Abstract

The impact that construction has on sustainability as a relevant consumer of materials is well known, especially with regard to cement, which contributes to high CO2 emissions. It is well known that in tile adhesives, cement add positive technical contributes, supporting tensile adhesion, especially after water immersion and freeze–thaw cycles. On the other hand, it is also known that that it is possible to replace Portland cement with alternative sources, such as blast furnace slag, fly and bottom ashes, or other pozzolanic materials. Even so, other materials can be also used to contribute to additional performance. This work intends to prove that using recycled materials or by-products is not just a potential way to replace existing materials, improving environmental sustainability, but also contributes additional value to mortars, such as cement-based tile adhesives. Different recycled waste materials are introduced to a cement-based tile adhesive and the evaluation of properties according to EN 12004 is conducted. The results show how the introduction of recycled rubber can contribute to improve the workability of a tile adhesive, acting as a lightweight aggregate. Moreover, it can contribute to reducing the dynamic elasticity modulus; thus, it has a potential contribution to reduce global tensions in tiling systems, and the adhesion results are maintained by the introduction of slag, another recycled material. The weight reduction reduces mortar consumption, one of the main targets to support indicated strategy and justify a more sustainable performance. The results indicate that the introduction of rubber and slag provide good technical and mechanical performance for the mortars, as well as excellent workability.

1. Introduction

Building construction presents an important economic axis for any country. However, the industry is also a relevant material consumer, with potential negative impacts on environmental sustainability. For instance, aggregates (as the main component of many construction materials) as mortars can represent annual consumptions of 8 ton/habitant/year just in the European Union, which is only overcome by water consumption. Consequently, it is fundamental to find alternative processes to decrease or prevent such negative potential impacts. The potential use of recycled aggregates or the use of materials with reduced consumption per surface area are possibilities to support this strategy. Additionally, cement represents great potential for harm due to its high consumption and respective CO2 emissions, considering that each produced ton of Portland cement contributes, in general, 0.8 ton of CO2. Thus a strategy to reduce this in construction building materials is required [1,2,3,4].

Cement-based tile adhesives, according to EN 12004, consist of a mix of cement, redispersible polymer (usually ethylene, vinyl acetate, or vinyl versate co-polymer), aggregates as silica sand, and specific adjuvants as cellulose ether, starch ether or accelerators to present good workability or improve the reactivity of the system. According to EN 12004 or ISO 13007-1, cementitious adhesives should comply with the C1 fundamental characteristics reported in Table 1, meaning a minimal adhesion value of 0.5 MPa under several curing conditions. Additional characteristics for C2 tile adhesives (improved performance) are also presented in the same table, requiring a minimal adhesion value of 1MPa. Concerning mechanical performance, an additional requirement can also be applied, named transverse deformation, which consists of the deflection recorded at the center when a beam of hardened adhesive is subjected to three-point loading [3,5,6].

Table 1.

Summary of specifications for cementitious adhesives, including fundamental and special characteristics [5,6].

Recent works have presented the stress distribution generated by thermal expansion in a ceramic bonding system through the use of finite element modeling, in which a thermal source induces a temperature variation carried out incrementally in the simulation. A temperature gradient is assumed from the exposed face, crossing the element interface until it reaches the internal mass of the ceramic adhesive interface. Using the same numerical model, this research led to the evaluation of thermal equivalent stresses according to the von Mises criterion, adopting different elastic modulus combinations for tile adhesive and joint grout. The results indicate that such a relation has an impact on tension, both at adhesive and support levels, and conditioning the decision related to the joint width between tiles and with supports such as EPS, render and concrete. This also means that, in addition to adhesion and transverse deformation by EN 12004, additional mechanical considerations of tile adhesives, as the dynamic elastic modulus, can contribute to the better performance of the products [7,8].

According to EN 15804 and ISO 14025, sustainability goals and scopes for mortar should include the functional unit used, the product’s description, application and the boundaries of the analyzed system. Additionally, an Inventory Analysis is considered, where energy, water, used resources, the emission of pollutants into the air, and waste production are quantified. Finally, an Impact Assessment is performed where the inputs and outputs of the system are translated into potential environmental impact and divided into different categories.

Considering the existing results of the Life Cycle Assessment for different categories, measure per functional area of 1kg of produced tile adhesive (class C2S), and phases A1–A3, Table 2 shows typical values for CO2 emission coming from different existing sources. In addition, Figure 1 also shows the main responsible impact per category. According to Figure 1, ordinary Portland cement (OPC) and redispersible polymer resin (RDP) represent the components with major impact in all categories, except ADP. Focusing on GWP (global warming performance, expressed in kg CO2 emission per kg of final product), any particular action that can contribute to reducing OPC and RDP dosage represents an important contribution to achieve a better performance on such a level, since these represent more than 50% of CO2 emissions for tile adhesives [9,10].

Table 2.

Impact evaluation for C2S tile adhesives according to different sources (modules A1–A3).

Figure 1.

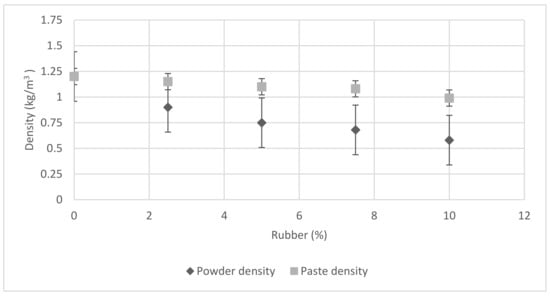

Powder and paste density of a C2S tile adhesive as a function of recycled rubber content.

Concerning tile adhesive mortars, a fundamental requirement is the ability of the mortar to be easy to apply, a property that is usually based on empirical evaluation, even if some rheological measures can be performed and linked to specific properties of the mortar, such as the fresh density and fine texture materials, providing smooth textures.

When considering the three previous questions, (a) relevant CO2 emissions values, highly impacted by Portland cement and polymer resin, (b) technical performance including a focus on additional properties such as Young modulus, and (c) improvement in workability to make the daily use easier for application, a combined arrangement of raw materials is considered in order to provide improvements for the three conditions. Additionally, the introduction of recycled materials is understood as a main part of the solution, considering that:

- The high use of redispersible polymer, to ensure adhesion level after heat storage conditions and transverse deformation, can be partially replaced by lightweight aggregates that can reduce the Young modulus of the mortar and ensure tension accommodation, for instance, as a result of temperature differentiation [11];

- Then, considering the need to include lightweight aggregates, recycled rubber can be used as a predilection material due to its low density and fine grain size. Vulcanized rubber is extensively used in many industrial sectors due to its good physical, mechanical and dynamic properties, as well as excellent durability, outstanding abrasive resistance and relatively low cost. Unfortunately, most post-consumer rubber-derived products are still discarded as waste, buried in landfills, or incinerated. Such materials require many years to degrade naturally due to (i) their complex cross-linked composition, and (ii) the additives used during manufacturing to extend the lifespan of rubber. Extensive research has investigated the use of end-of-life rubber as binders (e.g., elastomers, bitumen) or as conglomerates (cement, gypsums) to produce innovative composites in construction. To improve the properties of composites made with recycled rubber, the surface of rubber has been treated with different costly processes to work on the Interfacial Transition Zone (ITZ). However, the results available in the literature are inconsistent and many technical and practical aspects remain unsolved, thus preventing the cost-effective use of rubber in the construction industry [12,13];

- On the other hand, considering the introduction of lightweight aggregates, it is expected that more binder will be needed to maintain technical performances such as tensile adhesion, which can be contradictory to the intention to decrease CO2 emissions via reducing the Portland cement dosage. To overcome this question, mineral binder dosage can be completed by using another recycled material such as ground granulated blast slag (GGBS). This material is obtained by quenching molten iron slag (a by-product of iron and steel-making) from a blast furnace in water or steam to produce a glassy, granular product that is then dried and ground into a fine powder. GGBS has to be rapidly quenched in large volumes of water, as quenching optimizes the cementitious properties, resulting in a material with high CSH (calcium silicate hydrates) referred to as ‘GGBFS’ or ‘slag cement [14,15,16,17,18].

The main goal of this work is to show how the introduction of recycled materials, as rubber and blast furnace slag, can result in tile adhesive with improved mechanical properties and make application work easier for professionals. This research shows an improvement in sustainability levels by introducing recycled materials or by-products as one of the best strategies for the decarbonization of mortars.

2. Experimental Methodology

To develop the tile adhesive mortar we focused on two main materials: recycled rubber and blast furnace slag.

Considering the recycled rubber, the following properties were considered as the starting point to be introduced in tile adhesive mortars [19]:

| Characteristics | Requirements |

| Particle size (d50) | Minimum: 250 µm Maximum: 400 µm |

| Metal and fiber content | <0.1% |

| Ash (silica) content | <24% |

| Specific particle density (by pycnometric method) | 1150 kg/m3 |

| Bulk density (according EN 1097-3) | <400 kg/m3 |

Considering blast furnace slag, the following properties were considered [20]:

| Characteristics | Requirements |

| Chemical composition based on a chemical modulus (≥1.2 according to NF EN 206/CN) | (CaO + MgO)/SiO2 > 1.25 |

| Blaine-specific surface area | 4450+/−250 cm2/g |

| Particle size (d50) | 11 µm |

| Bulk density | 800 kg/m3 |

The tile adhesive mortar was evaluated according to EN 12004-1:2017 definitions and classification. Properties and test methods were performed following EN 12004-2:2017. Additionally, the dynamic elasticity modulus (EdL) was calculated according to EN 14146 through the fundamental resonance longitudinal vibration given by the following equation (valid to any mold format):

expressed in MPa ( in m; in kg/m3; FL in Hz).

Powder density was evaluated according to EN 459-2:2012; paste density was evaluated according to EN 1015-6; finally, the dry bulk density of hardened mortar was evaluated according to EN 1015-10.

Particularly, for the powder and paste densities and tensile adhesion properties, evaluation was made according to the recycled rubber content as the most relevant source of the aggregate added to the final formulation.

Dynamic elasticity modulus, transversal deformability and open time evaluation were made to the considered optimized formulation including rubber, in comparison with the conventional tile adhesives of the same EN 12004 class classification. The same procedure was completed for the GWP evaluation regarding sustainability impact, taking the Ecoinvent database as the source to specify the most considered components, i.e., Portland cement, polymer resin and recycled rubber [21].

3. Results and Discussion

Phase 1: Recycled rubber introduction to support workability improvement

First, we introduced rubber to understand the impact on mortar workability during its application. Starting from a C2S cement-based tile adhesive (40% of the weight of ordinary Portland cement, type I, 42.5N, 5% redispersible polymer, vinyl acetate-ethylene copolymer), different amounts of rubber powder (0; 2.5; 5; 7.5 and 10%) were added to this mortar in replacement of the equivalent dosage of silica sand.

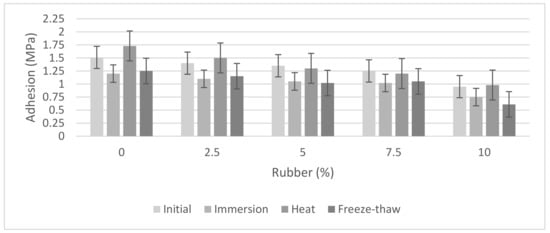

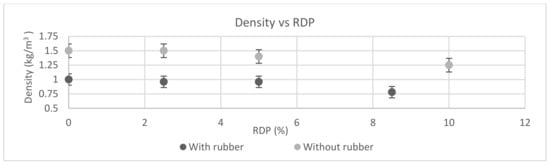

From the workability perspective, it was noticed that with a higher rubber content a better workability was obtained, in addition to the contribution to powder and paste density, according to the results from Figure 2. In fact, the results showed a continuous reduction in both densities, which suggests that this is an easier product to carry and apply during use. On the other hand, the results in Figure 3 indicate how adhesion level is impacted by rubber introduction. Looking at this trend, it can be noticed that an addition above 7.5% starts to contribute to a relevant decrease in adhesion values, especially after ageing conditions such as water immersion, freeze–thaw cycles, and heat storage.

Figure 2.

Tensile adhesion according to EN 12004 for a tile adhesive as a function of recycled rubber content.

Figure 3.

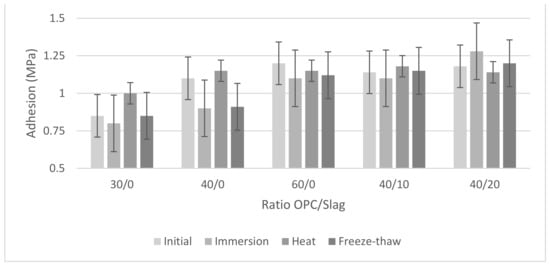

Tensile adhesion according to EN 12004 for a tile adhesive as a function of OPC and GGBS (slag) content, keeping rubber dosage constant.

Phase 2: Adhesion performance improvement by mineral binder content correction

Considering the positive impact of rubber introduction on workability/smooth texture, together with the interesting impact on powder and paste density (making the material easy to work with and to apply), there is a natural concern about the need to adjust binder quantity, such as Portland cement (OPC) or redispersible resin (RDP), in order to maintain good mechanical performance according to EN 12004 (as adhesion and transverse deformation). However, besides a possible cost increase due to potential higher dosages of Portland cement and redispersible resin, an additional concern is a potential negative impact on CO2 emissions.

To minimize both concerns, two corrective hypotheses are considered:

- The potential need for more cement can be compensated by the addition of blast furnace slag instead.

Figure 4 presents the adhesion results for a tile adhesive, with a constant content of recycled rubber and different amounts of mineral binder as a combination of ordinary Portland cement and GGBS (slag). As for all lightweight tile adhesives, additional mineral binder is essential to guarantee adhesion. In the present case, to obtain a C2 class (higher than 1 MPa), more than 50% mineral binder content was necessary. Additionally, it is also possible to notice that part of the OPC content can be replaced by slag and still maintain the desired performance.

Figure 4.

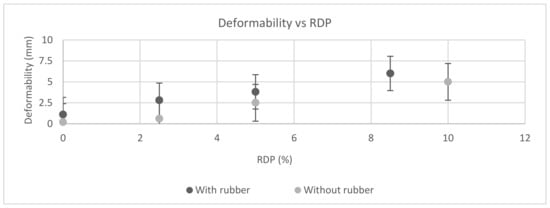

Transverse deformation according to EN 12004 for two tile adhesives, with and without recycle rubber incorporation, as a function RDP content.

- 2.

- The potential addition of rubber to compensate for part of the redispersible powder resin as a methodology to achieve desired transversal deformation and lower the dynamic elasticity modulus.

Considering that polymer resin is key to achieving transversal deformation [11], a hypothesis was raised about the possibility to optimize it by using rubber in the formulation. Considering transverse deformation and the elasticity modulus as properties that depend on similar parameters of the tile adhesive structure, it is well known that the impact of rubber introduction to reduce the elasticity modulus value of materials results in softer products, contributing to decreasing the hardened density of the material [12,13]. Taking this into consideration, a study was performed to test different polymer dosages in two tile adhesives: a standard one, without rubber introduction, and a new approach, based on rubber incorporation, following the previous results for workability and adhesion level.

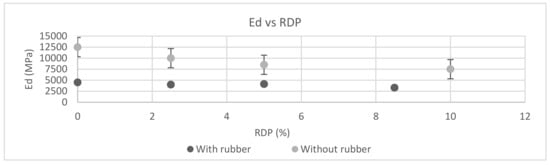

The results are presented in Figure 5, Figure 6 and Figure 7. Regarding transversal deformation, it is noticed that rubber introduction always results in a higher deformability level, even if a lower polymer resin is used (as compared to between 8.5 and 10% RDP). A similar trend shows that the dynamic elasticity modulus is strongly related to the impact on density decrease as a result of rubber introduction.

Figure 5.

Dynamic elasticity modulus for two tile adhesives with and without recycle rubber incorporation as a function RDP content.

Figure 6.

Hardened density for two tile adhesives with and without recycle rubber incorporation as a function of RDP content.

Figure 7.

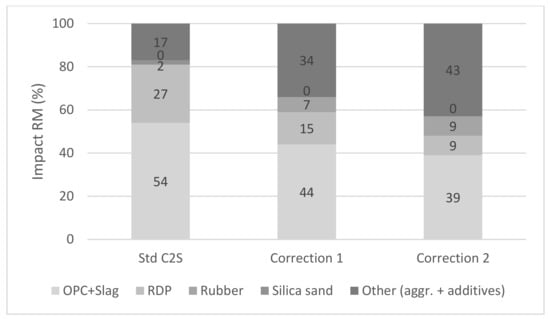

Impact of different components on CO2 emissions (kg CO2/kg adhesive) for three tile adhesive (standard version and corrected versions with rubber introduction).

Phase 3: Sustainability impact by measuring GWP (CO2 emissions)

Considering the possible corrective factors previously indicated, based on the use of the partial replacement of Portland cement by GGBS and polymer resin decreasing as a consequence of recycled rubber introduction, the following work presents the results of the related exercise regarding global warming performance based on CO2 emissions, with a particular focused on mineral binder, polymer and aggregate impact.

Figure 7 presents the impact of the different combinations promoted by the recycled rubber introduction and, consequently, the additional mineral binder content, but also the possibility to correct this by GGBS introduction plus polymer resin optimization (Correction 1: standard C2S tile adhesive; C2S tile adhesive with rubber introduction plus additional binder introduction to support adhesion. Correction 2: C2S tile adhesive with rubber introduction plus additional binder correction with GGBS and RDP optimization).

Table 3 presents the final results concerning CO2-equivalent emissions expressed in phases A1–A3:

Table 3.

CO2 emission evaluation for three tile adhesives (standard version and corrected versions with rubber introduction) according to different sources (module A1–A3).

- Weight (kg) of CO2 per weight (ton) of tile adhesive, following the conventional approach to mortars [9];

- Weight (kg) of CO2 per surface area (m2) of the applied surface, following a different approach for the functional unit. It should be considered that rubber introduction contributes to lower powder apparent density, implicating half of the consumption when applied (thus, implicating half of the consumed resources) when compared to conventional tile adhesive.

It is particularly relevant that the resulting version with rubber, corrected by GGBS binder introduction and resin polymer optimization, presented 18% less CO2 emissions than the conventional tile adhesive (considering functional unity and adhesive consumption per m2 of applied surface). From Figure 7, it can be noticed how Portland cement and polymer resin had a greater impact on sustainability performance.

4. Conclusions

Improvements at the circular economy level, including decreases in the CO2 emissions of mortars, demand continuous research into new possibilities and combinations of materials. In the particular case of tile adhesive mortars, it has been shown that recycled rubber can contribute positively to sustainability impact, even providing additional features, can add value to customers, for instance, and is related to better and easier workable products.

For the presented case, recycled rubber introduction contributed to lighter versions, reducing mortar consumption and contributing to polymer redispersible optimization, contributing to lowering the CO2 emissions. Finally, a positive trend in mechanical performance, with changes in transverse deformation and the dynamic elasticity modulus, was also achieved.

On the other hand, such actions can also result in critical consequences that need to be solved. In fact, this introduction demands higher binder content to keep adhesion level, with potential drawbacks related to global warming performance (CO2 emissions). Thus, the solution to overcoming this challenge consists of the introduction of another recycled material, ground granulated blast-furnace slag, a well-known material to provide good mechanical performance when combined with ordinary Portland cement (OPC).

As a main conclusion, our results clearly indicate the possibility of introducing recycled materials of a content higher than 30% of the weight of the cement-based tile adhesive, contributing to the circular economy and reducing the CO2 emissions of the applied mortar. This can also offer additional features related to mechanical performance and workability during application. However, the end CO2 emissions are still far from zero as result of it being very difficult to eliminate redispersable polymer and Portland cement, as the two main contributors, without losing mechanical performance.

Author Contributions

Conceptualization: L.S. and P.S.; methodology: A.L., V.F. and L.S.; software, A.L. and V.F.; validation, L.S., A.L., V.F. and P.S.; formal analysis, L.S. and P.S.; investigation: A.L., V.F., L.S. and P.S.; resources: A.L. and V.F.; data curation, A.L. and V.F.; writing—A.L. and L.S.; writing—review and editing: A.L., V.F., L.S. and P.S.; visualization: L.S.; supervision: L.S.; project administration: L.S. and P.S.; funding acquisition: Not applicable. All authors have read and agreed to the published version of the manuscript.

Funding

The authors received no financial support for the research, authorship, and/or publication of this article.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No applicable.

Conflicts of Interest

The authors declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

References

- European Commission. Directorate E-Industry and Environment-Management of Construction and Demolition Waste; Working document nº1 DG ENV.E.3–4 April 2000; European Commission: Luxembourg, 2000. [Google Scholar]

- Azevedo, A.; Alexandre, J.; Marvila, E. Influence of incorporation of glass waste on the rheological properties of adhesive mortar. Constr. Build. Mater. 2017, 148, 359–368. [Google Scholar] [CrossRef]

- Michalak, J. Ceramic Tile Adhesives from the Producer’s Perspective: A Literature Review. Ceramics 2021, 4, 378–390. [Google Scholar] [CrossRef]

- Hoffman, D. Allerte aux Pilleurs de Sable, Le Parasien: 19 Août 2013. Available online: https://www.leparisien.fr/week-end/international-alerte-aux-pilleurs-de-sable-19-08-2013-3064795.php (accessed on 11 June 2021).

- EN 12004-1:2017; Adhesives for Ceramic Tiles—Part 1: Requirements, Assessment and Verification of Constancy of Performance, Classification and Marking. CEN: Brussels, Belgium, 2017.

- ISO 13007-1:2014; Ceramic Tiles—Grouts and Adhesives, Part 1: Terms, Definitions and Specifications for Adhesives. ISO: Geneva, Switzerland, 2014.

- Silva, L.; Sequeira, P.; Melo, F.; Lopes, C.V. The evaluation of von Mises stress field in bonded tiling ceramics as function of the elastic modulus of the tile-adhesive and joint grout mortars. Proc. Inst. Mech. Eng. L J. Mater. Des. Appl. 2020, 235, 413–420. [Google Scholar] [CrossRef]

- Lopes, C.M.; Silva, L.; Sequeira, P.; Melo, F. Assessing the thermal degradation of bonded joints in flat ceramic tiles of building facades by numerical and experimental dynamic analysis. Proc. Inst. Mech. Eng. L J. Mater. Des. Appl. 2020, 234, 1129–1141. [Google Scholar] [CrossRef]

- Silva, L.; Sequeira, P.; Soares, L.; Matos, M. Desenvolvimento de Uma DAP Relativa a Uma Argamassa-Cola to Tipo C2S. In Proceedings of the CINCOS 14, Congress of Innovation on Sustainable Construction, Porto, Portugal, 13–14 November 2014. [Google Scholar]

- SNMI. Syndicat National des Mortiers Industriels; SNMI: Reston, VA, USA, 2007. [Google Scholar]

- Jenni, A.; Holzer, L.; Zurbriggen, R.; Herwegh, M. Influence of polymers on microstructure and adhesive strength of cementitious tile adhesive mortars. Cem. Concr. Res. 2005, 35, 35–50. [Google Scholar] [CrossRef]

- Cairns, R.A.; Kew, H.Y.; Kenny, M.J. The Use of Recycled Rubber Tyres in Concrete Construction. In Sustainable Waste Management and Recycling: Used/Post-Consumer Tyres; Limbachiya, M., Roberts, J., Eds.; Thomas Telford Ltd.: London, UK, 2004; Volume 3, pp. 135–142. ISBN 0727732862. [Google Scholar]

- Medina, N.F.; Garcia, R.; Hajirasouliha, I.; Pilakoutas, K.; Guadagnini, M.; Raffoul, S. Composites with recycled rubber aggregates: Properties and opportunities in construction. Constr. Build. Mater. 2018, 188, 884–897. [Google Scholar] [CrossRef]

- Snellings, R.; Mertens, G.; Elsen, J. Supplementary Cementitious Materials. Rev. Mineral. Geochem. 2012, 74, 211–278. [Google Scholar] [CrossRef]

- Juenger, M.; Winnefeld, F.; Provis, J.; Ideker, J. Advances in alternative cementitious binders. Cem. Concr. Res. 2011, 41, 1232–1243. [Google Scholar] [CrossRef]

- Ramirez, D.E.A.; DE Gutierrez, R.M.; Puertas, F. Alkali-activated Portland blast-furnace slag cement: Mechanical properties and hydration. Constr. Build. Mater. 2017, 140, 119–128. [Google Scholar] [CrossRef]

- Moranville-Regourd, M. Cements Made from Blast Furnace Slag, 4th ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 1998; pp. 637–678. [Google Scholar]

- Kolani, B.; Lacarrière, L.; Sellier, A.; Escadeillas, G.; Boutillon, L.; Linger, L. Hydration of slag-blended cements. Cem. Concr. Compos. 2012, 34, 1009–1018. [Google Scholar] [CrossRef]

- Tyre Recycled Solutions. TyreXol™ Product Data Sheet; Tyre Recycled Solutions: Préverenges, Switzerland, 2020. [Google Scholar]

- Ecocem. Technical Data Sheet Ground Granulated Blast Furnace Slag; Ecocem: Aix En Provence, France, 2017. [Google Scholar]

- Ecoinvent. Available online: https://www.ecoinvent.org/database/access-the-database/access-the-database.html (accessed on 11 June 2021).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).