Chloride Resistance of High-Strength Concrete Subjected to Different Curing Conditions and Chloride Concentrations

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Sample Preparation

2.2. Methods

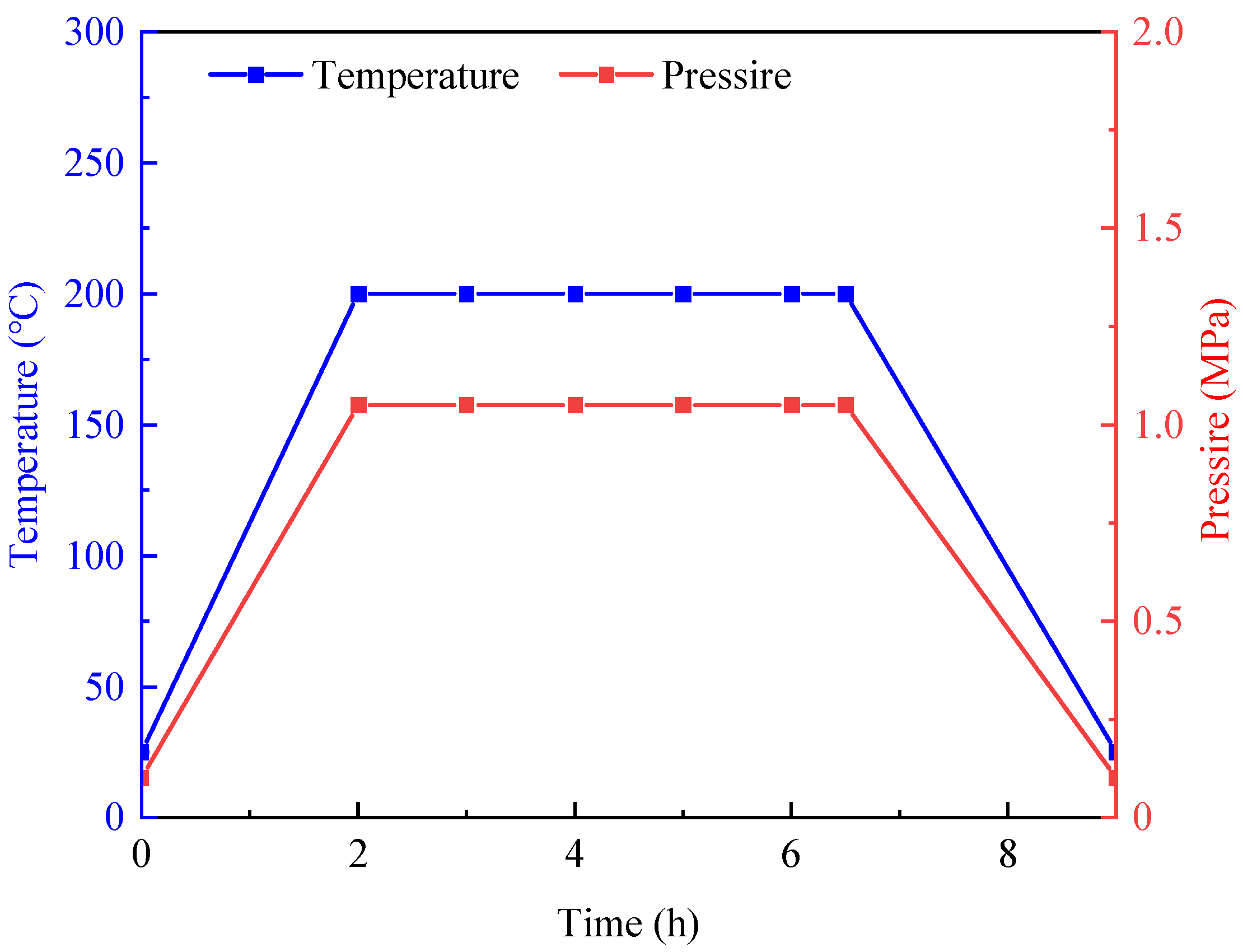

2.2.1. Curing Conditions

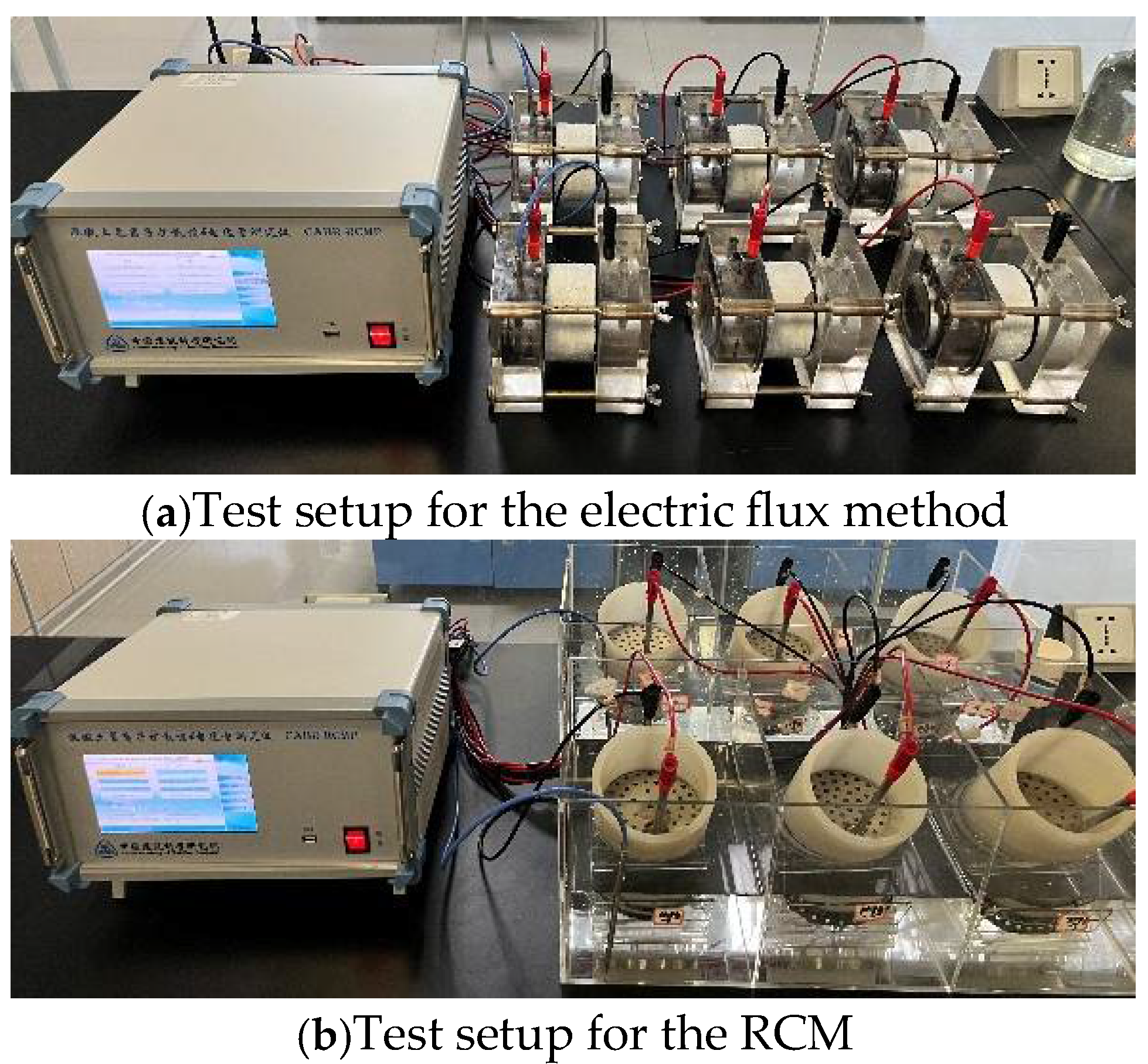

2.2.2. Electric Flux Method

2.2.3. Mechanical Properties After RCM Exposure

2.2.4. X-Ray Diffraction

2.2.5. Micro-Morphology

3. Results and Discussion

3.1. Electric Flux

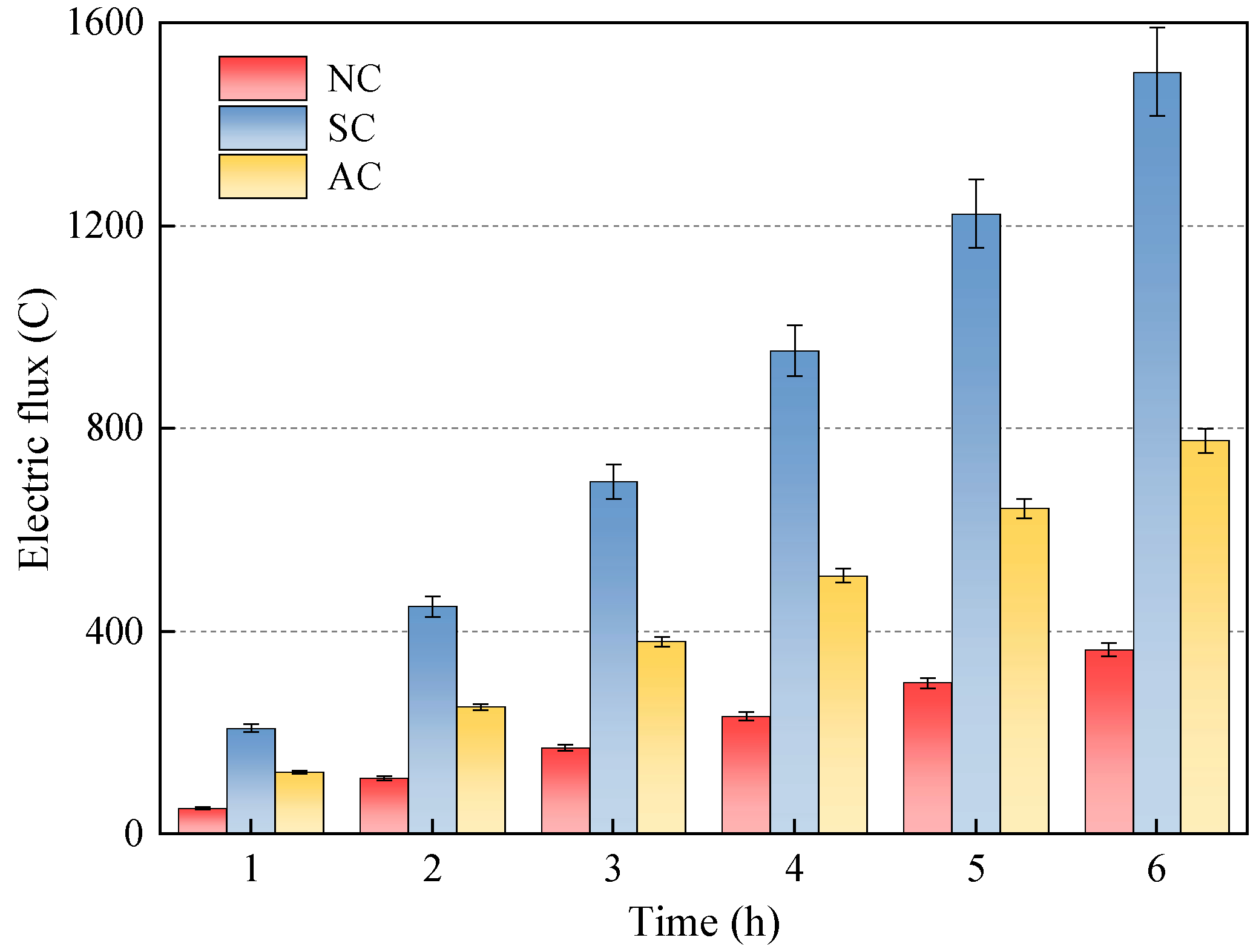

3.1.1. Effects of Curing Conditions

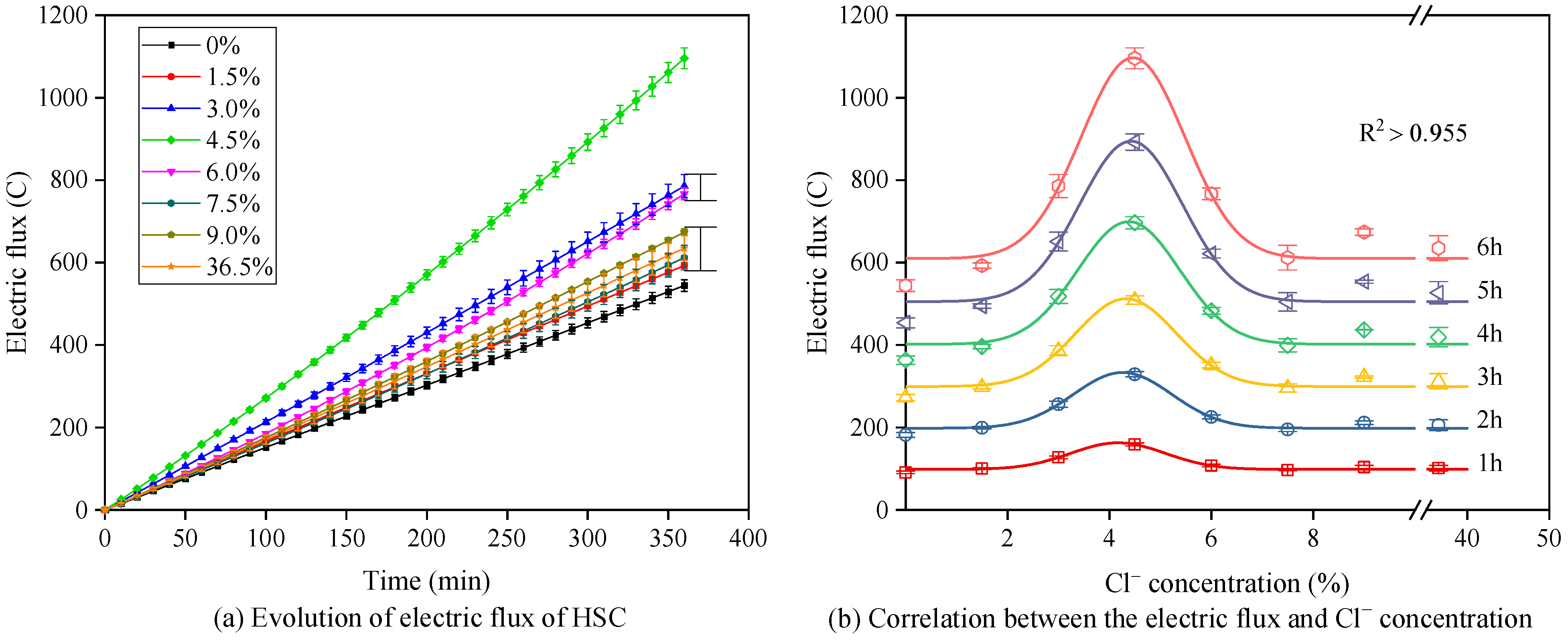

3.1.2. Effects of Chloride Concentrations

3.2. Mechanical Properties

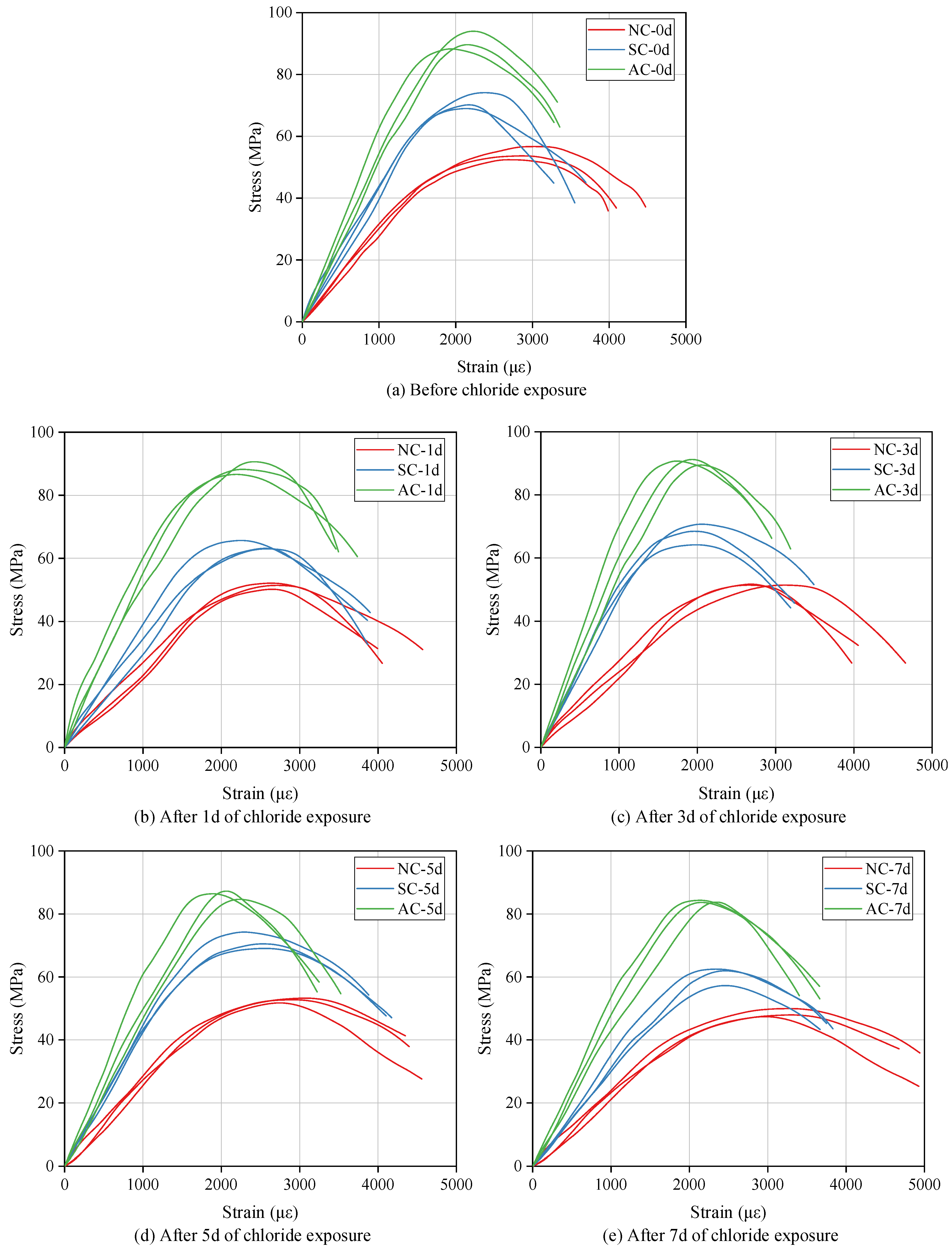

3.2.1. Axial Stress–Strain Behavior

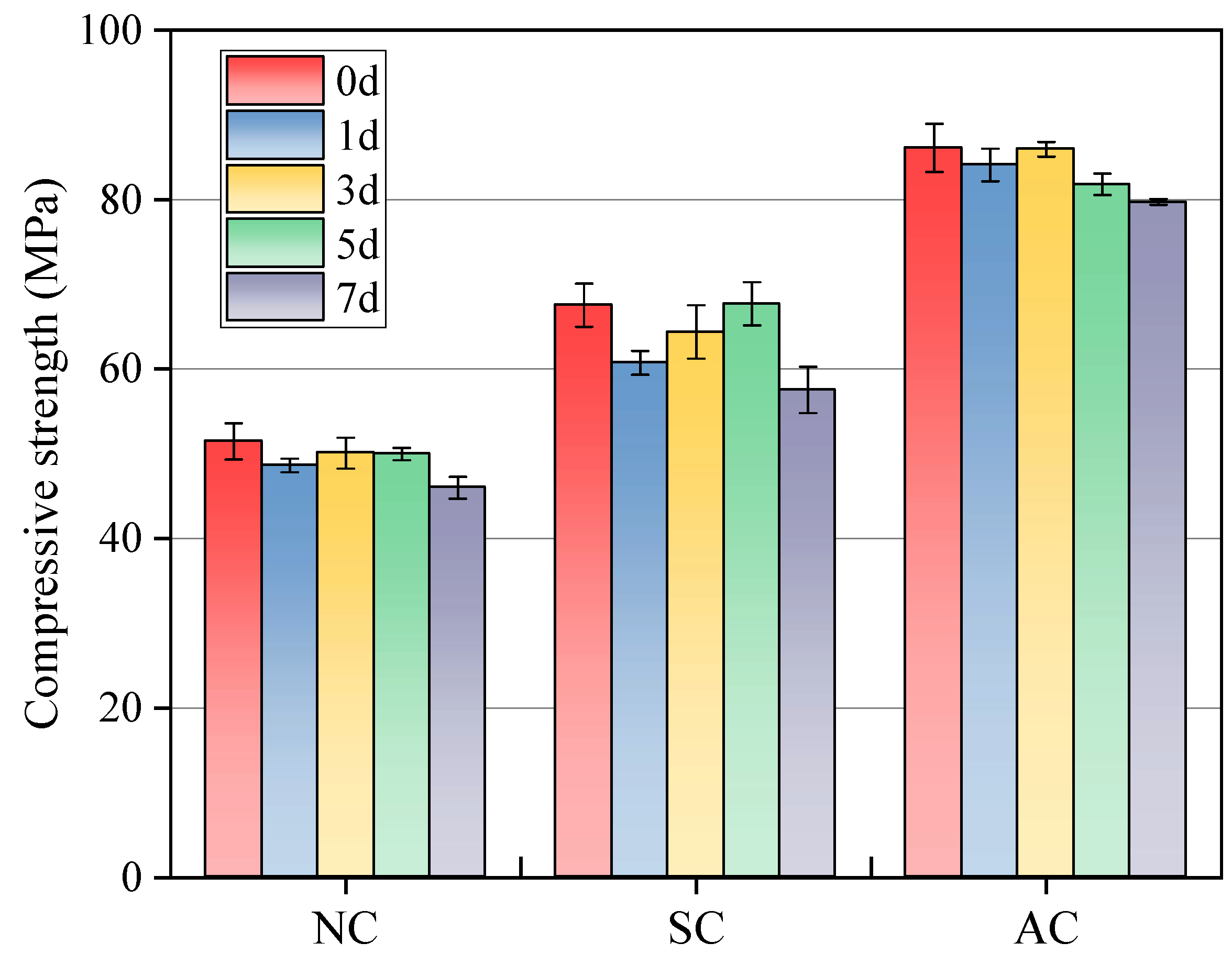

3.2.2. Compressive Strength

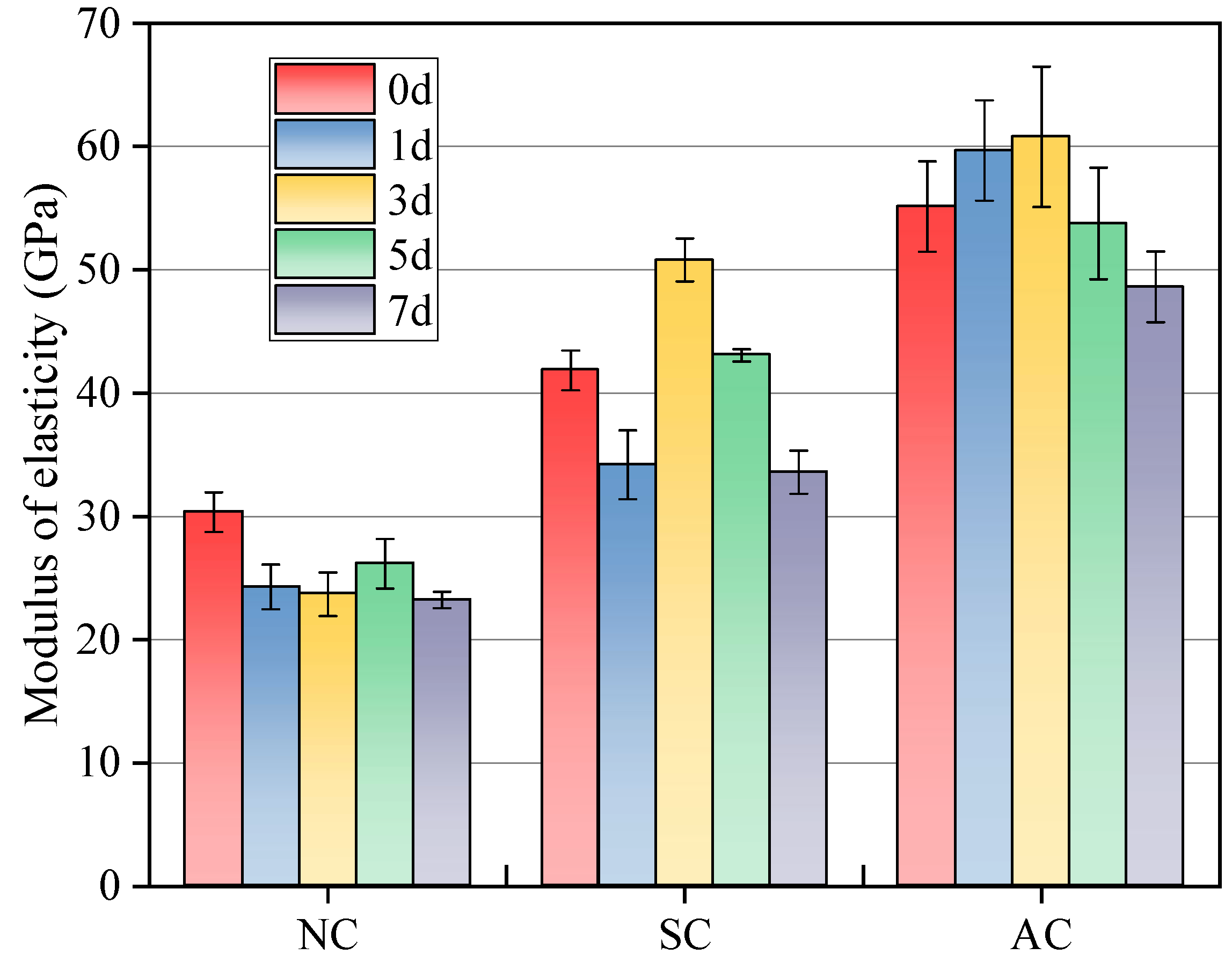

3.2.3. Modulus of Elasticity

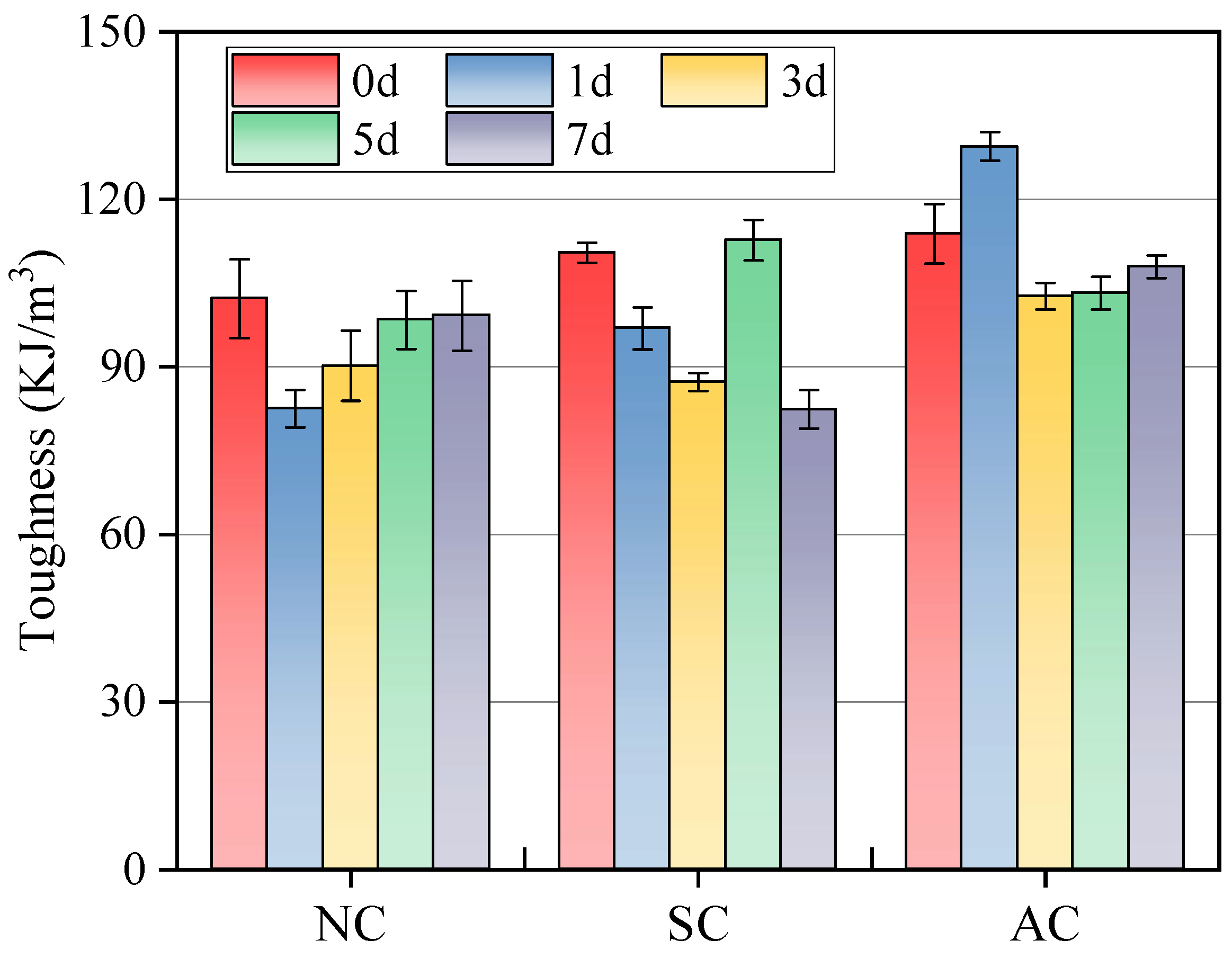

3.2.4. Toughness

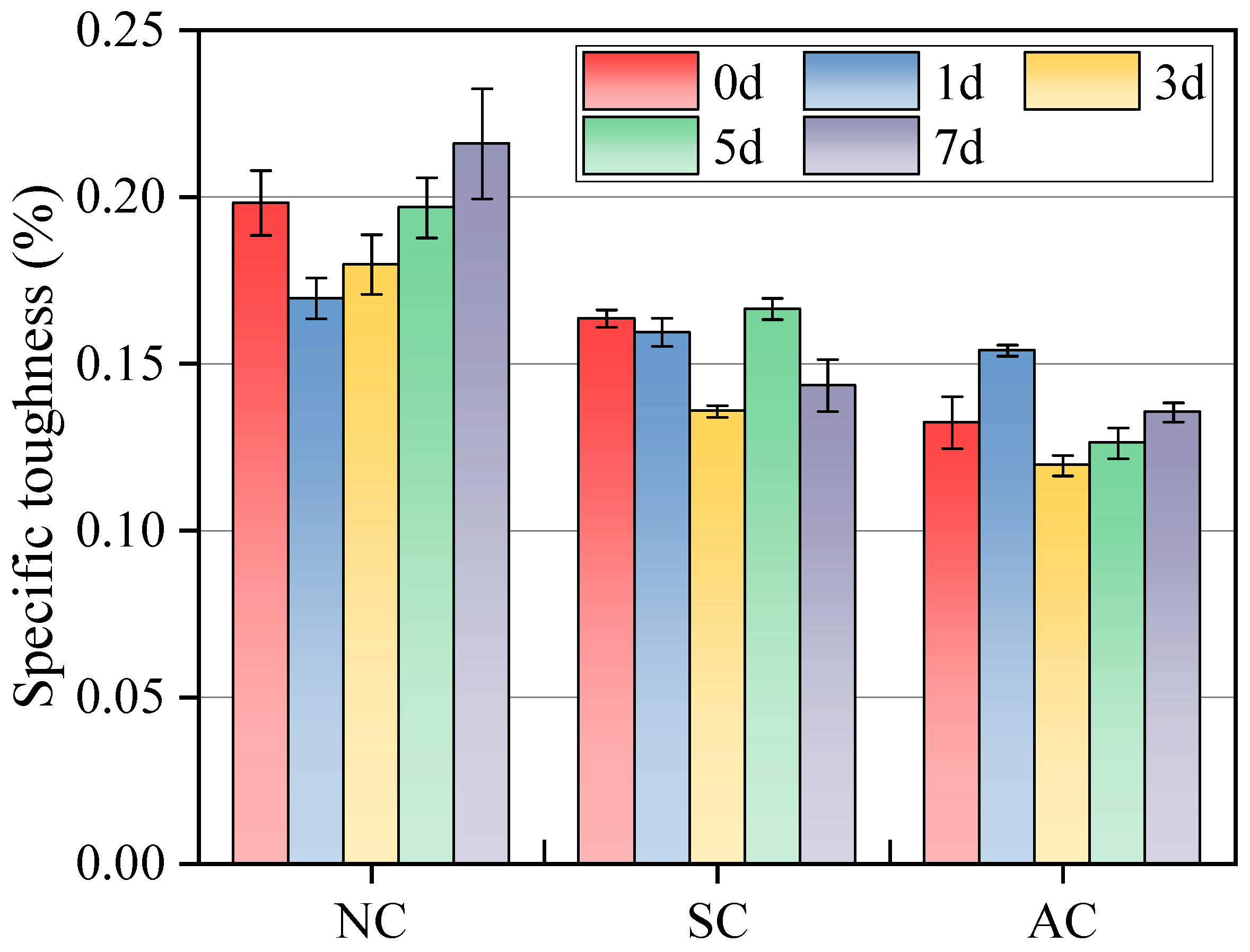

3.2.5. Specific Toughness

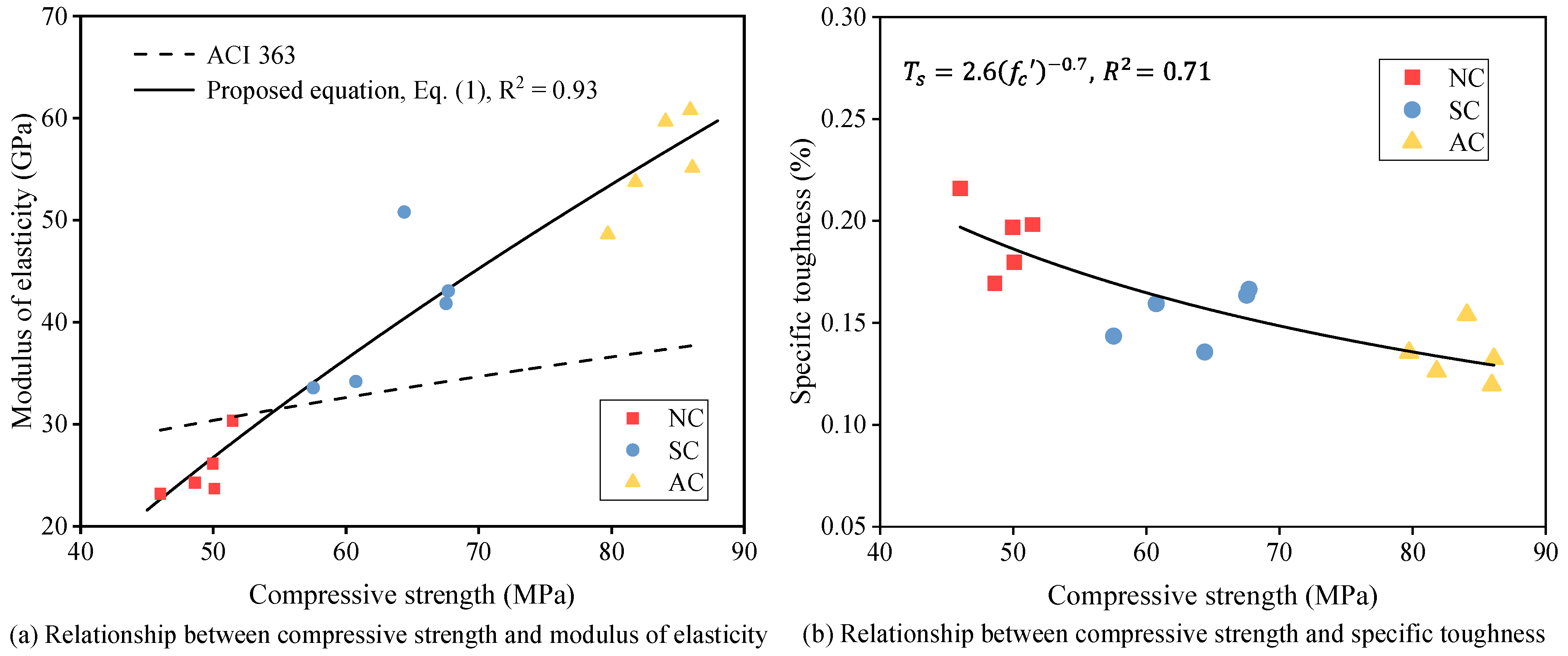

3.2.6. Relationship Among Mechanical Properties

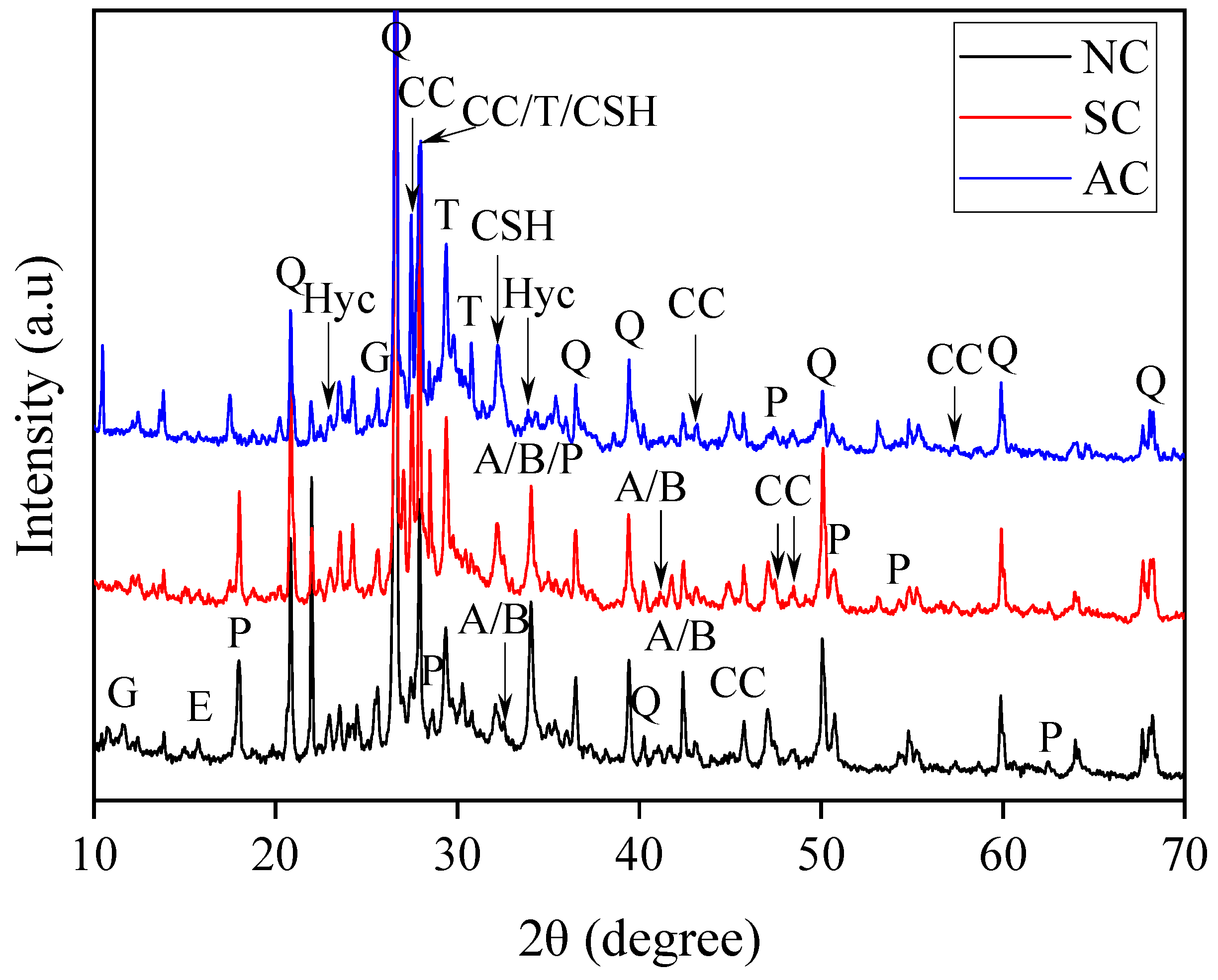

3.3. X-Ray Diffraction Analysis

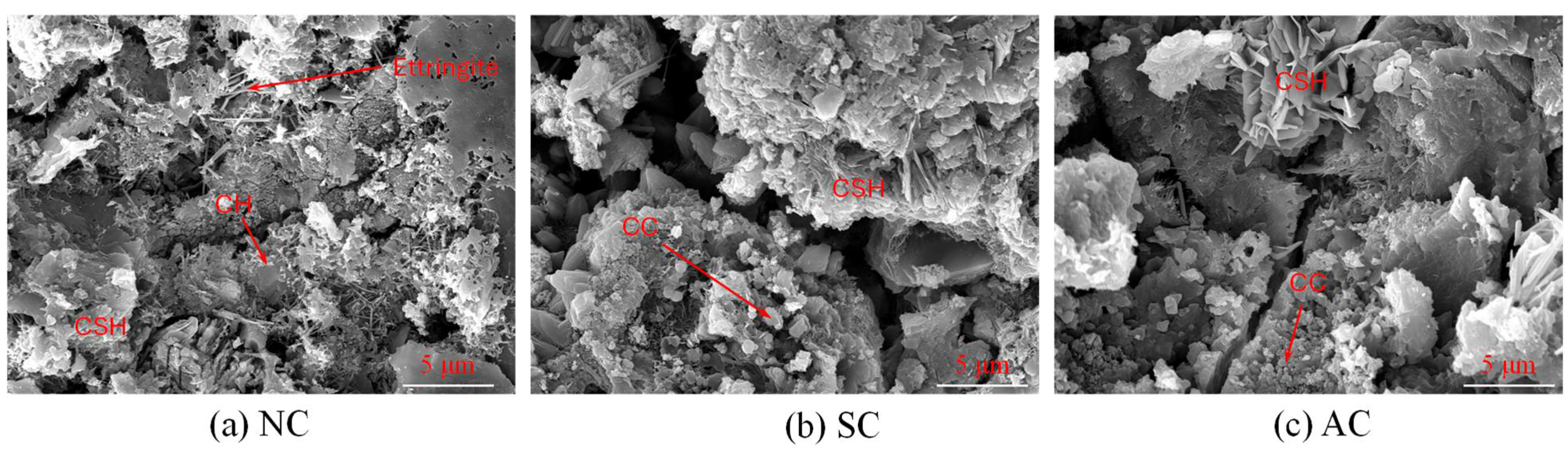

3.4. Microstructure Analysis

4. Conclusions

- Steam and autoclave curing significantly increased the electrical flux values, with SC specimens reaching over 1500 C, indicating high chloride permeability. In contrast, NC specimens maintained electrical flux values below 370 C, classifying them as having moderate permeability. The elevated permeability in SC is attributed to non-uniform and accelerated hydration, which promotes increased capillary porosity. While AC also raises permeability, it initiates pozzolanic reactions in silica sand, resulting in partial microstructural refinement and a slightly reduced permeability compared to SC.

- Chloride ingress exhibited a non-linear trend with respect to external chloride concentration. Maximum electrical flux was observed at a chloride concentration of 4.5 wt.%, beyond which flux values plateaued or slightly decreased. This trend suggests that optimal pore connectivity and ionic mobility occur at intermediate chloride levels, while higher concentrations potentially lead to reduced ion mobility due to thermal effects during prolonged electrical testing.

- SC and AC improved early-age mechanical properties. Compressive strength at 28 d increased from 68 MPa (NC) to 75 MPa (SC) and 80 MPa (AC). Similarly, the modulus of elasticity and flexural toughness were enhanced. However, under long-term chloride exposure, SC and AC specimens showed faster reductions in stiffness and toughness compared to NC. For instance, toughness degradation in SC specimens exceeded 30% after 60 d of chloride immersion, whereas NC specimens retained over 85% of their initial toughness.

- Microstructural and mineralogical analyses confirm that SC and AC accelerate cement hydration, reducing unhydrated clinker phases and portlandite content while promoting the formation of CSH and carbonation products. Despite these benefits, SC and AC also induce increased microcracking and porosity. Notably, microcracks formed under AC are smaller and less severe due to the secondary silica reactions, which partially refine and strengthen the microstructure.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, L.; Gong, W.; Li, J. Service life of prestressed high-strength concrete pile in marine environment considering effects of concrete stratification and temperature. Constr. Build. Mater. 2020, 253, 119233. [Google Scholar] [CrossRef]

- Akhnoukh, A.K.; Elia, H. Developing high performance concrete for precast/prestressed concrete industry. Case Stud. Constr. Mater. 2019, 11, e00290. [Google Scholar] [CrossRef]

- Yi, C.-Y.; Park, J.-Y.; Park, C.-Y.; Lee, J.-C.; Park, Y.-J. Eco-Economic Performance Estimation Method for Pretensioned Spun High-Strength Concrete Pile Installation. Sustainability 2022, 14, 11990. [Google Scholar] [CrossRef]

- Hu, S.; Liang, F. Settlement Analysis of Pre-stressed Concrete Pipe-Pile Foundations in Soft Ground: A Case Study. J. Civ. Eng. Urban Plan. 2023, 5, 21–30. [Google Scholar]

- Arockiasamy, M.; Arvan, P.A. Behavior, performance, and evaluation of prestressed concrete/steel pipe/steel H-pile to pile cap connections. Pract. Period. Struct. Des. Constr. 2022, 27, 03122001. [Google Scholar] [CrossRef]

- Kumar, D.R.; Kumar, P.; Thangavel, P.; Wipulanusat, W.; Thongchom, C.; Samui, P. Optimized machine learning models for predicting the tensile strength of high-performance concrete. J. Struct. Integr. Maint. 2025, 10, 2471682. [Google Scholar] [CrossRef]

- Wang, B.; Qi, L.; Yang, Y. Experimental study on bending resistance of new type joint of prestressed concrete pipe pile. Symmetry 2022, 14, 1920. [Google Scholar] [CrossRef]

- Cho, S.K.; Koo, T.H.; Cho, W.C. Structural performance at the joint of precast pile-supported pier structure. Mar. Struct. 2025, 99, 103722. [Google Scholar] [CrossRef]

- Wang, R.; Li, Y.; Liu, X.; Zhang, S.; Zhang, C.; Li, Z.; Wang, P. Research on advantages and disadvantages of prestressed concrete hollow square pile and pipe pile in pile foundation selection. IOP Conf. Ser. Earth Environ. Sci. IOP Publ. 2021, 787, 012022. [Google Scholar] [CrossRef]

- Qu, F.; Li, W.; Dong, W.; Tam, V.W.; Yu, T. Durability deterioration of concrete under marine environment from material to structure: A critical review. J. Build. Eng. 2021, 35, 102074. [Google Scholar] [CrossRef]

- Wu, L.; Jiang, H.; Ju, X.; Liu, M.; Di, Y.; Zhao, Y.; Xiang, Z. Service life evaluation of marine reinforced concrete structures in coastal soda residue soil subjected to chloride attack. Constr. Build. Mater. 2024, 455, 139222. [Google Scholar] [CrossRef]

- Pawar, Y.; Kate, S. Curing of concrete: A review. Int. Res. J. Eng. Technol. 2020, 7, 1820–1824. [Google Scholar]

- Safiuddin, M.; Kaish, A.A.; Woon, C.-O.; Raman, S.N. Early-age cracking in concrete: Causes, consequences, remedial measures, and recommendations. Appl. Sci. 2018, 8, 1730. [Google Scholar] [CrossRef]

- Xu, X.; Jin, Z.; Yu, Y.; Li, N. Impact properties of Ultra High Performance Concrete (UHPC) cured by steam curing and standard curing. Case Stud. Constr. Mater. 2022, 17, e01321. [Google Scholar] [CrossRef]

- Shen, P.; Lu, L.; He, Y.; Wang, F.; Hu, S. The effect of curing regimes on the mechanical properties, nano-mechanical properties and microstructure of ultra-high performance concrete. Cem. Concr. Res. 2019, 118, 1–13. [Google Scholar] [CrossRef]

- Amorim, P.; De Brito, J.; Evangelista, L. Concrete made with coarse concrete aggregate: Influence of curing on durability. ACI Mater. J. 2012, 109, 195–204. [Google Scholar] [CrossRef]

- Wang, J.; Long, G.; Xiang, Y.; Dong, R.; Tang, Z.; Xiao, Q.; Yang, Z.; Ma, K. Influence of rapid curing methods on concrete microstructure and properties: A review. Case Stud. Constr. Mater. 2022, 17, e01600. [Google Scholar] [CrossRef]

- Khomwan, N.; Mungsantisuk, P. Durability of precast prestressed concrete pile in exposure severe environment. J. Met. Mater. Miner. 2025, 35, e1917. [Google Scholar] [CrossRef]

- Moser, R.; Holland, R.B.; Kahn, L.; Singh, P.; Kurtis, K. Durability of Precast Prestressed Concrete Piles in Marine Environment: Reinforcement Corrosion and Mitigation–Part 1; ROSA P: Washington, DC, USA, 2011.

- Luo, D.; Wang, K.; Wang, D.; Sharma, A.; Li, W.; Choi, I.H. Artificial intelligence in the design, optimization, and performance prediction of concrete materials: A comprehensive review. npj Mater. Sustain. 2025, 3, 14. [Google Scholar] [CrossRef]

- Kareem, R.; Assi, L.N.; Alsalman, A.; Al-Manea, A. Effect of supplementary cementitious materials on RC concrete piles. AIP Conf. Proc. AIP Publ. 2021, 2404, 080036. [Google Scholar]

- Tan, K.; Zhu, J. Influences of steam and autoclave curing on the strength and chloride permeability of high strength concrete. Mater. Struct. 2017, 50, 56. [Google Scholar] [CrossRef]

- Wang, Y.; Deng, M.; Zhang, R.; Yu, X.; Xue, J.; Zhang, J. Durability of Prestressed Piles in a Leachate Environment. Materials 2024, 17, 2497. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Wei, J.; Xing, X.; Ma, F.; Wang, B.; Xu, N.; Li, M.; Geng, J.; Chen, L.; Zhu, W. Studying the interfacial transition zone microstructure of pre-stressed high-strength concrete pipe piles. Constr. Build. Mater. 2024, 448, 138045. [Google Scholar] [CrossRef]

- Güneyisi, E.; Özturan, T.; Gesoglu, M. Effect of initial curing on chloride ingress and corrosion resistance characteristics of concretes made with plain and blended cements. Build. Environ. 2007, 42, 2676–2685. [Google Scholar] [CrossRef]

- Chen, X.; He, Y.; Lu, L.; Wang, F.; Hu, S. Effects of curing regimes on the chloride binding capacity of cementitious materials. Constr. Build. Mater. 2022, 342, 127929. [Google Scholar] [CrossRef]

- Bahmani, H.; Mostafaei, H.; Santos, P.; Fallah Chamasemani, N. Enhancing the mechanical properties of Ultra-High-Performance Concrete (UHPC) through silica sand replacement with steel slag. Buildings 2024, 14, 3520. [Google Scholar] [CrossRef]

- Pachipala, S. A study on mechanical properties of concrete using silica sand as partial replacement of cement. Int. J. Civ. Eng. 2017, 4, 34–39. [Google Scholar] [CrossRef]

- Ramjan, S.; Tangchirapat, W.; Jaturapitakkul, C.; Chee Ban, C.; Jitsangiam, P.; Suwan, T. Influence of cement replacement with fly ash and ground sand with different fineness on alkali-silica reaction of mortar. Materials 2021, 14, 1528. [Google Scholar] [CrossRef]

- Ma, J.; Yang, Q.; Wang, X.; Peng, X.; Qin, F. Review of Prediction Models for Chloride Ion Concentration in Concrete Structures. Buildings 2025, 15, 149. [Google Scholar] [CrossRef]

- Shi, X.; Xie, N.; Fortune, K.; Gong, J. Durability of steel reinforced concrete in chloride environments: An overview. Constr. Build. Mater. 2012, 30, 125–138. [Google Scholar] [CrossRef]

- Poupard, O.; Aït-Mokhtar, A.; Dumargue, P. Corrosion by chlorides in reinforced concrete: Determination of chloride concentration threshold by impedance spectroscopy. Cem. Concr. Res. 2004, 34, 991–1000. [Google Scholar] [CrossRef]

- Niu, D.; Huang, D.; Fu, Q. Experimental investigation on compressive strength and chloride permeability of fiber-reinforced concrete with basalt-polypropylene fibers. Adv. Struct. Eng. 2019, 22, 2278–2288. [Google Scholar] [CrossRef]

- GB/T 50082-2024; Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2024.

- Qu, L.; Song, W.; Wang, Q.; Xu, S.; Hou, C. Effects of hydrophobic modified fly ash on resistance of chloride corrosion and water penetration of cement mortar in the early hydration stage. J. Build. Eng. 2023, 64, 105573. [Google Scholar] [CrossRef]

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. China Standard Press: Beijing, China, 2019.

- Wang, T.; Gao, X.; Li, Y.; Liu, Y. An orthogonal experimental study on the influence of steam-curing on mechanical properties of foam concrete with fly ash. Case Stud. Constr. Mater. 2024, 20, e02665. [Google Scholar] [CrossRef]

- Xiong, X.; Wu, M.; Shen, W.; Li, J.; Zhao, D.; Li, P.; Wu, J. Performance and microstructure of ultra-high-performance concrete (UHPC) with silica fume replaced by inert mineral powders. Constr. Build. Mater. 2022, 327, 126996. [Google Scholar] [CrossRef]

- Gao, Y.; Cai, J.; Xu, G.; Tian, Q.; Shen, W.; Liu, R.; Zhang, J. Effect of waste glass powder on quartz sand autoclaved material: Strength, hydration products and microstructure. Mater. Struct. 2024, 57, 161. [Google Scholar] [CrossRef]

- Rong, G.; He, T.; Zhang, G.; Li, Y.; Wang, Y.; Xie, W. A review on chloride transport model and research method in concrete. Mater. Res. Express 2023, 10, 042002. [Google Scholar] [CrossRef]

- Ju, X.; Wu, L.; Liu, M.; Jiang, H.; Zhang, W. Modelling of chloride concentration profiles in concrete by the consideration of concrete material factors under marine tidal environment. J. Mar. Sci. Eng. 2022, 10, 917. [Google Scholar] [CrossRef]

- Dong, W.; Sun, A.; Zhou, M. Microstructure and chloride transport of aeolian sand concrete under long-term natural immersion. Sci. Eng. Compos. Mater. 2024, 31, 20220242. [Google Scholar] [CrossRef]

- Karbala, M.M.; Iranfar, S.; Shahsavari, M.H.; Shakiba, M. Impact of dissolved salt type and content on mechanical and physical properties of porous cementitious materials. Int. J. Geo-Eng. 2025, 16, 18. [Google Scholar] [CrossRef]

- Weiss, J.; Snyder, K.; Bullard, J.; Bentz, D. Using a saturation function to interpret the electrical properties of partially saturated concrete. J. Mater. Civ. Eng. 2013, 25, 1097–1106. [Google Scholar] [CrossRef]

- Liang, K.; Zeng, X.; Zhou, X.; Qu, F.; Wang, P. A new model for the electrical conductivity of cement-based material by considering pore size distribution. Mag. Concr. Res. 2017, 69, 1067–1078. [Google Scholar] [CrossRef]

- Cho, C.; Ann, K.; Kim, H.; Hwang, W.; Kim, J.; Cho, W.; Jung, H. Mobility of chloride in concrete subjected to electrochemical treatment. ACI Mater. J. 2021, 118, 189–198. [Google Scholar] [CrossRef]

- Lee, N.; Jeong, Y.; Kang, H.; Moon, J. Heat-induced acceleration of pozzolanic reaction under restrained conditions and consequent structural modification. Materials 2020, 13, 2950. [Google Scholar] [CrossRef] [PubMed]

- Zeyad, A.M.; Johari, M.A.M.; Abutaleb, A.; Tayeh, B.A. The effect of steam curing regimes on the chloride resistance and pore size of high–strength green concrete. Constr. Build. Mater. 2021, 280, 122409. [Google Scholar] [CrossRef]

- Haigh, R.; Ameri Sianaki, O. Traditional and Advanced Curing Strategies for Concrete Materials: A Systematic Review of Mechanical Performance, Sustainability, and Future Directions. Appl. Sci. 2025, 15, 11055. [Google Scholar] [CrossRef]

- Gao, Y.; Wang, B.; Liu, C.; Hui, D.; Xu, Q.; Zhao, Q.; Qin, Y.; Dong, W. Experimental investigation on static compressive toughness of steel fiber rubber concrete. Rev. Adv. Mater. Sci. 2022, 61, 576–586. [Google Scholar] [CrossRef]

- Yu, W.; Jin, L.; Du, X. Experimental study on compression failure characteristics of basalt fiber-reinforced lightweight aggregate concrete: Influences of strain rate and structural size. Cem. Concr. Compos. 2023, 138, 104985. [Google Scholar] [CrossRef]

- Wu, Y.-F.; Kazmi, S.M.S.; Munir, M.J.; Zhou, Y.; Xing, F. Effect of compression casting method on the compressive strength, elastic modulus and microstructure of rubber concrete. J. Clean. Prod. 2020, 264, 121746. [Google Scholar] [CrossRef]

- ACI Committee 363. Report on High-Strength Concrete (ACI 363R-10); ACI: Farmington Hills, MI, USA, 2010; 27p. [Google Scholar]

- Gonzalez-Corominas, A.; Etxeberria, M.; Poon, C.S. Influence of steam curing on the pore structures and mechanical properties of fly-ash high performance concrete prepared with recycled aggregates. Cem. Concr. Compos. 2016, 71, 77–84. [Google Scholar] [CrossRef]

- Pyo, S.; Tafesse, M.; Kim, H.; Kim, H.-K. Effect of chloride content on mechanical properties of ultra high performance concrete. Cem. Concr. Compos. 2017, 84, 175–187. [Google Scholar] [CrossRef]

- Luo, D.; Wei, J. Hydration and phase evolution of blended cement composites containing lithium and saturated metakaolin. Cem. Concr. Compos. 2023, 144, 105268. [Google Scholar] [CrossRef]

- Wei, T.; Wei, F.; Zhou, J.; Wu, Z.; Zhang, C.; Zhuang, J.; Cheng, X. Formation and strengthening mechanisms of xonotlite in C3S-silica and C2S-silica powder systems under high temperature and pressure. Cem. Concr. Res. 2022, 157, 106812. [Google Scholar] [CrossRef]

- Ai, Y.; Wang, M.; Huang, R.; Cui, M.; Qi, W.; Su, R. Synergy between cellulose nanocrystals and calcium silicate hydrate-polycarboxylate ether enhances the strength and carbonation resistance of cement pastes. Constr. Build. Mater. 2024, 435, 136914. [Google Scholar] [CrossRef]

- Corro-Escorcia, I.A.; Hernández-Ávila, J.; Cerecedo-Sáenz, E.; Barrientos-Hernández, F.; Cruz-Hernández, M.; Toro, N.; Gálvez, E.; Gutiérrez-Amador, M.; Salinas-Rodríguez, E. Synthesis of tobermorite 11 Å during the formation of autoclaved aerated concrete with the addition of diatomite. Results Mater. 2025, 26, 100725. [Google Scholar] [CrossRef]

- Chen, M.; Lu, L.; Wang, S.; Zhao, P.; Zhang, W.; Zhang, S. Investigation on the formation of tobermorite in calcium silicate board and its influence factors under autoclaved curing. Constr. Build. Mater. 2017, 143, 280–288. [Google Scholar] [CrossRef]

- Wu, R.; Gu, Q.; Gao, X.; Huang, J.; Guo, Y.; Zhang, H. Effect of curing conditions on the alkali-activated blends: Microstructure, performance and economic assessment. J. Clean. Prod. 2024, 445, 141344. [Google Scholar] [CrossRef]

- Luo, D.; Wei, J. Hydration kinetics and phase evolution of Portland cement composites containing sodium-montmorillonite functionalized with a Non-Ionic surfactant. Constr. Build. Mater. 2022, 333, 127386. [Google Scholar] [CrossRef]

- Luo, D.; Wei, J. Understanding the role of a novel internal conditioning technique with functionalized montmorillonite in cement hydration kinetics. Constr. Build. Mater. 2023, 385, 131223. [Google Scholar] [CrossRef]

- Zdeb, T. An analysis of the steam curing and autoclaving process parameters for reactive powder concretes. Constr. Build. Mater. 2017, 131, 758–766. [Google Scholar] [CrossRef]

- Pushpan, S.; Ziga-Carbarín, J.; Rodríguez-Barboza, L.I.; Sanal, K.; Acevedo-Dávila, J.L.; Balonis, M.; Gómez-Zamorano, L.Y. Strength and microstructure assessment of partially replaced ordinary portland cement and calcium sulfoaluminate cement with pozzolans and spent coffee grounds. Materials 2023, 16, 5006. [Google Scholar] [CrossRef] [PubMed]

- Kaufmann, J.; Winnefeld, F.; Lothenbach, B. Stability of ettringite in CSA cement at elevated temperatures. Adv. Cem. Res. 2016, 28, 251–261. [Google Scholar] [CrossRef]

- El Bitouri, Y.; Azéma, N.; Le Saoût, G.; Lauten, R.A.; De Weerdt, K. Effect of plasticizer on hydration and rheological behavior of cement pastes. CivilEng 2022, 3, 748–759. [Google Scholar] [CrossRef]

- Szudek, W.; Szydłowski, J.; Buchała, I.; Kapeluszna, E. Synthesis and Characterization of Calcium Sulfoaluminate Hydrates—Ettringite (AFt) and Monosulfate (AFm). Materials 2024, 17, 5216. [Google Scholar] [CrossRef] [PubMed]

| Oxides | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | SO3 | LOI |

|---|---|---|---|---|---|---|---|

| Content (%) | 66.86 | 20.02 | 6.10 | 3.15 | 1.67 | 0.61 | 0.26 |

| Cement | Silica Sand Powder | River Sand | Limestone Gravel | Water | Water Reducer |

|---|---|---|---|---|---|

| 322 | 138 | 660 | 1194 | 126 | 10.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Z.; Luo, D.; Li, S.; Li, Z. Chloride Resistance of High-Strength Concrete Subjected to Different Curing Conditions and Chloride Concentrations. Infrastructures 2025, 10, 300. https://doi.org/10.3390/infrastructures10110300

Wu Z, Luo D, Li S, Li Z. Chloride Resistance of High-Strength Concrete Subjected to Different Curing Conditions and Chloride Concentrations. Infrastructures. 2025; 10(11):300. https://doi.org/10.3390/infrastructures10110300

Chicago/Turabian StyleWu, Zhengyu, Dayou Luo, Shuai Li, and Zhiguo Li. 2025. "Chloride Resistance of High-Strength Concrete Subjected to Different Curing Conditions and Chloride Concentrations" Infrastructures 10, no. 11: 300. https://doi.org/10.3390/infrastructures10110300

APA StyleWu, Z., Luo, D., Li, S., & Li, Z. (2025). Chloride Resistance of High-Strength Concrete Subjected to Different Curing Conditions and Chloride Concentrations. Infrastructures, 10(11), 300. https://doi.org/10.3390/infrastructures10110300