Design of Powering Wireless Medical Sensor Based on Spiral-Spider Coils

Abstract

:1. Introduction

- MRC-WPT system was practically implemented to provide sufficient power for heart-rate measurements in humans;

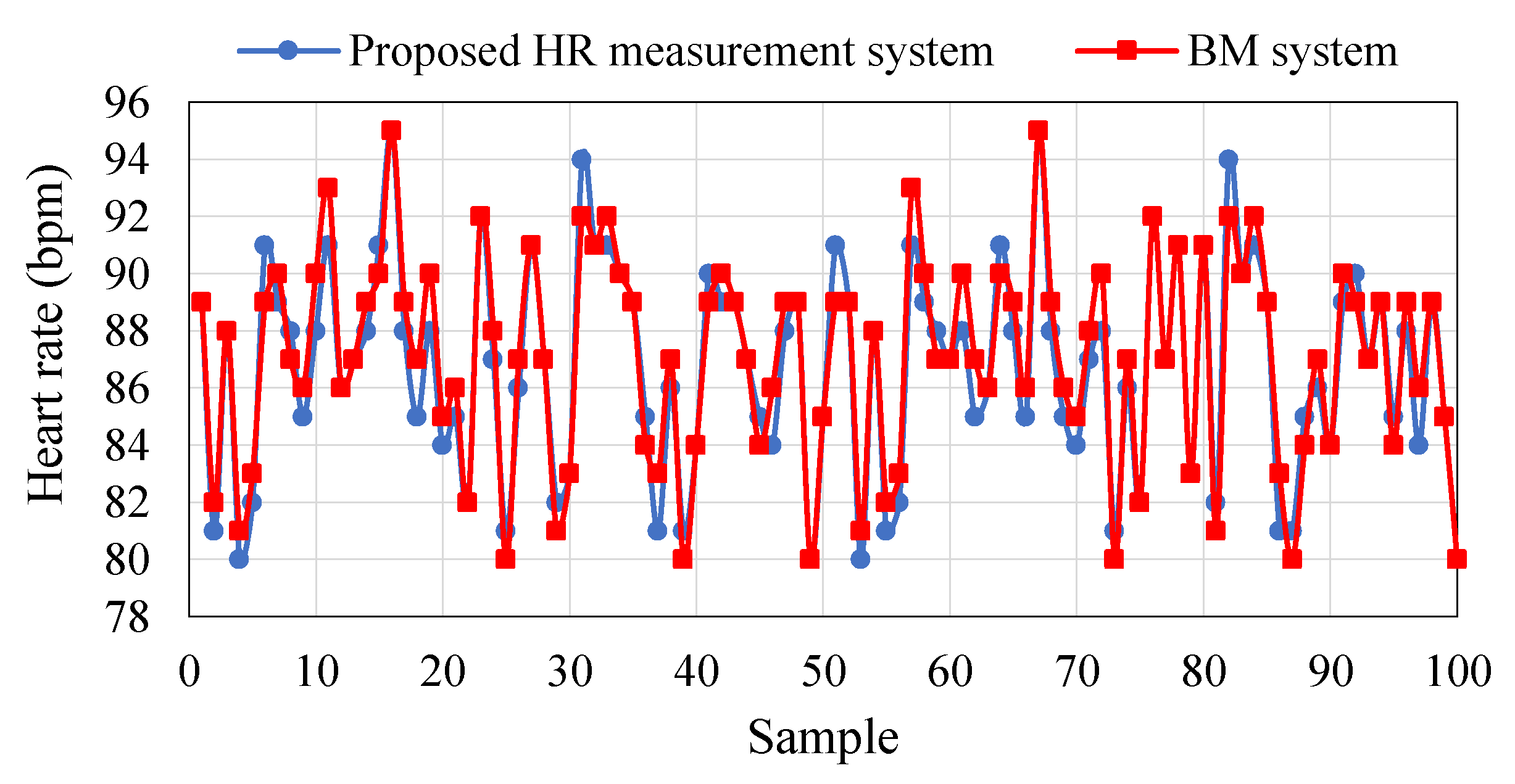

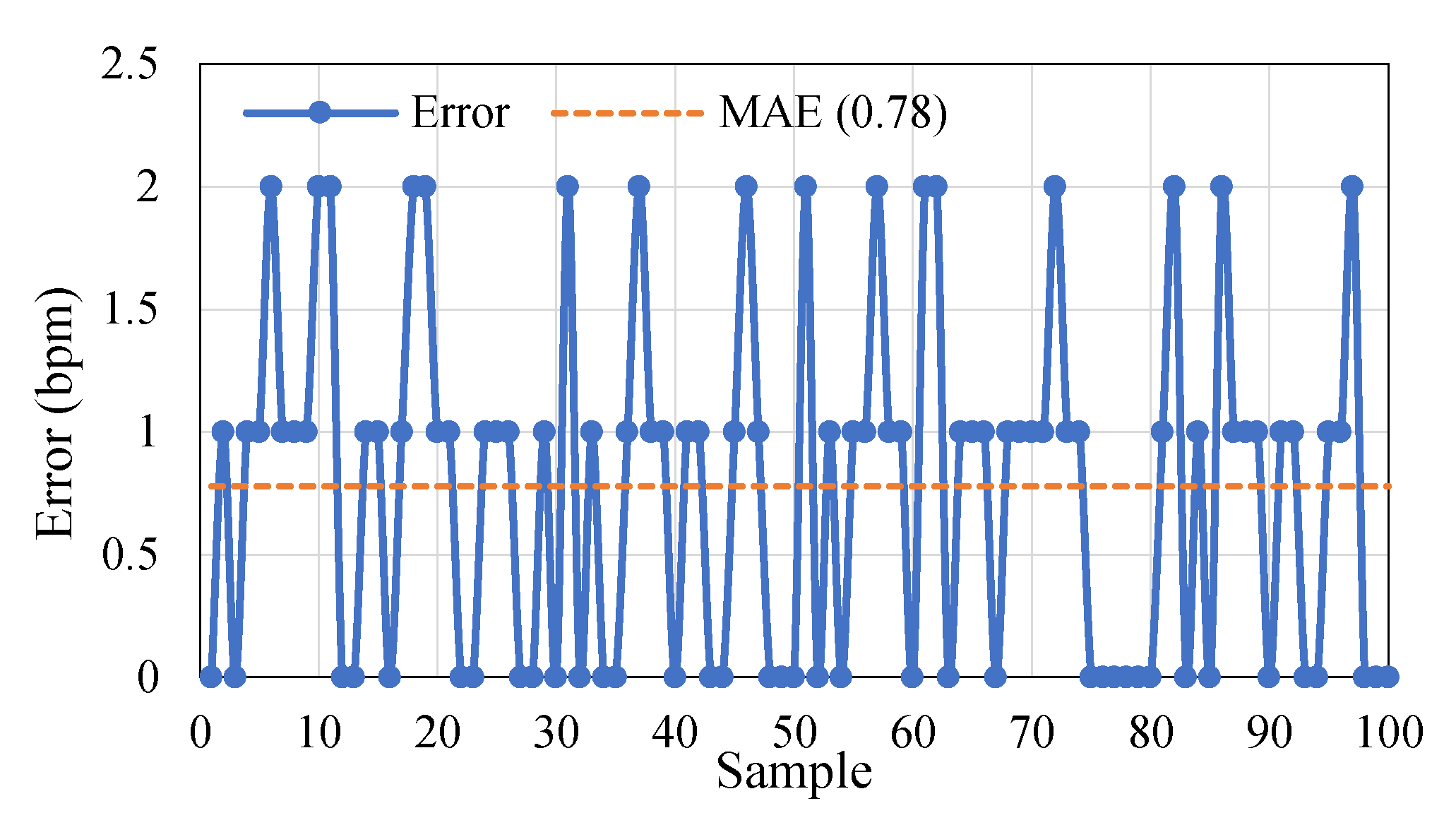

- The accuracy of patients’ heart-rate measurements was validated relative to the benchmark (BM) device;

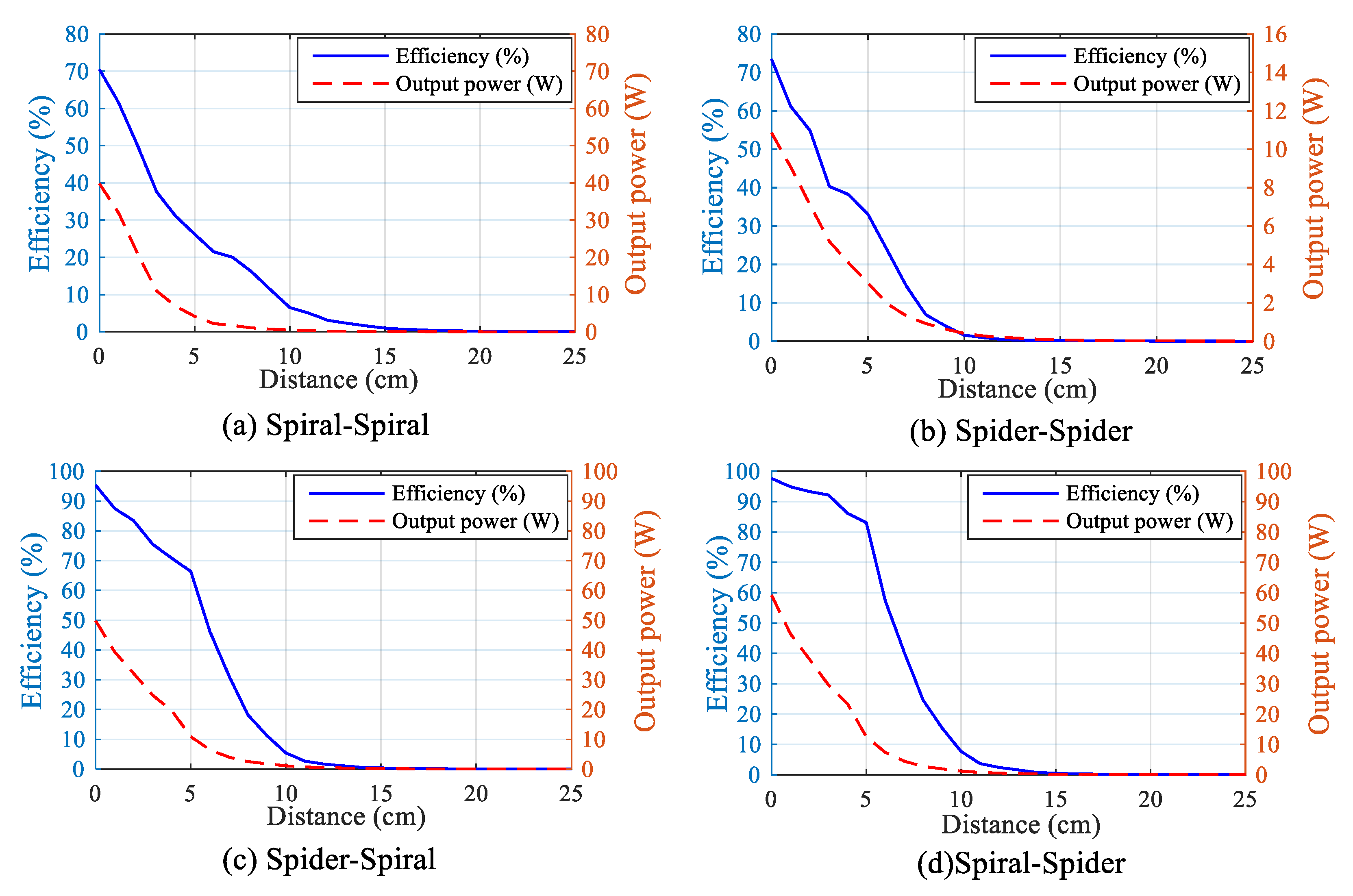

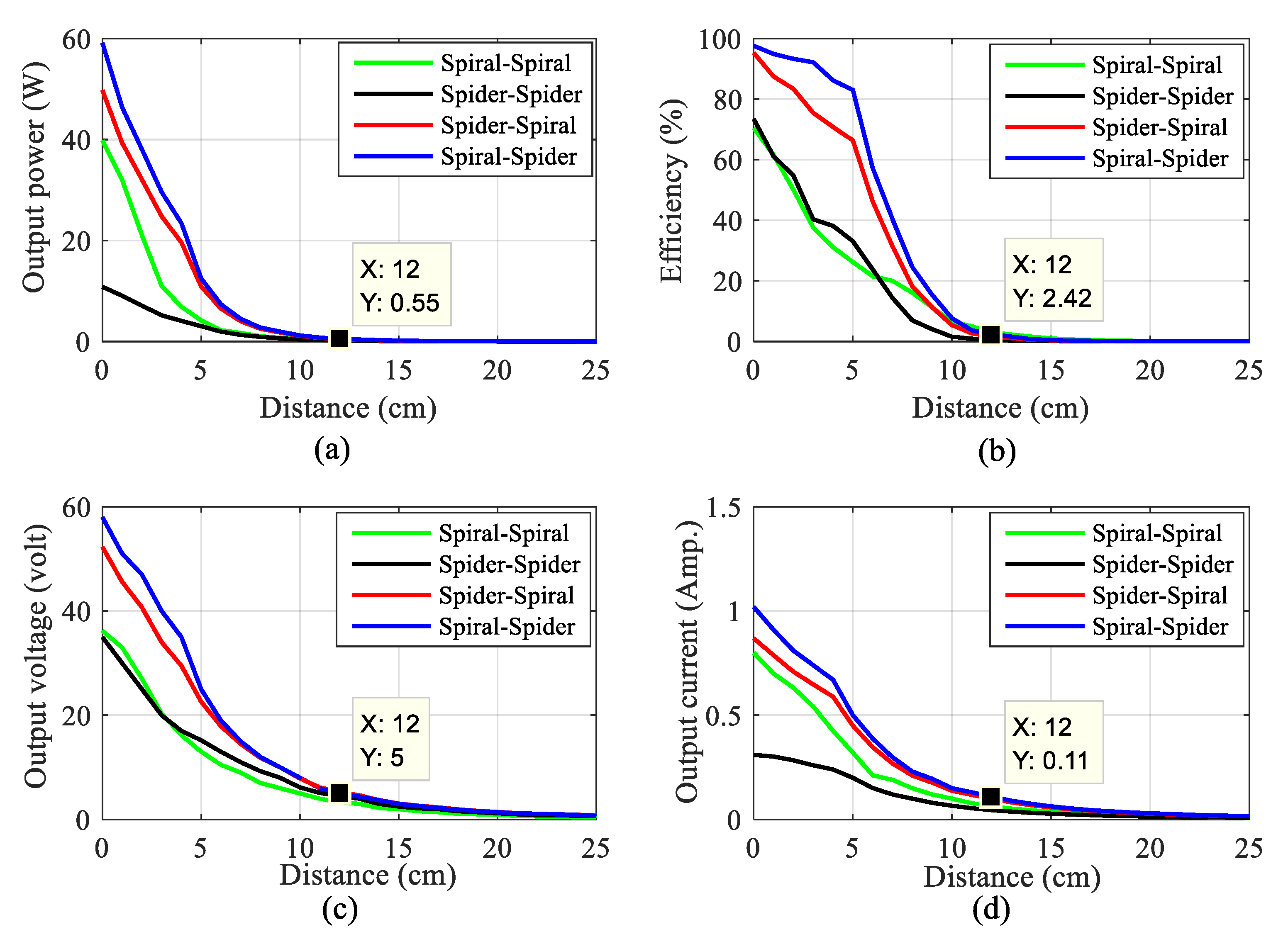

- Power transfer and efficiency were investigated for the proposed MRC-WPT system;

- The functionalities of the heart-rate measurement device were achieved based on MRC-WPT;

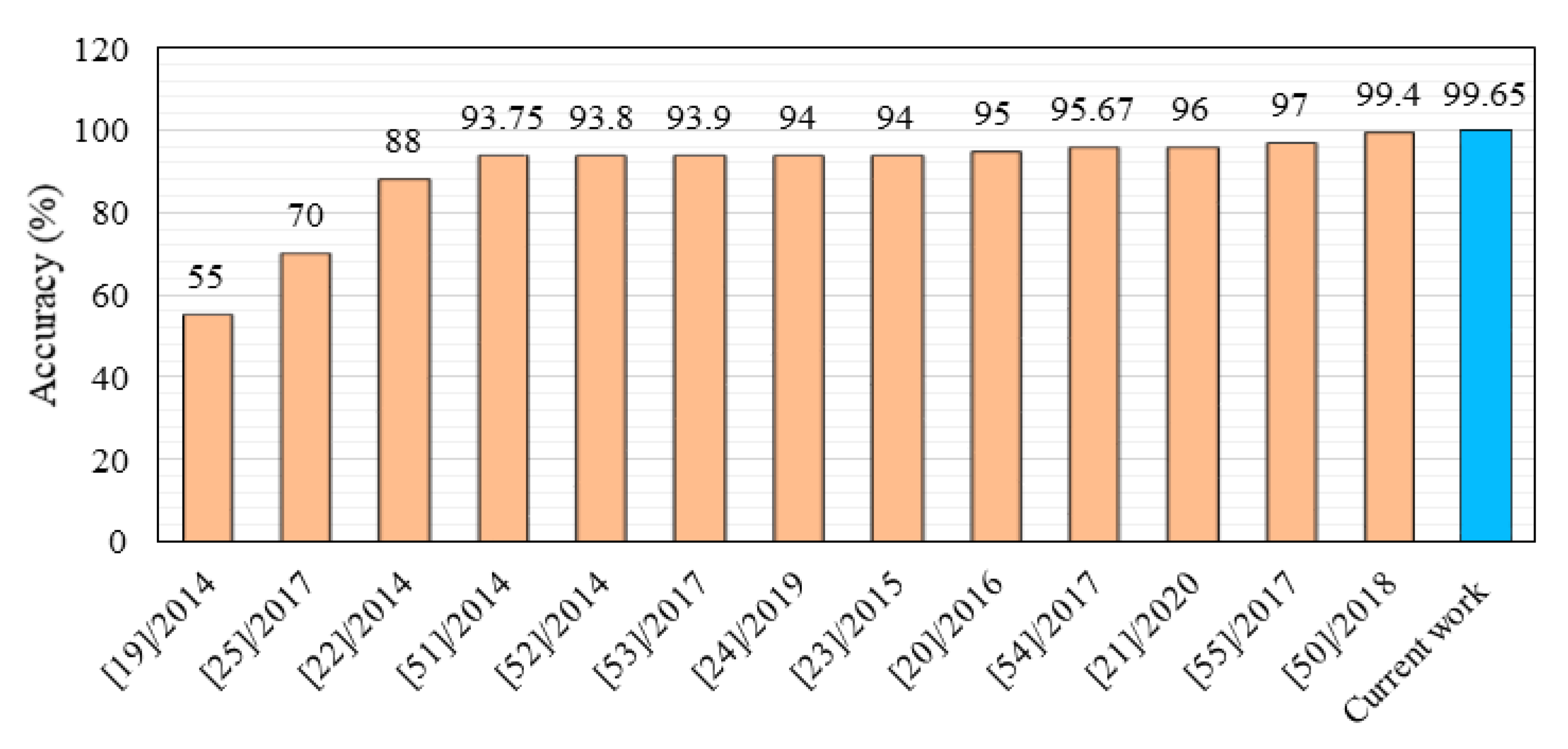

- The heart-rate measurement accuracy, and Transfer efficiency, and power transfer of the MRC-WPT are compared to those reported in related works to confirm its achievement.

2. Related Works

3. Research Methodology

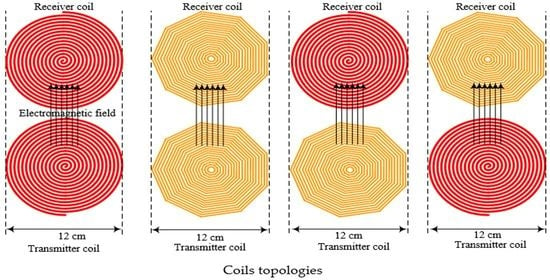

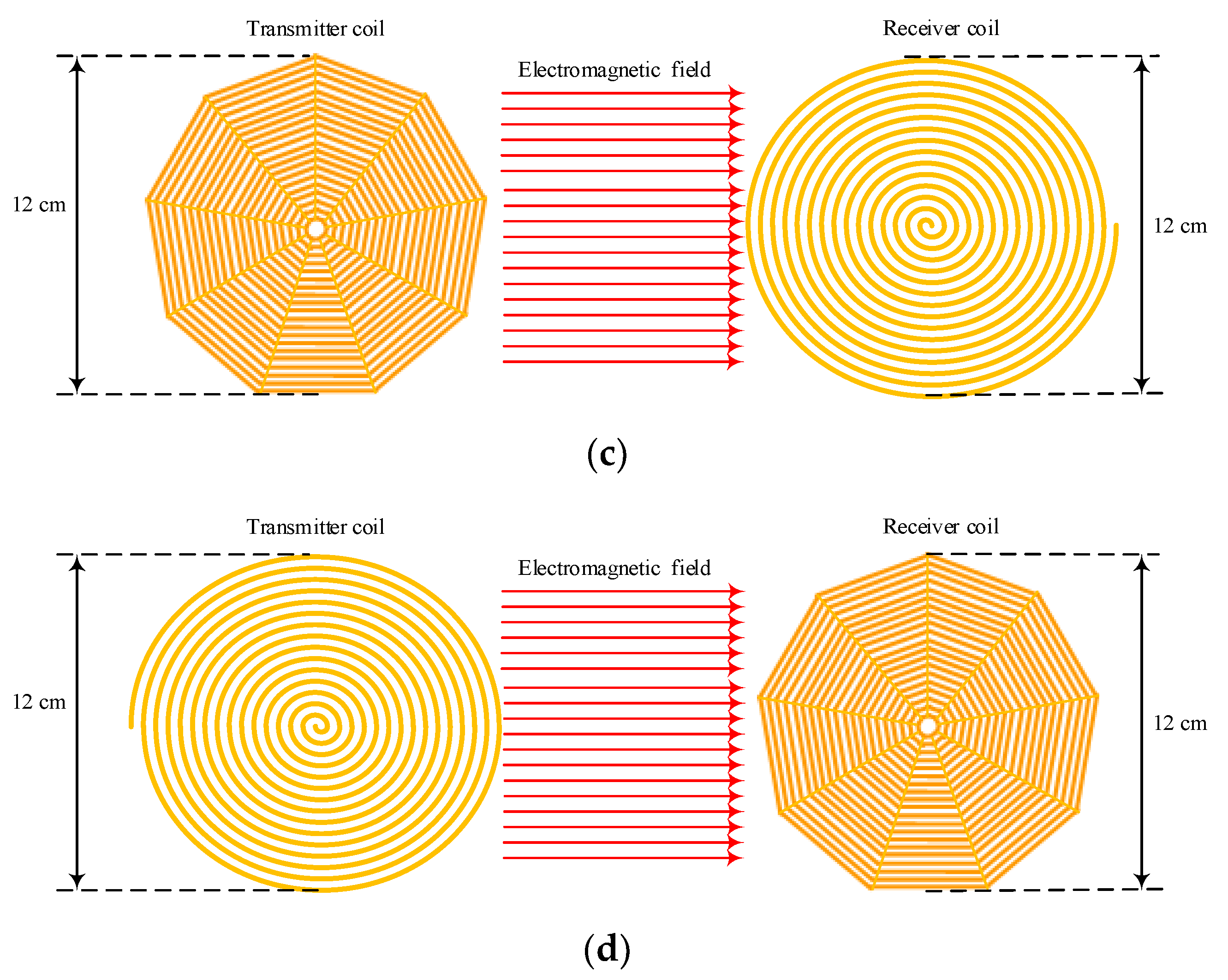

3.1. Coils Design

3.2. Performance of Transfer Power and Efficiency

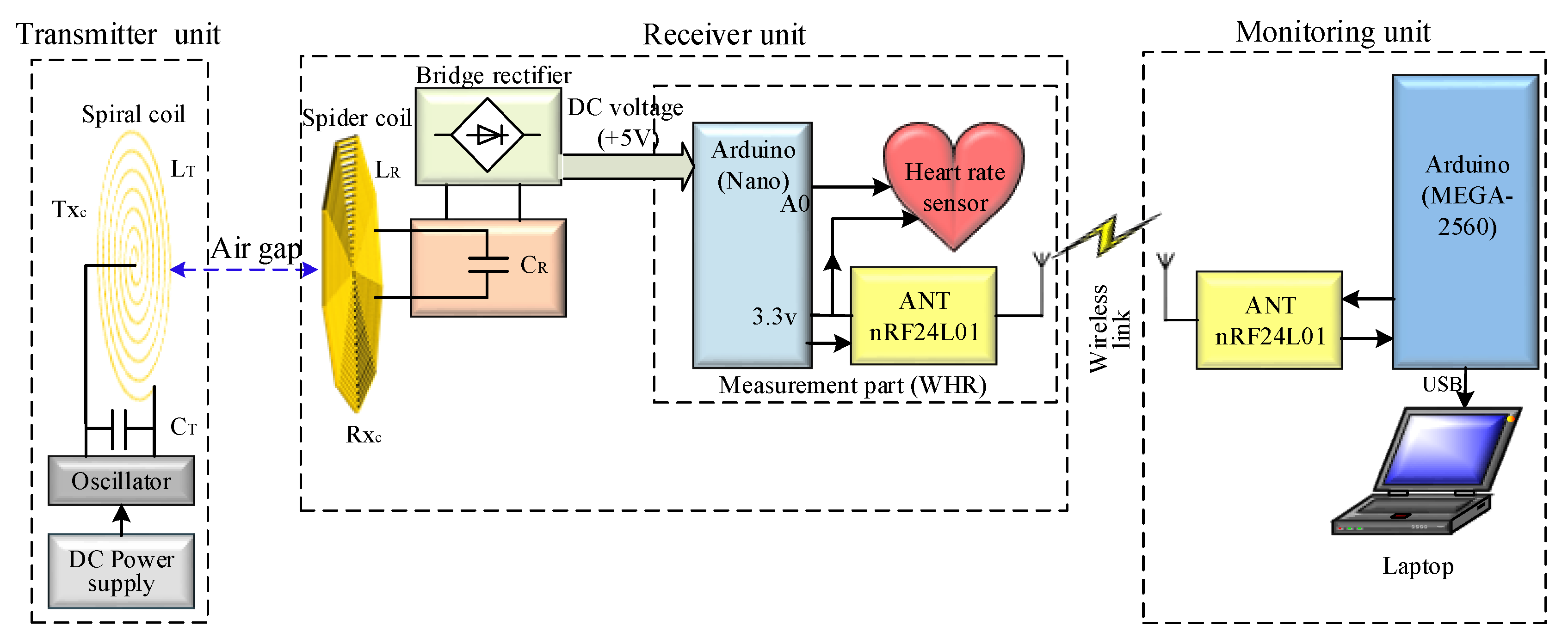

3.3. System Model

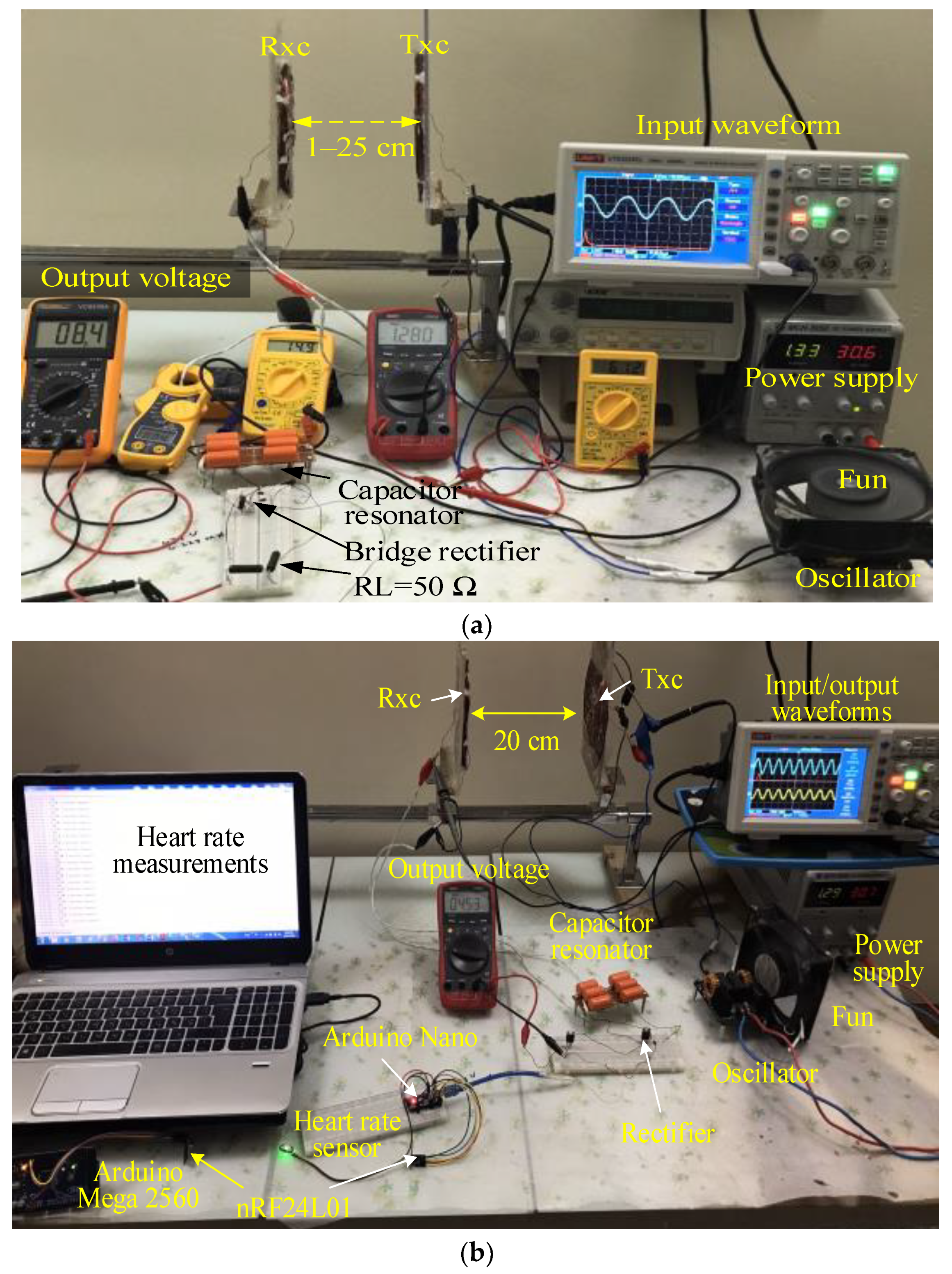

3.4. Experiment Configuration

3.5. Analysis and Validation of Collected Data

3.6. Measurement Accuracy of WHR

4. Results and Discussion

4.1. Result of Transfer Power and Efficiency

4.2. Measurement Validation of WHR

4.2.1. Error Test and Accuracy

4.2.2. Bland–Altman Test

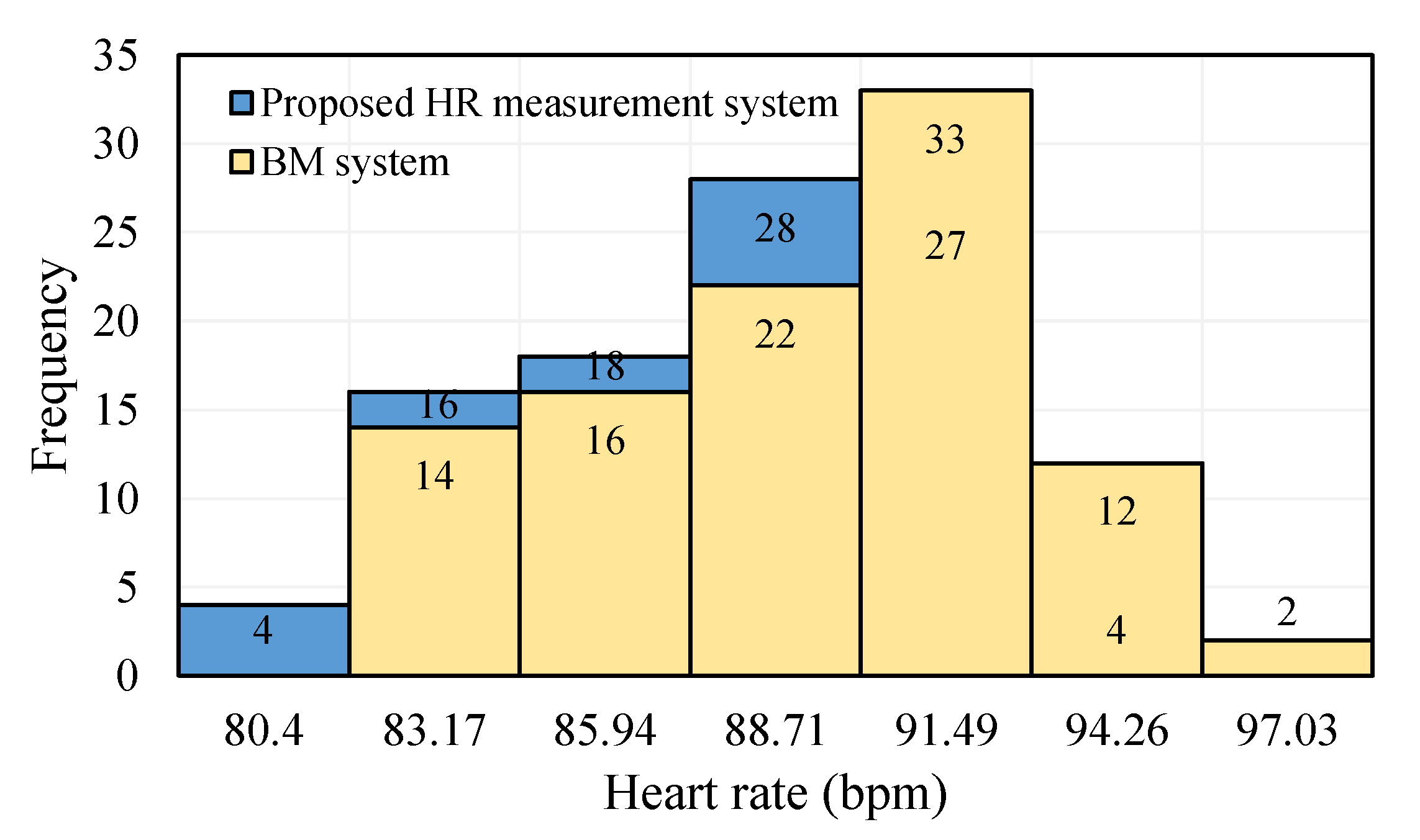

4.2.3. Histogram Test

5. Comparison with Previous Work

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mahmood, M.F.; Mohammed, S.L.; Gharghan, S.K. Free Battery-based Energy Harvesting Techniques for Medical Devices. IOP Conf. Ser. Mater. Sci. Eng. 2020, 745, 012094. [Google Scholar] [CrossRef]

- Mahmood, M.F.; Mohammed, S.L.; Gharghan, S.K. Ultrasound Sensor-Based Wireless Power Transfer for Low-Power Medical Devices. J. Low Power Electron. Appl. 2019, 9, 20. [Google Scholar] [CrossRef] [Green Version]

- Curry, E.J.; Ke, K.; Chorsi, M.T.; Wrobel, K.S.; Miller, A.N.; Patel, A.; Kim, I.; Feng, J.; Yue, L.; Wu, Q. Biodegradable piezoelectric force sensor. Proc. Natl. Acad. Sci. USA 2018, 115, 909–914. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Monti, G.; Arcuti, P.; Tarricone, L. Resonant Inductive Link for Remote Powering of Pacemakers. IEEE Trans. Microw. Theory Tech. 2015, 63, 3814–3822. [Google Scholar] [CrossRef]

- Moore, J.; Castellanos, S.; Xu, S.; Wood, B.; Ren, H.; Tse, Z.T.H. Applications of wireless power transfer in medicine: State-of-the-art reviews. Ann. Biomed. Eng. 2019, 47, 22–38. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mahmood, M.F.; Mohammed, S.L.; Gharghan, S.K. Energy Harvesting-Based Vibration Sensor for Medical Electromyography Device. Int. J. Electr. Electron. Eng. Telecommun. 2020, 9, 364–372. [Google Scholar]

- Thangasamy, V.; Kamsani, N.A.; Thiruchelvam, V.; Hamidon, M.N.; Hashim, S.J.; Bukhori, M.F.; Yusoff, Z. Wireless power transfer with on-chip inductor and class-E power amplifier for implant medical device applications. In Proceedings of the IEEE Student Conference on Research and Development (SCOReD), Kuala Lumpur, Malaysia, 13–14 December 2015; pp. 422–426. [Google Scholar]

- Ramachandran, H.; Bindu, G. Wireless powering of utility equipments in a smart home using magnetic resonance. In Proceedings of the IEEE Recent Advances in Intelligent Computational Systems (RAICS), Trivandrum, India, 19–21 December 2013; pp. 221–226. [Google Scholar]

- Na, K.; Jang, H.; Ma, H.; Bien, F. Tracking optimal efficiency of magnetic resonance wireless power transfer system for biomedical capsule endoscopy. IEEE Trans. Microw. Theory Tech. 2014, 63, 295–304. [Google Scholar] [CrossRef]

- Agarwal, K.; Jegadeesan, R.; Guo, Y.-X.; Thakor, N.V. Wireless power transfer strategies for implantable bioelectronics. IEEE Rev. Biomed. Eng. 2017, 10, 136–161. [Google Scholar] [CrossRef]

- Li, X.; Tsui, C.-Y.; Ki, W.-H. A 13.56 MHz wireless power transfer system with reconfigurable resonant regulating rectifier and wireless power control for implantable medical devices. IEEE J. Solid-State Circuits 2015, 50, 978–989. [Google Scholar] [CrossRef]

- Zhao, J.; Ghannam, R.; Yuan, M.; Tam, H.; Imran, M.; Heidari, H. Design, test and optimization of inductive coupled coils for implantable biomedical devices. J. Low Power Electron. 2019, 15, 76–86. [Google Scholar] [CrossRef]

- Gati, E.; Kokosis, S.; Patsourakis, N.; Manias, S. Comparison of Series Compensation Topologies for Inductive Chargers of Biomedical Implantable Devices. Electronics 2020, 9, 8. [Google Scholar] [CrossRef] [Green Version]

- Herbert, R.; Yeo, W. Stretchable, Implantable Nanomembrane Biosensor for Wireless, Real-Time Monitoring of Hemodynamics. In Proceedings of the IEEE 69th Electronic Components and Technology Conference (ECTC), Las Vegas, NV, USA, 28–31 May 2019; pp. 1233–1239. [Google Scholar]

- Kim, J.; Kim, H.; Kim, D.; Park, H.-J.; Ban, K.; Ahn, S.; Park, S.-M. A Wireless Power Transfer Based Implantable ECG Monitoring Device. Energies 2020, 13, 905. [Google Scholar] [CrossRef] [Green Version]

- Jiang, Q.; Qin, Y.; Zhao, Y.; Xu, C.-Z.; Wang, X. A receiver position estimation scheme in wireless power transfer system. In Proceedings of the IEEE International Conference on Consumer Electronics (ICCE), Las Vegas, NV, USA, 12–14 January 2018; pp. 1–4. [Google Scholar]

- Mohamadi, T. Working frequency in wireless power transfer for implantable biomedical sensors. In Proceedings of the 2011 International Conference on Electrical Engineering and Informatics, Bandung, Indonesia, 17–19 July 2011; pp. 1–5. [Google Scholar]

- Zhang, F.; Hackworth, S.A.; Liu, X.; Chen, H.; Sclabassi, R.J.; Sun, M. Wireless energy transfer platform for medical sensors and implantable devices. In Proceedings of the 2009 Annual International Conference of the IEEE Engineering in Medicine and Biology Society, Minneapolis, MN, USA, 3–6 September 2009; pp. 1045–1048. [Google Scholar]

- Campi, T.; Cruciani, S.; Feliziani, M.; Hirata, A. Wireless power transfer system applied to an active implantable medical device. In Proceedings of the 2014 IEEE Wireless Power Transfer Conference, Jeju, Korea, 8–9 May 2014; pp. 134–137. [Google Scholar]

- Gore, V.B.; Gawali, D.H. Wireless power transfer technology for medical applications. In Proceedings of the 2016 Conference on Advances in Signal Processing (CASP), Pune, India, 9–11 June 2016; pp. 455–460. [Google Scholar]

- Hussain, M.A.; Gharghan, S.K.; Qasim Hamood, H. Design and Implementation of Wireless Low-Power Transfer for Medical Implant Devices. IOP Conf. Ser. Mater. Sci. Eng. 2020, 745, 012087. [Google Scholar] [CrossRef]

- Zhang, Z.; Chau, K.; Liu, C.; Li, F.; Ching, T. Quantitative analysis of mutual inductance for optimal wireless power transfer via magnetic resonant coupling. IEEE Trans. Magn. 2014, 50, 1–4. [Google Scholar] [CrossRef]

- Zhang, Y.; Lu, T.; Zhao, Z.; He, F.; Chen, K.; Yuan, L. Employing load coils for multiple loads of resonant wireless power transfer. IEEE Trans. Power Electron. 2015, 30, 6174–6181. [Google Scholar] [CrossRef]

- Campi, T.; Cruciani, S.; De Santis, V.; Maradei, F.; Feliziani, M. Near field wireless powering of deep medical implants. Energies 2019, 12, 2720. [Google Scholar] [CrossRef] [Green Version]

- Zakaria, N.; Jusoh, M.; Ghazali, N.; Yasin, M.; Sabapathy, T.; Osman, M.; Ahmad, N.; Zakaria, M. A Computational Study on the Magnetic Resonance Coupling Technique for Wireless Power Transfer. In Proceedings of the MATEC Web of Conferences, Penang, Malaysia, 9–10 October 2017; p. 01025. [Google Scholar]

- Luo, Z.; Wei, X. Mutual Inductance Analysis of Planar Coils with Misalignment for Wireless Power Transfer Systems in Electric Vehicle. In Proceedings of the 2016 IEEE Vehicle Power and Propulsion Conference (VPPC), Hangzhou, China, 17–20 October 2016; pp. 1–6. [Google Scholar]

- Jawad, A.M.; Jawad, H.M.; Nordin, R.; Gharghan, S.K.; Abdullah, N.F.; Abu-Alshaeer, M.J. Wireless power transfer with magnetic resonator coupling and sleep/active strategy for a drone charging station in smart agriculture. IEEE Access 2019, 7, 139839–139851. [Google Scholar] [CrossRef]

- Pantic, Z.; Lukic, S.M. Framework and topology for active tuning of parallel compensated receivers in power transfer systems. IEEE Trans. Power Electron. 2012, 27, 4503–4513. [Google Scholar] [CrossRef]

- Mahmood, M.F.; Mohammed, S.L.; Gharghan, S.K.; Al-Naji, A.; Chahl, J. Hybrid Coils-Based Wireless Power Transfer for Intelligent Sensors. Sensors 2020, 20, 2549. [Google Scholar] [CrossRef] [PubMed]

- Pérez-Nicoli, P. Inductive Links for Wireless Power Transfer: Fundamental Concepts for Designing High-Efficiency Wireless Power Transfer Links; Springer: Cham, Switzerland, 2021; p. 18. [Google Scholar]

- Campi, T.; Cruciani, S.; De Santis, V.; Feliziani, M. EMF safety and thermal aspects in a pacemaker equipped with a wireless power transfer system working at low frequency. IEEE Trans. Microw. Theory Tech. 2016, 64, 375–382. [Google Scholar] [CrossRef]

- Technical Specifications of Schottky Barrier Rectifier. Available online: http://www.datasheetcatalog.com/datasheets_pdf/S/R/2/6/SR260.shtml (accessed on 30 September 2020).

- Furter, J.S.; Hauser, P.C. Interactive control of purpose built analytical instruments with Forth on microcontrollers-A tutorial. Anal. Chim. Acta 2019, 1058, 18–28. [Google Scholar] [CrossRef]

- Gharghan, S.K.; Nordin, R.; Ismail, M. Energy Efficiency of Ultra-Low-Power Bicycle Wireless Sensor Networks Based on a Combination of Power Reduction Techniques. J. Sens. 2016, 2016, 7314207. [Google Scholar] [CrossRef]

- Gharghan, S.K.; Nordin, R.; Ismail, M. An Ultra-Low Power Wireless Sensor Network for Bicycle Torque Performance Measurements. Sensors 2015, 15, 11741–11768. [Google Scholar] [CrossRef] [Green Version]

- Thomas, S.S.; Saraswat, A.; Shashwat, A.; Bharti, V. Sensing heart beat and body temperature digitally using Arduino. In Proceedings of the 2016 International Conference on Signal Processing, Communication, Power and Embedded System (SCOPES), Paralakhemundi, India, 3–5 October 2016; pp. 1721–1724. [Google Scholar]

- Valliappan, S.; Mohan, B.P.R.; Kumar, S.R. Design of low-cost, wearable remote health monitoring and alert system for elderly heart patients. In Proceedings of the 2017 International Conference on IoT and Application (ICIOT), Nagapattinam, India, 19–20 May 2017; pp. 1–7. [Google Scholar]

- Zhao, L.; Thrimawithana, D.J.; Madawala, U.K. Hybrid bidirectional wireless EV charging system tolerant to pad misalignment. IEEE Trans. Ind. Electron. 2017, 64, 7079–7086. [Google Scholar] [CrossRef]

- Parallax Data Acquisition Tool (PLX-DAQ) Software. Available online: https://www.parallax.com/package/plx-daq/ (accessed on 17 September 2021).

- Gharghan, S.K.; Nordin, R.; Ismail, M. Statistical validation of performance of ZigBee-based wireless sensor network for track cycling. In Proceedings of the International Conference on Smart Sensors and Application (ICSSA), Kuala Lumpur, Malaysia, 26–28 May 2015; pp. 44–49. [Google Scholar]

- Gharghan, S.K.; Mohammed, S.L.; Al-Naji, A.; Abu-AlShaeer, M.J.; Jawad, H.M.; Jawad, A.M.; Chahl, J. Accurate fall detection and localization for elderly people based on neural network and energy-efficient wireless sensor network. Energies 2018, 11, 2866. [Google Scholar] [CrossRef] [Green Version]

- Arduino Nano. Available online: https://store.arduino.cc/usa/arduino-nano (accessed on 12 September 2020).

- He, J.; Zhao, H. A new smart safety navigation system for cycling based on audio technology. Saf. Sci. 2020, 124, 104583. [Google Scholar] [CrossRef]

- Kamel Gharghan, S.; Saad Fakhrulddin, S.; Al-Naji, A.; Chahl, J. Energy-Efficient Elderly Fall Detection System Based on Power Reduction and Wireless Power Transfer. Sensors 2019, 19, 4452. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gharghan, S.K.; Nordina, R.; Ismaila, M. Development and Validation of a Track Bicycle Instrument for Torque Measurement Using the Zigbee Wireless Sensor Network. Int. J. Smart Sens. Intell. Syst. 2017, 10, 124–145. [Google Scholar]

- Jawad, A.M.; Nordin, R.; Gharghan, S.K.; Jawad, H.M.; Ismail, M.; Abu-AlShaeer, M.J. Single-tube and multi-turn coil near-field wireless power transfer for low-power home appliances. Energies 2018, 11, 1969. [Google Scholar] [CrossRef] [Green Version]

- Yang, C.; He, Y.; Qu, H.; Wu, J.; Hou, Z.; Lin, Z.; Cai, C. Analysis, design and implement of asymmetric coupled wireless power transfer systems for unmanned aerial vehicles. AIP Adv. 2019, 9, 025206. [Google Scholar] [CrossRef] [Green Version]

- Ben Fadhel, Y.; Ktata, S.; Sedraoui, K.; Rahmani, S.; Al-Haddad, K. A modified wireless power transfer system for medical implants. Energies 2019, 12, 1890. [Google Scholar] [CrossRef] [Green Version]

- Hussain, M.A.; Gharghan, S.K.; Hamood, H.Q. Single Tube Copper Coil via Strong Coupling Wireless Power Transfer for Low Power Devices. J. Adv. Res. Dyn. Control Syst. 2019, 11, 1818–1827. [Google Scholar]

- Fakhri, A.B.; Gharghan, S.K.; Mohammed, S.L. Statistical Validation of Patient Vital Signs Based on Energy-efficient wireless sensor network monitoring system. ARPN J. Eng. Appl. Sci. 2018, 13, 8258–8270. [Google Scholar]

- Roh, T.; Hong, S.; Yoo, H.-J. Wearable depression monitoring system with heart-rate variability. In Proceedings of the 36th Annual International Conference of the IEEE Engineering in Medicine and Biology Society, Chicago, IL, USA, 26–30 August 2014; pp. 562–565. [Google Scholar]

- Zhou, C.-C.; Tu, C.-L.; Gao, Y.; Wang, F.-X.; Gong, H.-W.; Lian, P.; He, C.; Ye, X.-S. A low-power, wireless, wrist-worn device for long time heart rate monitoring and fall detection. In Proceedings of the International Conference on Orange Technologies, Xi’an, China, 20–23 September 2014; pp. 33–36. [Google Scholar]

- Ngu, A.; Wu, Y.; Zare, H.; Polican, A.; Yarbrough, B.; Yao, L. Fall Detection Using Smartwatch Sensor Data with Accessor Architecture. In Proceedings of the ICSH: International Conference on Smart Health, Hong Kong, China, 26–27 June 2017; pp. 81–93. [Google Scholar]

- Di Rosa, M.; Hausdorff, J.M.; Stara, V.; Rossi, L.; Glynn, L.; Casey, M.; Burkard, S.; Cherubini, A. Concurrent validation of an index to estimate fall risk in community dwelling seniors through a wireless sensor insole system: A pilot study. Gait Posture 2017, 55, 6–11. [Google Scholar] [CrossRef]

- He, J.; Bai, S.; Wang, X. An Unobtrusive Fall Detection and Alerting System Based on Kalman Filter and Bayes Network Classifier. Sensors 2017, 17, 1393. [Google Scholar] [CrossRef] [PubMed]

| Ref/MRC Technique | Objective | Frequency (MHz) | Application | Accuracy (%) | Distance (cm) | Efficiency (%) | Power (W) |

|---|---|---|---|---|---|---|---|

| [17] | OTE | 0.00988 | LVAD | N/A | N/A | N/A | 1.5 |

| [18] | OTE | 7 | ID | 70 | 9 | 22.3 | N/A |

| [19] | OTDE | 0.3 | ICD | 55 | 6 | 7 | 1 |

| [20] | BT ch. | 0.3–13.56 | PM | 95 | 10 | N/A | 0.0004 |

| [21] | OTDE | 0.067 | TS | 96 | 3 | 1 | 0.05 |

| [22] | OTDE | N/A | MS | 88 | 4 | 67 | 14 |

| [24] | OTE | 4 | MD | 94 | 3 | 1 | 0.01 |

| [25] | OTE | 30 | MS | 70 | 5 | 14.7 | N/A |

| [23] | OTE | 0.3 | ID | 94 | 4 | 0.75 | N/A |

| Parameter | Spiral Coil | Spider Coil |

|---|---|---|

| Conductor diameter (mm) | 0.724 (21AWG) | 0.724 (21AWG) |

| Coil outer diameter (cm) | 12 | 12 |

| No. of turns | 91 | 150 |

| Inductance (µH) | 695 | 720 |

| Resonance capacitor (nF) | 200 | 190 |

| Operating frequency (kHz) | 13.5 | 13.5 |

| Parameter | Description |

|---|---|

| Coils | spiral and spider |

| Topologies | spiral-spiral, spider-spider, spider-spiral, spiral-spider |

| Oscillator circuit | ZVS 1000 W/20 A with a DC input voltage of 12–30 V |

| Resonance frequency of the oscillator | 13.5 kHz |

| Bridge rectifier | Schottky diodes (module SR260) |

| Heart rate sensor | Pulse sensor (SEN-11574) |

| Processing |

|

| Wireless protocol (nRF24L01) [35] |

|

| Laptop | Monitoring the heart rate measurements based on Arduino IDE software |

| Tested distance | 1–25 cm |

| Tested devices |

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahmood, M.F.; Gharghan, S.K.; Mohammed, S.L.; Al-Naji, A.; Chahl, J. Design of Powering Wireless Medical Sensor Based on Spiral-Spider Coils. Designs 2021, 5, 59. https://doi.org/10.3390/designs5040059

Mahmood MF, Gharghan SK, Mohammed SL, Al-Naji A, Chahl J. Design of Powering Wireless Medical Sensor Based on Spiral-Spider Coils. Designs. 2021; 5(4):59. https://doi.org/10.3390/designs5040059

Chicago/Turabian StyleMahmood, Mustafa F., Sadik Kamel Gharghan, Saleem Latteef Mohammed, Ali Al-Naji, and Javaan Chahl. 2021. "Design of Powering Wireless Medical Sensor Based on Spiral-Spider Coils" Designs 5, no. 4: 59. https://doi.org/10.3390/designs5040059

APA StyleMahmood, M. F., Gharghan, S. K., Mohammed, S. L., Al-Naji, A., & Chahl, J. (2021). Design of Powering Wireless Medical Sensor Based on Spiral-Spider Coils. Designs, 5(4), 59. https://doi.org/10.3390/designs5040059