Agile Powertrain Development: Considerations to Incorporate Agile Principles

Abstract

:1. Introduction

- Which powertrain development considerations are important for the incorporation of agile principles?

- How can the incorporation of agile development into an existing powertrain development process be supported?

2. Related Work

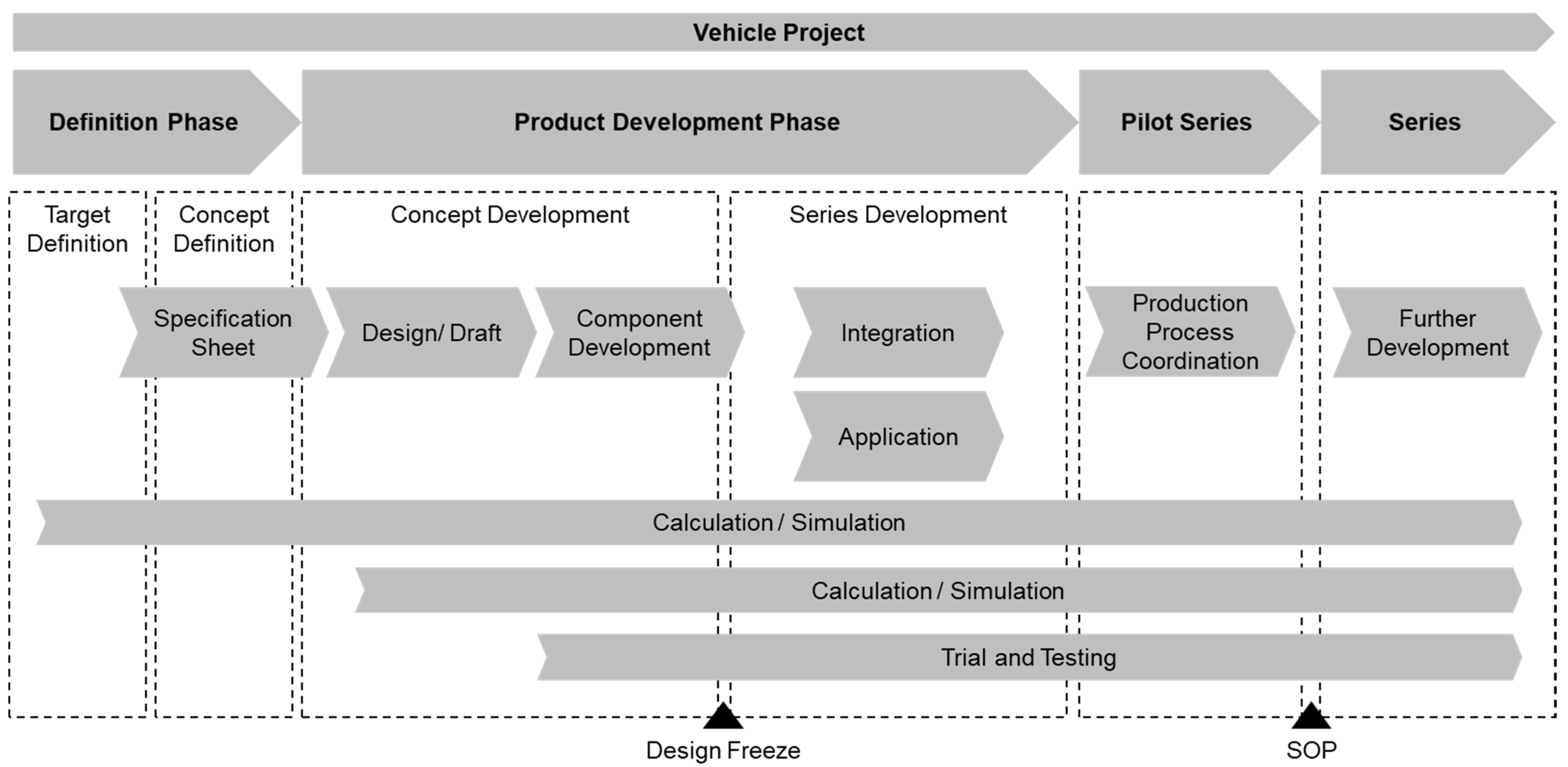

2.1. Conventional Product Development Approaches in the Automotive Industry

2.1.1. VDI 2221

- Step 1—Clarification and definition of the problem: Step one is the complete clarification of the customer’s requirements or internal requirements. This also includes defining the problem from the constructor’s perspective. The result of the first step is the requirements list.

- Step 2—The determination of functions and their structure: First, the main function that the product needs to fulfil is determined; then, subfunctions are defined. By structuring and combining these functions, one obtains the result of the work step as a function structure.

- Step 3—Search for solution principles and their structure: In step three, solutions are sought for all defined functions and implemented through effects. The result of this step is the principal solution, such as a schematic layout.

- Step 4—Division into realizable modules: Fourth, modules are created to make the principal solution feasible. Individual solution systems and subsystems as well as interfaces between the modules are already defined.

- Step 5—Design of the most important modules: Here, a concrete dimensioning of the most important modules takes place as far as the state of knowledge allows. The results of this step are preliminary designs, general layouts, or preliminary drafts such as rough-scale drawings.

- Step 6—Design of the entire product: In this step, final shapes or detailed designs are created by further refining the preliminary designs with details and adding the modules that have not yet been completed. The result is the overall design with scale drawings, parts lists, and so on.

- Step 7—Compilation of design and utility data: This is where decisions are made about the manufacturing and application of the product, as well as the usage specifications of the product. The result is the consolidation of all data, such as CAD drawings for product documentation.

2.1.2. Cooper’s Stage Gate

2.1.3. V Model

- Micro-level: general problem-solving cycle;

- Macro-level: V-Model;

- Predefined process steps for conduction of recurrent development steps.

2.2. Agile Product Development Approach

- Dynamic Systems Development: framework for the application of a prototypical procedural model for the rapid development of applications under consideration of defined principles.

- Scrum: Widely used framework in the software industry for project management and system development.

- Feature-Driven Development: A given process sequence with five phases and best practices iterative software development.

- Crystal: An application specific selection and adaption of a process model based on criteria of project criticality and team size.

- Extreme Programming: A synthesis of ideas and approaches from existing methods for development and planning activities for software.

- Adaptive Software Development: Adaptive life cycle for software development including development philosophy for change management.

- Agile Modeling: Values, principles, and methods for efficient modeling in combination with agile process models.

- Lean Software Development: Describes a transfer of the lean philosophy from the Toyota production system and IT into seven principles for software development.

- Agile Unified Process: Hybrid modeling approach of the Rational Unified Process with agile software development.

- Usability Driven Development: Iterative driven development process with a focus on the usability of the system.

- Kanban: Software development in consideration of throughput times, bottlenecks, etc., comparable to the method of the same name for lean production.

3. Considerations for Agile Powertrain Development

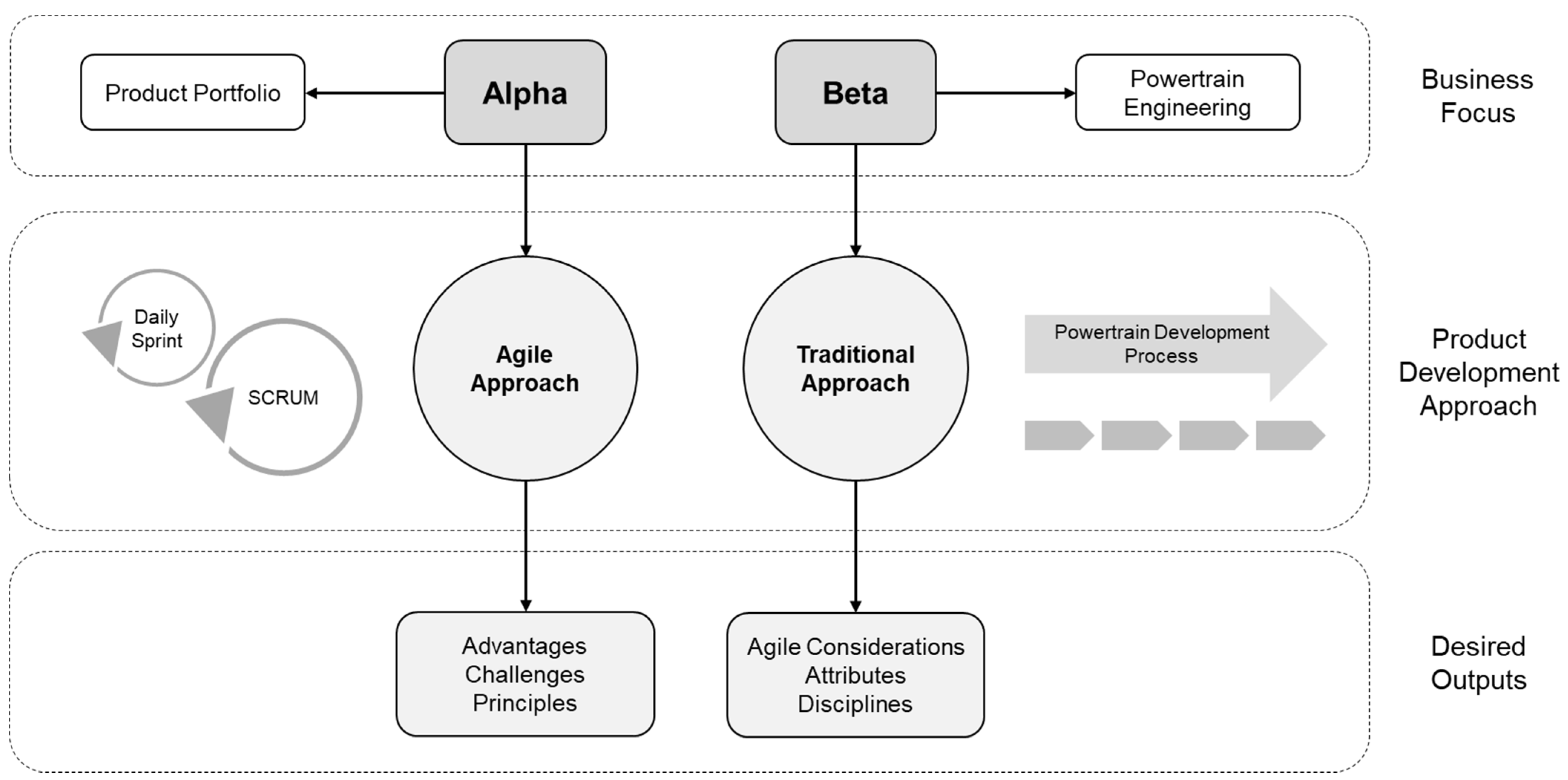

3.1. Research Approach

3.2. Alpha Division: Fundamentals of Agile Product Development

3.2.1. Challenges

3.2.2. Advantages

3.2.3. Principles

3.3. Beta Division: Fundamentals of Agile Powertrain Development

3.3.1. Basics for Agile Powertrain Development

3.3.2. Attributes of Powertrain Development

- The vehicle targets that are given by the OEM.

- The development framework that is used by the customer, as the powertrain development process needs to be closely linked to the vehicle development process.

- The setting of system borders and the considerations of the division of responsibilities between the OEM, the client, suppliers, and all other stakeholders.

- The OEM’s profile: e.g., the geographical origin.

- Interfaces to the vehicle.

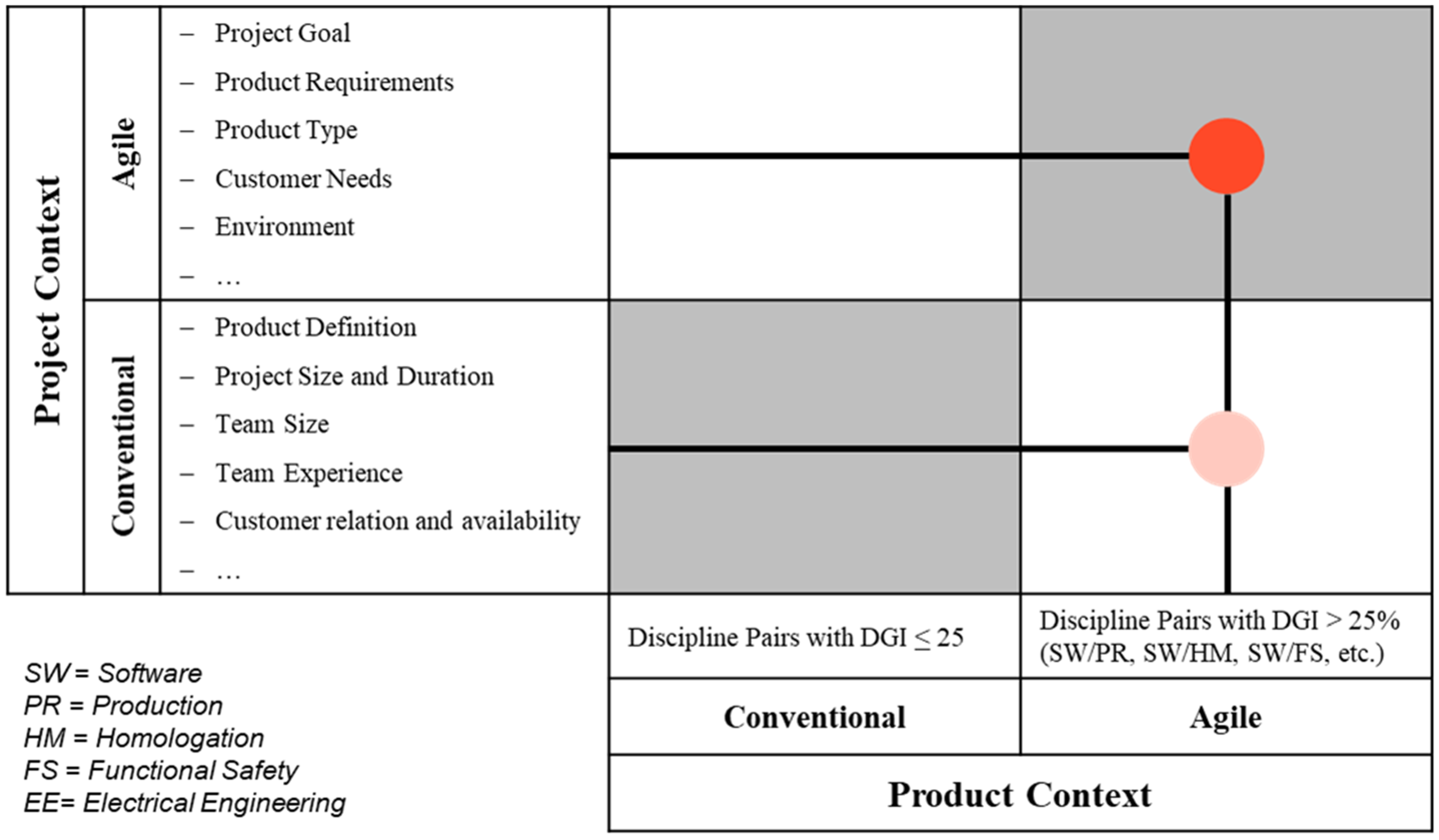

3.3.3. Disciplines Involved in Powertrain Development

- Design;

- Service (Testing);

- Systems Engineering;

- Electric and Electronics Engineering;

- Mechanical Engineering;

- Functional Safety;

- Production;

- Software;

- Purchasing;

- Homologation.

3.4. Comparison of Development Principles in Alpha and Beta

4. Procedural Model for Assessment of Project Development Approach Balance

- “2”: Attribute has not yet been implemented; increased effort is to be expected with regards to implementation; feasibility cannot be assessed as clearly positive; very high communication effort to be assumed.

- “1”: Attribute has not yet been implemented; no particular obstacles are to be expected in the implementation of the attribute; feasibility can be assessed as positive; increased communication effort.

- “0”: Attribute (or similar) has already been implemented; simple implementation; low communication effort.

5. Discussion

- Is the procedural model applicable to the development of powertrain systems?

- Does the procedural model support the incorporation of agile development into an existing powertrain development process?

- Do you consider the disciplines/attributes as suitable?

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Buckley, P.; Verbeke, A.; Jankowska, B.; Van Tulder, R. International Business in a VUCA World: The Changing Role of States and Firms, 1st ed.; Progress in International Business Research; Emerald Publishing Limited: Bingley, UK, 2020. [Google Scholar]

- Cooper, R.G. What’s Next?: After Stage-Gate. Res. Technol. Manag. 2014, 57, 20–31. [Google Scholar] [CrossRef]

- Smith, P.G. Flexible Product Development: Building Agility for Changing Markets; John Wiley & Sons/Jossey-Bass: San Francisco, CA, USA, 2007. [Google Scholar]

- Ramsauer, C.; Kayser, D.; Schmitz, C. Erfolgsfaktor Agilität. In Chancen für Unternehmen in Einem Volatilen Marktumfeld, 1st ed.; Wiley-VCH: Weinheim, Germany, 2017. [Google Scholar]

- Schuh, G.; Diels, F.; Ortlieb, C.; Riesener, M.; Schröder, S. Agile Produktentwicklung. In Internet of Production für Agile Unternehmen; Brecher, C., Klocke, F., Schmitt, R., Schuh, G., Eds.; AWK Aachener Werkzeugmaschinen-Kolloquium; Apprimus Verlag: Aachen, Germany, 2017; pp. 27–52. [Google Scholar]

- Žužek, T.; Gosar, Z.; Kušar, J.; Berlec, T. Adopting Agile Project Management Practices in Non-Software SMEs: A Case Study of a Slovenian Medium-Sized Manufacturing Company. Sustainability 2020, 12, 9245. [Google Scholar] [CrossRef]

- Volkswagen: Volkswagen Konzern Setzt auf Neue Formen der Zusammenarbeit. Hg. v. Volkswagen, 2017. Available online: https://www.volkswagenag.com/de/news/2017/07/Volkswagen_Konzern_setzt_auf_neue_Formen_der_Zusammenarbeit.html (accessed on 5 June 2020).

- Lührig, T. Risikomanagement in der Produktentwicklung der Deutschen Automobilindustrie: Von der Konzeptentwicklung bis zum Produktionsanlauf. Ph.D. Thesis, Technical University Darmstadt, Darmstadt, Germany, 2006. [Google Scholar]

- Schömann, S.O. Produktentwicklung in der Automobilindustrie: Managementkonzepte vor dem Hintergrund Gewandelter Herausforderungen; Gabler Verlag/Springer Fachmedien Wiesbaden GmbH (Gabler Research): Berlin, Germany, 2011. [Google Scholar]

- VDI 2221-Part 1. Design of Technical Products and Systems; Verein Deutscher Ingenieure: Düsseldorf, Germany, 2019. [Google Scholar]

- Cooper, R.G.; Sommer, A.F. Agile-Stage-Gate: New idea-to-launch method for manufactured new products is faster, more responsive. Ind. Mark. Manag. 2016, 59, 167–180. [Google Scholar] [CrossRef]

- Cooper, R.G. Stage-gate systems: A new tool for managing new products. Bus. Horiz. 1990, 33, 44–54. [Google Scholar] [CrossRef]

- VDI 2206. Design Methodology for Mechatronic Systems; Verein Deutscher Ingenieure: Düsseldorf, Germany, 2004. [Google Scholar]

- Boehm, B.; Turner, R. Balancing agility and discipline. In A Guide for the Perplexed; Addison-Wesley: Boston, MA, USA, 2004. [Google Scholar]

- Conforto, E.C.; Amaral, D. Agile project management and stage-gate model—A hybridframework for technology-based companies. J. Eng. Technol. Manag. 2016, 40, 1–14. [Google Scholar] [CrossRef]

- Conforto, E.C.; Amaral, D.C.; da Silva, S.L.; Di Felippo, A.; Kamikawachi, D.S.L. The agility construct on project management theory. Int. J. Proj. Manag. 2016, 34, 660–674. [Google Scholar] [CrossRef]

- Schuh, G. Agile Product Development. In International Benchmarking Study; Fraunhofer IPT, RWTH Aachen University: Aachen, Germany, 2019. [Google Scholar]

- Kantelberg, J. Gestaltung Agiler Entwicklungsprozesse Technischer Produkte. Design of Agile Product Development Processes. Ph.D. Thesis, RWTH Aachen University, Aachen, Germany, 2018. [Google Scholar]

- Takeuchi, H.; Nonaka, I. The new new product development game. Stop running the relay race and take up rugby. Harv. Bus. Rev. 1986, 64, 137–146. [Google Scholar]

- Klein, T. Agiles Engineering im Maschinen—Und Anlagenbau; Herbert Utz Verlag (Forschungsberichte IWB, 323): München, Germany, 2016. [Google Scholar]

- Cobb, C.G. Making Sense of Agile Project Management. In Balancing Control and Agility; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2011. [Google Scholar]

- Fernandez, D.J.; Fernandez, J.D. Agile Projectmanagement—Agilism Versus Traditional Approaches. J. Comput. Inf. Syst. 2008, 49, 10–17. [Google Scholar] [CrossRef]

- Wysocki, R.K. Effective project management. In Traditional, Agile, Extreme, 7th ed.; John Wiley & Sons: Indianapolis, IN, USA, 2014. [Google Scholar]

- Habermann, F. Hybrides Projektmanagement—Agile und klassische Vorgehensmodelle im Zusammenspiel. HMD 2013, 50, 93–102. [Google Scholar] [CrossRef]

- Hartel, D.H. Projektmanagement in Logistik und Supply Chain Management; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2019. [Google Scholar]

- Nerur, S.; Balijepally, V.G. Theoretical reflections on agile development methodologies. Commun. ACM 2007, 50, 79–83. [Google Scholar] [CrossRef]

- Schmidt, T.S.; Paetzold, K. Agilität als Alternative zu traditionellen Standards in der Entwicklung physischer Produkte: Chancen und Herausforderungen. Design for X—Beiträge zum 27. DfX-Symp. Oktober 2016, 255–267. [Google Scholar]

- Špundak, M. Mixed Agile/Traditional Project Management Methodology—Reality or Illusion? Procedia—Soc. Behav. Sci. 2014, 119, 939–948. [Google Scholar] [CrossRef] [Green Version]

- Book, M.; Gruhn, V.; Striemer, R. Erfolgreiche Agile Projekte; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Brehm, L.; Feldmüller, D.; Rieke, T. Konfiguration des hybriden Projektmanagements für die Entwicklung technischer, physischer Produkte. In Angewandte Forschung in der Wirtschaftsinformatik Prozesse, Technologie, Anwendungen, Systeme und Management; Barton, T., Herrmann, F., Meister, V., Müller, C., Seel, C., Eds.; Mana-Buch: Heide, Germany, 2017; pp. 30–39. [Google Scholar]

- Welge, M.; Friedrich, C.; Shair, A. Integration von agilen Methoden in der Systementwicklung. In Tag des Systems Engineering; Maik, M., Schulze (Hg.), S.-O., Eds.; Zusammenhänge Erkennen und Gestalten; Paderborn 7–9 November 2012; Hanser (Hanser eLibrary): München, Germany, 2013; pp. 341–350. [Google Scholar]

- Nerur, S.; Mahapatra, R.; Mangalaraj, G. Challenges of migrating to agile methodologies. Commun. ACM 2005, 48, 72–78. [Google Scholar] [CrossRef]

- Edmondson, A.C.; McManus, S.E. Methodological fit in management field research. Acad. Manag. Rev. 2007, 32, 1155–1179. [Google Scholar] [CrossRef] [Green Version]

- Ahlström, P. Research methods for operations management. In The Research Process; Karlsson, C., Ed.; Taylor & Francis: New York, NY, USA, 2016; pp. 46–78. [Google Scholar]

- Voss, C.; Johnson, M.; Godsell, J. Research Methods for Operations Management. In Case Research; Karlsson, C., Ed.; Taylor & Francis: New York, NY, USA, 2016; pp. 165–194. [Google Scholar]

- Yin, R.K. Case Study Research: Design and Methods, 4th ed.; Sage: Thousand Oaks, CA, USA, 2009. [Google Scholar]

- Schnöll, H.P. Integrierte Produktentstehung: Ein Vorgehensmodell zur Kontextspezifischen Gestaltung des Produktentstehungsprozesses von Bauteilen aus Faserverbundkunststoffen. Ph.D. Thesis, Graz University of Technology, Graz, Austria, 2015. [Google Scholar]

- Eppinger, S.D.; Browning, T.R. Design Structure Matrix Methods and Applications, 1st ed.; The MIT Press: Cambridge, MA, USA, 2012. [Google Scholar]

- Lindemann, U.; Maurer, M.; Braun, T. Structural Complexity Management: An Approach for the Field of Product Design, 1st ed.; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Egelhoff, W.G. Information-Processing Theory and the Multinational Enterprise. J. Int. Bus. Stud. 1991, 22, 341–368. [Google Scholar] [CrossRef]

- Blessing, L.T.M.; Chakrabarti, A. DRM, a Design Research Methodology; Springer: London, UK, 2009. [Google Scholar]

| No. | Criteria | Conventional | Agile | Source |

|---|---|---|---|---|

| 1 | Project goal | Predictability; stability; high assurance; clear Management of complicatedness | Rapid value; responding to change; not clear Management of complexity | [14,22,23,24] |

| 2 | Solution | Clear | Not clear | [22,23,24,25] |

| 3 | Goal on design | Optimization | Adaption; flexibility and responsiveness | [26,27] |

| 4 | Project (and product) size and duration | Large products; bigger projects (years) | Small products; smaller projects (months) | [3,14,20,25,28,29,30,31] |

| 5 | Product requirements | Foreseeable evolution requirements; stable requirements and specifications; clear initial requirements Priority and number of requirements stays the same | Unforeseen change; change often during project; unclear Priority and number of requirements is volatile | [3,11,14,20,24,28,29,30,31] |

| 6 | Product Definition | Established in detail upfront (>90%) | Partly established upfront (40–70%) | [2,29] |

| 7 | Product Type | Low product newness; new item in a product line; modification or improvement; renovation | High product newness; innovation; higher risk-initiative | [2,3,31] |

| 8 | Technology | Well known technology; mature; clear; in house | Some technical risks; newer technology but largely existing; may be new to company | [2,29] |

| 9 | Testing | Documented test plans and procedures | Executable test cases define requirements | [14] |

| 10 | Criticality | Extreme; Highly safety critical products; system failure consequences serious | Low; Non safety critical products; less critical systems | [3,11,14,25,26,27,28,29,30,31] |

| 11 | Environment | Stable; low change; predictable | Turbulent, high change; difficult to predict | [3,14,24,25,26,27,29,30,31] |

| 12 | Market and Competition + Market Size | Mature and well-known market; few market uncertainties or risks; large and defined; red ocean; many capable competitors | Existing and rapidly growing market; large potential to grow; many market uncertainties and risks; blue ocean; some early competitors | [2,29] |

| 13 | Collaboration and Communication | Low: business involvement only at start and end of project; formal communication | Continuous face-to-face business involvement; informal communication | [3,21,26,29] |

| 14 | Customer relation and availability | As-needed customer interactions; customer involvement at the beginning and end | Dedicated on site-customer interactions; customer involvement through whole process | [3,14,20,24,27,29,31,32] |

| 15 | Customer Needs | Well known and stable over time | Some known, some unarticulated Many unsolved customer problems and unresolved needs | [2,20,24] |

| 16 | Team size | Small teams | Large teams | [14,20,25,28,29,30] |

| 17 | Team Experience | Junior level; specialized; minimum communication skills | Senior (experienced); more experienced; good communication skills; interdisciplinary; | [3,11,14,25,29,30,31] |

| 18 | Team Members Dedication and Continuity | Team members on multiple projects concurrently; not accentuated; fluctuation expected; distributed teams | Team members dedicated to project; collocated and smaller teams | [2,3,28,30,31,32] |

| No. | Challenges | Advantages | Principles |

|---|---|---|---|

| 1 | Human factor | Coping with incomplete and missing customer requirements | Internal exchange through interdisciplinary core teams and daily meetings |

| 2 | Many meetings with a lot of stakeholders | Creates transparency | External exchange through Product Manager |

| 3 | Customer and supplier Involvement | Enforced communication and feedback | Frequent delivery through short iterative development in numerous cycles |

| 4 | Integration in company partner’s line organization | “One-Person Development” is prevented | Self-organized teams |

| 5 | Identification and integration of all involved departments | Individual team responsibility for decisions | Balance and control: agile development methodology with underlying development process |

| 6 | Integration with existing development process | Urge to deliver something worth showing after a sprint | Open-minded management support and commitment |

| 7 | Managing intersections of stakeholders and departments | Voluntary participation | |

| 8 | Team constellation | ||

| 9 | Rapid prototyping implementation |

| No. | Attribute |

|---|---|

| 1 | Vehicle Development (new, upgrade, derivate) |

| 2 | Powertrain Topology (ICE, battery, fuel cell, gearbox, etc.) |

| 3 | Degree of Maturity Entry (from scratch, after feasibility phase, into development phase) |

| 4 | Functional Requirements (weight, lifetime, power, consumption, etc.) |

| 5 | Legislative Requirements (emission standards, safety, etc.) |

| 6 | Generation/ Sample Quantity (2–6) |

| 7 | Hardware Test Quantity |

| 8 | Excluded Systems/Components |

| 9 | Testing (Virtual vs. Real) |

| 10 | Timeframe (24–48 months) |

| Key Disciplines Involved in Powertrain Development | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Design | Service | Systems Engineering | Electrical Engineering | Mechanical Engineering | Functional Safety | Production | Software | Purchasing | Homologation | |||

| Key Attributes of Powertrain Development | Vehicle Development | New | 2 | 0 | 2 | 1 | 1 | 2 | 2 | 2 | 2 | 2 |

| Upgrade | ||||||||||||

| Derivate | ||||||||||||

| Powertrain Topology | ICE | 2 | 2 | 1 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | |

| Battery | ||||||||||||

| Fuel Cell | ||||||||||||

| E-Motor | ||||||||||||

| … | ||||||||||||

| Degree of Maturity Entry | From scratch | 1 | 2 | 0 | 2 | 1 | 2 | 1 | 2 | 0 | 2 | |

| Feasibility | ||||||||||||

| Development | ||||||||||||

| … | … | … | … | … | … | … | … | … | … | … | ||

| Key Disciplines | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Design | Service | Systems Engineering | Electrical Engineering | Mechanical Engineering | Functional Safety | Production | Software | Purchasing | Homologation | ||

| Key Disciplines | Design | 28 | |||||||||

| Service | 23 | 26 | Novelty Values | ||||||||

| Systems Engineering | 22 | 15 | 21 | Interdependency Values | |||||||

| Electrical Engineering | 27 | 25 | 22 | 31 | |||||||

| Mechanical Engineering | 22 | 20 | 18 | 25 | 23 | ||||||

| Functional Safety | 28 | 27 | 20 | 28 | 22 | 33 | |||||

| Production | 31 | 26 | 26 | 32 | 25 | 32 | 37 | ||||

| Software | 28 | 24 | 24 | 31 | 24 | 30 | 34 | 34 | |||

| Purchasing | 25 | 19 | 23 | 25 | 20 | 24 | 30 | 28 | 29 | ||

| Homologation | 29 | 26 | 23 | 31 | 25 | 32 | 34 | 33 | 26 | 34 | |

| Key Disciplines | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Design | Service | Systems Engineering | Electrical Engineering | Mechanical Engineering | Functional Safety | Production | Software | Purchasing | Homologation | ||

| Key Disciplines | Design | 70% | |||||||||

| Service | 58% | 65% | Degrees of Novelty (DGN) | ||||||||

| Systems Engineering | 55% | 38% | 53% | Degrees of Interdependency (DGI) | |||||||

| Electrical Engineering | 68% | 63% | 55% | 78% | |||||||

| Mechanical Engineering | 55% | 50% | 45% | 63% | 58% | ||||||

| Functional Safety | 70% | 68% | 50% | 70% | 55% | 83% | |||||

| Production | 78% | 65% | 65% | 80% | 63% | 80% | 93% | ||||

| Software | 70% | 60% | 60% | 78% | 60% | 75% | 85% | 85% | |||

| Purchasing | 63% | 48% | 58% | 63% | 50% | 60% | 75% | 70% | 73% | ||

| Homologation | 73% | 65% | 58% | 78% | 63% | 80% | 85% | 83% | 65% | 85% | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lukas, A.; Moerth-Teo, O.; Schwarz, L.; Schnöll, H.P.; Wolf, M.; Ramsauer, C. Agile Powertrain Development: Considerations to Incorporate Agile Principles. Designs 2021, 5, 60. https://doi.org/10.3390/designs5040060

Lukas A, Moerth-Teo O, Schwarz L, Schnöll HP, Wolf M, Ramsauer C. Agile Powertrain Development: Considerations to Incorporate Agile Principles. Designs. 2021; 5(4):60. https://doi.org/10.3390/designs5040060

Chicago/Turabian StyleLukas, Andreas, Oliver Moerth-Teo, Lukas Schwarz, Hans P. Schnöll, Matthias Wolf, and Christian Ramsauer. 2021. "Agile Powertrain Development: Considerations to Incorporate Agile Principles" Designs 5, no. 4: 60. https://doi.org/10.3390/designs5040060

APA StyleLukas, A., Moerth-Teo, O., Schwarz, L., Schnöll, H. P., Wolf, M., & Ramsauer, C. (2021). Agile Powertrain Development: Considerations to Incorporate Agile Principles. Designs, 5(4), 60. https://doi.org/10.3390/designs5040060