Life-Cycle-Assessment-Based Quantification and Low-Carbon Optimization of Carbon Emissions in Expressway Construction

Abstract

1. Introduction

- (1)

- The first category is the quantitative method of carbon emission models based on the factor decomposition method [11,12]. By decomposing the contribution of different factors into carbon emissions, it analyzes the continuous impact of each link and provides a basis for phased emission reduction policies and structural optimization.

- (2)

- The second category is the emission accounting method based on the background of carbon trading [13,14], usually based on the emission factor guidelines issued by national or international climate specialized agencies. It is currently the most widely used and systematic carbon emission accounting method.

- (3)

- The third category is quantitative research on carbon emissions based on the life cycle assessment (LCA) method [15]. This method comprehensively evaluates the energy consumption and greenhouse gas emissions in the whole life cycle of products or projects from the systematic perspective of “cradle to grave” and can comprehensively reflect the carbon emission characteristics of road engineering in the whole process of material production, transportation, and construction [16]. Therefore, it has become the main technical route of carbon emission research in the field of road transportation.

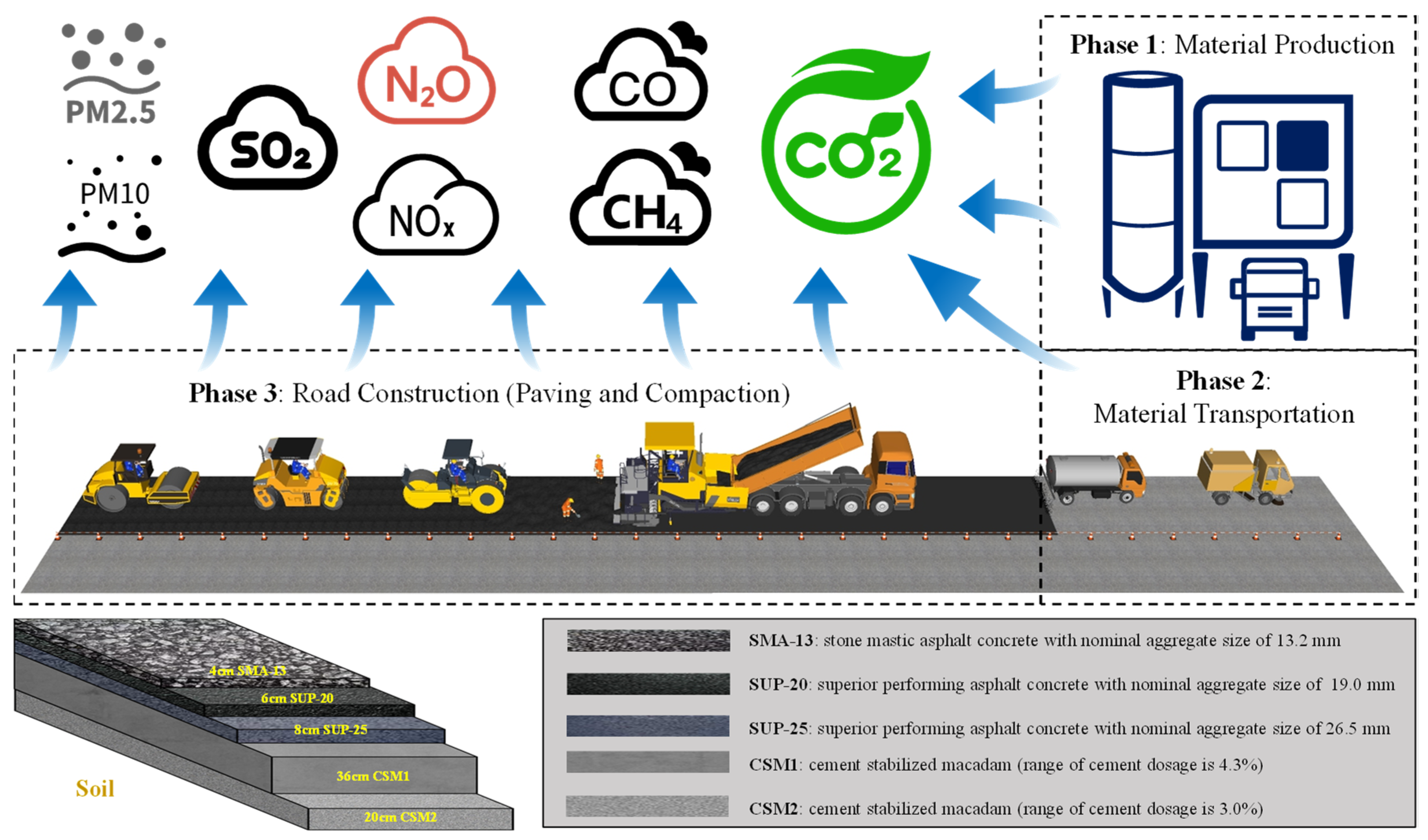

2. Methodology

2.1. LCA Framework

2.2. Function Unit and System Boundary Setting

2.3. Development of Carbon Emission Accounting Model

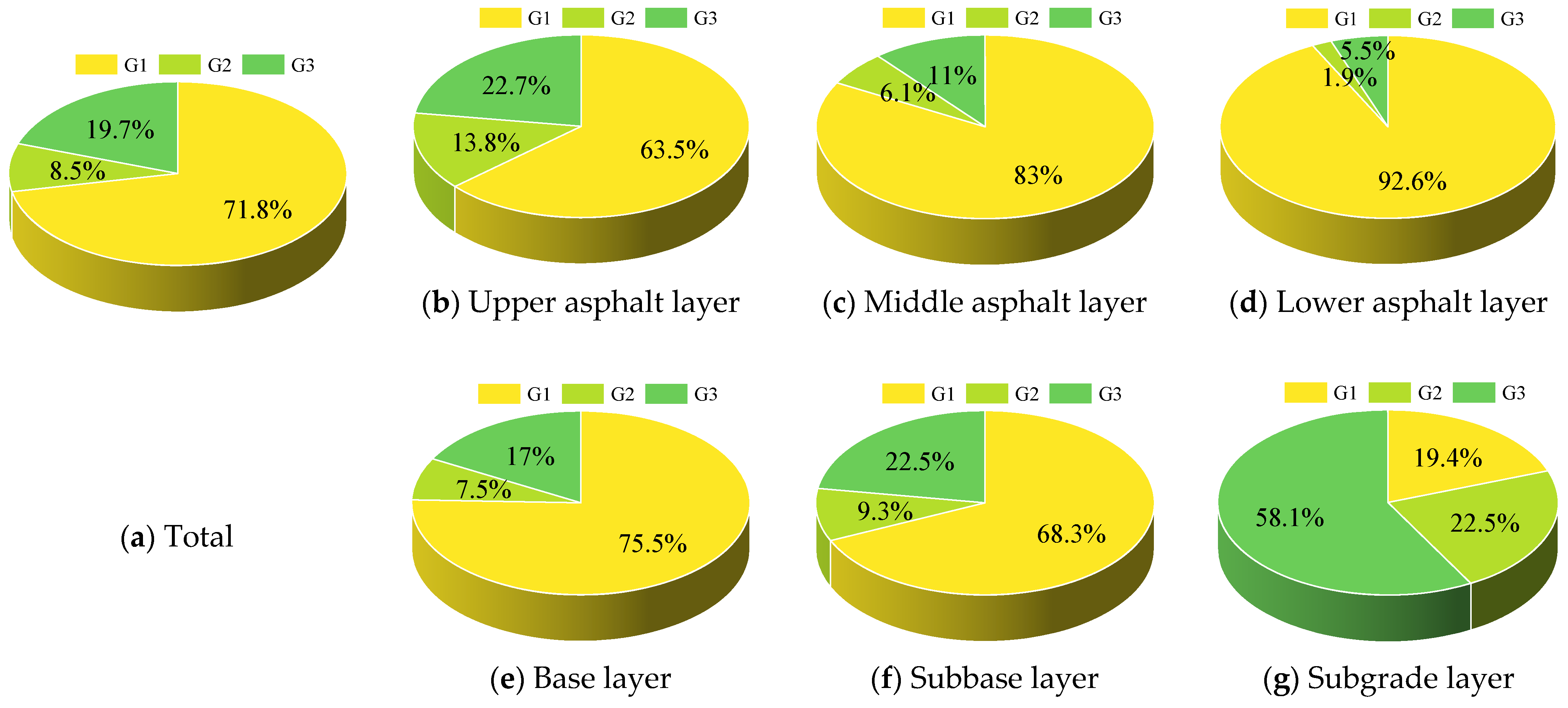

3. Results and Analysis

3.1. Carbon Emissions Accounting Results per Construction Phase

- Asphalt materials dominate surface carbon emissions, and the focus of optimization is on material technology.

- Cement base and subbase have dual emission pressures of G1 and G3, which is a structural difficulty in emission reduction.

- The energy consumption of soil construction is high, so attention should be paid to the energy efficiency of construction machinery and compaction technology.

3.2. Identification of Key Influencing Factors on Carbon Emissions

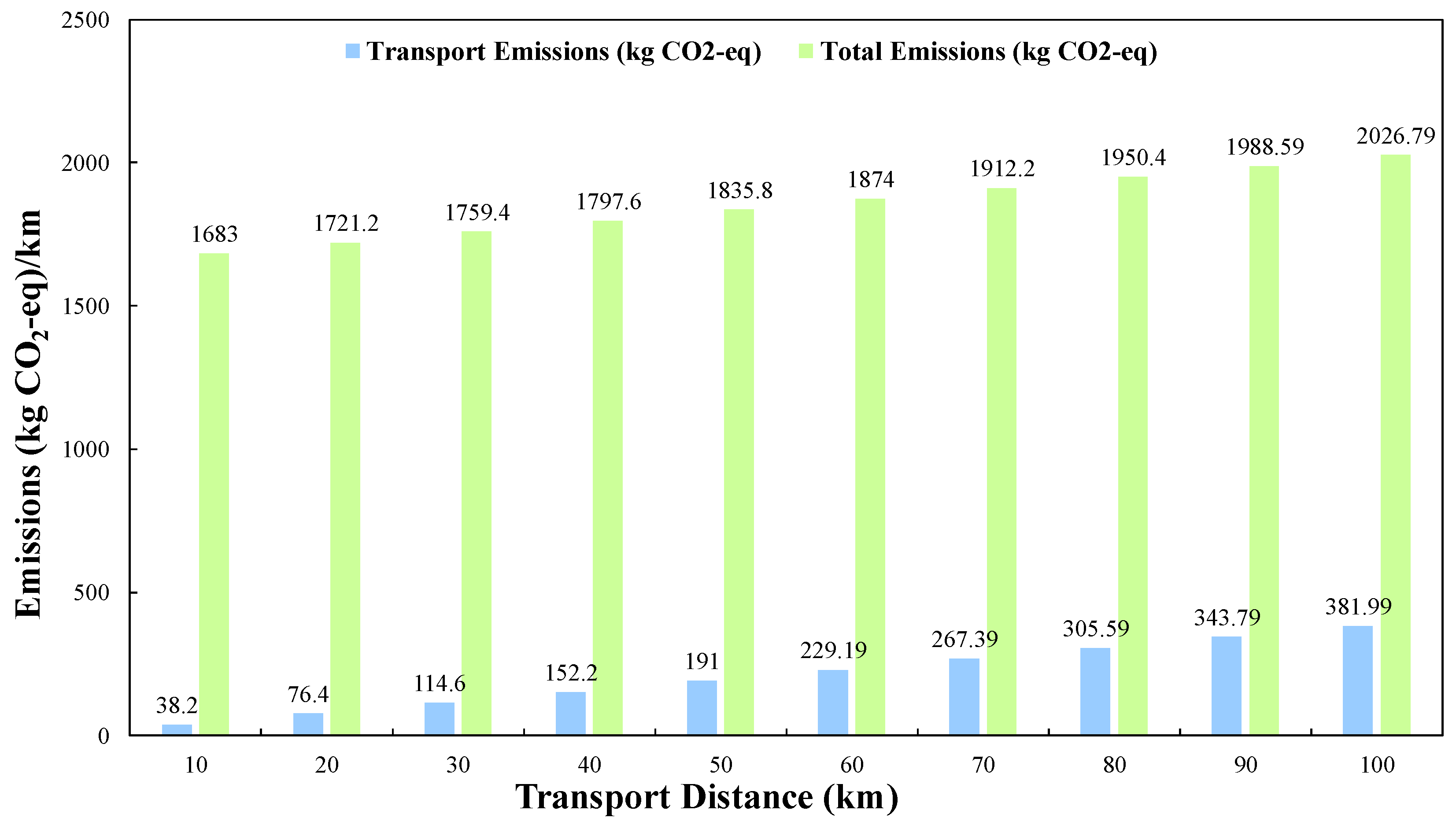

3.2.1. Impact of Transport Distance

- Optimize the layout of stock yards and give priority to localized raw materials.

- Set up an on-site temporary mixing station to reduce transportation frequency.

- Transport vehicles using low-carbon fuels or new energy sources.

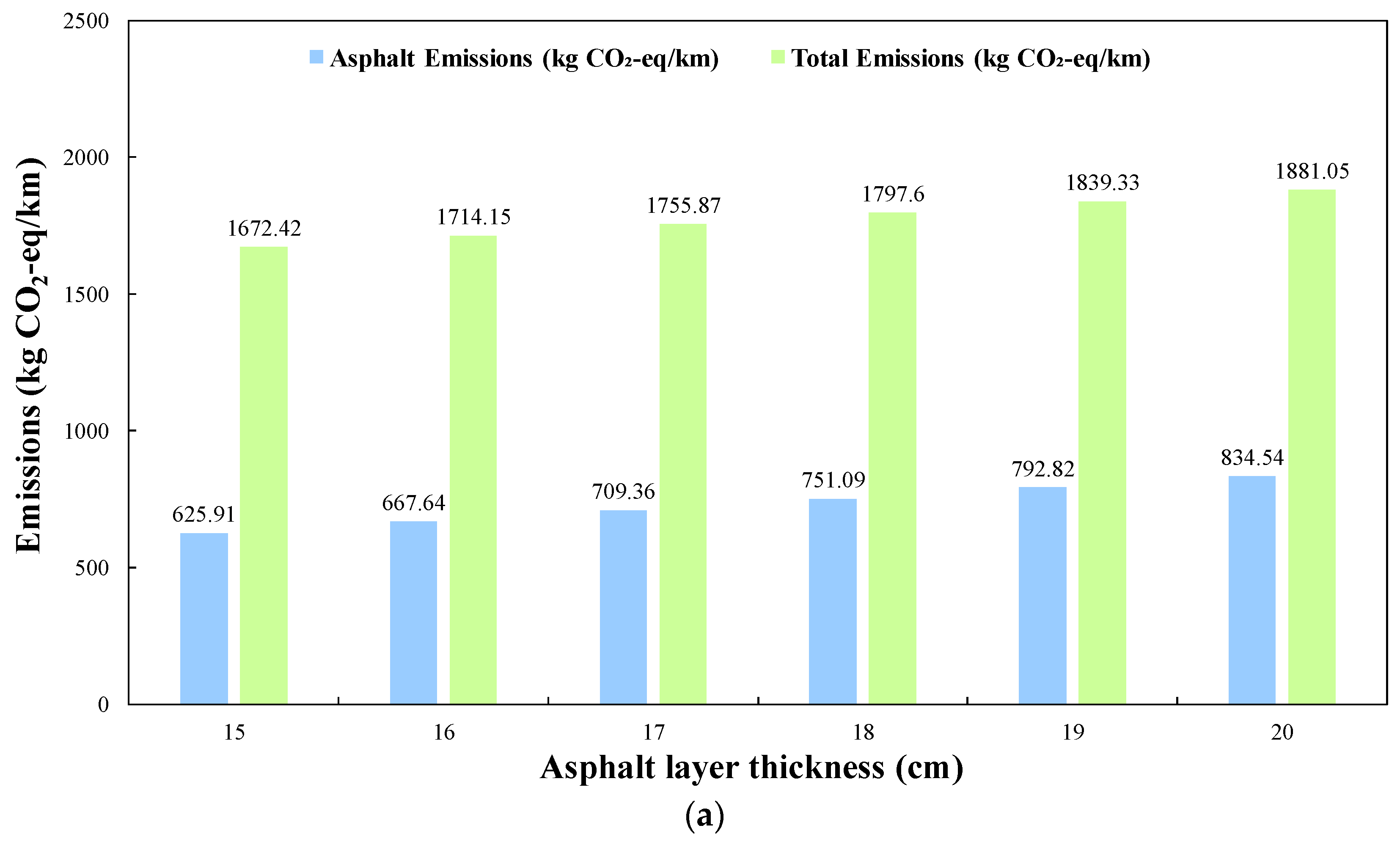

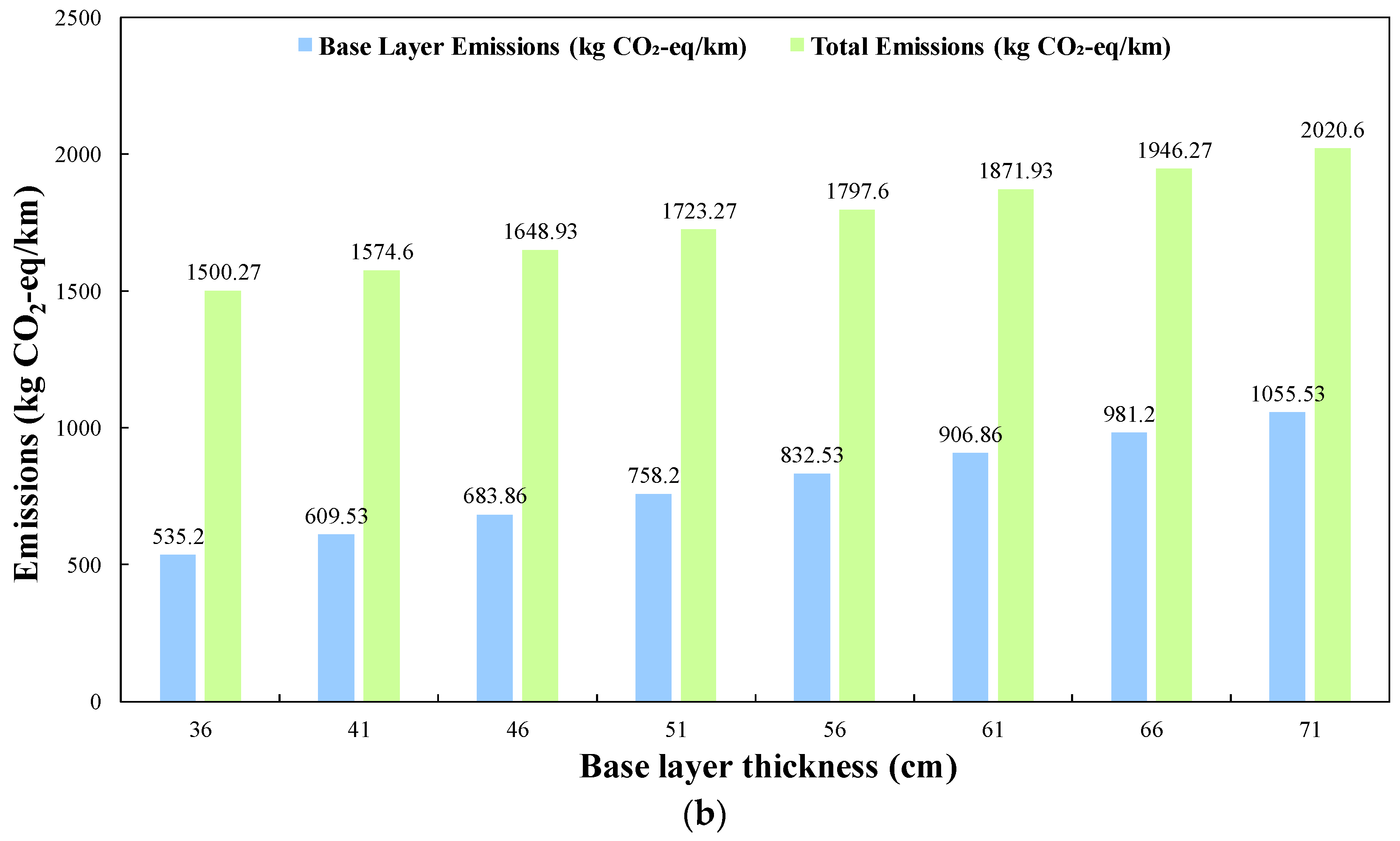

3.2.2. Impact of Structural Layer Thickness

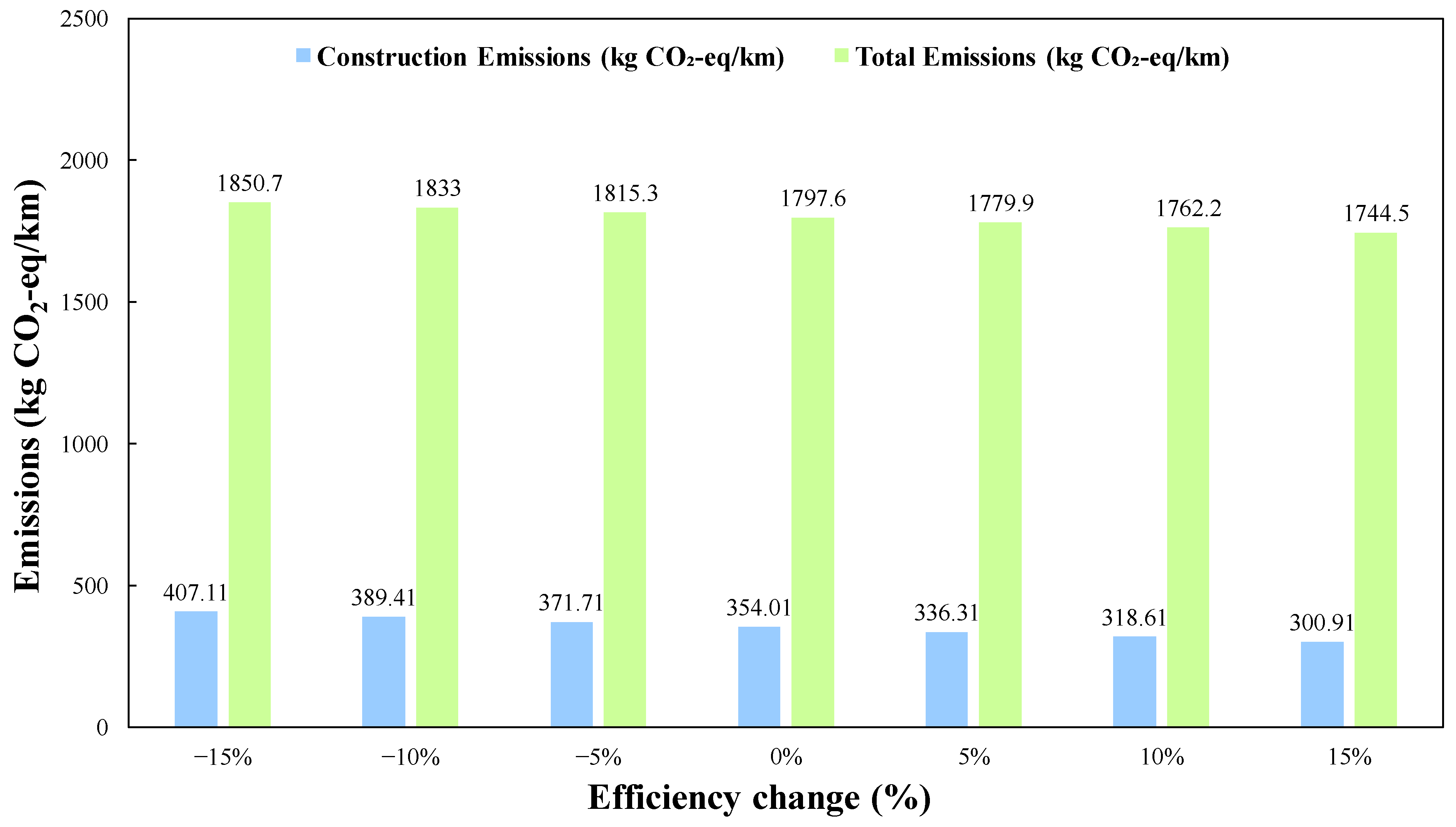

3.2.3. Impact of Construction Equipment Efficiency

- Promote fuel-saving construction equipment and improve engine thermal efficiency.

- Optimize construction procedures and organization to reduce idling and repetitive operations.

- Encourage the use of electrified and intelligent construction equipment to achieve low-carbon transformation.

3.2.4. Impact of Electricity Grid Factor

- Prioritize the use of clean electricity (such as green electricity price, photovoltaic energy supply, etc.).

- Promote electrified construction equipment to replace traditional diesel power.

- Optimize power allocation and load management in mixing stations and compaction processes.

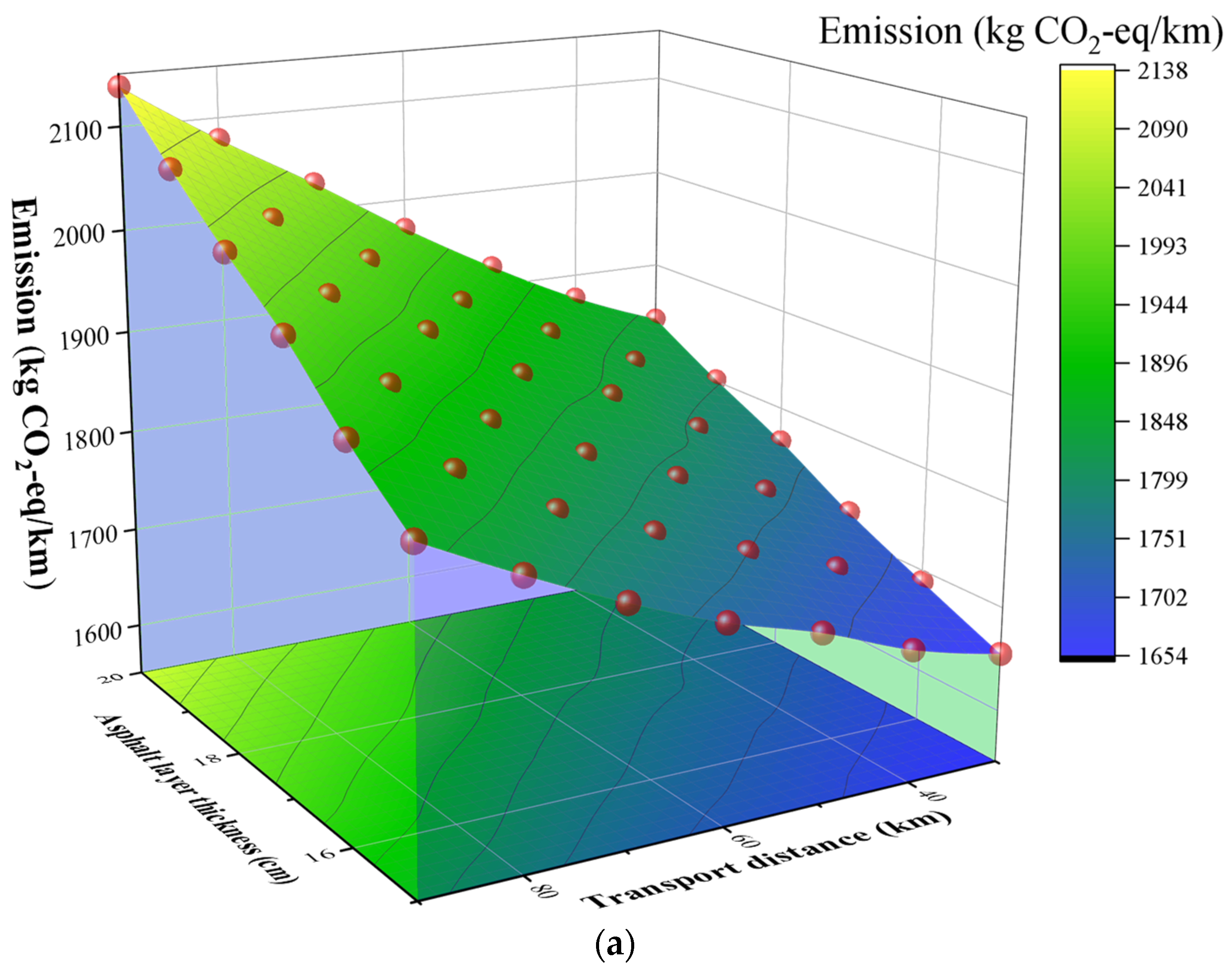

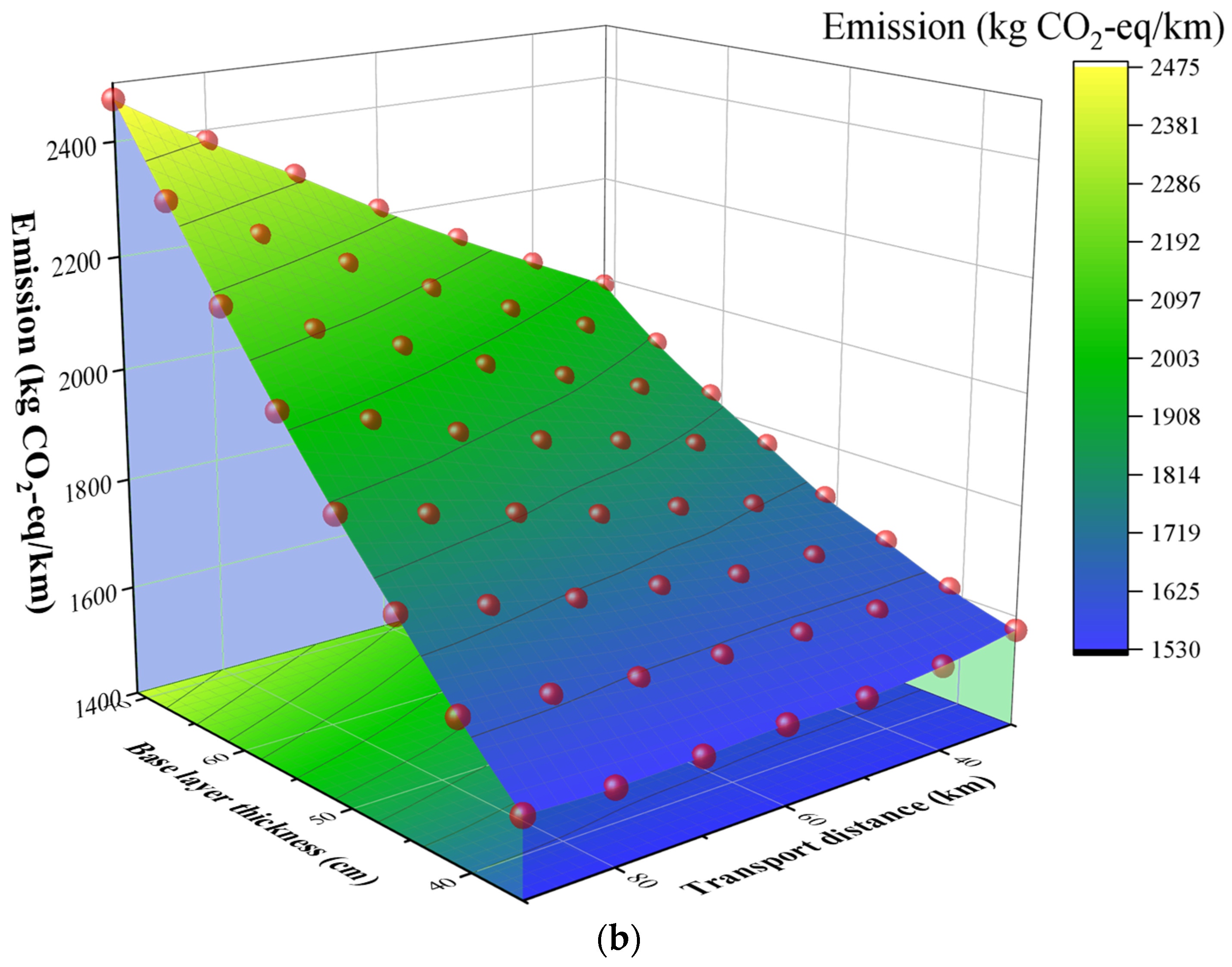

3.3. Multivariable Response Analysis of Carbon Emissions

- The thickness of the asphalt layer dominates the change of material carbon factor (G1 dominates), which belongs to high-carbon sensitive factors.

- The thickness of the base layer dominates the change of material volume and construction energy consumption (G1 + G3 double drive), which belongs to high-volume cumulative factors.

- The transportation distance forms a bridging effect between the two by affecting external energy consumption (G2).

4. Conclusions

- (1)

- The total carbon emissions per kilometer during the expressway construction phase are approximately 1.80 × 103 kg CO2-eq/km, with material production (G1) contributing about 60–70% and serving as the primary emission source. Although the construction (G3) and transportation (G2) stages account for smaller proportions, they still exert considerable influence due to their high energy consumption characteristics.

- (2)

- The thicknesses of the asphalt layer and base layer have the most significant impact on total carbon emissions. Their variations show linear or nonlinear positive correlations with emission levels. The asphalt layer represents a high-carbon and highly sensitive factor, while the base layer demonstrates a high-volume cumulative effect. Together, these two structural layers account for more than 60% of the total emissions during the construction phase.

- (3)

- Transportation distance and construction equipment efficiency are moderately sensitive parameters. A 50% increase in transportation distance results in an approximately 3.5% increase in total emissions, while a 10% improvement in equipment efficiency reduces emissions by about 2%. Although the influence of changes in the electricity grid emission factor is relatively minor, the potential for adopting clean electricity remains substantial.

- (4)

- The three-dimensional response surface model of asphalt layer thickness, base layer thickness, and transportation distance indicates that carbon emissions are affected by multiple variables with clear interaction effects. The combined increase in layer thickness and transportation distance significantly amplifies emissions, whereas the marginal effect of transport distance gradually diminishes. This model provides quantitative support for future low-carbon design and green construction strategies that can be further enhanced through intelligent optimization algorithms.

Funding

Data Availability Statement

Conflicts of Interest

References

- Cui, B.; Wang, H. Predicting Asphalt Pavement Deterioration Under Climate Change Uncertainty Using Bayesian Neural Network. IEEE Trans. Intell. Transp. Syst. 2025, 26, 785–797. [Google Scholar] [CrossRef]

- EN B. 15804; Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products. UNE: Madrid, Spain, 2012.

- Luo, W.; Sandanayake, M.; Zhang, G.; Tan, Y. Construction Cost and Carbon Emission Assessment of a Highway Construction—A Case towards Sustainable Transportation. Sustainability 2021, 13, 7854. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Y.; Li, D.; Feng, F.; Yu, Q.; Xue, S. Identification of the potential for carbon dioxide emissions reduction from highway maintenance projects using life cycle assessment: A case in China. J. Clean. Prod. 2019, 219, 743–752. [Google Scholar] [CrossRef]

- Cui, B.; Wang, H. Compatibility analysis of waste polymer recycling in asphalt binder using molecular descriptor and graph neural network. Resour. Conserv. Recycl. 2025, 212, 107950. [Google Scholar] [CrossRef]

- Gallivan, F.; Rose, E.; Choe, J.; Williamson, S.; Houk, J. FHWA Infrastructure Carbon Estimator: Final Report and User’s Guide; Federal Highway Administration: Washington, DC, USA, 2014. [Google Scholar]

- He, B.; Yuan, X.; Qian, S.; Li, B. Carbon Neutrality: A Review. J. Comput. Inf. Sci. Eng. 2023, 23, 060809. [Google Scholar] [CrossRef]

- Hao, J.; Chen, L.; Zhang, N. A Statistical Review of Considerations on the Implementation Path of China’s “Double Carbon” Goal. Sustainability 2022, 14, 11274. [Google Scholar] [CrossRef]

- Ozcan-Deniz, G.; Zhu, Y. Multi-objective optimization of greenhouse gas emissions in highway construction projects. Sustain. Cities Soc. 2017, 28, 162–171. [Google Scholar] [CrossRef]

- Hanson, C.S.; Noland, R.B. Greenhouse gas emissions from road construction: An assessment of alternative staging approaches. Transp. Res. Part D Transp. Environ. 2015, 40, 97–103. [Google Scholar] [CrossRef]

- Jiang, R.; Wu, P.; Wu, C. Driving Factors behind Energy-Related Carbon Emissions in the U.S. Road Transport Sector: A Decomposition Analysis. Int. J. Environ. Res. Public Health 2022, 19, 2321. [Google Scholar] [CrossRef]

- Gu, J.; Jiang, S.; Zhang, J.; Jiang, J. An analysis of the decomposition and driving force of carbon emissions in transport sector in China. Sci. Rep. 2024, 14, 30177. [Google Scholar] [CrossRef] [PubMed]

- Han, R.; Yu, B.-Y.; Tang, B.-J.; Liao, H.; Wei, Y.-M. Carbon emissions quotas in the Chinese road transport sector: A carbon trading perspective. Energy Policy 2017, 106, 298–309. [Google Scholar] [CrossRef]

- Li, J.; Lu, Q.; Fu, P. Carbon Footprint Management of Road Freight Transport under the Carbon Emission Trading Mechanism. Math. Probl. Eng. 2015, 2015, 814527. [Google Scholar] [CrossRef]

- Jiang, R.; Wu, C.; Song, Y.; Wu, P. Estimating carbon emissions from road use, maintenance and rehabilitation through a hybrid life cycle assessment approach—A case study. J. Clean. Prod. 2020, 277, 123276. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Y.; Li, D.; Yu, Q. Life cycle assessment for carbon dioxide emissions from freeway construction in mountainous area: Primary source, cut-off determination of system boundary. Resour. Conserv. Recycl. 2019, 140, 36–44. [Google Scholar] [CrossRef]

- Tokede, O.O.; Whittaker, A.; Mankaa, R.; Traverso, M. Life cycle assessment of asphalt variants in infrastructures: The case of lignin in Australian road pavements. Structures 2020, 25, 190–199. [Google Scholar] [CrossRef]

- Balaguera, A.; Carvajal, G.I.; Albertí, J.; Fullana-i-Palmer, P. Life cycle assessment of road construction alternative materials: A literature review. Resour. Conserv. Recycl. 2018, 132, 37–48. [Google Scholar] [CrossRef]

- Liu, Z.; Gu, X.; Wu, W. Deterioration Modeling of Pavement Performance in Cold Regions Using Probabilistic Machine Learning Method. Infrastructures 2025, 10, 212. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Y.; An, D. Life-cycle CO2 emissions and influential factors for asphalt highway construction and maintenance activities in China. Int. J. Sustain. Transp. 2018, 12, 497–509. [Google Scholar] [CrossRef]

- Hoxha, E.; Vignisdottir, H.R.; Barbieri, D.M.; Wang, F.; Bohne, R.A.; Kristensen, T.; Passer, A. Life cycle assessment of roads: Exploring research trends and harmonization challenges. Sci. Total Environ. 2021, 759, 143506. [Google Scholar] [CrossRef]

- Picardo, A.; Soltero, V.M.; Peralta, E. Life Cycle Assessment of Sustainable Road Networks: Current State and Future Directions. Buildings 2023, 13, 2648. [Google Scholar] [CrossRef]

- Azam, A.; Gabr, A.; Ezzat, H.; Arab, M.; Alshammari, T.O.; Alotaib, E.; Zeiada, W. Life cycle assessment and pavement performance of recycled aggregates in road construction. Case Stud. Constr. Mater. 2024, 20, e03062. [Google Scholar] [CrossRef]

- Hasan, U.; Whyte, A.; AlJassmi, H. A multi-criteria decision-making framework for sustainable road transport systems: Integrating stakeholder-cost-environment-energy for a highway case study in United Arab Emirates. J. Clean. Prod. 2024, 450, 141831. [Google Scholar] [CrossRef]

- Aryan, Y.; Dikshit, A.K.; Shinde, A.M. A critical review of the life cycle assessment studies on road pavements and road infrastructures. J. Environ. Manag. 2023, 336, 117697. [Google Scholar] [CrossRef]

- Finkbeiner, M.; Inaba, A.; Tan, R.; Christiansen, K.; Klüppel, H.-J. The New International Standards for Life Cycle Assessment: ISO 14040 and ISO 14044. Int. J. Life Cycle Assess. 2006, 11, 80–85. [Google Scholar] [CrossRef]

- Liu, Z.; Gu, X.; Ren, H. Rutting prediction of asphalt pavement with semi-rigid base: Numerical modeling on laboratory to accelerated pavement testing. Constr. Build. Mater. 2023, 375, 130903. [Google Scholar] [CrossRef]

- Cui, B.; Wang, H.; Gu, X.; Hu, D. Study of the inter-diffusion characteristics and cracking resistance of virgin-aged asphalt binders using molecular dynamics simulation. Constr. Build. Mater. 2022, 351, 128968. [Google Scholar] [CrossRef]

- Cui, B.; Wang, H. Cross-scale analysis of asphalt binder tensile fracture using molecular dynamics simulation. Constr. Build. Mater. 2024, 426, 136200. [Google Scholar] [CrossRef]

- Lu, Y.; Cui, B.; Wang, H.; Hajj, R. Experimental and simulation-based engineering of calcium alginate self-healing asphalt capsules. Chem. Eng. J. 2024, 499, 156212. [Google Scholar] [CrossRef]

- Change, I. 2006 IPCC Guidelines for National Greenhouse Gas Inventories; Institute for global environmental strategies: Hayama, Kanagawa, Japan, 2006. [Google Scholar]

- Mao, R.; Duan, H.; Dong, D.; Zuo, J.; Song, Q.; Liu, G.; Hu, M.; Zhu, J.; Dong, B. Quantification of carbon footprint of urban roads via life cycle assessment: Case study of a megacity-Shenzhen, China. J. Clean. Prod. 2017, 166, 40–48. [Google Scholar] [CrossRef]

- Yu, C.; Wu, L.; Liu, Y.; Ye, K.; Liang, G. Estimating Greenhouse Gas Emissions from Road Construction by Considering the Regional Differences in Carbon Emission Factors of Cement: The Case of China. Buildings 2022, 12, 1341. [Google Scholar] [CrossRef]

- Ecology, M. 2020 Press Conference Records of Ministry of Ecology and Environment, the People’s Republic of China; Springer Nature: Singapore, 2022. [Google Scholar]

- Chongxi, B.; Zhang, Z. Carbon emission quantification analysis of excavation engineering under road transport conditions. PLoS ONE 2025, 19, e0315765. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Lee, I.-S.; Kendall, A.; Harvey, J.; Lee, E.-B.; Kim, C. Life cycle energy consumption and GHG emission from pavement rehabilitation with different rolling resistance. J. Clean. Prod. 2012, 33, 86–96. [Google Scholar] [CrossRef]

- Barati, K.; Shen, X. Operational level emissions modelling of on-road construction equipment through field data analysis. Autom. Constr. 2016, 72, 338–346. [Google Scholar] [CrossRef]

- Liu, Z.; Sun, L.; Gu, X.; Wang, X.; Dong, Q.; Zhou, Z.; Tang, J. Characteristics, mechanisms, and environmental LCA of WMA containing sasobit: An analysis perspective combing viscosity-temperature regression and interface bonding strength. J. Clean. Prod. 2023, 391, 136255. [Google Scholar] [CrossRef]

| Phase | Major Activities | Inputs | Outputs (Emissions) |

|---|---|---|---|

| 1: Material Production | Extraction and processing of asphalt, cement, steel, aggregates, etc. | Raw materials (e.g., crude oil, limestone, ores), electricity, fuels (coal, gas), water, chemical additives [30] | CO2, CH4, N2O, industrial exhaust gases, process heat |

| 2: Material Transportation | Transport of construction materials to mixing plants or construction site | Construction materials, diesel fuel, transportation vehicles, road infrastructure | CO2, CH4, NOx, SO2, PM2.5, noise emissions |

| 3: Road Construction | Asphalt mixing, paving, rolling, spraying, field operations | Mixed materials, construction equipment, diesel, heavy oil, electricity, construction water, labor | CO2, CH4, N2O, dust emissions, machine noise, waste heat |

| Material Type | Unit | Emission Factor (kgCO2-eq/unit) |

|---|---|---|

| Petroleum Asphalt | t | 147.24 |

| SBS Modified Asphalt | t | 320.00 |

| Ordinary Portland Cement | t | 735.00 |

| Cement-Stabilized Crushed Stone | t | 35.00 |

| Coarse Aggregate (gravel) | t | 2.43 |

| Fine Aggregate (sand) | t | 1.20 |

| Material Type | Transport Ways | Emission Factor (kg CO2-eq) |

|---|---|---|

| Heavy-duty Diesel Truck | Road Transport | 0.130 |

| Medium-duty Diesel Truck | Road Transport | 0.102 |

| Equipment Type | Energy Type | Energy Consumption (kg/unit) or (kg/h) | Emission Factor (kgCO2-eq/kg) |

|---|---|---|---|

| Asphalt Paver | Diesel | 135 kg/unit | 3.17 |

| Vibratory Roller | Diesel | 70 kg/unit | 3.17 |

| Loader | Diesel | 90 kg/unit | 3.17 |

| Asphalt Mixing Plant (120 t/h) | Heavy Oil | 85 kg/h | 3.95 |

| Material Type | Consumption (t or m3) | Equipment Type | Diesel (kg) | Heavy Oil (kg) | Electricity (kWh) |

|---|---|---|---|---|---|

| Petroleum Asphalt | 546.3 | Asphalt Mixing Equipment | 84,055.5 | 408.2 | 37,643.5 |

| Modified Asphalt | 180.9 | Tire Roller Loader | 5445.0 | ||

| Emulsified Asphalt | 49.4 | Spraying Truck | 24,808.5 | ||

| Crushed Stone | 7237.8 | Asphalt Mixing Transporter | 1341.3 | ||

| Water | 521.6 | Light Vibratory Roller | 8031.0 | ||

| Cement | 371.5 | Grader | 864.0 |

| Structural Layers | G1 | G2 | G3 | Gtotal for Single Layer | Gtotal for Whole Road |

|---|---|---|---|---|---|

| AC-13 upper layer | 63 | 13.67 | 22.5 | 99.17 | 1797.6 |

| AC-20 upper layer | 213.4 | 15.62 | 28.2 | 257.22 | |

| AC-25 lower layer | 365.4 | 7.55 | 21.75 | 394.7 | |

| Base layer | 413.5 | 40.89 | 93.16 | 547.55 | |

| Subbase layer | 194.5 | 26.38 | 64.1 | 284.98 | |

| Subgrade layer | 41.6 | 48.08 | 124.3 | 213.98 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z. Life-Cycle-Assessment-Based Quantification and Low-Carbon Optimization of Carbon Emissions in Expressway Construction. Infrastructures 2025, 10, 291. https://doi.org/10.3390/infrastructures10110291

Liu Z. Life-Cycle-Assessment-Based Quantification and Low-Carbon Optimization of Carbon Emissions in Expressway Construction. Infrastructures. 2025; 10(11):291. https://doi.org/10.3390/infrastructures10110291

Chicago/Turabian StyleLiu, Zhen. 2025. "Life-Cycle-Assessment-Based Quantification and Low-Carbon Optimization of Carbon Emissions in Expressway Construction" Infrastructures 10, no. 11: 291. https://doi.org/10.3390/infrastructures10110291

APA StyleLiu, Z. (2025). Life-Cycle-Assessment-Based Quantification and Low-Carbon Optimization of Carbon Emissions in Expressway Construction. Infrastructures, 10(11), 291. https://doi.org/10.3390/infrastructures10110291