1. Introduction

1.1. Background

Aging infrastructure presents a global challenge, with many systems nearing or exceeding their intended service lives. As these structures deteriorate, their reliability diminishes, increasing the risk of catastrophic failures with far-reaching consequences, including structural collapses, power outages, and water shortages, which severely impact communities [

1]. Preserving existing infrastructure is essential for economic stability, public safety, and sustainability. Reliable infrastructure ensures uninterrupted business operations, fostering economic growth [

2], and reduces the risk of accidents and injuries caused by structural failures [

3]. It also aligns with the United Nations Sustainable Development Goal 9 (SDG 9), which emphasizes resilient infrastructure, sustainable industrialization, and innovation [

4].

Reinforced concrete structures constitute the foundation of modern infrastructure, making their durability essential to minimizing risks associated with structural failures. Although deterioration over time is inevitable, the urgency of addressing this issue has intensified in recent years. Critical infrastructure such as aging dams and nuclear power plants are experiencing diminished reliability as they approach or exceed their designed service lives [

5]. This degradation is further accelerated by compounding factors, including environmental stressors—such as extreme weather events, including heavy rainfall—and increasing traffic loads in urban environments. These factors exacerbate structural damage and elevate the risk of catastrophic failure, as evidenced by incidents like the failure at the Rapidan Dam [

6,

7]. The high financial burden associated with repair or replacement further highlights the necessity for proactive, innovative strategies to ensure long-term performance and safety [

7].

Innovative, sustainable solutions for extending the lifespan of concrete structures have emerged as critical areas of research and practice. These approaches aim to extend service life, reduce environmental impact, optimize resource use, and minimize long-term costs. Advances in materials science, such as low-carbon cements, supplementary cementitious materials, and self-healing concrete, enhance durability and sustainability. Similarly, advanced technologies like non-destructive evaluation methods and fiber-reinforced polymers (FRPs) are reshaping how infrastructure is assessed and rehabilitated.

This state-of-the-art review critically examines these sustainable strategies and technologies, focusing on their effectiveness, practical applications, and alignment with global sustainability goals. By synthesizing recent advancements and identifying gaps in current practices, it offers a comprehensive perspective on the potential for sustainable interventions to mitigate risks associated with aging reinforced concrete infrastructure.

1.2. Objectives of the Review

The primary objective of this review is to critically evaluate recent advancements in sustainable strategies and technologies for preserving, retrofitting, and rehabilitating aging reinforced concrete infrastructure. Specifically, this review aims to achieve the following:

Synthesize knowledge: aggregate and summarize research on innovative materials and technologies, such as low-carbon cements, fiber-reinforced polymers (FRPs), and non-destructive evaluation methods, to provide a comprehensive understanding of current developments.

Evaluate effectiveness: assess the practical applications, performance, and limitations of these advancements in extending service life and improving structural resilience.

Identify gaps: highlight existing knowledge and practice gaps, pinpointing areas where further research or technological development is needed.

Promote sustainability: explore how these advancements align with global sustainability goals, particularly in reducing environmental impact, optimizing resource use, and fostering resilient infrastructure systems.

Provide insights for stakeholders: offer actionable recommendations for researchers, engineers, and policymakers to guide future efforts in sustainable infrastructure development and management.

By addressing these objectives, this review bridges the gap between academic research and practical applications, advancing the field of sustainable infrastructure preservation and paving the way for innovative solutions to the challenges posed by aging concrete systems.

1.3. Scope and Significance

This review focuses on sustainable strategies and advanced technologies for preserving, retrofitting, and rehabilitating aging reinforced concrete infrastructure. Key areas of analysis include advancements in materials science, such as low-carbon cements and self-healing concrete, and technologies like fiber-reinforced polymers (FRPs) and non-destructive evaluation methods. This review synthesizes knowledge across these domains, evaluates their effectiveness, and identifies practical applications and research gaps requiring further exploration.

The significance of this work lies in its potential to address critical challenges in infrastructure management. With an increasing number of structures nearing the end of their service lives, innovative, cost-effective, and environmentally sustainable solutions are urgently needed. By connecting research advancements with practical implementation, this review contributes to global efforts to enhance infrastructure resilience, extend service life, and reduce the environmental impact of construction and maintenance activities.

Additionally, this review aligns with global sustainability priorities, including the United Nations Sustainable Development Goal 9 (SDG 9), by advocating for resilient, sustainable, and innovative infrastructure systems [

4]. The insights presented aim to guide researchers, engineers, and policymakers in developing strategies to tackle the challenges of aging concrete infrastructure while contributing to a more sustainable future.

2. Review Methodology and Ethics

2.1. Literature Search and Selection Criteria

The comprehensive literature review for this study was conducted using a systematic approach to ensure comprehensive coverage of relevant research. Multiple academic databases were utilized, including Scopus, Web of Science, Google Scholar, and ScienceDirect, to identify peer-reviewed journal articles, conference papers, and industry reports. These databases were chosen for their broad coverage of engineering, materials science, and sustainability-related fields, ensuring access to high-impact publications. Additionally, institutional repositories and government research publications were consulted to supplement the primary sources with industry insights and technical reports.

The search criteria were developed to capture a wide range of studies focused on sustainable strategies for the preservation, retrofitting, and rehabilitation of reinforced concrete infrastructure. Keywords such as “sustainable concrete”, “retrofitting techniques”, “green infrastructure”, “low-carbon cement”, “fiber-reinforced polymers (FRPs)”, and “non-destructive evaluation” were used in various combinations to filter relevant research. For example, combinations such as “low-carbon cement” AND “fiber-reinforced polymers” OR “retrofitting techniques” AND “durability” were employed to ensure coverage across overlapping research themes. Boolean operators (AND, OR) and wildcard symbols were used to link terms and capture variations in phrasing. This approach enabled the inclusion of both narrowly focused studies and broader thematic reviews relevant to sustainable concrete infrastructure. This review targeted literature published between 2010 and 2025 to ensure the inclusion of both foundational studies and the latest advancements in the field. Boolean operators (AND, OR) and wildcard symbols were employed to refine search results and ensure comprehensive coverage across different terminologies and research domains.

Inclusion criteria focused on peer-reviewed journal articles, technical reports, and highly relevant conference proceedings that presented experimental data, case studies, or comprehensive reviews of sustainable infrastructure practices. Studies were prioritized based on their relevance to concrete infrastructure longevity, innovative materials, and emerging retrofitting technologies. Conference proceedings were included selectively if they offered significant insights or pioneering research not yet available in journal publications. Conversely, non-peer-reviewed sources, articles with limited empirical data, and studies not directly addressing sustainability or reinforced concrete systems were excluded to maintain this review’s scientific rigor and relevance. Papers were assessed on their relevance to the topic, methodological rigor, publication date, the impact factor of the journal, the comprehensiveness of the research findings, and the study appropriateness for addressing the research question. This systematic review adheres to established best practices in civil engineering and sustainable construction literature reviews, as outlined by Khar et al. [

8], Kumar et al. [

9], Hurst et al. [

10], and Page et al. (PRISMA) [

11]. These methodologies emphasize the necessity of filtering high-quality, peer-reviewed literature to ensure reliable conclusions. Following these principles, this review adopts a structured approach to literature selection, incorporating predefined inclusion criteria, multi-step screening, and quality assessment to enhance transparency and reproducibility.

2.2. Review Framework

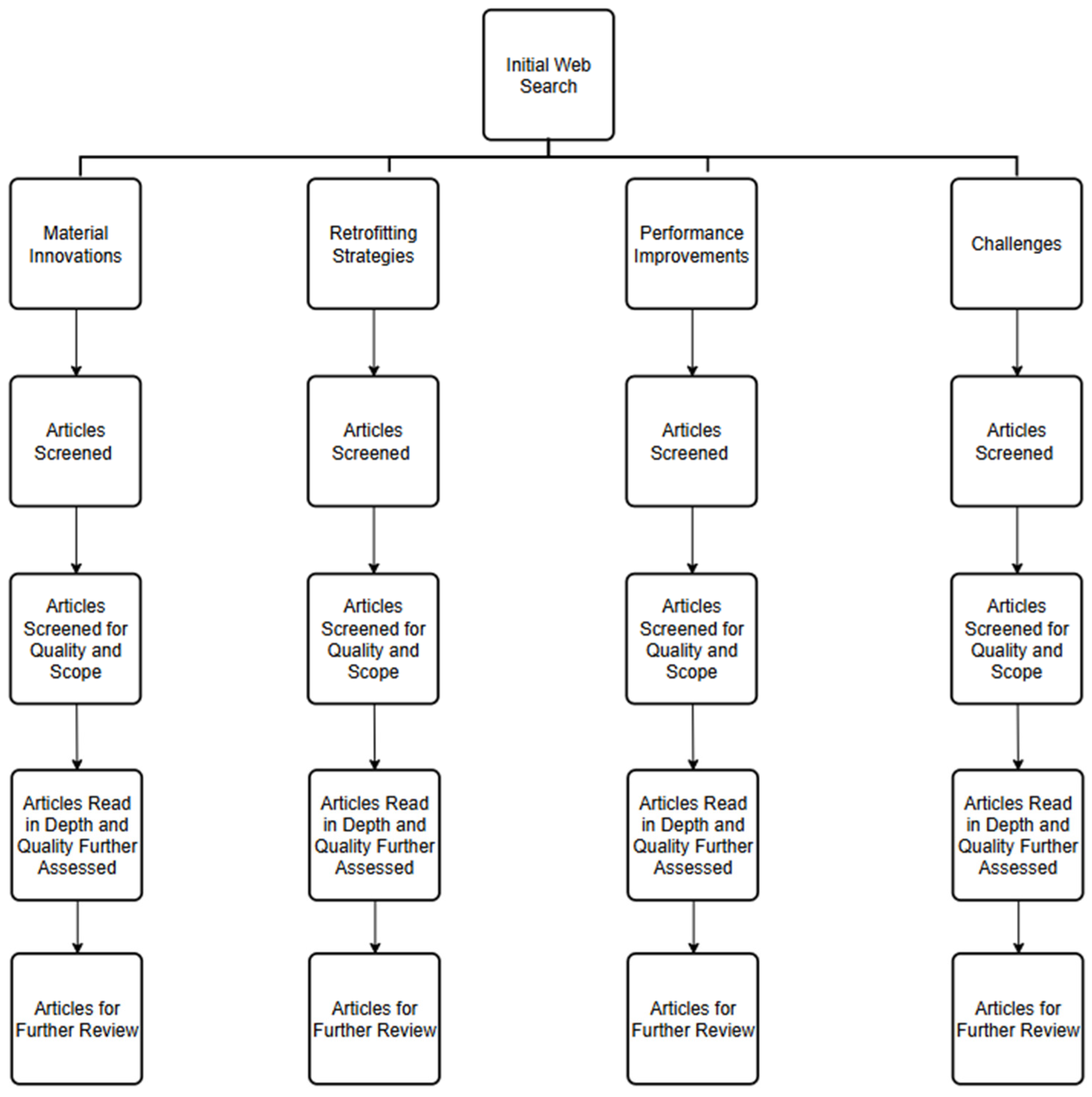

To provide a structured and comprehensive analysis, the comprehensive literature review was categorized into four key themes: material innovations, retrofitting strategies, performance improvements, and challenges.

Material innovations: this category focused on advancements such as low-carbon cements, supplementary cementitious materials, and self-healing concrete, aiming to enhance durability and sustainability.

Retrofitting strategies: studies on structural interventions, such as the use of fiber-reinforced polymers (FRPs) and bio-based reinforcement techniques, were reviewed to assess their practical applicability.

Performance improvements: this theme analyzed enhancements in structural resilience, load-bearing capacity, and long-term serviceability under environmental and operational stresses.

Challenges: research addressing barriers to implementation, including high costs, scalability issues, and regulatory constraints, was reviewed to identify gaps and future research needs.

A systematic multi-step screening procedure was implemented for each key theme, as depicted in

Figure 1. The process commenced with a preliminary review of article titles and abstracts to exclude clearly irrelevant materials. This was followed by an initial quality and scope assessment to ensure the selected studies aligned with the review objectives. The subsequent stage involved a comprehensive, in-depth evaluation of the full texts to further assess their methodological rigor, relevance, and contribution to the field. At each stage, articles that failed to meet the predefined criteria were excluded from further consideration.

Studies were evaluated for comprehensiveness based on the range and depth of the considered variables (e.g., mix design, exposure conditions, mechanical properties, durability metrics). For instance, studies that analyzed at least three mechanical or durability properties across multiple curing or environmental conditions were considered comprehensive. Additionally, the influencing factors used for classification included percentage replacement levels of SCMs (e.g., 10–50%), types of retrofitting (e.g., FRP wrapping vs. steel jacketing), and modeling variables (e.g., cement content, w/c ratio, aggregate type). Studies offering both experimental and computational insights were given higher weight during synthesis.

2.3. Quality Assessment

The quality of the reviewed studies was evaluated based on methodological rigor, data transparency, and the direct applicability of the findings to practical concrete infrastructure preservation. The majority of the included studies adhered to established scientific standards, featuring well-defined research objectives, robust experimental methodologies, and detailed documentation of results. However, this review identified key limitations, particularly a lack of long-term field data and challenges in scaling laboratory findings to real-world infrastructure applications. While numerous studies on advanced materials, such as fiber-reinforced polymers (FRPs) and low-carbon cement, indicate promising potential for enhancing concrete durability and sustainability, there remains a significant gap in understanding the real-world performance of these materials, especially under variable environmental conditions and in aging infrastructure.

A recurring issue was the lack of comprehensive lifecycle assessments in many studies, which are indispensable for evaluating the long-term sustainability and cost-effectiveness of proposed preservation strategies. Furthermore, several studies failed to address the dynamic interactions between different preservation methods and the structural behavior of concrete in diverse operational environments. These gaps highlight the need for more field-based studies that incorporate real-world exposure conditions and long-term monitoring to validate laboratory results.

It is also worth noting that only studies adhering to high scientific standards, as defined by peer-reviewed journals and reputable research practices, were included in this review. Articles failing to meet these criteria were excluded from this review.

2.4. Research Ethics

This review adheres to ethical research practices by ensuring that all sources are properly cited, findings are accurately represented, and no data have been fabricated or manipulated. Only publicly available, peer-reviewed, or institutionally published materials were included in this study. No human or animal subjects were involved, and no conflicts of interest influenced the analysis. The principles of transparency and academic integrity guided the review process.

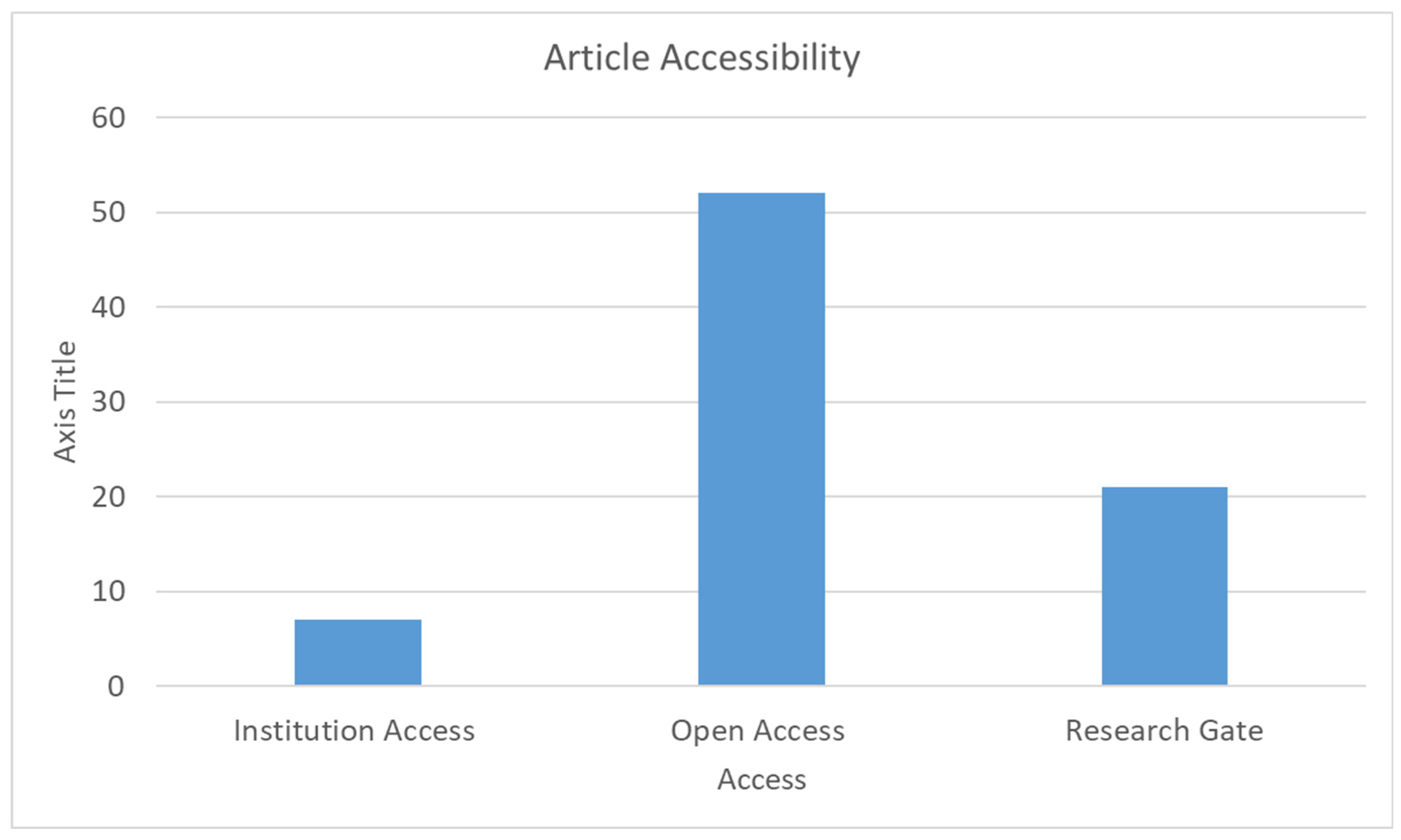

3. Overview of Analyzed Literature

This section presents an overview of the 81 articles analyzed in this state-of-the-art review. It highlights article accessibility, publication trends, and research focus to provide contextual insight into the scope and distribution of the reviewed literature. The accessibility distribution of these articles is illustrated in

Figure 2.

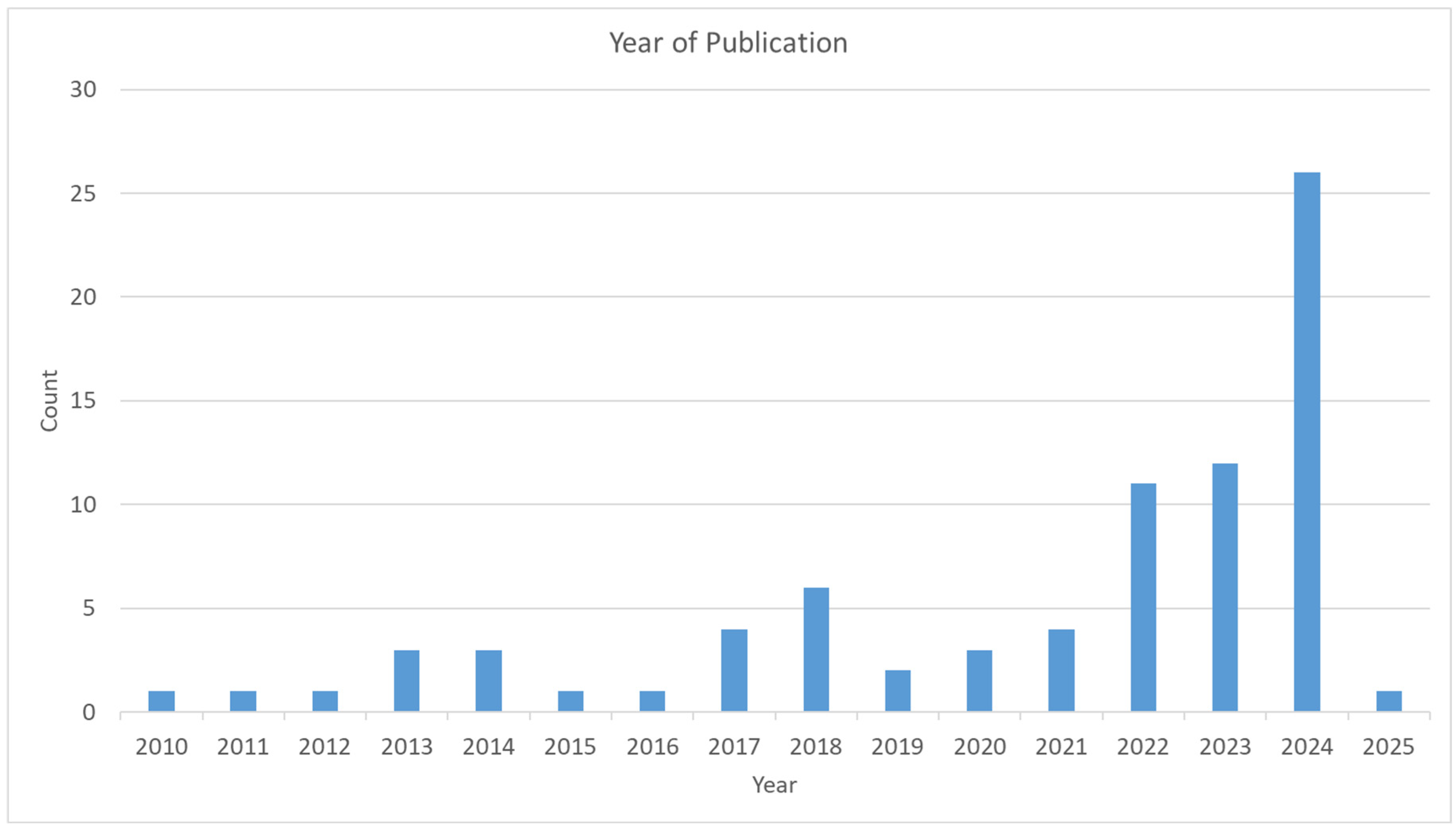

Figure 3 categorizes the articles by year, highlighting a predominant focus on recent research. Although studies dating back to 2010 were included, this review prioritized literature from the past five years to ensure relevance to current advancements. The data in

Figure 3 further indicate a growing research emphasis on sustainable strategies for concrete infrastructure, with a notable concentration of publications from 2024, reflecting the increasing momentum in this field.

In the following sub-sections, articles covering each of the key areas of “Sustainable Strategies for Concrete Infrastructure Prevention” are addressed.

4. Sustainable Materials for Infrastructure

The advancement of concrete materials has profoundly influenced the construction industry by enhancing sustainability, durability, and cost efficiency. Recent developments in material science have introduced innovative solutions such as the integration of industrial by-products and recycled aggregates, the development of low-carbon cementitious binders, the application of self-healing mechanisms through microbial and chemical agents, and the utilization of digital fabrication techniques like 3D printing for optimized structural performance.

4.1. Supplementary Cementing Materials (SCMs) and Geopolymer Concrete

Supplementary cementitious materials (SCMs), such as fly ash, slag, silica fume, and metakaolin, have become essential in reducing concrete’s carbon footprint. These materials not only enhance mechanical performance and durability but also improve resistance to environmental stressors like chloride ingress, sulfate attack, and freeze–thaw cycles [

12]. By partially replacing Portland cement, SCMs help curb greenhouse gas emissions from clinker production, one of the largest contributors to concrete-related carbon emissions [

13]. While SCMs offer significant environmental and performance benefits, challenges remain, including potential susceptibility to carbonation and variability in material availability and reactivity. Continued research is needed to optimize their use in sustainable concrete design [

14].

The development of geopolymer concrete (GPC) has provided a sustainable alternative to conventional cementitious materials by leveraging industrial by-products such as fly ash, ground granulated blast-furnace slag (GGBFS), and rice husk ash [

15]. GPC exhibits superior resistance to acid and sulfate attacks, reduced permeability, and enhanced durability, making it a viable option for high-performance infrastructure applications [

16]. Notably, pervious geopolymer concrete incorporating recycled concrete aggregate (RCA) has demonstrated the ability to improve water permeability while maintaining structural integrity, offering potential solutions for stormwater management and sustainable pavement systems [

17].

Recent research has further explored the use of coal bottom ash (CBA) and waste foundry sand (WFS) as partial replacements for fine aggregates in concrete, offering a sustainable alternative to virgin materials [

18]. Studies indicate that concrete incorporating these by-products maintains adequate compressive strength and durability while contributing to resource conservation and waste reduction. Additionally, the inclusion of cement kiln dust (CKD) as a supplementary material has shown potential in enhancing workability and mitigating the environmental impact associated with cement production [

18].

4.2. Low-Carbon Concrete and Alternative Binders

Beyond the use of supplementary cementitious materials (SCMs), the advancement of low-carbon concrete has gained considerable momentum. Alternative binders, such as calcined clays and limestone, have been shown to significantly reduce the carbon footprint of concrete production while maintaining or even enhancing mechanical properties [

15]. These low-carbon alternatives support global decarbonization efforts and provide a viable solution to the high energy demands and emissions associated with traditional clinker-based cement production [

13].

In parallel, recent studies have investigated strategies for reducing the carbon footprint of cement production, emphasizing alternative clinker technologies, carbon capture methods, and energy-efficient manufacturing processes [

13,

19]. Carbon capture and storage (CCS), along with CO

2 sequestration through accelerated carbonation, has emerged as a promising approach to mitigating the environmental impact of concrete production by directly reducing emissions and enhancing material sustainability [

14,

19].

An emerging strategy for reducing concrete’s carbon footprint involves the incorporation of biodegradable and agro-waste materials as partial cement replacements. Cassava peel ash (CPA), for example, has demonstrated pozzolanic properties comparable to fly ash, enhancing both compressive and flexural strength while reducing dependence on virgin raw materials [

20]. Similarly, agricultural and industrial by-products such as rice husk ash have been successfully processed into pozzolanic materials, contributing to improved durability and sustainability in concrete applications [

15,

21]. Ongoing research continues to evaluate the performance of these alternative supplementary cementitious materials (SCMs), focusing on their workability, mechanical behavior, and long-term durability, with a particular emphasis on their potential contribution to carbon-neutral construction [

22].

4.3. Recycling and Bio-Based Additives

A complementary approach to sustainable concrete involves the replacement of traditional cementitious materials with upcycled and bio-based alternatives. Recycled aggregates, waste glass powder, and bio-based polymers have shown significant potential in reducing concrete’s environmental impact while preserving its structural integrity [

17,

23].

Nanotechnology has significantly advanced concrete performance by incorporating nanomaterials such as nano-silica, carbon nanotubes (CNTs), and titanium dioxide (TiO

2). These materials enhance mechanical strength, reduce permeability, and introduce functional properties such as self-cleaning and pollution-reducing surfaces [

24,

25]. The integration of nano-engineered concrete is emerging as a transformative approach to sustainable construction, offering improved durability, energy efficiency, and long-term structural resilience [

25].

Additionally, digital fabrication techniques, particularly 3D concrete printing, have emerged as a promising solution for reducing material waste and enhancing construction efficiency [

26,

27]. Research indicates that digital fabrication can significantly lower embodied carbon while enabling complex structural geometries that are challenging to achieve with conventional methods [

27]. Recent advancements have also integrated computational modeling and AI-driven construction techniques to optimize concrete mix designs, improve material efficiency, and enhance sustainability in large-scale infrastructure projects [

28].

4.4. Self-Healing Concrete Technologies

Another groundbreaking advancement in concrete technology is the integration of self-healing mechanisms. Microbial self-healing concrete, in particular, has shown significant potential in autonomously repairing microcracks through the activity of bacteria such as

Bacillus species, which precipitate calcium carbonate to seal cracks [

24,

26]. This innovation enhances the durability and longevity of concrete structures while reducing maintenance costs and improving structural resilience [

26].

Recent research has expanded the scope of self-healing concrete by incorporating advanced materials such as encapsulated polyurethane and shape-memory polymers, which activate crack closure in response to environmental stimuli [

19]. Additionally, nanotube–hydrogel systems have been developed to sustain bacterial healing agents, enhancing long-term durability and providing increased resistance to chloride ingress [

29].

Research into biologically self-healing concrete has advanced with the development of nanoencapsulation techniques that protect bacterial spores and nutrients within the cement matrix. Halloysite clay nanotubes (HNTs) and calcium alginate microcapsules have been employed to enhance the resilience of self-healing agents in the harsh alkaline environment of concrete, ensuring their long-term viability. Studies show that these biologically driven self-healing mechanisms can reduce crack permeability by over 95% and restore approximately 75% of flexural strength over time [

29].

Furthermore, durability assessments of self-healing concrete under extreme environmental conditions have demonstrated that encapsulated healing agents significantly mitigate chloride penetration and reduce the risk of reinforcement corrosion, improving the longevity of concrete structures [

30]. Emerging research in biologically based self-healing materials is also exploring advanced metabolic pathways, utilizing bacteria-derived enzymes to accelerate mineral precipitation and further enhance the self-repair capabilities of concrete [

31]. These enzymatic processes provide a novel approach to improving the durability and sustainability of next-generation concrete infrastructure.

4.5. CO2 Sequestration and Carbon Capture in Concrete

The integration of CO

2 sequestration through accelerated carbonation treatments represents a significant advancement in sustainable concrete technology. This process facilitates the reaction between CO

2 and cementitious materials, transforming gaseous CO

2 into stable carbonate compounds, thereby reducing the carbon footprint of concrete production [

14,

19]. Ongoing research into CO

2 mineralization technologies aims to develop carbon-negative concrete, offering a viable pathway toward net-zero emissions in the construction sector [

19].

Additionally, advancements in low-carbon cements and innovative carbonation techniques have demonstrated considerable potential in lowering cement’s environmental impact while preserving its mechanical performance and durability [

13,

29]. Studies on carbon-negative concrete indicate that integrating captured CO

2 directly into concrete mixtures not only offsets emissions but also enhances material properties, contributing to more sustainable and resilient infrastructure [

29].

5. Retrofitting of Existing Infrastructure

The evolution of retrofitting strategies for reinforced concrete (RC) structures has been driven by the need to enhance structural integrity, extend service life, and improve resilience against environmental degradation and seismic loading. Modern retrofitting methodologies integrate advanced materials, innovative construction techniques, and computational optimization to maximize performance while ensuring cost efficiency. This section explores state-of-the-art retrofitting approaches, including fiber-reinforced polymer (FRP) strengthening systems, modularized steel reinforcement solutions, high-performance polyurea coatings, precision grouting techniques, and hybrid retrofitting methodologies that combine multiple reinforcement mechanisms for enhanced structural adaptability and load redistribution.

5.1. Fiber-Reinforced Polymer (FRP) Systems

Fiber-reinforced polymer (FRP) materials have become a widely adopted solution for retrofitting reinforced concrete (RC) structures due to their high strength-to-weight ratio, corrosion resistance, and ease of application. Extensive research has demonstrated that FRP significantly enhances the flexural, shear, and torsional capacities of RC beams and columns [

32,

33,

34,

35]. Experimental investigations further highlight its ability to improve load-bearing capacity and ductility, particularly under combined loading conditions [

32,

33,

35,

36]. More recently, advancements in closed-form FRP wrapping techniques have demonstrated superior torsional resistance and improved structural behavior compared to traditional open-form configurations [

34,

36,

37], providing a more effective and reliable retrofitting solution.

The bond interaction between concrete and FRP reinforcing bars is a critical factor in determining the effectiveness of FRP-based retrofitting. Experimental studies [

38] on commercially available FRP rebars have examined how fiber composition, bar diameter, and surface texture influence bond strength. Findings emphasize the importance of sand coating and surface roughness in enhancing load transfer efficiency, ultimately improving the structural performance of RC elements.

Seismic retrofitting strategies incorporating FRP-strengthened shear links have been developed to improve the performance of low-ductility RC frames, effectively reducing inter-story drift and minimizing structural degradation under seismic loading [

39,

40,

41]. Additionally, carbon fiber-reinforced polymer (CFRP) has been successfully applied to strengthen RC beams with openings, enhancing shear capacity and optimizing load redistribution [

32,

42]. CFRP reinforcement in eccentric steel bracing systems has also demonstrated significant improvements in the seismic resilience of existing buildings, reducing structural fragility and enhancing overall stability [

43].

Durability assessments have extensively examined the long-term performance of FRP sheets under various environmental stressors, including wet-dry cycles, chloride penetration, and sulfate exposure [

37,

44]. These studies highlight the material’s resistance to degradation, reinforcing its suitability for long-term structural applications. Additionally, innovative self-healing concrete technologies incorporating FRP materials have been introduced, integrating superabsorbent polymers and polypropylene fibers to enhance durability and improve crack mitigation over time [

45,

46].

5.2. Modularized Steel Reinforcement

Steel-based retrofitting techniques offer a robust alternative to composite materials for enhancing structural integrity and seismic resilience. The use of modularized steel plates for retrofitting RC beams has shown significant improvements in flexural capacity, ductility, and energy dissipation [

47]. Additionally, advanced seismic retrofitting methods incorporating aluminum shear links and eccentric steel chevron braces have been developed to improve the lateral load resistance of existing RC buildings [

43,

48]. These methods dissipate seismic energy effectively while minimizing damage to primary structural components.

Experimental studies [

49] have evaluated multiple retrofitting strategies for RC columns, comparing reinforced concrete jacketing, steel jacketing, and the integration of European wide-flange steel profiles. Findings indicate that reinforced concrete jacketing provides the most substantial structural enhancement, significantly increasing flexural and shear strength while reducing seismic vulnerability. Steel jacketing techniques, particularly those employing L-shaped angles and welded bands, also demonstrated notable improvements in ductility and lateral stiffness, making them a viable solution for strengthening aging RC structures. These results emphasize the need for careful selection of steel-based retrofitting methods, balancing structural performance requirements with economic feasibility to ensure effective and sustainable strengthening solutions.

5.3. Polyurea-Based Strengthening

Addressing limitations in FRP bonding interfaces, polyurea coatings have emerged as a promising alternative for structural retrofitting. Experimental studies on reinforced concrete (RC) columns strengthened with stiff-type polyurea have demonstrated significant improvements in seismic performance under both static and dynamic loading conditions [

45]. Unlike traditional FRP systems, polyurea eliminates adhesive bonding requirements, enhancing monolithic behavior and ensuring uniform load transfer across the retrofitted structure.

5.4. Grouting and Hybrid Techniques

Grouting combined with FRP sheets has been investigated as a repair strategy for spalled RC beams. Experimental evaluations indicate that while grouting alone does not fully restore flexural capacity, integrating glass fiber-reinforced polymer (GFRP) reinforcement enhances load-bearing performance, increasing structural capacity by up to 8.08% compared to untreated beams [

50].

Hybrid retrofitting techniques, incorporating steel jackets, X-bracing systems, and anchored FRP wraps, have been implemented for seismic strengthening applications. Case studies on school buildings demonstrate that these hybrid approaches effectively mitigate soft-story behavior and significantly enhance overall structural stability [

40,

42]. Additionally, anchored CFRP reinforcement has been shown to increase shear strength by 50%, reducing premature de-bonding failures and improving load transfer efficiency [

34].

Beyond structural performance, self-repairing materials have been explored to improve durability in hybrid retrofitting strategies. Studies incorporating autonomous repair technologies using superabsorbent polymers and polypropylene fibers have demonstrated enhanced crack control and extended service life [

45,

46].

5.5. Sustainability Considerations in Retrofitting

Sustainable retrofitting solutions are being actively explored to reduce environmental impact while maintaining structural performance and cost efficiency. Research into green natural fiber-reinforced polymer (GNFRP) plates for flexural strengthening has shown that these materials offer performance comparable to carbon-based FRP systems, with the added benefits of lower costs and improved sustainability [

48].

The sustainability of retrofit interventions in aging RC buildings has been a focal point of recent studies, emphasizing the critical role of floor integrity in overall structural resilience. Findings highlight that cost-effective retrofit solutions, such as targeted floor slab strengthening, can significantly enhance the seismic and load-bearing capacity of older structures [

47]. Additionally, FRP jacketing has been investigated as a durable and lightweight alternative to traditional steel retrofits, providing long-term structural performance with reduced material and labor costs [

51].

Basalt fiber-reinforced polymer (BFRP) reinforcement has also emerged as an eco-friendly alternative to conventional steel reinforcement. Experimental studies indicate that BFRP-reinforced beams exhibit sufficient shear and flexural performance for structural retrofitting applications [

39,

52]. However, due to the lower shear resistance of BFRP compared to steel, design modifications are necessary to optimize its effectiveness in shear-critical regions [

39,

52].

Furthermore, advancements in self-healing concrete technologies integrating superabsorbent polymers and FRP reinforcement have demonstrated promising improvements in long-term durability. These innovations provide a low-maintenance, eco-friendly retrofitting solution by reducing crack propagation and extending the service life of retrofitted structures [

45,

46].

6. Performance Improvements in Concrete Infrastructure Systems

The improvement of structural performance and sustainability of concrete infrastructure requires the integration of advanced materials, sophisticated computational modeling techniques, and optimized mixture designs. This section provides a detailed review of various methodologies aimed at enhancing structural performance, focusing on their effectiveness, practical applicability, and potential for extending service life while reducing environmental impact.

6.1. Performance Outcomes of Industrial By-Products in Concrete Systems

While

Section 4 introduces the material composition and sustainability rationale of SCMs and recycled materials, this section focuses specifically on their performance outcomes—particularly strength, durability, and structural reliability—based on empirical and modeling studies.

The utilization of industrial by-products has emerged as a viable approach for producing eco-friendly concrete mixes with superior mechanical properties and durability. Specifically, the incorporation of municipal solid waste (MSW) incinerator bottom ash and recycled demolition waste aggregates as partial replacements for fine and coarse aggregates has demonstrated enhanced compressive strength, tensile strength, and durability when compared to conventional concrete. Laboratory tank leaching tests have further indicated minimal environmental risks associated with these sustainable concrete mixes [

53].

Fly ash, one of the most extensively studied supplementary cementitious materials (SCMs), offers significant improvements in both strength and durability. Comparative studies between Class-C and Class-F fly ash have consistently demonstrated the superior performance of Class-F fly ash in terms of long-term compressive strength, moisture sorption resistance, and abrasion resistance. This enhancement is primarily attributed to the pozzolanic reaction and microstructural densification mechanisms associated with Class-F fly ash, which result in refined pore structures and improved interfacial bonding [

54,

55].

The integration of recycled aggregates contributes to enhanced sustainability. Experimental studies have shown that blending recycled aggregates with pozzolanic materials such as silica fume and nano-silica significantly improves the mechanical performance, chloride penetration resistance, and overall durability of concrete. The synergistic effects of these materials lead to densified microstructures and improved bonding between the cementitious matrix and recycled aggregates [

56]. Additionally, the use of non-selected construction and demolition waste aggregates has demonstrated satisfactory performance in terms of compressive strength, wear resistance, and robustness, making it a viable option for structural applications [

57].

Advancements in understanding cement hydration kinetics, particularly when incorporating SCMs like fly ash and slag, have also contributed to improved performance prediction models. Computational tools developed by the National Institute of Standards and Technology (NIST) have enhanced the precision of concrete mixture designs, enabling the optimization of durability and sustainability through tailored material selection and mix proportioning [

58].

6.2. Machine Learning and Computational Techniques

Recent advancements in computational methodologies have significantly enhanced the optimization of concrete mixtures, targeting improvements in both sustainability and structural performance. Conditional Variational Autoencoders (CVAEs) have emerged as powerful tools for generating concrete formulations that achieve reduced carbon emissions while meeting or exceeding specified compressive strength requirements. The successful deployment of AI-generated concrete formulations in real-world applications, such as Meta’s data center, underscores the practicality and scalability of this approach for widespread implementation [

59].

Probabilistic modeling techniques have been developed to accurately predict concrete mix properties, including durability, carbonation resistance, and chloride ion penetration. By integrating noisy datasets and leveraging advanced statistical inference methods, these models provide robust performance predictions that support the formulation of performance-based specifications for sustainable concrete design. The probabilistic framework also enables the quantification of uncertainties associated with material properties, enhancing the reliability of prediction models [

60].

Furthermore, Bayesian optimization has been applied to navigate complex multi-objective optimization problems, particularly in achieving optimized trade-offs between compressive strength and global warming potential. By utilizing surrogate models to approximate objective functions, Bayesian optimization allows for efficient exploration of the design space, enabling the identification of environmentally friendly concrete mixtures that maintain structural integrity. This approach offers substantial potential for enhancing the sustainability of concrete mixtures through optimized mix designs that balance mechanical performance and environmental impact [

61].

6.3. Fiber-Reinforced Composites

Fiber-reinforced composites (FRCs) have been extensively studied to enhance concrete durability, mechanical performance, and sustainability. Recent innovations in self-healing mechanisms involve the incorporation of microcapsules containing healing agents within the FRC matrix. Upon crack formation, these microcapsules rupture and release healing agents that react with moisture or other reactants, facilitating autogenous healing. Experimental studies have reported a substantial improvement in structural performance, including a 30% increase in compressive strength and a 40% reduction in crack width, effectively enhancing structural integrity, durability, and service life [

62].

Additionally, the incorporation of recycled steel fibers (RSFs) extracted from end-of-life tires presents a sustainable approach to improving the mechanical properties of concrete. The use of RSF has been shown to significantly enhance compressive strength, split tensile strength, and flexural strength by improving crack-bridging capabilities, energy absorption, and load-bearing capacity. Furthermore, RSF-reinforced concrete exhibits enhanced toughness, impact resistance, and durability under dynamic and static loading conditions. The effective utilization of RSF not only improves structural performance but also contributes to sustainable construction practices by repurposing waste materials and reducing the carbon footprint associated with conventional steel fiber production [

63].

6.4. Green Concrete Formulations

Efforts to develop high-performance green concrete have increasingly focused on incorporating recycled materials and optimizing mixture designs to enhance durability, mechanical performance, and sustainability. The utilization of recycled pumice and modified rubber powder has demonstrated notable improvements in the durability, frost resistance, and robustness of concrete, making these composites suitable for a wide range of structural applications. The incorporation of these materials contributes to enhanced toughness and resistance to freeze–thaw cycles, which are critical factors for infrastructure longevity [

64].

Furthermore, the inclusion of supplementary cementitious materials (SCMs) such as fly ash, as well as recycled aggregates, in high-performance concrete mixtures has effectively enhanced durability, reduced permeability, and decreased the overall environmental footprint. These mixtures present viable alternatives to conventional concrete systems by improving both mechanical performance and sustainability through reduced cement consumption and improved material efficiency [

57,

65].

Metakaolin (MK) and nano-silica (NS) have also been extensively studied as cementitious materials aimed at enhancing the mechanical properties and durability of concrete. The synergistic effects of MK and NS lead to reduced porosity, increased compressive strength, and improved interfacial bonding, thereby contributing to superior mechanical performance and durability. Additionally, the use of these materials lowers embodied carbon emissions, offering a substantial contribution to sustainable concrete design [

66].

Research on pile foundations utilizing recycled materials has highlighted the potential for enhanced load-bearing capacity, durability, and resilience, even under challenging geological conditions. Experimental studies have demonstrated that recycled aggregates combined with SCMs provide improved performance by refining the pore structure and enhancing the interfacial transition zone (ITZ) [

67].

Performance-engineered concrete mixture design approaches have emerged as effective methodologies for achieving a balance between durability, sustainability, and economic efficiency. These approaches support the broader adoption of performance-based specifications, enhancing infrastructure resilience and promoting the use of eco-friendly materials [

68].

Innovations in sustainable pavement materials have also made significant strides, particularly through the incorporation of recycled aggregates and geopolymer stabilization techniques. These advancements have shown promising results in reducing the environmental impact of road construction, improving mechanical performance, and enhancing durability under various loading and environmental conditions [

69].

The broader concept of sustainable infrastructure and climate resilience underscores the importance of integrating high-performance concrete materials, such as ultra-high-performance concrete (UHPC) and engineered cementitious composites (ECCs), which offer superior mechanical properties, enhanced durability, and improved resilience. Furthermore, promoting the use of renewable energy sources and eco-friendly materials within infrastructure systems remains essential for achieving long-term sustainability and minimizing environmental impacts [

70,

71,

72].

7. Challenges to Sustainable Implementation in Concrete Infrastructure

Despite significant advancements in sustainable strategies for concrete infrastructure, numerous challenges continue to hinder their widespread adoption. These challenges can be broadly categorized into technical, economic, regulatory, and social barriers. Addressing these obstacles is crucial for formulating effective strategies that facilitate the implementation of sustainable technologies and materials in concrete infrastructure systems.

7.1. Technical Challenges

The technical barriers to implementing sustainable concrete infrastructure predominantly stem from limitations in material properties, insufficient research, and the absence of standardized testing and design guidelines [

73,

74]. For example, the adoption of crumb rubber concrete (CRC) is constrained by concerns over reduced mechanical performance, inadequate understanding of leaching behavior, and uncertainties regarding CRC recyclability [

75]. Similarly, the advancement of 3D concrete printing is impeded by challenges related to standardizing printer nozzle designs, automating reinforcement placement, and accommodating coarse-graded aggregates in large-scale applications [

76].

The integration of smart materials, such as self-healing concrete and photocatalytic concrete, necessitates comprehensive research and development to ascertain their long-term performance, reliability, and economic feasibility [

77]. Low-carbon concrete also faces substantial technical hurdles, including the difficulty of establishing consistent performance criteria, ensuring long-term durability, and addressing compatibility issues between recycled construction materials (RCMs) and conventional construction standards [

74,

75,

77,

78].

Additionally, the deployment of modern methods of construction (MMCs) is challenged by complexities related to prefabrication techniques, modular construction systems, and industry reluctance to adopt novel technologies [

76,

79].

7.2. Economic Barriers

Economic constraints present substantial challenges to the widespread adoption of sustainable construction practices. The high cost of recycling crumb rubber, coupled with its limited availability for industrial-scale production, reduces its competitiveness compared to conventional concrete [

75]. Financial and planning limitations are frequently cited as critical barriers within the construction industry, where the elevated initial costs associated with sustainable technologies hinder their large-scale implementation [

80]. The absence of economic incentives or subsidies further exacerbates this issue, as companies are often reluctant to invest in innovative technologies that lack immediate financial returns. Moreover, the development and commercialization of low-carbon concrete are hampered by significant costs related to material processing, production scaling, and comprehensive research and development efforts [

77,

78,

81,

82,

83,

84].

7.3. Regulatory and Policy Barriers

Regulatory barriers significantly impede the implementation of sustainable construction practices, primarily due to inadequate environmental policies, lack of supportive legislation, and insufficient enforcement of existing regulations [

85]. The cement industry, in particular, encounters challenges resulting from the absence of robust regulatory frameworks that actively promote sustainable construction practices, as well as the lack of strategic initiatives designed to encourage the adoption of eco-friendly materials and methods [

81,

86,

87].

Additionally, regulatory biases and inconsistencies in the standardization of emerging construction materials, such as recycled construction materials (RCMs), further complicate efforts to achieve widespread acceptance. Limited funding for RCM research exacerbates these issues by stifling innovation and delaying the development of reliable, performance-based standards [

77]. Public procurement policies and environmental legislation are also perceived as contributing to increased costs and project delays, rather than serving as catalysts for promoting sustainability within the construction industry [

88,

89,

90].

7.4. Social Barriers to Adoption

Social acceptance of innovative materials and construction methods remains a significant barrier to the widespread adoption of sustainable construction practices. The construction industry is inherently conservative, with stakeholders demonstrating reluctance to embrace novel materials and technologies in the absence of comprehensive technical validation and proven performance [

75]. Insufficient awareness of the environmental and economic benefits associated with sustainable construction among clients, policymakers, and the general public further contributes to resistance against adopting these practices [

81,

86].

Moreover, the prevailing perception of increased costs, complexity, and uncertainty linked to sustainable construction methods continues to impede their acceptance [

73,

86,

88]. Resistance to change is exacerbated by the industry’s preference for established materials and conventional practices, which are often perceived as more reliable and economically viable [

75,

76,

89,

90].

8. Discussion

The findings of this review reveal substantial progress in developing sustainable strategies for preserving concrete infrastructure. These advancements span innovative materials, retrofitting techniques, performance enhancements, and the identification of critical barriers. To effectively leverage these developments, a cohesive framework must be established that integrates research findings with practical implementation.

8.1. Synthesis of Key Findings

Significant developments have been made in the area of material innovations, particularly through the development of supplementary cementitious materials (SCMs) and geopolymer concrete (GPC). These materials have been instrumental in reducing carbon emissions and enhancing durability; however, challenges related to availability, performance variability, and scalability continue to hinder broader adoption [

12,

13,

15]. Additionally, low-carbon binders such as calcined clays and limestone-based alternatives have demonstrated promising results in reducing the carbon footprint of concrete without compromising structural integrity, making them viable candidates for replacing traditional cementitious binders [

14,

19,

22]. Emerging technologies, including CO

2 sequestration, bio-based additives, and self-healing concrete, offer innovative pathways to enhance sustainability. Yet, their long-term performance, particularly under real-world conditions, requires further validation before these technologies can be widely implemented [

14,

19,

20,

24].

Parallel progress has been observed in retrofitting strategies aimed at improving the resilience and longevity of aging reinforced concrete structures. Fiber-reinforced polymer (FRP) systems have gained increasing attention due to their high strength-to-weight ratios, corrosion resistance, and ease of application. However, ensuring effective bonding between concrete and FRP remains a critical challenge influencing overall performance [

32,

33,

34,

38]. Similarly, modularized steel reinforcement and polyurea coatings have demonstrated effectiveness in enhancing seismic resilience and structural durability. These techniques offer cost-effective solutions but require further optimization to enhance reliability [

45,

47,

48]. Hybrid retrofitting approaches that combine various strengthening mechanisms have also shown considerable improvements in structural performance. However, the absence of standardized guidelines and testing procedures continues to limit their practical implementation, preventing widespread adoption [

40,

42,

43,

50].

Efforts to improve performance have also focused on the inclusion of recycled materials such as fly ash, industrial by-products, and recycled aggregates. These materials have proven effective in enhancing mechanical performance, durability, and environmental sustainability, providing the dual benefits of resource conservation and improved structural integrity [

53,

54,

55,

56,

57]. Furthermore, advanced computational tools and machine learning techniques are revolutionizing sustainable concrete design by optimizing material compositions for enhanced performance while minimizing carbon footprints. Despite their considerable potential, broader validation of these computational methods is needed to ensure their practicality and effectiveness [

58,

59,

60,

61]. Equally promising is the use of fiber-reinforced composites and self-healing mechanisms, which continue to yield substantial improvements in crack mitigation, mechanical properties, and durability, thereby extending the service life of infrastructure [

62,

63,

64].

Despite these advancements, several challenges and barriers remain. Technical issues, particularly inconsistent performance criteria and inadequate standardization, continue to impede the adoption of sustainable materials and methods [

73,

74,

75]. Economic factors, including high initial costs and insufficient financial incentives, pose additional obstacles to the commercialization and large-scale adoption of these technologies [

77,

78,

81]. Regulatory barriers, including the lack of clear legislative support and inconsistent standardization practices, further complicate efforts to promote sustainable construction [

81,

86,

87]. Moreover, social and cultural reluctance to adopt novel technologies underscores the need for enhanced awareness and education about the benefits of sustainable construction practices [

75,

81,

86].

8.2. Research Gaps and Future Directions

Despite these advancements, significant gaps remain that must be addressed to ensure the effective implementation of sustainable concrete technologies. Many of the identified challenges are interconnected with the key findings described above, highlighting the need for a comprehensive approach to overcoming technical, economic, and regulatory barriers. Laboratory testing has demonstrated promising results for low-carbon materials, self-healing concrete, and bio-based additives; however, these technologies have yet to be extensively validated under real-world conditions. Comprehensive, long-term field studies are necessary to assess their durability and effectiveness across various environmental and operational scenarios. Understanding how these materials perform over extended periods is crucial to ensuring their reliability and broad applicability.

Additionally, the lack of universally accepted standards for implementing SCMs, geopolymer concrete, FRP systems, and hybrid retrofitting techniques continues to hinder practical adoption. Research aimed at developing performance-based design guidelines and establishing standardized testing protocols is urgently needed to facilitate consistency in material characterization, performance evaluation, and structural design. This effort is essential for boosting confidence among engineers, policymakers, and stakeholders, ultimately enabling broader acceptance and implementation.

The economic feasibility of sustainable materials and techniques remains another significant research gap, particularly concerning their scalability to full-scale construction projects. While many of these technologies have shown potential at small scales, comprehensive lifecycle cost assessments, economic modeling, and cost–benefit analyses are essential to determine their true viability. Providing clear economic incentives and demonstrating cost-effectiveness will be pivotal for widespread commercial adoption. Similarly, the integration of computational tools and AI techniques into concrete infrastructure design is a rapidly advancing area that requires further development. Enhanced optimization algorithms and AI-driven design frameworks hold substantial potential to revolutionize sustainable concrete systems, yet their effectiveness must be rigorously validated and refined to meet real-world demands.

Addressing social and policy-related barriers is equally important, as public acceptance and regulatory support remain critical hurdles. Research dedicated to understanding public perception, promoting awareness of sustainable practices, and developing supportive policies will be essential for overcoming these challenges. Effective collaboration between researchers, industry professionals, and policymakers is necessary to formulate strategies that address technical challenges while also fostering societal acceptance and regulatory alignment. As sustainability continues to be a central priority, there is an increasing need to explore the integration of waste materials, recycling techniques, and circular economy principles within concrete infrastructure systems. Future research should focus on evaluating the environmental impact of these strategies through comprehensive lifecycle analyses, identifying areas where improvements can be made, and ensuring alignment with global sustainability goals. Addressing these gaps will require coordinated efforts from academia, industry, and government agencies. Continued research focused on these areas will be instrumental in advancing sustainable construction practices and improving the resilience and longevity of concrete infrastructure systems.

8.3. Implications for Practice

While

Section 8.2 emphasized research gaps and systemic challenges, this section focuses on translating sustainable strategies into practical implementation, particularly for engineers, contractors, and infrastructure managers. The successful adoption of sustainable materials and retrofitting techniques depends on more than technical validation—it requires usability, standardization, and alignment with on-site construction practices.

A major challenge lies in the lack of field-ready design guides, installation procedures, and standardized testing protocols. Practitioners often hesitate to adopt emerging technologies due to unclear specifications or limited integration within existing codes and procurement systems. Creating accessible technical documentation and clear implementation frameworks is essential for overcoming this hesitation.

Training and workforce development also play a critical role. Techniques like FRP wrapping, self-healing concrete application, or the use of low-carbon binders often require precise handling and execution. Without proper instruction, performance in the field may diverge significantly from controlled experimental conditions. Certification programs, hands-on workshops, and continuing education can support quality control and build practitioner confidence.

Pilot projects and demonstration programs can further encourage adoption by providing tangible evidence of performance under real-world conditions. Case studies showing long-term durability, constructability, and cost savings can help shift industry perception and promote broader acceptance of sustainable solutions.

To succeed at scale, sustainable technologies must be supported by practical tools, targeted education, and transparent evidence of field performance—bridging the gap between research innovation and day-to-day engineering practice.

9. Conclusions

This review has highlighted significant advancements in developing sustainable strategies for preserving, retrofitting, and enhancing the performance of concrete infrastructure. The integration of innovative materials such as low-carbon binders, supplementary cementitious materials (SCMs), geopolymer concrete, and self-healing technologies demonstrate promising potential to reduce environmental impact, enhance structural durability, and extend service life. However, the transition from laboratory-scale findings to real-world applications remains a critical challenge, primarily due to scalability issues, performance variability, and a lack of comprehensive long-term field studies.

Retrofitting strategies, particularly those involving fiber-reinforced polymer (FRP) systems, modularized steel reinforcement, and hybrid approaches, have shown effective solutions for enhancing resilience against environmental and operational stresses. Despite these advancements, limitations in bonding effectiveness, economic feasibility, and a lack of standardized guidelines continue to hinder their widespread implementation.

Computational tools and machine learning techniques have emerged as powerful instruments for optimizing concrete mixture designs and enhancing performance while minimizing carbon footprints. While these tools present exciting opportunities for sustainable infrastructure development, broader validation of these computational models is essential to ensure their practicality and reliability.

Addressing the identified gaps will require coordinated efforts across academia, industry, and regulatory bodies. Establishing performance-based guidelines, developing standardized testing protocols, and conducting comprehensive lifecycle assessments are essential steps toward achieving scalable solutions. Additionally, interdisciplinary collaboration, enhanced computational tools, and supportive regulatory frameworks will be critical in transitioning from research innovation to practical applications.

The implications of successfully implementing these sustainable strategies are profound, with the potential to enhance infrastructure resilience, reduce environmental impacts, and contribute to more cost-effective, durable concrete systems. These efforts align with broader global sustainability initiatives aimed at achieving net-zero emissions and climate resilience. Moving forward, continued research focused on overcoming existing challenges and enhancing practical implementation will be instrumental in ensuring resilient, durable, and environmentally responsible concrete infrastructure systems.

Importantly, the economic viability of sustainable materials remains a key factor for adoption. Construction companies are more likely to embrace materials that demonstrate cost savings over the lifecycle of a structure—especially when upfront costs are offset by reduced maintenance, extended service life, or decreased material volume. Therefore, aligning performance reliability with cost-effectiveness will be essential for accelerating real-world implementation.