Comprehensive Substantiation of the Impact of Pre-Support Technology on a 50-Year-Old Subway Station During the Construction of Undercrossing Tunnel Lines

Abstract

1. Introduction

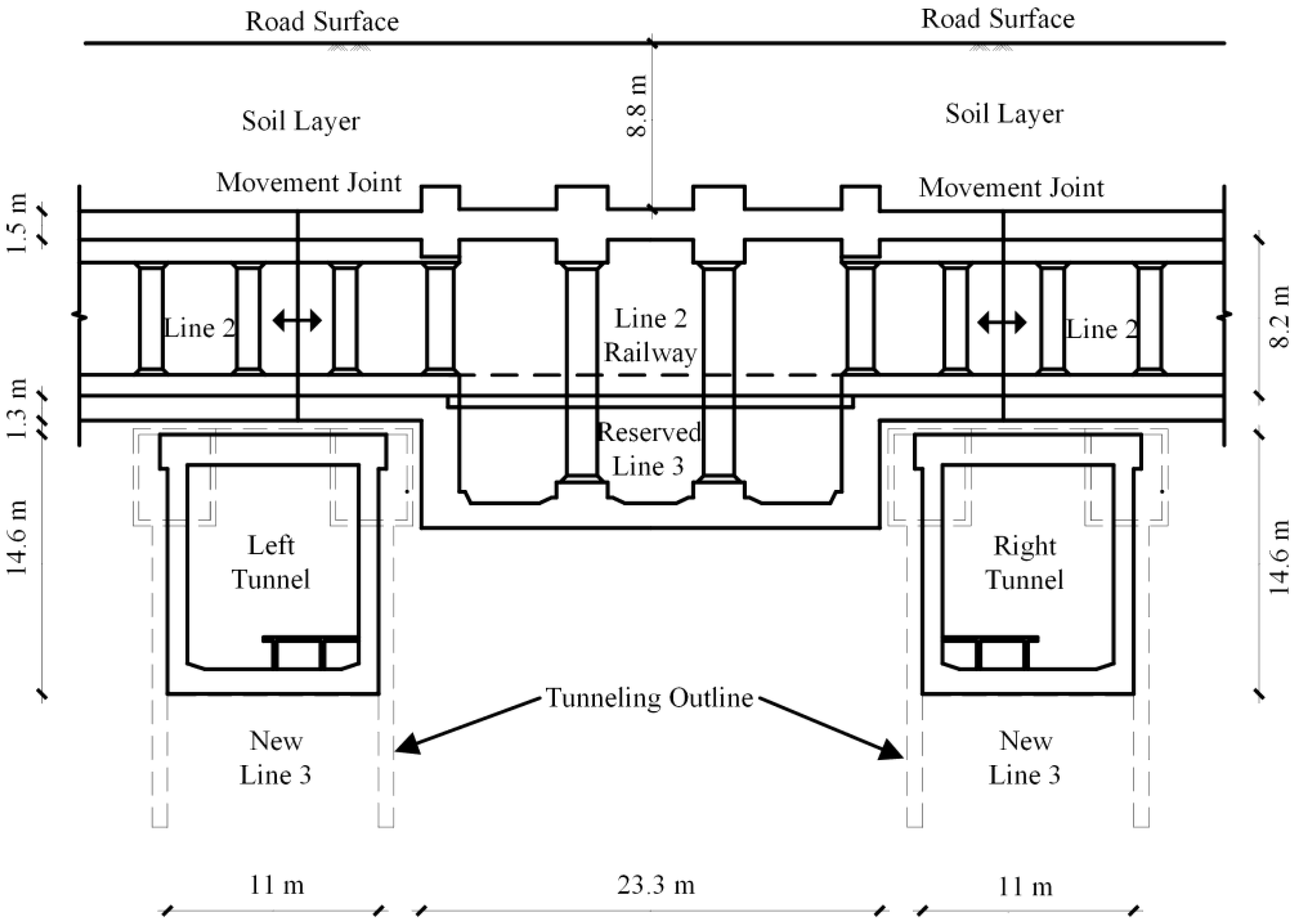

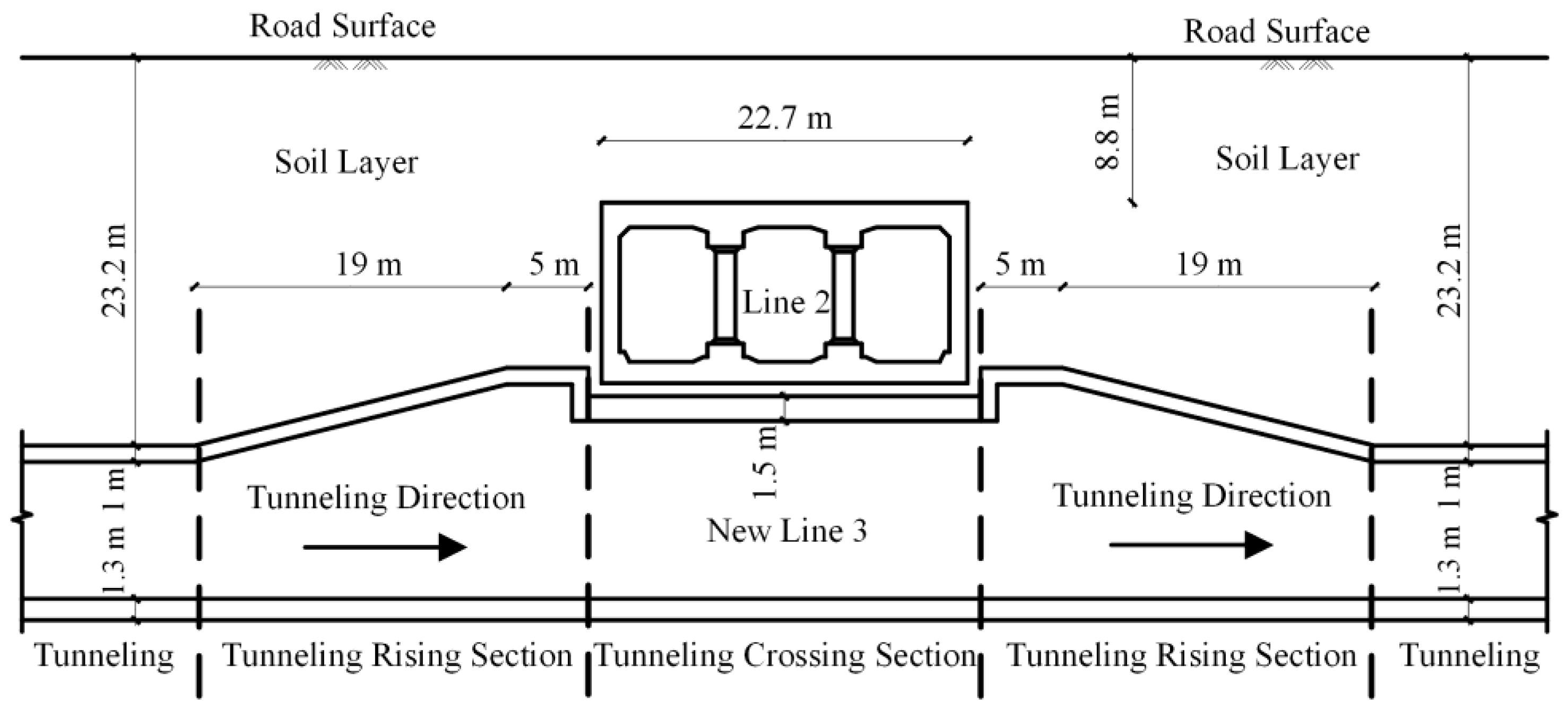

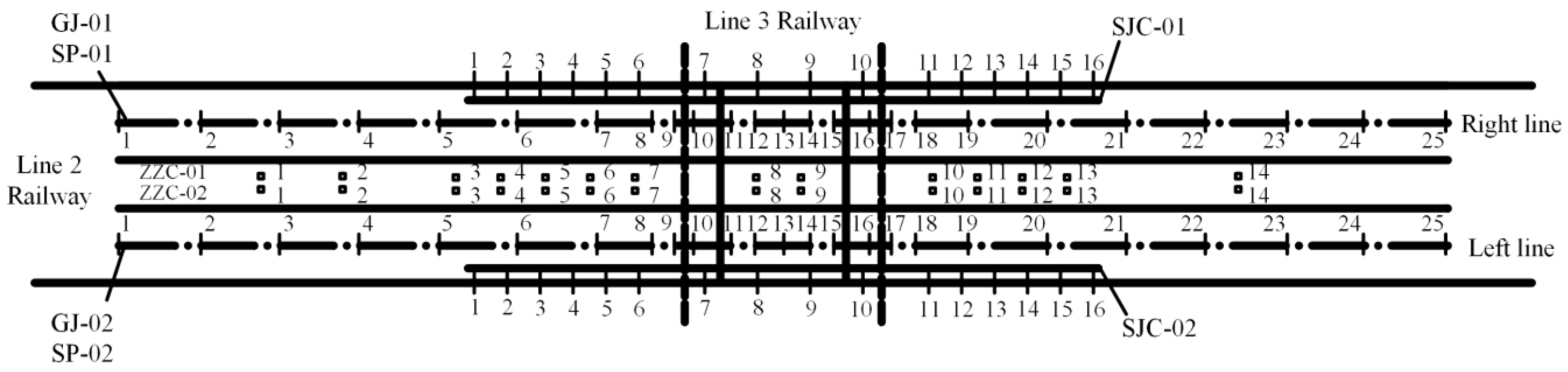

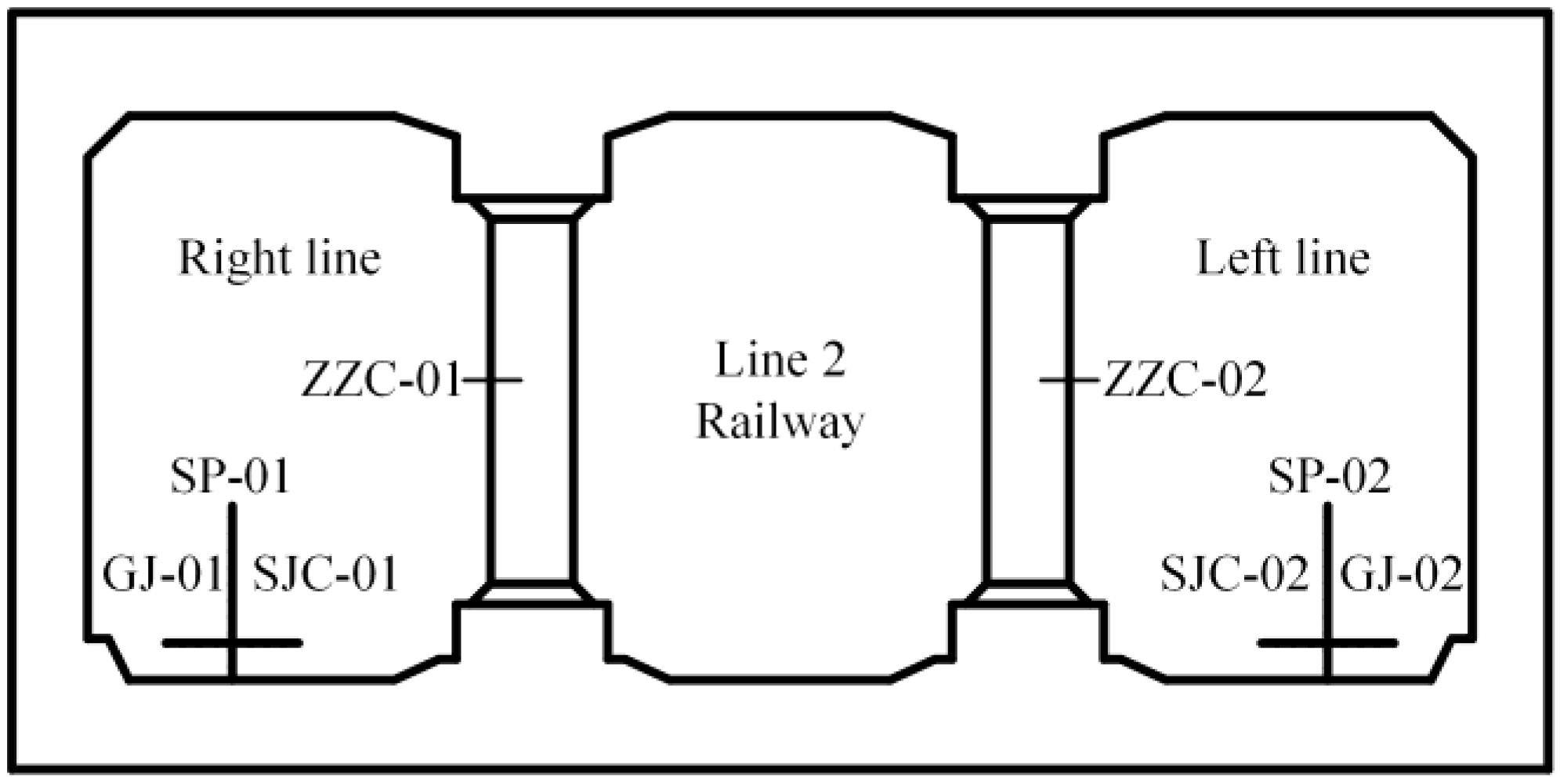

2. Research Background

2.1. Prototype Tunnel

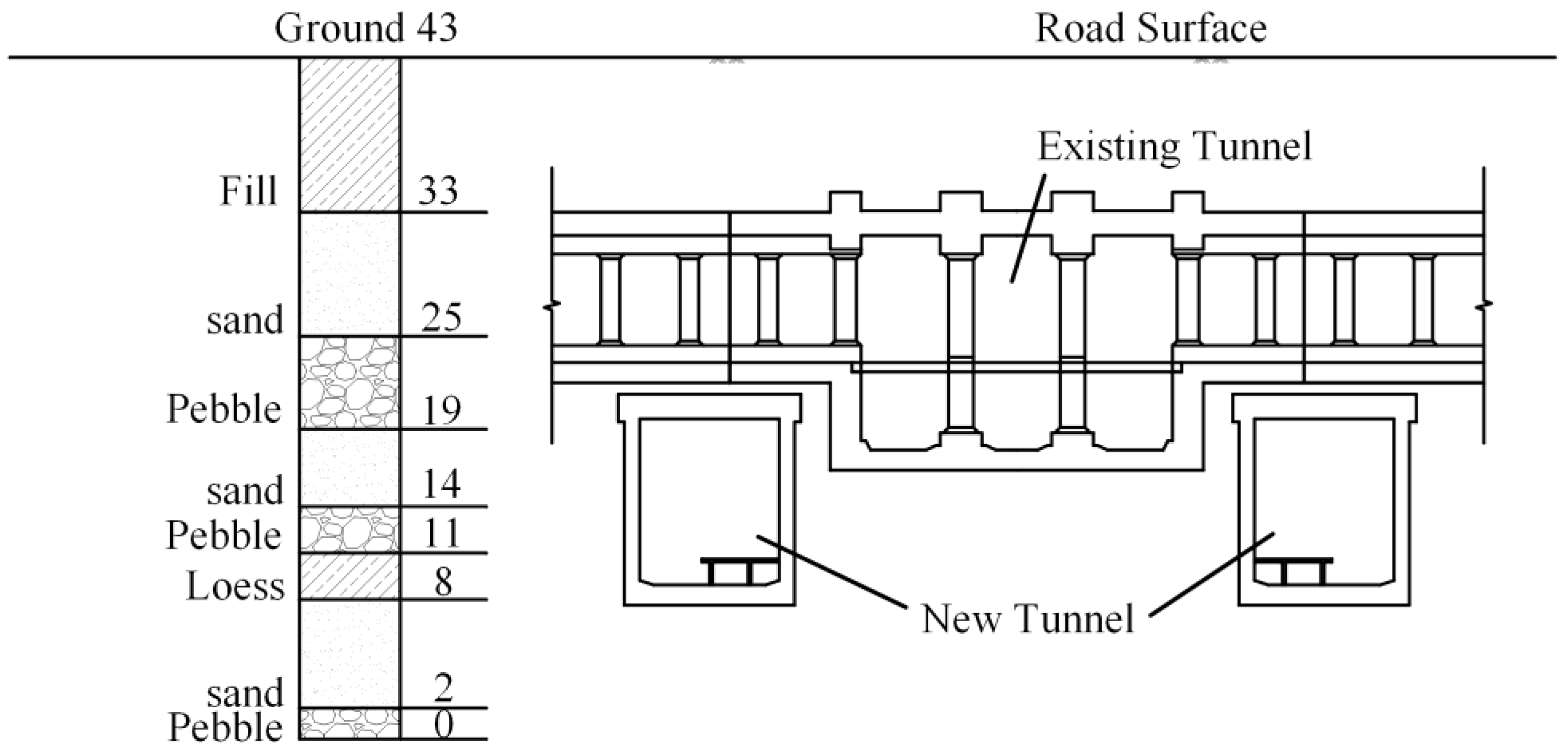

2.2. Geological Conditions

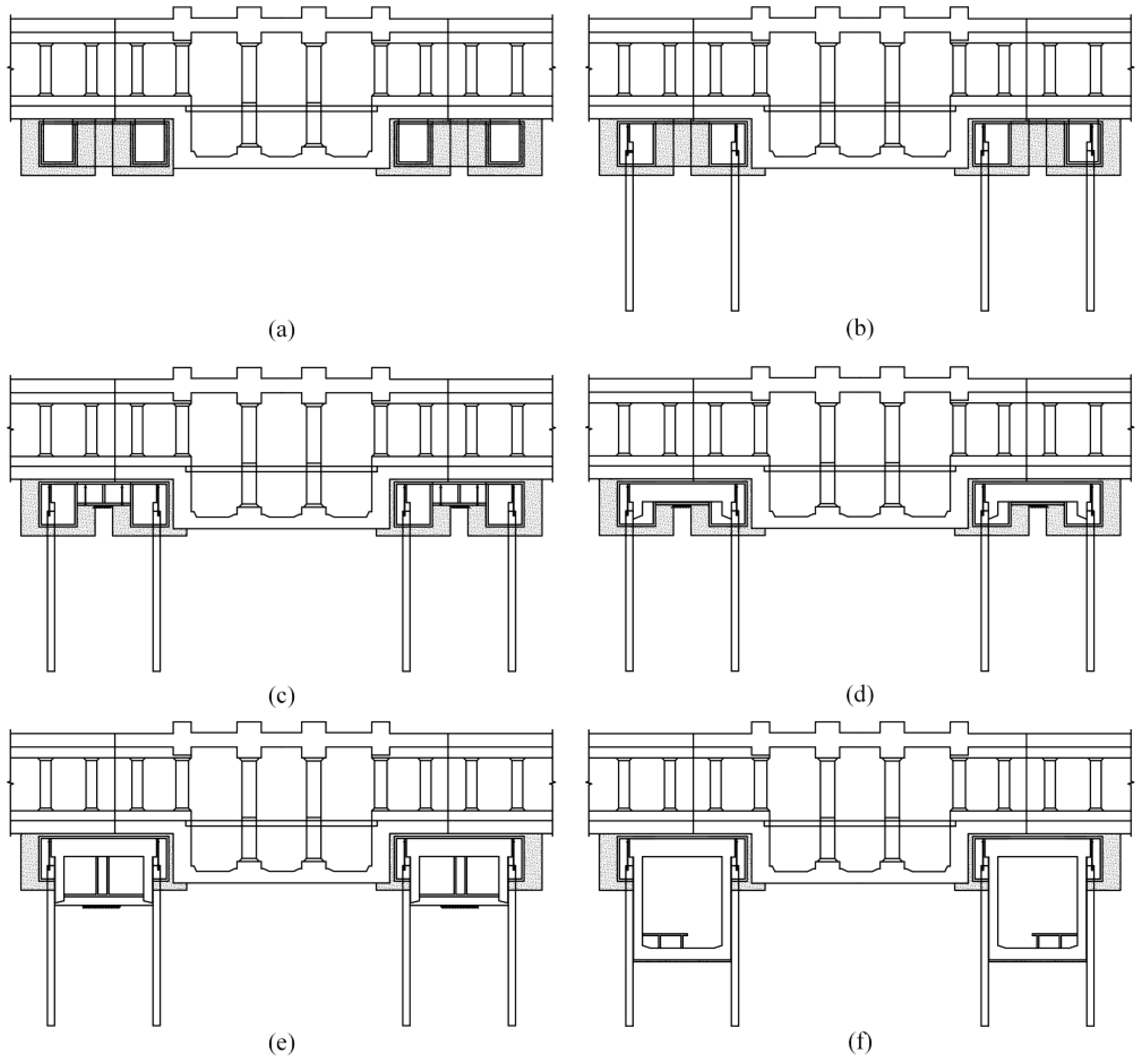

2.3. Construction Process

- (a)

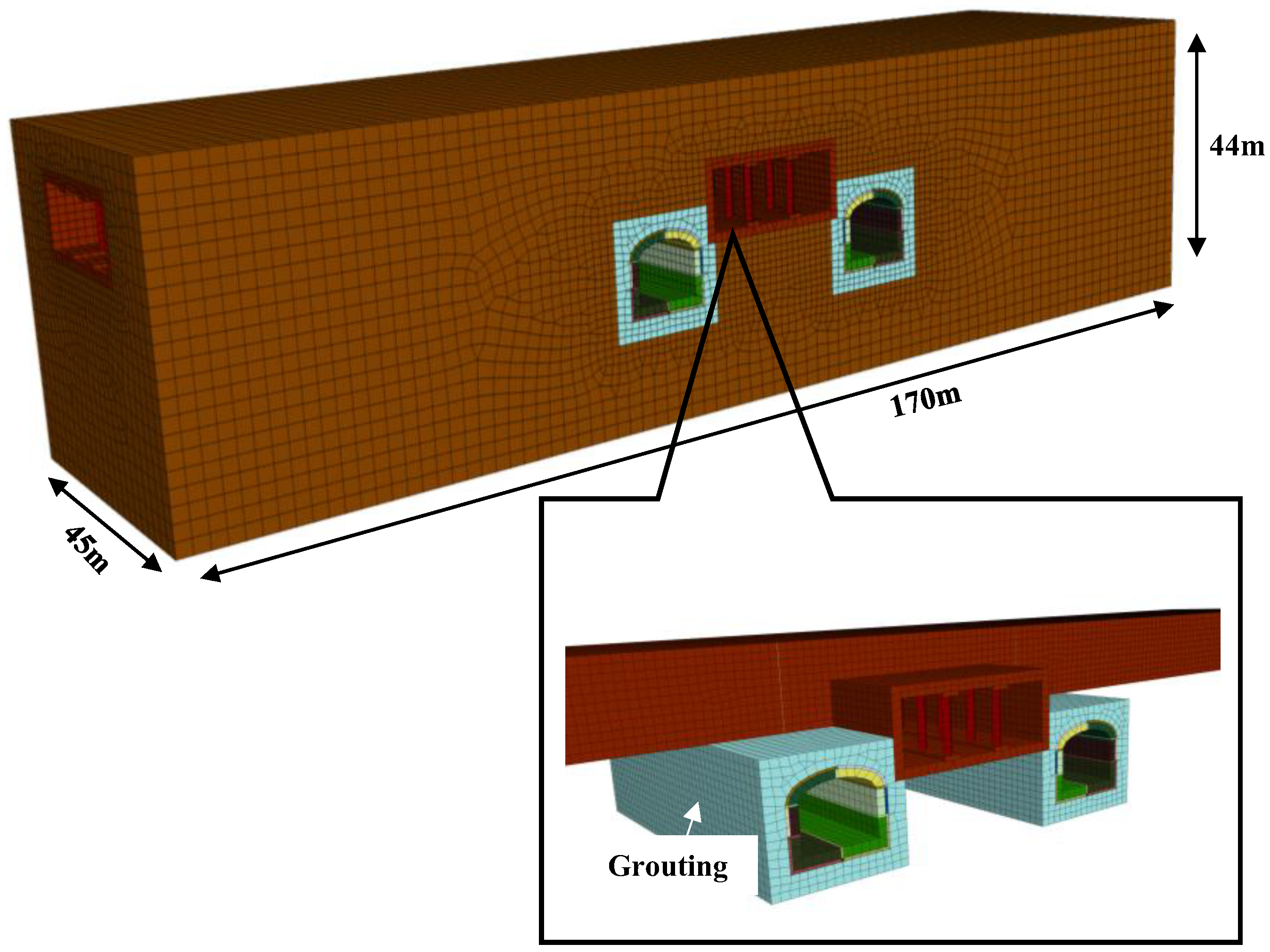

- The excavation face is reinforced by grouting in this method, and the symmetrical pilot tunnel is constructed by the bench method. After the construction of the pilot tunnel is completed, the back of the pilot tunnel should be grouted to ensure that the roof of the pilot tunnel is closely attached to the floor of the existing Line 2.

- (b)

- Bored piles are constructed in the pilot tunnel, and jacks are set on the top of the pile to support the top of the pilot tunnel. Concrete support is applied to grout the back and top of the support to increase the connection (Figure 7).

- (c)

- Excavate the middle guide hole and use the step method to excavate. After the initial support of the construction is completed, the jack is applied.

- (d)

- The roof and waterproof layer of the new tunnel are constructed.

- (e)

- The side wall and waterproof layer of the new tunnel are constructed.

- (f)

- The floor and waterproof layer of the new tunnel are constructed, and the construction of the main structure of the station is completed.

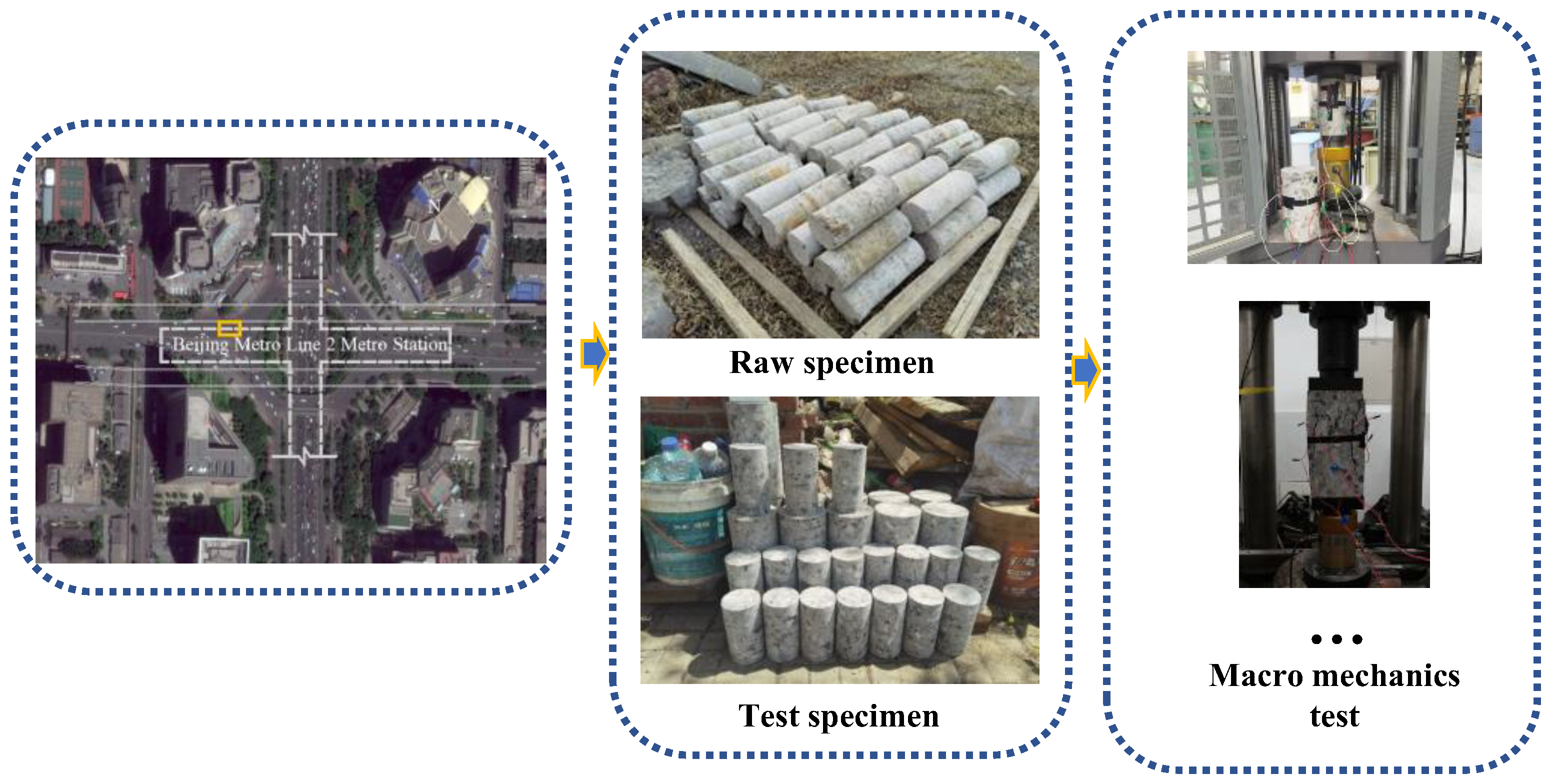

3. Field Test

3.1. Monitoring Scheme

3.2. Monitoring Results and Analysis

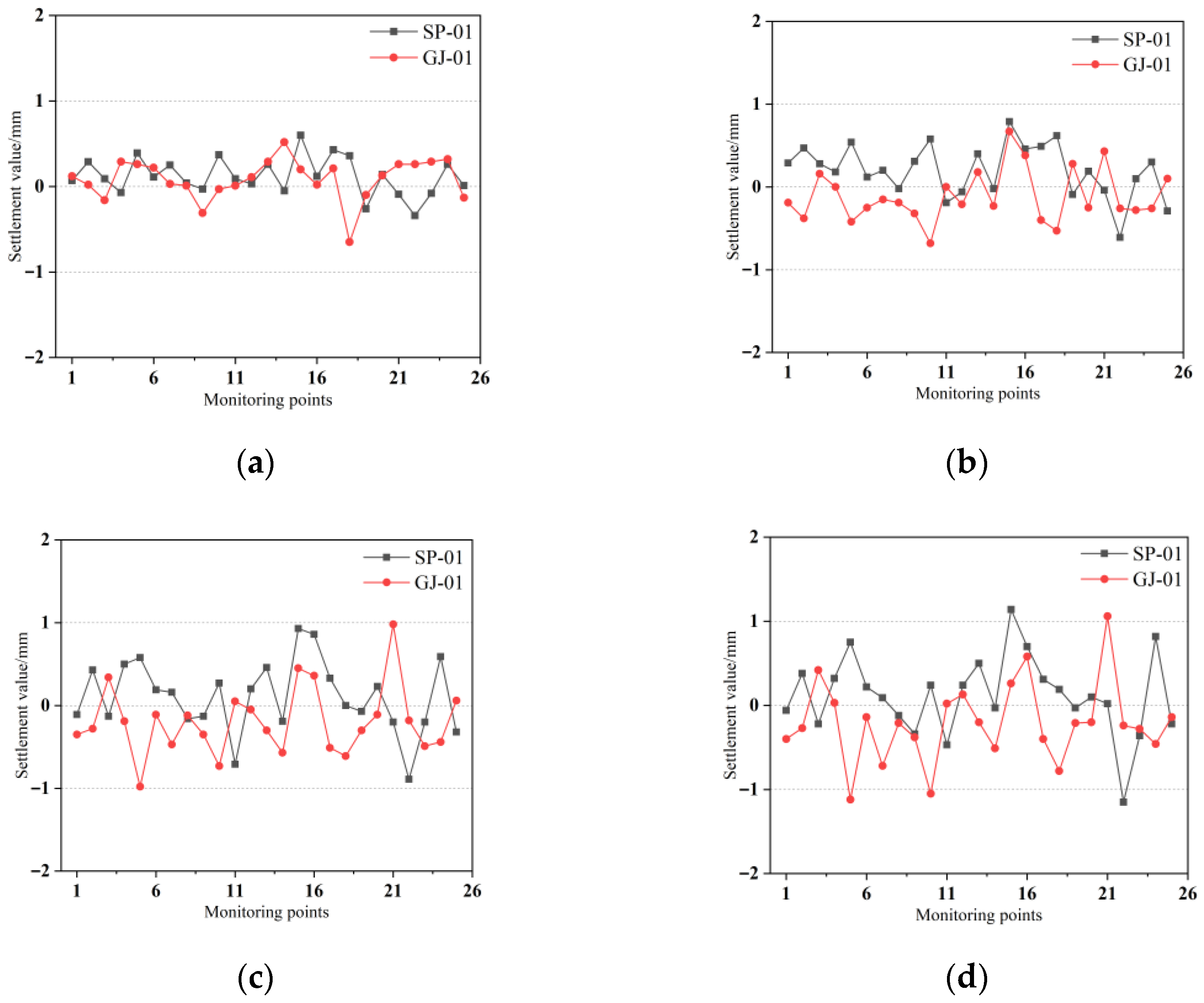

3.2.1. Track Spacing and Track Level

3.2.2. Floor and Load-Bearing Column

4. Simulation Methods and Materials

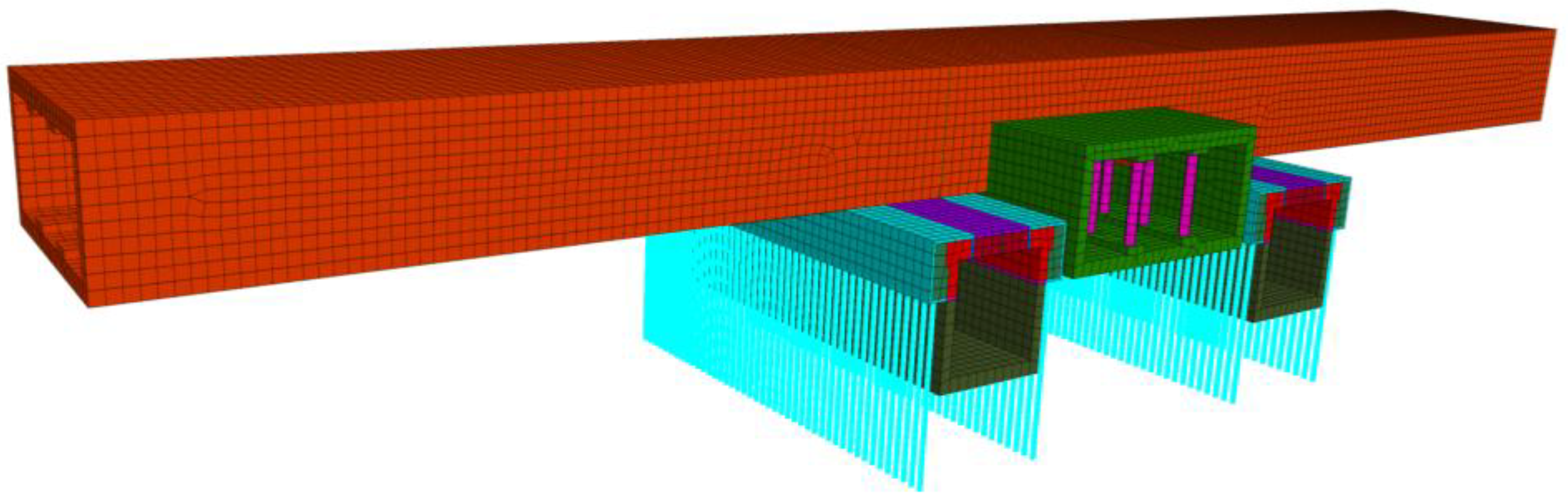

4.1. Finite Difference Model

4.2. Material and Parameters

4.3. Construction Schemes

5. Simulation Results and Analysis

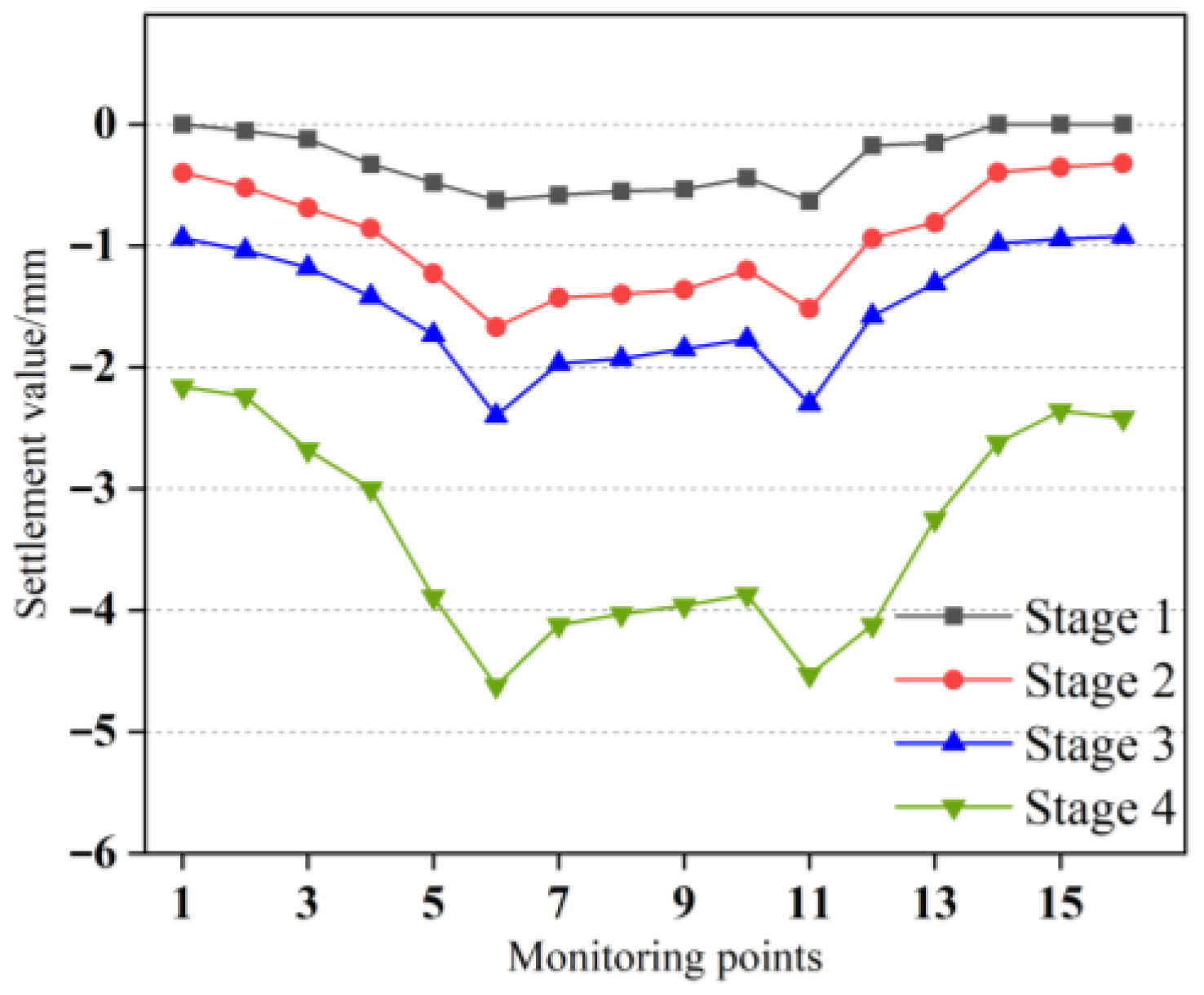

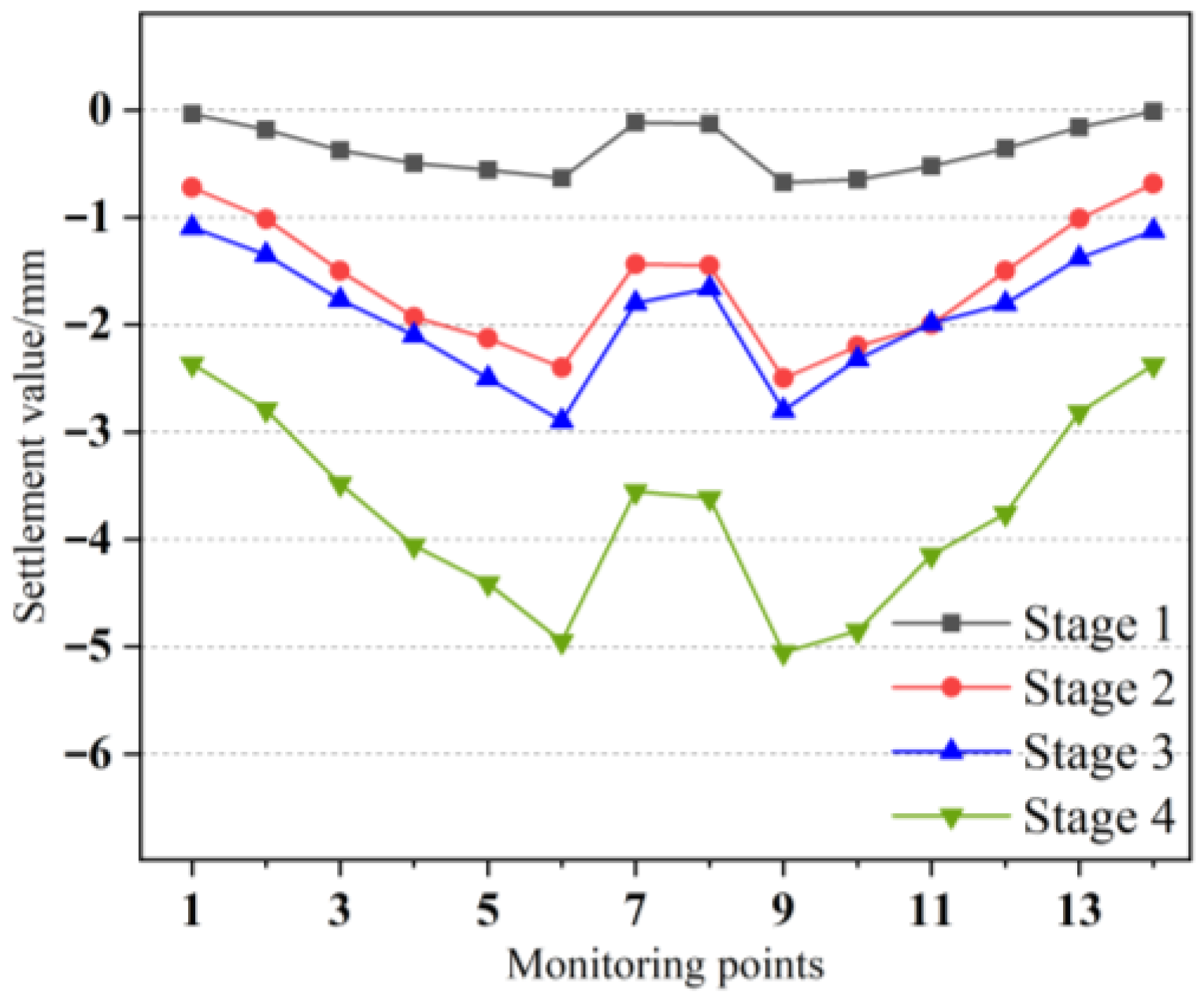

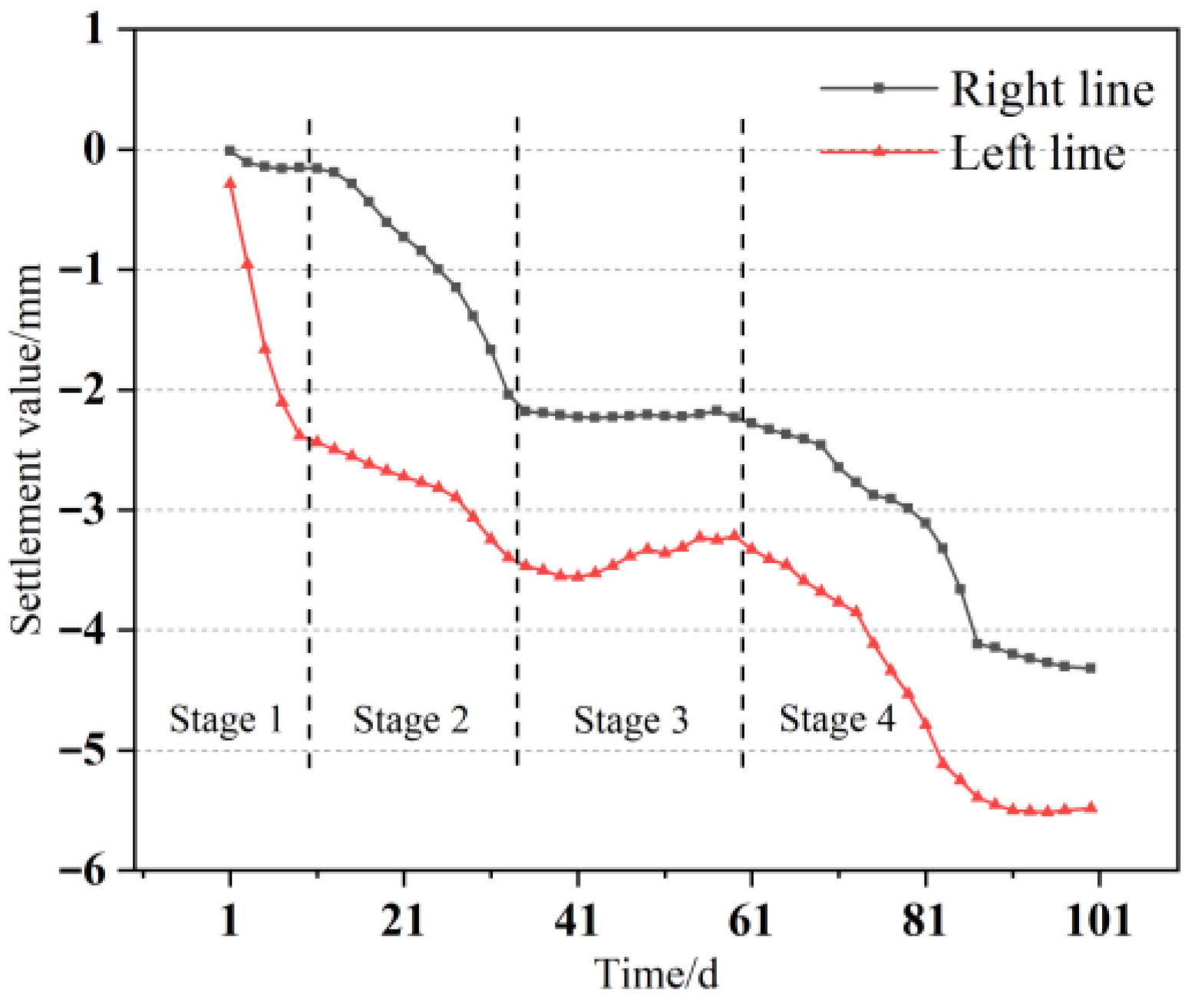

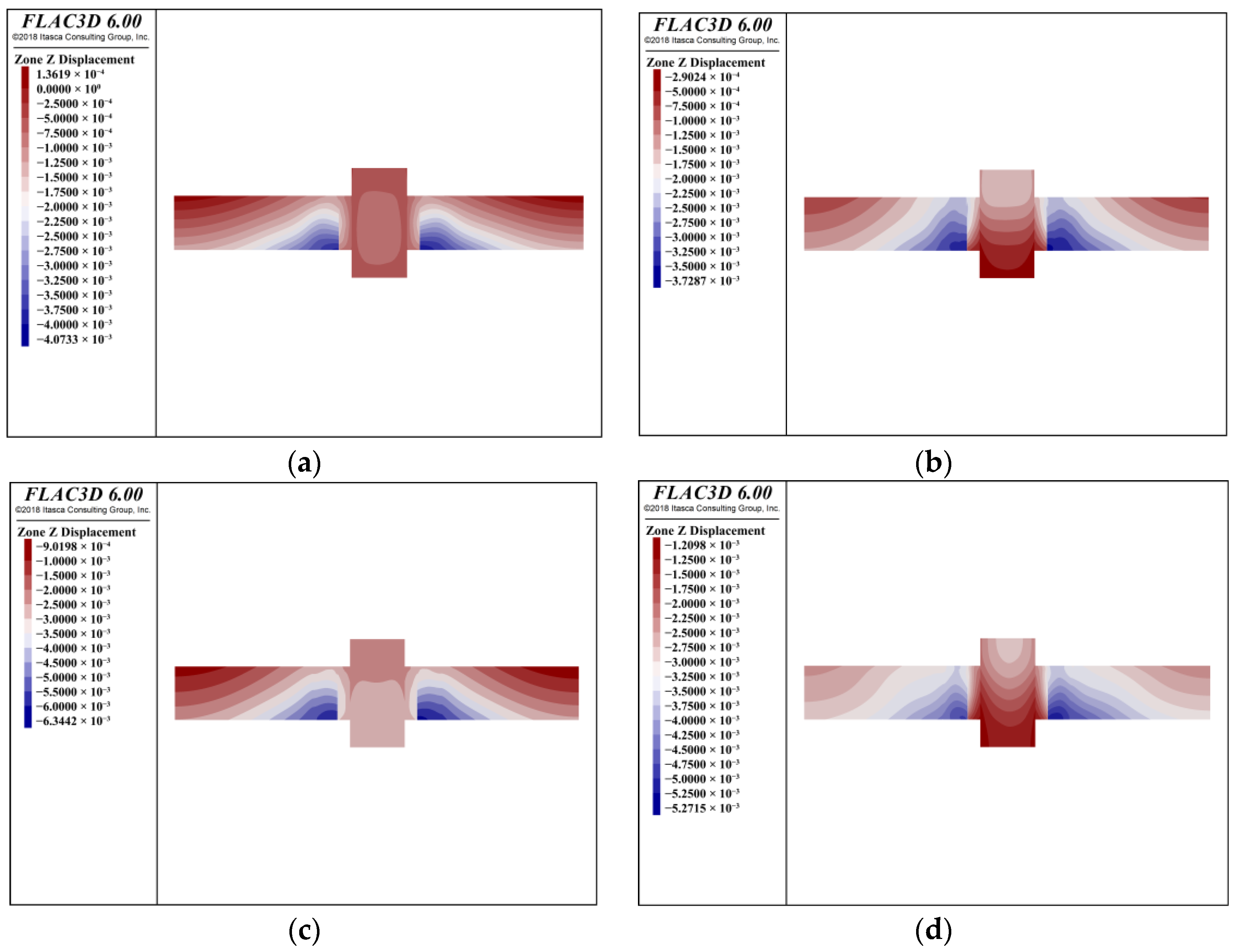

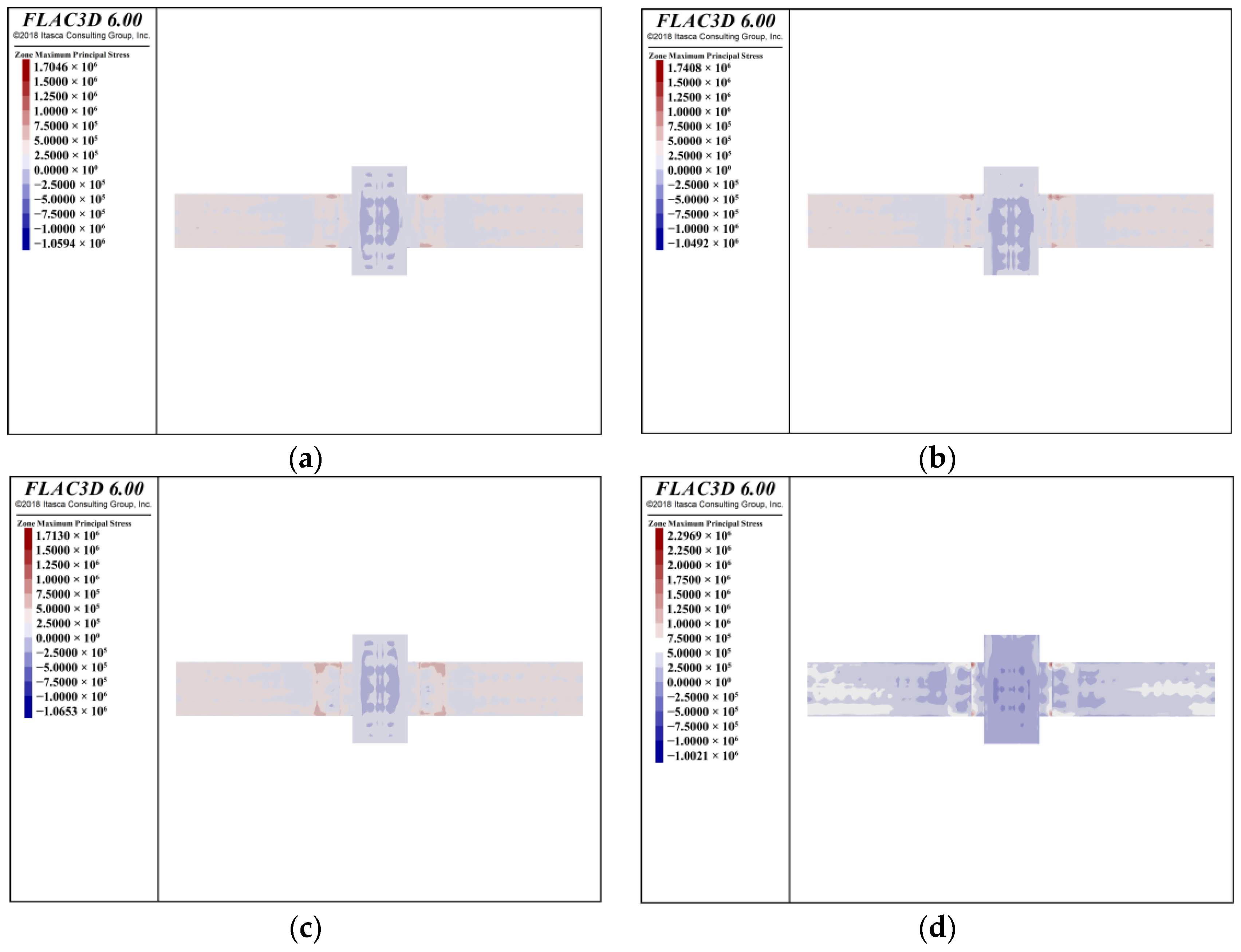

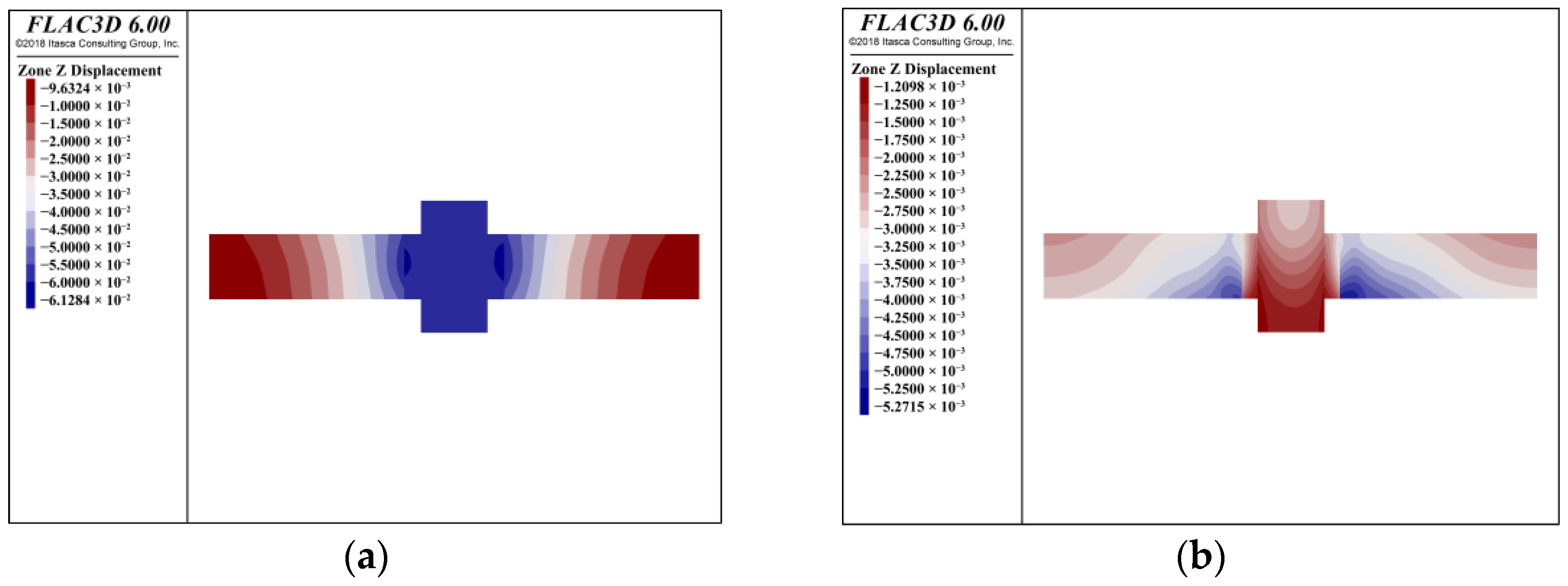

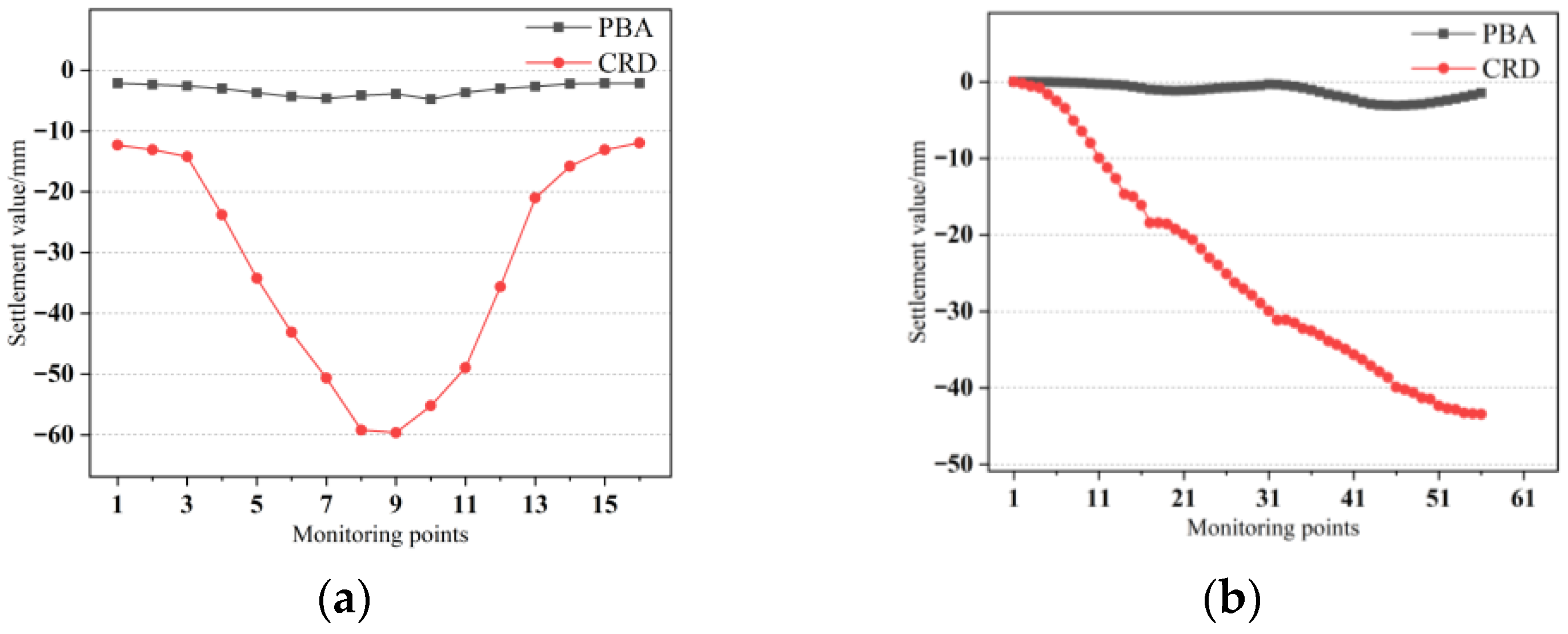

5.1. Settlement and Stress Analysis of the Existing Subway Line 2 Structure

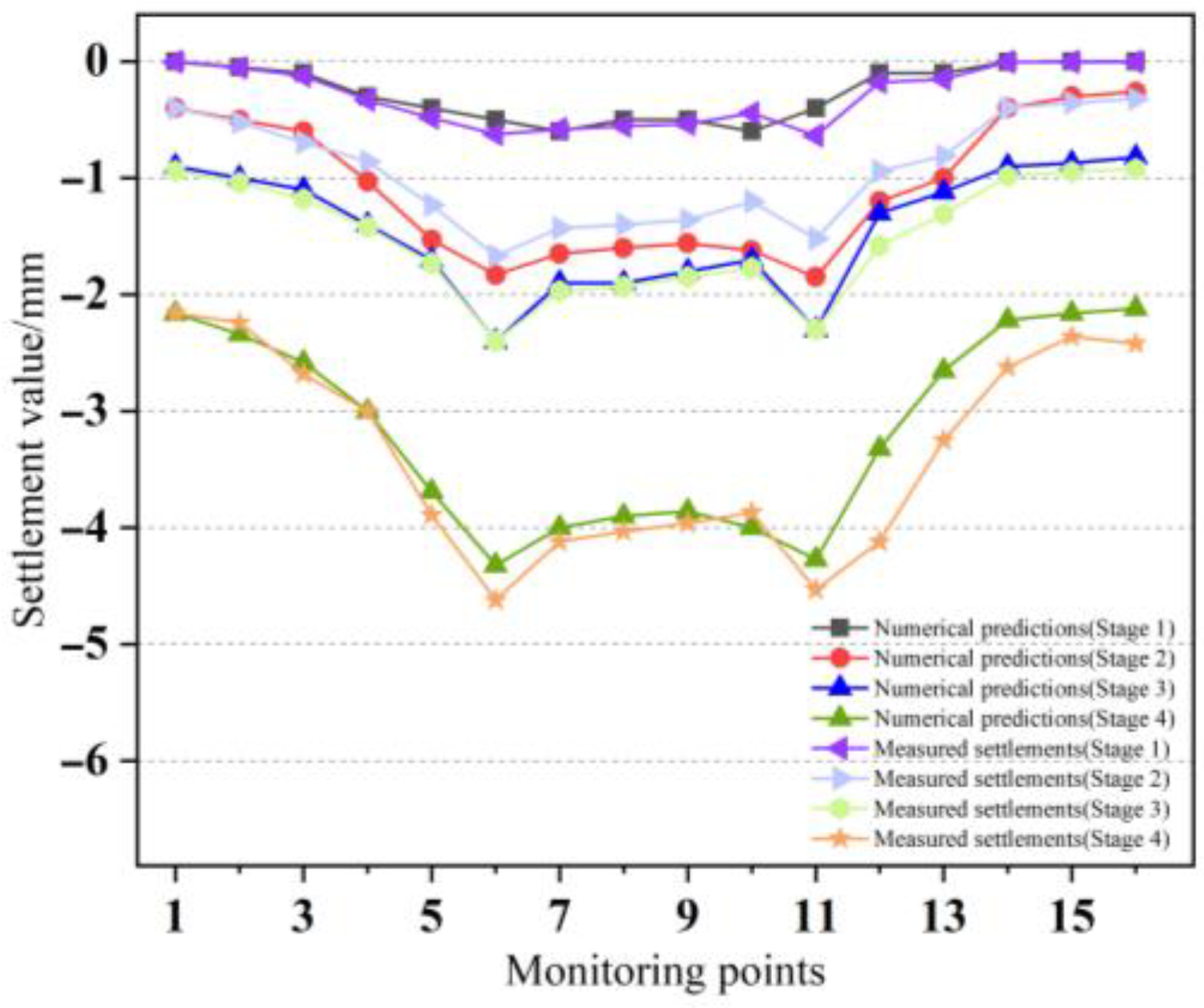

5.2. Comparison Between Field Tests and Simulation

5.3. Comparison of Settlement and Stress of the Existing Line 2 by Different Construction Methods

6. Discussion

- (1)

- The on-site monitoring of tracks and the existing Line 2 station structure during construction demonstrates that the pre-support technology effectively controls the disturbance to the structure caused by under-passing excavation, without inducing significant deformation. The numerical simulation of the construction process shows that the pre-support technology can effectively control the stress variation of structures without generating significant tensile and compressive stresses, thus keeping the structures within the elastic deformation range.

- (2)

- The differences in construction techniques and conditions lead to the fact that existing studies fail to achieve direct contact control over existing structures, thus causing significant soil disturbance during excavation and resulting in substantial deformation of existing structures. The pre-support technology, through the supporting action of bored piles and jacks, provides direct contact support to existing structures, offering more stable support than other construction methods and better controlling the displacement and stress variations of existing structures. The monitoring data of on-site displacement are affected by underground construction, while the numerical model only discusses the influence of the underpass construction process on the existing subway structure and does not consider the influence of other underground construction on the existing subway structure, which needs further study.

- (3)

- The comparative study on the impact of different construction methods on the existing Line 2 structure shows that the pre-support technology has obvious advantages over the commonly used CRD method, resulting in less displacement deformation and smaller stress variations in the existing Line 2. During the construction process, in the process of pilot tunnel excavation, pile foundation construction, and jack placement, the interval time between the processes should be minimized to ensure that the pile foundation and the jack are closely connected with the existing subway structure floor and ensure that the pile foundation is used as the support point to control the deformation of the subway structure.

7. Conclusions

- (1)

- The construction method in this paper controls the settlement of existing tunnels through cast-in-place piles, jacks, and crown beams, which is an effective measure to reduce stratum loss and stabilize the settlement of existing tunnels. The settlement deformation of the existing subway station is controlled within 1~3 cm, and the deformation stress is within the concrete strength range of existing structures, with the maximum tensile stress less than 3 MPa.

- (2)

- The settlement curve of the existing Line 2 floor jumps at the deformation joint. In addition, the section of the existing Line 2 affected by the new tunnel is mainly tilted as a rigid body because its stiffness is higher than that of the surrounding soil. The construction method proposed in this paper causes minimal impact on the deformation displacement of operational stations and slight changes in the smoothness of the subway rail surface. The fluctuation range basically remains within −1 to 1 mm, ensuring the safety of existing subway operations.

- (3)

- In terms of the deformation control of the existing station structure, the settlement and stress changes of the existing Subway Line 2 under the dross diaphragm (CRD) method are greater than those of the pre-supporting technical method, which has a greater impact on the existing structure during the construction stage. The maximum settlement and maximum tensile stress of the station in the cross diaphragm (CRD) method scheme are −61.28 mm and 2.47 MPa, respectively. The maximum settlement and maximum tensile stress of the station in the pre-support jacking scheme are −5.27 mm and 2.29 MPa, respectively. As a construction scheme, the pre-support technology has less influence on the structural deformation.

- (4)

- In this paper, by improving the PBA method, the settlement of the existing subway structure is reduced by increasing the support of the existing subway structure during the construction process. The application of this reinforcement measure in tunnel engineering in Beijing is the first time.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gao, G.; Zhuang, Y.; Wang, K.; Chen, L. Influence of Benoto Bored Pile Construction on Nearby Existing Tunnel: A Case Study. Soils Found. 2019, 59, 544–555. [Google Scholar] [CrossRef]

- Meng, F.; Chen, R.; Xu, Y.; Wu, K.; Wu, H.; Liu, Y. Contributions to Responses of Existing Tunnel Subjected to Nearby Excavation: A Review. Tunn. Undergr. Space Technol. 2022, 119, 104195. [Google Scholar] [CrossRef]

- Zhou, F.; Zhou, P.; Li, J.; Lin, J.; Ge, T.; Deng, S.; Ren, R.; Wang, Z. Deformation Characteristics and Failure Evolution Process of the Existing Metro Station under Unilateral Deep Excavation. Eng. Fail. Anal. 2022, 131, 105870. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, P.; Yan, X.; Zhao, X. Middle Displacement Monitoring of Medium–Small Span Bridges Based on Laser Technology. Struct. Control Health Monit. 2020, 27, e2509. [Google Scholar] [CrossRef]

- Nematollahi, M.; Molladavoodi, H.; Dias, D. Three-Dimensional Numerical Simulation of the Shiraz Subway Second Line—Influence of the Segmental Joints Geometry and of the Lagging Distance between Twin Tunnels’ Faces. Eur. J. Environ. Civ. Eng. 2020, 24, 1606–1622. [Google Scholar] [CrossRef]

- Cai, Q.; Hu, Q.; Ma, G. Improved Hybrid Reasoning Approach to Safety Risk Perception under Uncertainty for Mountain Tunnel Construction. J. Constr. Eng. Manag. 2021, 147, 04021105. [Google Scholar] [CrossRef]

- Yin, Y.; Wang, J.; Zou, B.; Zhang, J.; Su, Y.; Sun, Q. Evaluation of Controlled Blasting Quality for Rock-Mass Tunneling Based on Multiple Indices. J. Constr. Eng. Manag. 2023, 149, 04022155. [Google Scholar] [CrossRef]

- Ding, Z.; Zhang, M.-B.; Zhang, X.; Wei, X.-J. Theoretical Analysis on the Deformation of Existing Tunnel Caused by Under-Crossing of Large-Diameter Slurry Shield Considering Construction Factors. Tunn. Undergr. Space Technol. 2023, 133, 104913. [Google Scholar] [CrossRef]

- Guo, X.; Jiang, A. Study on the Stability of a Large-Span Subway Station Constructed by Combining with the Shaft and Arch Cover Method. Tunn. Undergr. Space Technol. 2022, 127, 104582. [Google Scholar] [CrossRef]

- Xu, X.; Li, Z.; Fang, Q.; Zheng, H. Challenges and Countermeasures for Using Pile-Beam-Arch Approach to Enlarge Large-Diameter Shield Tunnel to Subway Station. Tunn. Undergr. Space Technol. 2020, 98, 103326. [Google Scholar] [CrossRef]

- Fang, Q.; Liu, X.; Zeng, K.; Zhang, X.; Zhou, M.; Du, J. Centrifuge Modelling of Tunnelling below Existing Twin Tunnels with Different Types of Support. Undergr. Space 2022, 7, 1125–1138. [Google Scholar] [CrossRef]

- Chang, J.; Huang, H.; Zhang, D.; Wu, H.; Yan, J. Transverse Deformational Behaviors of Segmental Lining during Shield Tunneling: A Case Study. Struct. Control Health Monit. 2022, 29, e3097. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, K.; Yang, J.; Fu, J.; Wang, S.; Xie, Y. Reuse of Discharged Soil from Slurry Shield Tunnel Construction as Synchronous Grouting Material. J. Constr. Eng. Manag. 2022, 148, 04021193. [Google Scholar] [CrossRef]

- Zhou, M.; Su, X.; Chen, Y.; An, L. New Technologies and Challenges in the Construction of the Immersed Tube Tunnel of the Hong Kong-Zhuhai-Macao Link. Struct. Eng. Int. 2022, 32, 455–464. [Google Scholar] [CrossRef]

- Quan, X.J.; Gao, J.H.; Wang, B.; Xu, J.H.; Zhang, Q.Z. Damage Mechanisms of Soft Rock Tunnels in the Western China: A Case Study on the Dujiashan Tunnel. Struct. Eng. Int. 2022, 32, 369–377. [Google Scholar] [CrossRef]

- Wang, F.; Shi, J.; Huang, H.; Zhang, D.; Liu, D. A Horizontal Convergence Monitoring Method Based on Wireless Tilt Sensors for Shield Tunnels with Straight Joints. Struct. Infrastruct. Eng. 2021, 17, 1194–1209. [Google Scholar] [CrossRef]

- Jin, D.; Yuan, D.; Ng, Y.C.H.; Pan, Y. Effect of an Undercrossing Tunnel Excavation on an Existing Tunnel Considering Nonlinear Soil-Tunnel Interaction. Tunn. Undergr. Space Technol. 2022, 130, 104571. [Google Scholar] [CrossRef]

- Weng, X.; Yu, H.; Niu, H.; Hu, J.; Han, W.; Huang, X. Interactive Effects of Crossing Tunnel Construction on Existing Tunnel: Three-Dimensional Centrifugal Test and Numerical Analyses. Transp. Geotech. 2022, 35, 100789. [Google Scholar] [CrossRef]

- Yu, J.; Li, H.; Huang, M.; Li, Y.; Tan, J.Q.W.; Guo, Y. Timoshenko-Beam-Based Response of Existing Tunnel to Single Tunneling underneath and Numerical Verification of Opening and Dislocation. Comput. Geotech. 2022, 147, 104757. [Google Scholar] [CrossRef]

- Gan, X.; Yu, J.; Gong, X.; Liu, N.; Zheng, D. Behaviours of Existing Shield Tunnels Due to Tunnelling underneath Considering Asymmetric Ground Settlements. Undergr. Space 2022, 7, 882–897. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, J.; Chen, B.; Lu, G. The Influence of the Underpassing Frozen Connecting Passage on the Deformation of the Existing Tunnel. Res. Cold Arid Reg. 2022, 14, 258–266. [Google Scholar] [CrossRef]

- Fu, C.; Gao, Y. Numerical Analysis on the Behavior of Existing Tunnels Subjected to the Undercrossed Shield Tunneling at a Small Proximity. Adv. Civ. Eng. 2020, 2020, 8823331. [Google Scholar] [CrossRef]

- Zhou, Z.; Chen, Y.; Liu, Z.; Miao, L. Theoretical Prediction Model for Deformations Caused by Construction of New Tunnels Undercrossing Existing Tunnels Based on the Equivalent Layered Method. Comput. Geotech. 2020, 123, 103565. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, G.; Tang, C.; Wang, S.; Wang, K.; Wang, T. Influence of Undercrossing Tunnel Excavation on the Settlement of a Metro Station in Dalian. Bull. Eng. Geol. Environ. 2021, 80, 4673–4687. [Google Scholar] [CrossRef]

- Li, J.; Fang, Q.; Liu, X.; Du, J.; Wang, G.; Wang, J. Mechanical Behaviors of Existing Large-Diameter Tunnel Induced by Horseshoe-Shaped Undercrossing Twin Tunnels in Gravel. Appl. Sci. 2022, 12, 7344. [Google Scholar] [CrossRef]

- Wei, X.; Zhang, M.; Ma, S.; Xia, C.; Liu, X.; Ding, Z. Deformation Characteristics of Existing Twin Tunnels Induced by Double Shield Undercrossing with Prereinforcement: A Case Study in Hangzhou. Adv. Civ. Eng. 2021, 2021, 7869899. [Google Scholar] [CrossRef]

- Lin, X.-T.; Chen, R.-P.; Wu, H.-N.; Cheng, H.-Z. Deformation Behaviors of Existing Tunnels Caused by Shield Tunneling Undercrossing with Oblique Angle. Tunn. Undergr. Space Technol. 2019, 89, 78–90. [Google Scholar] [CrossRef]

- Liu, X.; Fang, Q.; Zhang, D. Mechanical Responses of Existing Tunnel Due to New Tunnelling below without Clearance. Tunn. Undergr. Space Technol. 2018, 80, 44–52. [Google Scholar] [CrossRef]

- Guan, L.; Wang, P.; Ding, H.; Qin, J.; Xu, C.; Feng, G. Analysis of Settlement of an Existing Tunnel Subjected to Undercrossing Tunneling Based on the Modified Vlasov Model. Int. J. Geomech. 2024, 24, 04023300. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhou, X.; Li, L.; Liu, X.; Wang, L.; Wang, Z. The Construction Methods and Control Mechanisms for Subway Station Undercrossing an Existing Tunnel at Zero Distance. Appl. Sci. 2023, 13, 8826. [Google Scholar] [CrossRef]

- Liang, J.; Tang, X.; Wang, T.; Lin, W.; Yan, J.; Fu, C. Analysis for Ground Deformation Induced by Undercrossed Shield Tunnels at a Small Proximity Based on Equivalent Layer Method. Sustainability 2022, 14, 9972. [Google Scholar] [CrossRef]

- Zhu, Q.; Ding, Y. Impact of New Undercrossing Tunnel Excavation on the Stability of the Existing Tunnel. Front. Earth Sci. 2022, 10, 915882. [Google Scholar] [CrossRef]

- Lai, H.; Zheng, H.; Chen, R.; Kang, Z.; Liu, Y. Settlement Behaviors of Existing Tunnel Caused by Obliquely Under-Crossing Shield Tunneling in Close Proximity with Small Intersection Angle. Tunn. Undergr. Space Technol. 2020, 97, 103258. [Google Scholar] [CrossRef]

- Chen, R.-P.; Lin, X.-T.; Kang, X.; Zhong, Z.-Q.; Liu, Y.; Zhang, P.; Wu, H.-N. Deformation and Stress Characteristics of Existing Twin Tunnels Induced by Close-Distance EPBS under-Crossing. Tunn. Undergr. Space Technol. 2018, 82, 468–481. [Google Scholar] [CrossRef]

- Jin, D.; Yuan, D.; Li, X.; Zheng, H. Analysis of the Settlement of an Existing Tunnel Induced by Shield Tunneling Underneath. Tunn. Undergr. Space Technol. 2018, 81, 209–220. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, X.; Fang, Q. Behaviors of Existing Twin Subway Tunnels Due to New Subway Station Excavation below in Close Vicinity. Tunn. Undergr. Space Technol. 2018, 81, 121–128. [Google Scholar] [CrossRef]

- Jin, D.; Yuan, D.; Li, X.; Zheng, H. An In-Tunnel Grouting Protection Method for Excavating Twin Tunnels beneath an Existing Tunnel. Tunn. Undergr. Space Technol. 2018, 71, 27–35. [Google Scholar] [CrossRef]

- Fu, J.; Zhao, N.; Qu, Y.; Yang, J.; Wang, S. Effects of Twin Tunnel Undercrossing Excavation on the Operational High Speed Railway Tunnel with Ballastless Track. Tunn. Undergr. Space Technol. 2022, 124, 104470. [Google Scholar] [CrossRef]

- Liu, B.; Yu, Z.; Zhang, R.; Han, Y.; Wang, Z.; Wang, S. Effects of Undercrossing Tunneling on Existing Shield Tunnels. Int. J. Geomech. 2021, 21, 04021131. [Google Scholar] [CrossRef]

- Liu, Z.; Xue, J.; Ye, J.; Qian, J. A Simplified Two-Stage Method to Estimate the Settlement and Bending Moment of Upper Tunnel Considering the Interaction of Undercrossing Twin Tunnels. Transp. Geotech. 2021, 29, 100558. [Google Scholar] [CrossRef]

- Liu, L.; Xu, G.; Li, R.; Fang, Z.; Chen, H.; Wu, S.; Xu, W.; Han, B.; Ma, C.; Shen, Q. Tunneling Construction Technology of Shafts and Cross-Passages under Strictly Controlling Deformation of the Existing Railway. Front. Earth Sci. 2023, 10, 1064772. [Google Scholar] [CrossRef]

- Zhou, Z.; Zheng, Y.; Hu, J.; Yang, H.; Gong, C. Deformation Analysis of Shield Undercrossing and Vertical Paralleling Excavation with Existing Tunnel in Composite Stratum. J. Cent. South Univ. 2023, 30, 3127–3144. [Google Scholar] [CrossRef]

- Sun, Z.; Zhang, D.; Liu, D.; Tai, Q.; Hou, Y. Insights into the Ground Response Characteristics of Shallow Tunnels with Large Cross-Section Using Different Pre-Supports. Int. J. Rock Mech. Min. Sci. 2024, 175, 105663. [Google Scholar] [CrossRef]

- Eller, B.; Rad Majid, M.; Fischer, S. Laboratory Tests and FE Modeling of the Concrete Canvas, for Infrastructure Applications. Acta Polytech. Hung. 2022, 19, 9–20. [Google Scholar] [CrossRef]

- Liu, Y.; Huang, Y. The Surface Settlement Law of Precipitation in Pile-Beam-Arch Station Adjacent to Pile Foundation. KSCE J. Civ. Eng. 2023, 27, 1441–1457. [Google Scholar] [CrossRef]

- Han, J.; Wang, J.; Cheng, C.; Zhang, C.; Liang, E.; Wang, Z.; Song, J.-J.; Leem, J. Mechanical Response and Parametric Analysis of a Deep Excavation Structure Overlying an Existing Subway Station: A Case Study of the Beijing Subway Station Expansion. Front. Earth Sci. 2023, 10, 1079837. [Google Scholar] [CrossRef]

- Sun, H.; Wu, J.; Zhang, J.; Du, Y.; Teng, L.; Qin, H. Deformation Analysis of a New Subway Transfer Channel Closely Undercrossing an Existing Station. Adv. Civ. Eng. 2023, 2023, 1–18. [Google Scholar] [CrossRef]

- Lv, J.; Lu, J.; Wu, H. Study on the Mechanical Characteristics and Ground Surface Settlement Influence of the Rise–Span Ratio of the Pile–Beam–Arch Method. Appl. Sci. 2023, 13, 5678. [Google Scholar] [CrossRef]

- Qi, Y.; Jia, F.; Li, W.; Shi, L.; Qin, X.; He, Y.; Li, S. Optimization and Energy Consumption Analyses of the Support System of a Super Large Deep Foundation Pit in the Xi’an Metro. Environ. Earth Sci. 2024, 83, 140. [Google Scholar] [CrossRef]

- Jiang, Z.; Zhu, S.; Que, X.; Ge, X. Deformation Effects of Deep Foundation Pit Excavation on Retaining Structures and Adjacent Subway Stations. Buildings 2024, 14, 2521. [Google Scholar] [CrossRef]

- Qi, W.; Yang, Z.; Jiang, Y.; Shao, X.; Yang, X.; He, Q. Structural Deformation of Existing Horseshoe-Shaped Tunnels by Shield Overcrossing. KSCE J. Civ. Eng. 2021, 25, 735–749. [Google Scholar] [CrossRef]

- Li, T.; Zhang, Z.; Luo, M.; Liu, B.; Wang, Y.; Li, L. Analytical Solution of Loosening Pressure Model for Shallow Tunnel Based on Pile-Beam-Arch Method. KSCE J. Civ. Eng. 2022, 26, 3648–3662. [Google Scholar] [CrossRef]

- Shi, C.; Zhao, Y.; Zhao, C.; Lou, Y.; Sun, X.; Zheng, X. Water-Sealed Blasting Control Measures of the Metro Station Undercrossing Existing Structures in Ultra-Close Distances: A Case Study. Front. Earth Sci. 2022, 10, 848913. [Google Scholar] [CrossRef]

- Guo, X.; Wang, Z.; Geng, P.; Chen, C.; Zhang, J. Ground Surface Settlement Response to Subway Station Construction Activities Using Pile–Beam–Arch Method. Tunn. Undergr. Space Technol. 2021, 108, 103729. [Google Scholar] [CrossRef]

- Ézsiás, L.; Tompa, R.; Fischer, S. Investigation of the Possible Correlations between Specific Characteristics of Crushed Stone Aggregates. Spectr. Mech. Eng. Oper. Res. 2024, 1, 10–26. [Google Scholar] [CrossRef]

- Ezsias, L.; Kozma, K.; Tompa, R.; Fischer, S. Crushed Stone Supply Challenges for Infrastructure Development in Hungary. Nauk. Visnyk Natsionalnoho Hirnychoho Universytetu 2024, 6, 28–37. [Google Scholar] [CrossRef]

- Libor, I.; Janka, S.; Michal, S. The Railway Superstructure Monitoring in Bratislava Tunnel No. 1—Section of Ballastless Track and Its Transition Areas. MATEC Web Conf. 2017, 117, 00063. [Google Scholar] [CrossRef]

- Libor, I.; Michal, Š.; Jana, M. The Quality Evaluation of the Ballastless Track Construction in the Area of Bratislava Tunnel No. 1. MATEC Web Conf. 2016, 86, 05001. [Google Scholar] [CrossRef]

- Jover, V.; Fischer, S. Statistical Analysis of Track Geometry Parameters on Tramway Line No. 1 in Budapest. Balt. J. Road Bridge Eng. Stat 2022, 17, 75–106. [Google Scholar] [CrossRef]

- Fischer, S. Investigation of the Settlement Behavior of Ballasted Railway Tracks Due to Dynamic Loading. Spectr. Mech. Eng. Oper. Res. 2025, 2, 24–46. [Google Scholar] [CrossRef]

- Standard DB11/490-2007; Technical Specification for Monitoring and Measurement of Metro Engineering. Beijing Municipal Bureau of Quality and Technical Supervision: Beijing, China, 2007.

- Guo, X.; Jiang, A.; Wang, S. Study on the Applicability of an Improved Pile-Beam-Arch Method of Metro Station Construction in the Upper-Soft and Lower-Hard Stratum. Adv. Civ. Eng. 2021, 2021, 1–13. [Google Scholar] [CrossRef]

- Ižvolt, L.; Dobeš, P. Measurements Result Analysis of Deformation Characteristics of Transition Zones on the Modernized Line Púchov—Považská Teplá. Civ. Environ. Eng. 2021, 17, 353–360. [Google Scholar] [CrossRef]

- Liu, N.; Tong, X.; Chang, L.; Lv, Y. The Influence of Pile-Beam-Arch Construction on the Stratum and Station Support Structure. Geofluids 2023, 2023, 5022418. [Google Scholar] [CrossRef]

- Liu, X.; Liu, Y.; Qu, W.; Tu, Y. Internal Force Calculation and Supporting Parameters Sensitivity Analysis of Side Piles in the Subway Station Excavated by Pile-Beam-Arch Method. Tunn. Undergr. Space Technol. 2016, 56, 186–201. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, X.; Guo, F.; Tao, L.; Liu, J.; Liao, W.; Tan, L.; Yang, X. Construction Techniques and Support Effect of Large-Diameter Pipe Roof for Ultra-Shallow Buried Subway Station. KSCE J. Civ. Eng. 2025, 29, 100098. [Google Scholar] [CrossRef]

- Liu, X.; Liu, Y.; Yang, Z.; He, C. Numerical Analysis on the Mechanical Performance of Supporting Structures and Ground Settlement Characteristics in Construction Process of Subway Station Built by Pile-Beam-Arch Method. KSCE J. Civ. Eng. 2017, 21, 1690–1705. [Google Scholar] [CrossRef]

| Stratum | Density (kg/m3) | Elastic Modulus (GPa) | Poisson Ratio | Angle of Friction (°) | Force of Cohesion (kN) |

|---|---|---|---|---|---|

| Filling soil | 1800 | 22.5 | 0.33 | 10 | 5 |

| Silty clay | 1950 | 27 | 0.3 | 18 | 27 |

| Fine medium sand | 1980 | 45 | 0.24 | 30 | 0 |

| Silty clay | 1970 | 27.9 | 0.33 | 18 | 27 |

| Pebbles | 2150 | 120 | 0.22 | 40 | 0 |

| Fine medium sand | 2050 | 67.5 | 0.24 | 34 | 0 |

| Sandy silty soil | 2030 | 110 | 0.25 | 28 | 22 |

| Supporting Structure | Density (kg/m3) | Elastic Modulus (GPa) |

|---|---|---|

| Guide hole | 2500 | 25.5 |

| New tunnel lining | 2500 | 33 |

| Piles | 2500 | 30 |

| Thousand jack | 7850 | 200 |

| Construction Characteristic | CRD | Pre-Support Technology Method |

|---|---|---|

| Technical features | Separate tunneling excavation | The pilot tunnel is constructed first, then the pile and the top arch support are constructed, and the tunnel structure is constructed after the top arch is formed. |

| Design and construction difficulty | Simple | Complex |

| Working space | Moderate | Smaller |

| Engineering cost | Lower | Higher |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, B.; He, S.; Ma, J.; He, J.; Li, Y.; Zheng, J. Comprehensive Substantiation of the Impact of Pre-Support Technology on a 50-Year-Old Subway Station During the Construction of Undercrossing Tunnel Lines. Infrastructures 2025, 10, 183. https://doi.org/10.3390/infrastructures10070183

Zhang B, He S, Ma J, He J, Li Y, Zheng J. Comprehensive Substantiation of the Impact of Pre-Support Technology on a 50-Year-Old Subway Station During the Construction of Undercrossing Tunnel Lines. Infrastructures. 2025; 10(7):183. https://doi.org/10.3390/infrastructures10070183

Chicago/Turabian StyleZhang, Bin, Shaohui He, Jianfei Ma, Jiaxin He, Yiming Li, and Jinlei Zheng. 2025. "Comprehensive Substantiation of the Impact of Pre-Support Technology on a 50-Year-Old Subway Station During the Construction of Undercrossing Tunnel Lines" Infrastructures 10, no. 7: 183. https://doi.org/10.3390/infrastructures10070183

APA StyleZhang, B., He, S., Ma, J., He, J., Li, Y., & Zheng, J. (2025). Comprehensive Substantiation of the Impact of Pre-Support Technology on a 50-Year-Old Subway Station During the Construction of Undercrossing Tunnel Lines. Infrastructures, 10(7), 183. https://doi.org/10.3390/infrastructures10070183