Abstract

The main objective of this research is to investigate the impact of the tendon profile layout on the shear strength of unbonded post-tensioned prestressed concrete bridge I-girders. This study involves an experimental investigation where ten unbonded post-tensioned bridge girders are cast and subjected to four-point loads. The focus of the investigation is on the effect of different tendon profile layouts, including trapezoidal, parabolic, and harped shapes. The experimental results reveal that the shear behavior of the specimens progresses through three distinct stages: the elastic stage, the elastic–plastic stage, and the plastic stage, with all specimens ultimately failing due to shear. The results show that tendon profiles with higher eccentricity at the end of the beams (80 mm above the neutral axis) had the highest ultimate load capacity for each tendon profile shape, coupled with the largest deflection. Conversely, profiles with lower eccentricity (80 mm below the neutral axis) demonstrated the lower ultimate load capacity for each tendon profile shape and minimal deflection. Among the various tendon profile layouts that were tested, the specimen with the harped tendon profile (GF-1 HA) showed the highest ultimate load capacity, with an increasing rate of 17.52% in ultimate load and a 45.55% increase in ultimate deflection compared to the control beam (GF-1 ST) with a straight tendon profile. On the other hand, the harped tendon profile specimen (GF-1 HA) exhibited the lowest deflection among the various tendon profile shapes with an increasing rate of 5.7% in ultimate load deflection in comparison with the control beam (GF-1 ST) with a straight tendon profile. These improvements in stiffness, load capacity, and deflection are attributed to enhanced resistance, particularly at the supports. Consequently, the optimized tendon layouts offer an increase in the overall structural efficiency, leading to potential cost savings in bridge girder production.

1. Introduction

Recent advancements in structural engineering focus on cost-effective solutions through the use of advanced design methods and stronger materials, resulting in reduced weight and cross-sectional dimensions of structures. This is particularly important in reinforced concrete, where dead loads often contribute significantly to the total load. Despite these improvements, issues like cracking and excessive deflection, especially in high-stiffness structures, remain prevalent. Prestressed concrete addresses these challenges by introducing internal stresses that counteract external loads, improving the strength, durability, and overall performance of traditional reinforced concrete [1,2].

There are two primary types of prestressed concrete systems: pre-tensioned and post-tensioned. In pre-tensioning, tendons are stretched before the concrete is poured, while in post-tensioning, tendons are tensioned after the concrete has cured. Both methods aim to improve structural effectiveness by overcoming stresses caused by external loads, thus enhancing strength and stability [3,4,5].

Post-tensioning is particularly advantageous in bridge construction due to its material efficiency, better deflection and cracking control, longer material life, faster construction, lower costs, and greater design flexibility. The system includes prestressing strands, protective ducts, grout, and anchorages, all of which work together to enhance concrete stiffness and overall structural performance [6,7].

The durability of post-tensioning depends on the quality of materials like prestressing steel, anchorages, and ducts, as well as installation and environmental protection measures [8].

Post-tensioned concrete can be either bonded, where tendons are in contact with the concrete, or unbonded, where tendons are isolated (not in contact with the concrete), influencing the stress distribution and structural behavior in distinct ways.

The layout of tendon profiles plays a critical role in reducing tension within concrete structures. The curvature of the tendons creates stresses in the concrete that are equal in magnitude but opposite in direction to the tensile forces. In most prestressed beams, tendons are placed with an eccentricity relative to the bottom (soffit) of the beam, which helps counteract the sagging bending moments caused by the external loads acting on the transverse components. As a result, prestressed beams experience upward deflection, or camber, due to the prestressing force. Since the bending moment is a multiplication of both the prestressing force and the tendon eccentricity, the tendon profile directly represents the bending moment diagram [9].

In prestressed concrete beams, two factors play an important role in minimizing the magnitude of diagonal tensile stresses under service load, as compared to conventional reinforced concrete that develops stresses without applying any prestress force to the concrete section. The first factor results from the mixture of longitudinal compressive stress and shearing stress. The second factor surrounds the tendon’s slope, which usually creates a shear force due to the prestress that opposes the shear force induced by the load. This opposing shear reduces diagonal tension in the beam during service. It should be noted that while prestressed beams deflect satisfactorily under service loads, checking diagonal tensile stresses at these loads is not necessarily sufficient for safety against failure. A small reduction in compressive stress or increase in shear stress, especially if a beam is overloaded, may result in an immoderate increase in principal tension. In addition, when inclined tendons are employed to resist shear, their contribution does not increase proportionally with load, implying small increments in shear can pose substantial design issues. Therefore, diagonal tension design in prestressed beams should be based on factored loads rather than service loads, as principal stress analysis enables you to predict the load where the first diagonal crack will occur [1].

Numerous experimental and numerical studies have been performed on the shear strength of unbonded prestressed concrete girders in the last few decades. In addition, several numerical studies have looked into the effects of different tendon profile arrangements on the overall functionality of such systems.

In their study, Rupf et al. [10] examined the behavior of post-tensioned beams with low shear reinforcement and flanges. Experimental data from twelve reinforced concrete beams are studied, with emphasis on shear strength, failure modes, and comparison with design codes and elastic–plastic stress field analysis. In their study, Huber et al. [11] emphasized the important influence of arching action on the shear resistance of slender post-tensioned beams. It has been found that the shear design models used in the assessment are excessively conservative, especially near interior supports. In particular, the flexural-shear crack model provides encouraging predictions of the shear capacity for post-tensioned beams with low shear reinforcement ratios. Ruiz et al. [12] examined the load-carrying mechanisms and strength of thin-webbed post-tensioned beams failing due to web crushing. They explore how cracking and stress disruptions from prestressing tendons reduce shear strength, using results from six full-scale tests on prestressed beams. Rana et al. [13] proposed a cost optimization technique for a post-tensioned PC I-girder bridge focused on reducing material, fabrication, and installation costs. The optimization includes girder spacing, tendon arrangement, and reinforcement of variables, utilizing Evolutionary Operation (EVOP) to create cost-efficient and feasible designs. Huber et al. [14] in their study presented experimental testing of the shear behavior of aging post-tensioned concrete bridges that frequently have low shear reinforcement. Testing four full-scale beams of varying tendon profiles and transverse reinforcement, the study investigated the shear mechanisms of aggregate interlock, stirrups, and dowel action. Results indicated that stirrups alone could not account for load-carrying behavior, and aggregate interlock had only a small effect. Experimental results were compared to estimates from new and existing design codes in order to understand the current design practice [15,16,17,18,19]. Lim et al. [20] studied the influence of high-strength stirrups on the shear behavior of prestressed concrete (PSC) beams. Experimental and finite element simulations demonstrated that the limit of the ACI 318-14 code for the yield strength of shear reinforcement is overly conservative and may be plotted up to 610 MPa [20,21]. In their study, Wang et al. [22] investigated experimentally the shear behavior of corroded post-tensioned prestressed concrete beams with full and insufficient grouting. There was an acceleration of corrosion, leading to diagonal crack development and reduced shear capacity. Specifically, inadequate grouting accelerated crack propagation, and corrosion losses of 31.7% reduced shear strength by as much as 15.44%. Peng et al. [23] investigated the shear behavior of post-tensioned concrete beams reinforced with longitudinal FRP strands but no stirrups. Results indicated that post-tensioned beams failed in shear compression or shear tension, with draping FRP tendons enhancing shear cracking strength by 8.8%; arching was significant to shear resistance. Qi et al. [24] studied the post-cracking shear behavior of externally prestressed concrete beams. Nine beams with different parameters, such as prestressing conditions and the ratio of shear reinforcement, were tested. Results indicated that prestressing increased concrete shear capacity by 68%, with shear strength reserves between 1.72 and 2.96. The beams exhibited large post-cracking deformability, with ductility factors varying from 3.0 to 7.6, and the stiffness decreased significantly after cracking.

Jaing et al. [25] provided a simplified design equation for the shear strength of prestressed concrete (PC) beams reinforced with steel plates. The formula, developed from the assumption of equilibrium equations, was based on a shear compression failure. Test data and a validated 3D finite element analysis showed the effectiveness of steel plates in increasing shear strength with a proposed strength-reduction factor of 0.494. The formula closely predicted experimental outcomes.

Ahmed et al. [26] examined the shear response of single-cell, box-like testing specimens similar to keyed joints in concrete segments. Tests evaluated shear capacity, crack development, and deformations of several joint types. Epoxied joints possessed 25–28% higher shear capacity than dry joints, higher shear transfer, and uniform stress distribution. The AASHTO design criterion conservatively estimates the shear capacity of epoxied and dry joints but overestimates it for the multi-key-type dry joints. Ahmed et al. [27] studied the shear behavior of box girder segmental bridges with bonded joints under direct shear load. Important parameters were confined stress, prestressing eccentricity, and concrete compressive strength. It was found that the shear capacity increased by 40% per 50% increase in confining stress. Concrete strength greatly increased joint shear strength. Comparison with design provisions showed an 11.3% underprediction of shear strength in keyed epoxied specimens.

Ma et al. [28] examined shear design in prestressed concrete beams due to there being a lack of a standardized procedure. They compiled 266 test results to evaluate the accuracy of five design codes and two models. The findings showed that Marí et al.’s method was the most accurate but had a higher coefficient of variation. A new simplified shear strength formula based on a truss-arch model was proposed, offering improved prediction accuracy and consistency, making it a promising alternative for shear strength analysis in prestressed concrete beams.

Ng et al. [29] revisit the load balancing method described in the implementation and present two samples to demonstrate the process. They show the method’s simplicity, even for curved continuous bridges, and argue that it should be used henceforth in standard design practices as it is a more efficient method than the traditional one. Jagarapu et al. [30] studied the optimal cost analysis of simply supported prestressed concrete beams with six design variables and practical constraints. The beam’s overall cost is given as a cost ratio, with allowance made for the volatile material costs. A parametric study investigates the effect of parameters such as population size, live load intensity, cable profile, and beam lengths, resulting in a database for a wide range of span lengths.

Khan et al. [31] propose a new method of designing cable layouts for prestressed concrete (PC) slabs, overcoming the limitations of parabolic profiles. On the other hand, the B-splines are employed to describe the actual smooth cable profile with the changing curvature. An efficient treatment, based on the B-spline convex hull property, is given. The method is successfully applied to design a two-span PC slab, including both friction and non-friction conditions. Colajanni et al. [32] proposed a design method aimed at optimizing the reinforcement layout in prestressed concrete beams subjected to both bending moments and shear forces. Their work addressed the complexities involved in calculating the behavior of beams under simultaneous loading conditions, focusing primarily on plastic models and directional field methods. The study presents a unified analytical approach for analyzing the interaction between axial force, bending moment, and shear force, which is validated through experimental data, nonlinear analysis, and a case history, including a detailed full-scale beam design example. Dixit et al. [33] created a three-dimensional finite element model (3D-FEM) of post-tensioned concrete beams in order to study the influences of eccentricity, prestressing force, and cable profile under concentrated point load. Results, verified through comparison with the analytical models using ANSYS 14.0, show the significance of these variables in the design. The developed 3D-FE model reasonably evaluates design attribute effects on beam performance. Naser [34] determined the best tendon profile arrangement for post-tensioned concrete bridges based on its effect on structural performance and vertical deflection. Two models of a bridge were investigated: simply supported and continuous tendon profiles. FEM outcomes indicated that the continuous tendon form generally led to lower vertical deflections with loads preloaded and loads serviced, indicating the continuous tendon type is advantageous for bridge utilization since it provides superior loads with extensive load-bearing capacities and also reduces deflection.

Mihaylov et al. [35] conducted an experimental study on eight post-tensioned concrete beams at the University of Toronto, examining the size effect on shear behavior and tendon layout variations. The beams, ranging from 250 mm to 1000 mm in depth, had unbonded tendons arranged in straight or harped configurations with varying eccentricities. Under a three-point bending test without stirrups, the beams showed arch action and size effects. The study found that shear strength increased with tendon eccentricity. A strut-and-tie model based on AASHTO guidelines accurately predicted the results, while a kinematic-based approach explained the high shear resistance of smaller beams. Yakov et al. [36] presented an approach for the optimization of the layout of post-tensioned cables in concrete slabs via three-dimensional B-splines by cable modeling in accordance with exact geometry. Savings of up to 20% for standard floor plans were shown, while savings of over 50% for irregular plans could be achieved, all with retained structural performance. Raini [37] emphasized the importance of the computer programming language C in developing analytical skills and problem-solving in civil engineering. They showed how computer systems make complex tasks like analyzing and designing prestressed beams of concrete with variable cable configurations easier. Using C programming, deflection estimation is highly efficient, and it is compared to conventional analytical methods. Mohamed et al. [38] examined the influence of external prestressing tendons on the behavior of reinforced concrete (RC) T-beams. Seven beams were tested with different tendon profiles and deviator arrangements. Results, processed with ANSYS WORKBENCH 19.2, exhibited that external tendons greatly enhanced load capacity, with U-shaped (trapezoidal) tendons having the highest load-carrying capacity and the ductility of the straight-line tendon being the greatest. Huber [39] tested four large post-tensioned beams with different tendon shapes and different levels of transverse reinforcement, which simulated the conditions of older post-tensioned concrete bridge girders. The outcomes showed that the shear capacity of the stirrups triggered by the critical shear cracks was inadequate to explain the load-carrying behavior of the beams. Experimental results were compared to the presented design predictions to verify their accuracy.

The tendon profile layout plays a vital role in the design of post-tensioned concrete bridges. However, most research focuses on the numerical analysis of its impact on the structural performance of prestressed concrete beams and slabs. Experimental studies do not exist, and if they do exist, there are very few.

This gap in the experimental research prompts the need for further investigation into the shear behavior of unbonded, post-tensioned, prestressed concrete bridge girders, particularly with varying tendon profile layouts and eccentricities at the end anchorages. To address this, this study presents experimental investigations involving ten simply supported I-sections, designed according to ACI 318M-19 [40] with different tendon profile shapes and eccentricities. This study focuses on key improvements, including enhanced load resistance, increased bending moment capacity, better deflection control, greater stiffness of prestressed concrete I-bridge girders, and reduced construction costs. The findings provide valuable insights and recommendations for engineers and designers, guiding the practical application and design of tendon profile layouts for unbonded prestressed concrete I-bridge girders.

2. Materials and Methods

2.1. Concrete Mix Design and Material Properties

The concrete mix used in this study was designed based on the ACI 211.1 standard and followed the recommendations of the ACI 211.1R recommendation [41]. A high-performance superplasticizer, Sika ViscoCrete 1681, Sika Iraq (Sika Trading L.L.C.) Erbil/Baghdad/Basra, was added to improve the workability and overall performance of the mixture. The detailed mixing proportions are presented in Table 1. The compressive strength of the concrete cubes (fcu) was set to reach a minimum of 55 MPa at 28 days.

Table 1.

Concrete mix proportions.

The concrete compressive strength was evaluated using 150 × 150 × 150 mm cubic samples, following the BS 12390-3 standard [42]. The compressive strength was determined by testing 12 concrete cubes at 28 days. For the first seven beams, which incorporated straight, trapezoidal, and parabolic tendon profiles, the average compressive strength was 62.8 MPa. In contrast, the last three beams, which featured a harped tendon profile, exhibited a higher average compressive strength of 69.7 MPa. These values were measured using a concrete compression testing machine.

The concrete splitting tensile strength (ft) was measured by testing cylindrical specimens with dimensions of 150 × 300 mm, in accordance with the ASTM C496/C496M standard [43]. For the first seven beams, which utilized straight, trapezoidal, and parabolic tendon profiles, the splitting tensile strength was found to be 3.96 MPa. In comparison, the last three beams with a harped tendon profile exhibited a lower average tensile strength of 2.74 MPa.

The concrete flexural strength was evaluated using 150 × 150 × 550 mm prism samples. The testing followed the standard procedure for determining concrete flexural strength using a simple beam with third-point loading, as specified in the ASTM C78/C78M standard [44,45]. The modulus of rupture (fr) for the first seven beams, which featured straight, trapezoidal, and parabolic tendon profiles, was measured at 4.8 MPa. For the last three beams with a harped tendon profile, the modulus of rupture was slightly higher at 5.3 MPa.

The modulus of elasticity for the tested beams was determined using a 150 × 300 mm cylindrical specimen, following the guidelines set out in ASTM C469/C469M [46]. Deformation was measured with an accuracy of 0.001 mm. The calculated modulus of elasticity (Ec) for the first seven beams, which featured straight, trapezoidal, and parabolic tendon profiles, was 32,552 MPa. For the final three beams, which incorporated a harped tendon profile, the modulus of elasticity (Ec) was calculated to be 37,096 MPa.

2.2. Specimen’s Shape, Size, and Dimensions

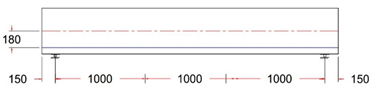

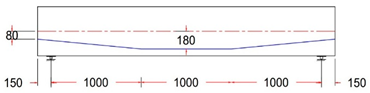

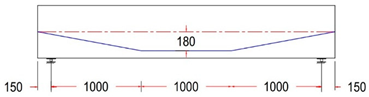

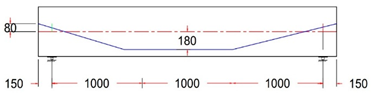

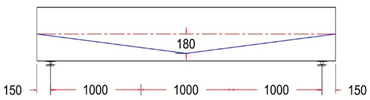

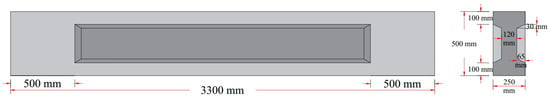

In this study, ten simply supported prestressed post-tensioned I-beams were designed using various unbonded single-strand tendon profiles, in accordance with the ACI 318M-19 code and AASHTO LRFD. All beams had identical geometry, with a length of 3300 mm, a width of 250 mm, and a depth of 500 mm. Solid rectangular end blocks were incorporated at both ends of the beams, as shown in Figure 1.

Figure 1.

Tested specimen’s dimension details.

The end blocks were specifically designed to accommodate the necessary end anchorage hardware and provided additional reinforcement. While they contributed to the structural integrity of the beam by securing the anchorage components, their role in reducing transverse tension or preventing cracking within the beam was minimal. Their primary function was to ensure proper anchorage and support, rather than to significantly influence the beam’s overall performance under load.

2.3. Prestressing and Reinforcement Details

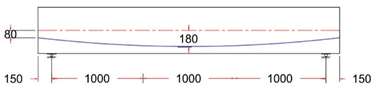

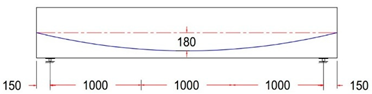

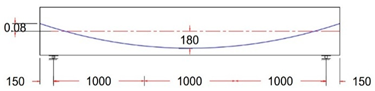

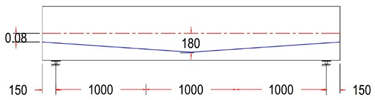

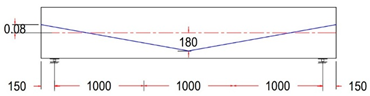

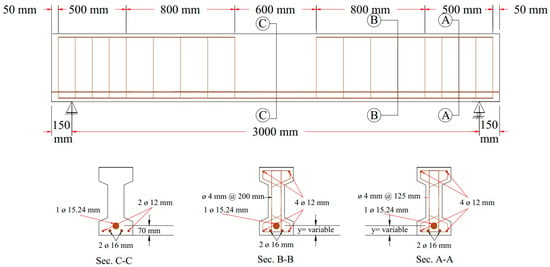

For all tested beams, the primary reinforcement comprised a single seven-wire, low-relaxation strand with a diameter of 15.24 mm (Grade 270). The strand served as the unbonded prestressing steel and was placed inside a plastic duct with an inner diameter of 20 mm. This configuration ensured the proper placement and protection of the prestressing steel during testing, contributing to the overall structural behavior and performance of the beams. The strand eccentricity for all tendon profiles at midspan, or section C-C, was consistently 180 mm from the neutral axis (N.A.). In contrast, the strand eccentricity at sections B-B and A-A varied across different tendon profiles. At the beam’s end anchorages, the eccentricity values ranged from −80 mm to 0 to 80 mm for each tendon profile shape (trapezoidal, parabolic, and harped), while for the straight tendon profile, the eccentricity remained constant at 180 mm from the neutral axis (N.A.). The longitudinal reinforcement consisted of deformed steel bars with diameters of 12 mm. To ensure the beams were designed to resist flexural failure, two longitudinal 16 mm bars were added at the bottom of the beam, and 4 mm steel wires were used for the vertical stirrups. The stirrups were spaced 200 mm along the beam’s length, with a tighter arrangement of 125 mm spacing within the anchorage zone. The reinforcement details for the post-tensioned I-beams, including the end blocks, are provided in Figure 2.

Figure 2.

Details of reinforcement.

The mechanical properties, including dimensions and material specifications, of the strands and steel reinforcement used in the experimental program are summarized in Table 2.

Table 2.

Physical properties of strand and reinforced bars.

2.4. Tested Specimens’ Preparation

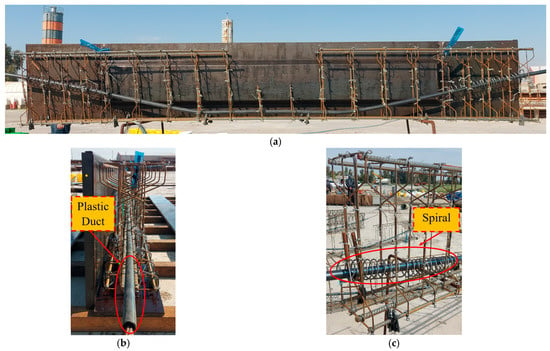

The reinforcement preparation process is shown in Figure 3a. One strand was cut to a length of 3.70 m for every beam. These strands were then placed inside plastic ducts with an inner diameter of 20 mm, which had been pre-embedded in the specimen body, as shown in Figure 3b. Additionally, spiral reinforcement was incorporated into the end block, particularly in the anchorage zone, as illustrated in Figure 3c. This reinforcement arrangement ensured proper prestressing and structural integrity during testing.

Figure 3.

(a) Specimen preparation details, (b) plastic duct, and (c) end block spiral.

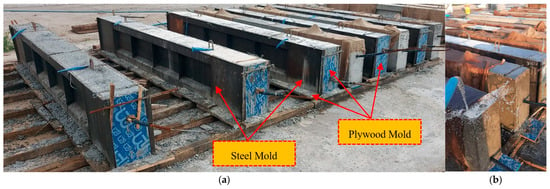

Molds made from steel and plywood were employed to cast the reinforced beams in distinct batches. A total of ten reinforced concrete beams were produced at the Kirkuk Limited Company, Kirkuk, Iraq for Concrete Girders, as shown in Figure 4a. After casting, the specimens were covered with wet cloths to ensure they remained damp. The curing process began after 15 h of casting and continued for a duration of 7 days, as presented in Figure 4b. This curing procedure was crucial to ensuring the proper hydration of the concrete, contributing to the beams’ strength and durability for the subsequent testing.

Figure 4.

The manufacturing of beams: (a) mold and (b) curing process.

The post-tensioning operation was carried out after 28 days by experienced staff with post-tensioning equipment as shown in Figure 5a. The strands were stressed up to 70% of their ultimate tensile strength (fpu) to obtain the design prestress under service load. The wedge and plate were put on hold by 20% of the amount of jacking force to fix them, and then the total amount of jacking force, 182.282 N, was imposed, as shown in Figure 5b.

Figure 5.

(a) Post-tensioning machine. (b) Tendon jacking.

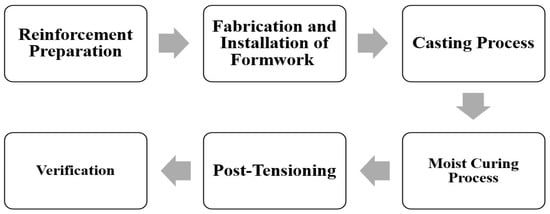

The post-tensioning process for each beam took approximately 15 min. Figure 6 provides the flowchart detailing the preparation process for the test specimens.

Figure 6.

Flowchart for the preparation of the test specimens.

2.5. Experimental Variables

Test variable selection was extensively evaluated, and specimens were prepared with a focus on the most important parameters. The variable of primary interest was tendon profile layout. Ten different tendon profiles, as listed in Table 3, were selected. Beam eccentricity at the midspan was always 180 mm, while eccentricity at the anchorages (located at the beam end face) varied with eccentricity between 180, 80, 0, and −80 mm.

Table 3.

List of specimens with tendon profile layouts.

2.6. Test Setup and Instrumentation

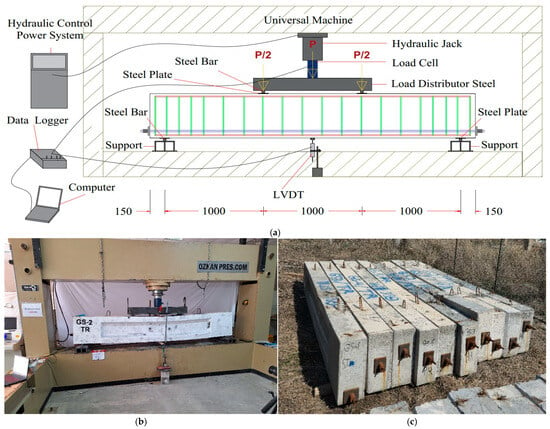

Experiments were carried out at the Civil Engineering Laboratory, Salahaddin University, Erbil, using four-point loading tests to study the shear responses of the beams. The beams were tested as simply supported at both ends. The testing machine had a maximum capacity of 2500 kN, as shown in Figure 7b; the load was exerted by a hydraulic jack, and a 100 ton load cell was used to read the load data. The force was transmitted with the aid of a steel beam.

Figure 7.

Tested specimens’ preparation: (a) tested setup, (b) testing device, and (c) tested beams.

Tests were performed at the Civil Engineering Laboratory at Salahaddin University at Erbil, and four-point loading was used to measure the shear capacity of the beams. Beams were subjected to four-point loading with supports at both ends. The load was carried out by a testing machine with a capacity up to 2500 kN, as presented in Figure 7b; the load was exerted using a hydraulic jack. A 100 ton load cell was used to measure and record load data, and the force was transferred to the specimen through a steel beam, which facilitated the accurate and uniform load application in the test. The steel beam, which distributed the loads, divided it into two areas 1000 mm apart, as shown in Figure 7a. To measure the midspan deflection of the beam, two linear variable displacement transducers (LVDTs) with a gauge length of 300 mm were used. The LVDTs were mounted at the midspan of the beam, with the first one mounted on the front face of the beam and the second on the rear side, and both at the midspan. This arrangement allowed us to estimate the average displacement. This was of particular significance when the steel tube did not maintain perfect alignment. The arrangement with the LVDTs is shown in Figure 7a and the beam specimens are depicted in Figure 7c.

2.7. Experimental Procedure

A universal testing machine was used for testing the beams, as illustrated in Figure 7a. The following procedure was carefully followed to ensure the consistency and accuracy of the experiment: To begin, the load cell and the LVDTs were connected to a data logger, which was tasked with recording the load and deflection of the specimen, as presented in Figure 7a. Next, the computer was linked to the data logger to record the data automatically, ensuring comprehensive data management.

Before the load was applied, the load adjustment control wheel was loosened to avoid the specimen experiencing any abrupt or inappropriate load. Once the specimen was properly centered in the testing rig, the load was applied by slowly turning the control wheel to apply load and to uniformly increase the load. The load was applied at an average rate of approximately 60 kN/min in the elastic stage. Cracks initiated, and the specimen became slightly more plastic, whilst during the test the digital load display did not give a constant load rate or stop to give a constant load rate, indicating the material had changed its behavior. The test was terminated when the load stopped increasing and began to slightly decrease, while the displacement significantly increased continuously, and the specimens exhibited signs such as significant cracking and excessive deflection, which led in one of the tests to concrete crashing. The whole test process, ranging from loading to failure, lasted approximately 30 min. Any cracking formed in the sample during the test was carefully highlighted and marked by a line. When the test was finished, we unset the load adjustment control wheel, turned off the machine, and pulled the plug connecting with the computer, finishing the experiment safely and tidily.

This step-by-step procedure ensured precise control and thorough monitoring of the specimen’s behavior during the testing, guaranteeing the accuracy and reliability of the data collected throughout the experiment.

3. Experimental Program

3.1. Load–Deflection Curves

Ten unbonded post-tensioned beams of the same cross-sectional dimensions and reinforcement arrangements but with different tendon profiles were tested under four-point load. The shear response of the beams was evaluated by load-deflection curves, crack developments, and failure modes to understand their structural behavior.

Table 4 gives the first crack, the ultimate load, and the ratio (Pcr/Pu), which is an important parameter that defines the beam ductility and the overall structural performance. This is a very useful number when one wants to understand how a beam behaves under increasing load, or its ability to be able to take more force before cracking happens and failure occurs, thus providing an estimate of how strong or tough the beam really is.

Table 4.

Experimental results.

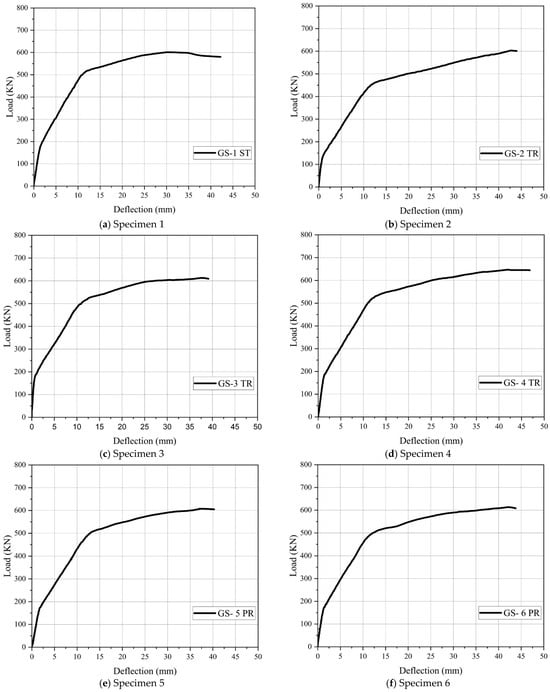

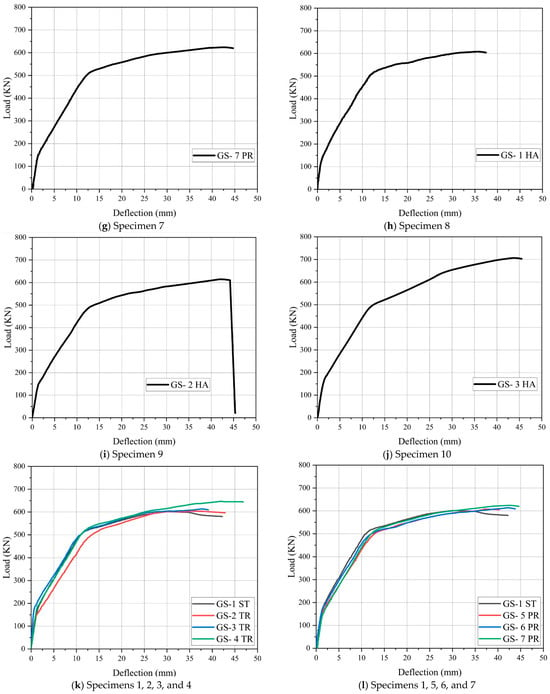

All specimens initially displayed a linear response up to the cracking load. After that, elastoplastic behavior was identified; as the applied load increased, the load-deflection ratio decreased, signaling a reduction in the strength of the beams. Then a plastic response followed, which was attributed to the yielding of the longitudinal rebar, and this behavior persisted until the test’s conclusion, as illustrated in Figure 8.

Figure 8.

Load vs. deflection relationship for tested beam specimens.

As shown in Figure 8a, the load-deflection curve for the control specimen (GS-1 ST) demonstrated an initial linear response during the elastic stage, where load increased proportionally with deflection. Upon reaching 167.17 kN and 1.36 mm deflection, the first cracks appeared, marking the transition to inelastic behavior in the elastoplastic stage. The load-deflection curve then showed a decrease in slope, indicating reduced beam stiffness due to cracking, with deflection increasing more rapidly than load. As the load continued to rise, the curve displayed a further reduction in slope, transitioning to a plastic response caused by the yielding of the longitudinal reinforcement, which continued until the test concluded. During this phase, the load stabilized while deflection increased sharply. The ultimate load reached 601.17 kN, with a deflection of 30.1 mm, and the Pcr/Pu ratio was 27.81%, as indicated in Table 4.

GS-2 TR, with eccentricity at the end of the beam (ee) of 80 mm, exhibited a different load-deflection response, as shown in Figure 8b. Its elastic stage was lower compared to the GS-1 ST; the first crack appeared at 137.98 kN and it had a deflection of 0.98 mm. This specimen demonstrated a higher ultimate load of 603.03 kN and a significantly greater deflection of 42.59 mm at failure. The ultimate load increased by 1.86 kN (a 0.31% increase), while the ultimate deflection increased by 12.59 mm, reflecting a 41.97% increase over the control specimen, as summarized in Table 5. The (Pcr/Pu) ratio for GS-2 TR was 22.88%, which was lower than that of the control beam, as detailed in Table 4.

Table 5.

Comparison of the control beam with other specimens in terms of ultimate load and ultimate load deflection.

GS-3 TR, with eccentricity at the anchorage point of zero, demonstrated a distinct behavior, as shown in Figure 8c. This specimen exhibited a larger elastic stage compared to the GS-1 ST, with the first crack appearing at 184.73 kN and a deflection of 0.79 mm. It reached a higher ultimate load of 613.42 kN and a lower deflection of 37.59 mm at failure. These values represent a 12.25 kN (2.04%) increase in ultimate load and a 7.49 mm (24.88%) increase in ultimate deflection compared to the control specimen, as summarized in Table 5. The (Pcr/Pu) ratio for GS-3 TR was 30.11%, higher than that of the GS-1 ST, as presented in Table 4.

GS-4 TR, with ee = −80 mm at the anchorage point, demonstrated unique load-deflection characteristics, as shown in Figure 8d. The elastic stage for this specimen was higher than that of the control beam, with the first cracks forming at 188.72 kN and a midspan deflection of 1.44 mm. The specimen exhibited a larger ultimate load of 647.08 kN and a larger deflection of 42 mm at failure. Compared to the control beam, this represents an increase in ultimate load of 45.91 kN (7.64%) and an increase in ultimate deflection of 11.9 mm (39.53%), as summarized in Table 5. The (Pcr/Pu) ratio for GS-4 TR was 29.16%, which was higher than that of the GS-1 ST, as presented in Table 4.

GS-5 PR, with ee = +80 mm at the anchorage point, demonstrated distinct load-deflection behavior, as shown in Figure 8e. This specimen exhibited a higher elastic stage compared to the control beam, with the first cracks appearing at 178.6 kN, surpassing the control beam’s cracking load, and a deflection 2 mm greater than that of the control specimen. The specimen achieved a larger ultimate load of 607.43 kN, with a corresponding deflection of 37.24 mm at failure. These values reflect an increase in ultimate load of 6.26 kN (1.04%) and an increase in ultimate deflection of 6.79 mm (22.56%) over the control beam, as summarized in Table 5. The (Pcr/Pu) ratio for GS-5 PR was 29.40%, which was higher than that of the control beam, as indicated in Table 4.

GS-6 PR, with ee = 0, exhibited unique load-deflection behavior, as depicted in Figure 8f. Compared to the GS1-ST, this specimen displayed a longer elastic stage, with the first cracks occurring at 183.95 kN and a deflection of 1.68 mm. It reached a larger ultimate load of 613.6 kN and a higher deflection of 42.04 mm at failure. These findings represent a 2.07% increase in ultimate load (12.43 kN) and a 39.67% increase in ultimate deflection (11.94 mm) compared to the control specimen, as summarized in Table 5. The (Pcr/Pu) ratio for GS-6 PR was 29.98%, which was lower than that of the GS-1 ST, as shown in Table 4.

GS-7 PR, with ee= −80 mm, exhibited distinct load-deflection behavior, as shown in Figure 8g. The elastic stage for this specimen was shorter than that of GS-1 ST. The first crack in the concrete appeared at a load of 151.2 kN with a deflection of 1.43 mm. It reached a larger ultimate load of 624 kN and a higher deflection of 42.26 mm at failure. These results represent a 3.80% increase in ultimate load (22.83 kN) and a 41.06% increase in ultimate deflection (12.36 mm) compared to the control specimen, as summarized in Table 5. The (Pcr/Pu) ratio for GS-7 PR was 24.23%, which was lower than that of GS-1 ST, as indicated in Table 4. These findings suggest that the eccentricity of the tendon profile contributed to an enhanced load-bearing capacity and deflection, although the ductility, as indicated by the (Pcr/Pu) ratio, was slightly reduced compared to the GS-1 ST.

GS-1 HA, with ee = +80 mm at the anchorage, displayed distinct load-deflection behavior, as shown in Figure 8h. The specimen exhibited a shorter elastic stage compared to the control beam, with the first crack appearing at 126.73 kN and a deflection of 0.86 mm. Despite this, GS-1 HA reached a larger ultimate load of 608.4 kN and a higher deflection of 35.82 mm at failure. These results correspond to a 1.20% increase in ultimate load and a 19.00% increase in ultimate deflection compared to the control beam, as detailed in Table 5. The (Pcr/Pu) was 20.83% lower than that of the GS-1 ST, as illustrated in Table 4.

GS-2 HA, with ee = 0, exhibited load-deflection behavior, as illustrated in Figure 8i. The elastic stage for this specimen was shorter compared to the GS-1 ST, with the first crack occurring at 145.88 kN and a deflection of 1.3 mm. However, this specimen reached a larger ultimate load of 615 kN and a greater deflection of 41.95 mm at failure. These results indicate a 2.30% increase in ultimate load and a 39.37% increase in ultimate deflection compared to the control beam, as summarized in Table 5. The (Pcr/Pu) for GS-2 HA was 23.72%, which was lower than that of GS-1 ST, as shown in Table 4. These findings suggest that the tendon configuration in GS-2 HA enhanced both the load-carrying capacity and deflection behavior, while slightly reducing the beam’s ductility, as evidenced by the (Pcr/Pu) ratio.

GF-3 HA, featuring (ee) of −80 mm at the anchorage, exhibited distinct load-deflection behavior, as shown in Figure 8j. Its elastic stage was shorter compared to the GS-1 ST, with the first cracks appearing at 166.48 kN and a deflection of 1.52 mm. This specimen demonstrated a significantly greater ultimate load of 706.5 kN and a higher deflection of 43.81 mm at failure. These results indicate a 17.52% increase in ultimate load and a 45.55% increase in ultimate deflection compared to the control beam, as summarized in Table 5. The (Pcr/Pu) for GF-3 HA was 23.56%, which was lower than that of the GS-1 ST, as presented in Table 4. These findings suggest that the harped tendon profile with eccentricity significantly improved both the load-bearing capacity and deflection performance, although the beam’s ductility, as indicated by the (Pcr/Pu) ratio, was slightly reduced.

When comparing all beams to the GS-1ST control, as depicted in Figure 8k–n, the improvement in ultimate loads and corresponding deflections can be attributed to variations in tendon profile layouts, which included straight, trapezoidal, parabolic, and harped shapes, as well as differences in tendon end anchorage. Beams with higher eccentricity at the end anchorages or steeper tendon slopes demonstrated a greater load capacity than those with lower eccentricity or straight tendons. This enhanced load capacity is primarily due to the influence of the tendon profile layout, where beams with greater eccentricity or steeper slopes experience a higher vertical component of the effective prestressing force (Vp). This increase in prestressing force results in a higher nominal shear (Vcw), which raises the point at which web-shear cracking occurs, ultimately leading to improved shear strength capacity and improved overall performance of the beams.

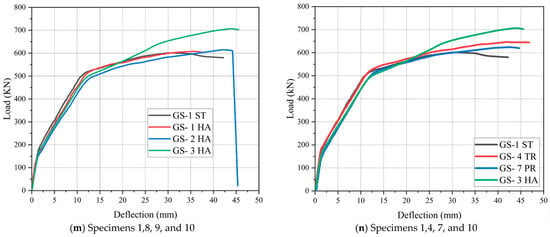

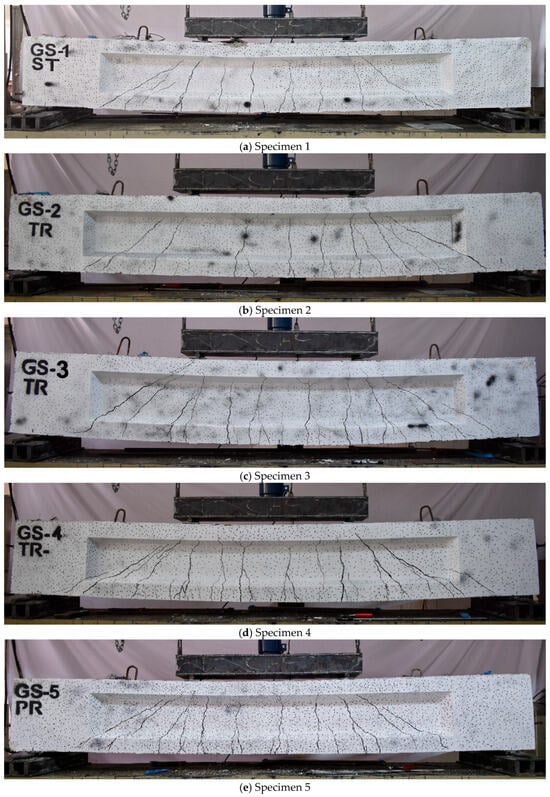

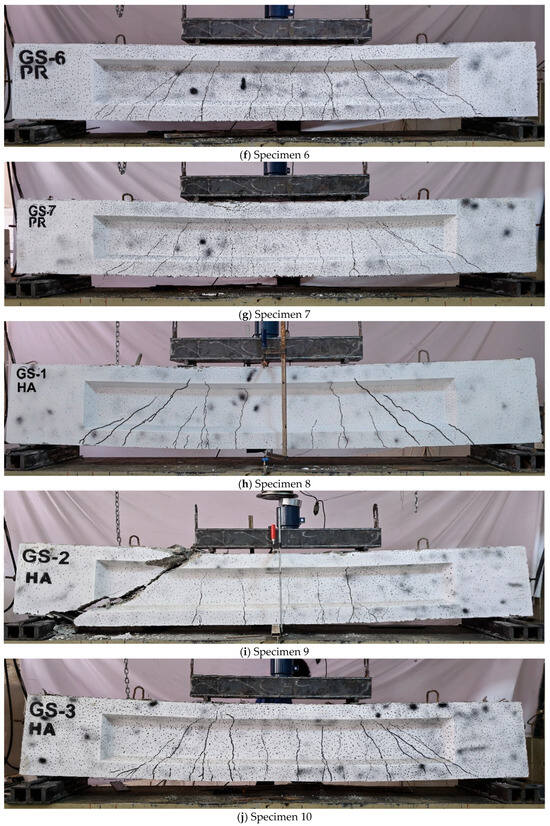

3.2. Crack Patterns and Mode of Failure

During testing, the cracking loads were recorded when the first oblique cracks appeared in the web, caused by high diagonal tension. As the load increased, these cracks spread diagonally, both upward and downward. This behavior was attributed to the thin web structure combined with high prestressing forces, which intensified the diagonal tension and facilitated crack propagation. The crack patterns and failure modes for each specimen are presented in Figure 9 and Table 4. Web-shear cracks formed in the shear span region of all specimens, initially appearing on either side of the web. In some cases, the first crack became dominant, while in others, cracks from the opposite side grew to prominence. As the load increased, these cracks expanded diagonally in both upward and downward directions, extending further within the shear span. Additionally, some flexural cracks developed from the bottom flange, extending toward the loading points. As the cracks progressed, a significant reduction in the beam’s load-bearing capacity and stiffness occurred, primarily due to the continued growth and propagation of these cracks.

Figure 9.

Crack patterns of the specimens.

4. Conclusions

This study aimed to investigate the impact of tendon profile layout on the shear strength of tested beams. Ten different I-girders with varying tendon profiles were tested, and several key conclusions emerged from the findings:

- The tendon profile layout significantly influenced the failure process in unbonded prestressed concrete I-girders.

- The shear behavior of the specimens was characterized by three stages: the elastic stage, the elastic–plastic stage, and the plastic (ductility) stage. All specimens experienced shear failure.

- The first cracks occurred at approximately 20.83% to 30.11% of the ultimate load, averaging around 26.17% for all specimens.

- Among the specimens with a trapezoidal tendon profile, the greater increase in ultimate load was observed in specimen GS-4 TR, which showed a 7.64% improvement compared to the control beam. For the specimens with a parabolic tendon profile, an increase of 3.8% in ultimate load was recorded, with specimen GS-7 PR achieving a maximum increase of 22.83 kN over the control beam. Specimens featuring a harped tendon profile also demonstrated a greater increase in ultimate load, with specimen GS-3 HA showing a significant 17.52 improvement over the control beam. The specimen GS-3 HA with a harped tendon profile showed the highest ultimate load in comparison with all other tendon profiles. These results highlight the beneficial impact of tendon profile layout on the load-carrying capacity of prestressed concrete beams.

- The vertical deflection measurements of the tendon profile specimens revealed distinct variations. For the trapezoidal tendon profile, specimen GS-3 TR exhibited the smallest ultimate load deflection at 37.59 mm, which was 24.88% greater than that of the GS-1 ST. Among the parabolic tendon profile specimens, GF-5 PR showed the lowest ultimate load deflection at 37.24 mm, 22.56% higher than GS-1 ST, while for the harped tendon profile, GS-1 HA recorded a lower ultimate load deflection of 35.82 mm, 19% greater than GS-1 ST. The specimen GS-1 HA with a harped tendon profile showed the lowest ultimate load deflection in comparison with the trapezoidal and parabolic tendon profiles. These findings highlight the influence of tendon profile shapes on ultimate load deflection, offering insights into their structural performance.

- This study revealed that each tendon profile shape (trapezoidal, parabolic, harped) exhibited the highest ultimate load capacity and ultimate load deflection when beams had higher eccentricity (80 mm above N.A.), while beams with lower eccentricity (80 mm below N.A.) resulted in the lowest load capacity and ultimate load deflection. Notably, specimen GS-3 HA, featuring the harped tendon profile, displayed the greatest ultimate load capacity, while specimen GS-1 HA, with the harped tendon profile, recorded the smallest ultimate load deflection. These findings highlight the significant influence of tendon profile shape and eccentricity on the structural performance of the specimens.

- The experimental results of girders tested with optimized tendon profiles indicated that their performance was enhanced remarkably in comparison with the control beam and the harped tendon profile showed the best improvements in performance in comparison with all other tendon profiles. These girders could carry higher loads, and these girders could sustain larger loads due to the more effective distribution of the prestressing forces along the girder length. The optimum tendon arrangements led to the more homogeneous distribution of stresses inside the concrete, fully utilizing a larger part of the cross-section. This study demonstrates the advantage of adopting optimized tendon profiles to enhance the performance of prestressed concrete bridge girders.

Finally, the findings from this research reveal that optimized tendon configurations lead to significant enhancements in load-carrying capacity and overall performance. These results offer valuable insights for the design and optimization of prestressed concrete girders, providing a basis for improving structural performance in bridge construction. This study underscores the potential of tendon layout optimization in advancing the efficiency and durability of prestressed concrete structures.

Author Contributions

Conceptualization, S.I.H. and O.Q.A.; methodology, S.I.H.; validation, S.I.H., O.Q.A. and A.M.L.; formal analysis, S.I.H.; investigation, S.I.H.; resources, S.I.H.; data curation, S.I.H.; writing—original draft preparation, S.I.H.; writing—review and editing, A.M.L. and O.Q.A.; visualization, S.I.H. and A.M.L.; supervision, A.M.L. and O.Q.A.; project administration, A.M.L. and O.Q.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to privacy restrictions.

Acknowledgments

The authors would like to acknowledge the Laboratory of Civil Engineering at the University of Salaheddin-Erbil for providing the facilities and resources required to conduct the experimental tests. Special thanks to the technical staff for their assistance and support throughout the research process. We extend our sincere gratitude to Kirkuk Limited Company for Concrete Girder for their expert technical support in the post-tensioning of beams. Special thanks to their skilled prestressing concrete plant staff, whose precision and professionalism were essential to this research.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Darwin, D.; Dolan, C.W. Design of Concrete Structures, 16th ed.; McGraw-Hill Education: Columbus, OH, USA, 2021; ISBN 9781260575118. [Google Scholar]

- Hao, H.; Bi, K.; Chen, W.; Pham, T.M.; Li, J. Towards next Generation Design of Sustainable, Durable, Multi-Hazard Resistant, Resilient, and Smart Civil Engineering Structures. Eng. Struct. 2023, 277, 115477. [Google Scholar] [CrossRef]

- Nilson, A.H. Design of Prestressed Concrete, 2nd ed.; Wiley: Hoboken, NJ, USA, 1987. [Google Scholar]

- Naser, A.F.; Zonglin, W. Strengthening of Jiamusi Pre-Stressed Concrete Highway Bridge by Using External Post-Tensioning Technology in China. J. Eng. Appl. Sci. 2010, 5, 60–69. [Google Scholar]

- Naser, A.F.; Zonglin, W. Finite Element and Experimental Analysis and Evaluation of Static and Dynamic Responses of Oblique Pre-Stressed Concrete Box Girder Bridge. Res. J. Appl. Sci. Eng. Technol. 2013, 6, 3642–3657. [Google Scholar] [CrossRef]

- Abdullah, A.B.M.; Rice, J.A.; Hamilton, H.R.; Consolazio, G.R. Damage Identification in Unbonded Tendons for Post-Tensioned Bridges. In Proceedings of the International Conference on Advances in Experimental Structural Engineering, Urbana, IL, USA, 1–2 August 2015; p. 8. [Google Scholar]

- Corven, J.; Natio, C.; Pessiki, S. Designing and Detailing Post-Tensioned Bridges to Accommodate Nondestructive Evaluation; Federal Highway Administration: Washington, DC, USA, 2018. [Google Scholar]

- Fuzier, J.-P.; Ganz, H.-R.; Matt, P. Durability of-Tensioning Tendons; Case Postale 88, CH-1015; International Federation for Structural Concrete: Lausanne, Switzerland, 2006. [Google Scholar]

- Nusrath, F.R.; Satheesh, V.S.; Manigandan, M.; Suresh, B.S. An Overview on Tendon Layout for Prestressed Concrete Beams. Int. J. Innov. Sci. Eng. Technol. 2015, 2, 944–949. [Google Scholar]

- Rupf, M.; Fernández Ruiz, M.; Muttoni, A. Post-Tensioned Girders with Low Amounts of Shear Reinforcement: Shear Strength and Influence of Flanges. Eng. Struct. 2013, 56, 357–371. [Google Scholar] [CrossRef]

- Huber, P.; Huber, T.; Kollegger, J. Experimental and Theoretical Study on the Shear Behavior of Single- and Multi-Span T- and I-Shaped Post-Tensioned Beams. Struct. Concr. 2019, 21, 393–408. [Google Scholar] [CrossRef]

- Ruiz, M.F.; Muttoni, A. Shear Strength of Thin-Webbed Post-Tensioned Beams. ACI Struct. J. 2008, 105, 308–317. [Google Scholar]

- Rana, S.; Ahsan, R. Design of Prestressed Concrete I-Girder Bridge Superstructure Using Optimization Algorithm. IABSE-JSCE Jt. Conf. Adv. Bridge Eng.-II 2010, 211–223. [Google Scholar]

- Huber, P.; Wien, T.U.; Huber, T.; Kollegger, J. Shear Behavior of Post-Tensioned Concrete Beams with a Low Amount of Transverse Reinforcement. In Proceedings of the Fib Symposium 2016 Cape Town, Cape Town, South Africa, 1 November 2016. [Google Scholar]

- Hillebrand, M.; Hegger, J. Fatigue Testing of Shear Reinforcement in Prestressed Concrete T-Beams of Bridges. Appl. Sci. 2020, 10, 5560. [Google Scholar] [CrossRef]

- Eisa, A.S.; Kotrasova, K.; Sabol, P.; Mihaliková, M.; Attia, M.G. Experimental and Numerical Study of Strengthening Prestressed Reinforced Concrete Beams Using Different Techniques. Buildings 2024, 14, 29. [Google Scholar] [CrossRef]

- Qi, H.; Jiang, H.; Wang, B.; Zhuge, P. Experimental Study on Shear Performance of Concrete Beams Reinforced with Externally Unbonded Prestressed CFRP Tendons. Fibers 2024, 12, 23. [Google Scholar] [CrossRef]

- Zhao, K.; Wang, H.; Li, H.; Wei, Y.; Lu, J.; Li, G. Experimental and Numerical Analysis of Shear Performance of 16 m Full-Scale Prestressed Hollow Core Slabs. Infrastructures 2025, 10, 2. [Google Scholar] [CrossRef]

- Jancy, A.; Stolarski, A.; Zychowicz, J. Experimental and Numerical Research of Post-Tensioned Concrete Beams. Materials 2023, 16, 4141. [Google Scholar] [CrossRef]

- Lim, H.-S.; Jun, B.-K.; Shin, D.-I.; Lee, J.-Y. Shear Capacity of Post-Tensioning Pre-Stressed Concrete Beams with High Strength Stirrups. Int. J. Struct. Civ. Eng. Res. 2016, 4, 258–264. [Google Scholar] [CrossRef]

- Yaqub, M.A.; Czaderski, C.; Matthys, S. Shear Strengthening of Precast Prestressed Bridge I-Girders Using Shape Memory Reinforcement. Eng. Struct. 2024, 305, 117743. [Google Scholar] [CrossRef]

- Wang, L.; Hu, Z.; Yi, J.; Dai, L.; Ma, Y.; Zhang, X. Shear Behavior of Corroded Post-Tensioned Prestressed Concrete Beams with Full/Insufficient Grouting. KSCE J. Civ. Eng. 2020, 24, 1881–1892. [Google Scholar] [CrossRef]

- Peng, F.; Xue, W. Experimental Investigation on Shear Behavior of FRP Post-Tensioned Concrete Beams without Stirrups. Eng. Struct. 2021, 244, 112835. [Google Scholar] [CrossRef]

- Qi, J.; Ma, Z.J.; Wang, J.; Bao, Y. Post-Cracking Shear Behaviour of Concrete Beams Strengthened with Externally Prestresssed Tendons. Structures 2020, 23, 214–224. [Google Scholar] [CrossRef]

- Jiang, C.; Xiong, W.; Ye, J. Simplified Design Formula for the Shear Capacity of Prestressed Concrete T-Beams Strengthened by Steel Plates. KSCE J. Civ. Eng. 2025, 29, 100013. [Google Scholar] [CrossRef]

- Ahmed, G.H.; Aziz, O.Q. Shear Behavior of Dry and Epoxied Joints in Precast Concrete Segmental Box Girder Bridges under Direct Shear Loading. Eng. Struct. 2019, 182, 89–100. [Google Scholar] [CrossRef]

- Ahmed, G.H.; Aziz, O.Q. Influence of Intensity & Eccentricity of Posttensioning Force and Concrete Strength on Shear Behavior of Epoxied Joints in Segmental Box Girder Bridges. Constr. Build. Mater. 2019, 197, 117–129. [Google Scholar] [CrossRef]

- Ma, G.; Wu, Y.; Hwang, H.J.; Shi, C. Database Evaluation of Shear Strength of Prestressed Concrete Beams. Structures 2025, 73, 108288. [Google Scholar] [CrossRef]

- Ng, P.L.; Kwan, A.K.H. Practical Determination of Prestress Tendon Profile by Load-Balancing Method. HKIE Trans. Hong Kong Inst. Eng. 2006, 13, 27–35. [Google Scholar] [CrossRef]

- Jagarapu, D.C.K.; Venkat, L. Genetic Algorithm Based Optimum Design of Prestressed Concrete Beam. Int. J. Comput. Civ. Struct. Eng. 2013, 3, 644–654. [Google Scholar] [CrossRef]

- Khan, A.A.; Pathak, K.K.; Dindorkar, N. Cable Layout Design of One Way Prestressed Slabs Using Fem. J. Eng. Sci. Manag. Educ. 2010, 2, 34–41. [Google Scholar]

- Colajanni, P.; Recupero, A.; Spinella, N. Design Procedure for Prestressed Concrete Beams. Comput. Concr. 2014, 13, 235–253. [Google Scholar] [CrossRef]

- Dixit, A.S.; Khurd, V.G. Effect of Prestressing Force, Cable Profile and Eccentricity on Post Tensioned Beam. Int. Res. J. Eng. Technol. 2017, 4, 626–632. [Google Scholar]

- Naser, A.F. Optimum Design of Vertical Steel Tendons Profile Layout of Post-Tensioning Concrete Bridges: Fem Static Analysis. ARPN J. Eng. Appl. Sci. 2018, 13, 9244–9256. [Google Scholar]

- Mihaylov, B.I.; Liu, J.; Simionopoulos, K.; Bentz, E.C.; Collins, M.P. Effect of Member Size and Tendon Layout on Shear Behavior of Post-Tensioned Beams. ACI Struct. J. 2019, 116, 265–274. [Google Scholar] [CrossRef]

- Yakov, Z.; Amir, O. Layout Optimization of Post-Tensioned Cables in Concrete Slabs. Struct. Multidiscip. Optim. 2021, 63, 1951–1974. [Google Scholar] [CrossRef]

- Rani, U.M. Effect of Tendon Profile on Deflections in Prestressed Concrete Beams Using C Programme. Int. J. Comput. Sci. Eng. 2021, 8, 6–8. [Google Scholar] [CrossRef]

- Mohamed, G.A.; Eisa, A.S.; Purcz, P.; Ručinský, R.; El-Feky, M.H. Effect of External Tendon Profile on Improving Structural Performance of RC Beams. Buildings 2022, 12, 789. [Google Scholar] [CrossRef]

- Huber, P.; Wien, T.U.; Huber, P.; Kollegger, J. Shear Strength of Post-Tensioned Concrete Girders with Minimum Shear Reinforcement. In Proceedings of the 11th CCC Congress, Hainburg, Austria, 1–2 September 2015. [Google Scholar]

- ACI Committee 318. Building Code Requirements for Structural Concrete (ACI 318-19) Commentary on Building Code Requirements for Structural Concrete (ACI 318R-19); American Concrete Institute: Farmington Hills, MI, USA, 2019. [Google Scholar]

- American Concrete Institute Committee 211. Selecting Proportions for Normal-Density and High-Density Concrete-Guide Inch-Pound Units Selecting Proportions for Normal-Density and High-Density Concrete-Guide; American Concrete Institute: Farmington Hills, MI, USA, 2022. [Google Scholar]

- British Standards Institution. Part 3, Compressive Strength of Test Specimens. In Testing Hardened Concrete; British Standards Institution: London, UK, 2019; ISBN 9780580984426. [Google Scholar]

- ASTM C496/C496M-17; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens (ASTM C496/C496M-17). ASTM International: West Conshohocken, PA, USA, 2017; Volume 04.02.

- Fakhrulddin Abdullah, A.; Burhan Al-Deen Abdul-Rahman, M.; Abbas Al-Attar, A. Investigate the Mechanical Characteristics and Microstructure Of-Geopolymer Concrete Exposure to High Temperatures. J. Rehabil. Civ. Eng. 2025, 14, 2141. [Google Scholar]

- Husain, H.M.; Oukaili, N.K.; Jomaa’h, M.M. Effect of Prestressing Force on Torsion Resistance of Concrete Beams. J. Eng. 2007, 13, 1902–1918. [Google Scholar]

- ASTM C469/C469M-14; Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression (ASTM C469/C469M-14). ASTM International: West Conshohocken, PA, USA, 2014; Volume 04.02.

- ASTM A416/A416M-24; Standard Specification for Low-Relaxation Seven-Wire Steel Strand for Prestressed Concrete. ASTM International: West Conshohocken, PA, USA, 2024; Volume 01.04.

- ASTM A615/A615M-15a; Standard Specification for Deformed and Plain Carbon-Steel Bars for Concrete. ASTM International: West Conshohocken, PA, USA, 2015; Volume 01.04.

- ASTM A1064/A1064M-18a; Standard Specification For-Steel Wire and Welded Wire Reinforcement, Plain and Deformed, for Concrete1. ASTM International: West Conshohocken, PA, USA, 2018; Volume 01.04.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).