Low-Temperature Performance of Polymer-Modified Binders in Stone Mastic Asphalts

Abstract

1. Introduction

1.1. Low-Temperature Performance of Asphalt Mixtures

1.2. Characteristics of Stone Mastic Asphalt

1.3. Polymer Modification of Asphalt Binders

2. Materials and Methods

2.1. Materials

2.2. Production of Modified Binders

2.3. Characterization of the Asphalt Binders

2.3.1. Softening Point and Penetration

2.3.2. Rheological Characterization

2.3.3. Elastic Recovery

2.3.4. Force Ductility

2.4. Production and Characterization of Asphalt Mixtures and Specimens

2.4.1. Asphalt Mixture Production

2.4.2. Specimens Production

2.4.3. Specimen Characterization

2.5. Low-Temperature Mechanical Characterization of the Asphalt Mixtures

2.5.1. Testing Conditions and Apparatus

2.5.2. Uniaxial Tension Stress Test

2.5.3. Thermal Stress Restrained Specimen Test

2.5.4. Relaxation Test

2.5.5. Tensile Creep Test

2.5.6. Uniaxial Cyclic Tension Stress Test

3. Results and Discussion

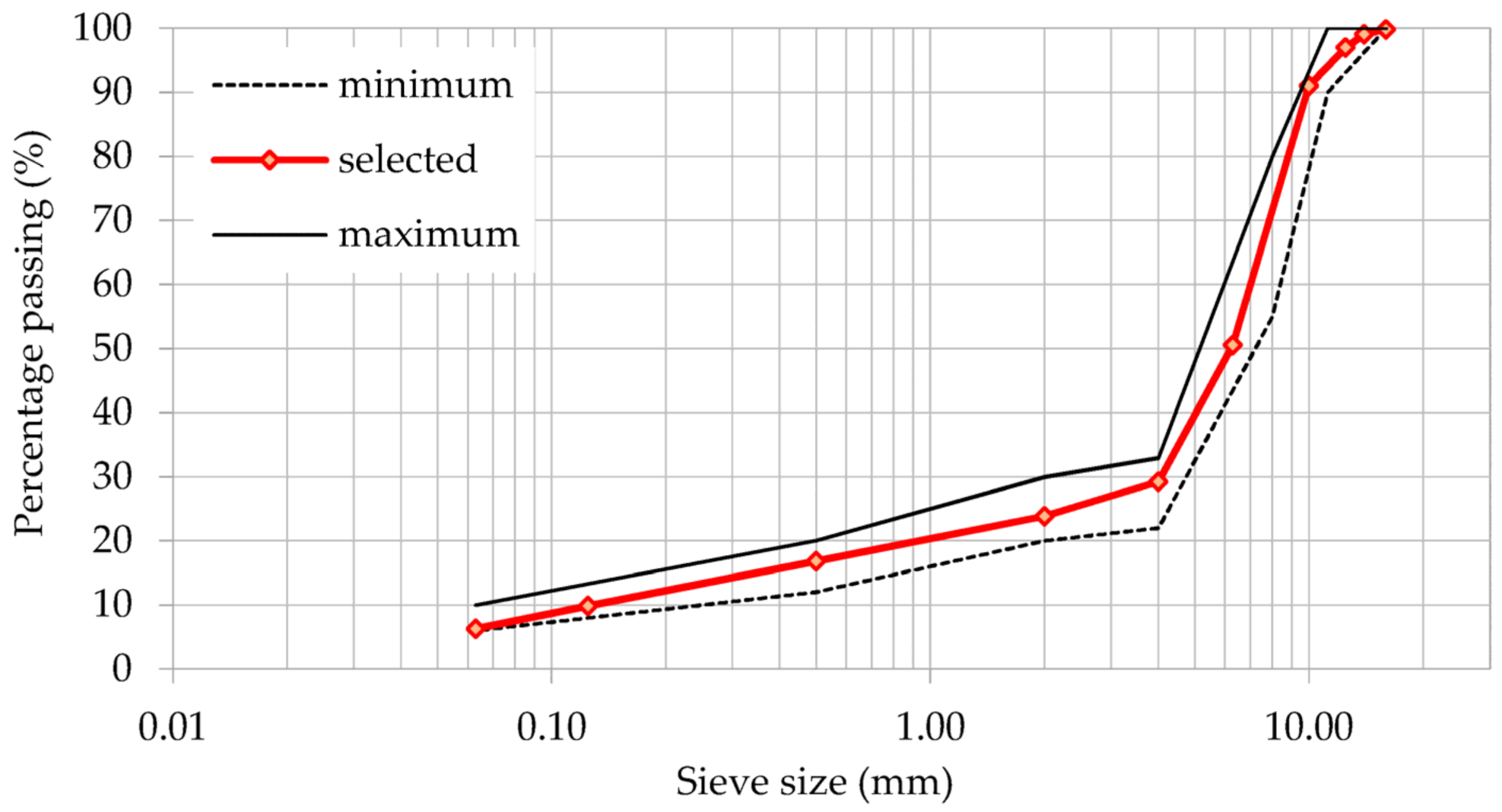

3.1. Aggregate Particle Size Distribution of the Studied Mixture

- Limestone filler = 8%;

- Granite aggregate 0/4 = 20%;

- Granite aggregate 4/6 = 15%;

- Granite aggregate 4/10 = 42%;

- Granite aggregate 6/14 = 15%.

3.2. Analysis of the Asphalt Binders

3.2.1. Softening Point and Penetration

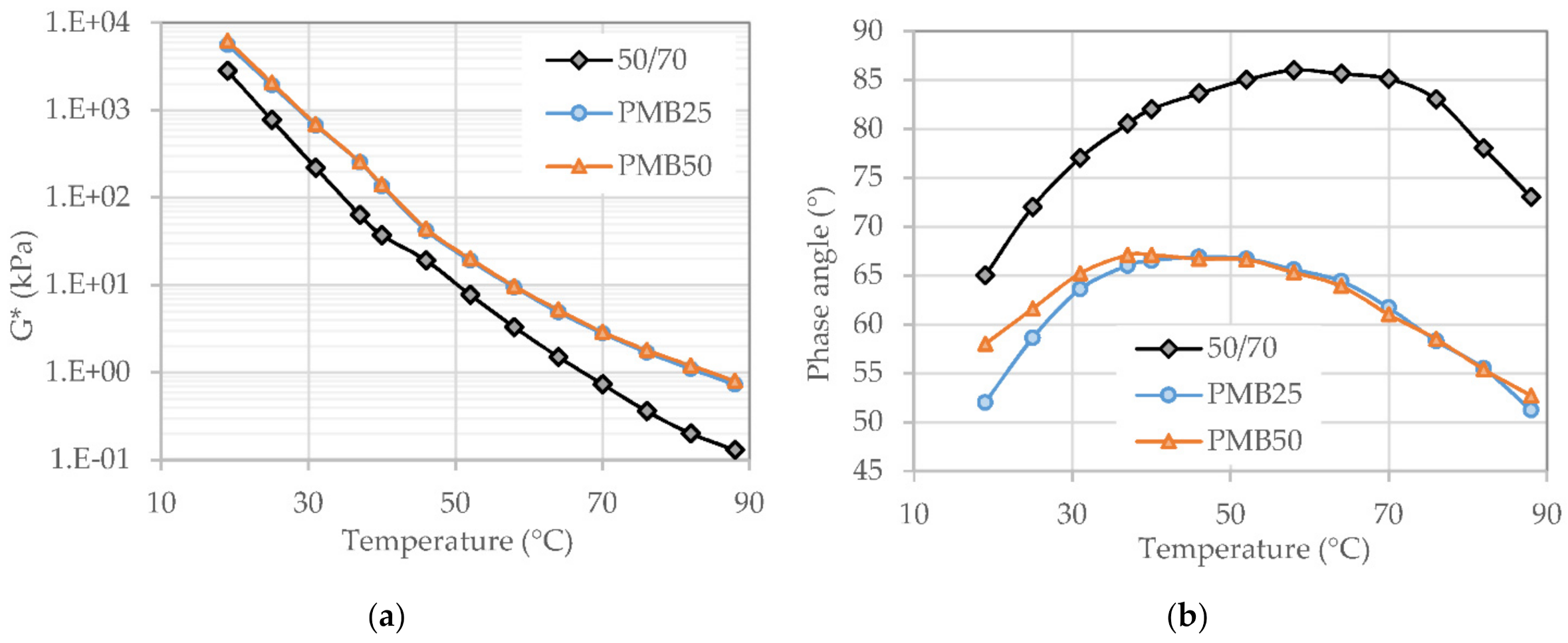

3.2.2. Rheological Characterization

3.2.3. Elastic Recovery

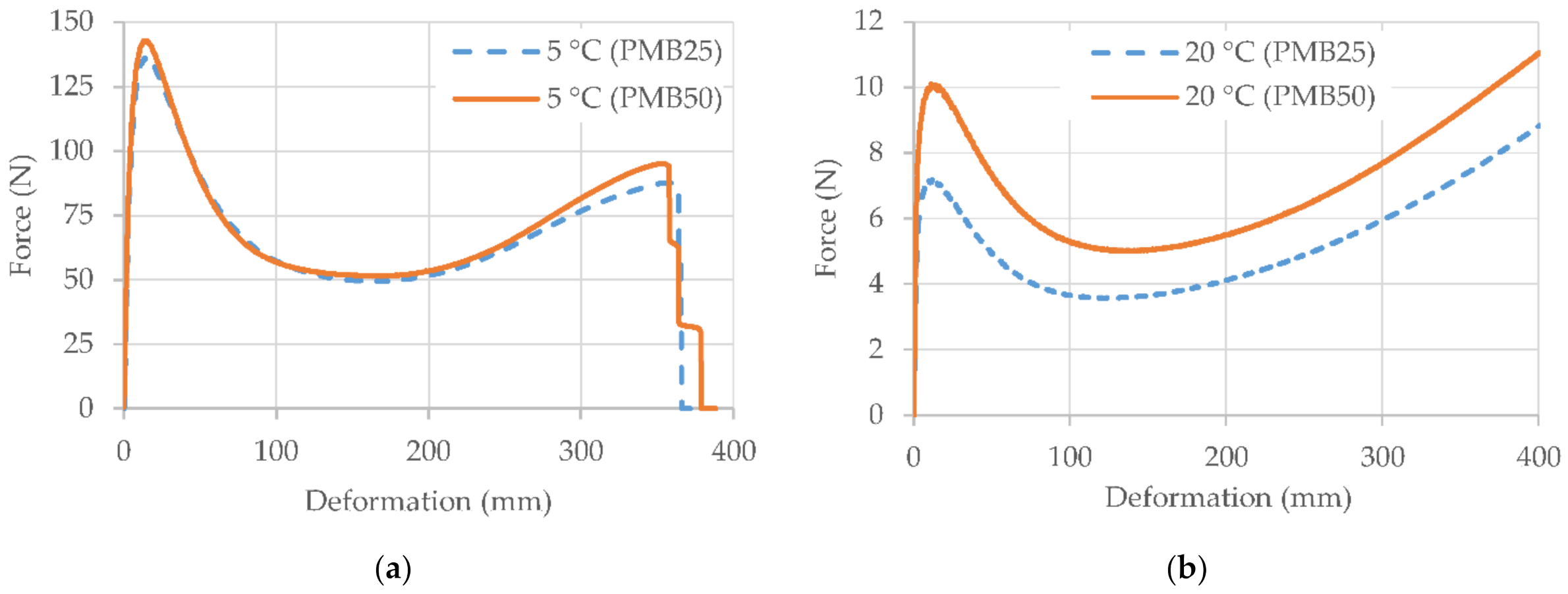

3.2.4. Force Ductility

3.3. Analysis of the Asphalt Mixtures and Specimens

3.4. Mechanical Low-Temperature Performance of the Asphalt Mixtures

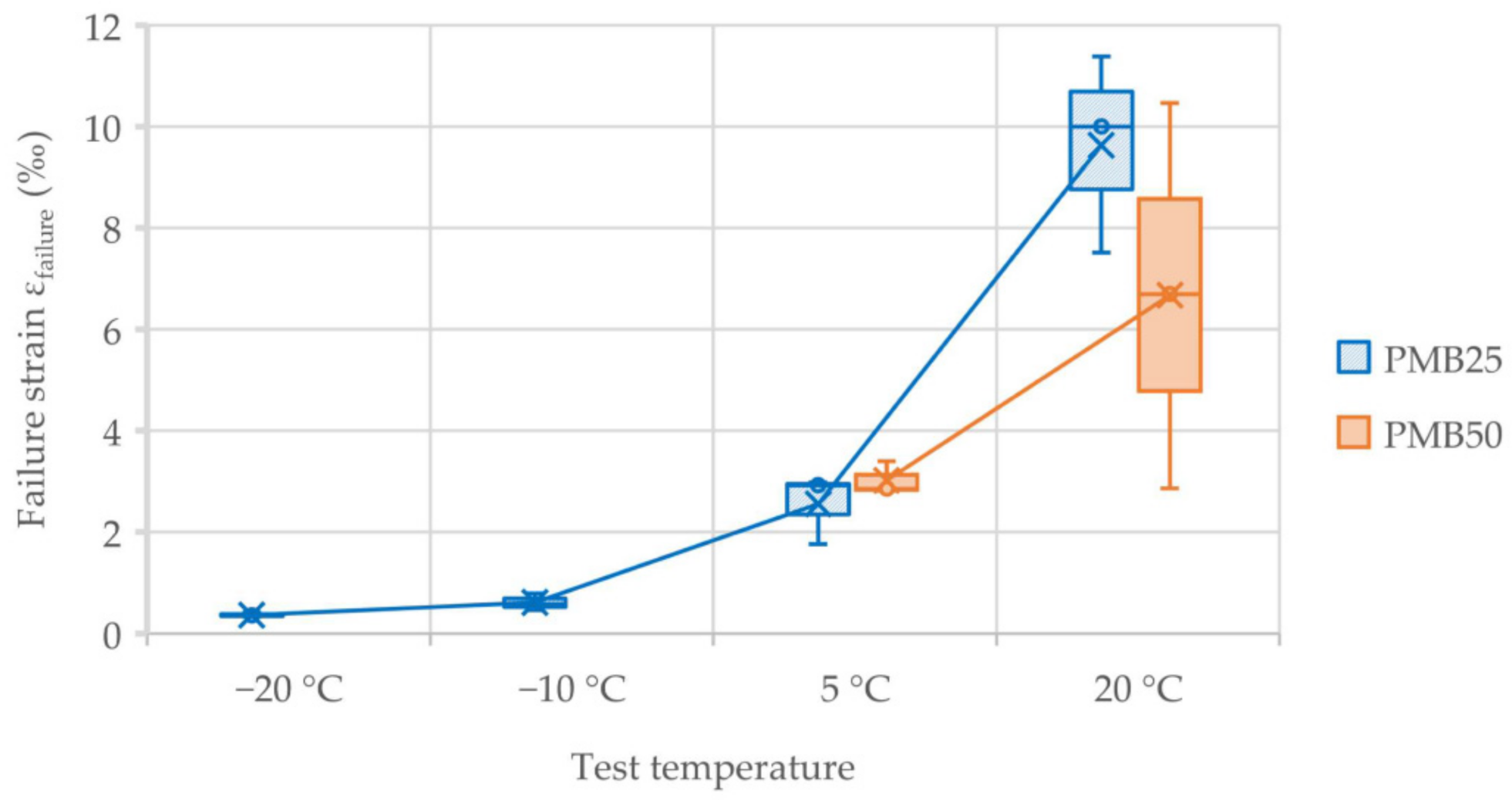

3.4.1. Uniaxial Tension Stress Test (UTST)

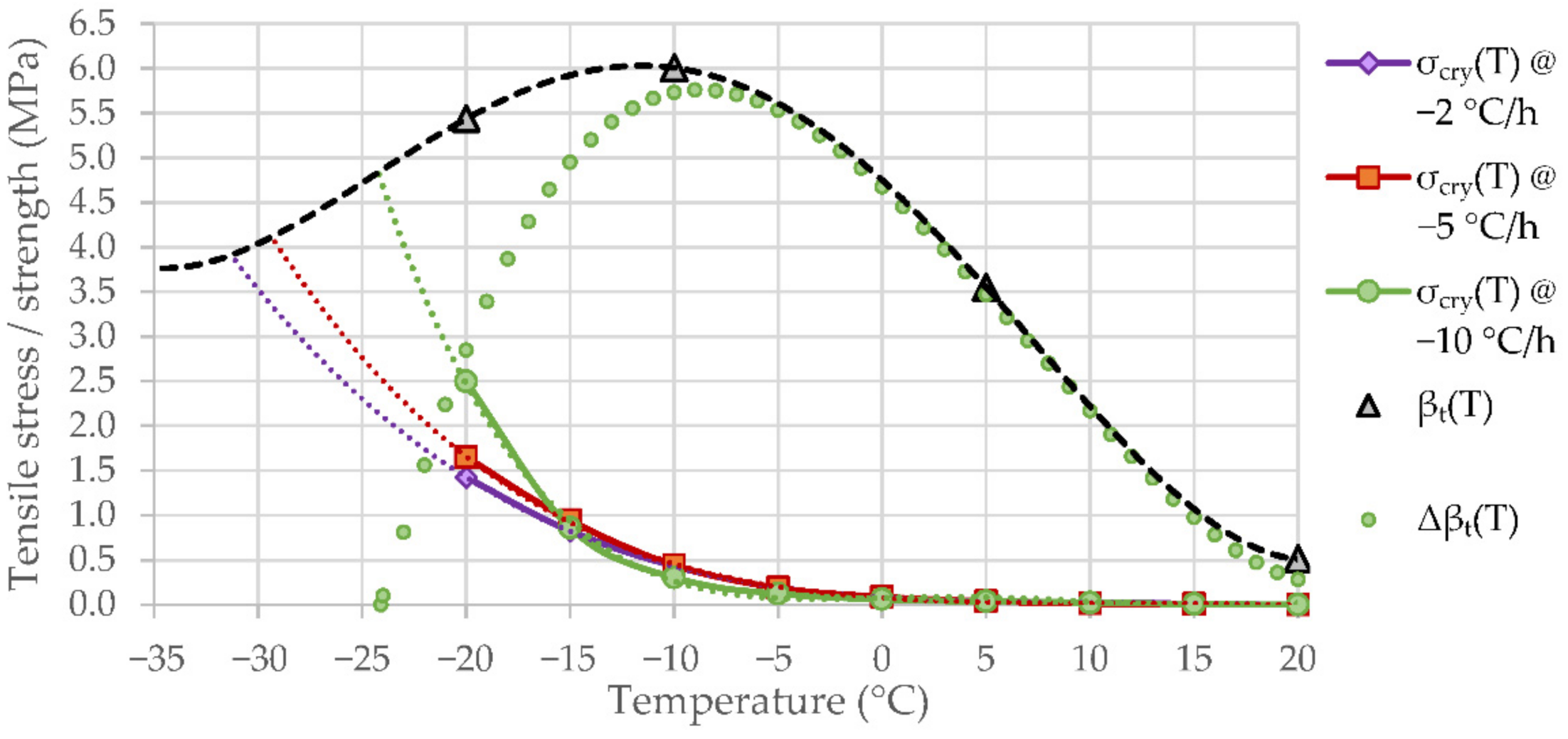

3.4.2. Thermal Stress Restrained Specimen Test (TSRST)

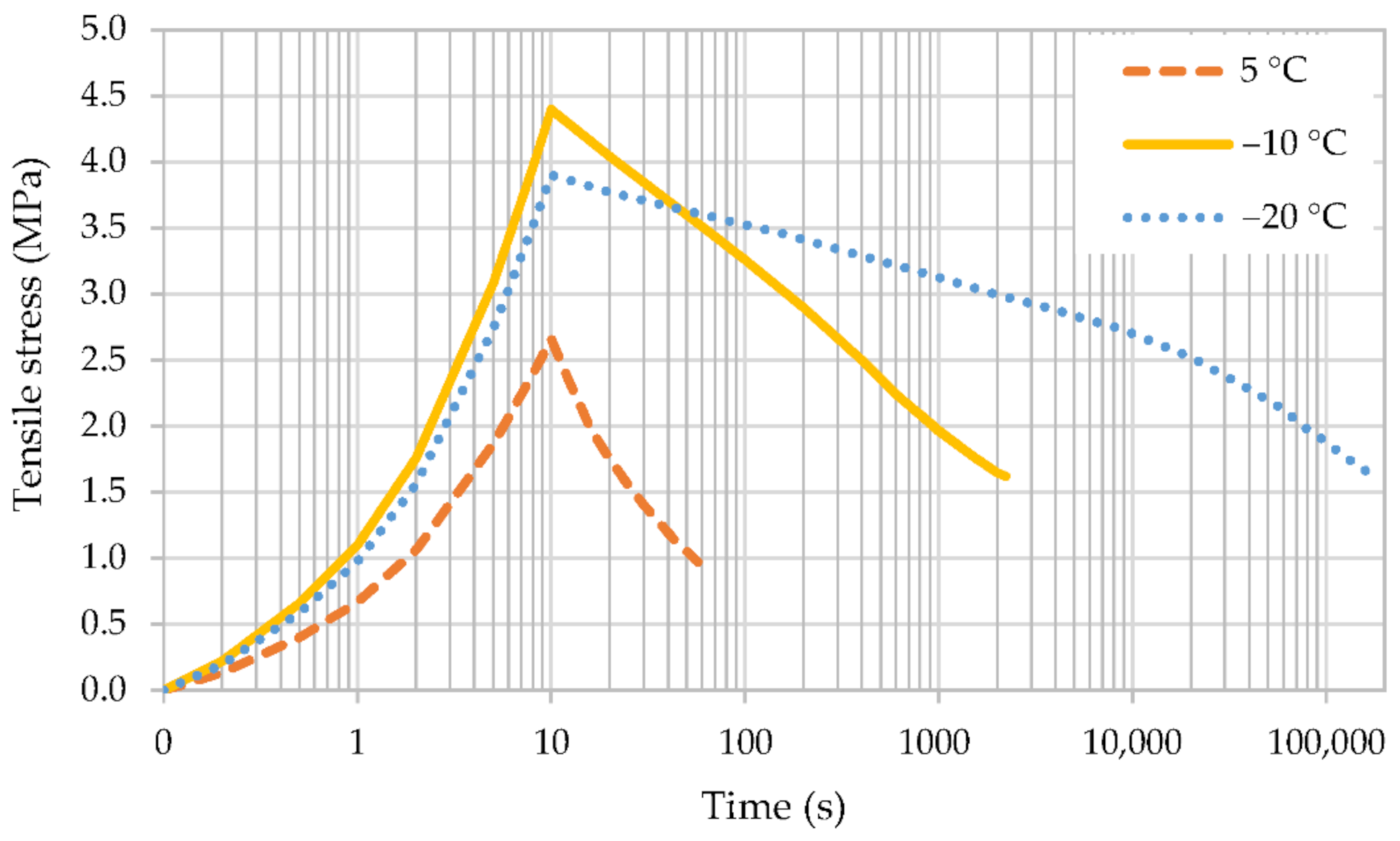

3.4.3. Relaxation Test (RT)

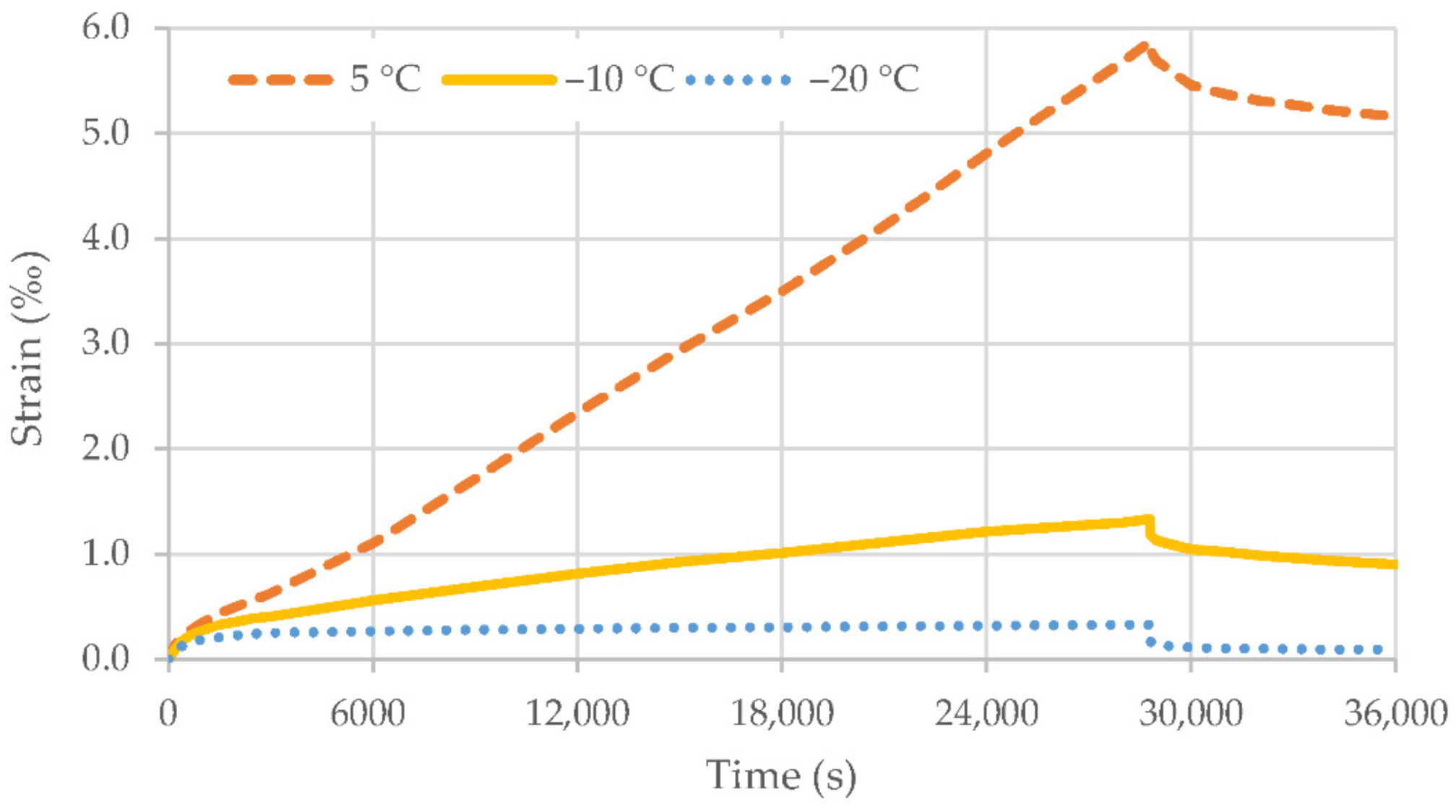

3.4.4. Tensile Creep Test (TCT)

3.4.5. Uniaxial Cyclic Tensile Stress Test (UCTST)

4. Conclusions

- The modification of bitumen with SBS increased the stiffness, reducing the penetration and increasing the softening point temperature.

- The PMBs presented an excellent elastic recovery and force-ductility performance.

- The tensile strength of the SMA mixtures achieved its maximum value at −10 °C. Then, the tensile strength slightly decreased when the temperature was further reduced.

- The failure strain decreased with the test temperature reduction as the asphalt mixture becomes brittle. At the lowest tested temperature, the SMA presents a failure strain over twenty times shorter than the one measured at 20 °C.

- PMB25 was selected for the remainder of this work. Its lower cost and similar results between both asphalt binders, including in the UTST tests, justified this selection.

- The TSRST thermal failure was estimated to occur at temperatures lower than −24 °C, although the stress reserve is small below −22 °C.

- The SMA mixture presents an excellent relaxation behavior at temperatures equal to or higher than −10 °C, but some slow relaxation issues may occur at very low temperatures (−20 °C).

- The TCT test results indicate that SMA mixture is not likely to present creep deformation issues at very low temperatures, but the same cannot be said at 5 °C.

- The low accumulations of strains at −10 and −20 °C justify the absence of failure due to cyclic loading (UCTST) under these conditions, unlike the SMA mixture’s failure after 12,500 cycles when tested at 5 °C.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alataş, T.; Yilmaz, M. Low temperature properties of hot mix asphalts prepared with different polymer modified binders. J. Croat. Assoc. Civ. Eng. 2017, 69, 93–104. [Google Scholar]

- Pangarova, D.; Nikolov, A. Study of the Low Temperature Characteristics of Binders and the Asphalt Mixtures Produced with Them. In Proceedings of the 6th Eurasphalt & Eurobitume Congress, Prague, Czech Republic, 1–3 June 2016. [Google Scholar]

- Polacco, G.; Kříž, P.; Filippi, S.; Stastna, J.; Biondi, D.; Zanzotto, L. Rheological properties of asphalt/SBS/clay blends. Eur. Polym. J. 2008, 44, 3512–3521. [Google Scholar] [CrossRef]

- Costa, L.M.B.; Silva, H.M.R.D.; Peralta, J.; Oliveira, J.R.M. Using waste polymers as a reliable alternative for asphalt binder modification—Performance and morphological assessment. Constr. Build. Mater. 2019, 198, 237–244. [Google Scholar] [CrossRef]

- Fernandes, S.; Pereira, S.; Silva, H.; Oliveira, J.; Palha, C. Avaliação de métodos de caracterização de betumes modificados. In Proceedings of the 1st Congresso de Ensaios e Experimentação em Engenharia Civil, IST, Lisboa, Portugal, 4–6 July 2016. [Google Scholar]

- Costa, L.M.B.; Peralta, J.; Oliveira, J.R.M.; Silva, H.M.R.D. A New Life for Cross-Linked Plastic Waste as Aggregates and Binder Modifier for Asphalt Mixtures. Appl. Sci. Basel 2017, 7, 603. [Google Scholar] [CrossRef]

- Pszczola, M.; Jaczewski, M.; Szydlowski, C. Assessment of Thermal Stresses in Asphalt Mixtures at Low Temperatures Using the Tensile Creep Test and the Bending Beam Creep Test. Appl. Sci. 2019, 9, 846. [Google Scholar] [CrossRef]

- Wang, T.-H.; Su, L.-J.; Zhai, J.-Y. A case study on diurnal and seasonal variation in pavement temperature. Int. J. Pavement Eng. 2014, 15, 402–408. [Google Scholar] [CrossRef]

- Stimilli, A.; Virgili, A.; Canestrari, F.; Bahia, H.U. Estimation of low-temperature performance of recycled asphalt mixtures through relaxation modulus analysis. Cold Reg. Sci. Technol. 2017, 133, 36–45. [Google Scholar] [CrossRef]

- Guo, Q.; Wang, H.; Gao, Y.; Jiao, Y.; Liu, F.; Dong, Z. Investigation of the low-temperature properties and cracking resistance of fiber-reinforced asphalt concrete using the DIC technique. Eng. Fract. Mech. 2020, 229, 106951. [Google Scholar] [CrossRef]

- Wang, W.; Tan, G.; Liang, C.; Wang, Y.; Cheng, Y. Study on Viscoelastic Properties of Asphalt Mixtures Incorporating SBS Polymer and Basalt Fiber under Freeze–Thaw Cycles. Polymers 2020, 12, 1804. [Google Scholar] [CrossRef]

- Pszczola, M.; Szydlowski, C. Influence of Bitumen Type and Asphalt Mixture Composition on Low-Temperature Strength Properties According to Various Test Methods. Materials 2018, 11, 2118. [Google Scholar] [CrossRef]

- Das, P.; Tasdemir, Y.; Birgisson, B. Low temperature cracking performance of WMA with the use of the Superpave indirect tensile test. Constr. Build. Mater. 2012, 30, 643–649. [Google Scholar] [CrossRef]

- Isacsson, U.; Zeng, H. Relationships between bitumen chemistry and low temperature behaviour of asphalt. Constr. Build. Mater. 1997, 11, 83–91. [Google Scholar] [CrossRef]

- Kim, K.W.; Hussein, M.E. Variation of fracture toughness of asphalt concrete under low temperatures. Constr. Build. Mater. 1997, 11, 403–411. [Google Scholar] [CrossRef]

- Soenen, H.; Vansteenkiste, S.; Kara De Maeijer, P. Fundamental approaches to predict moisture damage in asphalt mixtures: State-of-the-art review. Infrastructures 2020, 5, 20. [Google Scholar] [CrossRef]

- Chilukwa, N.; Lungu, R. Determination of layers responsible for rutting failure in a pavement structure. Infrastructures 2019, 4, 29. [Google Scholar] [CrossRef]

- Saliani, S.S.; Carter, A.; Baaj, H.; Tavassoti, P. Characterization of asphalt mixtures produced with coarse and fine recycled asphalt particles. Infrastructures 2019, 4, 67. [Google Scholar] [CrossRef]

- Kommidi, S.R.; Kim, Y.R. Dynamic shear rheometer testing and mechanistic conversion to predict bending beam rheometer low temperature behavior of bituminous binder. Constr. Build. Mater. 2021, 267, 120563. [Google Scholar] [CrossRef]

- Lv, S.T.; Xia, C.D.; Liu, C.C.; Zheng, J.L.; Zhang, F.C. Fatigue equation for asphalt mixture under low temperature and low loading frequency conditions. Constr. Build. Mater. 2019, 211, 1085–1093. [Google Scholar] [CrossRef]

- Blazejowski, K. Stone Matrix Asphalt Theory and Practice; CRC Press Taylor & Francis Group: Abingdon, UK, 2011. [Google Scholar]

- Fernandes, S.; Silva, H.M.R.D.; Oliveira, J.R.M. Mechanical, surface and environmental evaluation of stone mastic asphalt mixtures with advanced asphalt binders using waste materials. Road Mater. Pavement Des. 2019, 20, 316–333. [Google Scholar] [CrossRef]

- Cheng, Y.; Tao, J.; Jiao, Y.; Tan, G.; Guo, Q.; Wang, S.; Ni, P. Influence of the properties of filler on high and medium temperature performances of asphalt mastic. Constr. Build. Mater. 2016, 118, 268–275. [Google Scholar] [CrossRef]

- EAPA. Heavy Duty Surfaces the Arguments for SMA; European Asphalt Pavement Association: Brussels, Belgium, 2018. [Google Scholar]

- Fernandes, S.R.M.; Silva, H.M.R.D.; Oliveira, J.R.M. Developing enhanced modified bitumens with waste engine oil products combined with polymers. Constr. Build. Mater. 2018, 160, 714–724. [Google Scholar] [CrossRef]

- Shekar, P.C.; Rajath, B.H.; Vishwas, J.S. Experimental investigation of Stone Mastic Asphalt by varying mix design. Int. Res. J. Eng. Technol. 2018, 5, 300–305. [Google Scholar]

- Judycki, J. Influence of low-temperature physical hardening on stiffness and tensile strength of asphalt concrete and stone mastic asphalt. Constr. Build. Mater. 2014, 61, 191–199. [Google Scholar] [CrossRef]

- Porto, M.; Caputo, P.; Loise, V.; Eskandarsefat, S.; Teltayev, B.; Rossi, C.O. Bitumen and Bitumen Modification: A Review on Latest Advances. Appl. Sci. 2019, 9, 742. [Google Scholar] [CrossRef]

- Ding, X.; Chen, L.; Ma, T.; Ma, H.; Gu, L.; Chen, T.; Ma, Y. Laboratory investigation of the recycled asphalt concrete with stable crumb rubber asphalt binder. Constr. Build. Mater. 2019, 203, 552–557. [Google Scholar] [CrossRef]

- Quirk, R.P.; Kinning, D.J.; Fetters, L.J. 1—Block Copolymers. Compr. Polym. Sci. Suppl. 1989, 7, 1–26. [Google Scholar]

- Airey, G.D. Rheological properties of styrene butadiene styrene polymer modified road bitumens. Fuel 2003, 82, 1709–1719. [Google Scholar] [CrossRef]

- Vonk, W.; Scholten, E.J.; Korenstra, J. Novel Class of SBS Polymers for Enhanced Effectiveness in Bitumen Modification. In Proceedings of the Australian Asphalt Paving Association Thirteenth International Flexible Pavements Conference, Queensland, Australia, 11–14 October 2010. [Google Scholar]

- Mandal, T.; Sylla, R.; Bahia, H.; Barmand, S. Effect of cross-linking agents on the rheological properties of polymer-modified bitumen. Road Mater. Pavement Des. 2015, 16, 349–361. [Google Scholar] [CrossRef]

- SABITA. Technical Guideline: The Use of Modified Bituminous Binder in Road Construction; Southern African Bitumen Association (Sabita): Cape Town, South Africa, 2015. [Google Scholar]

- Fernandes, S.R.M.; Silva, H.M.R.D.; Oliveira, J.R.M. Recycled stone mastic asphalt mixtures incorporating high rates of waste materials. Constr. Build. Mater. 2018, 187, 1–13. [Google Scholar] [CrossRef]

- Becker, Y.; Méndez Maryro, P.; Rodríguez, Y.E. Polymer modified asphalt. Vis. Tecnol. 2001, 9, 39–50. [Google Scholar]

- Pszczola, M.; Szydlowski, C.; Jaczewski, M. Influence of cooling rate and additives on low-temperature properties of asphalt mixtures in the TSRST. Constr. Build. Mater. 2019, 204, 399–409. [Google Scholar] [CrossRef]

- Pszczola, M.; Judycki, J.; Ryś, D. Evaluation of Pavement Temperatures in Poland During Winter Conditions. Transp. Res. Procedia 2016, 14, 738–747. [Google Scholar] [CrossRef]

- Hassan, N.; Airey, G.; Putra Jaya, R.; Mashros, N.; Aziz, M.A. A Review of Crumb Rubber Modification in Dry Mixed Rubberised Asphalt Mixtures. J. Teknol. 2014, 70, 70. [Google Scholar]

- Behnood, A.; Ameri, M. Experimental investigation of stone matrix asphalt mixtures containing steel slag. Sci. Iran. 2012, 19, 1214–1219. [Google Scholar] [CrossRef]

- Remišová, E.; Holý, M. Changes of Properties of Bitumen Binders by Additives Application; IOP Conference Series: Materials Science and Engineering; IOP Publishing Ltd.: Bristol, UK, 2017. [Google Scholar]

- Laukkanen, O.V.; Soenen, H.; Winter, H.H.; Seppälä, J. Low-temperature rheological and morphological characterization of SBS modified bitumen. Constr. Build. Mater. 2018, 179, 348–359. [Google Scholar] [CrossRef]

- Kommidi, S.R.; Kim, Y.-R. Investigation of DSR Test Methods to Determine Binder Low Temperature Properties. Neb. Dep. Transp. Res. Rep. 2019, 218, 77. [Google Scholar]

- Lu, X.; Uhlback, P.; Soenen, H. Investigation of bitumen low temperature properties using a dynamic shear rheometer with 4 mm parallel plates. Int. J. Pavement Res. Technol. 2017, 10, 15–22. [Google Scholar] [CrossRef]

- Lin, P.; Huang, W.; Li, Y.; Tang, N.; Xiao, F. Investigation of influence factors on low temperature properties of SBS modified asphalt. Constr. Build. Mater. 2017, 154, 609–622. [Google Scholar] [CrossRef]

- Zheng, X.; Xu, W.; Feng, H.; Cao, K. High and low temperature performance and fatigue properties of silica fume/SBS compound modified asphalt. Materials 2020, 13, 4446. [Google Scholar] [CrossRef]

- Sun, Y.; He, D. High and low-temperature performance evaluation and microanalysis of smcsbs compound-modified asphalt. Materials 2021, 14, 771. [Google Scholar] [CrossRef]

- Zhang, B.; Chen, H.; Zhang, H.; Kuang, D.; Wu, J.; Zhang, X. A Study on Physical and Rheological Properties of Rubberized Bitumen Modified by Different Methods. Materials 2019, 12, 3538. [Google Scholar] [CrossRef]

- Mollenhauer, K.; Tušar, M. FunDBitS: Functional Durability-Related Bitumen Specification. Deliverable D.2c, Correlations between Bitumen and Asphalt Properties: Low Temperature Cracking. In Proceedings of the Conférence Européenne des Directeurs des Routes—Conference of European Directors of Roads (CEDR), Brussels, Belgium, 20 October 2016; p. 18. [Google Scholar]

- Brown, E.; Mallick, R.; Haddock, J.; Bukowski, J. Performance of Stone Matrix Asphalt (SMA) Mixtures in the United States; NCAT Report No. 97-1; National Center for Asphalt Technology: Auburn, AL, USA, 1997. [Google Scholar]

- Stock, A.F.; Arand, W. Low Temperature Cracking in Polymer Modified Binders; Asphalt Paving Technology: Austin, TX, USA, 1993. [Google Scholar]

- Nicholls, C. Asphalt Mixture Specification and Testing; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Sun, Y.; Gu, Z.; Wang, J.; Fang, C.; Yuan, X. Study on Relaxation Damage Properties of High Viscosity Asphalt Sand under Uniaxial Compression. Adv. Civ. Eng. 2018, 2018, 1498480. [Google Scholar] [CrossRef]

- Hischke, G. Understanding Creep in Asphalt Concrete; Illinois Asphalt Paving Association (IAPA): Springfield, IL, USA, 2019. [Google Scholar]

- Sohm, J.; Gabet, T.; Hornych, P.; Piau, J.-M.; Di Benedetto, H. Creep tests on bituminous mixtures and modelling. Road Mater. Pavement Des. 2012, 13, 832–849. [Google Scholar] [CrossRef]

- Pszczoła, M.; Judycki, J. Testing of low temperature behaviour of asphalt mixtures in bending creep test. In Proceedings of the 7th International RILEM Symposium ATCBM09 on Advanced Testing and Characterization of Bituminous Materials, Rhodes, Greece, 27–29 May 2009. [Google Scholar]

- Mollenhauer, K.; Wistuba, M. Evaluation of hot-mix asphalt susceptibility to temperature-induced top-down fatigue cracking by means of Uniaxial Cyclic Tensile Stress Test. Road Mater. Pavement Des. 2012, 13, 171–190. [Google Scholar] [CrossRef]

| Sieve Size (mm) | SMA 11 (%) |

|---|---|

| 16 | 100 |

| 11.2 (11) | 90–100 |

| 8 | 55–80 |

| 4 | 22–33 |

| 2 | 20–30 |

| 0.5 | 12–20 |

| 0.063 | 6–10 |

| Temperature (°C) | Proportion of βt(T) (%) |

|---|---|

| −25 | 50 |

| −20 | 43 |

| −10 | 30 |

| +5 | 10 |

| +20 | 5 |

| Asphalt Binder | Penetration at 25 °C (0.1 mm) | Softening Point (°C) |

|---|---|---|

| Base 50/70 bitumen | 55.2 | 50.5 |

| PMB25 | 42.7 | 90.9 |

| PMB50 | 42.3 | 89.5 |

| Parameter | 5 °C | 20 °C | ||

|---|---|---|---|---|

| PMB25 | PMB50 | PMB25 | PMB50 | |

| Mean value | 65% | 51% | 98% | 95% |

| Standard deviation | 1% | 1% | 0% | 0% |

| Coefficient of variation | 2% | 1% | 0% | 0% |

| Properties | Unit | SMA 11 PMB25 | SMA 11 PMB50 | ||||

|---|---|---|---|---|---|---|---|

| Mean Value | Standard Deviation | Coefficient of Variation | Mean Value | Standard Deviation | Coefficient of Variation | ||

| Maximum density, ρmv | (Mg/m3) | 2.461 | - | - | 2.469 | - | - |

| Bulk density, ρbssd | (Mg/m3) | 2.405 | 0.011 | 0.5% | 2.399 | 0.015 | 0.6% |

| Air voids, Va | (%) | 2.27 | 0.46 | 20.1% | 2.83 | 0.62 | 22.1% |

| Property | Test Temperature (°C) | SMA 11 PMB25 | SMA 11 PMB50 | ||||

|---|---|---|---|---|---|---|---|

| Mean Value | Standard Deviation | Coefficient of Variation | Mean Value | Standard Deviation | Coefficient of Variation | ||

| Tensile strength βt (MPa) | −20 | 5.437 | 0.466 | 9% | - | - | - |

| −10 | 6.008 | 0.636 | 11% | - | - | - | |

| 5 | 3.550 | 0.303 | 9% | 3.445 | 0.147 | 4% | |

| 20 | 0.510 | 0.063 | 12% | 0.539 | 0.025 | 5% | |

| Parameter | −20 °C | −10 °C | 5 °C | |

|---|---|---|---|---|

| Input value | 75% peak stress from UTST (MPa) | −4.078 | −4.506 | −2.663 |

| Corresponding input strain (‰) | 0.30 | 0.48 | 0.93 | |

| Final result | Actual imposed stress (MPa) | −3.902 | −4.399 | −2.645 |

| Relaxation stress (MPa) | −1.436 (not reached) | −1.619 | −0.973 | |

| Relaxation time trel (s) | Not reached | 2206 | 47 | |

| Test stopping time (s) | 172,800 | 2206 | 47 | |

| Remaining tensile stress σrem (MPa) | −1.625 | −1.619 | −0.973 | |

| Parameter | −20 °C | −10 °C | 5 °C | |

|---|---|---|---|---|

| Input value | Base stress σcry(T) @ −10 °C/h (MPa) | −2.50 | −0.30 | −0.04 |

| Traffic load Δσ (MPa) | −1.60 | −1.60 | −1.60 | |

| Peak stress σtot (MPa) | −4.10 | −1.90 | −1.64 | |

| Final result | Type of failure | Not reached | Not reached | Fracture |

| Number of load applications, Nfailure | >2.0 million | >2.0 million | 12,500 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dias, A.; Silva, H.; Palha, C.; Oliveira, J. Low-Temperature Performance of Polymer-Modified Binders in Stone Mastic Asphalts. Infrastructures 2021, 6, 58. https://doi.org/10.3390/infrastructures6040058

Dias A, Silva H, Palha C, Oliveira J. Low-Temperature Performance of Polymer-Modified Binders in Stone Mastic Asphalts. Infrastructures. 2021; 6(4):58. https://doi.org/10.3390/infrastructures6040058

Chicago/Turabian StyleDias, Ana, Hugo Silva, Carlos Palha, and Joel Oliveira. 2021. "Low-Temperature Performance of Polymer-Modified Binders in Stone Mastic Asphalts" Infrastructures 6, no. 4: 58. https://doi.org/10.3390/infrastructures6040058

APA StyleDias, A., Silva, H., Palha, C., & Oliveira, J. (2021). Low-Temperature Performance of Polymer-Modified Binders in Stone Mastic Asphalts. Infrastructures, 6(4), 58. https://doi.org/10.3390/infrastructures6040058