Assessing Engineering Behavior of Fly Ash-Based Geopolymer Concrete: Empirical Modeling

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Mixtures

2.2. GPC Casting and Testing

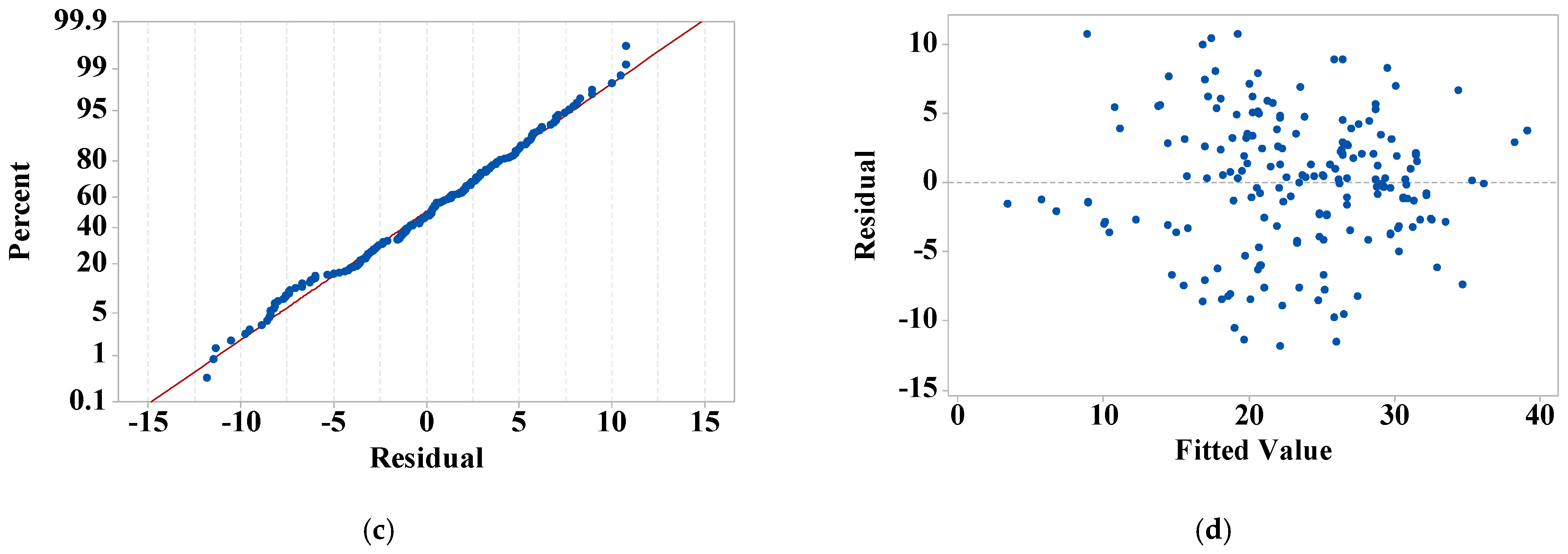

2.3. Modeling and Dataset Preparation

3. Results and Discussion

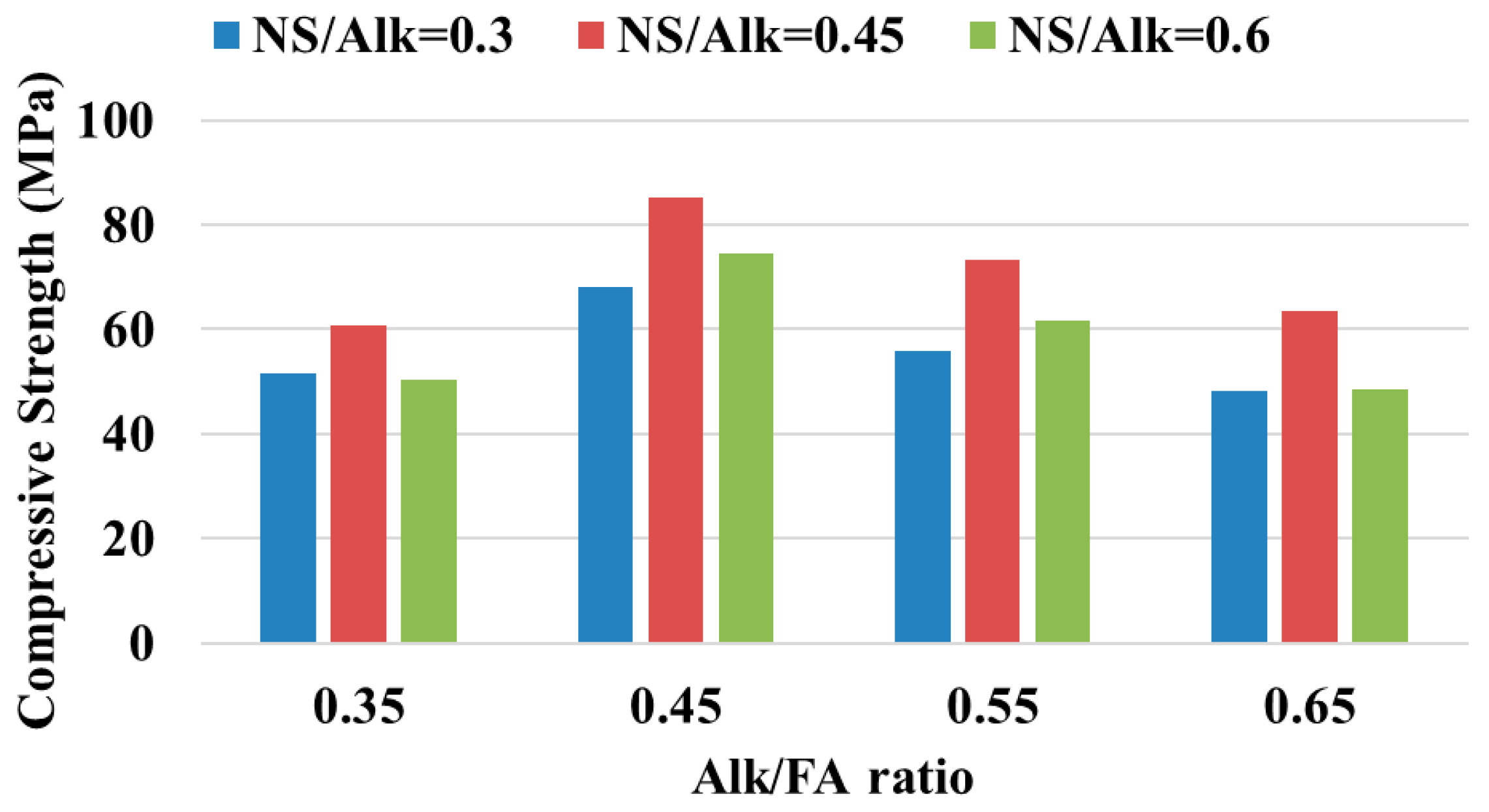

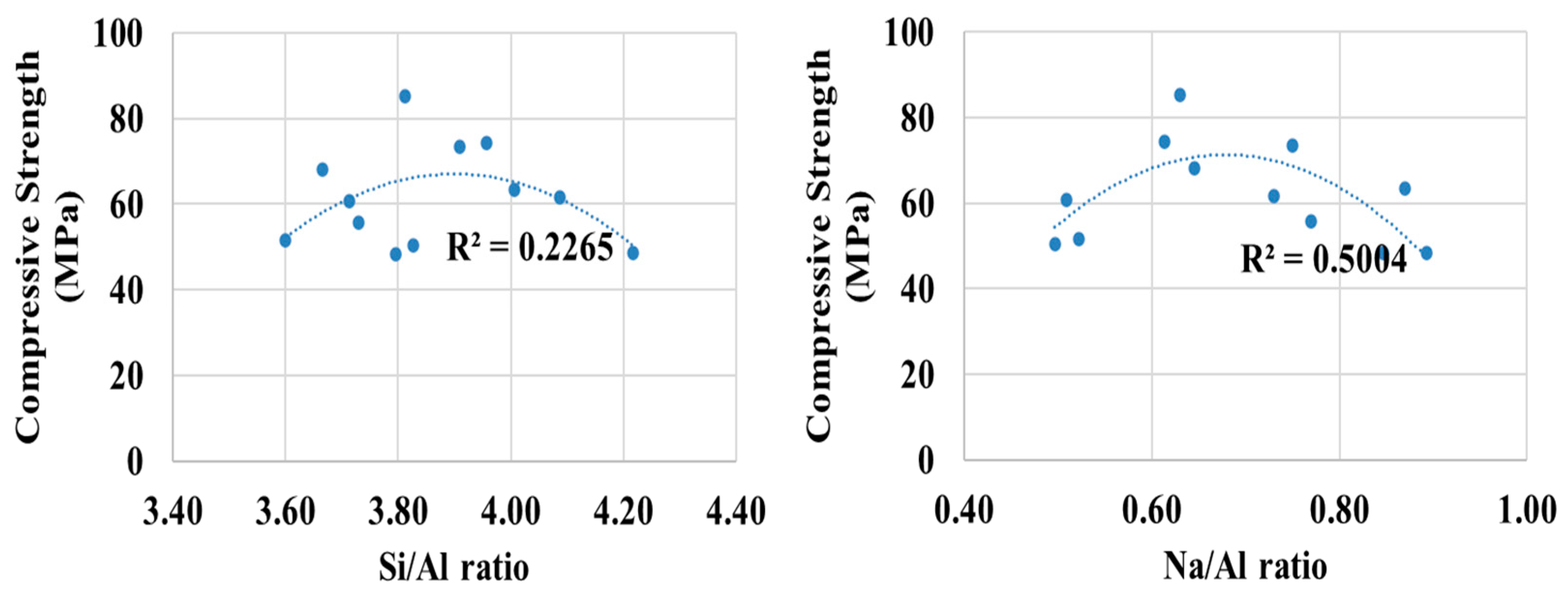

3.1. Compressive Strength

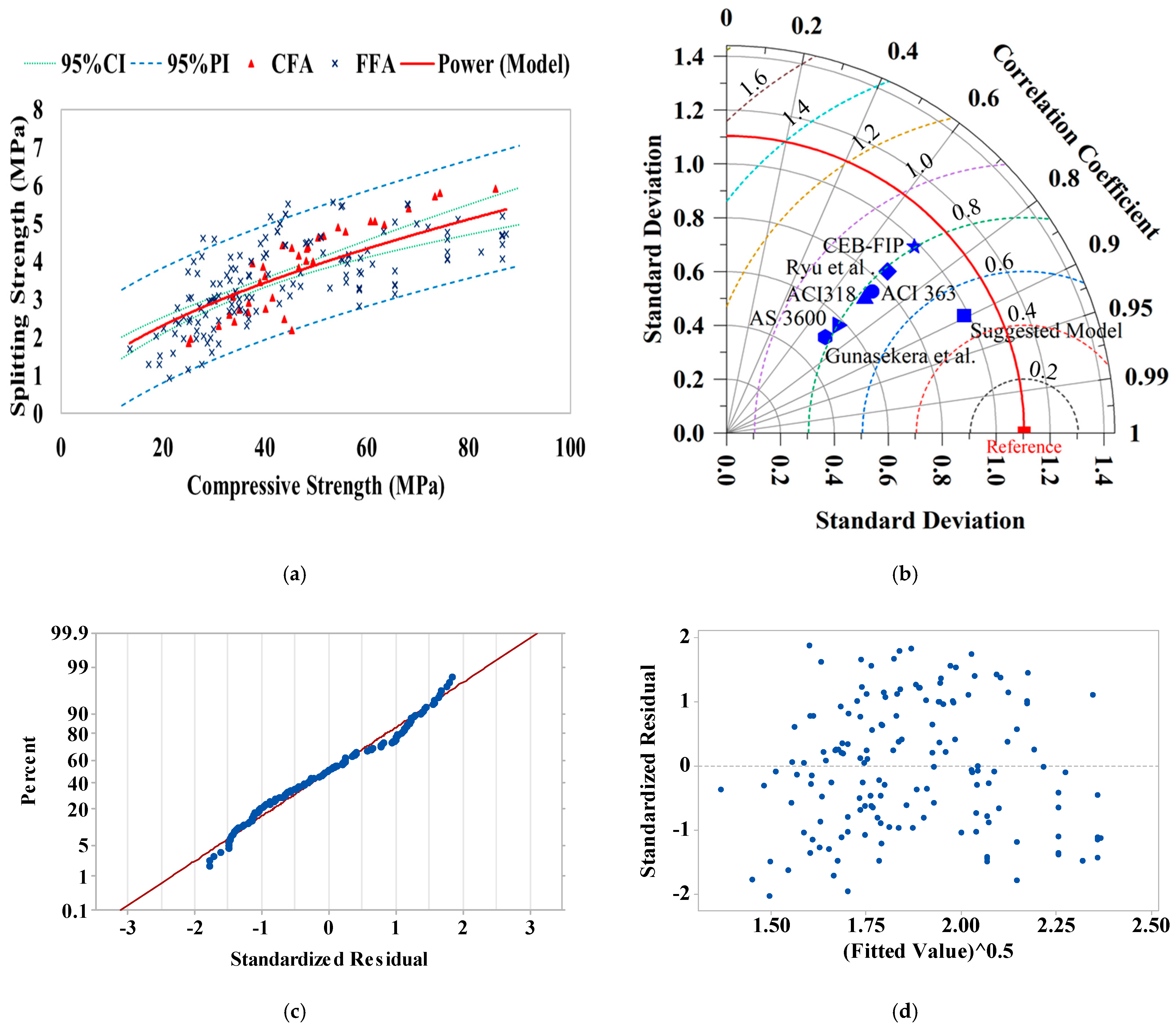

3.2. Splitting Tensile Strength

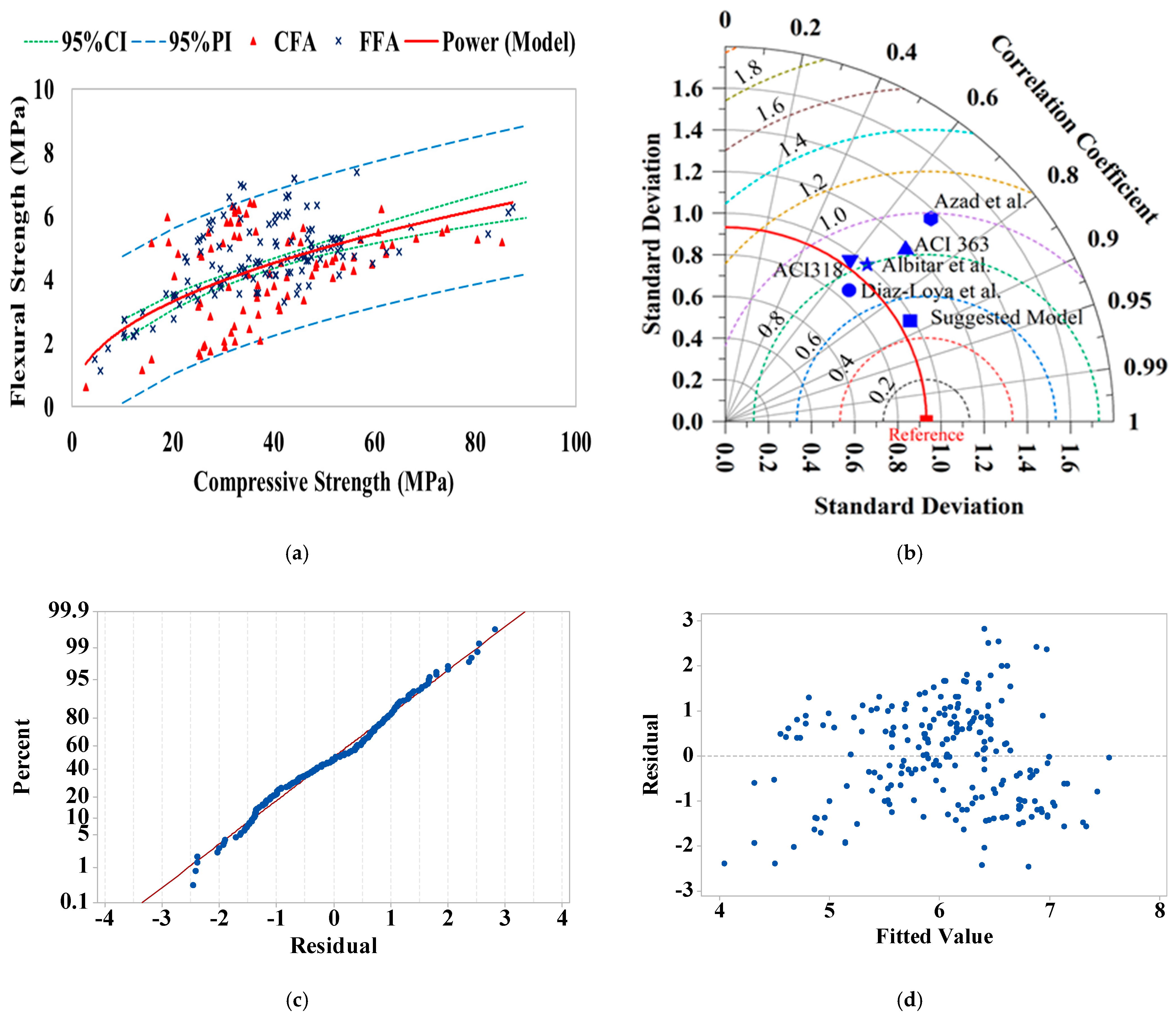

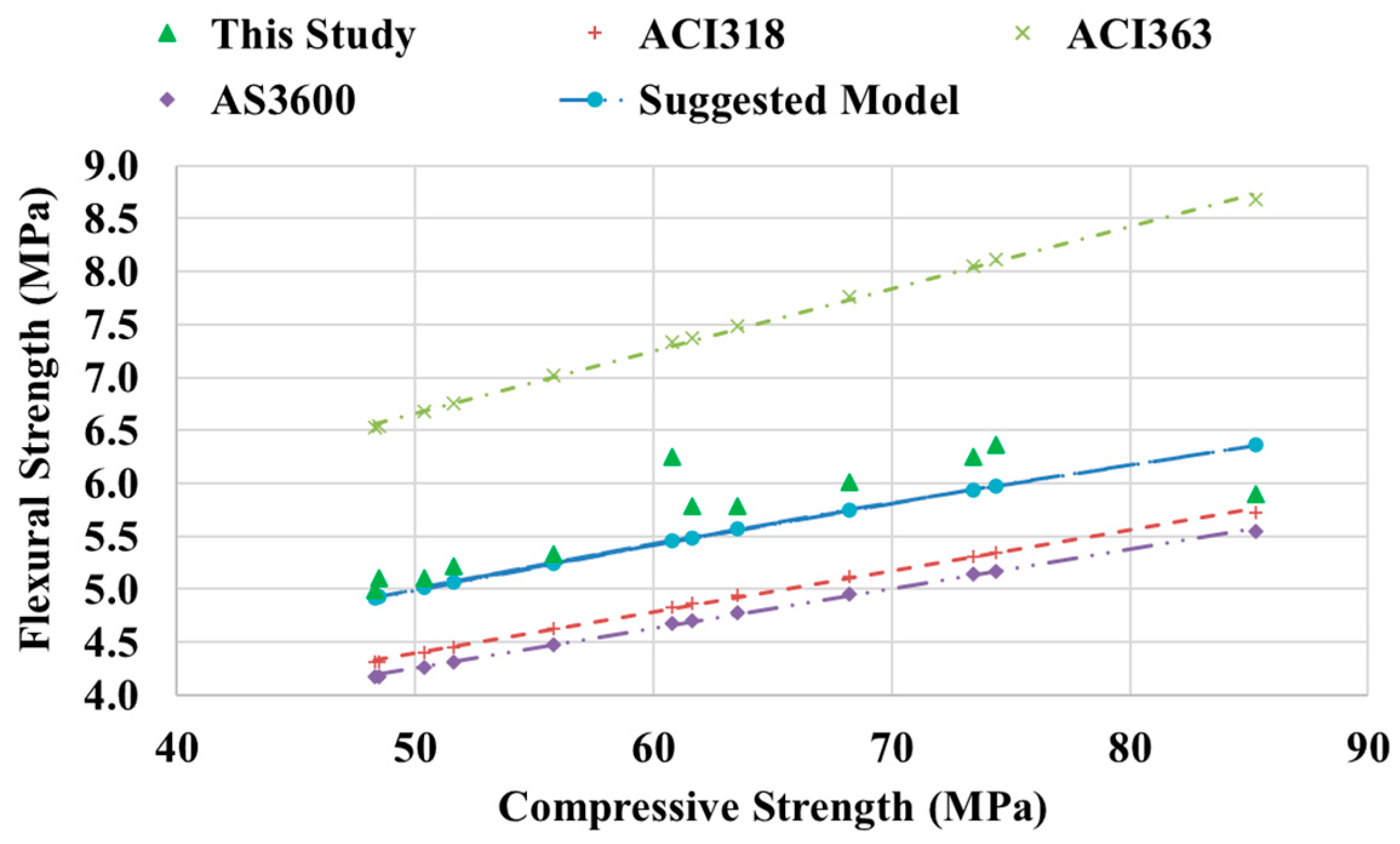

3.3. Flexural Strength

3.4. Modulus of Elasticity

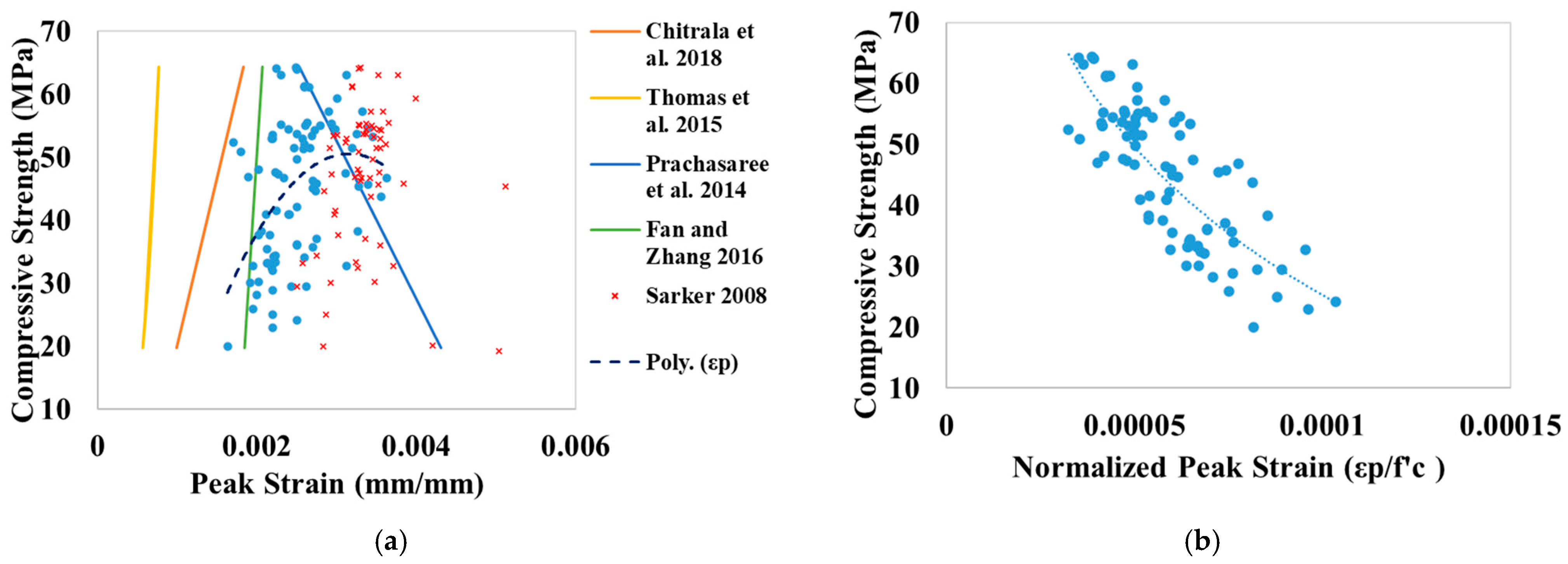

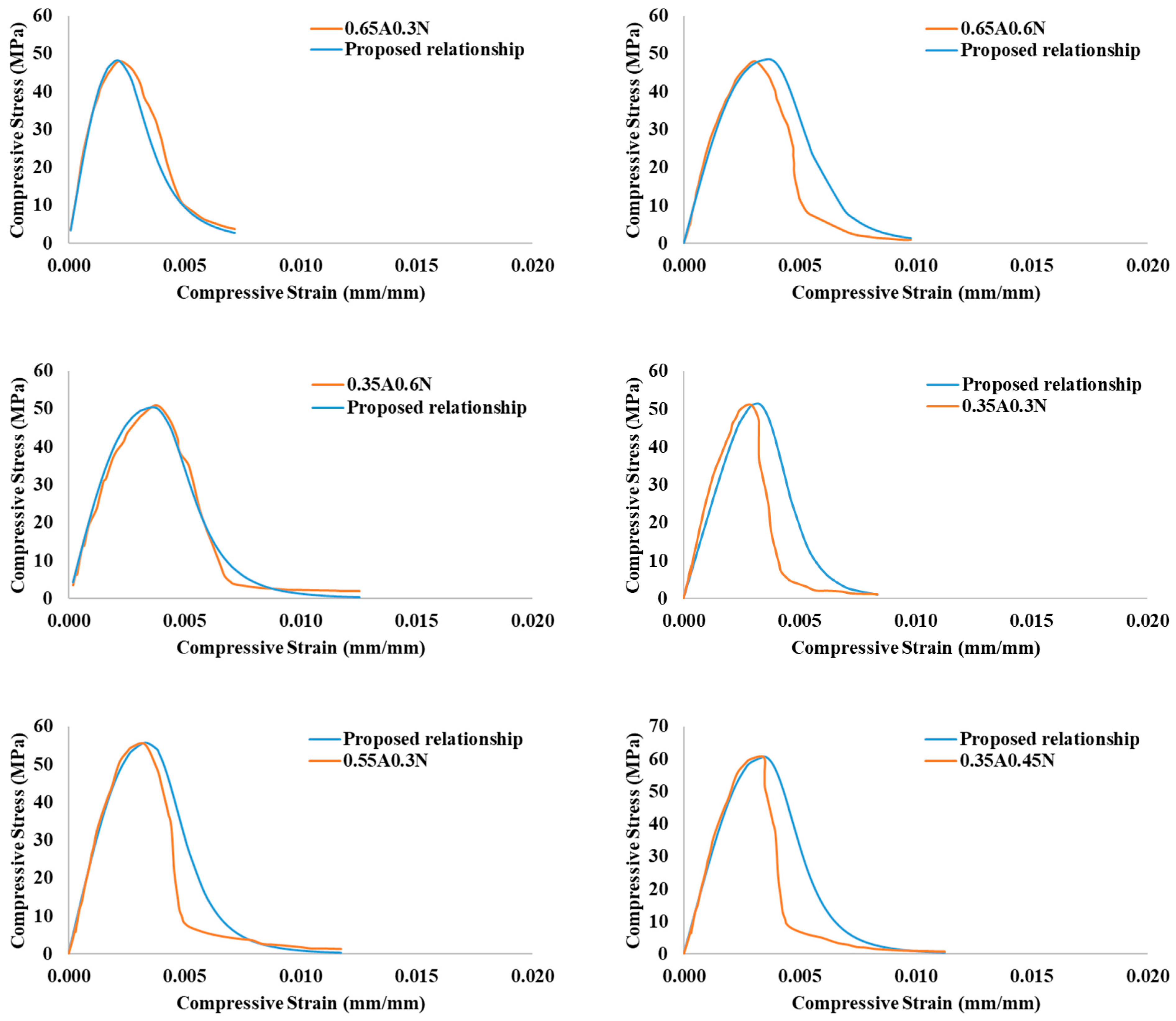

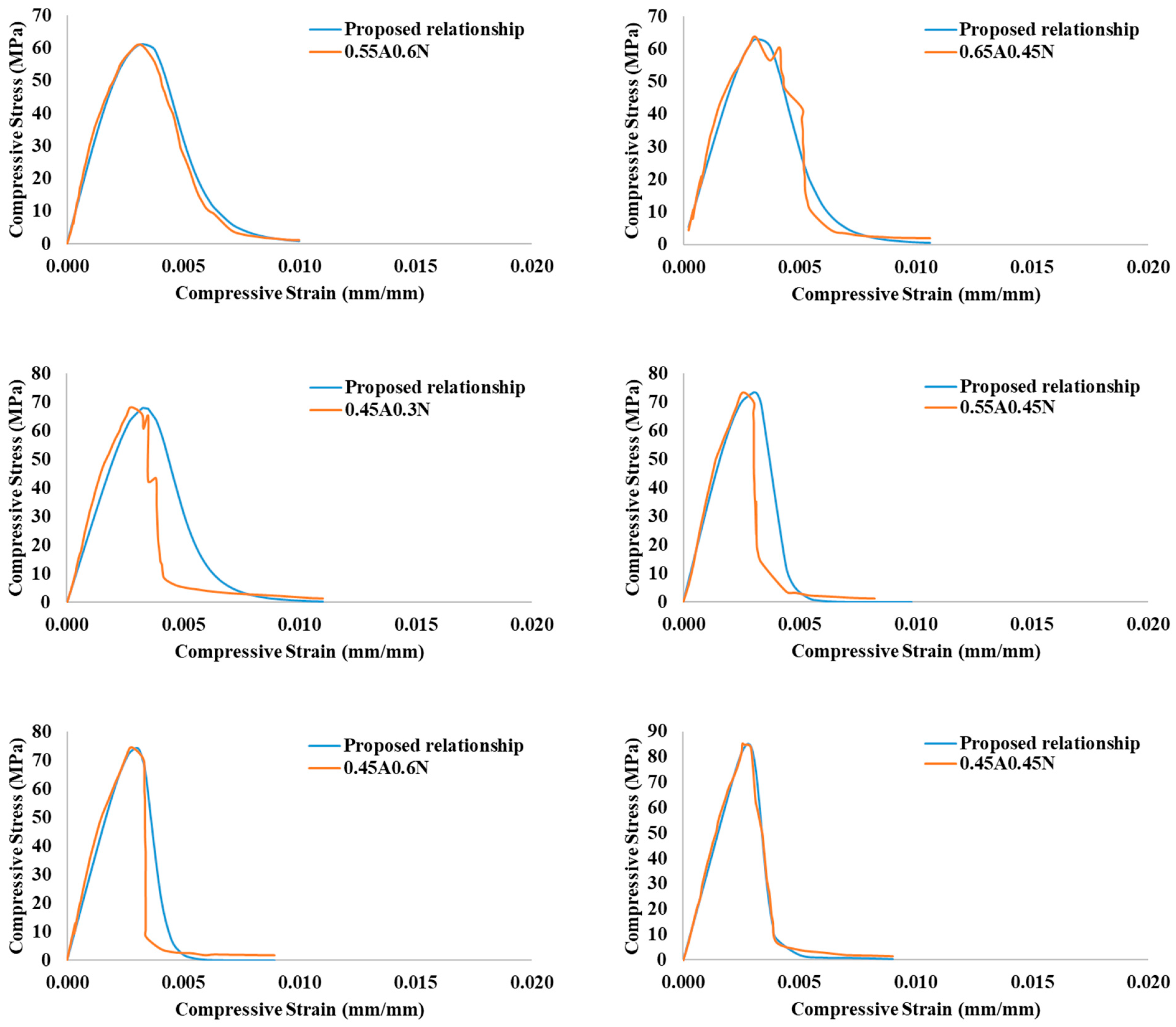

3.5. Stress–Strain Relationship

4. Conclusions

- For design purposes, the lower prediction intervals are recommended to account for safety margins, as they approximate 70% of the mean strength.

- The effect of FA type (CFA or FFA) is not critical on the splitting and compressive strengths relationship. Consequently, a single model can be used to express their relationships with good accuracy. The same note was observed in the case of flexural and compressive strength relationships.

- Design codes for OPC concrete, including ACI 318, ACI 363, and CEB-FIP, are shown to generally underestimate the splitting tensile strength when applied to FA-GPC. Notably, the CEB-FIP code’s predictions are the closest to the actual values.

- Design codes for OPC concrete, including ACI 318 and AS3600, are shown to generally underestimate the flexural tensile strength when applied to FA-GPC, while the ACI363 code’s predictions tend to overestimate the actual values.

- Existing design models for the modulus of elasticity of OPC concrete in ACI 318, ACI 363, and AS 3600 codes generally overestimate its value. However, for CFA-based GPC, these models can offer reasonably good predictions. Given the differing trends observed between CFA and FFA-based GPC, different models were proposed. Moreover, including density in such models is found to increase the model’s accuracy.

- FA-GPC provides more linear elastic behavior up to the peak stresses indicated by its lower linearity index value. On the other hand, the deformation of GPC was observed to be larger with a higher strain rate at peak stresses and higher ultimate strain as compared to OPC concrete.

- While environmental impact and economic feasibility are important considerations in the broader evaluation of GPC, the present study is focused specifically on developing and validating predictive models for its mechanical performance. Detailed environmental or cost analysis is, therefore, beyond the current scope, but it is recommended for future investigations to complement the findings presented here.

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rissman, J.; Bataille, C.; Masanet, E.; Aden, N.; Morrow, W.R.; Zhou, N.; Elliott, N.; Dell, R.; Heeren, N.; Huckestein, B.; et al. Technologies and policies to decarbonize global industry: Review and assessment of mitigation drivers through 2070. Appl. Energy 2020, 266, 114848. [Google Scholar] [CrossRef]

- The International Energy Agency (IEA). 2025 Statistical Review of World Energy. 2025. Available online: https://www.iea.org/data-and-statistics/charts/global-energy-related-co2-emissions-by-sector (accessed on 22 June 2025).

- Lee, S. Special Issue: “Recent Developments in Geopolymers and Alkali-Activated Materials”. Materials 2024, 17, 245. [Google Scholar] [CrossRef] [PubMed]

- Panchami, R.; Deepa Raj, S. Geopolymer Concrete—Advancements, Challenges and Future Prospects. In Technologies for Sustainable Buildings and Infrastructure; Springer: Singapore, 2024; pp. 217–228. [Google Scholar]

- Alahmari, T.S.; Abdalla, T.A.; Rihan, M.A.M. Review of Recent Developments Regarding the Durability Performance of Eco-Friendly Geopolymer Concrete. Buildings 2023, 13, 3033. [Google Scholar] [CrossRef]

- AS 3972-2010; General Purpose and Blended Cements. Standards Australia: Sydney, Australia, 2010.

- EN 206:2013+A2:2021; Concrete—Specification, Performance, Production and Conformity. European Standard: Brussels, Belgium, 2021.

- ASTM C1897-20; Standard Test Methods for Measuring the Reactivity of Supplementary Cementitious Materials by Isothermal Calorimetry and Bound Water Measurements. ASTM: West Conshohocken, PA, USA, 2020.

- RILEM TC-283-CAM:2023; Chloride Transport in Alkali-Activated Materials. The International Union of Laboratories and Experts in Construction Materials, Systems and Structures: Champs-sur-Marne, France, 2023.

- Davidovits, J. State of the Geopolymer R&D. In Proceedings of the Geopolymer Camp 2014, Saint Quentin, France, 7–9 July 2014. [Google Scholar]

- The World Bank Group. Electricity Production from Coal Sources; International Bank for Reconstruction and Development/The World Bank: Washington, DC, USA, 2024. [Google Scholar]

- Hamed, Y.R.; Keshta, M.M.; Elshikh, M.M.Y.; Elshami, A.A.; Matthana, M.H.S.; Youssf, O. Performance of Sustainable Geopolymer Concrete Made of Different Alkaline Activators. Infrastructures 2025, 10, 41. [Google Scholar] [CrossRef]

- Al-Akhras, N.M.; Jamal Shannag, M.; Malkawi, A.B. Evaluation of shear-deficient lightweight RC beams retrofitted with adhesively bonded CFRP sheets. Eur. J. Environ. Civ. Eng. 2016, 20, 899–913. [Google Scholar] [CrossRef]

- Nuruddin, M.F.; Malkawi, A.B.; Fauzi, A.; Mohammed, B.S.; Almattarneh, H.M. Geopolymer concrete for structural use: Recent findings and limitations. IOP Conf. Ser. Mater. Sci. Eng. 2016, 133, 12021. [Google Scholar] [CrossRef]

- ACI-318-Committee. Building Code Requirements for Structural Concrete (ACI 318-14) and Commentary; American Concrete Institute: Farmington Hills, MI, USA, 2014. [Google Scholar]

- Albitar, M.; Visintin, P.; Mohamed Ali, M.S.; Drechsler, M. Assessing behaviour of fresh and hardened geopolymer concrete mixed with class-F fly ash. KSCE J. Civ. Eng. 2014, 19, 1445–1455. [Google Scholar] [CrossRef]

- Atiş, C.D.; Bilim, C.; Çelik, Ö.; Karahan, O. Influence of activator on the strength and drying shrinkage of alkali-activated slag mortar. Constr. Build. Mater. 2009, 23, 548–555. [Google Scholar] [CrossRef]

- Sarker, P.K. Bond strength of reinforcing steel embedded in fly ash-based geopolymer concrete. Mater. Struct. 2010, 44, 1021–1030. [Google Scholar] [CrossRef]

- Hardjito, D.; Rangan, B.V. Development and Properties of Low-Calcium Fly Ash-Based Geopolymer Concrete; Curtin University of Technology: Perth, Australia, 2005; p. 94. [Google Scholar]

- Topark-Ngarm, P.; Chindaprasirt, P.; Sata, V. Setting Time, Strength, and Bond of High-Calcium Fly Ash Geopolymer Concrete. J. Mater. Civ. Eng. 2015, 27, 4014198. [Google Scholar] [CrossRef]

- Khalaj, M.-J.; Khoshakhlagh, A.; Bahri, S.; Khoeini, M.; Nazerfakhari, M. Split tensile strength of slag-based geopolymer composites reinforced with steel fibers: Application of Taguchi method in evaluating the effect of production parameters and their optimum condition. Ceram. Int. 2015, 41, 10697–10701. [Google Scholar] [CrossRef]

- Thomas, R.J.; Peethamparan, S. Alkali-activated concrete: Engineering properties and stress–strain behavior. Constr. Build. Mater. 2015, 93, 49–56. [Google Scholar] [CrossRef]

- Ryu, G.S.; Lee, Y.B.; Koh, K.T.; Chung, Y.S. The mechanical properties of fly ash-based geopolymer concrete with alkaline activators. Constr. Build. Mater. 2013, 47, 409–418. [Google Scholar] [CrossRef]

- Diaz-Loya, E.I.; Allouche, E.N.; Vaidya, S. Mechanical properties of fly-ash-based geopolymer concrete. ACI Mater. J. 2011, 108, 300–306. [Google Scholar]

- Diaz, E.; Allouche, E. Recycling of fly ash into geopolymer concrete: Creation of a database. In Proceedings of the 2010 IEEE Green Technologies Conference, Grapevine, TX, USA, 15–16 April 2010; pp. 1–7. [Google Scholar]

- Joseph, B.; Mathew, G. Influence of aggregate content on the behavior of fly ash based geopolymer concrete. Sci. Iran. 2012, 19, 1188–1194. [Google Scholar] [CrossRef]

- Malkawi, A.B. Effect of Aggregate on the Performance of Fly-Ash-Based Geopolymer Concrete. Buildings 2023, 13, 769. [Google Scholar] [CrossRef]

- Haider, G.M.; Sanjayan, J.G.; Ranjith, P.G. Complete triaxial stress–strain curves for geopolymer. Constr. Build. Mater. 2014, 69, 196–202. [Google Scholar] [CrossRef]

- Ganesan, N.; Abraham, R.; Deepa Raj, S.; Sasi, D. Stress–strain behaviour of confined Geopolymer concrete. Constr. Build. Mater. 2014, 73, 326–331. [Google Scholar] [CrossRef]

- Jwaida, Z.; Dulaimi, A.; Mashaan, N.; Othuman Mydin, M.A. Geopolymers: The Green Alternative to Traditional Materials for Engineering Applications. Infrastructures 2023, 8, 98. [Google Scholar] [CrossRef]

- Khan, Q.S.; Akbar, H.; Qazi, A.U.; Kazmi, S.M.S.; Munir, M.J. Bond Stress Behavior of a Steel Reinforcing Bar Embedded in Geopolymer Concrete Incorporating Natural and Recycled Aggregates. Infrastructures 2024, 9, 93. [Google Scholar] [CrossRef]

- Sarker, P.K. Analysis of geopolymer concrete columns. Mater. Struct. 2009, 42, 715–724. [Google Scholar] [CrossRef]

- Nuruddin, M.F.; Malkawi, A.B.; Fauzi, A.; Mohammed, B.S.; Almattarneh, H.M. Evolution of geopolymer binders: A review. IOP Conf. Ser. Mater. Sci. Eng. 2016, 133, 012052. [Google Scholar] [CrossRef]

- Mahameid, A.; Yasin, A.; Malkawi, A. Prediction of the Compressive and Tensile Strengths of Geopolymer Concrete Using Artificial Neural Networks. Civ. Eng. Archit. 2024, 12, 3193–3206. [Google Scholar] [CrossRef]

- Winnefeld, F.; Leemann, A.; Lucuk, M.; Svoboda, P.; Neuroth, M. Assessment of phase formation in alkali activated low and high calcium fly ashes in building materials. Constr. Build. Mater. 2010, 24, 1086–1093. [Google Scholar] [CrossRef]

- Al-Mattarneh, H.; Rawashdeh, A.; Ismail, R.; Matalkah, F.; Alhussien, N.; Malkawi, A. User-Friendly Software System for Geopolymer Concrete Slump and Strength Prediction. In Proceedings of the 2024 IEEE 30th International Conference on Telecommunications (ICT), Amman, Jordan, 24–27 June 2024; pp. 1–7. [Google Scholar]

- Luan, C.; Wang, Q.; Yang, F.; Zhang, K.; Utashev, N.; Dai, J.; Shi, X. Practical Prediction Models of Tensile Strength and Reinforcement-Concrete Bond Strength of Low-Calcium Fly Ash Geopolymer Concrete. Polymers 2021, 13, 875. [Google Scholar] [CrossRef]

- Gunasekera, C.; Setunge, S.; Law, D.W. Correlations between Mechanical Properties of Low-Calcium Fly Ash Geopolymer Concretes. J. Mater. Civ. Eng. 2017, 29, 4017111. [Google Scholar] [CrossRef]

- Olivia, M.; Nikraz, H. Properties of fly ash geopolymer concrete designed by Taguchi method. Mater. Des. 2012, 36, 191–198. [Google Scholar] [CrossRef]

- Sofi, M.; Van Deventer, J.; Mendis, P.; Lukey, G. Engineering properties of inorganic polymer concretes (IPCs). Cem. Concr. Res. 2007, 37, 251–257. [Google Scholar] [CrossRef]

- Aliabdo, A.A.; Abd Elmoaty, A.E.M.; Salem, H.A. Effect of cement addition, solution resting time and curing characteristics on fly ash based geopolymer concrete performance. Constr. Build. Mater. 2016, 123, 581–593. [Google Scholar] [CrossRef]

- Chang, E.H. Shear and bond behaviour of reinforced fly ash-based geopolymer concrete beams. Ph.D. Thesis, Curtin University, Perth, Australia, 2009. [Google Scholar]

- Nikoloutsopoulos, N.; Sotiropoulou, A.; Kakali, G.; Tsivilis, S. Physical and Mechanical Properties of Fly Ash Based Geopolymer Concrete Compared to Conventional Concrete. Buildings 2021, 11, 178. [Google Scholar] [CrossRef]

- Hassan, A.; Arif, M.; Shariq, M. Effect of curing condition on the mechanical properties of fly ash-based geopolymer concrete. SN Appl. Sci. 2019, 1, 1694. [Google Scholar] [CrossRef]

- Shaji, P.; Manoj, A.; Emmanuel, F.; Sreelakshmi, G.; Venu, S.M. Study of Mechanical Properties of Fly Ash Based Geopolymer Concrete. Int. Res. J. Eng. Technol. 2018, 5, 3613–3618. Available online: https://www.irjet.net/archives/V5/i3/IRJET-V5I3847.pdf (accessed on 17 June 2025).

- Raijiwala, D.B.; Patil, H.S. Geopolymer concrete A green concrete. In Proceedings of the 2010 2nd International Conference on Chemical, Biological and Environmental Engineering, Cairo, Egypt, 2–4 November 2010; pp. 202–206. [Google Scholar]

- Raijiwala, D.; Patil, H. Geopolymer concrete: A concrete of next decade. J. Eng. Res. Stud. 2011, 2, 19–25. [Google Scholar]

- Islam, R.; Montes, C.; Allouche, E. Correlation between chemical and phase composition of fly ash and mechanical properties of geopolymer concrete. Int. J. Environ. Eng. Nat. Resour. 2014, 1, 235–239. [Google Scholar]

- Wardhono, A.; Gunasekara, C.; Law, D.W.; Setunge, S. Comparison of long term performance between alkali activated slag and fly ash geopolymer concretes. Constr. Build. Mater. 2017, 143, 272–279. [Google Scholar] [CrossRef]

- Gunasekara, M.; Law, D.W.; Setunge, S. The effect of type of fly ash on mechanical properties of geopolymer concrete. In Proceedings of the 27th Biennial National Conference of the Concrete Institute of Australia, Adelaide, Australia, 30 August–2 September 2015; pp. 586–595. [Google Scholar]

- Pan, Z.; Sanjayan, J.G.; Rangan, B.V. Fracture properties of geopolymer paste and concrete. Mag. Concr. Res. 2011, 63, 763–771. [Google Scholar] [CrossRef]

- Gomaa, E.; Sargon, S.; Kashosi, C.; Gheni, A.; ElGawady, M.A. Mechanical Properties of High Early Strength Class C Fly Ash-Based Alkali Activated Concrete. Transp. Res. Rec. 2020, 2674, 430–443. [Google Scholar] [CrossRef]

- Bhikshma, V.; Koti, R.M.; Srinivas, R.T. An experimental investigation on properties of geopolymer concrete (no cement concrete). Asian J. Civ. Eng. 2012, 13, 841–853. [Google Scholar]

- Nguyen, K.T.; Ahn, N.; Le, T.A.; Lee, K. Theoretical and experimental study on mechanical properties and flexural strength of fly ash-geopolymer concrete. Constr. Build. Mater. 2016, 106, 65–77. [Google Scholar] [CrossRef]

- Phoo-ngernkham, T.; Phiangphimai, C.; Damrongwiriyanupap, N.; Hanjitsuwan, S.; Thumrongvut, J.; Chindaprasirt, P. A Mix Design Procedure for Alkali-Activated High-Calcium Fly Ash Concrete Cured at Ambient Temperature. Adv. Mater. Sci. Eng. 2018, 2018, 2460403. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, P.K. Flexural strength and elastic modulus of ambient-cured blended low-calcium fly ash geopolymer concrete. Constr. Build. Mater. 2017, 130, 22–31. [Google Scholar] [CrossRef]

- Evin; Rachmansyah. The ratio between flexural strength to compressive strength of geopolymer concrete. IOP Conf. Ser. Earth Environ. Sci. 2023, 1195, 012034. [Google Scholar] [CrossRef]

- Yost, J.R.; Radlińska, A.; Ernst, S.; Salera, M.; Martignetti, N.J. Structural behavior of alkali activated fly ash concrete. Part 2: Structural testing and experimental findings. Mater. Struct. 2013, 46, 449–462. [Google Scholar] [CrossRef]

- Fernandez-Jimenez, A.M.; Palomo, A.; Lopez-Hombrados, C. Engineering properties of alkali-activated fly ash concrete. ACI Mater. J. 2006, 103, 106–112. [Google Scholar]

- Hardjito, D.; Sumajouw, D.M.; Wallah, S.; Rangan, B. Fly ash-based geopolymer concrete. Aust. J. Struct. Eng. 2005, 6, 77–86. [Google Scholar] [CrossRef]

- Noushini, A.; Aslani, F.; Castel, A.; Gilbert, R.I.; Uy, B.; Foster, S. Compressive stress-strain model for low-calcium fly ash-based geopolymer and heat-cured Portland cement concrete. Cem. Concr. Compos. 2016, 73, 136–146. [Google Scholar] [CrossRef]

- Hardjito, D.; Wallah, S.E.; Sumajouw, D.M.J.; Rangan, B.V. Introducing Fly Ash-Based Geopolymer Concrete: Manufacture and Engineering Properties. In Proceedings of the 30th Conference on Our World In Concrete & Structures, Singapore, 23–24 August 2005. [Google Scholar]

- Mohammed, A.A.; Ahmed, H.U.; Mosavi, A. Survey of Mechanical Properties of Geopolymer Concrete: A Comprehensive Review and Data Analysis. Materials 2021, 14, 4690. [Google Scholar] [CrossRef] [PubMed]

- Özbayrak, A.; Kucukgoncu, H.; Atas, O.; Aslanbay, H.H.; Aslanbay, Y.G.; Altun, F. Determination of stress-strain relationship based on alkali activator ratios in geopolymer concretes and development of empirical formulations. Structures 2023, 48, 2048–2061. [Google Scholar] [CrossRef]

- Apichat, J.; Piyawat, F.; Patcharapol, P.; Nonthaseith, L.; Ampol, W.; Vanchai, S.; Prinya, C. Stress-Strain Relationship of Geopolymer Concrete Under Compressive Loading. GEOMATE J. 2025, 28, 71–78. [Google Scholar]

- Farhan, N.A.; Sheikh, M.N.; Hadi, M.N.S. Investigation of engineering properties of normal and high strength fly ash based geopolymer and alkali-activated slag concrete compared to ordinary Portland cement concrete. Constr. Build. Mater. 2019, 196, 26–42. [Google Scholar] [CrossRef]

- Prachasaree, W.; Limkatanyu, S.; Hawa, A.; Samakrattakit, A. Development of Equivalent Stress Block Parameters for Fly-Ash-Based Geopolymer Concrete. Arab. J. Sci. Eng. 2014, 39, 8549–8558. [Google Scholar] [CrossRef]

- Yazıcı, Ş.; İnan Sezer, G. The effect of cylindrical specimen size on the compressive strength of concrete. Build. Environ. 2007, 42, 2417–2420. [Google Scholar] [CrossRef]

- Kadleček, V.; Modrý, S.; Kadleček, V. Size effect of test specimens on tensile splitting strength of concrete: General relation. Mater. Struct. 2002, 35, 28–34. [Google Scholar] [CrossRef]

- Al Bakri, A.M.; Kamarudin, H.; Bnhussain, M.; Rafiza, A.; Zarina, Y. Effect of Na2SiO3/NaOH ratios and NaOH molarities on compressive strength of fly-ash-based geopolymer. ACI Mater. J. 2012, 109, 503–508. [Google Scholar]

- Risdanareni, P.; Ekaputri, J.J.; Triwulan, T. The Influence of Alkali Activator Concentration to Mechanical Properties of Geopolymer Concrete with Trass as a Filler. Mater. Sci. Forum 2014, 803, 125–134. [Google Scholar] [CrossRef]

- Duxson, P.; Lukey, G.; Separovic, F.; Van Deventer, J. Effect of alkali cations on aluminum incorporation in geopolymeric gels. Ind. Eng. Chem. Res. 2005, 44, 832–839. [Google Scholar] [CrossRef]

- Frías, M.; Martínez-Ramírez, S.; Blasco, T.; Rodríguez, M.F.; Viehland, D. Evolution of Mineralogical Phases by27Al and29Si NMR in MK-Ca(OH)2System Cured at 60 °C. J. Am. Ceram. Soc. 2013, 96, 2306–2310. [Google Scholar] [CrossRef]

- Hos, J.; McCormick, P.; Byrne, L. Investigation of a synthetic aluminosilicate inorganic polymer. J. Mater. Sci. 2002, 37, 2311–2316. [Google Scholar] [CrossRef]

- Diaz, E.I.; Allouche, E.N.; Eklund, S. Factors affecting the suitability of fly ash as source material for geopolymers. Fuel 2010, 89, 992–996. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, P.K. Effect of GGBFS on setting, workability and early strength properties of fly ash geopolymer concrete cured in ambient condition. Constr. Build. Mater. 2014, 66, 163–171. [Google Scholar] [CrossRef]

- Sathonsaowaphak, A.; Chindaprasirt, P.; Pimraksa, K. Workability and strength of lignite bottomash geopolymer mortar. J. Hazard. Mater. 2009, 168, 44–50. [Google Scholar] [CrossRef] [PubMed]

- FIB (Federation Internationale Du Beton). Fib Model Code for Concrete Structures 2010; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Committee, A.C.I. High-Strength Concrete (ACI 363R). Am. Concr. Inst. 2005, 228, 79–80. [Google Scholar] [CrossRef]

- AS3600-2001; Concrete Structures. Standards Australia: Sydney, Australia, 2018.

- Lee, S.; Shin, S. Prediction on Compressive and Split Tensile Strengths of GGBFS/FA Based GPC. Materials 2019, 12, 4198. [Google Scholar] [CrossRef] [PubMed]

- Dissanayake, D.; Dissanayake, D.; Pathirana, C. Strength properties of fly ash based geopolymer concrete cured at different temperatures. Electron. J. Struct. Eng. 2022, 22, 19–26. [Google Scholar] [CrossRef]

- Jindal, B.B.; Parveen; Singhal, D.; Goyal, A. Predicting relationship between mechanical properties of low calcium fly ash-based geopolymer concrete. Trans. Indian Ceram. Soc. 2017, 76, 258–265. [Google Scholar] [CrossRef]

- Rawlings, J.O.; Pantula, S.G.; Dickey, D.A. Applied Regression Analysis: A Research Tool; Springer: New York, NY, USA, 1998. [Google Scholar]

- Lee, N.; Lee, H. Setting and mechanical properties of alkali-activated fly ash/slag concrete manufactured at room temperature. Constr. Build. Mater. 2013, 47, 1201–1209. [Google Scholar] [CrossRef]

- ACI-318-Committee. Building Code Requirements for Structural Concrete (ACI 318-11) and Commentary; American Concrete Institute: Farmington Hills, MI, USA, 2011. [Google Scholar]

- Chitrala, S.; Jadaprolu, G.J.; Chundupalli, S. Study and predicting the stress-strain characteristics of geopolymer concrete under compression. Case Stud. Constr. Mater. 2018, 8, 172–192. [Google Scholar] [CrossRef]

- Sarker, P. A constitutive model for fly ash-based geopolymer concrete. Arch. Civ. Eng. Environ. 2008, 1, 113–120. [Google Scholar]

- Fan, X.; Zhang, M. Behaviour of inorganic polymer concrete columns reinforced with basalt FRP bars under eccentric compression: An experimental study. Compos. Part B Eng. 2016, 104, 44–56. [Google Scholar] [CrossRef]

- Fletcher, R.A.; MacKenzie, K.J.; Nicholson, C.L.; Shimada, S. The composition range of aluminosilicate geopolymers. J. Eur. Ceram. Soc. 2005, 25, 1471–1477. [Google Scholar] [CrossRef]

| Composition | CaO | MgO | MnO | ZnO | LOI | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fly ash | 45.2 | 13.4 | 19.3 | 10.9 | 1.1 | 0.4 | 0.6 | 1.0 | 2.0 | 1.2 | 0.3 | 3.6 |

| Designation | Alk/FA | NS/Alk | Si/Al | Na/Al |

|---|---|---|---|---|

| 0.35A0.3N | 0.35 | 0.3 | 3.60 | 0.52 |

| 0.45A0.3N | 0.45 | 0.3 | 3.67 | 0.65 |

| 0.55A0.3N | 0.55 | 0.3 | 3.73 | 0.77 |

| 0.65A0.3N | 0.65 | 0.3 | 3.80 | 0.89 |

| 0.35A0.45N | 0.35 | 0.45 | 3.71 | 0.51 |

| 0.45A0.45N | 0.45 | 0.45 | 3.81 | 0.63 |

| 0.55A0.45N | 0.55 | 0.45 | 3.91 | 0.75 |

| 0.65A0.45N | 0.65 | 0.45 | 4.01 | 0.87 |

| 0.35A0.6N | 0.35 | 0.6 | 3.83 | 0.50 |

| 0.45A0.6N | 0.45 | 0.6 | 3.96 | 0.61 |

| 0.55A0.6N | 0.55 | 0.6 | 4.09 | 0.73 |

| 0.65A0.6N | 0.65 | 0.6 | 4.22 | 0.85 |

| Item | Mean | Standard Deviation | Minimum | Maximum | Grubbs’ Test | p |

|---|---|---|---|---|---|---|

| 3.59 | 1.10 | 0.94 MPa | 5.92 MPa | 2.40 | 1.000 | |

| 4.49 | 1.33 | 0.62 MPa | 7.39 MPa | 2.92 | 0.688 | |

| 24.07 | 8.73 | 1.87 GPa | 47.51 GPa | 2.68 | 1.000 | |

| 44.26 | 17.43 | 13.5 MPa | 87.4 MPa | 2.47 | 1.000 | |

| Peak ε | 0.00252 | 0.00045 | 0.00163 | 0.00363 | 2.5 | 0.948 |

| Ultimate ε | 0.00602 | 0.00364 | 0.00230 | 0.01658 | 2.89 | 0.053 |

| Strength Grade (MPa) | Shape and Size of Specimen | ||

|---|---|---|---|

| Cylinder 10 × 20 cm | Cube 10 cm | Cube 15 cm | |

| 0.901 | 0.825 | 0.915 | |

| G20–40 | 0.971 | 0.762 | 0.800 |

| 0.971 | 0.790 | 0.830 | |

| 0.971 | 0.819 | 0.860 | |

| 0.971 | 0.833 | 0.875 | |

| 0.971 | 0.848 | 0.890 | |

| Reference | m | n | Reference | m | n |

|---|---|---|---|---|---|

| CEB-FIP [78] (OPC) | 0.30 | 0.67 | ACI 363 [79] (OPC) | 0.59 | 0.50 |

| AS 3600 [80] (OPC) | 0.4 | 0.5 | ACI318 [15] (OPC) | 0.56 | 0.50 |

| Ryu et al. [23] (GPC) | 0.17 | 0.75 | Gunasekera et al. [38] (GPC) | 0.45 | 0.50 |

| Luan et al. [37] (GPC) | 0.203 | 0.722 | Lee et al. [81] (GPC) | 0.47 | 0.52 |

| Dissanayake [82] (GPC) | 0.27 | 0.67 | Jindal et al. [83] (GPC) | 0.426 | 0.519 |

| Albitar et al. [16] (GPC) | 0.6 | 0.5 | Thomas et al. [22] (GPC) | 0.40 | 0.778 |

| Reference | m | n | Reference | m | n |

|---|---|---|---|---|---|

| ACI 363 [79] (OPC) | 0.94 | 0.5 | AS 3600 [80] (OPC) | 0.6 | 0.5 |

| ACI318 [15] (OPC) | 0.62 | 0.5 | Gunasekera et al. [38] (GPC) | 0.7 | 0.5 |

| Albitar et al. [16] (GPC) | 0.75 | 0.5 | Azad et al. [63] (GPC) | 0.293 | 0.765 |

| Diaz-Loya et al. [24] (GPC) | 0.69 | 0.5 | Islam R. et al. [48] (GPC) | 0.64 | 0.5 |

| Gomaa E. et al. [52] (GPC) | 0.65 | 0.5 | Nath P. et al. [56] (GPC) | 0.93 | 0.5 |

| Reference | Model |

|---|---|

| CEB-FIP [78] (OPC) | is a factor ranging from 0.7 to 1.2 to consider the effect of aggregate type |

| ACI318 [15] (OPC) | ) |

| ACI 363 [79] (OPC) | |

| AS 3600 [80] (OPC) | |

| Gunasekera et al. [38] (GPC) | |

| Diaz-Loya et al. [24] (GPC) | |

| Nath and Sarker [56] (GPC) | |

| Lee and Lee (GPC) [85] | |

| Hassan and Shariq [44] (GPC) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malkawi, A.B. Assessing Engineering Behavior of Fly Ash-Based Geopolymer Concrete: Empirical Modeling. Infrastructures 2025, 10, 168. https://doi.org/10.3390/infrastructures10070168

Malkawi AB. Assessing Engineering Behavior of Fly Ash-Based Geopolymer Concrete: Empirical Modeling. Infrastructures. 2025; 10(7):168. https://doi.org/10.3390/infrastructures10070168

Chicago/Turabian StyleMalkawi, Ahmad B. 2025. "Assessing Engineering Behavior of Fly Ash-Based Geopolymer Concrete: Empirical Modeling" Infrastructures 10, no. 7: 168. https://doi.org/10.3390/infrastructures10070168

APA StyleMalkawi, A. B. (2025). Assessing Engineering Behavior of Fly Ash-Based Geopolymer Concrete: Empirical Modeling. Infrastructures, 10(7), 168. https://doi.org/10.3390/infrastructures10070168