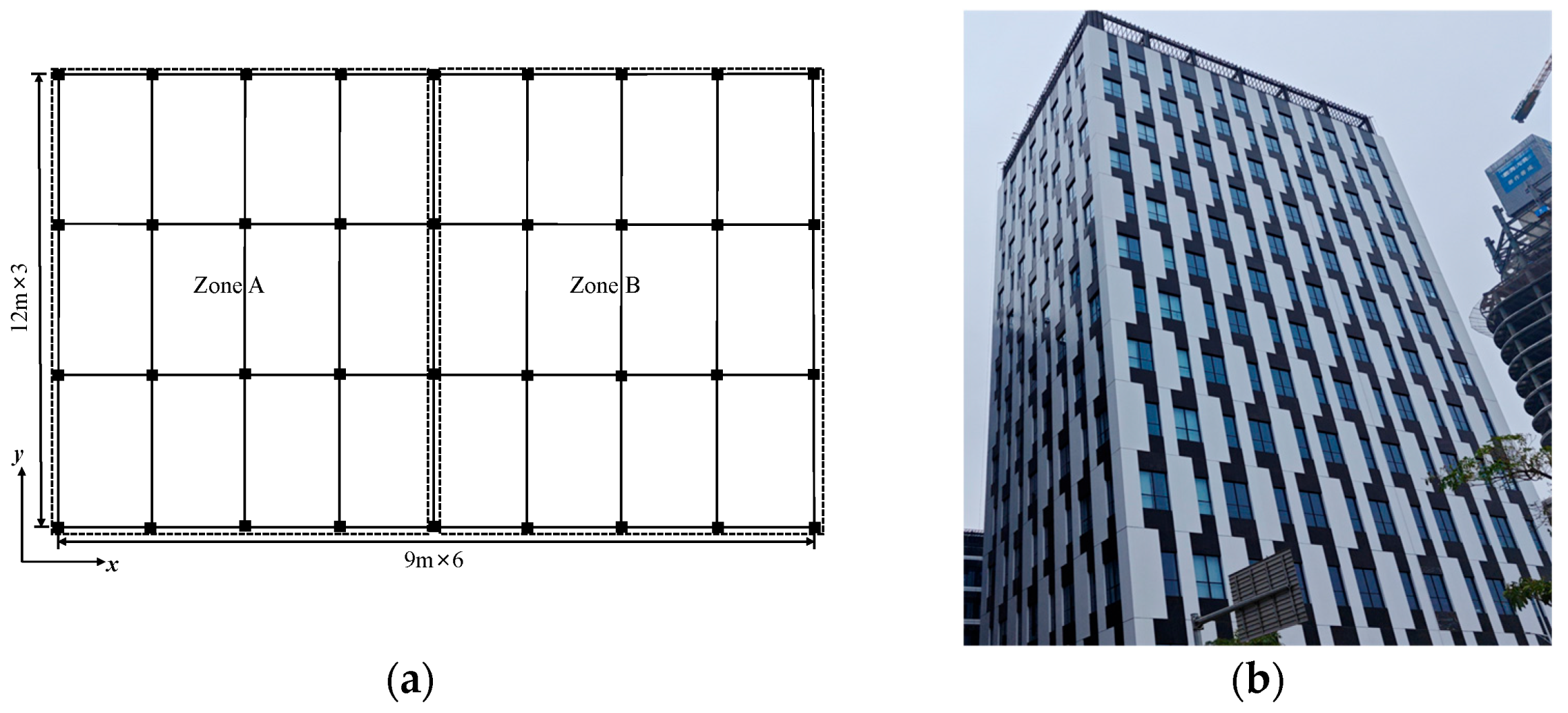

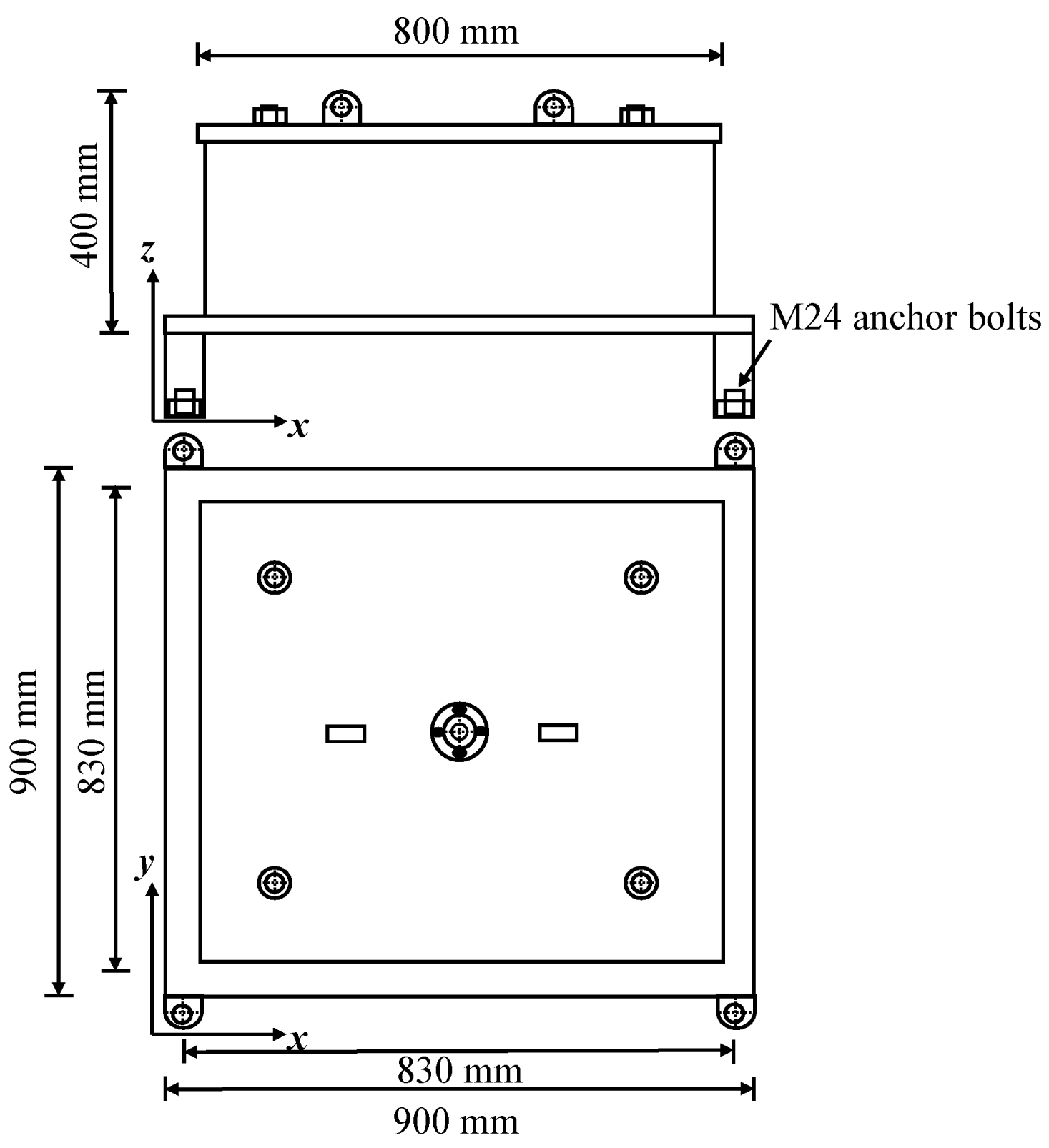

2.1. Forced Vibration of a Rectangular Plate Structure with Simply Supported on All Four Edges

Consider a simply supported rectangular plate, that is a typical model of a concrete floor slab. The four edges of the slab are defined by

,

,

, and

, respectively. It is assumed that the following pressure wave load

acts on the surface of the plate [

17], which is

where

is the amplitude of a pressure wave;

is the circular frequency of the pressure wave;

is the wave number in the

-direction of the pressure wave; and

denotes time. We nevertheless acknowledge that a broadband or time-varying load would require a spectral input model, and, in that case, the analytical framework presented here would need to be extended to account for multiple frequencies.

Equation (1) represents the propagation of a vibrational pressure wave along the

-direction, with a propagation speed,

, of

At a given time

and location

,

represents the sinusoidal component in the

-direction. Thus

where

represents the wave number in the

-direction.

We consider the case when the half-wave length of the pressure is equal to the length of the plate in the

-direction. Thus,

The displacement of the plate,

, satisfies the following equation:

where

is the bending stiffness of the plate;

is the density of the plate; and

is the thickness of the plate. By assigning a complex bending stiffness

, the internal damping of the plate can be considered, where

is the damping loss factor.

The solution of Equation (5) consists of two parts: the particular solution and the complementary solution. The particular solution represents the response of an infinitely long plate in the -direction, describing the propagation of pressure waves in the -direction. The complementary solution represents the response of a finite-length plate. The waves will be reflected when they propagate and encounter the plate boundaries, and the structural wave reflected from all boundaries will generate the far-field wave and near-field wave.

Therefore, the total displacement

can be expressed as

where

,

, and

is an unknown coefficient.

The solution includes four unknowns, which can be determined by satisfying the four boundary conditions. For the case of simply supported edges, the boundary conditions are

at

and

, and

at

and

.

The four unknown constants,

(

1, 2, 3, and 4), can be obtained by solving Equation (9):

Therefore, for given

and

, the displacement at any point on the plate can be expressed as

where

represents the wave response function.

By taking the first and second derivatives of Equation (10) with respect to , the velocity and acceleration of the plate can be obtained.

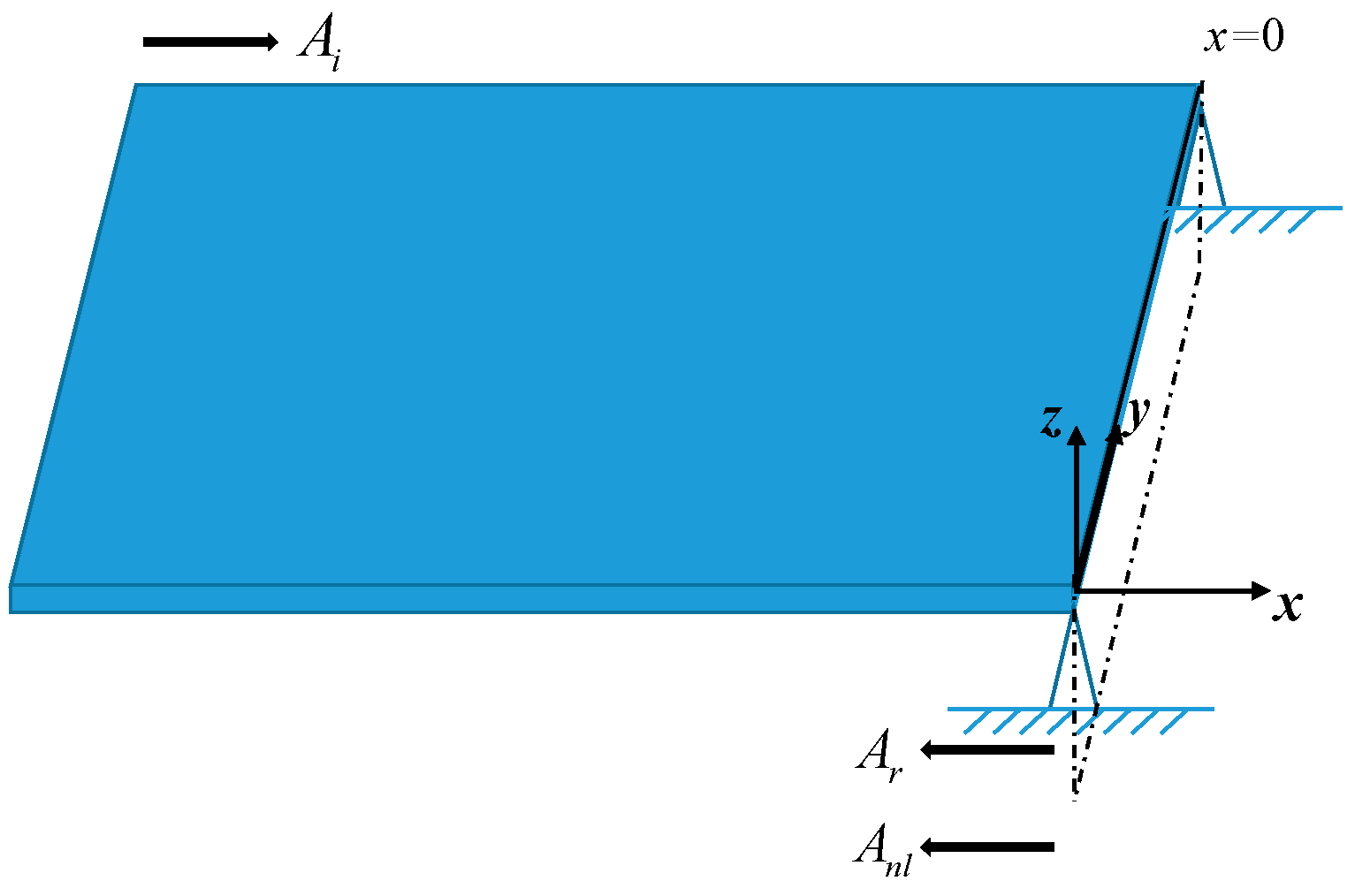

2.2. Wave Propagation at the Vertical Incidence of Bending Wave in Boundary Interface

Part or all of the waves travelling through a structure will reflect during propagation when meeting discontinuities and generate near-field waves on the reflecting interface.

Assume that the uniform plate structure shown in

Figure 2 is discontinuous at

. The incident pressure wave

in the region where

is

where

represents the amplitude of the pressure wave;

is the circular frequency of the pressure wave; and

is the wave number of the pressure wave.

Structural wave reflection and transmission occur at

. The reflected wave can be expressed as

where

represents the amplitude of the reflected wave.

The near-field wave generated from the reflection interface is

where

represents the amplitude of the reflected near-field wave.

Therefore, the displacements,

, of the plate on the left-hand sides of the discontinuity can be described as

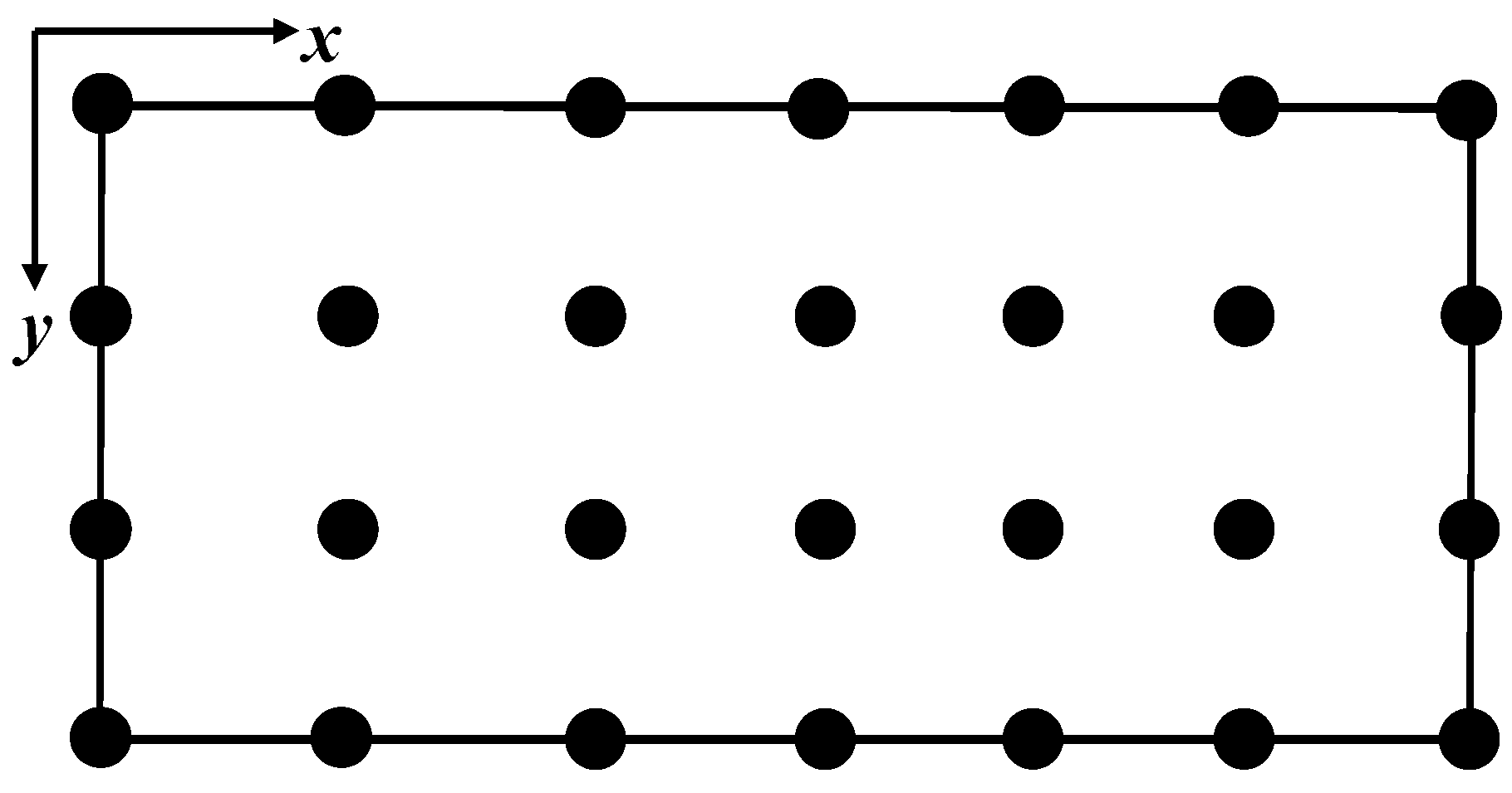

Based on the solutions in

Section 2.1, a MATLAB R2021a code is formulated to calculate the propagation of vibration waves across a single floor. The boundary conditions along the outside beams are treated as simply supported edges (marked green in

Figure 3).

Consider wave propagation in a plate with a simply supported edge at the end, as shown in

Figure 2, where both displacement

and bending moment

and

must be zero, i.e.,

Substituting Equation (14) into Equation (15), two reflected wave amplitudes,

and

, can be obtained, which are as follows:

2.3. Calculation of Vibration Wave Propagation via Insertion Loss-Based Correction Under TMD Control

As described above, vibrational waves are generated under external load and then propagate across the floor. For slab–column connection, the resultant force

at the column base is obtained by integrating the normal stress distribution in the floor slab as follows:

where

is the contact stress between the column end and the floor slab;

is the cross sectional area of the column;

is the Young’s modulus of the floor slab; and

is the displacement of the floor slab in the slab–column contact area.

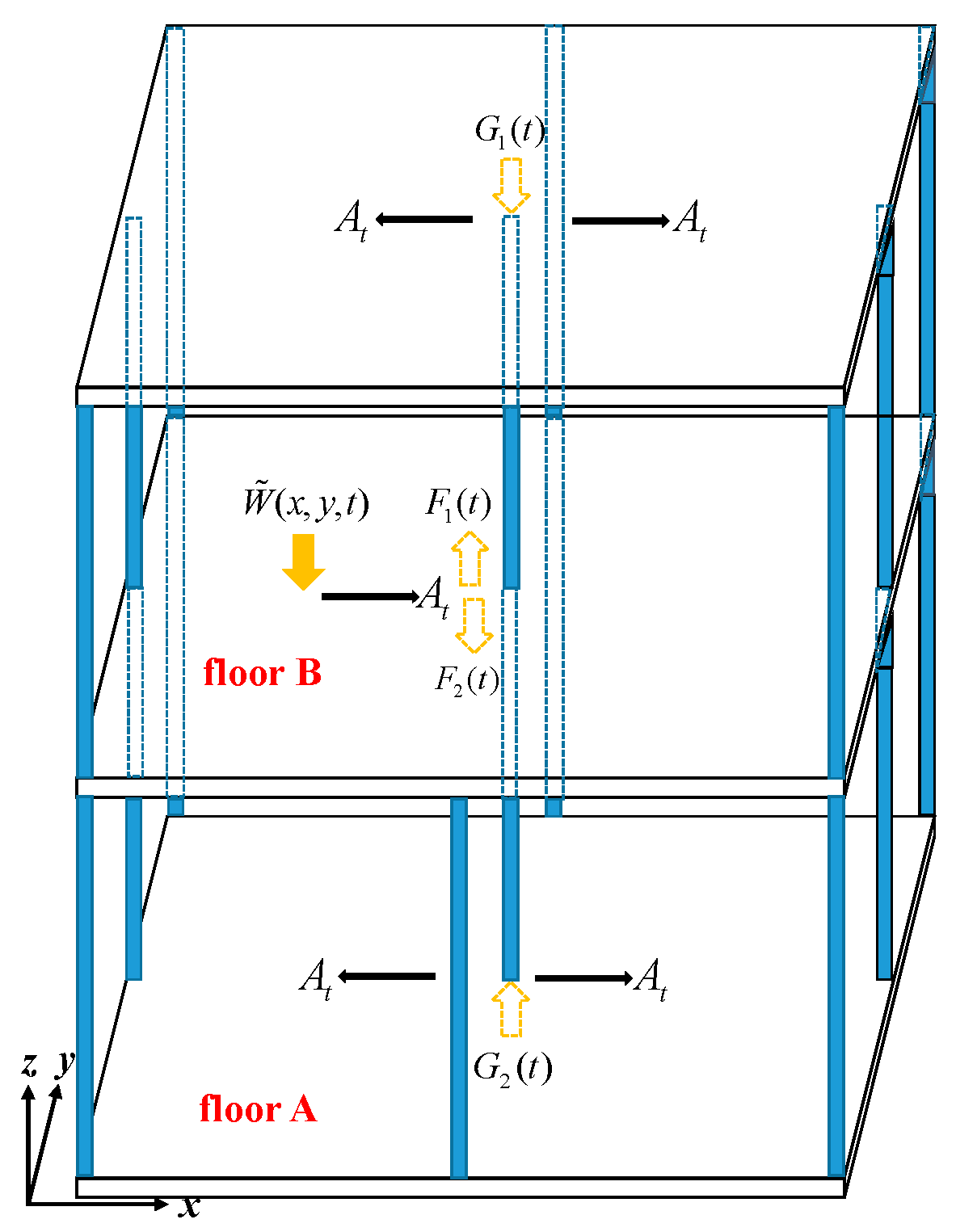

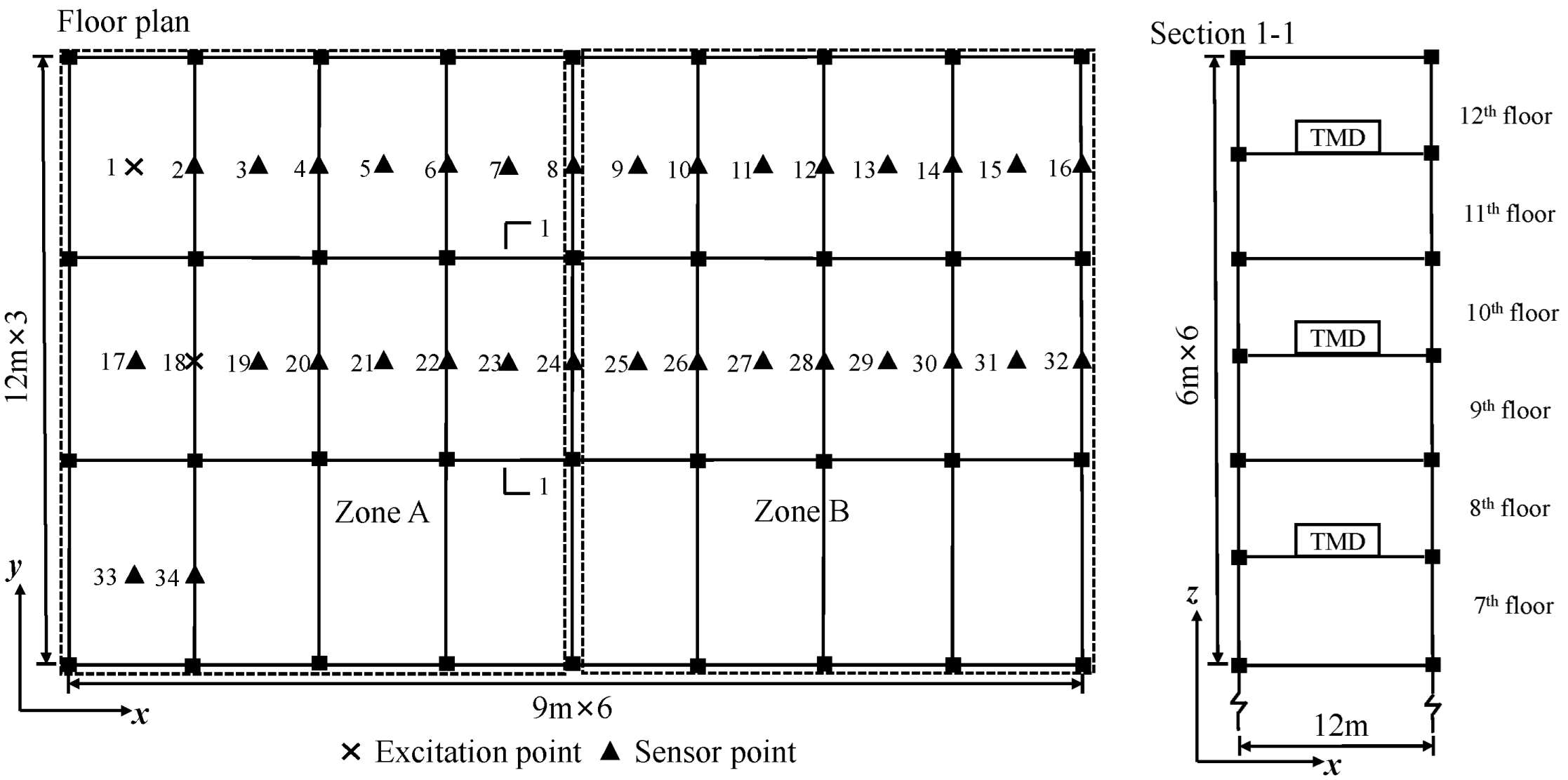

Assuming that floor B is the source of vibration,

Figure 4 schematically illustrates how the force is transmitted from floor B to floor A through a slab–column connections, where

and

represent, respectively, the axial force (load) acting at the bottom end of the column of floor B and the top end of the column of floor A. Equation (17) can be used to calculate the resultant force,

, at the bottom end slab–column connection of floor B. The force is simultaneously transmitted to the top end of the column of floor A, which is denoted by

.

Considering the relatively low stiffness of the slabs in comparison to the axial stiffness of the columns, the force in the column of floor B is considered to be fully transmitted to the column of floor A, i.e., .

The forces, and , propagate along their respect column axis in the opposite direction. The transmitted force of at the top end of the column of floor B is denoted by , and transmitted force of at the bottom end of the column of floor A is denoted by .

The propagation of the longitudinal waves in the columns satisfy

where

represents the propagation speed of longitudinal waves. The free vibration wave,

, expressed using a complex exponential form, is

where

and

are unknown coefficients;

is the wave number of the pressure wave; and

is the circular frequency of the pressure wave.

Due to the time delay in force transmission within the column, the solution of Equation (18) can be expressed as a single-variable function

where

.

By substituting Equation (20) into Equation (18), the following equation is obtained

Clearly, the equation satisfies the consistency condition. Therefore, the solution of Equation (18) can be any function propagating along the .

Since the one-dimensional wave equation is a second-order partial differential equation, its general solution should include two independent solutions. Assuming the solution is the sum of two independent functions, it is represented as follows:

where

represents the upward-propagating wave in the column of floor B; and

represents the downward-propagating wave in the column of floor A.

Therefore, an upward-propagating wave is generated when the external force

is applied at the bottom end of the column, which is

The wave reaches the top of the column when at .

The stress and velocity of the column satisfy the following relationship:

where

represents the wave impedance of the column; and

denotes the velocity of a particle within the column.

At the bottom end of the column of floor B, i.e., at

, the relationship between the resultant force and velocity is given by

where

Thus, the velocity at the top end of the floor B column is the time-delayed form of the velocity at the bottom end of the column.

Due to the effect of damping in the column, the resultant force at the top of the column on floor B,

, is given by

where

, and

is the damping loss factor.

Similarly, the resultant force at the bottom end of the column on floor A, , can be calculated by following the procedure from Equations (20)–(27).

To incorporate the effect of tuned mass dampers (TMDs) into the wave propagation framework, an insertion loss (IL)-based correction approach is introduced. Specifically, the theoretical floor-to-floor transmitted force

, previously derived in Equation (27), is modified through a convolution with a time-domain correction filter

that accounts for the energy absorption effect of the TMD

where

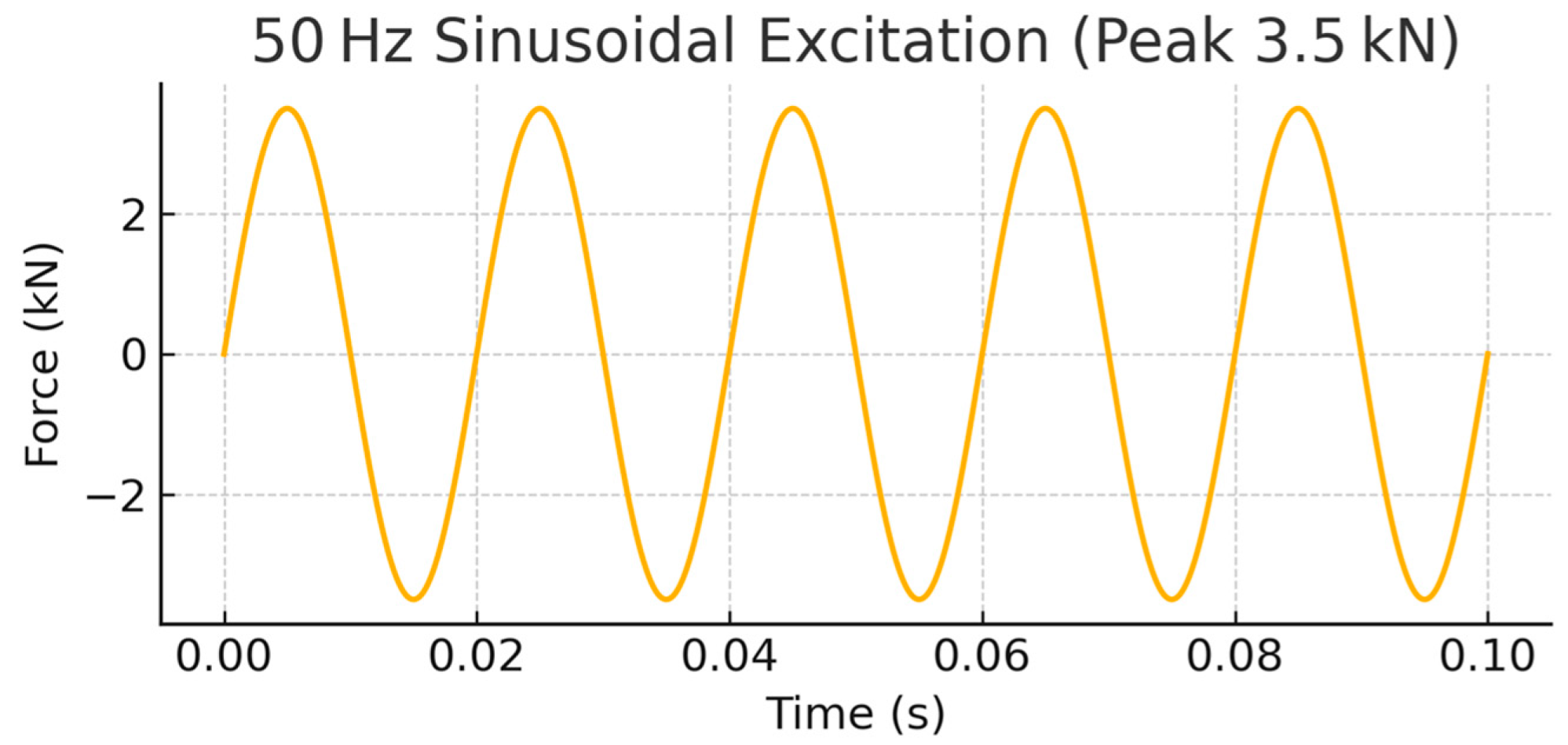

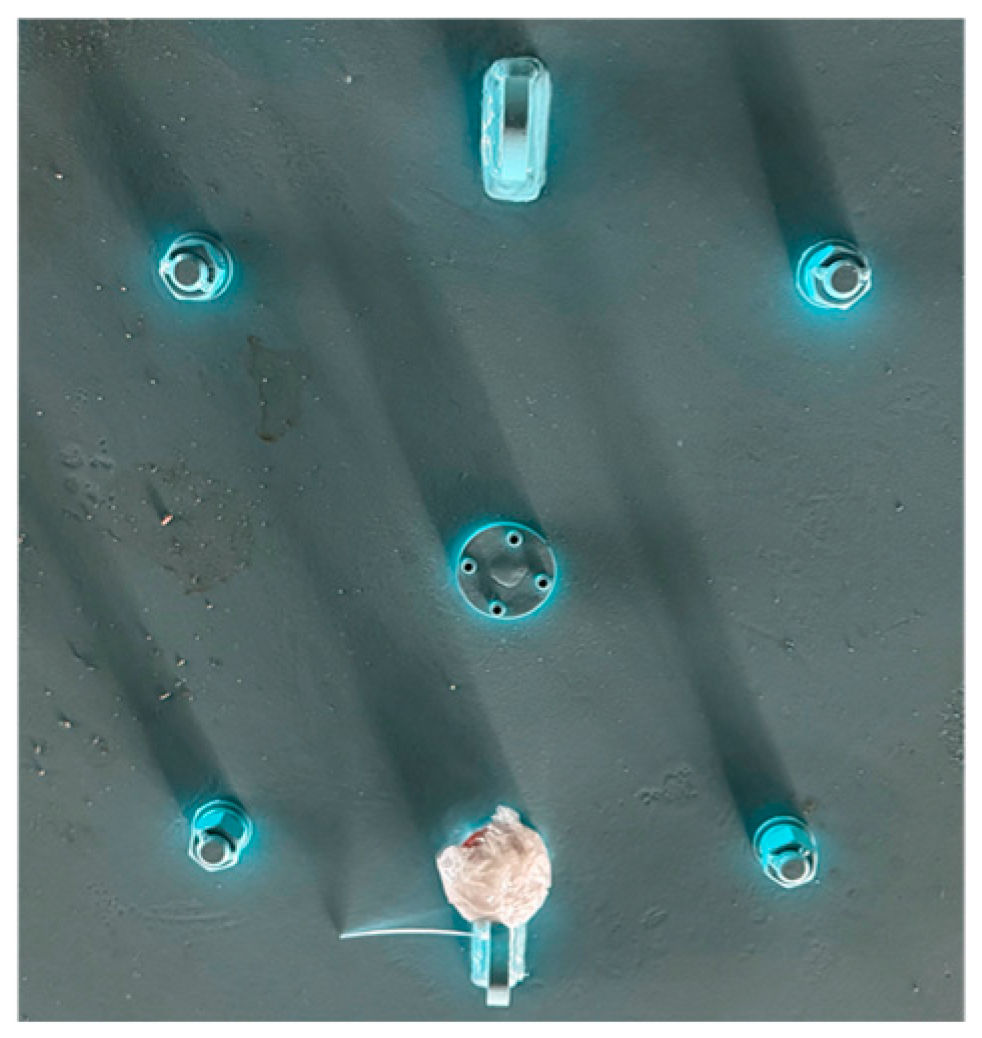

represents a finite impulse response (FIR) filter, characterising the frequency-dependent reduction in transmitted vibration due to the TMD. The procedure to derive this filter from experimental measurements is as follows:

(1) Obtain the Fourier transforms of the acceleration responses at the target location under two configurations—without TMD and with TMD—denoted as and , respectively.

(2) Define the insertion loss as a frequency-dependent function representing the vibration attenuation caused by the TMD

(3) Convert the insertion loss into a transmissibility function:

which quantifies the retained vibration amplitude at each frequency.

(4) Perform the inverse Fourier transform of

to derive the correction filter:

This filter can be convolved with the theoretical time-domain wave propagation response to yield the modified response under influence.

This method enables the integration of experimental TMD effects into the theoretical framework. It further allows parametric studies and response prediction across various TMD configurations without reconstructing the full dynamic model.

The calculated and serve as the forces acting on the ceiling slab of floor B and the floor slab of floor A, respectively. This enables the calculation of vibration wave propagation through slabs of different floors. Hence, the vibration response of a multiple-floor building due to the excitation from a particular floor can be studied by repeating the above solution process progressively until the waves have reached the top and the bottom of the building.

The calculation procedure described above is summarised below in

Figure 5.