Effect of Chases with Renovation Techniques on the Load Carrying Capacity of Masonry Walls

Abstract

:1. Introduction

2. Experimental Programme

2.1. Material Used

2.2. Properties of Cement Mortar

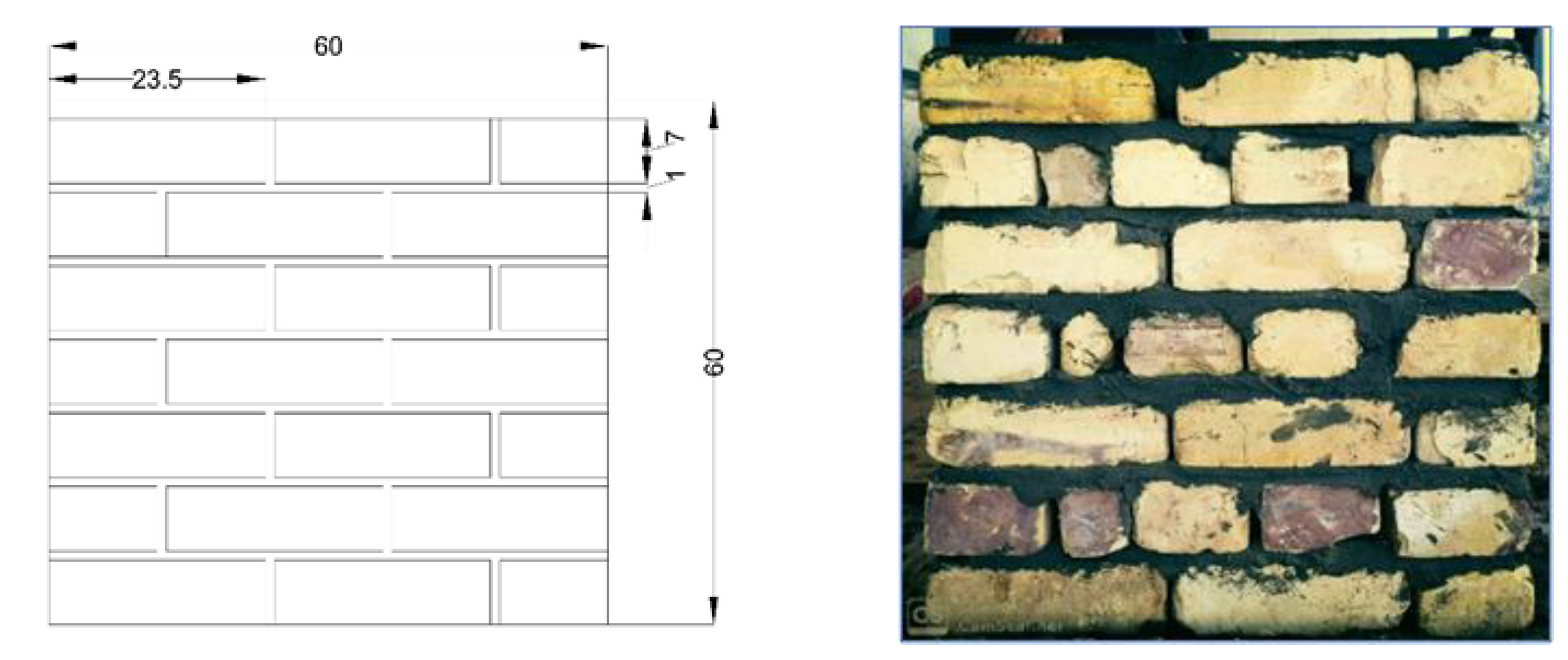

2.3. Formulation of the Masonry Wallettes

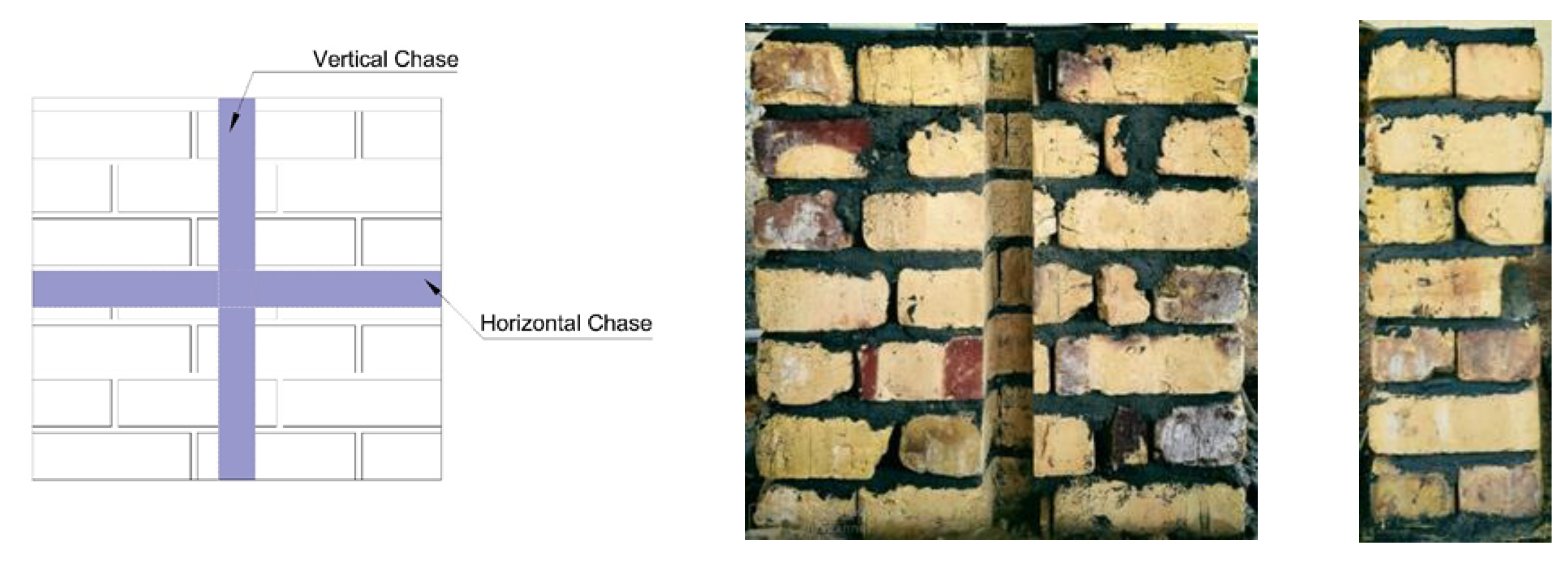

2.4. Creation of the Chases

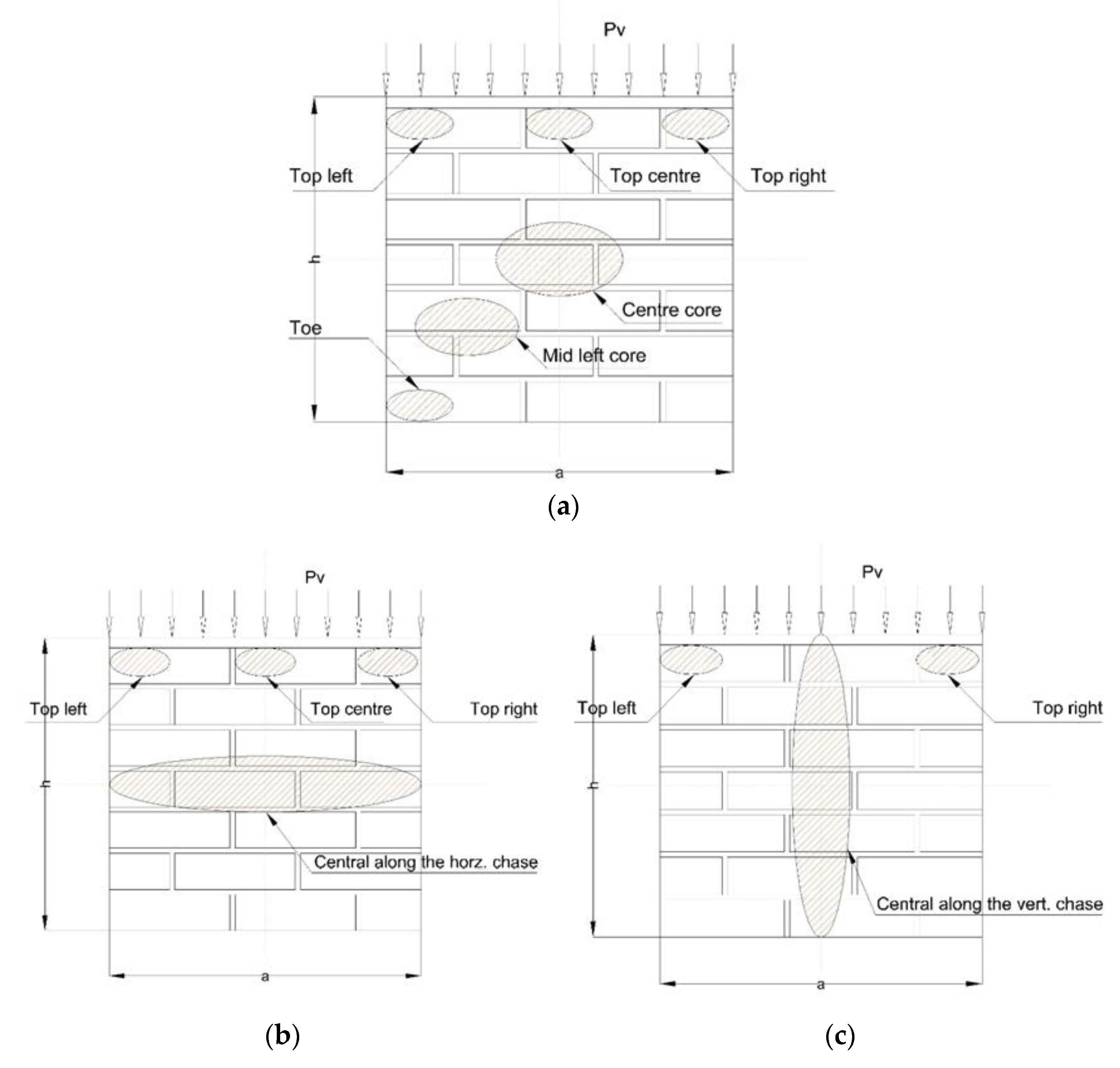

2.5. Method of the Test and Measured Parameters

3. Results

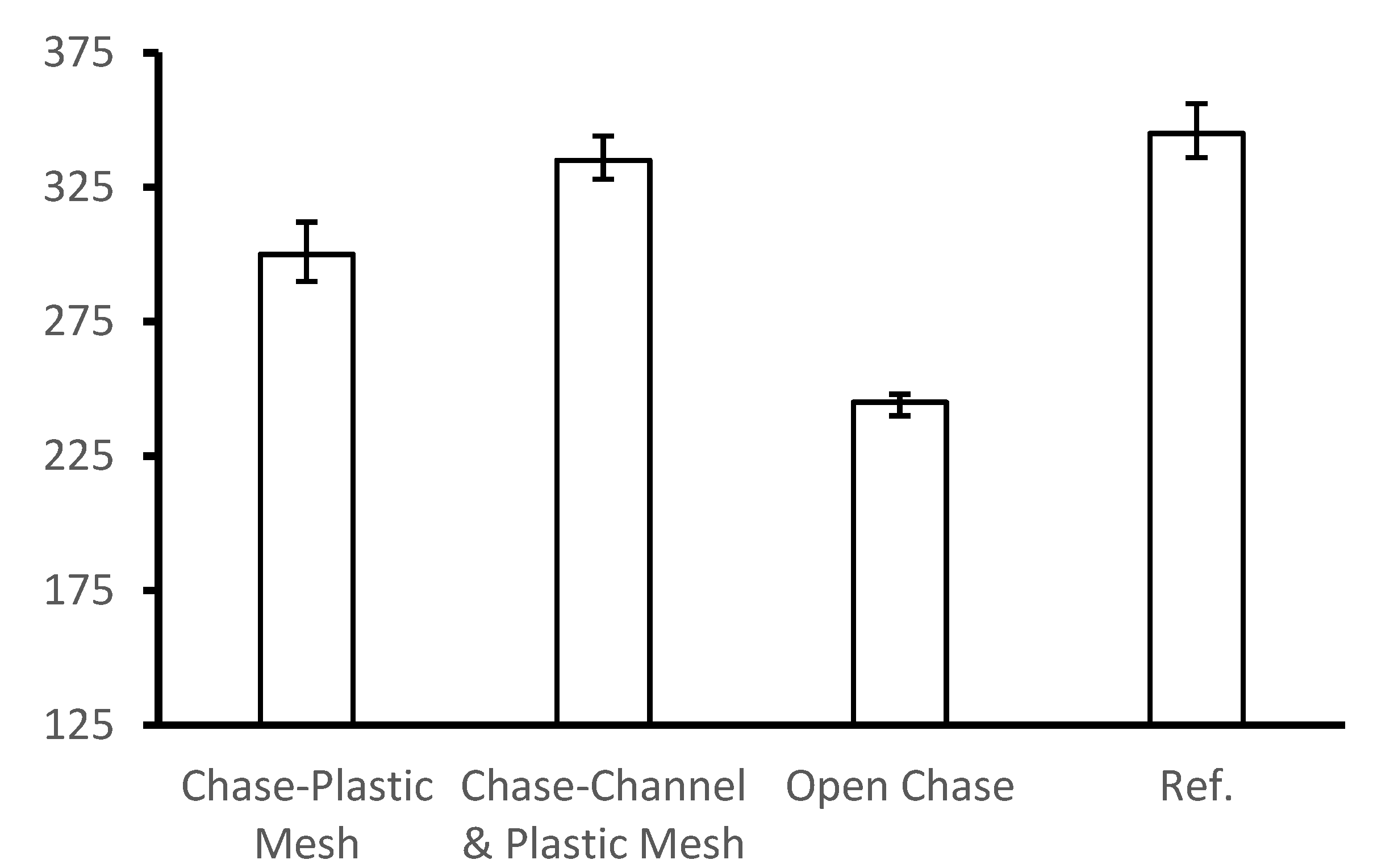

4. Discussion

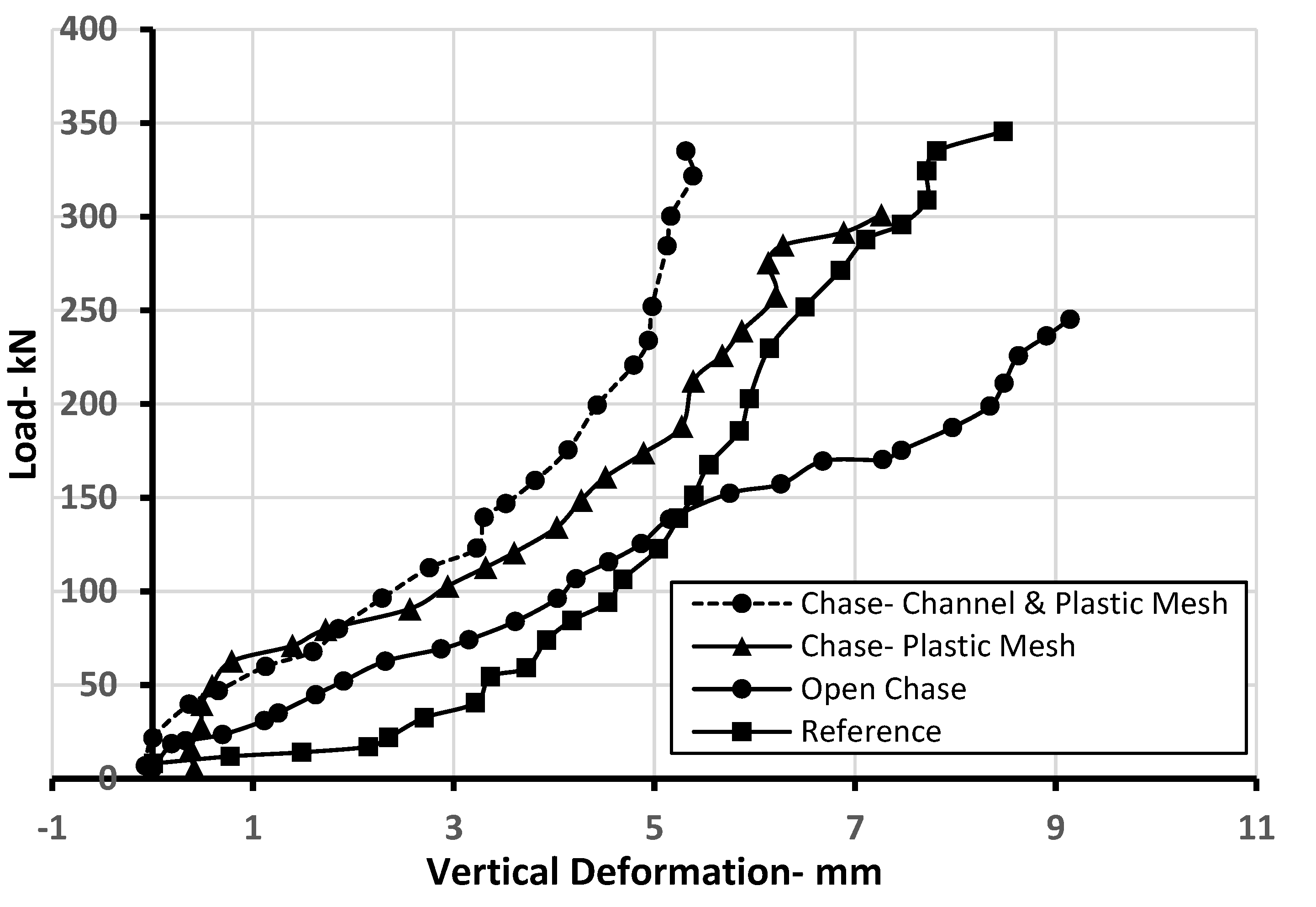

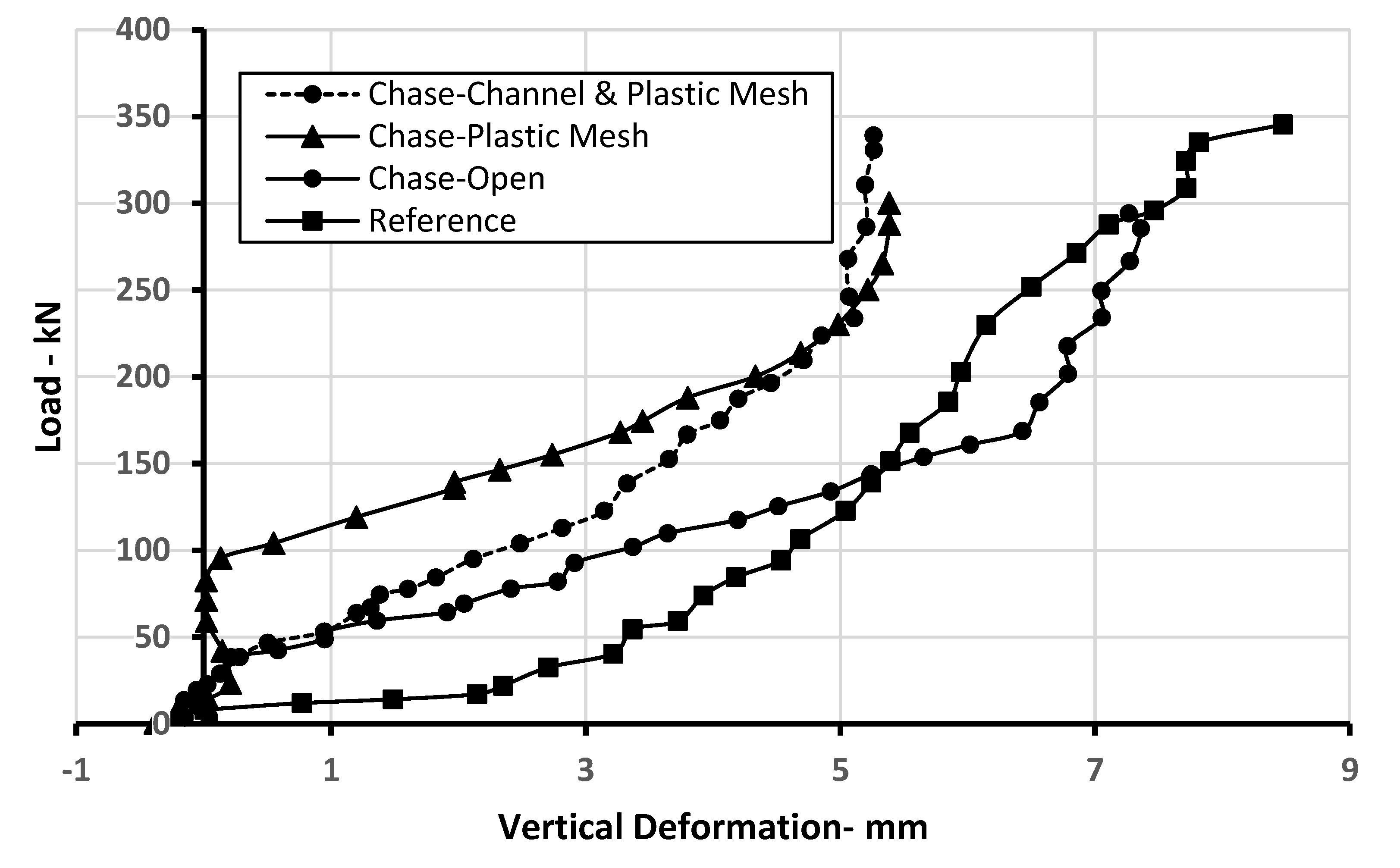

4.1. Load- Deformation Behaviour

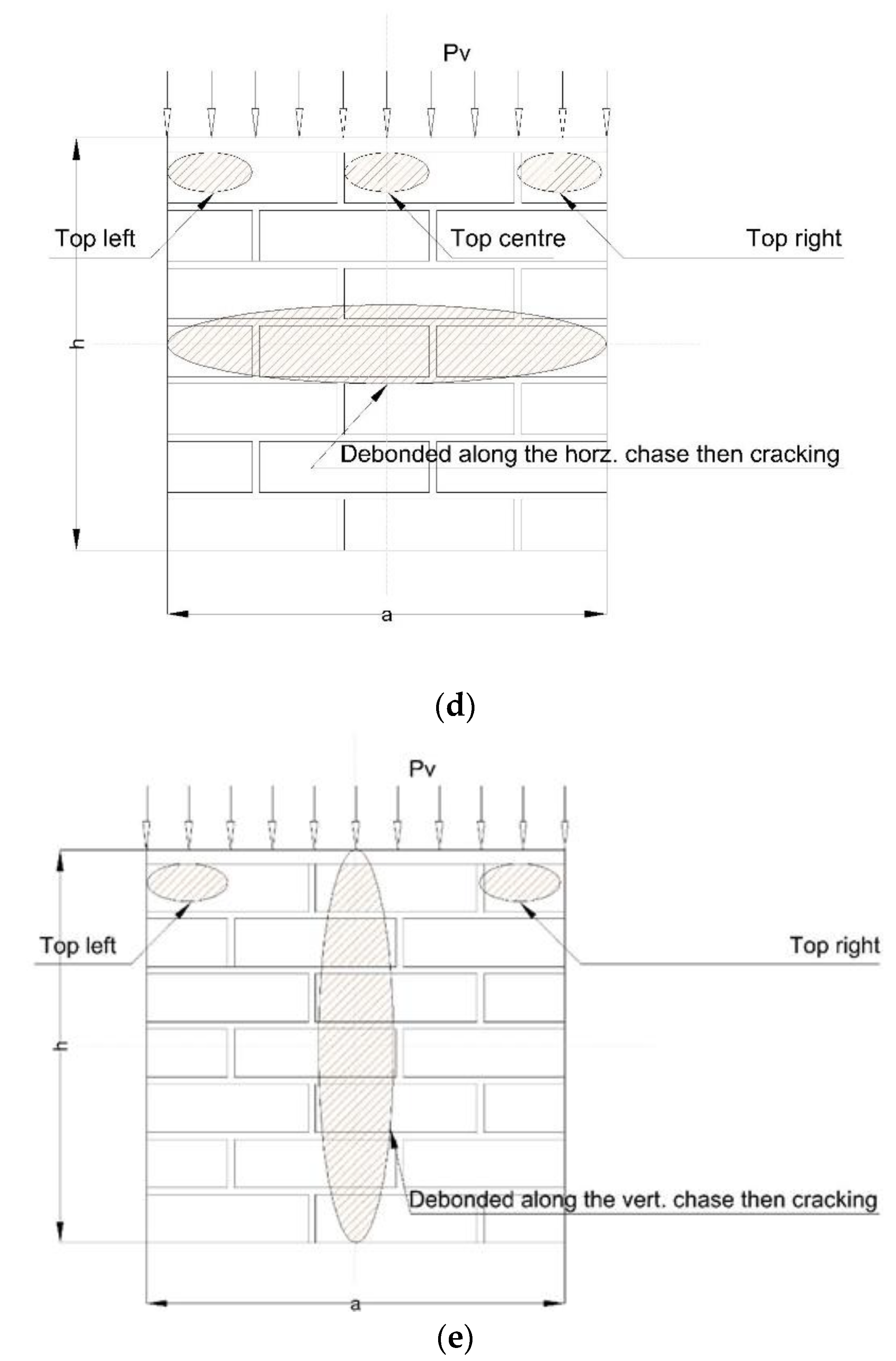

4.2. Failure Modes

4.3. Comparison with the Constitutive Formulae Given in Codes of Practice

5. Conclusions

- Lower load bearing capacity was achieved when chases are introduced in a newly built masonry walls in different directions. Approximately, 29% less strength was noted compared with the case of free chase walls.

- The worst condition of the chases was observed for the case of a chase created in the horizontal direction in which the applied load acts in a perpendicular way on the zone containing the chase.

- The reduction in the load carrying capacity was due to concentration of stresses in the chase region and the latter is due to the inclination of the load flow as a result of the chase depth.

- Using galvanized steel channel and/or plastic wire mesh with cement mortar has a clear beneficial role in recovering the strength lost due to introduction of the chases with percentages recovery of 55% and 93%, respectively. This behaviour is attributed to the infill and adhesion characteristics of such renovation techniques.

- The reference masonry wallette exhibited less lateral deformation due to its brittleness behaviour. In contrast, the repaired wallettes showed more deformation resulting from the ductile nature of the infill materials.

- The dominated failure was the de-bonded of the renovation components from the interior surfaces of the chases. The beginning of the de-bonded was noted at the one third of the ultimate load carrying capacity.

- The expressions suggested by BS EN codes for calculating the values of the compressive strength and modulus of elasticity of masonry walls need to be amended taken in consideration using a suitable factor of safety to overcome the adverse effect of the chases.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Al-Sibahy, A.; Edwards, R. Characterization of the clay masonry units and construction technique at the ancient city of Nippur. Eng. Struct. 2017, 147, 517–529. [Google Scholar] [CrossRef] [Green Version]

- Al-Sibahy, A.; Edwards, R. Structural evaluation for the historic Palace of King Ghazi and mechanism of its rehabilitation. Case Stud. Constr. Mater. 2020, 13, e00371. [Google Scholar]

- Al-Sibahy, A.; Edwards, R. Behaviour of masonry wallettes made from a new concrete formulation under compression loads at ambient temperatures: Testing and modelling. Constr. Build. Mater. 2014, 63, 271–280. [Google Scholar] [CrossRef]

- Fischer, K. The effects of chasing on the compressive strength of brickwork. In Proceedings of the 3rd International Brick Masonry Conference, Essen, Germany, 8–11 January 1973; pp. 106–114. [Google Scholar]

- Kirtschig, K.; Metje, W.R. Influence of chases and recesses on the strength of masonry. Proc. Br. Mason. Soc. 1988, 2, 61–63. [Google Scholar]

- SIA 266:2003. Structural Masonry; Swiss Society of Engineers and Architects: Zurich, Switzerland, 2003. [Google Scholar]

- ACI 530-08/ASCE 5-08/TMS 402-08. Building Code Requirements and Specifications for Masonry Structures; Masonry Standards Joint Committee (MSJC), Boulder/Farmington Hills: Reston, WV, USA, 2008. [Google Scholar]

- AS3700:2001. Masonry Structures; Standards Australia: Sydney, Australia, 2001. [Google Scholar]

- Sahlin, S. Fischer’s tests on chasing revisited the effects of chasing on the compressive strength of brickwork (3. IBMAC, Essen 1973). Mason. Int. 2007, 20, 85–90. [Google Scholar]

- EN 1996-1-1:2005. Design of Masonry Structures—Part 1: General Rules for Reinforced and Unreinforced Masonry; European Committee for Standardization: Brussels, Belgium, 2005. [Google Scholar]

- Mojsilovic, N. Masonry elements with chases: Behaviour under compression. Construct. Build. Mater. 2011, 25, 4415–4425. [Google Scholar] [CrossRef]

- Milani, A.S.; Lübeck, A.; Mohamad, G.; Neto, A.B.d.S.; Budny, J. Experimental investigation of small-scale clay blocks masonry walls with chases under compression. Construct. Build. Mater. 2021, 273, 121539. [Google Scholar] [CrossRef]

- I.Q.S No. 25. Clay Building Bricks; The Central Organization for Standardization and Quality Control: Baghdad, Iraq, 1988; Available online: https://www.google.com.hk/search?newwindow=1&source=univ&tbm=isch&q=I.Q.S+No.+25.+Clay+Building+Bricks;+The+Iraqi+Standards++:+1988.&fir=efAW8aZx17ofyM%252CoNEQCZqo8gnZeM%252C_%253BTZ7feq-XiWG1EM%252CQFPN060DwzniuM%252C_%253B2Itf7VvnFr_LPM%252C3PM3pedmUsdf9M%252C_%253B0UkI4QH3BXrcJM%252CoNEQCZqo8gnZeM%252C_%253B60yL6sNFs48RbM%252C2GzR70mWFedU8M%252C_%253B55g_8YrHaYM6LM%252C9Y6WtkACGpM4qM%252C_%253BzqNvoeC9rtPubM%252CoNEQCZqo8gnZeM%252C_%253BdXMjZ6ecE_vjcM%252C67UXnZk0ry3LMM%252C_%253BfAbQvBVqQpb6RM%252CoNEQCZqo8gnZeM%252C_%253BjZlKI9I5VuNCYM%252C9Y6WtkACGpM4qM%252C_&usg=AI4_-kRaGxhgXxAcqyM7yUDxoxcfQ58D8g&sa=X&ved=2ahUKEwjKpM_Y1Yf0AhWOfXAKHd_VCWUQjJkEegQIHxAC&biw=2144&bih=1004&dpr=0.9 (accessed on 2 November 2021).

- EN BS 197-1. Cement, Part 1: Compositions, Specification and Conformity Criteria for Common Cements; British Standards: 2000. Available online: http://www.puntofocal.gov.ar/notific_otros_miembros/mwi40_t.pdf (accessed on 2 November 2021).

- BS 882 1992. Aggregates for Concrete, Specification for Aggregates from Natural Sources for Concrete. Available online: https://shop.bsigroup.com/products/specification-for-aggregates-from-natural-sources-for-concrete-1 (accessed on 2 November 2021).

- BS 5628-1. Code of Practice for the Use of Masonry: Part 1: Structural Use of Unreinforced Masonry; British Standards: 2005. Available online: https://shop.bsigroup.com/products/code-of-practice-for-the-use-of-masonry-structural-use-of-unreinforced-masonry (accessed on 2 November 2021).

- BS EN 1052-1. Methods of Test for Masonry: Part 1: Determination of Compressive Strength; British Standards: 1999. Available online: https://www.thenbs.com/PublicationIndex/documents/details?Pub=BSI&DocID=247929 (accessed on 2 November 2021).

- Oliveira, D.V. Experimental and Numerical Analysis of Blocky Masonry Structures under Cyclic Loading. Ph.D. Thesis, The University of Minho, Braga, Portugal, 2003. [Google Scholar]

- Drysdale, R.G.; Hamid, A.A. Masonry structures behavior and design. In The Masonry Society, 3rd ed.; The Masonry Society: Longmont, CO, USA, 2008. [Google Scholar]

- BS ISO 1920-10. Testing of Concrete, Part 10: Determination of Static Modulus of Elasticity; British Standards: 2009. Available online: https://civilnode.com/download-standard/10661023633076/iso-1920-10-testing-of-concrete-part-10-determination-of-static-modulus-of-elasticity-in-compression (accessed on 2 November 2021).

- BS EN 772-1. Methods of Test for Masonry Units: Part 1: Determination of Compressive Strength; British Standards: 2000. Available online: https://standards.iteh.ai/catalog/standards/cen/1fa1b3c1-83ab-4a43-b744-bea787fe5b2c/en-772-1-2000 (accessed on 2 November 2021).

| Compression Test Results | Absorption Test Results | Limitations of Iraqi Standards No. 25-1998 [13] | |||||

|---|---|---|---|---|---|---|---|

| No. of Sample | Individual Reading | Average | Individual Reading | Average | Lower Limits of Compression | ||

| 1 | 8.43 | 9.71 | 23.82 | 23.98 | Type | Individual | Average |

| 2 | 8.69 | 25.20 | A | 16 | 18 | ||

| 3 | 8.66 | 22.34 | B | 11 | 13 | ||

| 4 | 13.31 | 25.76 | C | 7 | 9 | ||

| 6 | 10.17 | 17.36 | Upper limits of absorption | ||||

| 7 | 9.65 | 23.50 | Type | Individual | Average | ||

| 8 | 10.86 | 24.25 | A | 22 | 20 | ||

| 9 | 7.77 | 29.67 | B | 26 | 24 | ||

| 10 | 8.69 | 23.60 | C | 28 | 26 | ||

| No. | Type of Specimen | Fmax (kN) | Aw (m2) | (MPa) | E (MPa) | Max. Ver.Disp (mm) | Max. Lat.Disp. (mm) | |

|---|---|---|---|---|---|---|---|---|

| 1 | Reference | 345 | 0.144 | 2.39 | 95 | 8.5 | 0.8 | - |

| 2 | Horizontal-Chase open | 245 | 0.144 | 1.70 | 94 | 9.1 | 1.8 | −29 |

| 3 | Horizontal-Chase with plastic mesh | 300 | 0.144 | 2.08 | 151 | 7.2 | 3.3 | −13 |

| 4 | Horizontal-Chase-channel and plastic mesh | 335 | 0.144 | 2.32 | 158 | 5.3 | 1.5 | −2.8 |

| 5 | Vertical-Chase open | 295 | 0.144 | 2.04 | 121 | 7.3 | 1.6 | −14 |

| 6 | Vertical-Chase with plastic mesh | 301 | 0.144 | 2.09 | 774 | 5.7 | 5.4 | −12.5 |

| 7 | Vertical-Chase-channel and plastic mesh | 339 | 0.144 | 2.35 | 167 | 5.2 | 1.5 | −1.7 |

| No. | Type of Specimen | The Measured Value of | The Theoretical Value of | F. S |

|---|---|---|---|---|

| 1 | Reference | 2.39 | 3.5 | 0.68 |

| 2 | Horizontal-Chase open | 1.70 | 3.5 | 0.49 |

| 3 | Horizontal-Chase with plastic mesh | 2.08 | 3.5 | 0.59 |

| 4 | Horizontal-Chase-channel and plastic mesh | 2.32 | 3.5 | 0.66 |

| 5 | Vertical-Chase open | 2.04 | 3.5 | 0.58 |

| 6 | Vertical-Chase with plastic mesh | 2.09 | 3.5 | 0.60 |

| 7 | Vertical-Chase-channel and plastic mesh | 2.35 | 3.5 | 0.67 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Sibahy, A.; Edwards, R. Effect of Chases with Renovation Techniques on the Load Carrying Capacity of Masonry Walls. Infrastructures 2021, 6, 160. https://doi.org/10.3390/infrastructures6110160

Al-Sibahy A, Edwards R. Effect of Chases with Renovation Techniques on the Load Carrying Capacity of Masonry Walls. Infrastructures. 2021; 6(11):160. https://doi.org/10.3390/infrastructures6110160

Chicago/Turabian StyleAl-Sibahy, Adnan, and Rodger Edwards. 2021. "Effect of Chases with Renovation Techniques on the Load Carrying Capacity of Masonry Walls" Infrastructures 6, no. 11: 160. https://doi.org/10.3390/infrastructures6110160

APA StyleAl-Sibahy, A., & Edwards, R. (2021). Effect of Chases with Renovation Techniques on the Load Carrying Capacity of Masonry Walls. Infrastructures, 6(11), 160. https://doi.org/10.3390/infrastructures6110160