Mortars with CDW Recycled Aggregates Submitted to High Levels of CO2

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

3. Results and Discussion

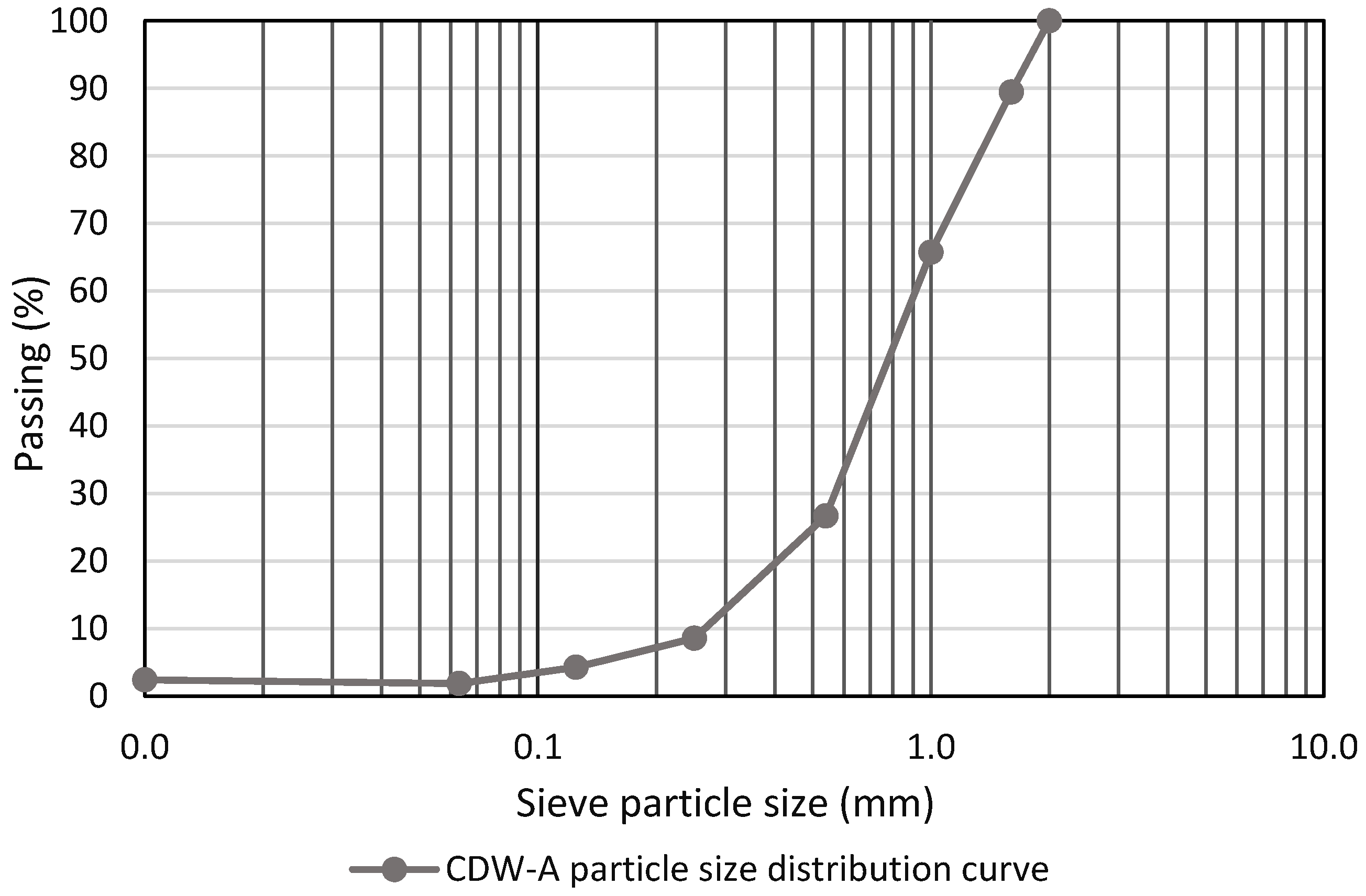

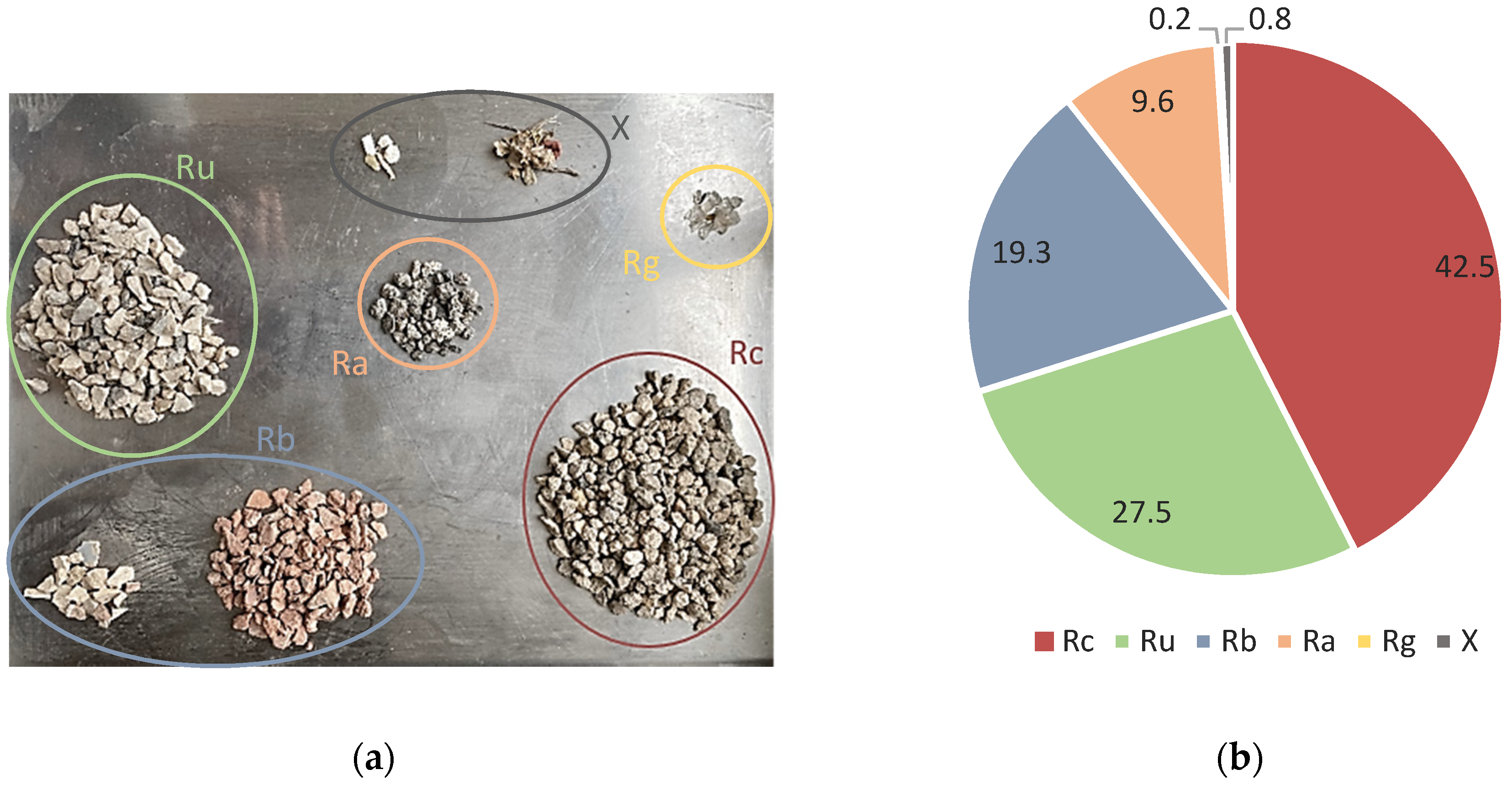

3.1. Recycled Aggregates

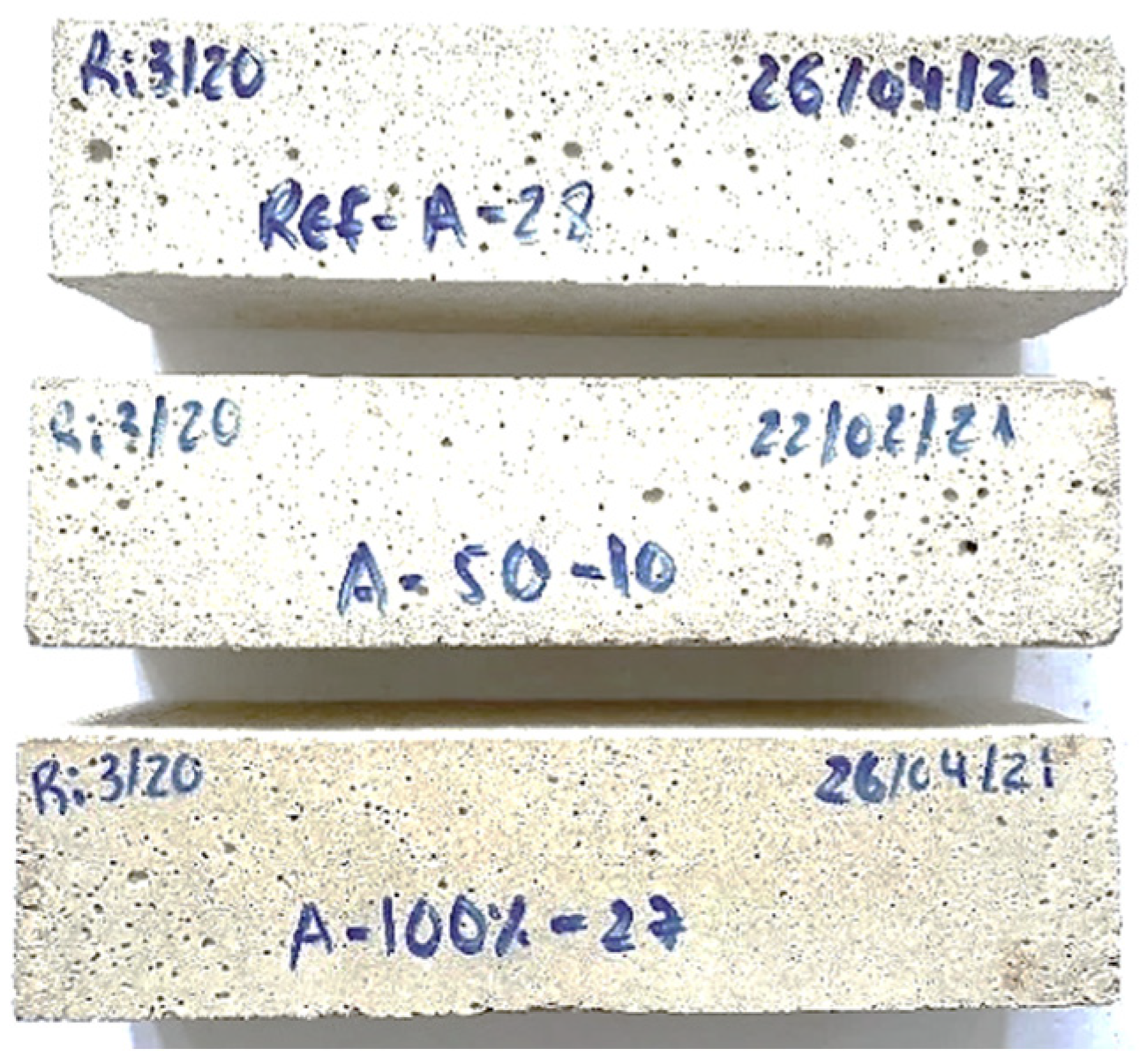

3.2. Mortars

3.2.1. Fresh-State Properties

3.2.2. Hardened State

Bulk Density

Modulus of Elasticity by Frequency of Resonance

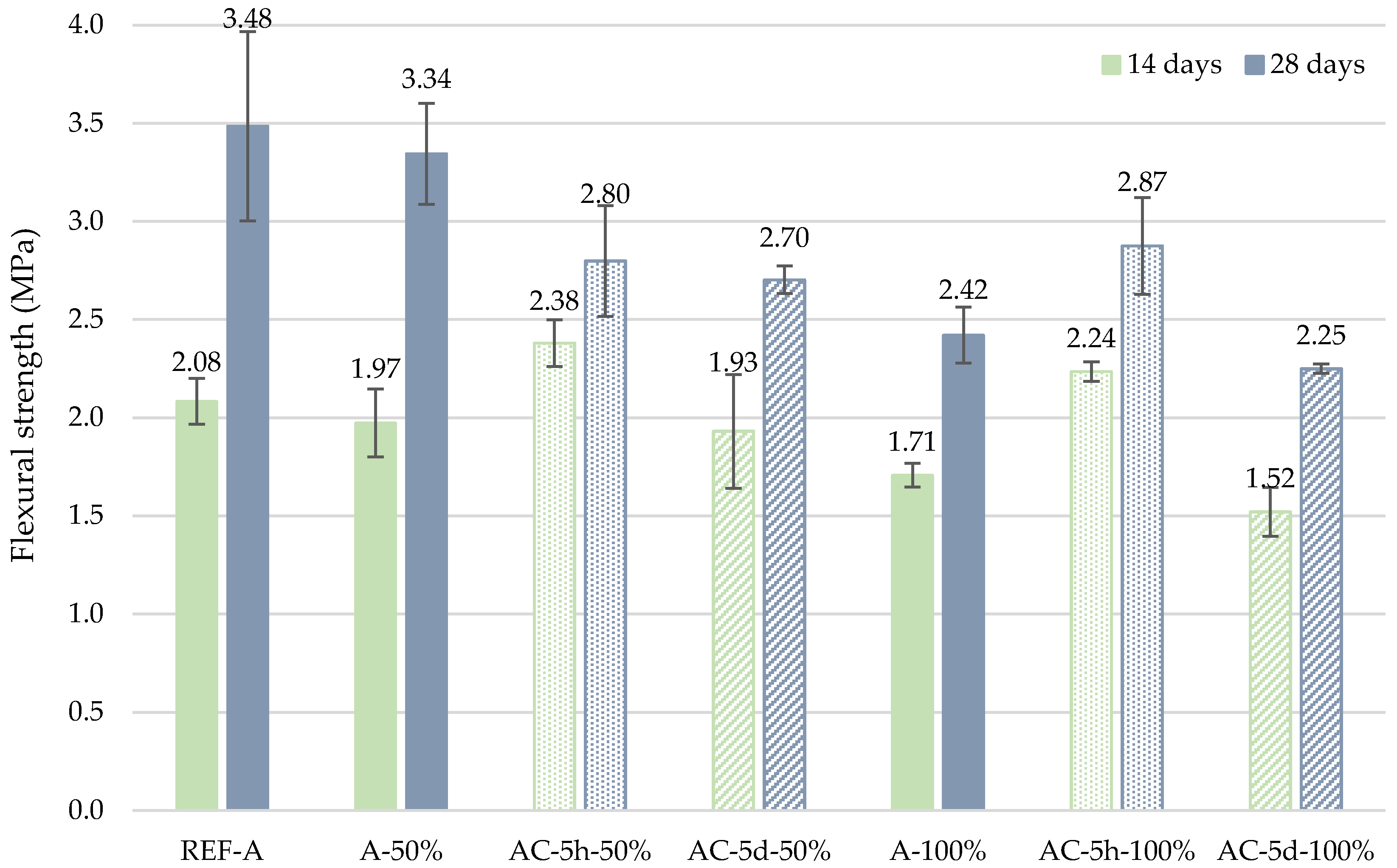

Flexural Strength

Compressive Strength

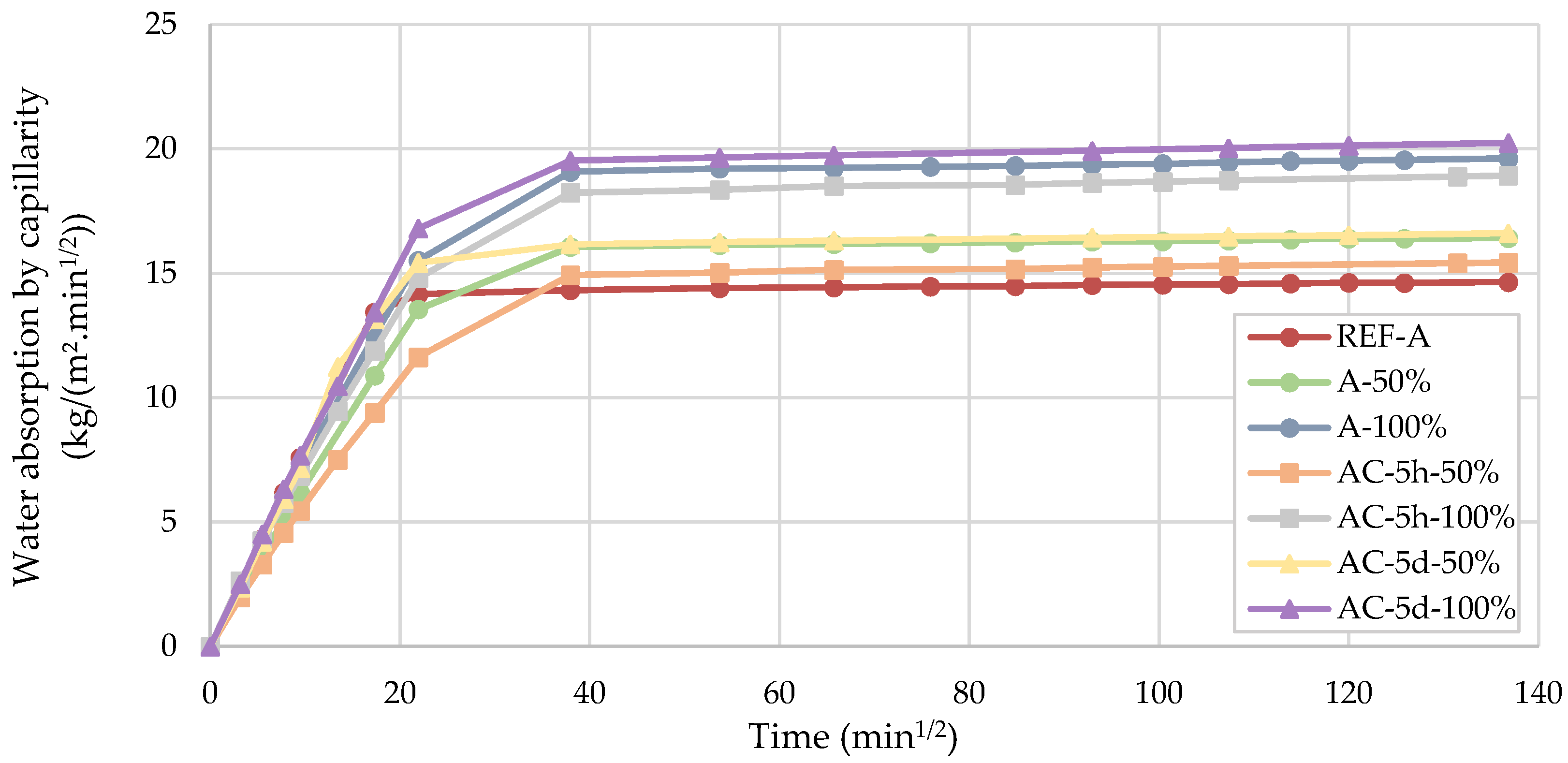

Water Absorption by Capillarity

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sanjuán, M.Á.; Andrade, C.; Mora, P.; Zaragoza, A. Carbon dioxide uptake by mortars and concretes made with Portuguese cements. Appl. Sci. 2020, 10, 646. [Google Scholar] [CrossRef] [Green Version]

- Directorate-General for Environment (European Commission). EU Construction & Demolition Waste Management Protocol; European Commission: Brussels, Belgium, 2016; pp. 1–22. [Google Scholar] [CrossRef] [Green Version]

- CEMBUREAU. The Role of Cement in the 2050 Low Carbon Economy; The European Cement Association: Brussels, Belgium, 2013. [Google Scholar]

- Morandeau, A.; Thiéry, M.; Dangla, P. Investigation of the carbonation mechanism of CH and C-S-H in terms of kinetic microstructure changes and moisture properties. Cem. Concr. Res. 2014, 56, 153–170. [Google Scholar] [CrossRef] [Green Version]

- Zhan, B.; Poon, C.S.; Liu, Q.; Kou, S.; Shi, C. Experimental study on CO2 curing for enhancement of recycled aggregate properties. Constr. Build. Mater. 2014, 67, 3–7. [Google Scholar] [CrossRef]

- Zhan, B.J.; Yang, K.H.; Seo, E.A.; Tae, S.H. Carbonation and CO2 uptake of concrete. Constr. Build. Mater. 2020, 67, 7880–7887. [Google Scholar] [CrossRef]

- Pade, C.; Guimaraes, M. The CO2 uptake of concrete in a 100 year perspective. Cem. Concr. Res. 2007, 37, 1348–1356. [Google Scholar] [CrossRef]

- Zhang, J.; Shi, C.; Li, Y.; Pan, X.; Poon, C.S.; Xie, Z. Influence of carbonated recycled concrete aggregate on properties of cement mortar. Constr. Build. Mater. 2015, 98, 1–7. [Google Scholar] [CrossRef]

- Li, L.; Xiao, J.; Xuan, D.; Poon, C.S. Effect of carbonation of modeled recycled coarse aggregate on the mechanical properties of modeled recycled aggregate concrete. Cem. Concr. Compos. 2018, 89, 169–180. [Google Scholar] [CrossRef]

- Gomes, R.I.; Bastos, D.; Farinha, C.; Veiga, R.; de Brito, J.; Faria, P.; Silva, A.S.; Bogas, A. Carbonation potential of recycled aggregates from construction and demolition waste. In Proceedings of the 2021 fib Symposium, Lisbon, Portugal, 14–16 June 2021; pp. 825–832, ISBN 978-2-940643-08-0. [Google Scholar]

- EN 933-11. Tests for Geometrical Properties of Aggregates. Part 11: Classification Test for the Constituents of Coarse Recycled Aggregate; European Committee for Standardization (CEN): Brussels, Belgium, 2009. [Google Scholar]

- EN 13242. Aggregates for Unbound and Hydraulically Bound Materials for Use in Civil Engineering Work and Road Construction; European Committee for Standardization (CEN): Brussels, Belgium, 2007. [Google Scholar]

- EN 1097-3. Tests for Geometrical Properties of Aggregates-Part 3: Determination of Loose Bulk Density and Voids; European Committee for Standardization (CEN): Brussels, Belgium, 1998. [Google Scholar]

- EN 1097-6. Tests for Mechanical and Physical Properties of Aggregates-Part 6: Determination of Particle Density and Water Absorption; European Committee for Standardization (CEN): Brussels, Belgium, 2003. [Google Scholar]

- EN 1015-3. Methods of Test for Mortar for Masonry-Part 3: Determination of Consistence of Fresh Mortar (by Flow Table); European Committee for Standardization (CEN): Brussels, Belgium, 1999. [Google Scholar]

- Cahier 2669-4. Certification CSTB des Enduits Monocouches d’imperméabilisation, Modalités d’essais; CSTB: Marne la Vallée, France, 1993. [Google Scholar]

- EN 1015-10. Methods of Test for Mortar for Masonry–Part 10: Determination of Dry Bulk Density of Hardened Mortar; European Committee for Standardization (CEN): Brussels, Belgium, 1999. [Google Scholar]

- EN 14146. Natural Stone Tests Methods: Determination of the Dynamic Modulus of Elasticity (by Measuring the Fundamental Resonance Frequency); European Committee for Standardization (CEN): Brussels, Belgium, 2004. [Google Scholar]

- EN 1015-11. Methods of Test for Mortar for Masonry-Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar; European Committee for Standardization (CEN): Brussels, Belgium, 1999. [Google Scholar]

- EN 1015-18. Methods of Test for Mortar for Masonry-Part 18: Determination of Water Absorption Coefficient due to Capillary Action of Hardened Mortar; European Committee for Standardization (CEN): Brussels, Belgium, 2002. [Google Scholar]

- De Brito, J.; Agrela, F.; Silva, R.V. Construction and demolition waste. In New Trends in Eco-efficient and Recycled Concrete; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1–22. [Google Scholar]

- Jiménez, J.R.; Ayuso, J.; López, M.; Fernández, J.M.; de Brito, J. Use of fine recycled aggregates from ceramic waste in masonry mortar manufacturing. Constr. Build. Mater. 2013, 40, 679–690. [Google Scholar] [CrossRef]

- Tabsh, S.W.; Abdelfatah, A.S. Influence of recycled concrete aggregates on strength properties of concrete. Constr. Build. Mater. 2009, 23, 1163–1167. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, Y.; Zhu, P.; Feng, J.; Hu, K. Mechanical Properties and ITZ Microstructure of Recycled Aggregate Concrete Using Carbonated Recycled Coarse Aggregate. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2018, 33, 648–653. [Google Scholar] [CrossRef]

- Gomes, R.I.; Farinha, C.B.; Veiga, R.; de Brito, J.; Faria, P.; Bastos, D. CO2 sequestration by construction and demolition waste aggregates and effect on mortars and concrete performance—An overview. Renew. Sustain. Energy Rev. 2021, 152, 111668. [Google Scholar] [CrossRef]

- Lu, B.; Shi, C.; Cao, Z.; Guo, M.; Zheng, J. Effect of carbonated coarse recycled concrete aggregate on the properties and microstructure of recycled concrete. J. Clean. Prod. 2019, 233, 421–428. [Google Scholar] [CrossRef]

- Luo, S.; Ye, S.; Xiao, J.; Zheng, J.; Zhu, Y. Carbonated recycled coarse aggregate and uniaxial compressive stress-strain relation of recycled aggregate concrete. Constr. Build. Mater. 2018, 188, 956–965. [Google Scholar] [CrossRef]

- Kou, S.C.; Zhan, B.J.; Poon, C.S. Use of a CO2 curing step to improve the properties of concrete prepared with recycled aggregates. Cem. Concr. Compos. 2014, 45, 22–28. [Google Scholar] [CrossRef]

- Gholizadeh-Vayghan, A.; Bellinkx, A.; Snellings, R.; Vandoren, B.; Quaghebeur, M. The effects of carbonation conditions on the physical and microstructural properties of recycled concrete coarse aggregates. Constr. Build. Mater. 2020, 257, 119486. [Google Scholar] [CrossRef]

- Shi, C.; Wu, Z.; Cao, Z.; Ling, T.C.; Zheng, J. Performance of mortar prepared with recycled concrete aggregate enhanced by CO2 and pozzolan slurry. Cem. Concr. Compos. 2018, 86, 130–138. [Google Scholar] [CrossRef]

- Abate, S.Y.; Song, K.I.; Song, J.K.; Lee, B.Y.; Kim, H.K. Internal curing effect of raw and carbonated recycled aggregate on the properties of high-strength slag-cement mortar. Constr. Build. Mater. 2018, 165, 64–71. [Google Scholar] [CrossRef]

- Muñoz, A.; Torres, N.; Guzmán, A. Evaluación de un mortero preparado con agregados reciclados de un concreto mejorado por carbonatación: Una mirada a la construcción sustentable Assessment of a mortar with recycled aggregate from a concrete improved by carbonation: A look to a sustainable. Rev. Ing. Constr. 2019, 34, 25–32. Available online: www.ricuc.cl (accessed on 22 June 2021). [CrossRef] [Green Version]

- Farinha, C.B.; de Brito, J.; Veiga, R. Incorporation of fine sanitary ware aggregates in coating mortars. Constr. Build. Mater. 2015, 83, 194–206. [Google Scholar] [CrossRef]

- Westerholm, M.; Lagerblad, B.; Silfwerbrand, J.; Forssberg, E. Influence of fine aggregate characteristics on the rheological properties of mortars. Cem. Concr. Compos. 2008, 30, 274–282. [Google Scholar] [CrossRef]

- Santos, A.R.; Veiga, M.D.R.; Silva, A.S.; de Brito, J.; Álvarez, J.I. Evolution of the microstructure of lime based mortars and influence on the mechanical behaviour: The role of the aggregates. Constr. Build. Mater. 2018, 187, 907–922. [Google Scholar] [CrossRef]

| Mortar | NA | RA | CRA-5h | CRA-5d | Cement |

|---|---|---|---|---|---|

| REF-A | 0.8 | - | - | - | 0.2 |

| A-50% | 0.4 | 0.4 | - | - | 0.2 |

| AC-5h-50% | 0.4 | - | 0.4 | - | 0.2 |

| AC-5d-50% | 0.4 | - | - | 0.4 | 0.2 |

| A-100% | - | 0.8 | - | - | 0.2 |

| AC-5h-100% | - | - | 0.8 | - | 0.2 |

| AC-5d-100% | - | - | - | 0.8 | 0.2 |

| Test | Ages Analysed (Days) | Standard |

|---|---|---|

| Consistency by flow table Bulk density Bulk density | Fresh state | EN 1015-3 [15] |

| Fresh state | Cahier 2669-4 [16] | |

| 14, 28 | EN 1015-10 [17] | |

| Modulus of elasticity by frequency of resonance Flexural strength | 14, 28 | EN 14146 [18] |

| 14, 28 | EN 1015-11 [19] | |

| Compressive strength Water absorption by capillarity | 14, 28 | EN 1015-11 [19] |

| 28 | EN 1015-18 [20] |

| Test | Sand | CDW-A | CDW-A-5h | CDW-A-5d |

|---|---|---|---|---|

| Loose bulk density (kg/m3) | 1560 ± 0.8 | 1260 ± 2.4 | 1278 ± 1.7 | 1268 ± 0.9 |

| Particle density (kg/m3) | 2631 | 2212 | 2437 | 2551 |

| Water absorption (%) | 0.19 | 7.48 | 3.47 | 7.68 |

| Mortar | Flow Table (mm) | w/b Ratio | Bulk Density (kg/m3) |

|---|---|---|---|

| REF-A | 162 | 1.03 | 2060 ± 14 |

| A-50% | 162 | 1.06 | 1972 ± 7 |

| AC-5h-50% | 162 | 1.03 | 1983 ± 15 |

| AC-5d-50% | 163 | 1.06 | 1964 ± 12 |

| A-100% | 161 | 1.21 | 1917 ± 15 |

| AC-5h-100% | 162 | 1.20 | 1900 ± 14 |

| AC-5d-100% | 161 | 1.21 | 1919 ± 10 |

| Mortar | Bulk Density (kg/m3) | |

|---|---|---|

| 14 Days | 28 Days | |

| REF-A | 1933 ± 70 | 1942 ± 4 |

| A-50% | 1902 ± 15 | 1886 ± 4 |

| AC-5h-50% | 1845 ± 3 | 1838 ± 10 |

| AC-5d-50% | 1900 ± 14 | 1865 ± 11 |

| A-100% | 1851 ± 50 | 1771 ± 10 |

| AC-5h-100% | 1807 ± 7 | 1768 ± 15 |

| AC-5d-100% | 1796 ± 16 | 1802 ± 14 |

| Mortar | Capillary Coefficient (kg/(m2·min1/2)) |

|---|---|

| REF-A | 0.81 ± 0.03 |

| A-50% | 064 ± 0.04 |

| AC-5h-50% | 0.55 ± 0.01 |

| AC-5d-50% | 0.76 ± 0.04 |

| A-100% | 0.72 ± 0.04 |

| AC-5h-100% | 0.67 ± 0.01 |

| AC-5d-100% | 0.82 ± 0.03 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Infante Gomes, R.; Bastos, D.; Brazão Farinha, C.; Pederneiras, C.M.; Veiga, R.; de Brito, J.; Faria, P.; Santos Silva, A. Mortars with CDW Recycled Aggregates Submitted to High Levels of CO2. Infrastructures 2021, 6, 159. https://doi.org/10.3390/infrastructures6110159

Infante Gomes R, Bastos D, Brazão Farinha C, Pederneiras CM, Veiga R, de Brito J, Faria P, Santos Silva A. Mortars with CDW Recycled Aggregates Submitted to High Levels of CO2. Infrastructures. 2021; 6(11):159. https://doi.org/10.3390/infrastructures6110159

Chicago/Turabian StyleInfante Gomes, Ricardo, David Bastos, Catarina Brazão Farinha, Cinthia Maia Pederneiras, Rosário Veiga, Jorge de Brito, Paulina Faria, and António Santos Silva. 2021. "Mortars with CDW Recycled Aggregates Submitted to High Levels of CO2" Infrastructures 6, no. 11: 159. https://doi.org/10.3390/infrastructures6110159

APA StyleInfante Gomes, R., Bastos, D., Brazão Farinha, C., Pederneiras, C. M., Veiga, R., de Brito, J., Faria, P., & Santos Silva, A. (2021). Mortars with CDW Recycled Aggregates Submitted to High Levels of CO2. Infrastructures, 6(11), 159. https://doi.org/10.3390/infrastructures6110159