1. Introduction

As the world is facing an urgent need to shift towards more sustainable practices, the construction industry, which accounts for massive resource use and carbon emissions, must develop its own path towards sustainability. One potential method is to build from materials that are renewable, circular, and do not require the use of raw and prime materials, e.g., through the use of waste streams or by-products. In this paper, we present a case study involving the use of forestry by-products which are transformed into building materials using live fungus and a 3D-printing process. Based on this case study, we suggest that a transcalar methodology that may be generally applicable within the emerging field of biodesign.

Biodesign is designing with, as or for living matter. In this paper, we employed the definition of biodesign provided by Myers and Antonelli [

1] within the more specific context of biofabrication, which is “the incorporation of living organisms as essential components […]. It goes beyond mimicry to integration, dissolving boundaries and synthesizing new hybrid typologies”.

Biology is the most powerful manufacturing technology we know of. By harnessing properties that inherent in biology such as circularity, adaptability and self-organization, the field may hold significant potential for improving the sustainability of our material culture. Of particular interest to us is the construction industry, in which some of the biggest sources of pollution and resource consumption are found. Sustainability problems arise in linear consumption chains which rely on non-renewable resources. The negative ecological footprint of the built environment can be significantly reduced by employing biological growth in the manufacture of a new class of performative materials for architecture.

Selecting biological processes that take place at a molecular level and applying them to the scale of buildings and cities can be key to replacing mineral extraction and centralized, energy-intensive production with local circularity—but it comes with a host of new challenges. One of the most pressing is bridging the two fields’ vastly different scales.

Although traditional architectural materials account for small scale behaviours such as moisture transport or thermal conductivity, they are traditionally employed as bulk materials with little spatial differentiation and homogenous behaviours. This is contrary to the biological world, wherein material differentiation and variability is continuous across scales [

2]. The specificity, heterogeneity and dynamic nature of such systems is fundamental not only for the performative or functional output, but for the very formation and generation of structures [

3] and therefore needs to be considered in biodesign.

This paper explores how these scales, i.e., the biomolecular to the architectural, can be bridged in a continuous and interrelated manner. What challenges does this present to the designer, and what methods and tools can be employed to overcome these challenges? Based on this question, we outline a methodology for the design and fabrication with living matter. The methodology was developed and implemented in the project Pulp Faction, which employs 3D printing with fungal lignocellulosic biocomposites in the making of an architectural-scale building component, named Protomycokion. The processes used in this project are studied in this paper and described from the perspective of transcalar design, and their general applicability and implications are discussed.

2. Background

The field of biodesign is gaining increasing momentum. The field is characterized by the use of nature-based solutions, including living agents in the making of new materials, and new classes of materials. Currently, there are projects employing several organisms in biofabrication for architectural elements, such as fungi, bacteria and plants; however, this paper will focus on the kingdom of fungi, as they are relevant to the case study presented here.

The ‘Hy-Fi’ tower at MOMA PS1 in New York constructed by The Living in collaboration with Arup and Ecovative from 2014 [

4] is one of the early large-scale installations built from fungal materials in the form of stacked blocks and steel supporting arches. ‘Mycotree’, constructed by Block Research Group at ETH Zurich with the Karlsruhe Institute for Technology, was exhibited at the Seoul Biennale in 2017 [

5] and is a compression-only structure made from fungal blocks and wood connectors. ‘El Monolito Micelio’ was produced in 2018 [

6] as a monolithic cast in a plywood formwork. These projects all used casting, and while this method is useful for efficient mass-production, it also has some drawbacks, such as a lower level of possible customization and reduced growth (and therefore biotransformation) on the inside of the resulting components.

Through the introduction of digital fabrication in the production of such biomaterials, these limitations can potentially be removed. Elsacker et al. [

7] used robotic wire-cutting for the processing of bulk fungal materials. The ‘Tilted Arch’ project [

8] investigated the 3D printing of fungal biocomposites and the bio-welding of the fabricated components.

The research in this manuscript presents a novel methodology of integrating and orchestrating behaviour at multiple scales, through digital technologies for design and fabrication, for the production of biomaterials.

3. Materials and Methods

3.1. Terminology

In the biofabrication methodology of the Pulp Faction project, we employ several terms. Substrate is the mix of components before inoculation with fungus. This acts as a scaffolding onto which the living cells perform their biotransformation though some material remains in its original form at the end of the process, forming an in situ biocomposite. Pulp is the substrate that is inoculated with the living agent, and therefore becomes the living material that is 3D printed.

The term

transcalar refers to processes and structures that range across multiple interconnected scales. This is a term that has been used more extensively in the field of global studies. Jan Aart Scholte distinguishes between

multilevel and

transcalar: Multilevel concerns each level separately whereas transcalar places the emphasis on the interrelation between the various scales or levels. “In contrast, a trans-scalar approach explains politics by treating spatial scales as overlapping, interrelated and mutually constitutive.” [

9].

By this definition, transcalar processes are nonlinear: it is not ideal to consider any singular scale in isolation without taking its interactions into account. Manuel de Landa describes nonlinear processes in a multitude of contexts, namely sociological, geological and not least biological. He states that such systems require new methodologies, particularly because nonlinear equations (and by extension, systems) are very difficult to solve analytically. They exhibit emergent properties: “…properties of the combination as a whole which are more than the sum of its individual parts. These emergent (or ‘synergistic’) properties belong to the interaction between parts, so it follows that a top-down analytical approach […] is bound to miss precisely those properties” [

10].

3.2. Methodology

In order to manage the transcalar and nonlinear aspects of biodesign, we relied on a research-by-design methodology with an emphasis on transdisciplinarity.

Architecture presents a wicked problem in that no solution can be derived from an exhaustive list of problem specifications. Such problems are not suitable for exclusively reductionist experimentation but require a reflection-in-action type of approach to the design task. The problem is further reinforced by the fact that living matter has its own agency. According to Sharma, experimental reductionism in combination with “the global perspective of systems-level experiments, [allows one to] link the fine and the coarse, the local and the global, and the bottom-up and top-down knowledge.” [

11].

Research-by-design methodology emphasises the importance of making, here suggested as a material practice with physical prototyping for the investigation of the problem and probing the solution space. This implies a series of material experimentations and prototyping growing in scope and resulting in a

demonstrator [

12], which in this research, is a Protomycokion. The prototypes explored sets of parameters that concern different aspects of the biofabrication (such as substrate composition, printing parameters, fungal species, methods of inoculation, growth time, etc.) through iterative testing in order to establish a workable design path.

The

demonstrator speaks of what is in disciplinary terms called the architectural scale, i.e., a scale fitted to the needs and corporeal dimensions of human beings. The

demonstrator is a synthesis of a temporally evolving spectrum of prototypes, bringing the divergent investigations into one concluding context: “Rather than presenting an array of possible solutions, the demonstrator necessitates the prioritisation of one solution space over another in decision-making.” [

13]. As in a wicked problem, the “information needed [to] understand the problem depends on one’s idea for solving it” [

14]. Following this, the solutions presented here are to be seen as the results of successive developments of a designed artefact, not as quantitively optimized solutions—solutions for this specific context that point out similar possible approaches in the future. The character of the problem and the chosen approach to produce and follow the building of a demonstrator, also means that this article is in a large part devoted to method descriptions combined with design reflections on varying scales.

As biodesign spans across a wide range of length-scales, we emphasized two important perspectives of scale in this context:

Addressing all scales with the specificities and transformations that take place at each level.

Linking the process of design across scales, i.e., in terms of how behaviours at one level effect and constrain across scalar boundaries.

The Pulp Faction project led to the development of a design and fabrication protocol that targets a number of variable and specific scales ranging from nanometres to meters. We developed a strategy of design that works at the level of each of these scales, connecting them in a reciprocal way. Although material scales are continuous and span several domains, we have for the sake of clarity chosen to present the scales in a linear manner starting from the smallest. In the following sections, we outline the transformations that take place at five different scales and present an interpretation of the architectural implications.

3.2.1. Nano

At the molecular level, transformations are of a chemical nature. The fungus grows on and inside the material, which results in the biotransformation of part of the original material into a living tissue. Elements of this transformation involve the partial consumption of cellulose and lignin and the gradual build-up of chitin, proteins, and other various carbohydrates in structured matrices. Through biofabrication, we employed the biochemical fungal factory to transform the existing material at the molecular level into compounds that can impart properties that did not originally exist in the substrate.

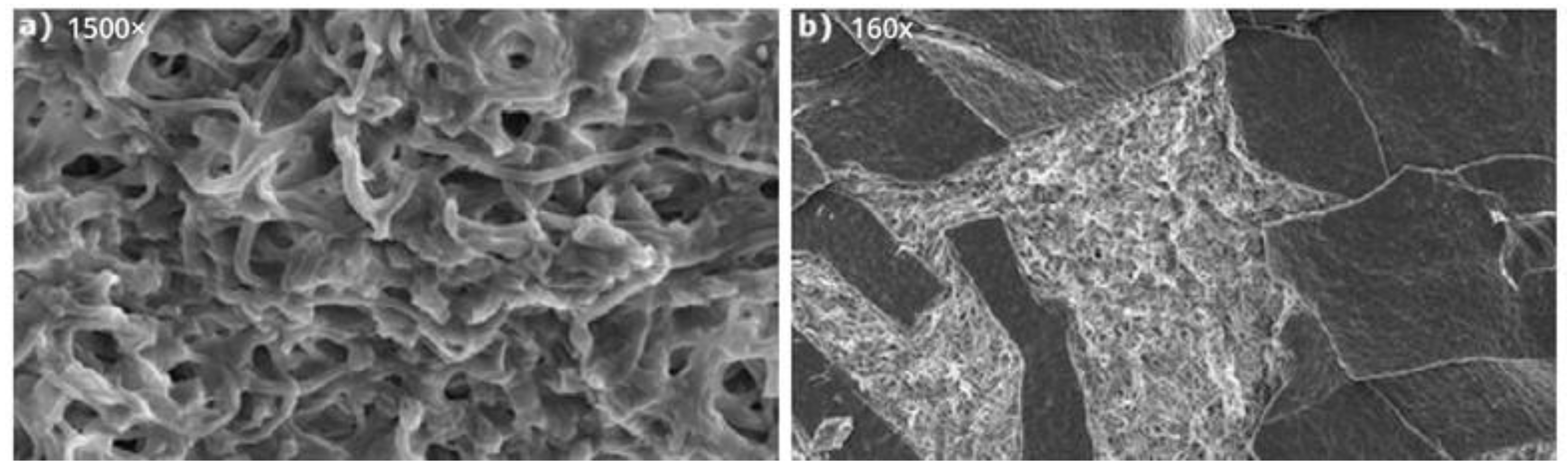

An additional transformation takes place through the metabolism of organic carbon found in the material, which is transformed into the leaving tissue of the fungal species consisting largely of protein, chitin, and extracellular polymeric substances (EPS). One component of this biotransformation process that is of particular interest is the production of EPS, which is common when microorganisms colonize surfaces (

Figure 1). Their composition varies depending on nutrient condition, type of organism, growth stage, and other environmental factors [

15]. EPS substances have different roles [

16], but one of the most relevant in this project is that they anchor the hyphae to the substrate. Through adhesion and aggregation, they effectively act as a glue between these. The EPS is layered at nano and micro scales and grows to the millimetre scale when matured [

15]. The conditions in which these are produced have design implications for several scales.

A further aspect of the molecular transformations is the production of hydrophobins, which are small proteins that increase the hydrophobicity of the mycelium [

18]. We assume that the production of hydrophobins, which are a common element of fungal mycelium, along with chitin, which is itself hydrophobic, led to an overall hydrophobicity of the final biomaterial.

3.2.2. Micro

At the micro scale, we looked at the transformations through the biological lens. Filamentous fungi, such as the one used in Pulp Faction, produce cylindrical cells of a few micrometres’ length, termed hyphae. The hyphae exhibit uniform growth and interconnect to form a complex, highly organized network of filaments that become the mycelium. The mycelium can cover large areas and volumes of substrate, to the extent that the total length of hyphae included in 1 g of soil can measure up to 600 km [

19]. In this project, the nanoscale processes described above resulted in the partial biotransformation of the pulp into living mycelium. Here, the role of the mycelium is to surround and bind wood, cellulose, and clay particles into a matrix that consists of living cells and abiotic material. This is the next level of transformation whereby the more amorphous (lignin) and fibrous (cellulose) structures of wood are interconnected with the network of the fungal mycelium. At the same time, the mycelium acts as an extensive natural network of highways through which the fungus translocates nutrients across the construct to further colonize and biotransform the material (

Figure 2). The microorganism freely determines the distribution of nutrients across the pulp; interestingly, this results in a relatively uniform type of growth across the material, at least at the milli and meso scales.

A high ratio of fungal cells to the substrate is desired for a higher degree of biotransformation of the pulp. This occurs naturally over time, as the substrate becomes colonized. To accelerate the growth time, the strategy employed at this scale was to blend the inoculum. A fungus that was grown in a Petri dish for 5 days was blended with sterilized water, and this liquid inoculum was added to the substrate. The blending process cuts the mycelium into numerous fragments and their addition into the pulp results in the simultaneous development of many colonies, which eventually merge across the material. This results in a significant reduction in the time required for growth and a more homogeneous age of the mycelium.

3.2.3. Milli

This level is concerned with the larger material scale, wherein mechanical transformation can be observed. The main parts of the process at this scale were the composition of the substrate and the extrusion of the pulp.

Composition

The composition of the material is a crucial aspect of the research. There are several factors that influence the results in several ways, namely the water content, fibre size, and additives. Different scales have contradicting requirements regarding water content. For the stability of the component, a drier extruded material is desired. Additionally, the higher the water content, the higher the resulting volumetric shrinkage and distortion [

20], providing another reason for lowering the water content in the pulp. However, a higher water content is necessary for a fast and homogenous colonization of the substrate by the fungus. A successful percentage that satisfies both conditions has been found at 59.4 percent of the total weight (wt%).

The fibre sources are wood fragments and paper pulp. Several sources have been tested and evaluated, with an emphasis on finding a working solution rather than the best possible composition. Besides water, the lignocellulosic fibres were at the highest percentage in the composition at 21.7 wt%. Out of these, cellulose fibres make up at 5.4 wt%. The size of the wood particles is of high importance, as larger particles improve the mechanical performance of the end result (under a threshold of 5 mm [

21]) and increase fungal growth [

22]. However, large wood particles impede the extrusion as they cause frequent clogging. Therefore, the largest fibres that successfully printed without clogging were employed. Filtering the wood particles with a sieve of mesh size 2 mm produced the most stable results.

Besides water and lignocellulosic fibres, additives were necessary due to the requirements of the 3D-printing process. Xanthan is a polysaccharide produced by the bacterial species Xanthomonas campestris. It was employed as a stabiliser to prevent water and fibres from separating in the process of extrusion, at 2.6 wt%. Clay powder as inorganic matter is a secondary additive to the substrate. Mixed with water, it results in a highly extrudable material, so when combined with the rest of the substrate it acts as a support material. Additionally, this reduced the amount of water necessary to achieve a continuous extrusion, which is desirable. However, it should ideally be kept minimal, as it does not contribute to conversion into fungal biomass. A percentage of 16.3 wt% (considerably less by volume) was found to be suitable for our process.

Extrusion

The inoculated substrate was extruded on a layer-by-layer basis, similar to FDM (fused deposition modelling) and LDM (liquid deposition modelling) 3D-printing methods. However, unlike FDM (which relies on the thermoplasticity of plastics for the binding of deposited layers) and LDM (which relies on the evaporation of water or chemical reactions to achieve rigidity [

20]), there were no chemical or thermo-setting agents in the pulp. The binding took place post-extrusion in the growth stage, at which point the hyphae grow and fuse the layers together (

Figure 3). This printing method is termed bioFDM (bio-fused deposition modelling).

The dimensioning of the printing nozzle is also at this scale, and it has repercussions for the lower and higher scales. A wider nozzle provides an increased stability of the printed component and because it deposits more material at once, it reduces the total printing time of the final column. However, it also reduces the surface to volume ratio—which as described below is not desirable as it lowers the total growth of the fungus. The dimensions that have been employed are similar to the project reference of the fungal combs (Termitomyces and termite symbiosis, [

23]), where the expectation is that the fungal hyphae grow throughout the bulk of the pulp. The final nozzle size employed was 3.2 mm diameter.

Several properties that were defined at smaller scales could be observed here, namely hydrophobicity, dispersion in water, humidity absorption, tension, and compression strength.

3.2.4. Meso

This is the scale of the 3D-printed component (

Figure 4), where the demands and constraints of the organism, the printing process, and structural integrity of the component itself as well as the larger macro scale all come into play. Each component was designed to connect to an adjacent one, following the overall computed structure.

The design was managed using computational models which are able to negotiate these disparate needs. The surface area to volume ratio (SA:V) was increased by a reaction-diffusion model. The SA:V in the 3D-printed component that was algorithmically generated was found to be 0.509, compared to 0.046 for the same size component if simplified for the casting process. This enhanced oxygen access, which maximized hyphae growth [

23]. This led to higher EPS production, which induced the desired chemical and physical properties of the resulting biocomposite.

The bioFDM process relies on stabilizing the component during the growth stage and finalizing the rigidity at the desiccation stage—therefore in the printing stage it is weak. This limits the total height that the component could be printed at. A scaffolding system, either independent, robotic or 3D printed, could be used to overcome this limitation partially or fully.

However, geometry plays an important role at this scale. Curved and folded geometries are structurally more rigid compared to flat surfaces; therefore, by employing a complex algorithm, the stability was improved. A computation script was further employed to increase the connections between neighbouring channels in the extrusion toolpath. This introduced more lateral connections, which provided supports during printing and therefore reduced the weakness in the printing and growth stage. Moreover, these lateral supports strengthened the geometry in the desiccation stage, reducing global component distortions.

3.2.5. Macro

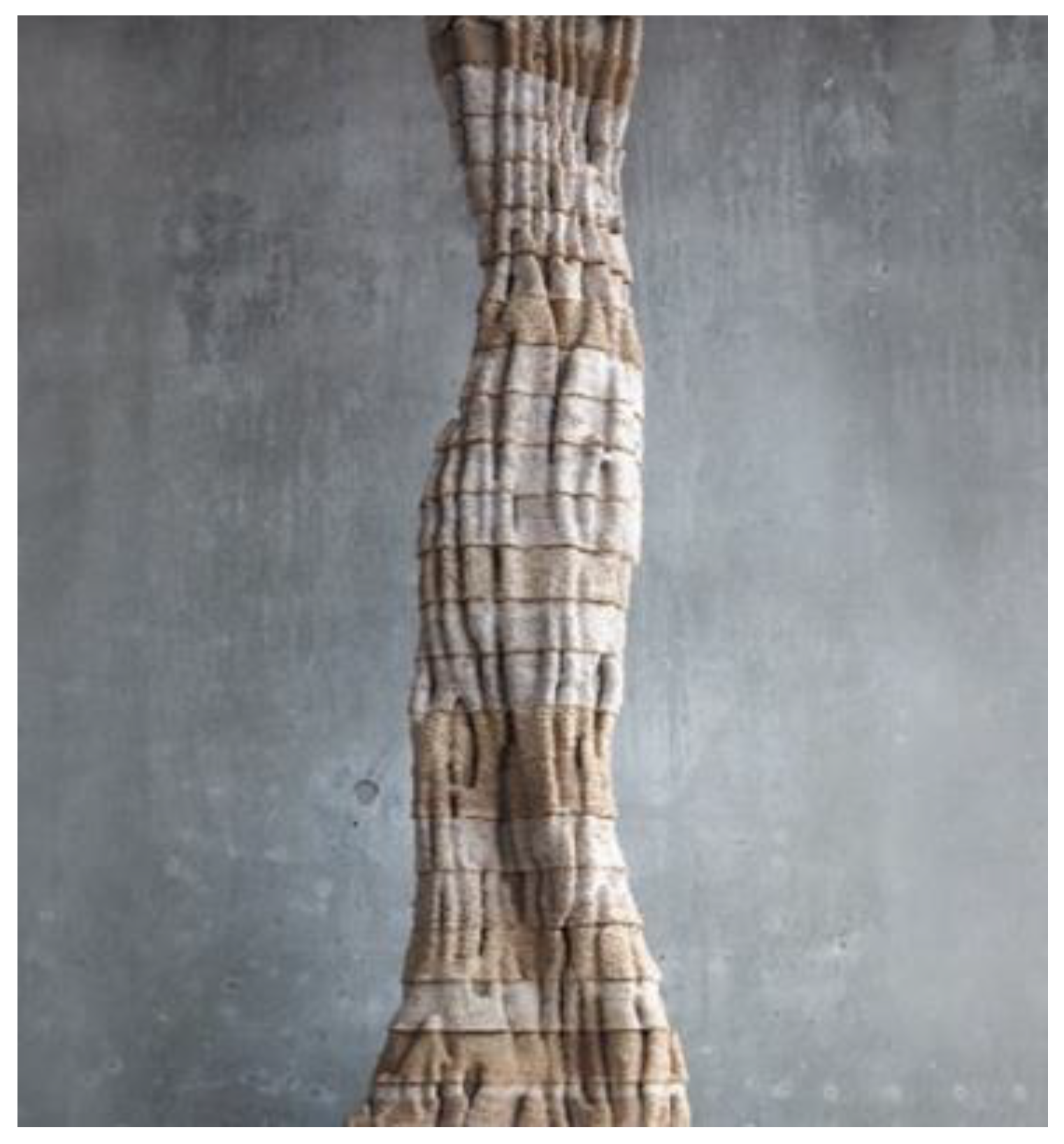

The macro scale is the demonstrator, where the output is experienced as architecture relating to the scale of the human body. To achieve the full extent of the macro scale, a two-step printing process was implemented. The building element was subdivided into smaller components (see above meso scale) that were individually printed, grown and dried. When the individual components had achieved their full strength, they were assembled and bonded together, facilitating the larger (macro) scale.

The bonding at this second stage utilised the same process as the first stage of printing, with living pulp being applied to each joint. When placed in a controlled high humidity environment, the mycelium in this joint grew into the dried components, effectively bonding them together as a result.

As the pulp dried, it contracted, resulting in a shrinkage of the final component. This was limited in the horizontal plane through the fabrication process, which resulted in a mostly vertical shrinkage. This was found to be approximately 20% and it was accounted for in the design process.

At this scale, the characteristics and behaviours of the smaller scales (nano, milli, meso) come into effect as carriers or enablers of architectural performance. The hyphae network covering the surface of the components not only binds and strengthens it but imparts hydrophobicity that reduces the risk of liquid water ingress. Because of the microscopic properties and arrangement of the fibres, water vapor can still be absorbed by or released from the material, allowing it to function as an effective humidity buffer.

The arrangement at the milli scale of the printed material, which was formed in response to the fungus’ physiological requirements and fabrication process, also assists in these functions. Thus, a clear transcalar function becomes apparent. The high surface area and vertically connected voids facilitate the exchange of moisture, air and heat between the column and the surrounding (human inhabited) spaces or rooms. These voids also provide a pathway for liquid water runoff and permit the controlled and efficient drying of the structure. In their ultimate form, these interconnected and defined channels can perform important roles in managing the internal climate, effectively forming a building-scale vascular system.

The variable material appearance, influenced by a myriad of parameters and microscopic behaviours, transformed at the macro scale (

Figure 5). Viewed together as a whole, the variation of texture and colour is perceived as unified. This effect was reinforced by the generative design, which never repeats itself yet follows a clearly distinguishable pattern, resulting from the reaction diffusion algorithm and the process of fabrication.

4. Results

Central to the transcalar approach described and discussed in this paper is the interdependence of variable scales, systems and materials which results in nonlinear interactions and rapidly increasing complexity. These conditions, which are the norm in biological systems, place a hard limit on traditional engineering approaches due to exponential increase in formal and functional complexity [

24]. Bentley suggests that nature and biological processes rely on a fundamentally different “design” logic which is better suited to complex and interrelated problems and that makes it possible to break through this “complexity ceiling”.

The project and design processes outlined in this paper demonstrate that computational or algorithmic design enables a similar approach in architecture. Instead of drawing form, architects can define—through computer code—a series of processes that only have meaning when placed in a context. In responding to this context, the resulting form becomes locally adapted at multiple scales and can exhibit unlimited variability in principle while maintaining consistency in terms of the internal and external logics. Such locally operating algorithms can suggest and negotiate high levels of complexity and interdependence [

25]. We also found that the use of digital fabrication serves an important role in linking the computational design to the complexities of the physical reality and the construction process. Without this technology, the making process becomes a bottleneck that forces top-down reductionism, eliminating or reducing the effectiveness of the computational design approach.

Data-driven design can span multiple scales and reach high resolutions without relying on the repetition and homogeneity of forms and material as is the norm in industrial mass-production. By encoding algorithmic behaviours into the making process and allowing these to interact with the biological processes themselves, a combination of specificity and large scale can be achieved. In this way, biological growth can be guided using digital tools. Emerging computational models enable new modes of creation that allow for a plurality of scales, languages and priorities to coexist, relate, and negotiate within a single model, including design intent, fungal needs, fabrication parameters, structural constraints and human requirements.

The design of Protomycokion relies on a series of algorithmic processes that make the transcalar relations possible. The critical aspect of digital fabrication is the ability to combine high specificity and articulation with large volumes, which is necessary when advancing the field of biodesign, increasing its capacity to make a profound change to resource-use and manufacturing in architecture. As Gorochowski states [

26], “Being able to scale our ability to harness biology will be crucial for addressing the many grand challenges we face, such as shifts toward sustainable manufacturing, clean energy production, and new forms of advanced medicine. CAD applied to synthetic biology is likely to play a key role in realizing these ambitions”.

5. Discussion

One of the most exciting aspects of using biofabrication in construction is the great potential for adaptation and variability. With regard to mycelium biocomposites, different fungal strains lead to different outcomes both in terms of fabrication process and the performance of the architectural object. From a biological point of view, growth speed under a broad range of conditions, branching patterns, genetic stability, competitiveness, and lack of spores and toxin production are important factors in the selection of a fungal strain. From an architectural point of view, factors such as tensile and compressive strength, fibre adhesiveness, heat conductivity, hydrophobicity, appearance and durability will all come into play and are influenced by the biological characteristics of different fungal strains, as well as biofabrication conditions. Depending on the intended application, these will be of varying importance and different strains or even combinations of strains may be relevant for different projects.

In different environments, various raw materials are likely to be available and sustainable. In Pulp Faction, forestry by-products were used, but in different contexts agricultural waste, recycled urban waste, or even on-site grown plant materials could be relevant. By adjusting the strain of fungus used, these could potentially all be suitable raw materials which means that the process is not per se reliant on centralised infrastructures or monocultures. This is a critical aspect for the overall sustainability of the biofabrication) paradigm. If biofabrication is scaled up and employed in the construction industry and follows previous industrial logics, problems will arise with regard to biodiversity, transportation and other issues. Local raw materials and local fungal and other microbial strains can shape how biomaterials blend and match with the local environment and can reduce the need for transportation. The potential of using locally sourced and highly varied raw material through the transformative power of microorganisms is a key component in battling these challenges.

Therefore, it is unsuitable to develop a single form, product, or process through which to implement biodesign and biofabrication. As has been described in the paper, the variables operating at all the different scales within the process are highly interdependent. The fungal strain used is not an independent factor, but influences and is influenced by the raw materials, the extrusion process and post treatment, and the architectural role and context the output has.

This is the core of the transcalar approach—the interdependence of the involved scales represents both the challenge and the potential of biodesign. Computer models based on algorithmic and self-organizing logics can regulate and negotiate such nonlinear processes and are critical for a successful and sustainable implementation of a biodesign construction paradigm.

6. Conclusions

The project output—the column Protomycokion and the processes through which it was designed and fabricated—serves as a proof-of-concept for the use of biofabrication in combination with 3D printing to create architectural-scale artefacts. It demonstrates that these can achieve properties that would otherwise be difficult if not impossible. Doing so introduces a vast range of scalar interdependencies that result in a nonlinear and complex design process. In the making of the Protomycokion, we demonstrated the first successful example of the 3D printing of an architectural-scale fungal lignocellulosic structure, demonstrating the potential of this approach. We outlined how this requires a new approach to generate and control the resulting complexity, which we defined as a transcalar design methodology. This is based on the integration of research by design, computational design and fabrication, as well as applied microbiology.

This transcalar process and its complex interdependence needs to be managed using computational design tools. These algorithmic approaches allow every scale to be individually addressed through its own internal logic, while the consequences for connected scales can be tracked and considered. In addition to the computational tools themselves, the research-by-design approach proved to be a powerful tool to address these interdependencies, and particularly, the use of a physical-design prototype facilitated the transdisciplinary workflows.

The design-centred methodology with a transcalar focus facilitates a rapid and agile exploration of complex and interdependent systems. This needs to be complemented with experiments undertaken in a more conventional reductionist manner. The design approach, and particularly the demonstrator, should be coupled in an iterative manner with these experiments, and serves multiple functions in that it allows for the rapid establishment of parameters and design species, links disciplines and facilitates interactions between them, communicates design and scientific intent and most of all it manifests the transcalar effects of decisions made at a reductionist level.

Through an explorative laboratory-based design approach, the study shows that there is the potential for more sustainable lines of production of architectural elements, where the use of locally fabricated biomaterials and the successively generated design of architectural elements can not only perform well technologically but also leaves room for advanced and adaptive architectural formation.

Author Contributions

Conceptualization, A.G. and D.A.; methodology, A.G., D.A. and D.F.; software, A.G.; validation, A.G. and D.F.; formal analysis, A.G., D.A. and D.F.; investigation, A.G.; resources, D.A. and D.F.; data curation, A.G.; writing—original draft preparation, A.G.; writing—review and editing, A.G., D.A. and D.F.; visualization, A.G.; supervision, D.A. and D.F.; project administration, D.A.; funding acquisition, D.A. All authors have read and agreed to the published version of the manuscript.

Funding

The making of the Protomycokion was funded by the Swedish National Board of Housing, Building and Planning (grant no. 6418/2018), and the article written with the support of Formas (grant no. 2020-00429).

Acknowledgments

The authors would like to thank Gunnar Sandin for the support and discussions.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Myers, W.; Antonelli, P. Bio Design: Nature, Science, Creativity; Museum of Modern Art: New York, NY, USA, 2012. [Google Scholar]

- Weibel, E.R. Fractal geometry: A design principle for living organisms. Am. J. Physiol. Lung Cell Mol. Physiol. 1991, 261, L361–L369. [Google Scholar] [CrossRef] [PubMed]

- Turner, J.S. Homeostasis, complexity, and the problem of biological design. Emerg. Complex. Organ. 2008, 10, 76–89. [Google Scholar]

- Nagy, D.; Locke, J.; Benjamin, D. Computational brick stacking for constructing free-form structures. In Proceedings of the Design Modelling Symposium: Modelling Behaviour, 1st ed.; Springer: Cham, Switzerland, 2015; pp. 203–212. [Google Scholar] [CrossRef]

- Heisel, F.; Lee, J.; Schlesier, K.; Rippmann, M.; Saeidi, N.; Javadian, A.; Nugroho, A.R.; Mele, T.V.; Block, P.; Hebel, D.E. Design, cultivation and application of load-bearing mycelium components: The MycoTree at the 2017 Seoul biennale of architecture and urbanism. Int. J. Sustain. Energy Dev. 2017, 6, 296–303. [Google Scholar] [CrossRef]

- Dessi-Olive, J. Monolithic Mycelium: Growing Vault Structures. In Proceedings of the 18th International Conference Non-Conventional Materials and Technologies, Nairobi, Kenya, 24–26 July 2019; Available online: https://www.academia.edu/39909593/Monolithic_Mycelium_Growing_Vault_Structures (accessed on 13 February 2022).

- Elsacker, E.; Søndergaard, A.; Van Wylick, A.; Peeters, E.; De Laet, L. Growing living and multifunctional mycelium composites for large-scale formwork applications using robotic abrasive wire-cutting. Constr. Build. Mater. 2021, 283, 122732. [Google Scholar] [CrossRef]

- Modanloo, B.; Ghazvinian, A.; Matini, M.; Andaroodi, E. Tilted Arch; implementation of additive manufacturing and bio-welding of mycelium-based composites. Biomimetics 2021, 6, 68. [Google Scholar] [CrossRef] [PubMed]

- Scholte, J.A. Civil society and global governance: Exploring transscalar connections. Interest Groups Advocacy 2019, 8, 490–498. [Google Scholar] [CrossRef]

- De Landa, M. A Thousand Years of Nonlinear History; Zone Books: New York, NY, USA, 1997. [Google Scholar]

- Sharma, S. Designing the Organism-Environment Relationship. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2020. [Google Scholar]

- Thomsen, M.R.; Tamke, M. Narratives of making: Thinking practice led research in architecture. In Proceedings of the Communicating (by) Design 2009; Elsevier: Brussels, Belgium, 2009; pp. 1–8. [Google Scholar]

- Thomsen, M.R.; Tamke, M. Prototyping Practice: Merging Digital and Physical Enquiries. In Rethink! Prototyping; Springer: Cham, Switzerland, 2015; pp. 49–62. [Google Scholar]

- Rittel, H.W.J.; Webber, M.M. Dilemmas in a General Theory of Planning. In Policy Sciences; Elsevier Scientific Publishing Company: Amsterdam, The Netherlands, 1973; Volume 4, pp. 155–169. [Google Scholar]

- Gazzè, S.A.; Saccone, L.; Smits, M.M.; Duran, A.L.; Leake, J.R.; Banwart, S.A.; Ragnarsdottir, K.V.; McMaster, T.J. Nanoscale Observations of Extracellular Polymeric Substances Deposition on Phyllosilicates by an Ectomycorrhizal Fungus. Geomicrobiol. J. 2013, 30, 721–730. [Google Scholar] [CrossRef]

- Costa, O.Y.; Raaijmakers, J.M.; Kuramae, E.E. Microbial extracellular polymeric substances: Ecological function and impact on soil aggregation. Front. Microbiol. 2018, 9, 1636. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Válková, H.; Novotný, Č.; Malachová, K.; Šlosarčíková, P.; Fojtík, J. Effect of bacteria on the degradation ability of Pleurotus ostreatus. Sci. Total Environ. 2017, 584–585, 1114–1120. [Google Scholar] [CrossRef] [PubMed]

- Berger, B.W.; Sallada, N.D. Hydrophobins: Multifunctional biosurfactants for interface engineering. J. Biol. Eng. 2019, 13, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Ekblad, A.; Wallander, H.; Godbold, D.L.; Cruz, C.; Johnson, D.; Baldrian, P.; Björk, R.G.; Epron, D.; Kieliszewska-Rokicka, B.; Kjøller, R.; et al. The production and turnover of extramatrical mycelium of ectomycorrhizal fungi in forest soils: Role in carbon cycling. Plant Soil 2013, 366, 1–27. [Google Scholar] [CrossRef] [Green Version]

- Rosenthal, M.; Henneberger, C.; Gutkes, A.; Bues, C.-T. Liquid Deposition Modeling: A promising approach for 3D printing of wood. Eur. J. Wood Wood Prod. 2017, 76, 797–799. [Google Scholar] [CrossRef]

- Elsacker, E.; Vandelook, S.; Brancart, J.; Peeters, E.; De Laet, L. Mechanical, physical and chemical characterisation of mycelium-based composites with different types of lignocellulosic substrates. PLoS ONE 2019, 14, e0213954. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Schmidt, C.G.; Furlong, E.B. Effect of particle size and ammonium sulfate concentration on rice bran fermentation with the fungus rhizopus oryzae. Bioresour. Technol. 2012, 123, 36–41. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Goidea, A.; Floudas, D.; Andréen, D. Pulp Faction: 3d Printed Material Assemblies Through Microbial Biotransformation. In Fabricate 2020: Making Resilient Architecture; Burry, J., Sabin, J., Sheil, B., Skavara, M., Eds.; UCL Press: London, UK, 2020; pp. 42–49. [Google Scholar] [CrossRef]

- Bentley, P. Climbing Through Complexity Ceilings. In Network Practices: New Strategies in Architecture and Design; Burke, A., Tierney, T., Eds.; Princeton Architectural Press: New York, NY, USA, 2007; pp. 178–197. [Google Scholar]

- Varenne, F. The Nature of Computational Things-Models and Simulations in Design and Architecture. In Naturalizing Architecture: ArchiLab 2013; Brayer, M.-A., Migayrou, F., Eds.; Hyx Editions: Orléans, France, 2013; pp. 96–105. [Google Scholar]

- Gorochowski, T.E.; Karr, J.R.; Parmeggiani, F.; Yordanov, B. Editorial: Computer-Aided Biodesign Across Scales. Front. Bioeng. Biotechnol. 2021, 9, 700418. [Google Scholar] [CrossRef] [PubMed]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).