The Analysis of Axial Compression Performance of Reinforced Concrete Columns Strengthened with Prestressed Carbon Fiber Sheets

Abstract

1. Introduction

2. Material Properties and Model Verification

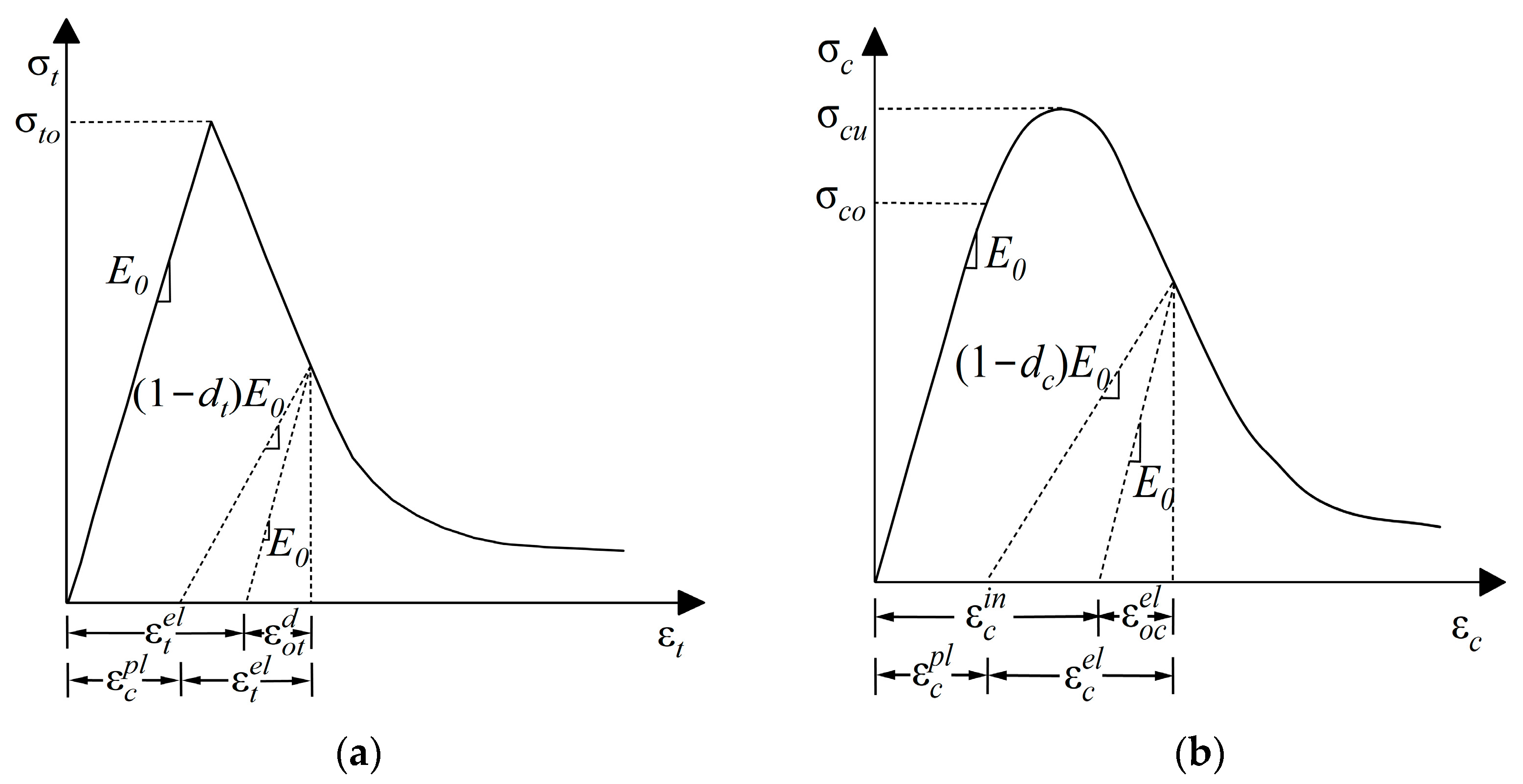

2.1. Constitutive Model of RC Columns

2.2. Constitutive Model of CFRP

2.3. Model Element Selection and Meshing

2.4. Contact Relationships and Boundary Conditions

2.5. Finite Element Model Validation

3. Parameter Analysis

3.1. Parameter Determination

3.2. Prestress Application and Temperature Drop Value Correction

4. Factors Affecting CFRP Sheet Reinforcement Effect

4.1. Effect of Initial Prestress on CFRP Sheets

4.2. Influence of Width and Space of Prestressed CFRP Sheets

4.3. Influence of Constraint Ratio of Prestressed CFRP Sheets

5. Conclusions

- In finite element analysis, the temperature reduction method can effectively simulate the application of prestress in structures. However, partial prestress loss may occur during the application process. By employing iterative calculations of a correction factor, the prestress loss can be minimized to achieve the target prestress level.

- Prestressed CFRP sheets can effectively strengthen large-scale reinforced concrete (RC) columns by improving the bonding performance with the structure, enhancing overall stiffness, reducing deformation, and increasing load-bearing capacity. As the initial prestress level increases, the ultimate bearing capacity of the structure also improves, with a maximum increase of up to 89.9%. In addition, prestressing helps mitigate the stress lag issue of CFRP sheets, enabling them to engage earlier during loading and enhancing both the stability and capacity of structural members.

- The wrapping method of CFRP sheets significantly affects the strengthening performance. At the same width and a prestress level of 0.2, reducing the wrapping spacing increases the ultimate bearing capacity by 21.8% to 50.4%. With constant spacing, increasing the width results in an enhancement of 38.7% to 58%. Full wrapping using continuous CFRP sheets can achieve up to a 73.2% increase in ultimate load capacity, although it involves significantly higher material consumption and cost.

- When the CFRP confinement ratio varies, the ultimate bearing capacity of specimens increases with higher confinement ratios, with an improvement range of 21.8% to 59.9%. Under the same confinement ratio, increasing both width and spacing leads to a reduction in capacity improvement from 44.5% to 35.3%. This indicates that the CFRP confinement ratio should be considered as a primary factor in selecting a strengthening scheme, with spacing and width optimized accordingly to determine the most effective and efficient design.

- This study recommends that future work should focus on experimental validation of the numerical results and investigate the long-term durability of prestressed CFRP-strengthened large-scale reinforced concrete structures to further advance the practical application of this technology in engineering.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ji, B.H.; Fu, Z.Q. Analysis of recent domestic bridge collapse accidents. J. Civ. Eng. 2010, 43, 495–498. [Google Scholar]

- Ye, L.; Feng, P. Applications and development of fiber-reinforced polymer in engineering structures. J. Civ. Eng. 2006, 39, 24–36. [Google Scholar]

- Zhang, K.P.; Jiang, Y.L.; Zeng, X.F. Development and prospects of bridge reinforcement. Highway 2005, 8, 299–301. [Google Scholar]

- Teng, J.G.; Chen, J.F.; Smith, S.T.; Lam, L. Behaviour and strength of FRP-strengthened RC structures: A state-of-the-art review. Proc. Inst. Civ. Eng.-Struct. Build. 2003, 156, 51–62. [Google Scholar] [CrossRef]

- Yue, Q.R.; Yang, Y.X. Introduction to durability of concrete strengthened with fiber reinforced polymers. J. Build. Struct. 2009, 30, 8–15. [Google Scholar]

- Yu, W.C.; Lei, Y.; Zhu, W.X.; Liu, L.; Ou, W.; Wu, W.D. Dynamic performance test of damaged RC beams repaired and reinforced by CFRP under impact load. Eng. Seismol. Strength. Reconstr. 2023, 45, 150–159. [Google Scholar]

- Zhang, X.Z.; Wen, L.X.; Li, X.Q.; Li, S.B.; Zhang, S.H. Seismic performance study of prefabricated concrete-filled steel tube composite short columns with earthquake damage strengthened by steel tube confinement and externally bonded carbon fiber fabric. J. Build. Struct. 2024, 45, 92–106. [Google Scholar]

- Editorial Board of Journal of China Highways. Overview of academic research on bridge engineering in China 2021. J. China Highw. 2021, 34, 1–97. [Google Scholar]

- Lu, C.L.; Wang, P.; Wang, Q. Study on axial compression behavior of concrete columns strengthened with prestressed CFRP sheets. Eng. Seismol. Strength. Reconstr. 2019, 41, 99–107+166. [Google Scholar]

- He, X.F.; Peng, H.; Luo, J. Engineering application and evaluation of externally applied prestressed carbon fiber panel technology for strengthening bridge structures. China Railw. Sci. 2007, 2, 139–144. [Google Scholar]

- Shang, S.P.; Peng, H.; Tong, H.; Wei, D.; Zeng, L. Study of strengthening reinforced concrete beam using prestressed carbon fiber sheet. J. Build. Struct. 2003, 24, 24–30. [Google Scholar]

- Yin, R.P.; Chi, E.J.; Wang, Z.H.; Pei, X.Q.; Zhong, C.C. Experimental research on anchorage position of reinforced concrete beams strengthened with CFRP. Bull. Silic. 2019, 38, 3675–3680+3686. [Google Scholar]

- Cheng, D.H.; Yang, Y.H. Research on axial compressive properties of preloaded concrete columns strengthened with prestressed CFRP sheets. J. Build. Sci. Eng. 2017, 34, 34–40. [Google Scholar]

- Zhou, C.; Qiu, Y.; Pan, Q. Experimental investigation of axial compressive behavior of large-scale circular concrete columns confined by prestressed CFRP strips. J. Struct. Eng. 2019, 145, 04019070. [Google Scholar] [CrossRef]

- Deng, Y.; Guo, Z.; Zhang, H.; Limkatanyu, S.; Sukontasukkul, P.; Yuen, T.Y.; Wong, S.H.; Hansapinyo, C.; Adom-Asamoah, M.; Shen, M.; et al. Experimental study on flexural behaviours of fresh or aged hollow reinforced concrete girders strengthened by prestressed CFRP plates. Eng. Struct. 2023, 294, 116776. [Google Scholar] [CrossRef]

- Kim, Y.J.; Shi, C.; Green, M.F. Ductility and cracking behavior of prestressed concrete beams strengthened with prestressed CFRP sheets. J. Compos. Constr. 2008, 12, 274–283. [Google Scholar] [CrossRef]

- Cheng, D.H.; Wang, X.T.; Fan, Y.X.; Chen, S.B. Research on mechanical properties of concrete columns with square section strengthened with CFRP strips. Build. Sci. 2021, 37, 105–112. [Google Scholar]

- Zhu, H.L.; Xu, R.T.; Liang, Y.H.; Liang, Y.; Yang, Q.; Chen, Z.P. Axial Compressive performance experimental study and finite element analysis on coral aggregate seawater sea-sand concrete columns confined with CFRP-PVC tube. Bull. Silic. 2024, 43, 891–904. [Google Scholar]

- Li, N.; Xia, Y.Y.; Li, W.P.; Li, S. Experimental study on axial compression behavior of reinforced concrete columns strengthened by combined FRP-ECC. J. Huazhong Univ. Sci. Technol. (Nat. Sci. Ed.) 2024, 52, 7–12. [Google Scholar]

- Zhang, F.; Ma, J.X.; Nan, Y. Parameters selection and verification calculation of concrete plastic damage model. Concr. Cem. Prod. 2021, 1, 7–11+29. [Google Scholar]

- Song, C.; Liu, J.; Ai, T.; Li, Z. The study on damage factors in concrete plastic damage model of ABAQUS. Eng. Constr. 2017, 49, 1–5. [Google Scholar]

- GB 50010-2010; Code for Design of Concrete Structures. Construction Industry Press: Beijing, China, 2010.

- Wang, Z.; Shen, S.; Cui, Y. Experimental analysis on size effect of axial compressive behavior for reinforced concrete columns strengthened with CFRP. J. Harbin Inst. Technol. 2020, 52, 112–120. [Google Scholar]

- Lu, C.L.; Lei, Z.X.; Guo, C.; Wang, Q. Influence of component performance on seismic behavior of bridge piers strengthened with prestressed CFRP. J. Railw. Sci. Eng. 2023, 20, 3437–3452. [Google Scholar]

| /MPa | /MPa | /MPa | /MPa | /MPa | /MPa |

|---|---|---|---|---|---|

| 3461 | 89 | 185 | 42 | 120 | 135 |

| /MPa | /MPa | /MPa | /MPa | /MPa | /MPa |

|---|---|---|---|---|---|

| 241,000 | 1000 | 0.28 | 4500 | 4500 | 3600 |

| Specimen Number | Sectional Dimension/mm | Height/mm | Thickness of the Protective Layer/mm | Longitudinal Reinforcement | Stirrup Spacing | Number of Plies CFRP | Chamfer Radius/mm |

|---|---|---|---|---|---|---|---|

| S1L1H2C | 200 × 200 | 600 | 15 | 8C8 | A6@133 | 1 | 32 |

| S2L2H2C | 400 × 400 | 1200 | 30 | 8C16 | A8@118 | 2 | 64 |

| S3L3H1C | 600 × 600 | 1800 | 45 | 8C25 | A10@123 | 3 | 96 |

| Species | Standard Value of Tensile Strength/MPa | Thickness of CFRP/mm | Elasticity Modulus/MPa |

|---|---|---|---|

| CFRP | 3461 | 0.167 | 2.41 × 105 |

| Bar Diameter/mm | Steel Bar Grade | Yield Strength/MPa | Ultimate Strength/MPa |

|---|---|---|---|

| 6 | HPB300 | 381 | 536 |

| 8 | HPB300 | 386 | 452 |

| Specimen Number | Width of CFRP/mm | Gap of CFRP/mm | Constraint Ratio | Prestressed Degree | Number of Plies CFRP |

|---|---|---|---|---|---|

| DBZ1 | 0 | 0 | 0 | 0 | 0 |

| DBZ2 | whole package | 0 | 1 | 0 | 3 |

| W1800-T0-0.1 | whole package | 0 | 1 | 0.1 | 3 |

| W1800-T0-0.2 | whole package | 0 | 1 | 0.2 | 3 |

| W1800-T0-0.25 | whole package | 0 | 1 | 0.25 | 3 |

| W100-T250-0.2 | 100 | 250 | 0.29 | 0.2 | 3 |

| W100-T200-0.2 | 100 | 200 | 0.33 | 0.2 | 3 |

| W100-T150-0.2 | 100 | 150 | 0.4 | 0.2 | 3 |

| W100-T100-0.2 | 100 | 100 | 0.5 | 0.2 | 3 |

| W150-T100-0.2 | 150 | 100 | 0.6 | 0.2 | 3 |

| W100-T60-0.2 | 100 | 60 | 0.63 | 0.2 | 3 |

| W260-T100-0.2 | 260 | 100 | 0.72 | 0.2 | 3 |

| W350-T100-0.2 | 350 | 100 | 0.78 | 0.2 | 3 |

| W45-T45-0.2 | 45 | 45 | 0.5 | 0.2 | 3 |

| W90-T90-0.2 | 90 | 90 | 0.5 | 0.2 | 3 |

| W120-T120-0.2 | 120 | 120 | 0.5 | 0.2 | 3 |

| W150-T150-0.2 | 150 | 150 | 0.5 | 0.2 | 3 |

| W180-T180-0.2 | 180 | 180 | 0.5 | 0.2 | 3 |

| Prestressed Degree | Target Prestress/MPa | Theoretical Temperature Drop Value/°C | Actual Prestressed Value P2/MPa | Prestress Difference ∆P1/MPa | Error Before Correction/% | Correction Factor c | The Corrected Temperature Drop Value/°C | Modified Prestress/MPa | The Corrected Prestress Difference/MPa | Corrected Error/% |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.1 | 346.1 | −2051.6 | 322.4 | 23.7 | 6.8 | 1.07 | −2109.5 | 345.9 | 0.2 | 0.05 |

| 0.2 | 692.2 | −4103.1 | 644.8 | 47.4 | 6.8 | 1.07 | −4326.9 | 692.0 | 0.2 | 0.02 |

| 0.25 | 865.3 | −5129.2 | 804.1 | 61.2 | 7.1 | 1.08 | −5484.4 | 863.2 | 2.1 | 0.24 |

| 0.3 | 1038.3 | −6154.7 | 968.2 | 70.1 | 6.8 | 1.07 | −6585.5 | 1036.9 | 1.45 | 0.14 |

| 0.4 | 1384.4 | −8206.3 | 1290.2 | 94.2 | 6.8 | 1.07 | −8780.7 | 1384.2 | 0.2 | 0.01 |

| Specimen No. | Yield Load/103 KN | Yield Load Increase Range/% | Ultimate Load/103 KN | Limit Load Increase Range/% |

|---|---|---|---|---|

| DBZ1 | 8.9 | / | 11.9 | / |

| DBZ2 | 9.8 | 10.1 | 14.4 | 21.0 |

| W1800-T0-0.1 | 12.8 | 43.8 | 17.3 | 45.4 |

| W1800-T0-0.2 | 16.1 | 80.9 | 20.6 | 73.1 |

| W1800-T0-0.25 | 16.8 | 88.8 | 22.6 | 89.9 |

| W100-T250-0.2 | 11.2 | 25.8 | 14.5 | 21.8 |

| W100-T200-0.2 | 11.3 | 27.0 | 14.9 | 25.2 |

| W100-T150-0.2 | 12.3 | 38.2 | 15.6 | 31.1 |

| W100-T100-0.2 | 13.3 | 49.4 | 16.5 | 38.7 |

| W150-T100-0.2 | 13.4 | 50.6 | 17.4 | 46.2 |

| W100-T60-0.2 | 14.5 | 62.9 | 17.9 | 50.4 |

| W260-T100-0.2 | 14.3 | 60.7 | 18.2 | 52.9 |

| W350-T100-0.2 | 14.5 | 62.9 | 18.8 | 58.0 |

| W45-T45-0.2 | 13.2 | 48.3 | 17.1 | 43.7 |

| W90-T90-0.2 | 11.6 | 30.3 | 16.7 | 40.3 |

| W120-T120-0.2 | 13.1 | 47.2 | 16.5 | 38.7 |

| W150-T150-0.2 | 12.2 | 37.1 | 16.4 | 37.8 |

| W180-T180-0.2 | 12.5 | 40.4 | 16.1 | 35.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, Y.; Teng, Y.; Li, X.; Liu, J.; Lu, C.; Zhang, C. The Analysis of Axial Compression Performance of Reinforced Concrete Columns Strengthened with Prestressed Carbon Fiber Sheets. Infrastructures 2025, 10, 210. https://doi.org/10.3390/infrastructures10080210

Lv Y, Teng Y, Li X, Liu J, Lu C, Zhang C. The Analysis of Axial Compression Performance of Reinforced Concrete Columns Strengthened with Prestressed Carbon Fiber Sheets. Infrastructures. 2025; 10(8):210. https://doi.org/10.3390/infrastructures10080210

Chicago/Turabian StyleLv, Yiquan, Yang Teng, Xing Li, Junli Liu, Chunling Lu, and Cheng Zhang. 2025. "The Analysis of Axial Compression Performance of Reinforced Concrete Columns Strengthened with Prestressed Carbon Fiber Sheets" Infrastructures 10, no. 8: 210. https://doi.org/10.3390/infrastructures10080210

APA StyleLv, Y., Teng, Y., Li, X., Liu, J., Lu, C., & Zhang, C. (2025). The Analysis of Axial Compression Performance of Reinforced Concrete Columns Strengthened with Prestressed Carbon Fiber Sheets. Infrastructures, 10(8), 210. https://doi.org/10.3390/infrastructures10080210