Effect of Waste Mask Fabric Scraps on Strength and Moisture Susceptibility of Asphalt Mixture with Nano-Carbon-Modified Filler

Abstract

1. Introduction

- -

- To assess the impact of WMFS fiber length (8, 12, 18 mm) and content (0.3%, 0.5% by aggregate weight) combined with NCMF (5–7%) on Marshall stability, moisture susceptibility (TSR), and indirect tensile strength (ITS).

- -

- To investigate the fatigue resistance of WMFS/NCMF-modified asphalt under controlled-stress loading (300–500 kPa) at intermediate temperatures (25–40 °C).

- -

- To develop predictive models for key performance indicators (stability, TSR, fatigue life) using Design-Expert software, establishing optimal fiber–filler parameters.

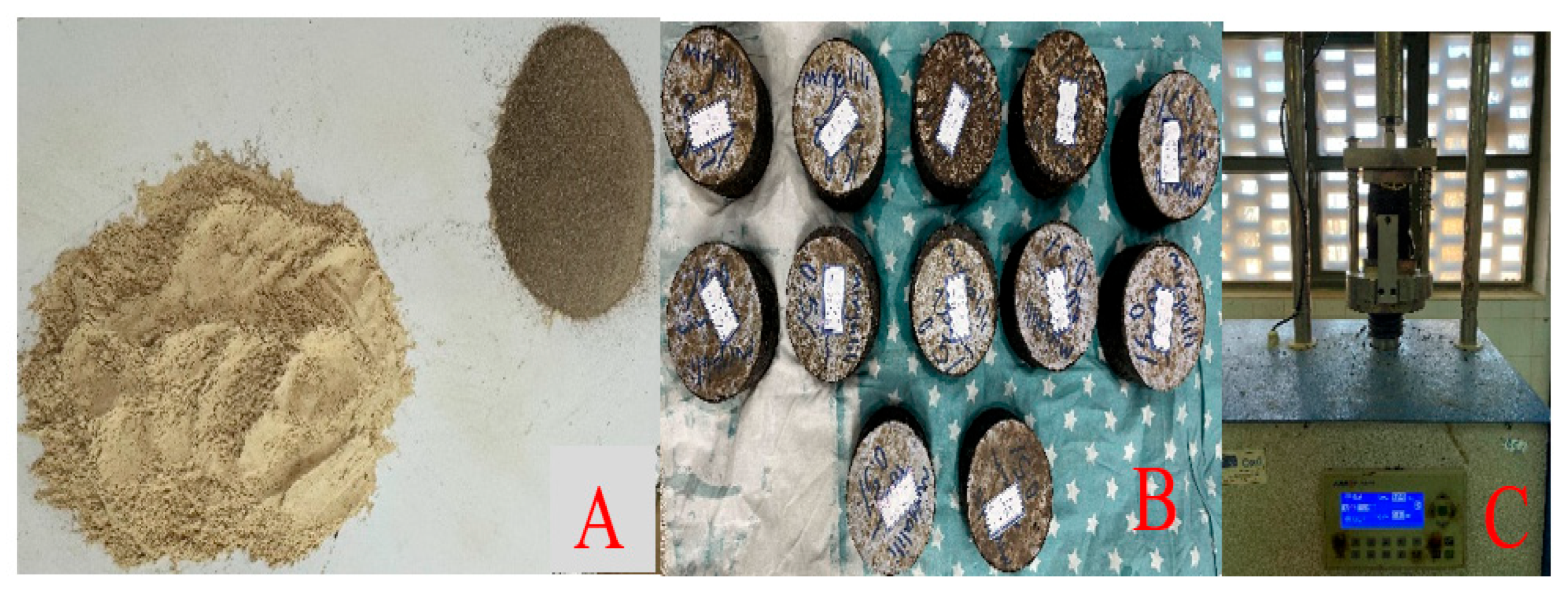

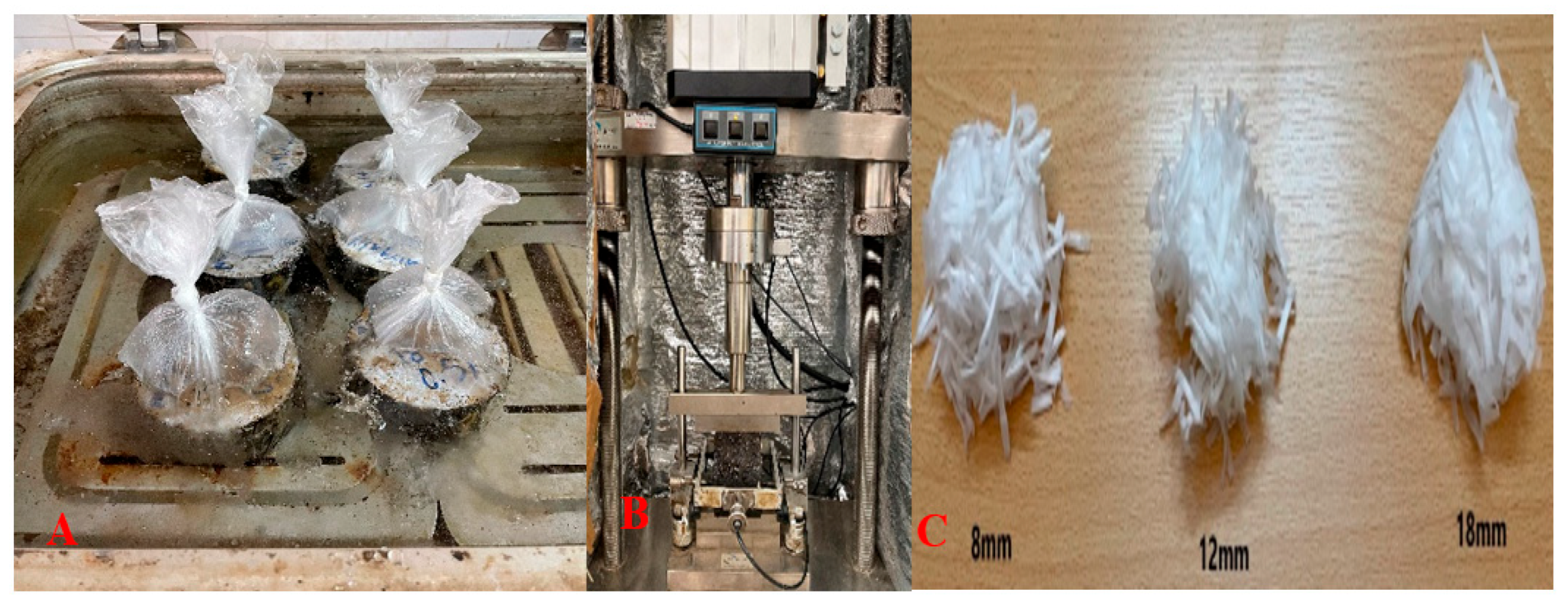

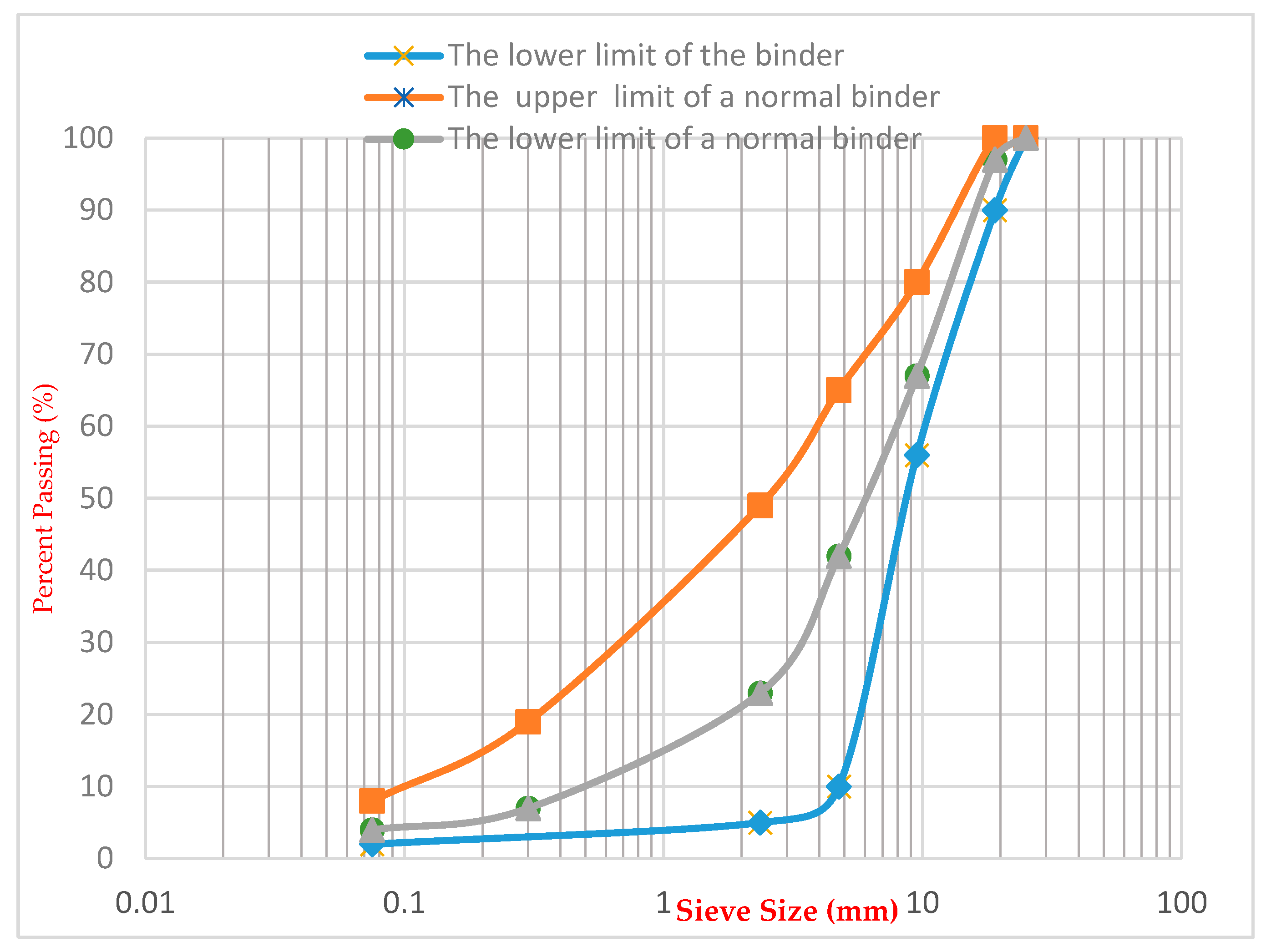

2. Research Methodology

3. Results Analysis

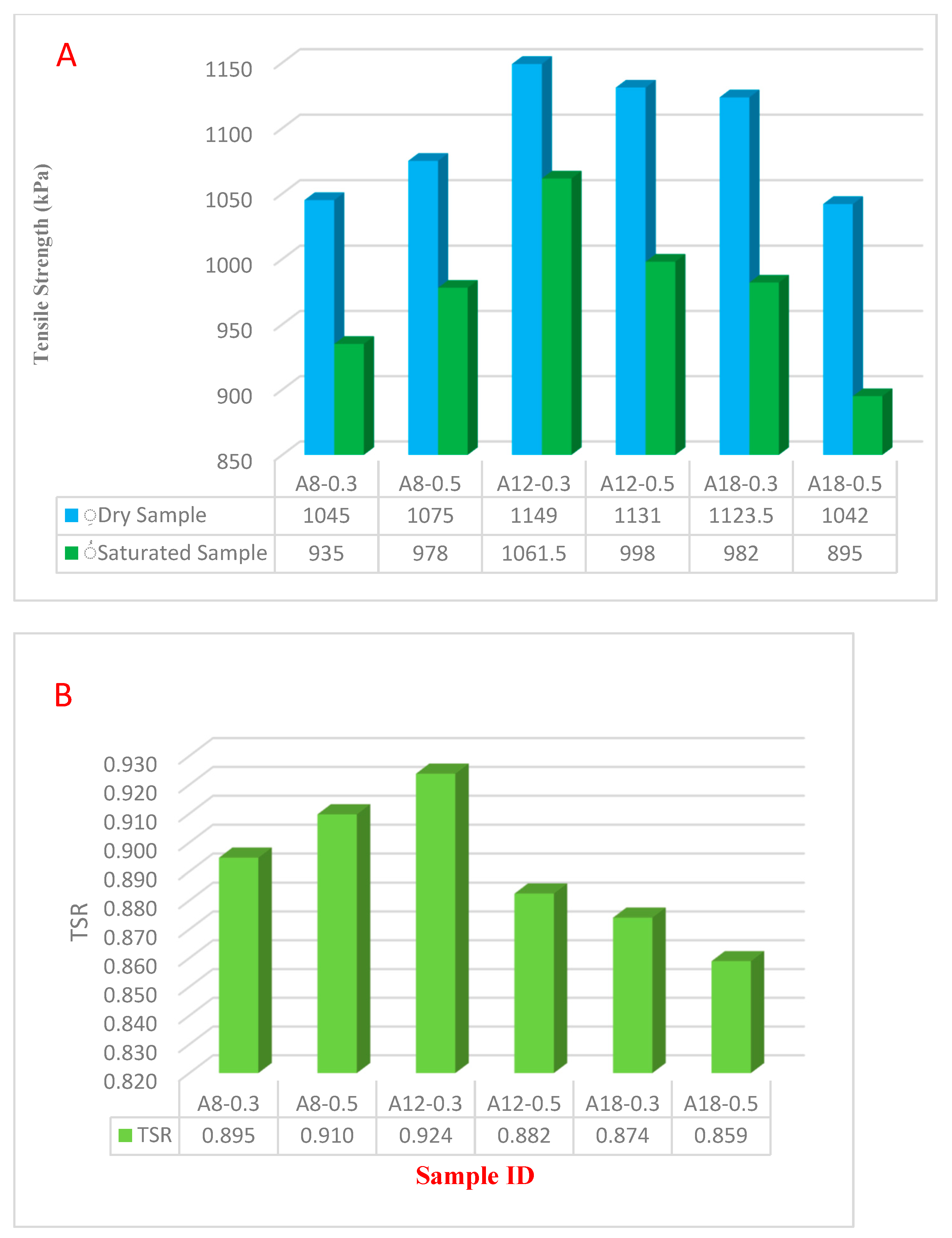

3.1. Indirect Tensile Strength Testing

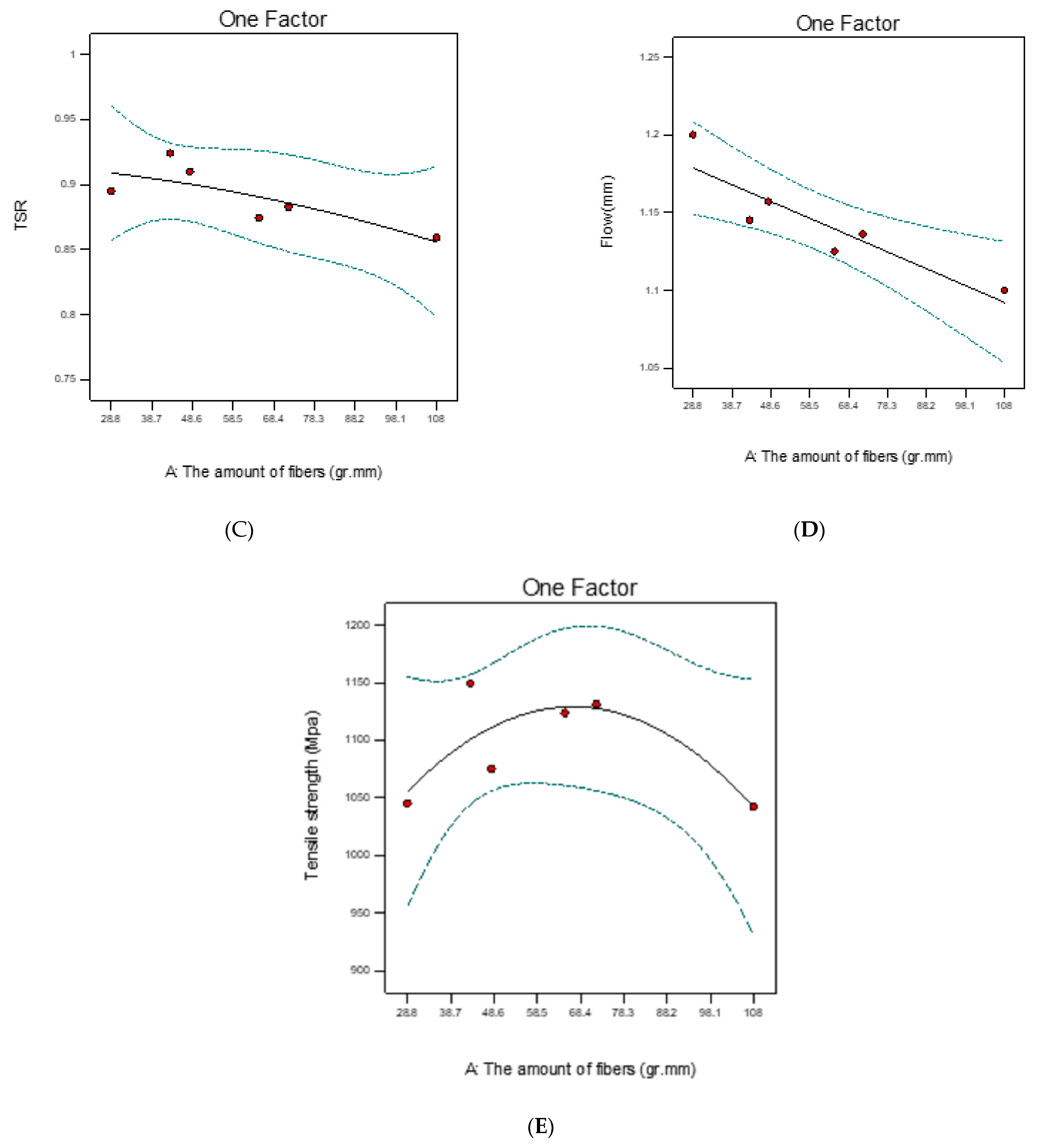

3.2. Moisture Susceptibility Testing

3.3. Fatigue and Marshall Stability Testing; Analysis

3.4. Effects of WMFSs on Asphalt Properties

4. Discussion and Data Interpretation

5. Conclusions

- All properties peaked at 12 mm/0.3% WMFS, then declined due to fiber clustering.

- The WMFS-NCMF blend enhanced tensile strength by 33% versus control samples.

- Moisture resistance improved by 17%, and fatigue deformation was reduced by 70%.

- Marshall stability increased by 39% through optimized fiber–matrix synergy.

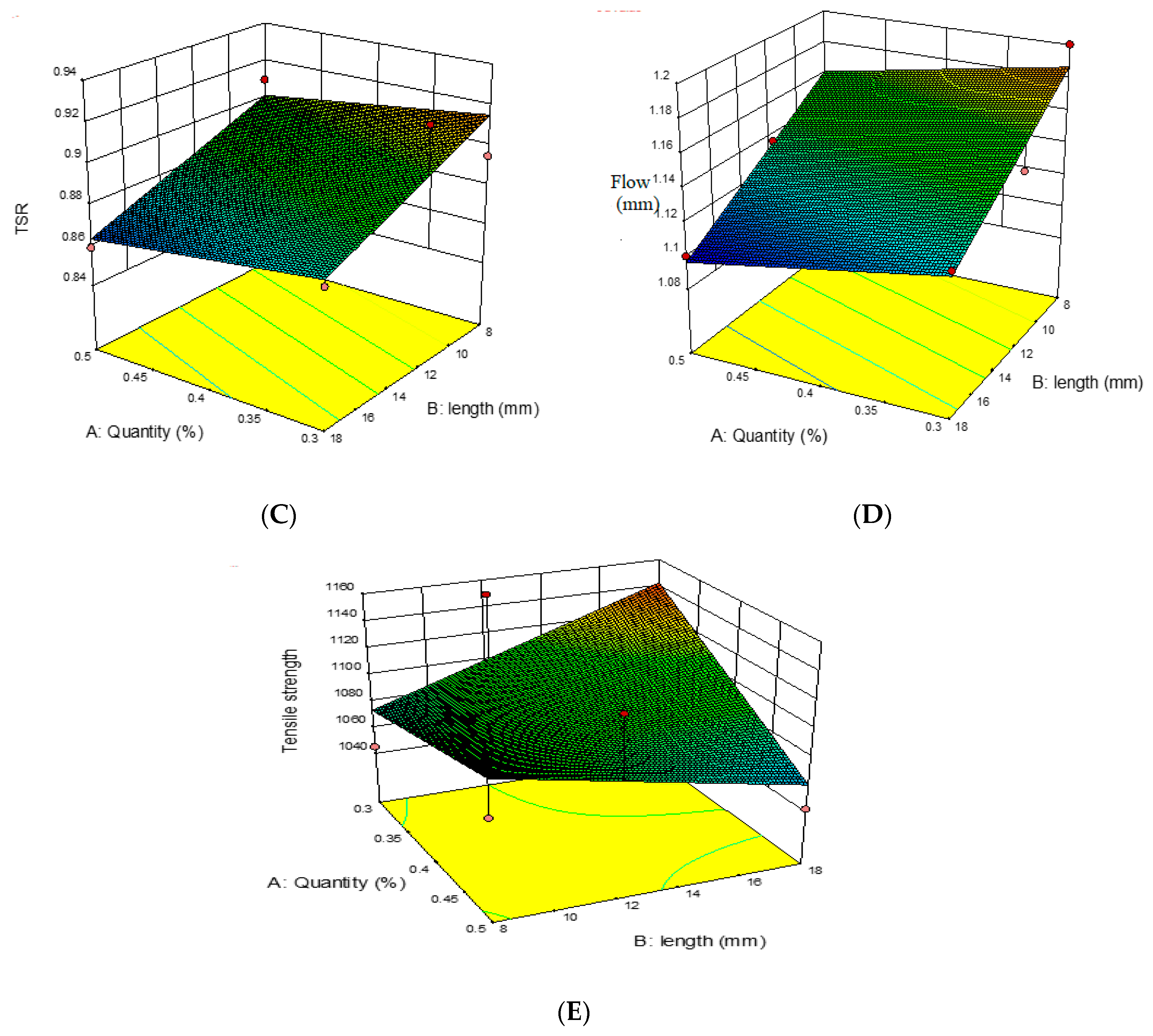

- The addition of WMFSs initially enhanced the indirect tensile strength by 9.9%, followed by a 3.9% decrease at higher fiber contents. The 12 mm and 0.3% WMFS sample exhibited the highest tensile strength.

- Similarly, moisture susceptibility initially improved by 2.3% with the addition of WMFSs, subsequently decreasing by 7% at higher concentrations. Again, the 12 mm and 0.3% WMFS sample demonstrated the best resistance to water damage.

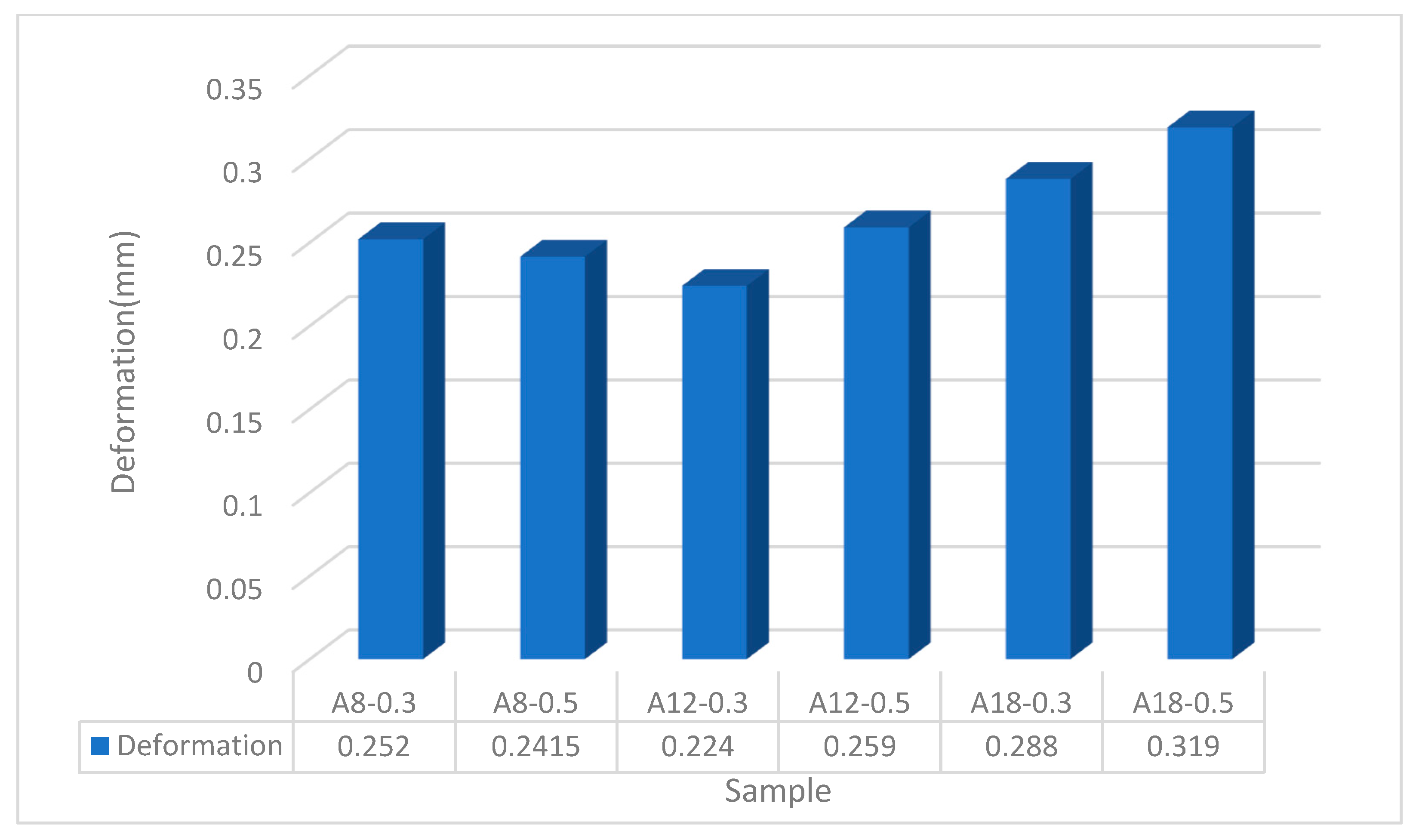

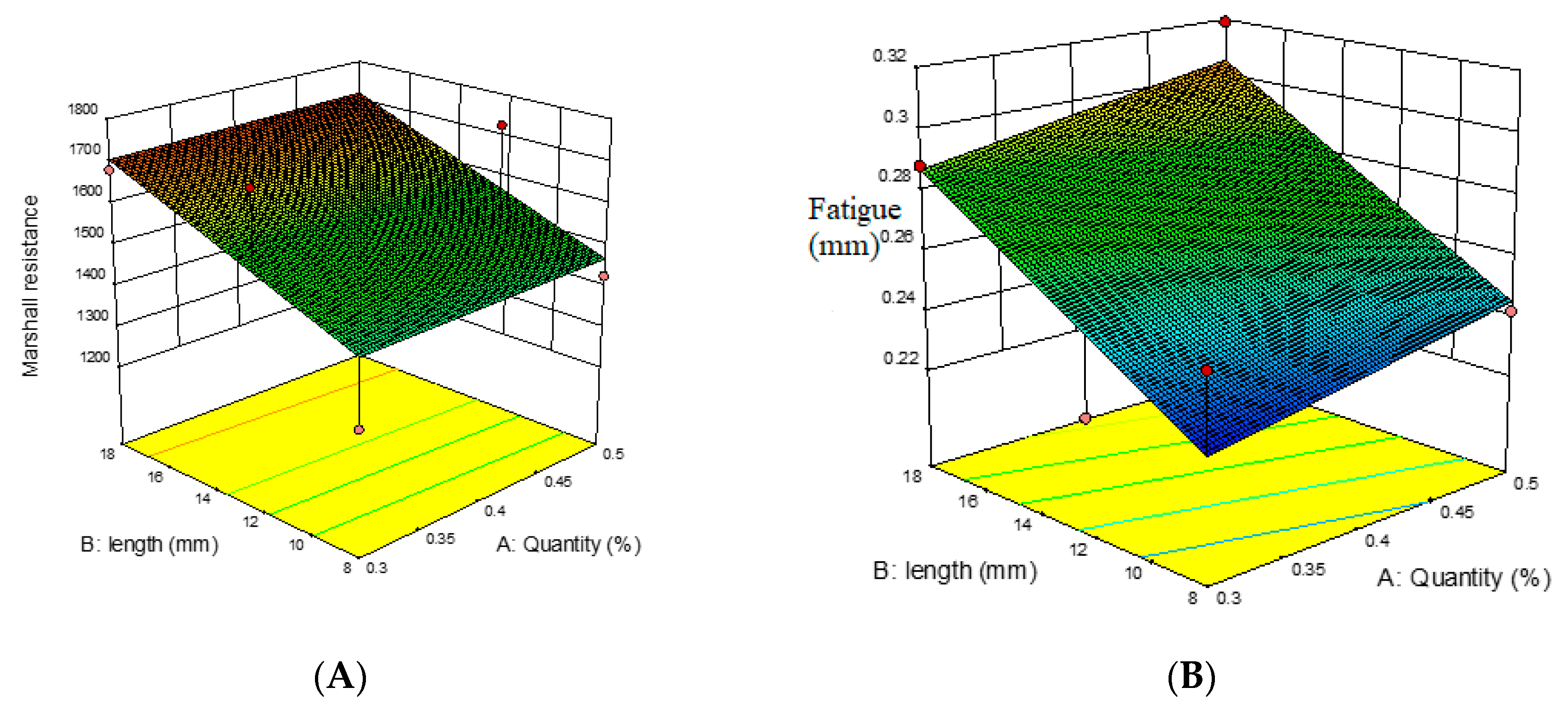

- Fatigue performance peaked at 0.3% WMFS/12 mm length (lowest deformation: 0.224 mm), with higher contents increasing deformation.

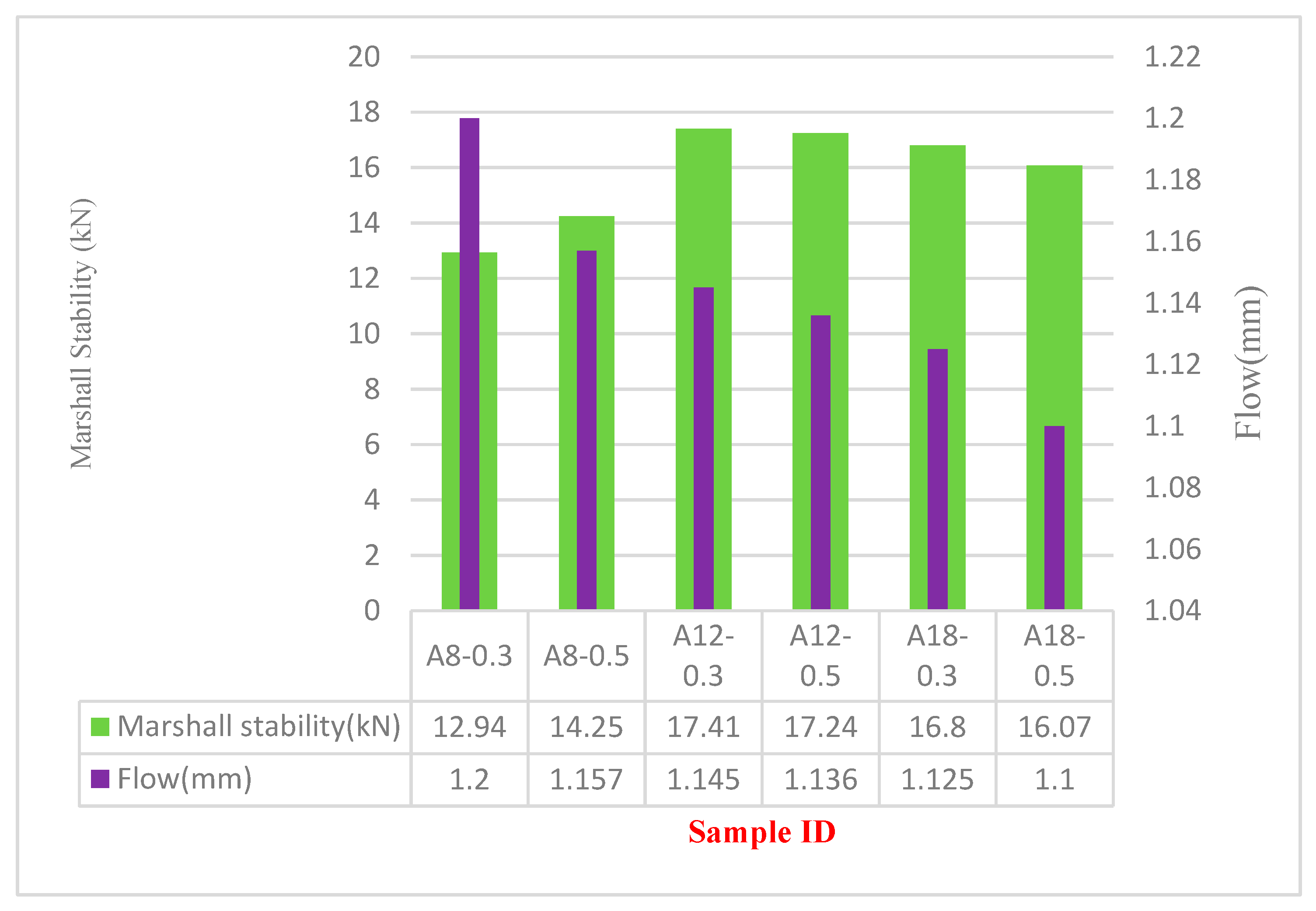

- Marshall stability tests revealed an initial increase in compressive strength up to 1741 kN with increasing fiber content, followed by an 8% decrease to 1607 kN. The highest and lowest Marshall stability values were observed for the 12 mm and 8 mm samples at 0.3% WMFS, respectively. Maximum and minimum flow values corresponded to the 8 mm samples at 0.3% and 0.5% WMFS, respectively.

- Based on a thorough analysis of the test results, the 12 mm sample at 0.3% WMFS, which combines NCMF and WMFSs, emerged as the optimal blend. It demonstrated the highest tensile strength and Marshall stability, along with the lowest fatigue deformation and moisture susceptibility. The tensile strength of this sample increased by approximately 33% compared to control samples and 13% compared to those with only NCMF. Additionally, moisture susceptibility improved by approximately 17%, and fatigue deformation was reduced by 70% (to 30% of the control value) relative to control samples.

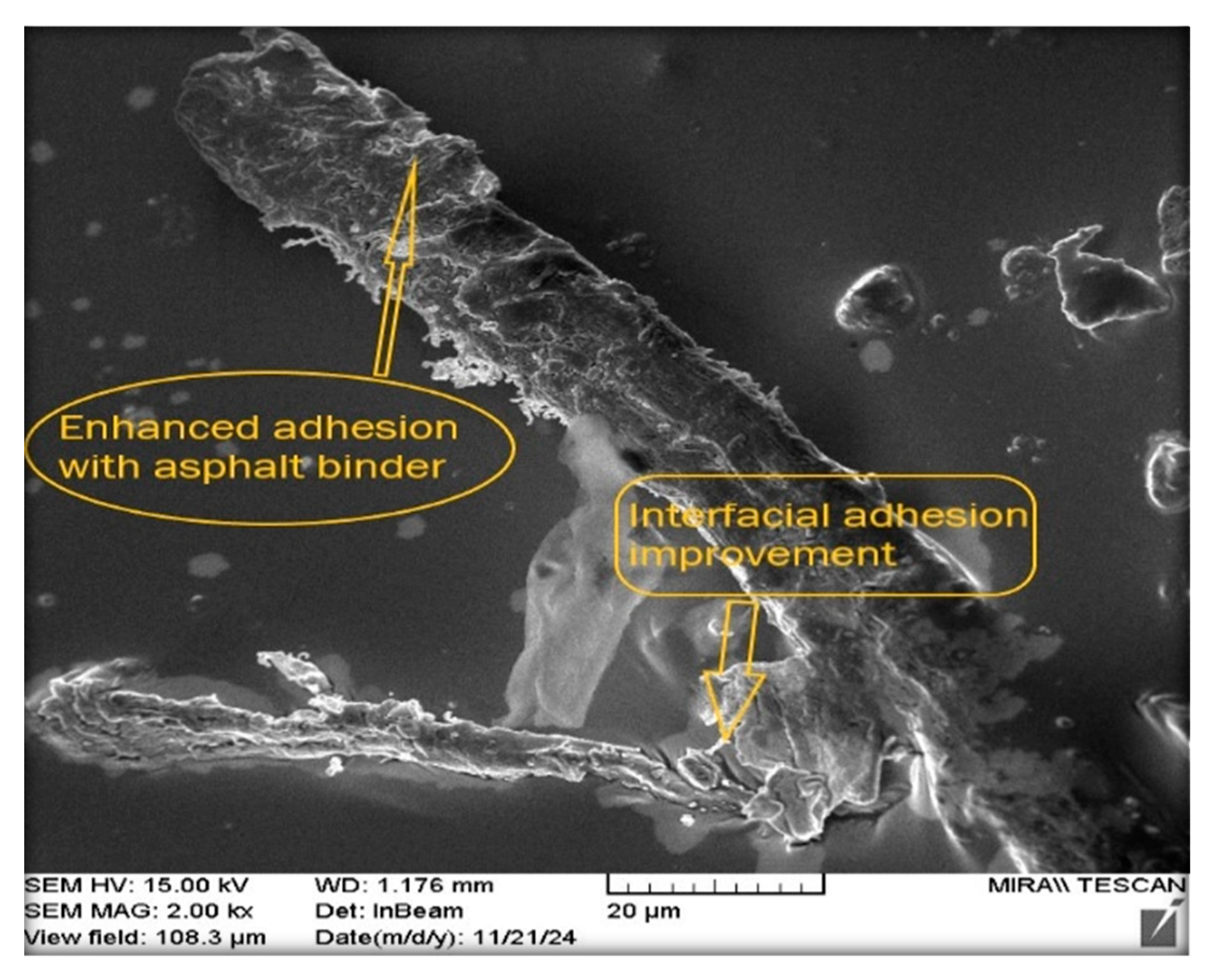

- WMFSs enabled macroscale reinforcement via stress distribution and crack bridging.

- NCMF enhanced bitumen–aggregate adhesion through hydrophobic nano-coatings.

- The 12 mm/0.3% threshold defines industrial optimization for sustainable asphalt.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Haider, S.; Hafeez, I.; Ullah, R. Sustainable use of waste plastic modifiers to strengthen the adhesion properties of asphalt mixtures. Constr. Build. Mater. 2020, 235, 117496. [Google Scholar] [CrossRef]

- Albayati, A.H.; Al-Kheetan, M.J.; Mohammed, A.M.; Al-ani, A.F.; Moudhafar, M.M. Performance Assessment of Eco-Friendly Asphalt Binders Using Natural Asphalt and Waste Engine Oil. Infrastructures 2024, 9, 224. [Google Scholar] [CrossRef]

- Prata, J.C.; Silva, A.L.; Walker, T.R.; Duarte, A.C.; Rocha-Santos, T. COVID-19 pandemic repercussions on the use and management of plastics. Environ. Sci. Technol. 2020, 54, 7760–7765. [Google Scholar] [CrossRef]

- Rahman, A.; Sarkar, A.; Yadav, O.P.; Achari, G.; Slobodnik, J. Potential human health risks due to environmental exposure to nano-and microplastics and knowledge gaps: A scoping review. Sci. Total Environ. 2021, 757, 143872. [Google Scholar] [CrossRef]

- Peng, Y.; Wu, P.; Schartup, A.T.; Zhang, Y. Plastic waste release caused by COVID-19 and its fate in the global ocean. Proc. Natl. Acad. Sci. USA 2021, 118, e2111530118. [Google Scholar] [CrossRef]

- Sun, X.; Liu, J.; Qiu, J.; Wu, P.; Zhao, Y. Alkali activation of blast furnace slag using a carbonate-calcium carbide residue alkaline mixture to prepare cemented paste backfill. Constr. Build. Mater. 2022, 320, 126234. [Google Scholar] [CrossRef]

- Hoghoghi, M.E.; Khabiri, M.M.; Mansourian, A. Impact of Nanocarbon-Coated Calcium Carbonate on Asphalt Rutting: Experimental and Numerical Analyses. Processes 2024, 12, 2244. [Google Scholar] [CrossRef]

- Yarahmadi, A.M.; Shafabakhsh, G.; Asakereh, A. Laboratory investigation of the effect of nano Caco3 on rutting and fatigue of stone mastic asphalt mixtures. Constr. Build. Mater. 2022, 317, 126127. [Google Scholar] [CrossRef]

- Sadat Hosseini, A.; Hajikarimi, P.; Fini, E.H. Simulation of sustainable structural composites produced from waste plastics and bitumen. Clean Technol. Environ. Policy 2024, 27, 1021–1035. [Google Scholar] [CrossRef]

- Zhao, Z.; Wu, S.; Liu, Q.; Xie, J.; Yang, C.; Wang, F.; Wan, P. Recycling waste disposable medical masks in improving the performance of asphalt and asphalt mixtures. Constr. Build. Mater. 2022, 337, 127621. [Google Scholar] [CrossRef]

- Ayyadurai, A.; Saravanan, M.M.; Devi, M. Effect on stability of asphalt using COVID-19 single use face mask and saline tube waste. Int. J. Adv. Technol. Eng. Explor. 2023, 10, 792. [Google Scholar] [CrossRef]

- Ghanizadeh, A.R.; Salehi, M.; Mamou, A.; Koutras, E.I.; Jalali, F.; Asteris, P.G. Investigation of subgrade stabilization life-extending benefits in flexible pavements using a non-linear mechanistic-empirical analysis. Infrastructures 2024, 9, 33. [Google Scholar] [CrossRef]

- Musa, N.F.; Aman, M.Y.; Shahadan, Z.; Taher, M.N.; Noranai, Z. Utilization of synthetic reinforced fiber in asphalt concrete—A review. Int. J. Civ. Eng. Technol 2019, 10, 678–694. [Google Scholar]

- Kaloush, K.E.; Biligiri, K.P.; Zeiada, W.A.; Rodezno, M.C.; Reed, J.X. Evaluation of fiber-reinforced asphalt mixtures using advanced material characterization tests. J. Test. Eval. 2010, 38, 400–411. [Google Scholar] [CrossRef]

- Noorvand, H.; Salim, R.; Medina, J.; Stempihar, J.; Underwood, B.S. Effect of synthetic fiber state on mechanical performance of fiber reinforced asphalt concrete. Transp. Res. Rec. 2018, 2672, 42–51. [Google Scholar] [CrossRef]

- Sabouri, M.; Sadeghi, M. Investigation on properties of cold recycled asphalt mixtures reinforced with polypropylene fibers. Amirkabir J. Civ. Eng. 2023, 55, 583–602. [Google Scholar] [CrossRef]

- Do, T.C.; Tran, V.P.; Lee, H.J.; Kim, W.J. Mechanical characteristics of tensile strength ratio method compared to other parameters used for moisture susceptibility evaluation of asphalt mixtures. J. Traffic Transp. Eng. (Engl. Ed.) 2019, 6, 621–630. [Google Scholar] [CrossRef]

- Miera-Dominguez, H.; Lastra-González, P.; Indacoechea-Vega, I.; Castro-Fresno, D. Evaluation of the mechanical performance of AC mixtures with recycled fibres. Dev. Built Environ. 2024, 18, 100435. [Google Scholar] [CrossRef]

- Ziari, H.; Divandari, H.; Hajiloo, M.; Amini, A. Investigating the effect of amorphous carbon powder on the moisture sensitivity, fatigue performance and rutting resistance of rubberized asphalt concrete mixtures. Constr. Build. Mater. 2019, 217, 62–72. [Google Scholar] [CrossRef]

- Albayati, A.H.; Latief, R.H.; Al-Mosawe, H.; Wang, Y. Nano-additives in asphalt binder: Bridging the gap between traditional materials and modern requirements. Appl. Sci. 2024, 14, 3998. [Google Scholar] [CrossRef]

- McDaniel, R. NCHRP Synthesis 475: Fiber Additives in Asphalt Mixtures; National Academies of Sciences, Engineering, and Medicine; The National Academies Press: Washington, DC, USA, 2015; Available online: https://nap.nationalacademies.org/catalog/22191 (accessed on 25 August 2025).

- Giungato, P.; Rana, R.L.; Tricase, C. Strategies to Reduce the Carbon Footprint of Protective Face Masks. In Carbon Footprint Assessments: Case Studies & Best Practices 2024 Nov 23; Springer Nature: Cham, Switzerland, 2024; pp. 131–156. [Google Scholar] [CrossRef]

- Chang, C.M.; Hossain, A. A Climate Adaptation Asset Risk Management Approach for Resilient Roadway Infrastructure. Infrastructures 2024, 9, 226. [Google Scholar] [CrossRef]

- Jia, H.; Sheng, Y.; Guo, P.; Underwood, S.; Chen, H.; Kim, Y.R.; Li, Y.; Ma, Q. Effect of synthetic fibers on the mechanical performance of asphalt mixture: A review. J. Traffic Transp. Eng. (Engl. Ed.) 2023, 10, 331–348. [Google Scholar] [CrossRef]

- Correia, N.D. Performance of Flexible Pavements Enhanced Using Geogrid-Reinforced Asphalt Overlays. Ph.D. Thesis, São Carlos School of Engineering, São Paulo, Brazil, 2014. Available online: http://www.teses.usp.br/teses/disponiveis/18/18132/tde-05032015-100057/ (accessed on 25 August 2025).[Green Version]

- Zou, Y.; Gao, Y.; Chen, A.; Wu, S.; Li, Y.; Xu, H.; Wang, H.; Yang, Y.; Amirkhanian, S. Adhesion failure mechanism of asphalt-aggregate interface under an extreme saline environment: A molecular dynamics study. Appl. Surf. Sci. 2024, 645, 158851. [Google Scholar] [CrossRef]

- Antunes, V.; Freire, A.C.; Quaresma, L.; Micaelo, R. Effect of the chemical composition of fillers in the filler–bitumen interaction. Constr. Build. Mater. 2016, 104, 85–91. [Google Scholar] [CrossRef]

- Dongre, R.; Myers, L.; D’Angelo, J.; Paugh, C.; Gudimettla, J. Field evaluation of Witczak and Hirsch models for predicting dynamic modulus of hot-mix asphalt (with discussion). J. Assoc. Asph. Paving Technol. 2005, 74, 381–442. [Google Scholar]

- Ceylan, H.; Gopalakrishnan, K.; Kim, S. Advanced approaches to hot-mix asphalt dynamic modulus prediction. Can. J. Civ. Eng. 2008, 35, 699–707. [Google Scholar] [CrossRef]

- Bhat, F.S.; Mir, M.S. A study investigating the influence of nano Al2O3 on the performance of SBS modified asphalt binder. Constr. Build. Mater. 2021, 271, 121499. [Google Scholar] [CrossRef]

- Suleiman, G.; Taqa, A.A.; Ergun, M.; Qtiashat, D.; Aburumman, M.O.; Mohsen, M.O.; Senouci, A.; Kesten, A.S. Green Technology: Performance of Sustainable Asphalt Mixes Modified with Linear Low-Density Polyethylene Waste. Buildings 2024, 14, 3089. [Google Scholar] [CrossRef]

- Razavi, S.H.; Kavussi, A. The role of nanomaterials in reducing moisture damage of asphalt mixes. Constr. Build. Mater. 2020, 239, 117827. [Google Scholar] [CrossRef]

- Li, K.; Liu, Q.; Tian, Y.; Du, C.; Xu, Z. The Consequences of Dimension Reduction for Open Graded Friction Course (OGFC) Asphalt Mixtures: Morphological Characteristics and Finite Element Model (FEM) Simulation. Buildings 2024, 14, 545. [Google Scholar] [CrossRef]

- Yang, S.; Bieliatynskyi, A.; Pershakov, V.; Shao, M.; Ta, M. Asphalt concrete based on a polymer–bitumen binder nanomodified with carbon nanotubes for road and airfield construction. J. Polym. Eng. 2022, 42, 458–466. [Google Scholar] [CrossRef]

- Canestrari, F.; Ingrassia, L.P. A review of top-down cracking in asphalt pavements: Causes, models, experimental tools and future challenges. J. Traffic Transp. Eng. (Engl. Ed.) 2020, 7, 541–572. [Google Scholar] [CrossRef]

- Al-Hadidy, A.I.; Yi-qiu, T. Effect of polyethylene on life of flexible pavements. Constr. Build. Mater. 2009, 23, 1456–1464. [Google Scholar] [CrossRef]

- Akram, H.; Hozayen, H.A.; Abdelfatah, A.; Khodary, F. Fiber Showdown: A Comparative Analysis of Glass vs. Polypropylene Fibers in Hot-Mix Asphalt Fracture Resistance. Buildings 2024, 14, 2732. [Google Scholar] [CrossRef]

- Wang, W.; Shen, A.; Jin, X.; Yang, J. Optimization and performance evaluation of steel slag asphalt mixture modified with fibers under freeze–thaw cycles. J. Mater. Civ. Eng. 2023, 35, 04022419. [Google Scholar] [CrossRef]

- ASTM International. Annual Book of ASTM Standards, Volume 04.03: Road and Paving Materials; Vehicle-Pavement systems; ASTM International: West Conshohocken, PA, USA, 2025; Available online: https://www.astm.org/ (accessed on 25 August 2025).

- Shanbara, H.K.; Ruddock, F.; Atherton, W. A laboratory study of high-performance cold mix asphalt mixtures reinforced with natural and synthetic fibres. Constr. Build. Mater. 2018, 172, 166–175. [Google Scholar] [CrossRef]

- Goli, A.; Sadeghi, P. Evaluation on the use of COVID-19 single-use face masks to improve the properties of hot mix asphalt. Road Mater. Pavement Des. 2023, 24, 1371–1388. [Google Scholar] [CrossRef]

- Zhang, D.; Guo, Y.; Liu, Z.; Xu, P.; Ma, Z.; Zhan, J. Laboratory investigation on added-value application of the COVID-19 disposable mask in hot mix asphalt (HMA). Sci. Total Environ. 2023, 860, 160243. [Google Scholar] [CrossRef] [PubMed]

- Haghoghi, M.E. Resistance to Rutting of Warm Asphalt Mixture Using Carbon Nanocoating on Micronized Calcium Carbonate Powder as Modified Filler. Master’s Thesis, Yazd University, Yazd, Iran, 2024. (In Persian). [Google Scholar]

| Aspect | Conventional Asphalt Filler | Waste Mask Fabric Scraps (WMFSs) | Nano-Carbon-Modified Filler (NCMF) | Target Synergistic Effect |

|---|---|---|---|---|

| Primary Composition | Limestone/Portland cement | Polypropylene (PP) polymers | CaCO3 + carbon nanostructures | Hybrid reinforcement |

| Dominant Mechanism | Void filling | 3D fiber reinforcement | Bitumen activation | Interfacial bond strength |

| Critical Parameter | Particle size (µm) | fiber length (mm) | Nano-carbon concentration (%) | Fiber–filler interaction |

| Waste Integration | Not applicable | 129 billion masks/year recycled | Industrial byproduct utilization | Circular economy pavement |

| Performance Gap | Limited crack resistance | Unquantified durability impact | Unknown moisture inter | Fatigue–moisture balance |

| Test Type (ASTM Standard [39]) | Result | Unit |

|---|---|---|

| Flash Point (ASTM D92) | 292 | Degrees (°C) |

| Viscosity (ASTM D4402) | 0.33 | Pascal-seconds (Pa·s) |

| Dynamic Shear (ASTM D7175) | 1.174 | kPa |

| Specific Gravity (ASTM D70) | 1.03 | - |

| Penetration Grade (ASTM D5) | 64 | 0.1 mm |

| Softening Point (ASTM D36) | 51 | Degrees (°C) |

| Property | Value/Description | Unit |

|---|---|---|

| Material Type | 100% spunbond | - |

| Color | White | - |

| Specific Gravity | 0.91 | - |

| Thickness | 79 | Microns (µm) |

| Melting Point | 168 | Degrees (°C) |

| Tensile Strength | 3.86 | - |

| Tear and Abrasion Resistance | High | Qualitative description |

| Acid and Alkali Resistance | High | Qualitative description |

| Material Properties | Standard Code [39] | Unit | Purpose |

|---|---|---|---|

| Binder Flash Point | ASTM D92 | °C | Safety during heating |

| Binder Viscosity | ASTM D4402 | Pa·s | Flow resistance measurement |

| Binder Penetration | ASTM D5 | 0.1 mm | Consistency evaluation |

| Binder Softening Point | ASTM D36 | °C | Temperature susceptibility |

| WMFS Thickness | - | μm | Fiber dimensional property |

| WMFS Tensile Strength | - | MPa | Reinforcement capacity |

| Performance Tests | |||

| Marshall Stability | ASTM D6927 | kN | Load-bearing capacity |

| Indirect Tensile Strength | ASTM D3967 | kPa | Cracking resistance |

| Moisture Susceptibility | AASHTO T283 | TSR (ratio) | Water damage resistance |

| Fatigue Life | AASHTO T321 | Nf (cycles) | Durability under repeated load |

| Dynamic Shear | ASTM D7175 | kPa | Rutting resistance |

| Sample ID | Fiber Length (mm) | WMFS Content (% by agg. Weight) | NCMF Content (% by agg. Weight) | Nano-Carbon in NCMF (%) |

|---|---|---|---|---|

| Control | 0 | 0 | 6 | 5 |

| A8-0.3 | 8 | 0.3 | 6 | 5 |

| A8-0.5 | 8 | 0.5 | 6 | 5 |

| A12-0.3 | 12 | 0.3 | 6 | 5 |

| A12-0.5 | 12 | 0.5 | 6 | 5 |

| A18-0.3 | 18 | 0.3 | 6 | 5 |

| A18-0.5 | 18 | 0.5 | 6 | 5 |

| Parameter | Comparison | Sig. | 0.05> | Result |

|---|---|---|---|---|

| Fatigue | Group 1 vs. 2 | 0.00 | Yes | Significant difference |

| Group 1 vs. 3 | 0.00 | Yes | Significant difference | |

| Marshall Stability | Group 1 vs. 2 | 0.048 | Yes | Significant difference |

| Group 1 vs. 3 | 0.005 | Yes | Significant difference | |

| Flow | Group 1 vs. 2 | 0.00 | Yes | Significant difference |

| Group 1 vs. 3 | 0.002 | Yes | Significant difference | |

| Moisture Susceptibility | Group 1 vs. 2 | 0.00 | Yes | Significant difference |

| Group 1 vs. 3 | 0.00 | Yes | Significant difference | |

| Tensile Strength | Group 1 vs. 2 | 0.00 | Yes | Significant difference |

| Group 1 vs. 3 | 0.00 | Yes | Significant difference |

| Parameter | Comparison | Sig. | Result |

|---|---|---|---|

| Fatigue | Group 1 vs. 2 | 0.00 | Significant difference |

| Group 1 vs. 3 | 0.00 | Significant difference | |

| Marshall Stability | Group 1 vs. 2 | 0.048 | Significant difference |

| Group 1 vs. 3 | 0.005 | Significant difference | |

| Flow | Group 1 vs. 2 | 0.00 | Significant difference |

| Group 1 vs. 3 | 0.002 | Significant difference | |

| Moisture Susceptibility | Group 1 vs. 2 | 0.00 | Significant difference |

| Group 1 vs. 3 | 0.00 | Significant difference | |

| Tensile Strength | Group 1 vs. 2 | 0.00 | Significant difference |

| Group 1 vs. 3 | 0.00 | Significant difference |

| R-Squared | Relationship | Dependent Variable |

|---|---|---|

| 0.72 | Fatigue = 0.15038 + 0.0925 × Quantity + 0.00604 × Length | Fatigue |

| 0.58 | Marshall Stability = 1234.79167 + 68.33333 × Quantity + 24.96382 × Length | Marshall stability |

| 0.92 | Flow = 1.27683 − 0.12833 × Quantity − 0.00644 × Length | Flow |

| 0.61 | TSR = 0.96615 − 0.06923 × Quantity − 0.00377 × Length | Tensile strength ratio |

| 0.57 | Tensile Strength = 842.25 + 587.5 × Quantity + 23.553 × Length − 55.526 × Quantity × Length | Tensile strength |

| R-Squared | Relationship | Dependent Variable |

|---|---|---|

| 0.75 | Fatigue = 0.2421 − 0.00036 × X + 0.00001 × X2 | Fatigue |

| 0.60 | Marshall Stability = 777.8541 + 23.9484 × X − 0.1510 × X2 | Marshall stability |

| 0.81 | Flow = 1.2101 − 0.0011 × X | Flow |

| 0.64 | TSR = 0.9164 − 0.00016 × X − 0.000004 × X2 | Tensile strength ratio (TSR) |

| 0.65 | Tensile Strength = 900.9919 + 6.8442 × X − 0.0513 × X2 | Tensile strength |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mirjalili, M.A.-S.; Khabiri, M.M. Effect of Waste Mask Fabric Scraps on Strength and Moisture Susceptibility of Asphalt Mixture with Nano-Carbon-Modified Filler. Infrastructures 2025, 10, 233. https://doi.org/10.3390/infrastructures10090233

Mirjalili MA-S, Khabiri MM. Effect of Waste Mask Fabric Scraps on Strength and Moisture Susceptibility of Asphalt Mixture with Nano-Carbon-Modified Filler. Infrastructures. 2025; 10(9):233. https://doi.org/10.3390/infrastructures10090233

Chicago/Turabian StyleMirjalili, Mina Al-Sadat, and Mohammad Mehdi Khabiri. 2025. "Effect of Waste Mask Fabric Scraps on Strength and Moisture Susceptibility of Asphalt Mixture with Nano-Carbon-Modified Filler" Infrastructures 10, no. 9: 233. https://doi.org/10.3390/infrastructures10090233

APA StyleMirjalili, M. A.-S., & Khabiri, M. M. (2025). Effect of Waste Mask Fabric Scraps on Strength and Moisture Susceptibility of Asphalt Mixture with Nano-Carbon-Modified Filler. Infrastructures, 10(9), 233. https://doi.org/10.3390/infrastructures10090233