Characterization of Recycled Aggregates from Building Demolition Waste for Use in Road Infrastructures

Abstract

1. Introduction

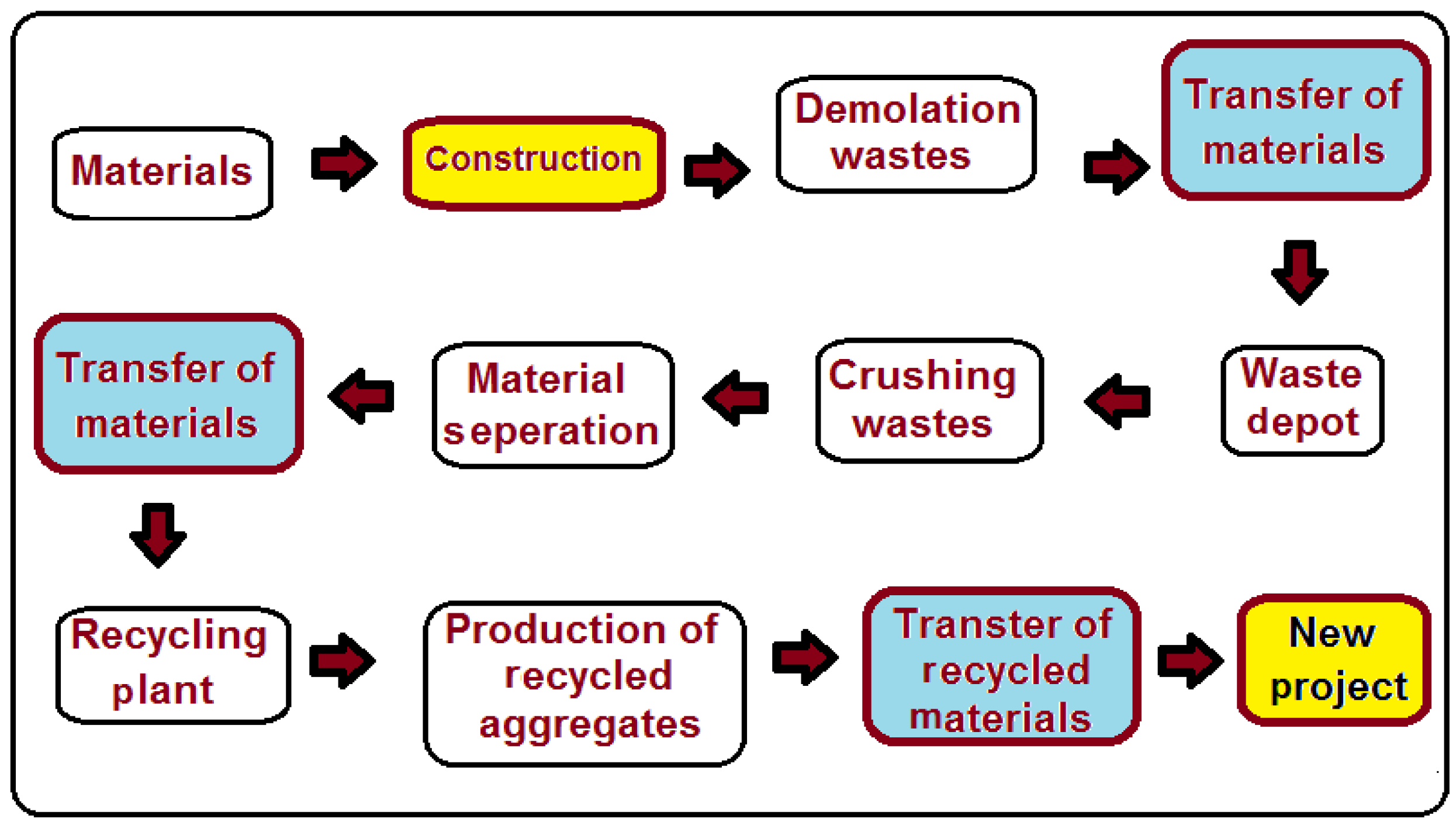

2. Methods and Materials

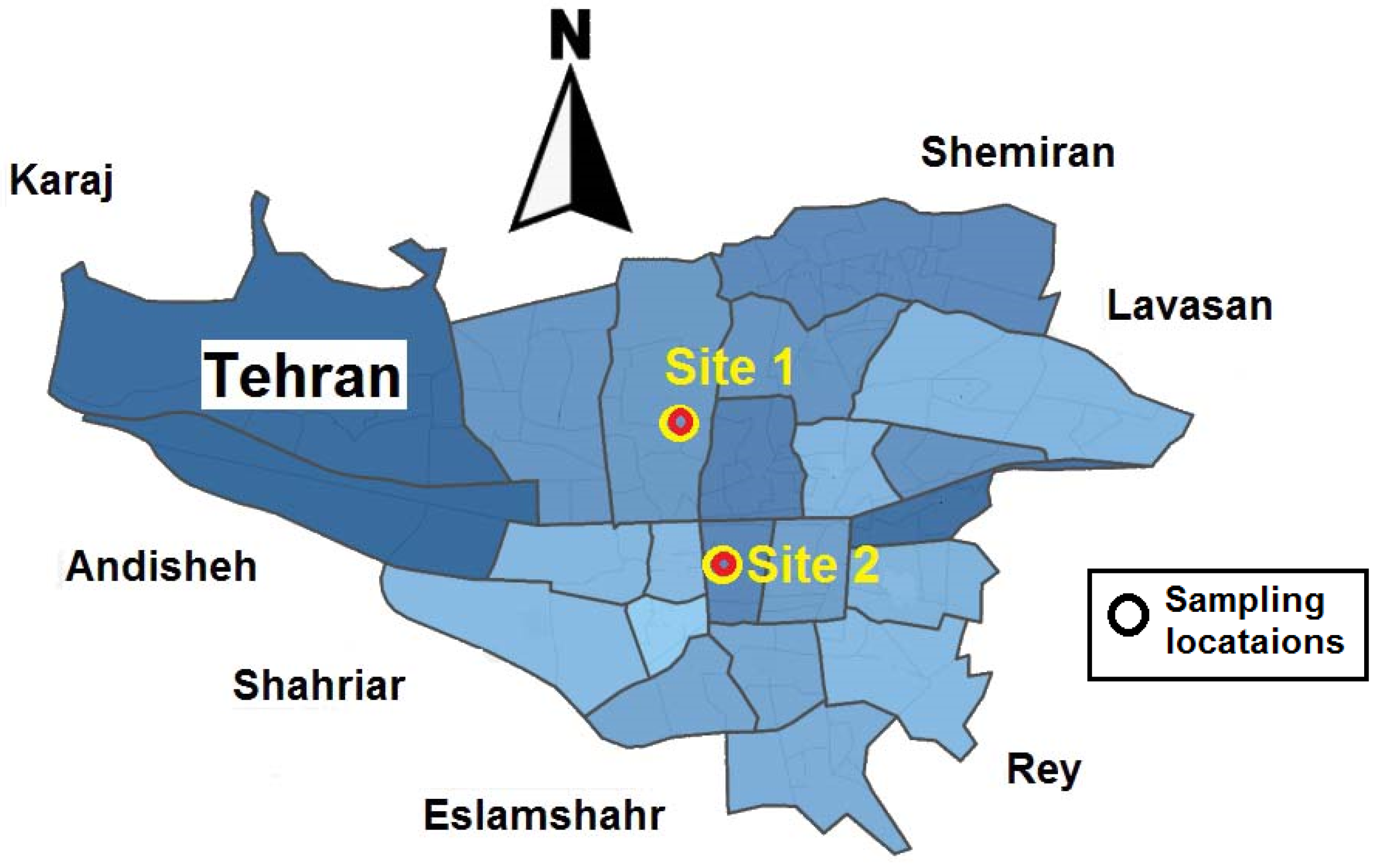

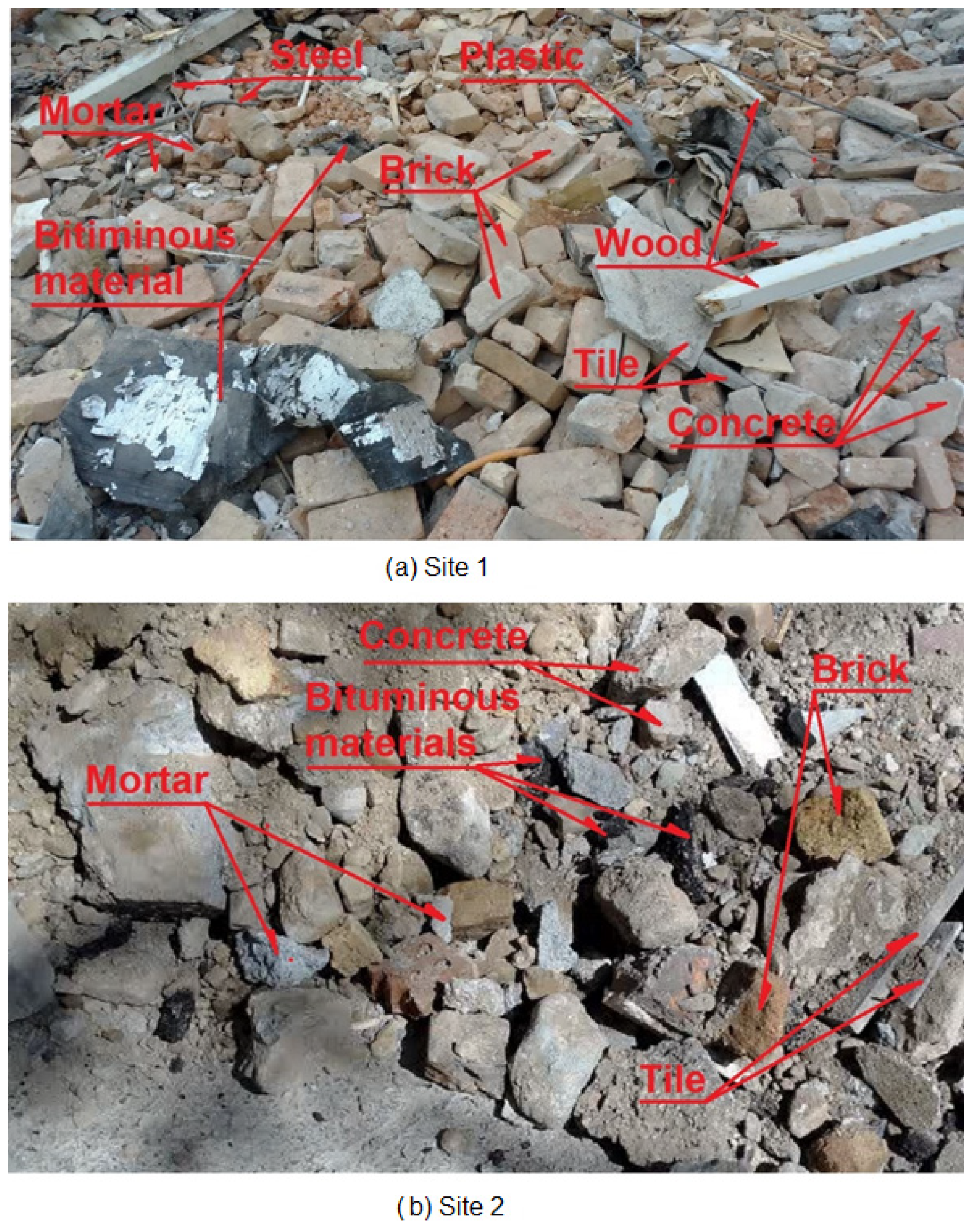

2.1. BDWM

2.2. NM

2.3. Experiments

3. Results of Basic Laboratory Testing for the Identification of BDWM and NM Properties

3.1. WAT

3.2. FI

3.3. LAAT

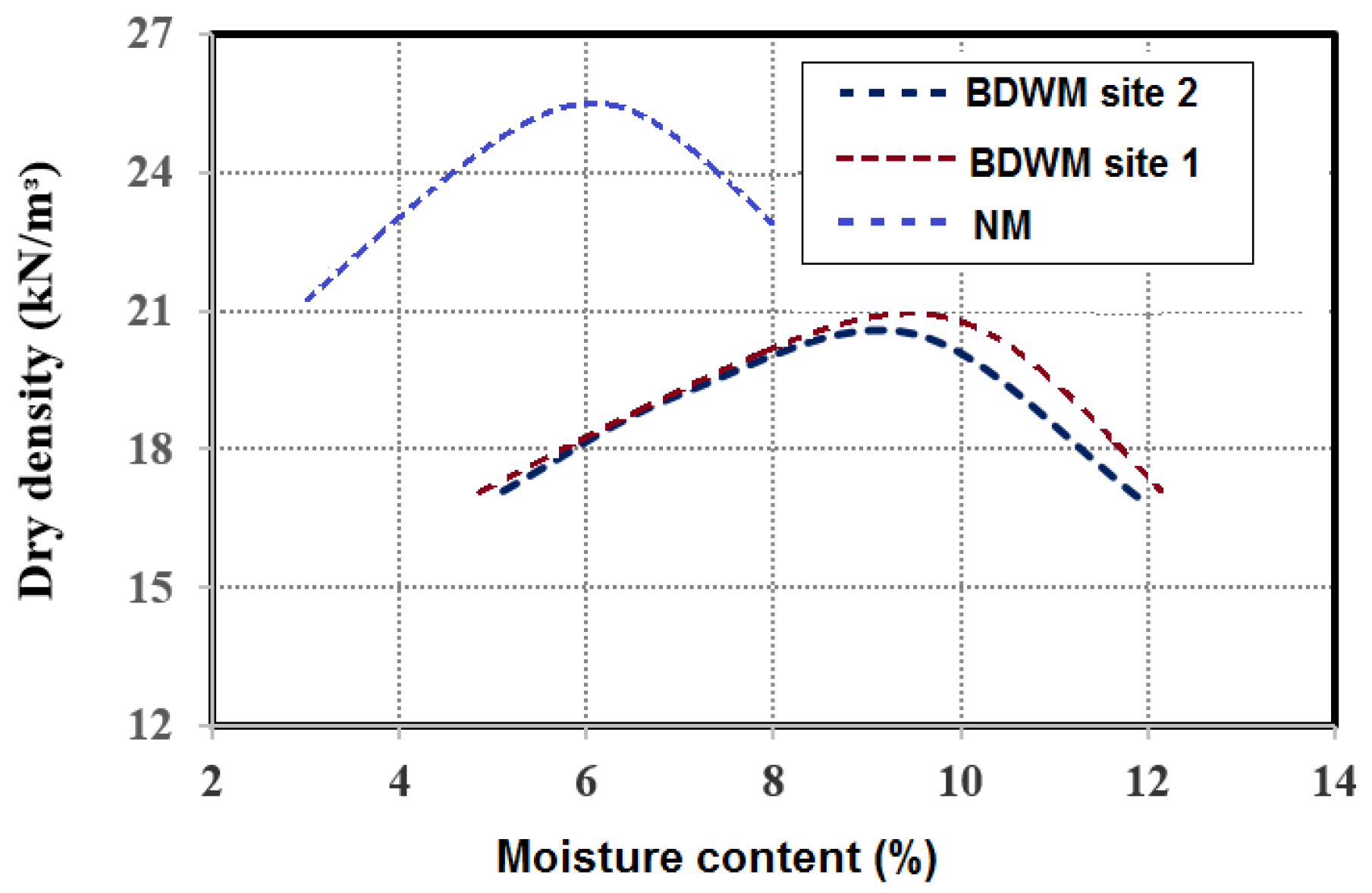

3.4. Modified PSCT

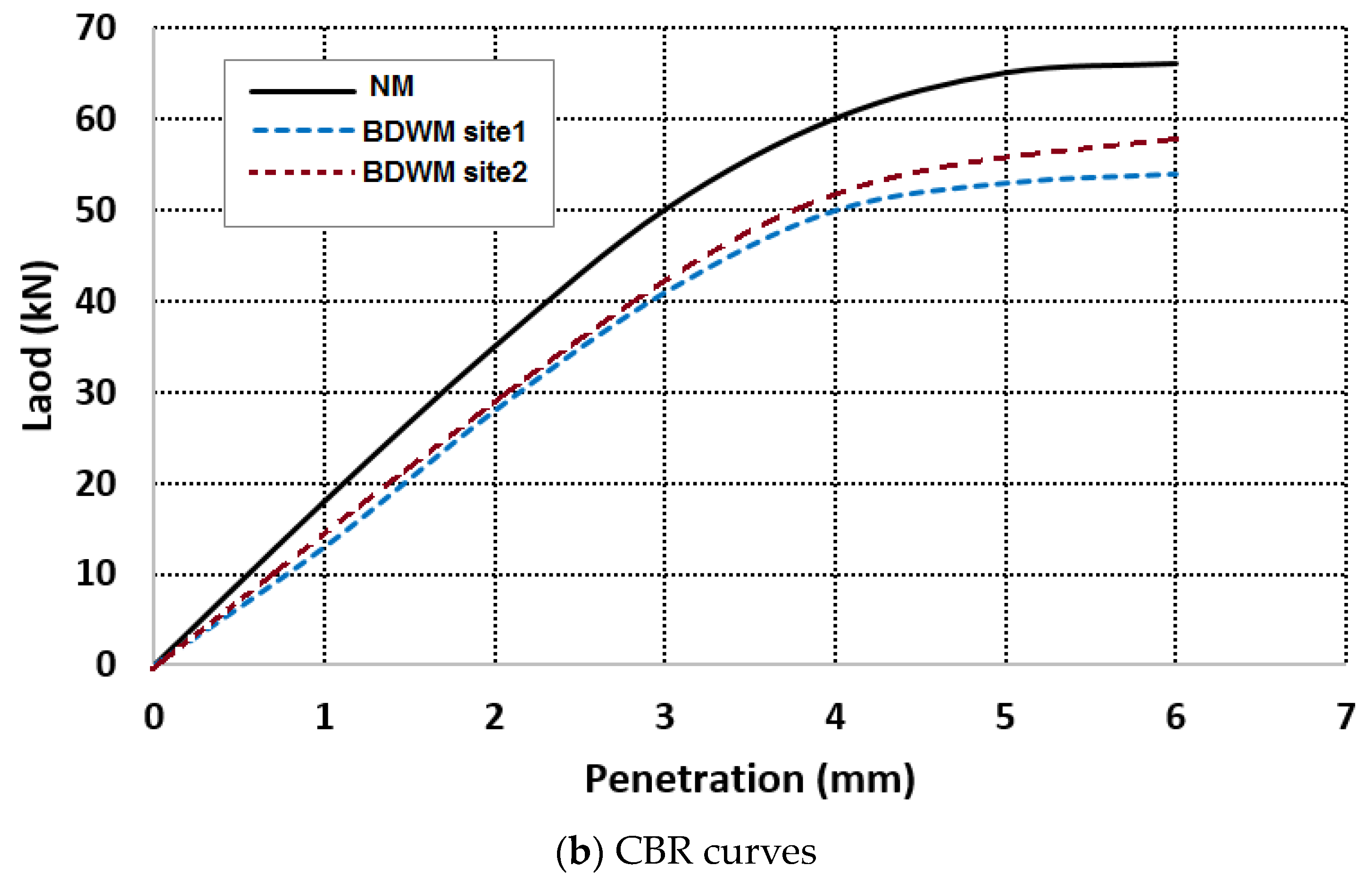

3.5. CBR

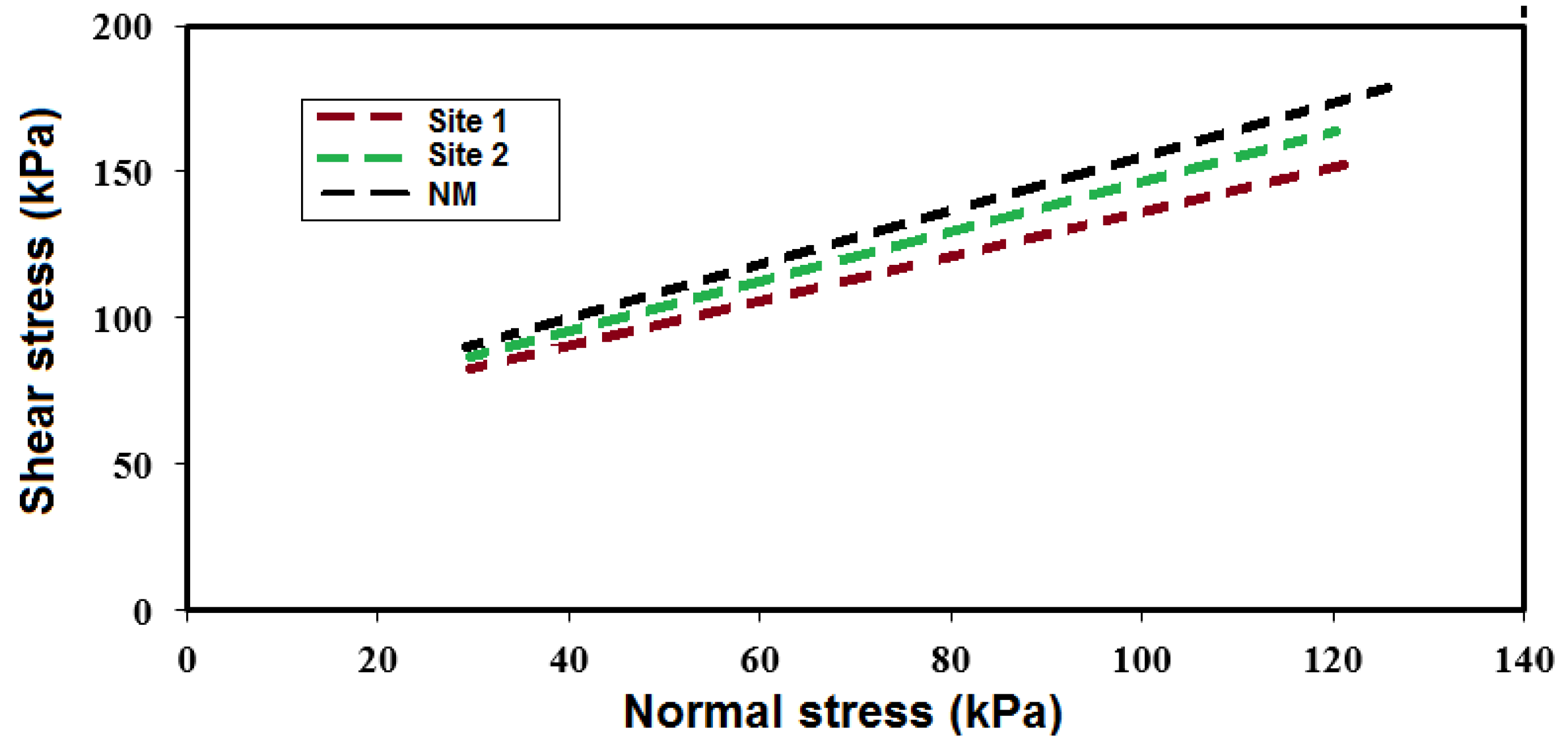

3.6. Strength Behavior of BDWM and NM

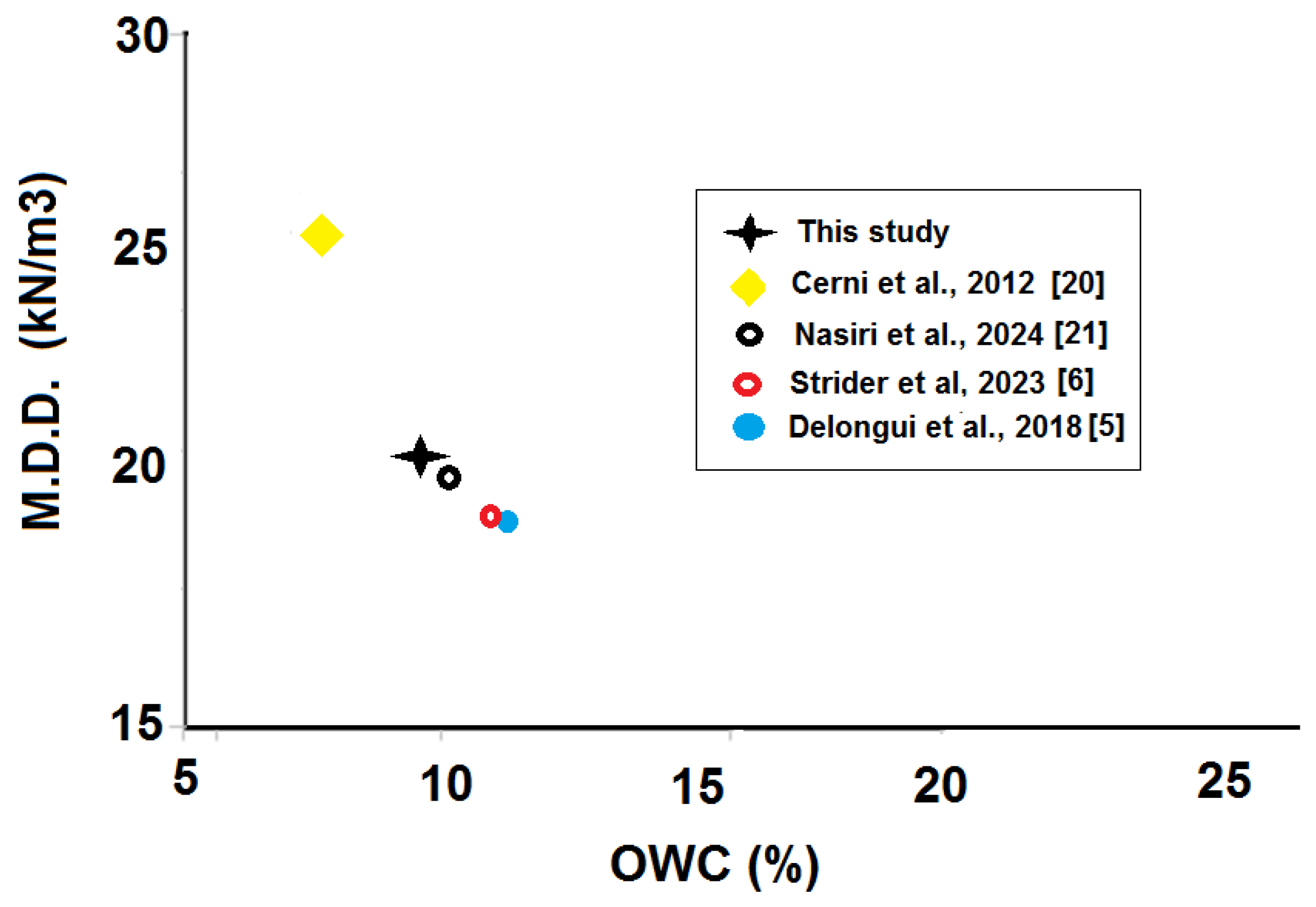

4. Comparing Using BDWM with Similar Trends

| Cases | Types of Aggregates | Properties of Waste | ||||||

|---|---|---|---|---|---|---|---|---|

| Cu | Cc | MDD (kN/m3) | LAAT (%) | C (kPa) | φ (°) | CBR (%) | ||

| Current Research (Site 1) | BDWM | 28.1 | 1.2 | 19.51 | 35.3 | 61 | 42 | 69 |

| Current Research (Site 2) | BDWM | 28.3 | 1.21 | 19.35 | 34.5 | 63 | 44 | 73 |

| Arulrajah et al., 2013 [9] | RCA | 31.2 | 0.9 | 19.13 | 28 | 44 | 49 | - |

| Herrador et al., 2012 [19] | RCA-RAP-CB | 30 | 1.29 | - | 34 | - | - | - |

| Cerni et al., 2012 [20] | CD waste | 85.71 | 1.93 | 25.7 | 37 | - | - | - |

| Nasiri et al., 2024 [21] | CD waste | 29.4 | 1.32 | 19.5 | 42.4 | 70 | 34 | 59 |

| Strider et al., 2023 [6] (AASHTO Hammer) | CDW1 | 86.7 | 2.5 | 18.4 | - | 60 | 51 | - |

| Strider et al., 2023 [6] (Vibrating Hammer) | CDW1 | 86.7 | 2.5 | 18.4 | - | 59 | 52 | - |

| Delongui et al., 2018 [5] | CDW | 20.3 | 0.6 | 18.7 | 57 | - | - | - |

5. Possibility of Using BDWM for Road Engineering

5.1. Slopes and Filling Materials

5.2. BDWM in Geo-Synthetic Reinforced Road Construction

5.3. Pavement Materials

6. Conclusions

- According to basic laboratory testing and identification of the BDWM from the study sites, the average composition was brick, concrete, mortar, tile, and others.

- In the current study, the physical properties of the NMs were compared to those of the recycled BDWMs, which were obtained from mines in Tehran, Iran. The mean particle size distribution at each site was then compared to the FHWA’s lower and upper limits. The SA results also revealed that the BDWMs were suitable for road base applications according to ASTM-D1241 and could be combined for highway sub-base and base.

- In this study, the LAAT values of the BDWM were 31.3–35.2%, while the FI score was 15.2–15.6% for the two sites. On the other hand, the BDWM’s FI, the Gs of the coarse and fine parts, uniformity and curvature coefficients, total LAAT values, OWC, and MDD all met the NM’s specified maximum amount.

- According to the experimental tests conducted in this study, the WAT values of the BDWM were 4 and 6.6 times higher than those of the NM for coarse and fine materials, respectively.

- The California bearing ratio values for the BDWM were 69–73%. The recycled materials also had a lower CBR than the NM. The state road authorities approved California bearing ratio values for sub-base and base materials of at least 80%. To achieve higher performance from recycled BDWM, those with CBR values of less than 80% could be mixed with NM.

- Considering the high percentage of CBs and RCA, the MDD and OWC were also 20.9 kN/m3 and 9.6%, respectively. As evidenced in previous research, the WAT values of the BDWM varied between 1 and 10%.

- In comparing the direct shear test results for the BDWM and NM, the curve trends were comparable. The values appeared to have good cohesion, which was enhanced by hydration via water absorption from the given mixture. Another reason for the cohesion was the low concentration of RAP in the samples.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| NM | Natural material |

| BDWM | Building demolition waste material |

| Gs | Specific gravity |

| LL | Liquid limit |

| PL | Plastic limit |

| PI | Plasticity index |

| OWC | Optimum water content |

| MDD | Maximum dry density |

| CBR | California bearing ratio |

| WAT | Water absorption test |

| RCA | Recycled concrete aggregate |

| FI | Flakiness index |

| LAAT | Los Angeles abrasion test |

| DST | Direct shear test |

| C | Cohesion |

| Fe | Angle of internal friction |

| SA | Sieve analysis |

| AL | Atterberg limits |

| Cu | Uniformity coefficient |

| Cc | Coefficient of curvature |

| PSCT | Modified proctor soil compaction test |

| PSD | Particle size distribution |

| CBs | recycled crushed bricks |

References

- Akbarimehr, D.; Rahai, A.; Eslami, A.; Karakouzian, M. Deformation Characteristics of Rubber Waste Powder–Clay Mixtures. Sustainability 2023, 15, 12384. [Google Scholar] [CrossRef]

- Eslami, A.; Nasiri, A.; Fahimifar, A. Improving the Geotechnical Properties of Recycled Non-Selected Construction Waste Using Geogrid Reinforcement. Int. J. Civ. Eng. 2022, 21, 583–602. [Google Scholar] [CrossRef]

- Nasiri, A.; Eslami, A.; Fahimifar, A.; Akbarimehr, D. Application of Geoelectrical Methods to Identify the Subsurface Layering Structure of Construction and Demolition Waste Depot. J. Environ. Eng. Geophys. 2024, 29, 93–102. [Google Scholar] [CrossRef]

- Jahangard, H.; Hosseini, S.M.M.M.; Ebadi, T.; Akbarimehr, D. Effect of gas oil contamination on dynamic geotechnical properties of clay–sand mixtures. Arab. J. Geosci. 2022, 15, 278. [Google Scholar] [CrossRef]

- Delongui, L.; Matuella, M.; Núñez, W.P.; Fedrigo, W.; da Silva Filho, L.C.P.; Ceratti, J.A.P. Construction and demolition waste parameters for rational pavement design. Constr. Build. Mater. 2018, 168, 105–112. [Google Scholar] [CrossRef]

- Strieder, H.L.; Schreinert, G.G.; Matuella, M.F.; Fedrigo, W.; Delongui, L.; Rutzen, D.; Núñez, W.P. Mechanical behavior of construction and demolition waste as pavement materials: Influence of mix composition and compaction conditions. Constr. Build. Mater. 2023, 408, 133698. [Google Scholar] [CrossRef]

- Fedrigo, W.; Kleinert, T.R.; Nunez, W.P.; Graeff, Â.G.; Pinto da Silva Filho, L.C.; Brito, L.A.T. Shrinkage of cold recycled cement-treated mixtures of asphalt pavement materials. J. Test. Eval. 2023, 51, 2230–2244. [Google Scholar] [CrossRef]

- Fedrigo, W.; Heller, L.F.; Brito, L.A.T.; Núñez, W.P. Fatigue of cold recycled cement-treated pavement layers: Experimental and modeling study. Sustainability 2023, 15, 7816. [Google Scholar] [CrossRef]

- Arulrajah, A.; Piratheepan, J.; Disfani, M.M.; Bo, M.W. Geotechnical and geoenvironmental properties of recycled construction and demolition materials in pavement subbase applications. J. Mater. Civ. Eng. 2013, 25, 1077–1088. [Google Scholar] [CrossRef]

- Vieira, C.S.; Pereira, P.M. Use of recycled construction and demolition materials in geotechnical applications: A review. Resour. Conserv. Recycl. 2015, 103, 192–204. [Google Scholar] [CrossRef]

- Agyeman, S.; Ampadu, S.I. Exploring the techno-economic feasibility of mine rock waste utilisation in road works: The case of a mining deposit in Ghana. Waste Manag. Res. 2016, 34, 156–164. [Google Scholar] [CrossRef] [PubMed]

- Tavira, J.; Jiménez, J.R.; Ayuso, J.; Sierra, M.J.; Ledesma, E.F. Functional and structural parameters of a paved road section constructed with mixed recycled aggregates from non-selected construction and demolition waste with excavation soil. Constr. Build. Mater. 2018, 164, 57–69. [Google Scholar] [CrossRef]

- Coelho, A.; De Brito, J. Generation of construction and demolition waste in Portugal. Waste Manag. Res. 2011, 29, 739–750. [Google Scholar] [CrossRef] [PubMed]

- Melbouci, B. Compaction and shearing behaviour study of recycled aggregates. Constr. Build. Mater. 2009, 23, 2723–2730. [Google Scholar] [CrossRef]

- Eslami, A.; Akbarimehr, D.; Rahai, A.; Karakouzian, M. Investigation of constitutive properties of high plasticity clay soils mixed with crushed rubber tire waste. Heliyon 2024, 10, e26655. [Google Scholar] [CrossRef]

- Dalhat, M.A.; Al-Adham, K.; Adesina, A.Y. High-temperature performance of recycled low-density polyethylene-modified asphalt binder reinforced with thermally treated polyacrylonitrile fiber. Arab. J. Sci. Eng. 2020, 45, 4257–4272. [Google Scholar] [CrossRef]

- Nataatmadja, A.; Tan, Y.L. Resilient response of recycled concrete road aggregates. J. Transp. Eng. 2001, 127, 450–453. [Google Scholar] [CrossRef]

- Sivakugan, N.; Das, B.M. Geotechnical Engineering: A Practical Problem Solving Approach; J. Ross Publishing: Plantation, FL, USA, 2009. [Google Scholar]

- Herrador, R.; Pérez, P.; Garach, L.; Ordóñez, J. Use of recycled construction and demolition waste aggregate for road course surfacing. J. Transp. Eng. 2012, 138, 182–190. [Google Scholar] [CrossRef]

- Cerni, G.; Cardone, F.; Bocci, M. Permanent deformation behaviour of unbound recycled mixtures. Constr. Build. Mater. 2012, 37, 573–580. [Google Scholar] [CrossRef]

- Nasiri, A.; Eslami, A.; Fahimifar, A.; Akbarimehr, D. Laboratory and Field Study of Construction and Demolition Waste for Roller-Compacted Concrete Pavement. Int. J. Geomech. 2024, 24, 04024290. [Google Scholar] [CrossRef]

- Behera, M.; Bhattacharyya, S.; Minocha, A.; Deoliya, R.; Maiti, S. Recycled aggregate from C&D waste & its use in concrete—A breakthrough towards sustainability in construction sector: A review. Constr. Build. Mater. 2014, 68, 501–516. [Google Scholar]

- Ok, B.; Sarici, T.; Talaslioglu, T.; Yildiz, A. Geotechnical properties of recycled construction and demolition materials for filling applications. Transp. Geotech. 2020, 24, 100380. [Google Scholar] [CrossRef]

- Federal Highway Administration. Standard Specifications for Construction of Roads and Bridges on Federal Highway Projects; Federal Highway Administration: Washington, DC, USA, 1996.

- Yin, Y.; Chen, H.; Kuang, D.; Song, L.; Wang, L. Effect of chemical composition of aggregate on interfacial adhesion property between aggregate and asphalt. Constr. Build. Mater. 2017, 146, 231–237. [Google Scholar] [CrossRef]

- Ghernaout, D. Reverse Osmosis Process Membranes Modeling—A Historical Overview. J. Civ. Constr. Environ. Eng. 2017, 2, 112–122. [Google Scholar]

- Trottier, C.; Zahedi, A.; Ziapour, R.; Sanchez, L.; Locati, F. Microscopic assessment of recycled concrete aggregate (RCA) mixtures affected by alkali-silica reaction (ASR). Constr. Build. Mater. 2021, 269, 121250. [Google Scholar] [CrossRef]

- Wartman, J.; Grubb, D.G.; Nasim, A.S.M. Select engineering characteristics of crushed glass. J. Mater. Civ. Eng. 2004, 16, 526–539. [Google Scholar] [CrossRef]

- Piratheepan, J.; Arulrajah, A.; Disfani, M.M. Large-scale direct shear testing of recycled construction and demolition materials. Adv. Civ. Eng. Mater. 2013, 2, 25–36. [Google Scholar] [CrossRef]

- Christopher, B.R.; Schwartz, C.W.; Boudreaux, R.; Berg, R.R. Geotechnical Aspects of Pavements; United States. Federal Highway Administration: Washington, DC, USA, 2006.

- Berry, J.R.; Tayabji, S.D. Report on Roller-Compacted Concrete Pavements; ACI Committee Report; American Concrete Institute: Farmington Hills, MI, USA, 2001. [Google Scholar]

- Gao, P.; Wu, S.; Lin, P.; Wu, Z.R.; Tang, M.S. The characteristics of air void and frost resistance of RCC with fly ash and expansive agent. Constr. Build. Mater. 2006, 20, 586–590. [Google Scholar] [CrossRef]

| Tests | Standards | Results | Tested Samples |

|---|---|---|---|

| SA | ASTM D422 | Physical characterization analysis | BDWM, NM |

| Gs | ASTM D854 | BDWM, NM | |

| WAT | Conventional tests | BDWM, NM | |

| FI | BS 812-105.1 | BDWM, NM | |

| LL and PL | ASTM D4318 | BDWM, NM | |

| LAAT | ASTM C 131 | BDWM, NM | |

| Modified PSCT | ASTM D 1557 | Compaction analysis | BDWM, NM |

| CBR | ASTM D1883 | Load-displacement curves analysis | BDWM, NM |

| DST | ASTMD5321 | Shear strength analysis | BDWM, NM |

| Materials | Gs (Coarse) | Gs (Fine) | WAT (Coarse) (%) | WAT (Fine) (%) | PL (%) | LL (%) | FI | LAAT (%) | MDD (kN/m3) | OWC (%) | CBR (%) | C (kPa) | Φ (°) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| BDWM (Site 1) | 2.75 | 2.65 | 4.0 | 6.2 | 20.4 | 29.3 | 15.2 | 31.3 | 20.8 | 9.3 | 73 | 60 | 41 |

| BDWM (Site 2) | 2.73 | 2.62 | 4.1 | 7.1 | 21.5 | 31.2 | 15.6 | 35.2 | 21 | 9.9 | 69 | 59 | 43 |

| NM | 2.79 | 2.72 | 0.9 | 1.0 | 5.4 | 10.4 | 11.0 | 25.0 | 27 | 6.2 | 89 | 64 | 45 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmadpour, M.; Akbarimehr, D.; Rahai, M.; Momeni, A. Characterization of Recycled Aggregates from Building Demolition Waste for Use in Road Infrastructures. Infrastructures 2025, 10, 167. https://doi.org/10.3390/infrastructures10070167

Ahmadpour M, Akbarimehr D, Rahai M, Momeni A. Characterization of Recycled Aggregates from Building Demolition Waste for Use in Road Infrastructures. Infrastructures. 2025; 10(7):167. https://doi.org/10.3390/infrastructures10070167

Chicago/Turabian StyleAhmadpour, Majid, Davood Akbarimehr, Mohammad Rahai, and Ali Momeni. 2025. "Characterization of Recycled Aggregates from Building Demolition Waste for Use in Road Infrastructures" Infrastructures 10, no. 7: 167. https://doi.org/10.3390/infrastructures10070167

APA StyleAhmadpour, M., Akbarimehr, D., Rahai, M., & Momeni, A. (2025). Characterization of Recycled Aggregates from Building Demolition Waste for Use in Road Infrastructures. Infrastructures, 10(7), 167. https://doi.org/10.3390/infrastructures10070167