Development of an Intelligent Monitoring System for Settlement Prediction of High-Fill Subgrade

Abstract

1. Introduction

2. Research Objectives

- (1)

- To implement a full-cycle subgrade settlement monitoring system by dividing the subgrade into three height-based layers and installing sensors at specific construction stages.

- (2)

- To ensure efficient and proactive safety management by recording settlement data at 10 min intervals.

- (3)

- To enhance the predictive capability for high-fill subgrade settlement by employing back-propagation (BP) neural network models.

3. Establishment of Intelligent Monitor Systems for Subgrade

3.1. Site Parameters of Subgrade

3.2. Layered Drilling

3.3. Sensor Embedding

3.4. Line Burial

3.5. Installation and Debugging of Automated Acquisition System

4. Experimental Design

4.1. Intelligent Monitoring Solution of Subgrade

4.1.1. Technological Requirement

- (1)

- The subgrade deformation observation mainly includes surface and internal settlement observation of high-fill subgrade [10,31,32,33], settlement observation of the foundation center in the soft soil foundation treatment section, settlement observation of the subgrade slope toe in the soft soil foundation treatment section, and settlement observation of high-fill subgrade in the transition section area.

- (2)

- The settlement deformation observation section after subgrade construction should be set according to the engineering structure, topographic and geological conditions, foundation treatment methods, filling and excavation sections, subgrade height, construction methods, settlement control standards; and other specific conditions. At the same time, the observation sections should be adjusted or added based on the terrain and geological changes learned during the construction process.

- (3)

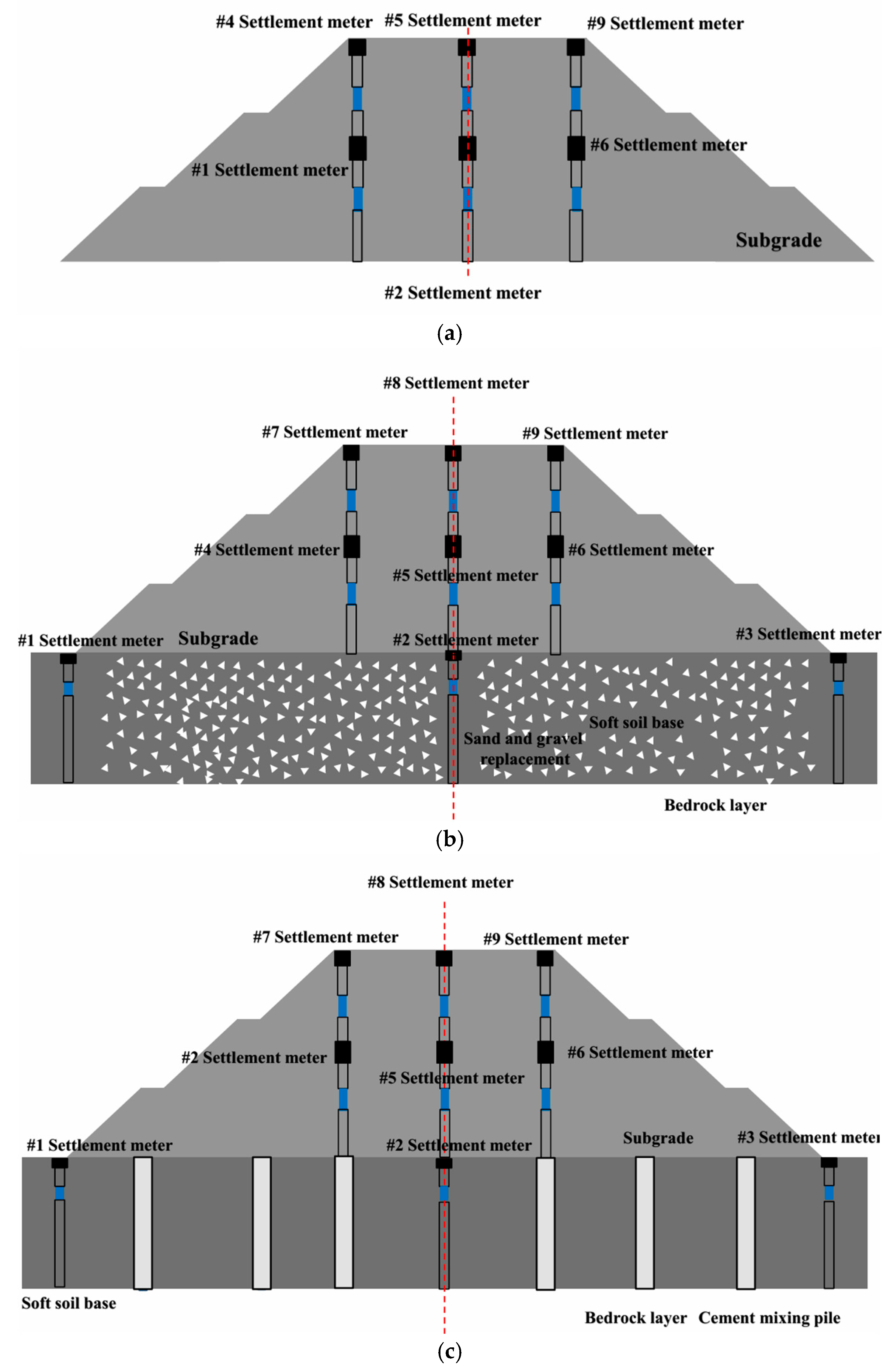

- This project mainly adopts an intelligent automatic settlement observation system for key sections of the subgrade (soft soil foundation, high fill, transition section, slope, etc.). There are three foundation treatment methods for no soft-base treatment, sand and gravel replacement, and cement mixing pile used in the current research study, as shown in Figure 6. As for controlling soil stratification, the thickness of each backfill layer is generally controlled at 30~50 cm. If different materials need to be filled in layers (such as gravel cushion + fine sand), a transition layer should be designed. At the same time, bulldozers, pavers, or loaders are used to spread fill evenly, which can avoid direct contact between materials with large particle size differences. Regarding controlling soil compaction quality, vibratory rollers are employed for sand, heavy rollers or vibratory rollers are used for gravel, and compaction tests or on-site moisture testers are used to control the moisture content within the optimal range.

- (4)

- The information regarding the layout and equipment of the subgrade settlement intelligent monitoring system is as follows.

- The intelligent single-point settlement meter should be buried on the outside of the foot of the subgrade slope (measured inside the ditch), the center of the subgrade, and the shoulders on both sides. The automated chassis should be placed on the outside of the foot of the slope and equipped with an anti-theft box. After the construction site is leveled and cleared, and before subgrade filling is carried out, it is necessary to drill holes and embed the settlement meter under good weather conditions, without rain or snow. If it rains, the meter must be installed two days after the weather clears. A total of 3–5 days after the single-point settlement meter is installed, a reading instrument is used to test the initial displacement during installation behind the shrinkage cavity, and the burial specifications of the single-point settlement meter are prepared, as required.

- The intelligent single-point settlement meter is composed of an electrical displacement sensor, measuring rod, metal hose, anchor head, extension rod, and bottom opening pin.

- The intelligent single-point settlement meter exhibits an accuracy of 0.5%, a range of 400 mm, and a sensitivity of 0.01 mm, and the principle of inductor magnetic flux frequency modulation technology is designed. The product offers higher stability, reliability, and durability. It is buried as a whole, and the wires are led out from the side, which does not affect the construction of road compaction and makes the measured values consistent with the actual working conditions.

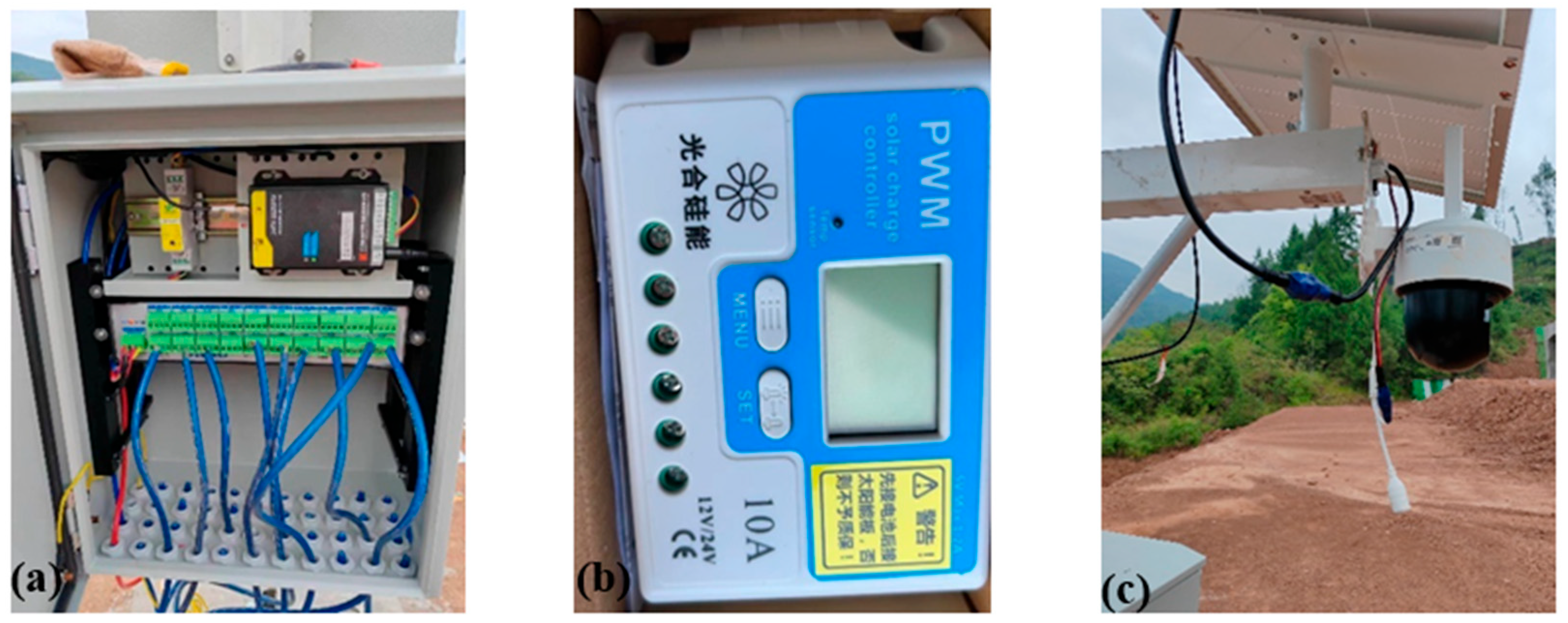

- The automation chassis adopts a standardized design and can contain two built-in automatic acquisition modules and a power module, including DTU and lightning protection switch modules, supporting up to 20 interfaces for multiple monitoring sections (such as Class I and II observation sections). In addition, collaborative monitoring can also be achieved.

- The intelligent power module is powered by solar rechargeable batteries. It can automatically manage to ensure that the power supply is not interrupted, the output load capacity is strong, and the ripple is small. At the same time, the product has over-current, over-voltage, and short-circuit protection and can realize remote monitoring and remote control of the power supply current, voltage, power, and other parameter data.

- The drill is pointed downward at the reference point, and the hole diameter should be 101 mm. In addition, the settlement meter is inserted into the hole until the bottom anchor head is pressed to the bedrock, and the instrument and installation accessories should not drop into the hole during the installation process.

4.1.2. Observation Requirements

- (1)

- The settlement observation should be carried out from the beginning of subgrade filling in the subgrade section. There should be a settlement observation and adjustment period of not less than 12 months after the subgrade filling is completed or the preload is applied.

- (2)

- The observed value of settlement displacement during subgrade filling construction should meet the following requirements: if there is an abnormality in the subgrade monitoring data, filling should be stopped immediately and resumed after the observed value returns to below the limit value.

- (3)

- During the observation period, the daily observation data must be sorted and analyzed in a timely manner, and settlement observation data must be provided to relevant units without delay [34,35,36]. If the actual measured value of subgrade settlement exceeds the design value (Table 2), the cause should be promptly identified in conjunction with construction, survey, and design units, and geological review should be conducted, if necessary [31,37,38]. The calculation parameters should be adjusted based on the actual measurement results, and the design-predicted settlement should be revised or settlement control measures should be taken.

4.2. Back-Propagation (BP) Neural Networks Model

4.2.1. Influence Factors

4.2.2. Time Series Multi-Step Rolling

5. Results and Discussions

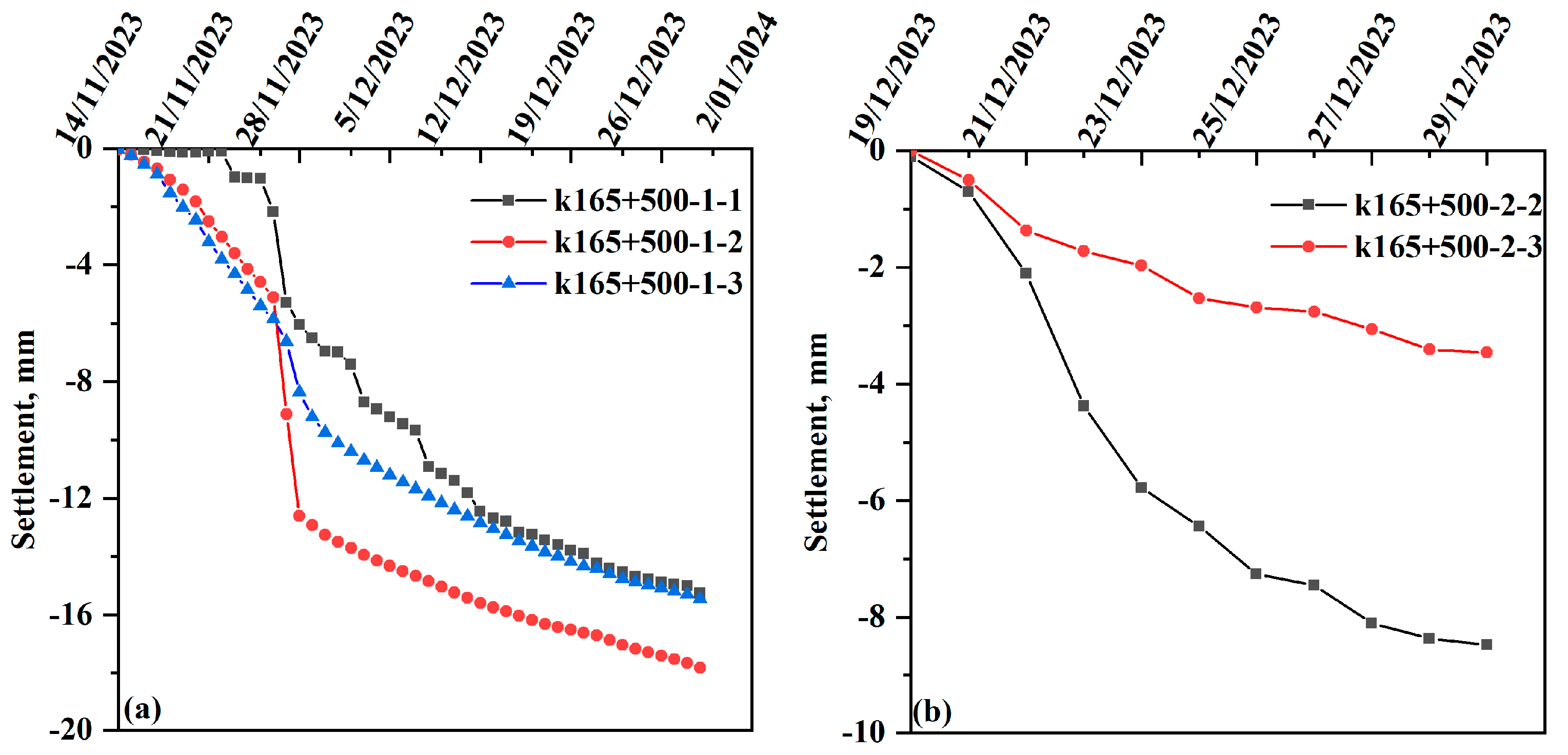

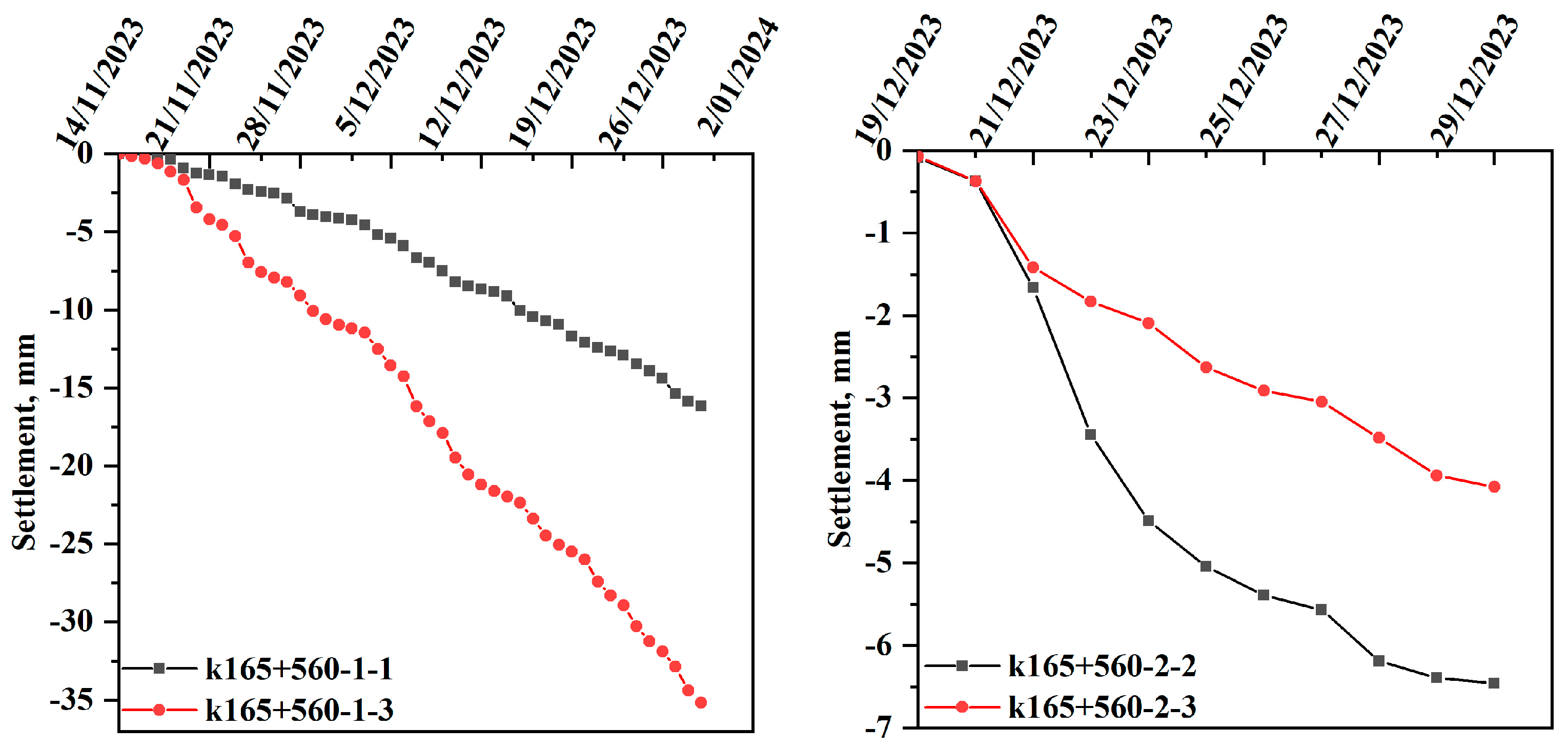

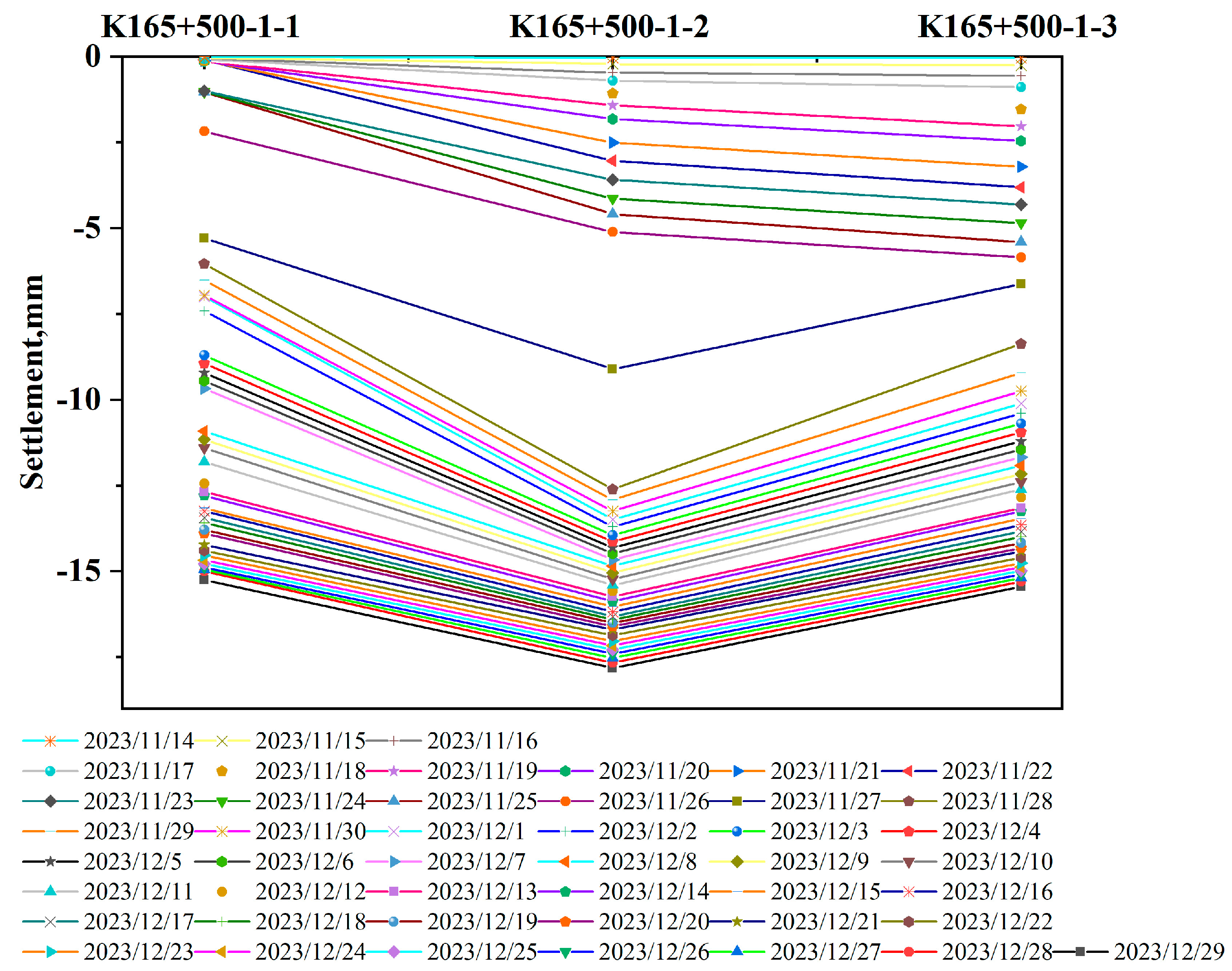

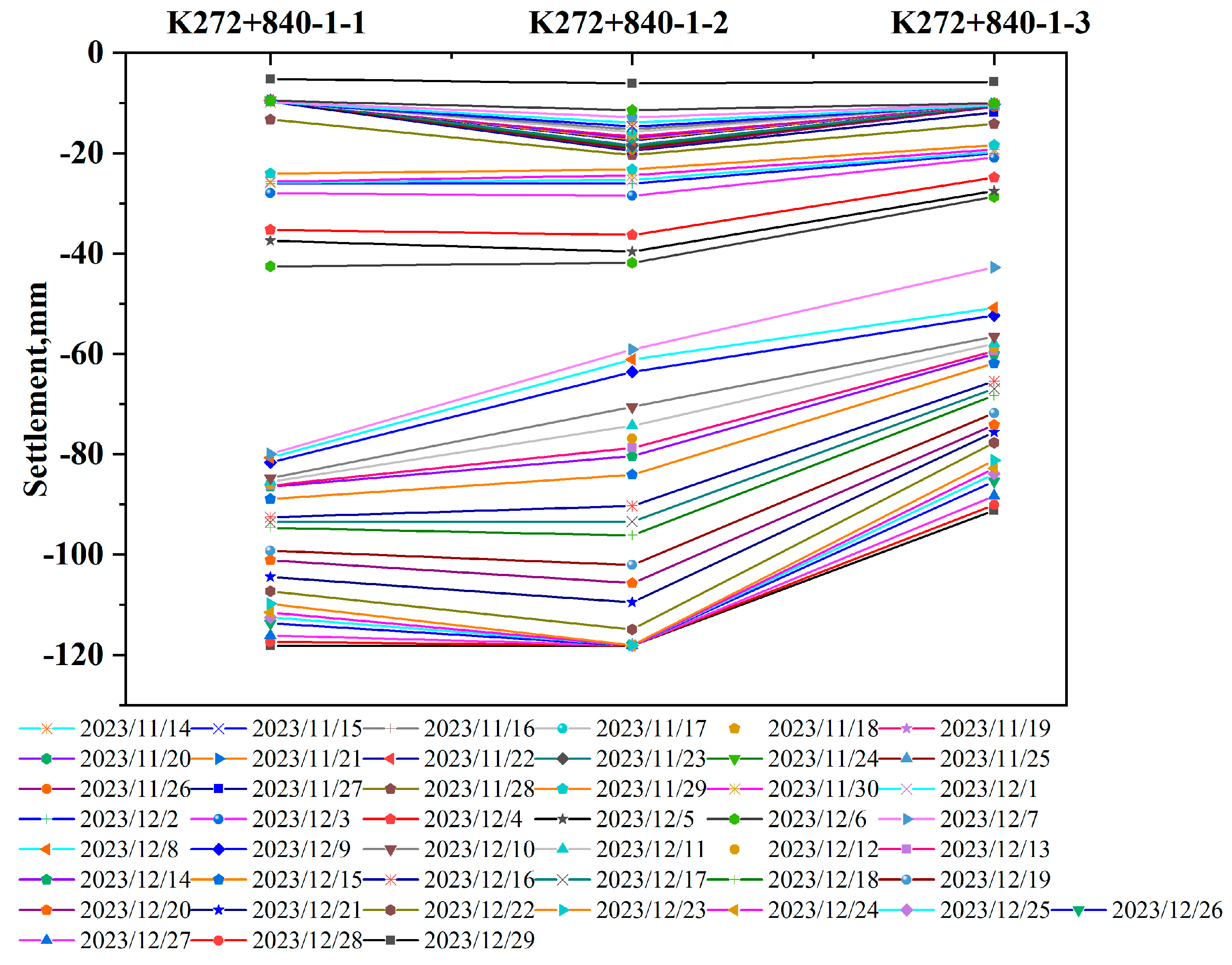

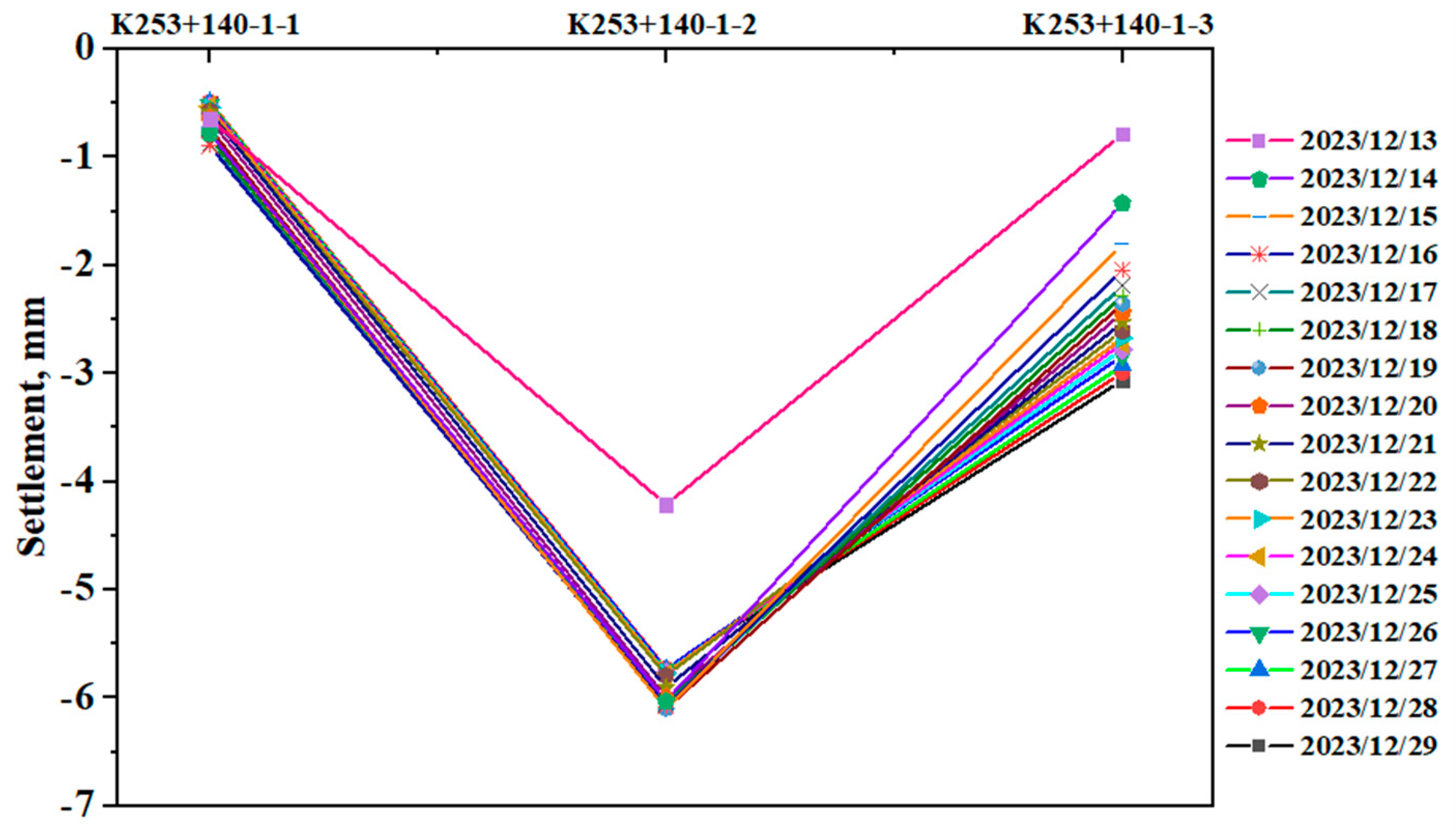

5.1. Settlement Curve Prediction of Subgrade

5.2. Settlement Basin Prediction of Subgrade

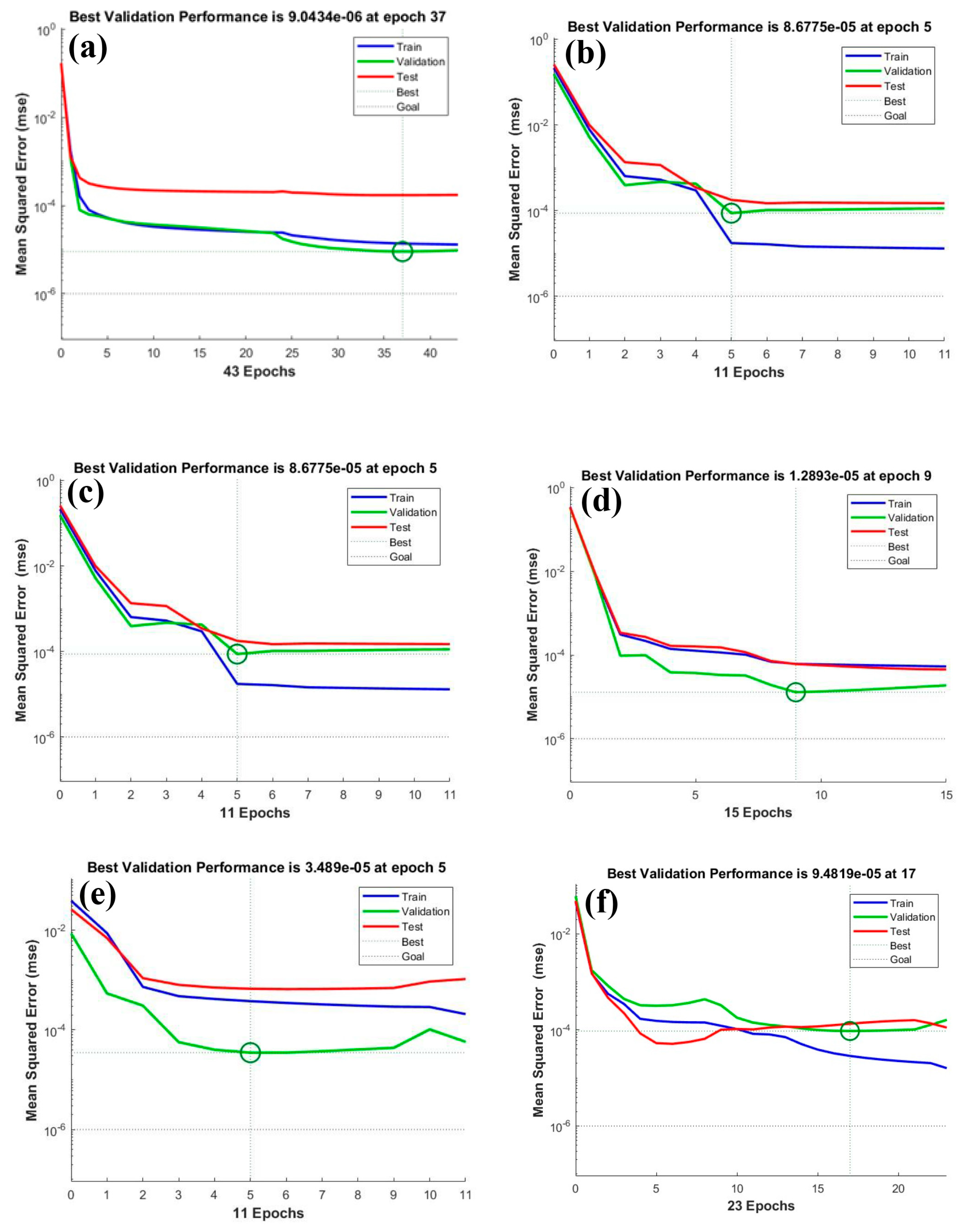

5.3. Settlement Prediction of BP Neural Network Model

6. Conclusions and Recommendations

- (1)

- The on-site monitoring system and video surveillance system are integrated into the Engineering Pulse Internet Cloud Platform, and the intelligent monitoring system can collect data generated by sensors in real time to ensure timely acquisition of foundation settlement information.

- (2)

- The layered settlement monitoring program helps to monitor the settlement of various parts of the subgrade, identify whether there is differential settlement, and enable early detection of problems that may lead to uneven settlement of the structure so that remedial measures can be taken in a timely manner.

- (3)

- The system displays a variety of built-in data preprocessing methods to automatically generate multi-point curves and correlation curves. Using data processing algorithms and analysis techniques, the system can identify and distinguish various influencing factors to improve the accuracy and reliability of monitoring data.

- (4)

- The settlement rate at the initial settlement of the subgrade is relatively fast. Afterwards, the soil enters the rapid consolidation stage. As the consolidation process of the fill gradually unfolds, the settlement rate of the subgrade gradually slows down. Finally, the rate of subgrade settlement enters a relatively stable stage.

- (5)

- Based on the above settlement rules, it is recommended to build vertical drainage channels in the foundation to accelerate the discharge of pore water during preloading or to use high-energy rammers to repeatedly tamp the ground to compact the soil and improve the density and bearing capacity to control settlement of high-fill subgrade.

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Di Zornberg, J.G.; Azevedo, M.; Sikkema, M.; Odgers, B. Geosynthetics with enhanced lateral drainage capabilities in roadway systems. Transp. Geotech. 2017, 12, 85–100. [Google Scholar] [CrossRef]

- Matias, S.R.; Ferreira, P.A. Railway slab track systems: Review and research potentials. Struct. Infrastruct. Eng. 2020, 16, 1635–1653. [Google Scholar] [CrossRef]

- Zhao, G.; Song, D.; Peng, Z.; Yan, Z. Analysis on control indicators for settlement and deformation of the rock-filled subgrade in mountainous area. Int. J. Pavement Res. Technol. 2022, 15, 213–220. [Google Scholar] [CrossRef]

- Wang, C.; Wang, B.; Guo, P.; Zhou, S. Experimental analysis on settlement controlling of geogrid-reinforced pile-raft-supported embankments in high-speed railway. Acta Geotech. 2015, 10, 231–242. [Google Scholar] [CrossRef]

- Yang, G.Q.; Liu, H.; Zhou, Y.T.; Xiong, B.L. Post-construction performance of a two-tiered geogrid reinforced soil wall backfilled with soil-rock mixture. Geotext. Geomembr. 2014, 42, 91–97. [Google Scholar] [CrossRef]

- Anbazhagan, S.; Ramesh, V. Landslide hazard zonation mapping in ghat road section of Kolli hills, India. J. Mt. Sci. 2014, 11, 1308–1325. [Google Scholar] [CrossRef]

- Dunning, S.A.; Massey, C.I.; Rosser, N.J. Structural and geomorphological features of landslides in the Bhutan Himalaya derived from Terrestrial Laser Scanning. Geomorphology 2009, 103, 17–29. [Google Scholar] [CrossRef]

- Jin, H.; Hao, J.; Chang, X.; Zhang, J.; Yu, Q.H.; Qi, J.; Lü, L.; Wang, S. Zonation and assessment of frozen-ground conditions for engineering geology along the China–Russia crude oil pipeline route from Mo’he to Daqing, Northeastern China. Cold Reg. Sci. Technol. 2010, 64, 213–225. [Google Scholar] [CrossRef]

- Abella, E.A.C.; Van Westen, C.J. Qualitative landslide susceptibility assessment by multicriteria analysis: A case study from San Antonio del Sur, Guantánamo, Cuba. Geomorphology 2008, 94, 453–466. [Google Scholar] [CrossRef]

- Wang, K.; Zhang, J.; Gao, G.; Qiu, J.; Zhong, Y.; Guo, C.; Zhao, W.; Tang, K.; Su, X. Causes, risk analysis, and countermeasures of urban road collapse in China from 2019 to 2020. J. Perform. Constr. Facil. 2022, 36, 04022054. [Google Scholar] [CrossRef]

- Zheng, J.L.; Zhang, R.; Yang, H.P. Highway subgrade construction in expansive soil areas. J. Mater. Civ. Eng. 2009, 21, 154–162. [Google Scholar] [CrossRef]

- Liu, J.; Zou, D.; Kong, X. A three-dimensional state-dependent model of soil–structure interface for monotonic and cyclic loadings. Comput. Geotech. 2014, 61, 166–177. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, T.; Zhang, Z.; Huangfu, Z.; Li, Q.; An, Z. Unmanned rolling compaction system for rockfill materials. Autom. Constr. 2019, 100, 103–117. [Google Scholar] [CrossRef]

- Wang, R.; Hu, Z.; Ma, J.; Ren, X.; Li, F.; Zhang, F. Dynamic response and long-term settlement of a compacted loess embankment under moving train loading. KSCE J. Civil Eng. 2021, 25, 4075–4087. [Google Scholar] [CrossRef]

- Zhu, C.; Li, N. Ranking of influence factors and control technologies for the post-construction settlement of loess high-filling embankments. Comput. Geotech. 2020, 118, 103320. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, W.; Zhang, Y.; Xu, J. A bibliometric review on stability and reinforcement of special soil subgrade based on CiteSpace. J. Traffic Transp. Eng. (Engl. Ed.) 2022, 9, 223–243. [Google Scholar] [CrossRef]

- Wang, X.; Dong, X.; Zhang, Z.; Zhang, J.; Ma, G.; Yang, X. Compaction quality evaluation of subgrade based on soil characteristics assessment using machine learning. Transp. Geotech. 2022, 32, 100703. [Google Scholar] [CrossRef]

- Benedetto, A.; Pensa, S. Indirect diagnosis of pavement structural damages using surface GPR reflection techniques. J. Appl. Geophys. 2007, 62, 107–123. [Google Scholar] [CrossRef]

- Nautiyal, A.; Sharma, S. Methods and factors of prioritizing roads for maintenance: A review for sustainable flexible pavement maintenance program. Innov. Infrastruct. Solut. 2022, 7, 190. [Google Scholar] [CrossRef]

- Chen, Z.J.; Feng, W.Q.; Yin, J.H. A new simplified method for calculating short-term and long-term consolidation settlements of multi-layered soils considering creep limit. Comput. Geotech. 2021, 138, 104324. [Google Scholar] [CrossRef]

- Ren, Y.; Zhang, Z.; Huang, M. A review on settlement models of municipal solid waste landfills. Waste Manag. 2022, 149, 79–95. [Google Scholar] [CrossRef]

- Phoon, K.K.; Cao, Z.J.; Ji, J.; Leung, Y.F.; Najjar, S.; Shuku, T.; Tang, C.; Yin, Z.-Y.; Ikumasa, Y.; Ching, J. Geotechnical uncertainty, modeling, and decision making. Soils Found. 2022, 62, 101189. [Google Scholar] [CrossRef]

- Tolooiyan, A.; Gavin, K.; Dyson, A.P. Estimation of spudcan penetration in variable sand deposits with the Arbitrary Lagrangian Eulerian Finite Element Method. Ocean Eng. 2023, 281, 114955. [Google Scholar] [CrossRef]

- Ren, J.J.; Liu, W.; Du, W.; Zheng, J.L.; Wei, H.; Zhang, K.Y.; Ye, W.L. Identification method for subgrade settlement of ballastless track based on vehicle vibration signals and machine learning. Constr. Build. Mater. 2023, 369, 130573. [Google Scholar] [CrossRef]

- Kardani, N.; Kumar, A.; Kumar, S.; Karr, O.; Bardhan, A. A Deep Learning Approach for Modelling of Resilient Modulus of Compacted Subgrade Subjected to Freezing-Thaw Cycles and Moistures. Transp. Infrastruct. Geotechnol. 2024, 11, 3805–3828. [Google Scholar] [CrossRef]

- Thapa, I.; Ghani, S. Explainable AI-Enhanced Machine Learning for CBR Prediction in Stabilized and Unstabilized Subgrade Soils. Appl. Soft Comput. 2025, 178, 113275. [Google Scholar] [CrossRef]

- Shao, Y.; Li, L.; Li, J.; Li, Q.; An, S.; Hao, H. Out-of-plane full-field vibration displacement measurement with monocular computer vision. Autom. Constr. 2024, 165, 105507. [Google Scholar] [CrossRef]

- Huang, Y.; Feng, R.; Zhong, C.; Tong, X.; Shao, X.; Gu, L.; Hui, Z. Computer vision-based real-time deflection monitoring of complex and sizeable steel structures. Eng. Struct. 2024, 305, 117752. [Google Scholar] [CrossRef]

- Wang, Z.; Zhu, J.; Ma, T. Review on monitoring of pavement subgrade settlement: Influencing factor, measurement and advancement. Measurement 2024, 237, 115225. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, L.; Yang, H. An overview of intelligent construction and maintenance technology for highway subgrade engineering. Intell. Transp. Infrastruct. 2023, 2, liad019. [Google Scholar] [CrossRef]

- Chen, D.; Ling, J.; Li, D.; Zheng, C. Monitoring and evaluating techniques of highway subgrade safety in the operation period. Road Mater. Pavement Des. 2017, 18, 215–225. [Google Scholar] [CrossRef]

- Wei, K.H.; Pei, X.J.; Zhang, S.S.; Ran, C.Y.; Xiao, H.B.; Li, T.T. Deformation Characteristics of a Vertical Support Structure in a High-Filled Loess Slope Associated with Temperature Fluctuations. Soil Mech. Found. Eng. 2021, 58, 353–360. [Google Scholar] [CrossRef]

- Yao, Y.; Zhang, Y.; Ma, C.; Zhao, Y.; Lv, G. Study on deformation of filling composite geological body in loess mountainous area. Nat. Hazards 2022, 110, 1469–1493. [Google Scholar] [CrossRef]

- Bae, A.; Stoffels, S.M.; Antle, C.E.; Lee, S.W. Observed evidence of subgrade moisture influence on pavement longitudinal profile. Can. J. Civil Eng. 2008, 35, 1050–1063. [Google Scholar] [CrossRef]

- Heydinger, A.G. Evaluation of seasonal effects on subgrade soils. Transp. Res. Rec. 2003, 1821, 47–55. [Google Scholar] [CrossRef]

- Hossain, M.; Romanoschi, S.; Gisi, A.J. Seasonal and spatial variation of subgrade response. In Pavement Subgrade, Unbound Materials, and Nondestructive Testing; American Society of Civil Engineers: Reston, VA, USA, 2000; pp. 150–166. [Google Scholar]

- Ntambakwa, E.; Yu, H.; Guzman, C.; Rogers, M. Geotechnical design considerations for onshore wind turbine shallow foundations. In Geotechnical and Structural Engineering Congress 2016; American Society of Civil Engineers: Reston, VA, USA, 2016; pp. 1153–1165. [Google Scholar]

- Qian, W.; Qi, T.; Zhao, Y.; Le, Y.; Yi, H. Deformation characteristics and safety assessment of a high-speed railway induced by undercutting metro tunnel excavation. J. Rock Mech. Geotech. Eng. 2019, 11, 88–98. [Google Scholar] [CrossRef]

- Yang, E.; Wang, K.; He, J.; Liu, K.; Wang, J.; Zhang, H.; Qiu, Y. Settlement prediction of a high embankment based on non-linear regression and neural network algorithm. Transp. Geotech. 2025, 50, 101443. [Google Scholar] [CrossRef]

| Number | Road Section | Observation Section | Fill Height (m) | Filling Quantity (m3) | Foundation Treatment | Earthwork Transportation |

|---|---|---|---|---|---|---|

| 1 | A | K165+460-K165+500 | 36 | 200,000 | No soft base treatment | Cut-and-fill balance |

| 2 | B | k272+880 | 22.1 | 430,000 | Replacement gravel (34,837 m3) + filler (18,638 m3) | Borrow pit |

| 3 | C | K250+080 | 29.94 | 850,000 | Cement mixing pile (544,098 m3) | Cut-and-fill balance |

| Road Grade | Location, m | ||

|---|---|---|---|

| Adjacent to Bridge Abutment and Subgrade | Culverts, Box Culverts, Passages | General Section | |

| Highway | ≤0.10 | ≤0.30 | ≤0.30 |

| Secondary roads as trunk roads | ≤0.20 | ≤0.30 | ≤0.50 |

| Input | Output |

|---|---|

| X1, X2, …, Xm | Xm+1 |

| X1, X2, …, Xm+1 | Xm+2 |

| … | … |

| Xk, Xk+1, …, Xk+m−1 | Xk+m |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liao, M.; Wang, K.; Zhou, X.; Tian, L.; Wang, J.; Zhang, H.; Du, Y.; Yang, E. Development of an Intelligent Monitoring System for Settlement Prediction of High-Fill Subgrade. Infrastructures 2025, 10, 220. https://doi.org/10.3390/infrastructures10080220

Liao M, Wang K, Zhou X, Tian L, Wang J, Zhang H, Du Y, Yang E. Development of an Intelligent Monitoring System for Settlement Prediction of High-Fill Subgrade. Infrastructures. 2025; 10(8):220. https://doi.org/10.3390/infrastructures10080220

Chicago/Turabian StyleLiao, Manhong, Kai Wang, Xin Zhou, Liang Tian, Junxin Wang, Haopeng Zhang, Yunchuan Du, and Enhui Yang. 2025. "Development of an Intelligent Monitoring System for Settlement Prediction of High-Fill Subgrade" Infrastructures 10, no. 8: 220. https://doi.org/10.3390/infrastructures10080220

APA StyleLiao, M., Wang, K., Zhou, X., Tian, L., Wang, J., Zhang, H., Du, Y., & Yang, E. (2025). Development of an Intelligent Monitoring System for Settlement Prediction of High-Fill Subgrade. Infrastructures, 10(8), 220. https://doi.org/10.3390/infrastructures10080220