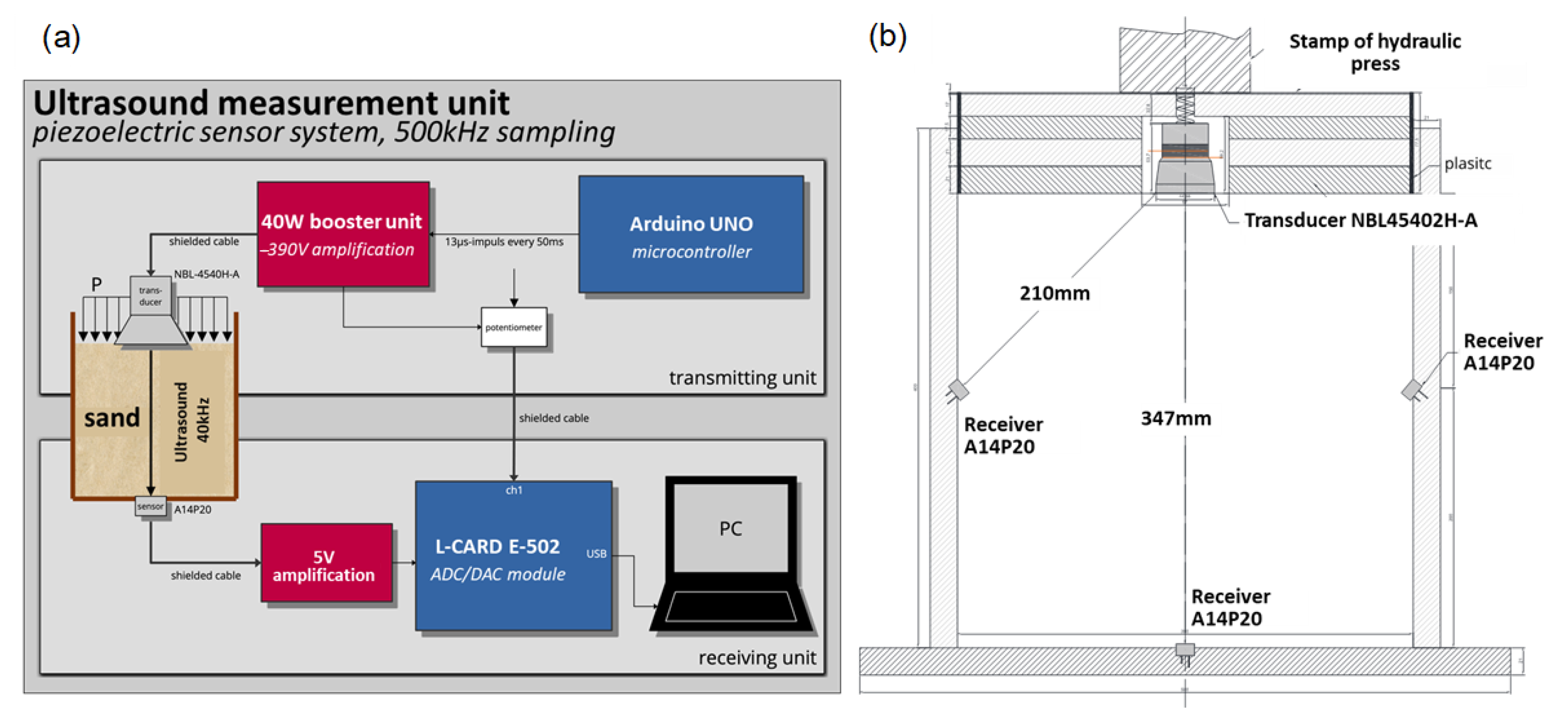

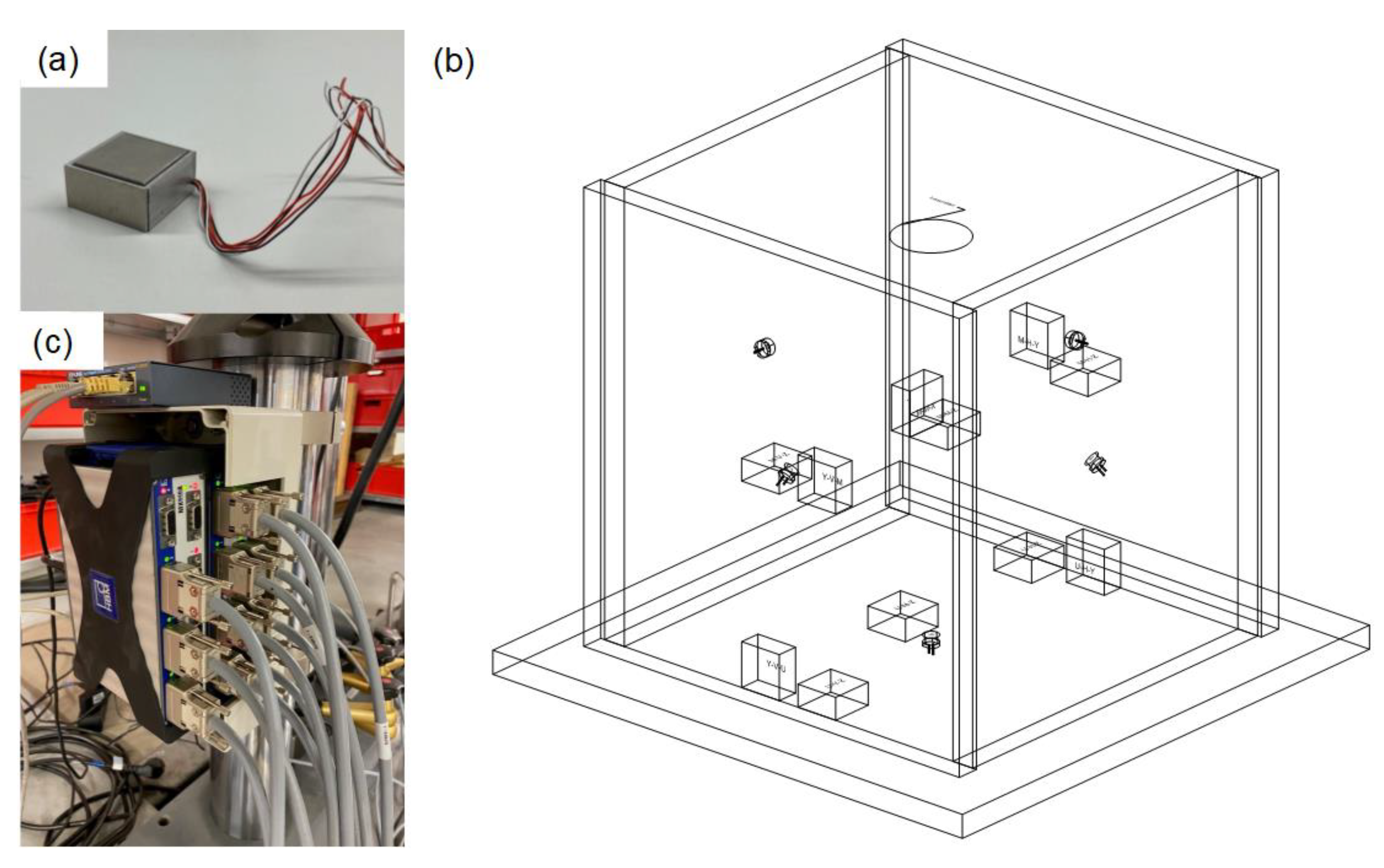

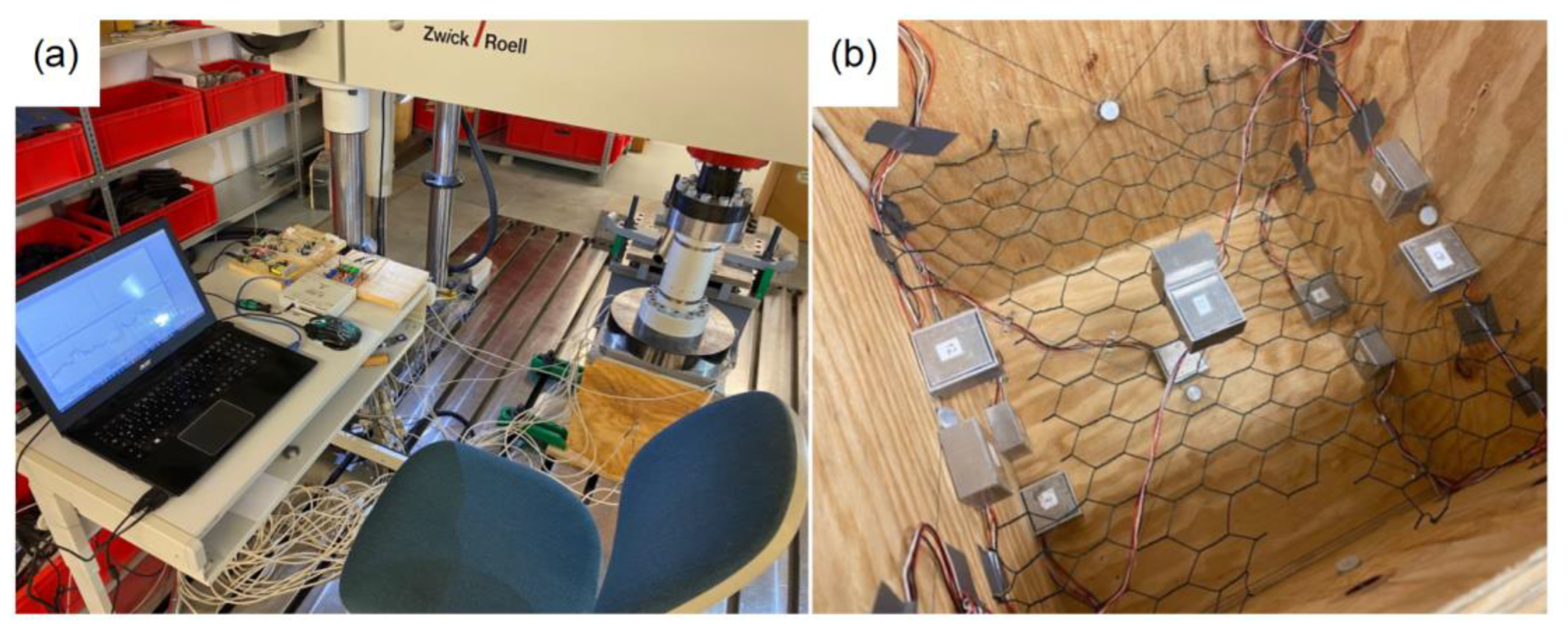

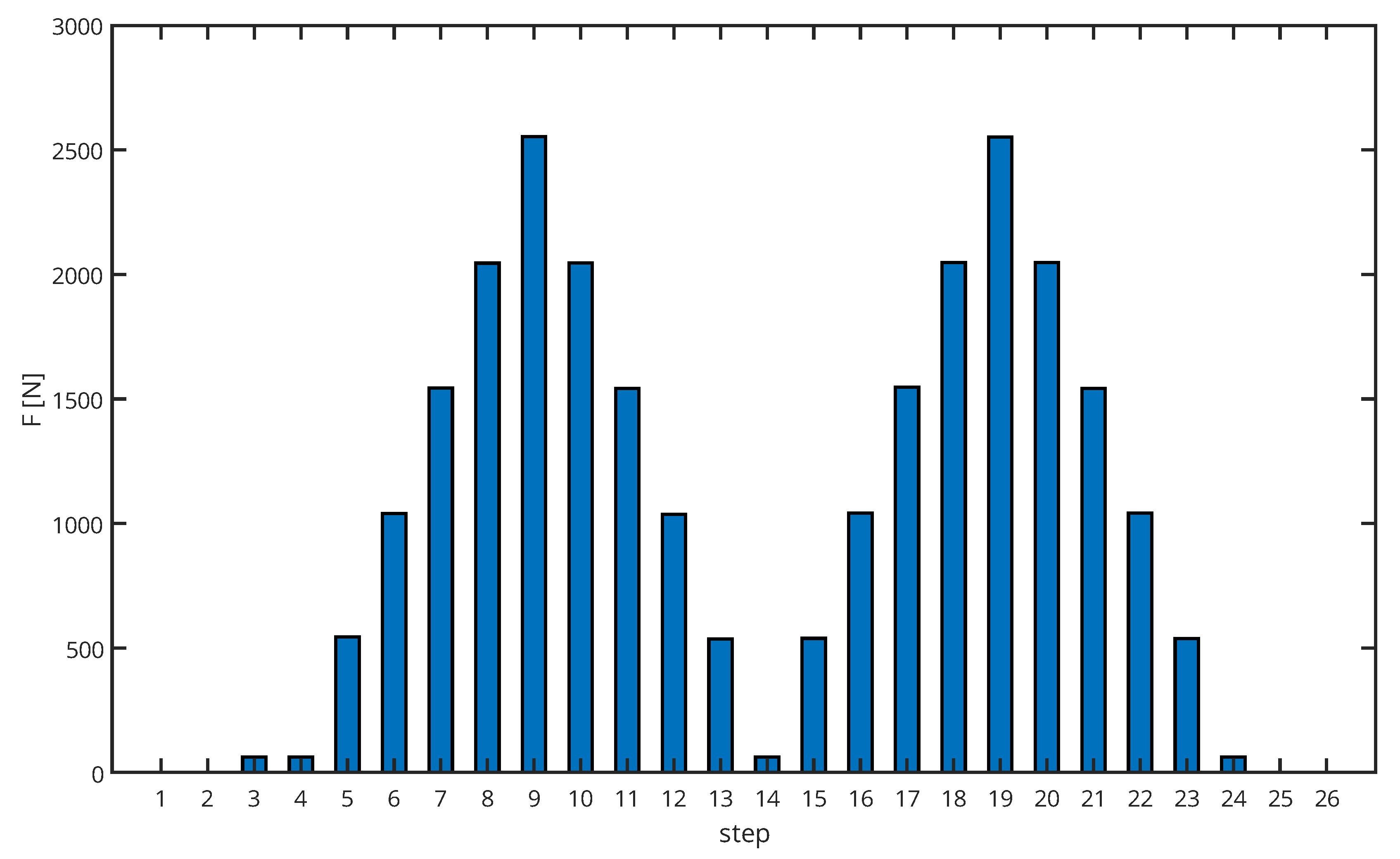

2. Laboratory Measurements

3. Analysis and Interpretation

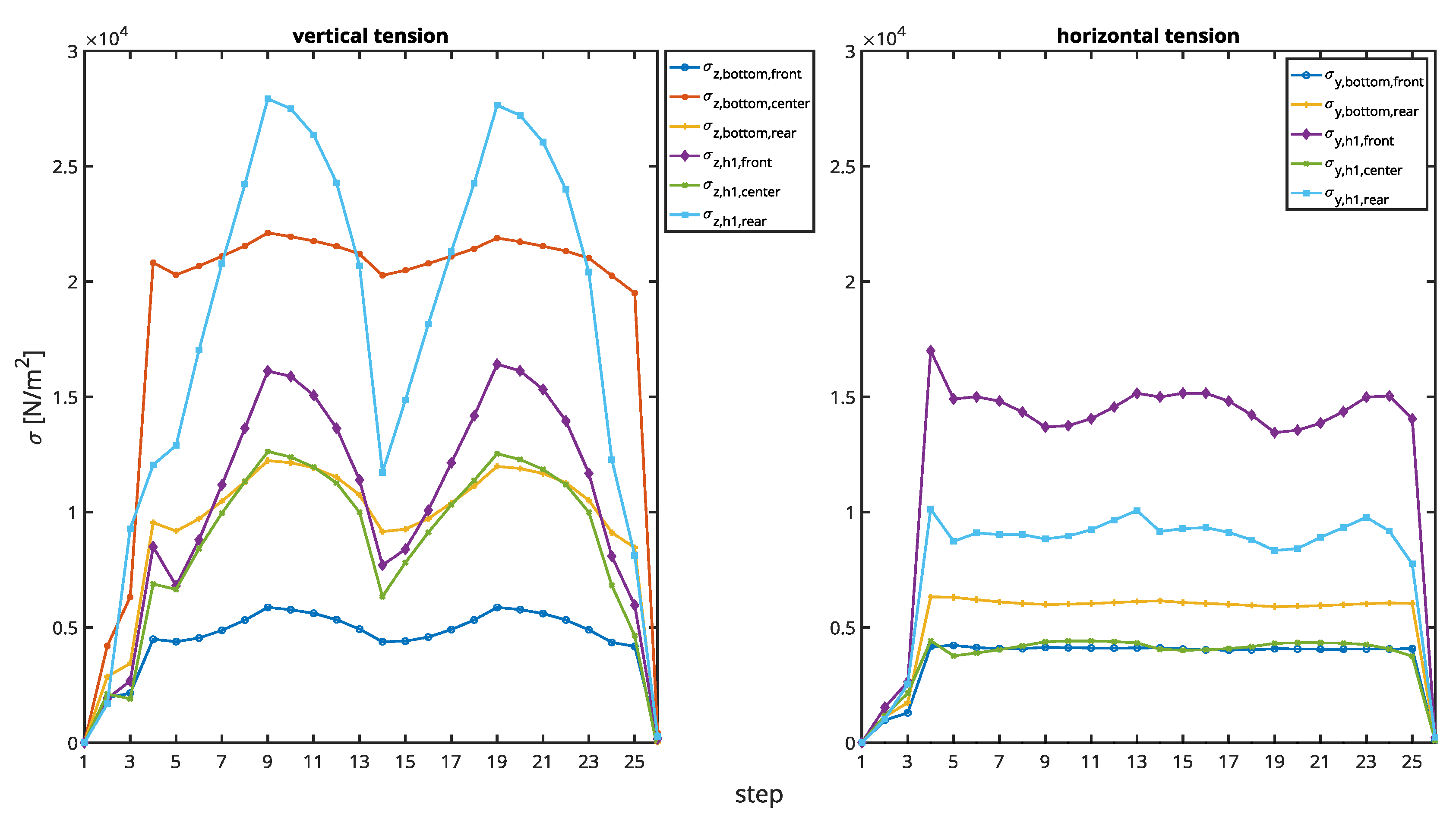

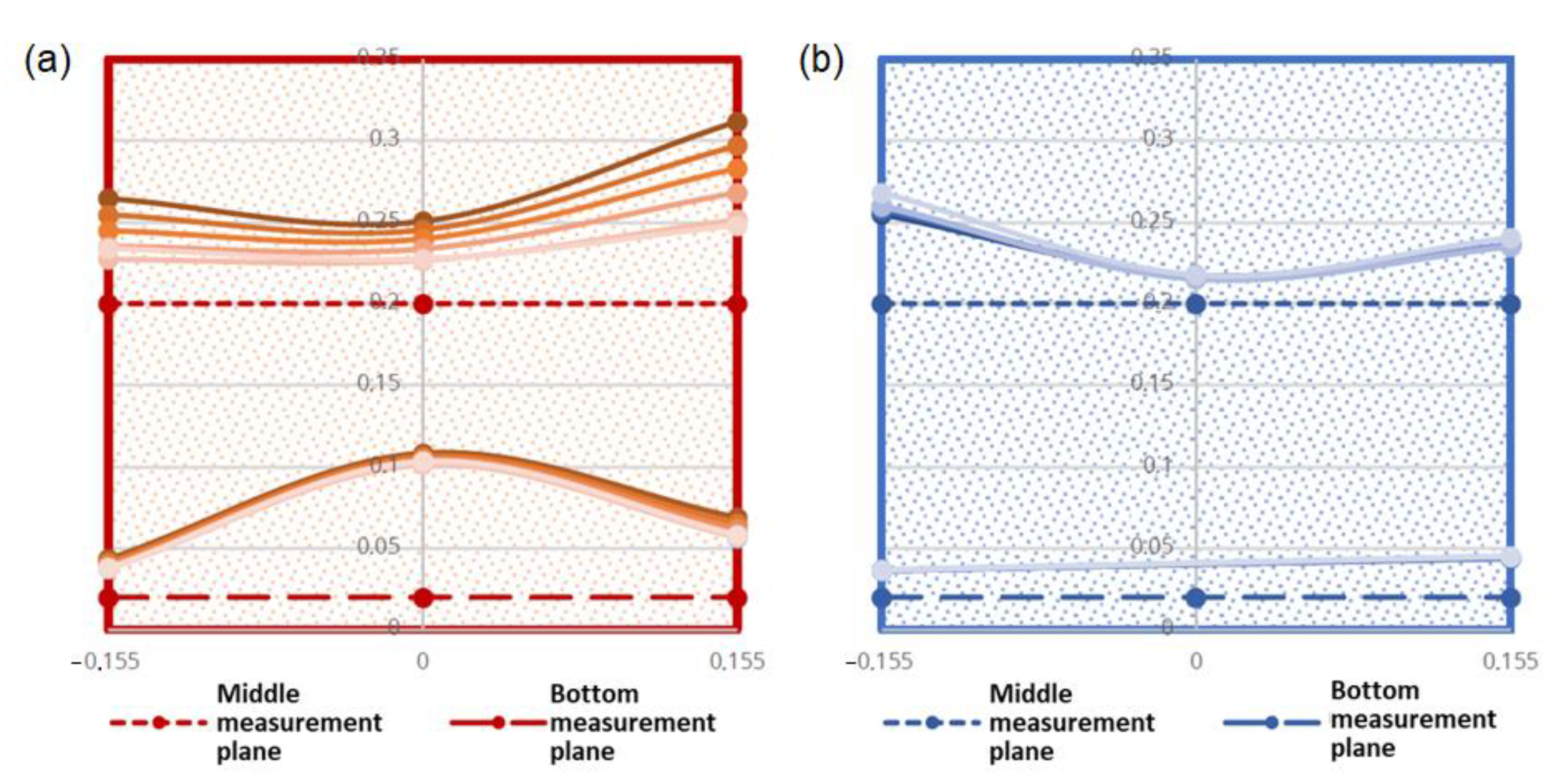

3.1. Local Pressure

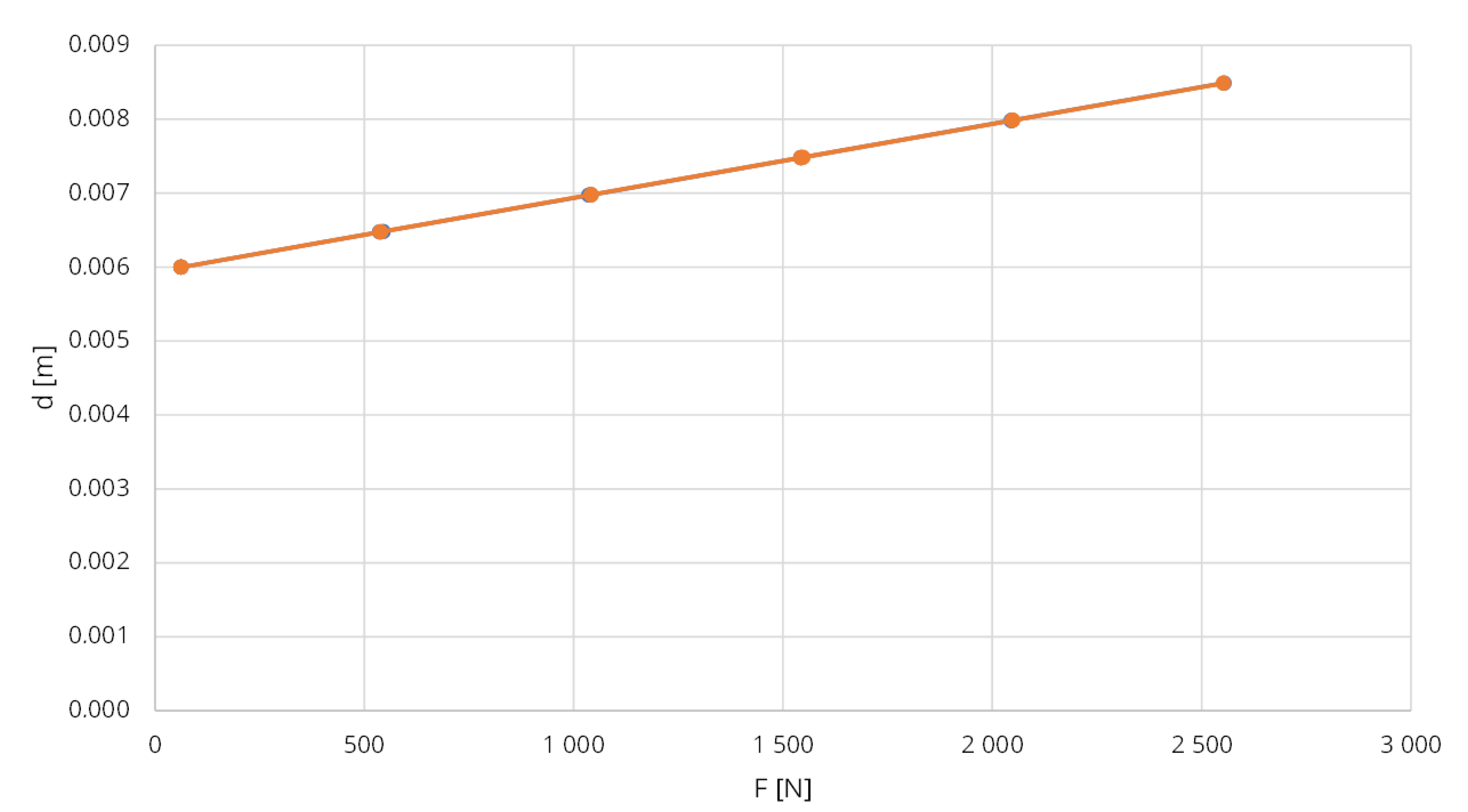

- The energy from the stamp was converted into a vertical, elastically movement of sand soil, as shown in Figure 11.

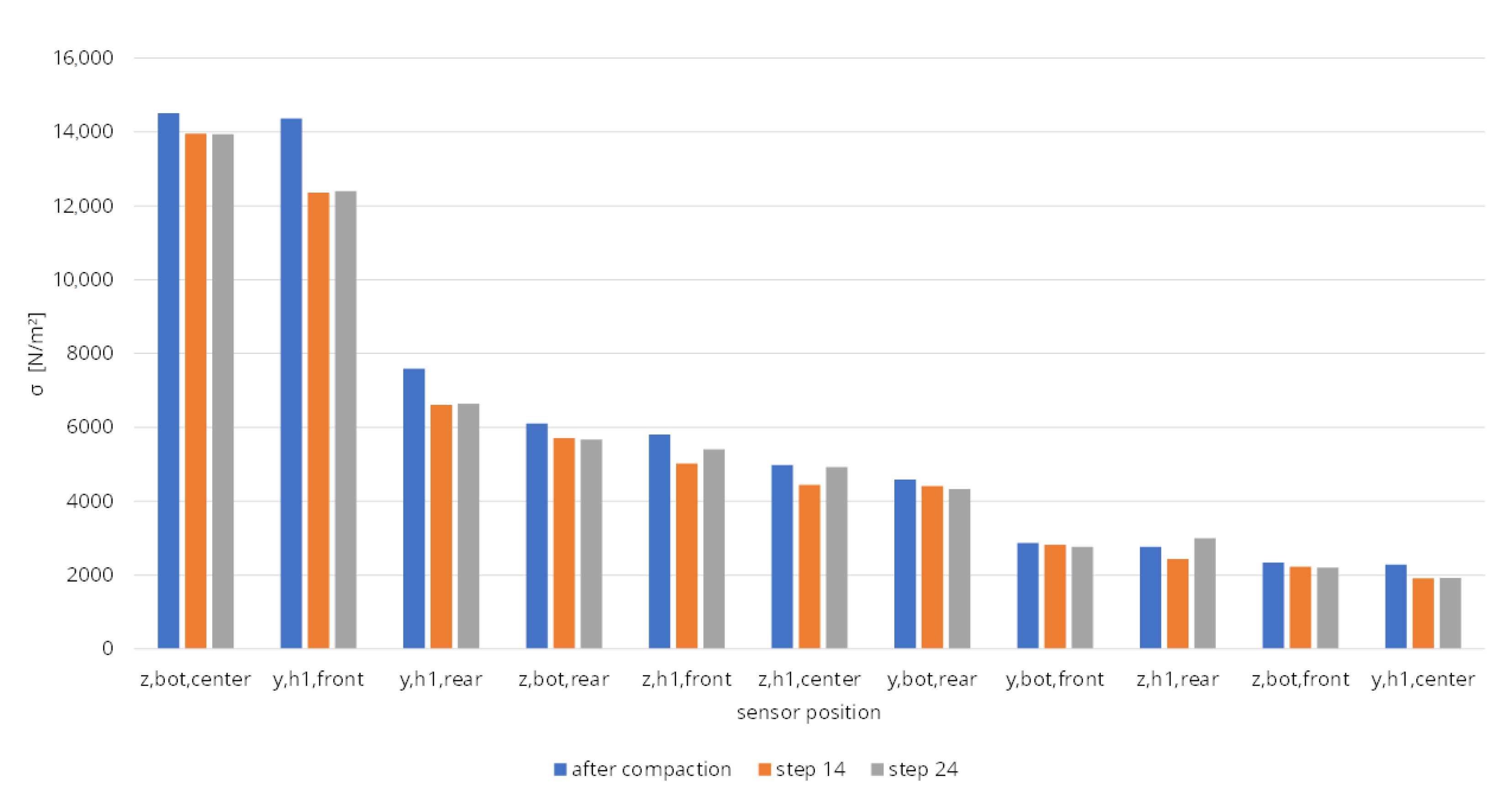

- On the sidewalls, the movement energy was mainly consumed by friction with the wooden walls since high vertical dynamic in combination with pronounced horizontal tensions appeared in these spots. In the center, the movement energy caused a high material pressure which can be concluded from the reduction of the dynamic and the rising static share in tension from top to bottom.

- The distribution of tension was inhomogeneous.

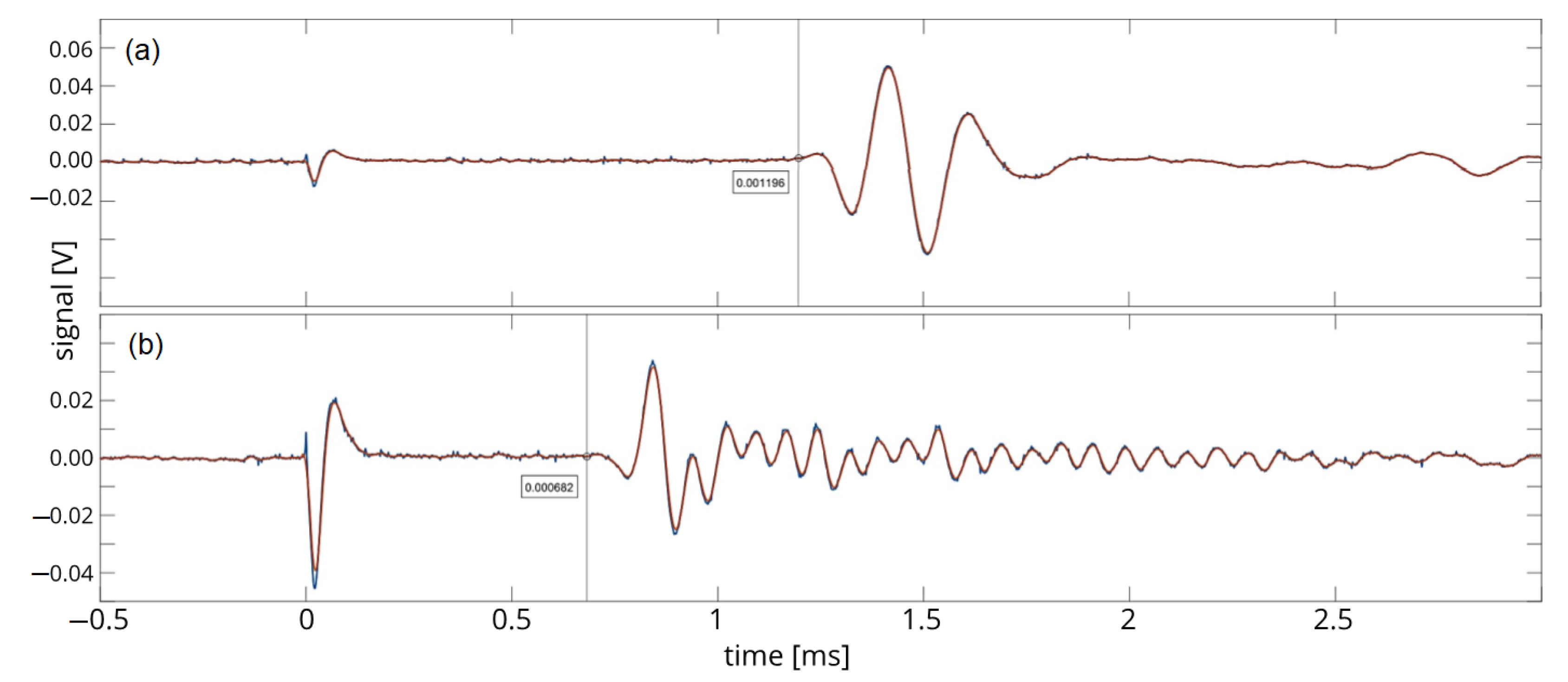

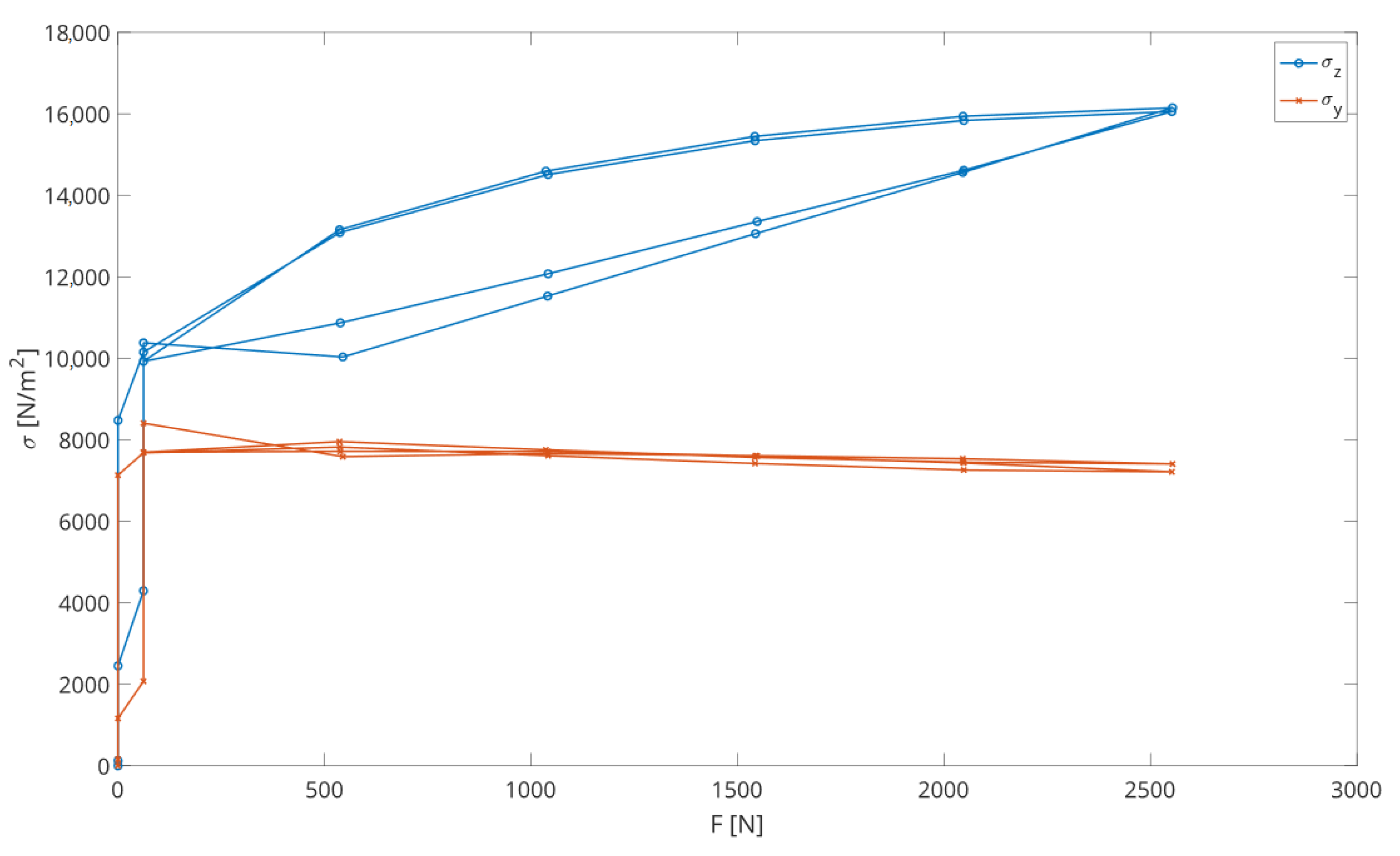

3.2. P-Wave Propagation Velocity

4. Discussion

5. Conclusions

- Internal pressure in the land layer influences the pressure wave propagation velocity. Increase of the pressure from 2 to 23 kPa at the bottom of the box results in an increase in the vertical wave velocity from 180 to 360 m/s. The relation between ballast pressure and wave propagation velocity is nonlinear.

- The vertical stress distribution over the ballast box is subjected to high local inhomogeneity with up to two times the stress concentration in the central part of the box bottom.

- The residual pressure appears at the bottom of the ballast box and accumulates after the loading cycles. The residual stresses amount to up to 60% of the maximal ones.

- The residual pressure has an influence on the wave propagation velocity.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fischer, S. Geogrid Reinforcement of Ballasted Railway Superstructure for Stabilization of the Railway Track Geometry–A Case Study. Geotext. Geomembr. 2022, 50, 1036–1051. [Google Scholar] [CrossRef]

- Kuchak, A.J.T.; Marinkovic, D.; Zehn, M. Parametric Investigation of a Rail Damper Design Based on a Lab-Scaled Model. J. Vib. Eng. Technol. 2021, 9, 51–60. [Google Scholar] [CrossRef]

- Kuchak, A.J.T.; Marinkovic, D.; Zehn, M. Finite Element Model Updating-Case Study of a Rail Damper. Struct. Eng. Mech. 2020, 73, 27–35. [Google Scholar] [CrossRef]

- Macura, D.; Laketić, M.; Pamučar, D.; Marinković, D. Risk Analysis Model with Interval Type-2 Fuzzy FMEA–Case Study of Railway Infrastructure Projects in the Republic of Serbia. Acta Polytech. Hung. 2022, 19, 103–118. [Google Scholar] [CrossRef]

- Yan, B.; Cheng, R.; Xie, H.; Zhang, X. Vertical Nonlinear Temperature Gradient and Temperature Load Mode of Ballastless Track in China. Mathematics 2022, 10, 120. [Google Scholar] [CrossRef]

- Jiang, H.; Li, Y.; Wang, Y.; Yao, K.; Yao, Z.; Xue, Z.; Geng, X. Dynamic Performance Evaluation of Ballastless Track in High-Speed Railways under Subgrade Differential Settlement. Transp. Geotech. 2022, 33, 100721. [Google Scholar] [CrossRef]

- Bian, X.; Jiang, H.; Cheng, C.; Chen, Y.; Chen, R.; Jiang, J. Full-Scale Model Testing on a Ballastless High-Speed Railway under Simulated Train Moving Loads. Soil Dyn. Earthq. Eng. 2014, 66, 368–384. [Google Scholar] [CrossRef]

- Lichtberger, B. Track Compendium; Eurailpress Tetzlaff-Hestra GmbH & Co.: Hamburg, Germany, 2005. [Google Scholar]

- Fischer, S.; Kocsis, S. Detection process of energy loss in electric railway vehicles. Facta Univ. Ser. Mech. Eng. 2023, 21, 11368. [Google Scholar] [CrossRef]

- Jover, V.; Fischer, S. STATISTICAL ANALYSIS OF TRACK GEOMETRY PARAMETERS ON TRAMWAY LINE NO. 1 IN BUDAPEST. Balt. J. Road Bridge Eng. 2022, 17, 75–106. [Google Scholar] [CrossRef]

- Szalai, S.; Dogossy, G. Speckle Pattern Optimization for DIC Technologies. Acta Tech. Jaurinensis 2021, 14, 228–243. [Google Scholar] [CrossRef]

- Szalai, S.; Szürke, S.K.; Harangozó, D.; Fischer, S. Investigation of Deformations of a Lithium Polymer Cell Using the Digital Image Correlation Method (DICM). Rep. Mech. Eng. 2022, 3, 206–224. [Google Scholar] [CrossRef]

- Szalai, S.; Eller, B.; Juhász, E.; Movahedi, R.M.; Németh, A.; Harrach, D.; Baranyai, G.; Fischer, S. Investigation of Deformations of Ballasted Railway Track during Collapse Using the Digital Image Correlation Method (DICM). Rep. Mech. Eng. 2022, 3, 258–282. [Google Scholar] [CrossRef]

- Szürke, S.K.; Dineva, A.; Szalai, S.; Lakatos, I. Determination of Critical Deformation Regions of a Lithium Polymer Battery by Dic Measurement and Wowa Filter. Acta Polytech. Hung. 2022, 19, 113–134. [Google Scholar] [CrossRef]

- Esveld, C. Modern Railway Track; MRT Production: Zaltbommel, The Netherlands, 2014. [Google Scholar]

- Eller, B.; Majid, M.R.; Fischer, S. Laboratory Tests and FE Modeling of the Concrete Canvas, for Infrastructure Applications. Acta Polytech. Hung. 2022, 19, 9–20. [Google Scholar] [CrossRef]

- de Bold, R. Non-Destructive Evaluation of Railway Trackbed Ballast; The University of Edinburgh: Edinburgh, UK, 2011. [Google Scholar]

- Kim, D.S.; Hwang, S.H.; Kono, A.; Matsushima, T. Evaluation of Ballast Compactness during the Tamping Process by Using an Image-Based 3D Discrete Element Method. Proc. Inst. Mech. Eng. F J. Rail Rapid Transit 2018, 232, 1951–1964. [Google Scholar] [CrossRef]

- Saussine, G.; Azéma, E.; Perales, R.; Radjaï, F. Compaction of Railway Ballast during Tamping Process: A Parametric Study. AIP Conf. Proc. 2009, 1145, 469–472. [Google Scholar] [CrossRef]

- Dama, N.; Ahmadian, M. Discrete Element Modeling of Railway Ballast for Studying Railroad Tamping Operation. In Proceedings of the Joint Rail Conference, St. Louis, MO, USA, 20–22 April 2020. [Google Scholar]

- Kumara, J.; Hayano, K. Model Tests on Settlement Behaviour of Ballasts Subjected to Sand Intrusion and Tie Tamping Application. In Proceedings of the 18th International Conference on Soil Mechanics and Geotechnical Engineering: Challenges and Innovations in Geotechnics, ICSMGE 2013, Paris, France, 2–6 September 2013; pp. 1305–1308. [Google Scholar]

- Przybylowicz, M.; Sysyn, M.; Kovalchuk, V.; Nabochenko, O.; Parneta, B. Experimental and Theoretical Evaluation of Side Tamping Method for Ballasted Railway Track Maintenance. Transp. Probl. 2020, 15, 93–106. [Google Scholar] [CrossRef]

- Suwal, L.P.; Pokhrel, A.; Kuwano, R. Upgrading Disk Transducer to Measure Elastic Waves on Coarse-Grained Granular Materials: Development and Performance Revelation. Soils Found. 2020, 60, 1020–1035. [Google Scholar] [CrossRef]

- Jia, F.; Cheng, H.; Liu, S.; Magnanimo, V. Elastic Wave Velocity and Attenuation in Granular Material. EPJ Web Conf. 2021, 249, 11001. [Google Scholar] [CrossRef]

- Cheng, H.; Luding, S.; Saitoh, K.; Magnanimo, V. Elastic Wave Propagation in Dry Granular Media: Effects of Probing Characteristics and Stress History. Int. J. Solids Struct. 2020, 187, 85–99. [Google Scholar] [CrossRef]

- Dutta, T.T.; Otsubo, M. Assessment of Elastic Wave Velocities through Granular Soils during Monotonic Loading. In Proceedings of the 16th Asian Regional Conference on Soil Mechanics and Geotechnical Engineering, ARC, Taipei, Taiwan, 14–18 October 2019. [Google Scholar]

- Dutta, T.T.; Otsubo, M.; Kuwano, R. Stress Wave Transmission and Frequency-Domain Responses of Gap-Graded Cohesionless Soils. Soils Found. 2021, 61, 857–873. [Google Scholar] [CrossRef]

- Tang, X.; Yang, J. Modelling Wave Propagation in Dry Granular Materials. In Micro to MACRO Mathematical Modelling in Soil Mechanics Trends in Mathematics; Birkhäuser: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Tang, X.; Yang, J. Wave Propagation in Granular Material: What Is the Role of Particle Shape? J. Mech. Phys. Solids 2021, 157, 104605. [Google Scholar] [CrossRef]

- Li, Y.; Otsubo, M.; Kuwano, R. DEM Analysis on the Stress Wave Response of Spherical Particle Assemblies under Triaxial Compression. Comput. Geotech. 2021, 133, 104043. [Google Scholar] [CrossRef]

- Muttashar, W.R.; Bryson, L.S. Constitutive Model for Predicting Stress-Strain Behavior of Fine-Grained Sediments Using Shear-Wave Velocity. Mar. Georesour. Geotechnol. 2020, 38, 896–910. [Google Scholar] [CrossRef]

- Kurhan, D.; Kurhan, M. Modeling the Dynamic Response of Railway Track. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Kharkiv, Ukraine, 20–22 November 2019. [Google Scholar] [CrossRef]

- Kurhan, D.M. The Basis Of Mathematical Description For Wave Model Of Stresses Propagation In Railway Track. Sci. Transp. Progress 2016, 65, 101–113. [Google Scholar] [CrossRef]

- Kurhan, D.; Fischer, S. Modeling of the Dynamic Rail Deflection Using Elastic Wave Propagation. J. Appl. Comput. Mech. 2022, 8, 379–387. [Google Scholar] [CrossRef]

- Jayasuriya, C.; Indraratna, B.; Ngoc Ngo, T. Experimental study to examine the role of under sleeper pads for improved performance of ballast under cyclic loading. Transp. Geotech. 2019, 19, 61–73. [Google Scholar] [CrossRef]

- Li, H.; McDowell, G.R. Discrete element modelling of under sleeper pads using a box test. Granul. Matter 2018, 20, 26. [Google Scholar] [CrossRef]

- Kraśkiewicz, C.; Zbiciak, A.; Wasilewski, K.; Al Sabouni-Zawadzka, A. Laboratory Tests and Analyses of the Level of Vibration Suppression of Prototype under Ballast Mats (UBM) in the Ballasted Track Systems. Materials 2021, 14, 313. [Google Scholar] [CrossRef]

- Lima, A.D.O.; Dersch, M.S.; Qian, Y.; Tutumluer, E.; Edwards, J.R. Laboratory fatigue performance of under-ballast mats under varying loads and support conditions. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2019, 233, 606–613. [Google Scholar] [CrossRef]

- Indraratna, B.; Nimbalkar, S.; Navaratnarajah, S.K.; Rujikiatkamjorn, C.; Neville, T. Use of shock mats for mitigating degradation of railroad ballast. Sri Lankan Geotech. J. Spec. Issue Ground Improv. 2014, 6, 32–41. [Google Scholar]

- Sysyn, M.; Nabochenko, O.; Kovalchuk, V.V.; Przybyłowicz, M.; Fischer, S. Investigation of Interlocking Effect of Crushed Stone Ballast during Dynamic Loading. Rep. Mech. Eng. 2021, 2, 65–76. [Google Scholar] [CrossRef]

- MathWorks MATLAB R2020b. Available online: https://www.mathworks.com/products/new_products/release2020b.html (accessed on 22 November 2022).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schumacher, L.B.; Sysyn, M.; Gerber, U.; Fischer, S. Analysis of the Stressed State of Sand-Soil Using Ultrasound. Infrastructures 2023, 8, 4. https://doi.org/10.3390/infrastructures8010004

Schumacher LB, Sysyn M, Gerber U, Fischer S. Analysis of the Stressed State of Sand-Soil Using Ultrasound. Infrastructures. 2023; 8(1):4. https://doi.org/10.3390/infrastructures8010004

Chicago/Turabian StyleSchumacher, Lukas Benedikt, Mykola Sysyn, Ulf Gerber, and Szabolcs Fischer. 2023. "Analysis of the Stressed State of Sand-Soil Using Ultrasound" Infrastructures 8, no. 1: 4. https://doi.org/10.3390/infrastructures8010004

APA StyleSchumacher, L. B., Sysyn, M., Gerber, U., & Fischer, S. (2023). Analysis of the Stressed State of Sand-Soil Using Ultrasound. Infrastructures, 8(1), 4. https://doi.org/10.3390/infrastructures8010004