Abstract

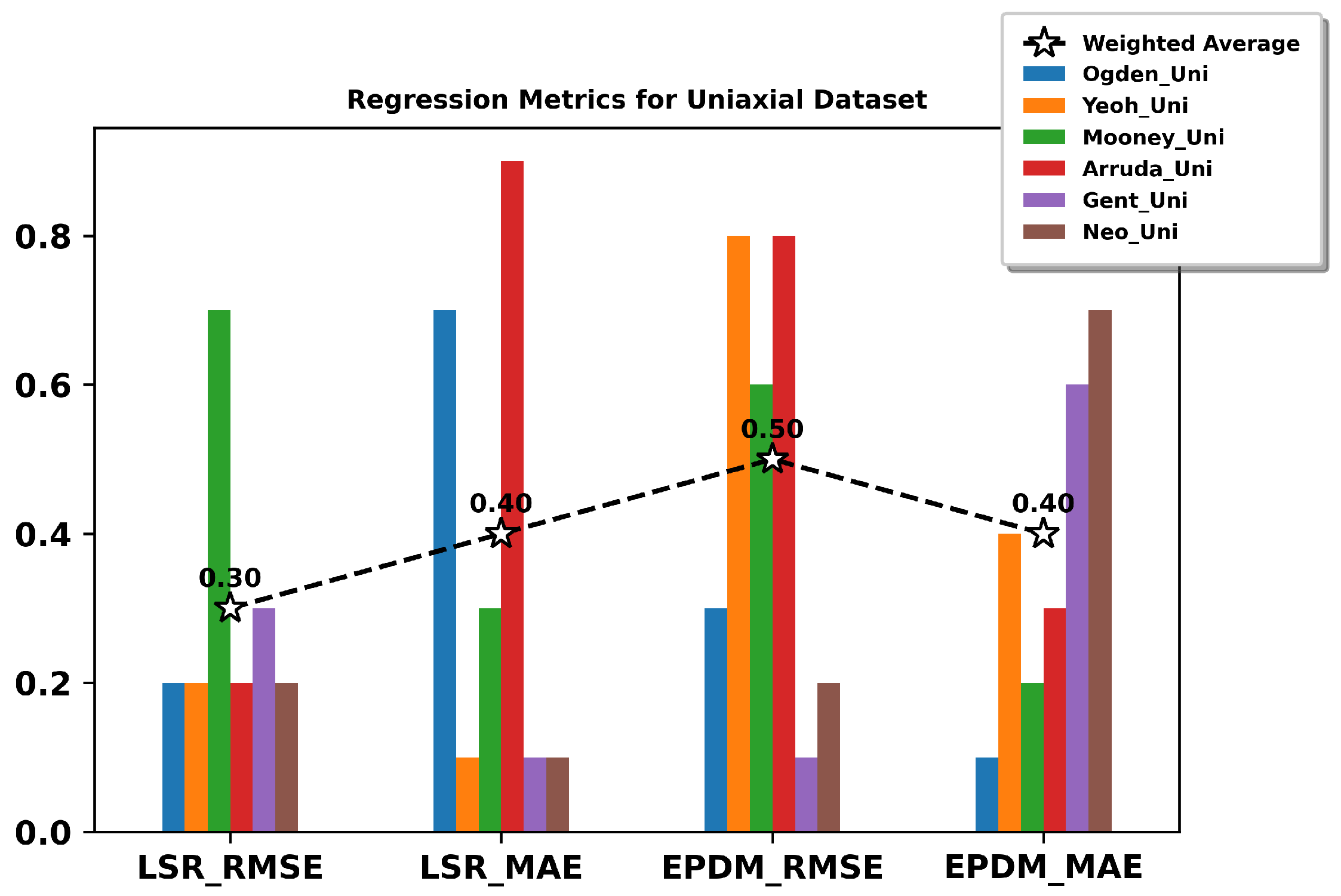

Ensuring the safety of electric vehicles is paramount, and one critical concern is the potential for hazardous hydrogen fuel leaks caused by the degradation of Proton-Exchange Membrane Fuel Cell (PEMFC) gasket materials. This study employs advanced techniques to address this issue. We leverage Finite Element Analysis (FEA) to rigorously assess the suitability of gasket materials for PEMFC applications, focusing on two crucial conditions: ageing and tensile stress. To achieve this, we introduce a comprehensive “dual degradation framework” that considers the effects of contact pressure and von Mises stress. These factors are instrumental in evaluating the performance and durability of Liquid Silicon Rubber (LSR) and Ethylene Propylene Diene Monomer (EPDM) materials. Our findings reveal the Yeoh model as the most accurate and efficient choice for ageing simulations, boasting a minimal Mean Absolute Percentage Error (MAPE) and computational time of just 0.27 s. In contrast, the Ogden model, while accurate, requires more computational resources. In assessing overall model performance using MAE, Root Mean Square Error (RMSE), and R-squared metrics, both LSR and EPDM materials proved promising, with LSR exhibiting superior performance in most areas. Furthermore, our study incorporates uniaxial tensile testing, which yields RMSE and MAE values of 0.30% and 0.40%, respectively. These results provide valuable insights into material behaviour under tensile stress. Our research underscores the pivotal role of FEA in identifying optimal gasket materials for PEMFC applications. Notably, LSR is a superior choice, demonstrating enhanced FEA modelling performance under ageing and tensile conditions. These findings promise to significantly contribute to developing safer and more reliable electric vehicles by advancing gasket material design.

1. Introduction

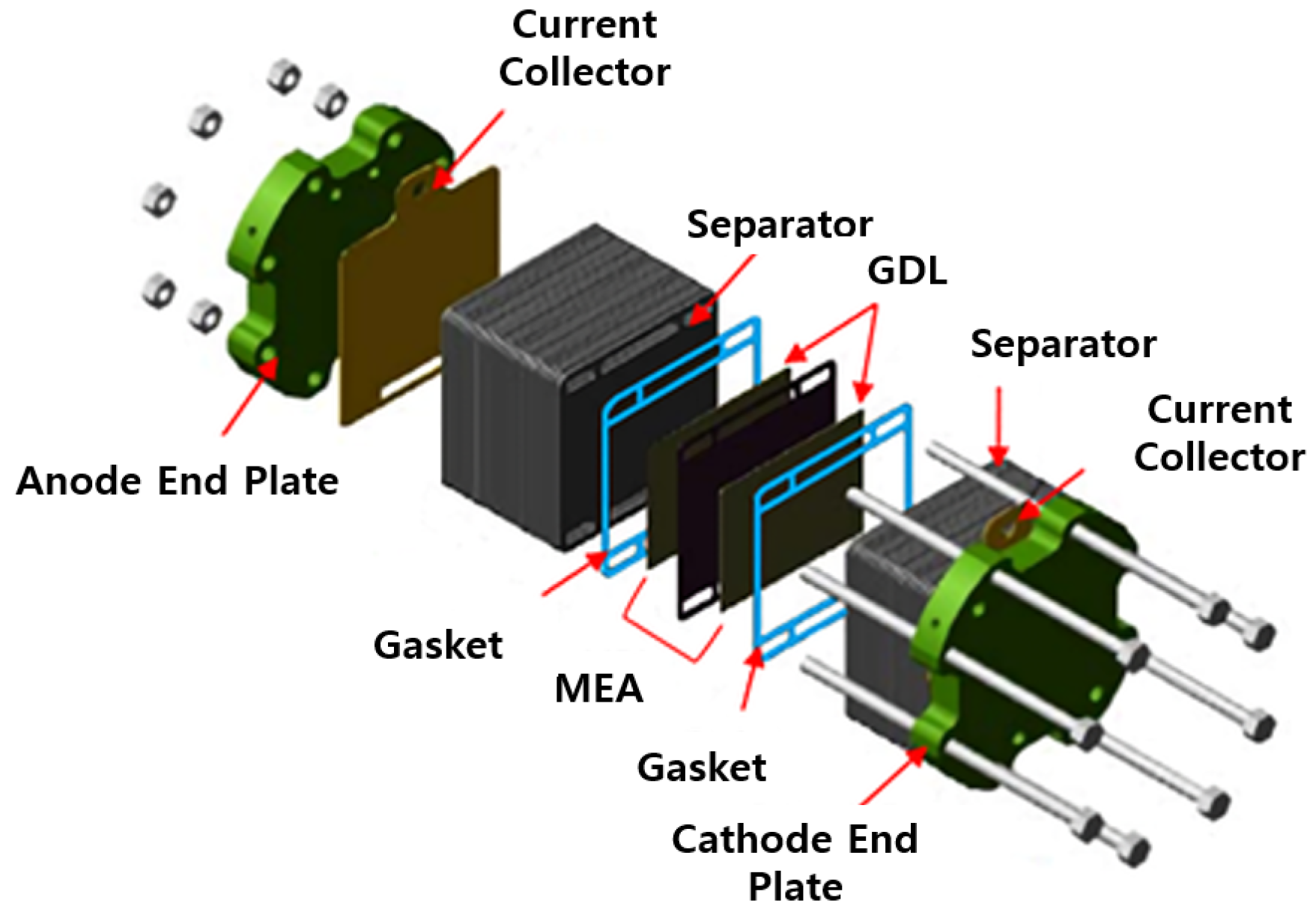

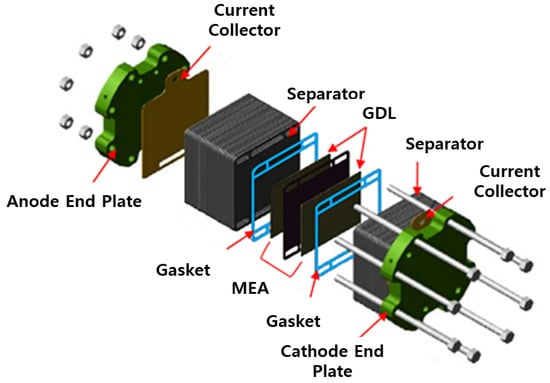

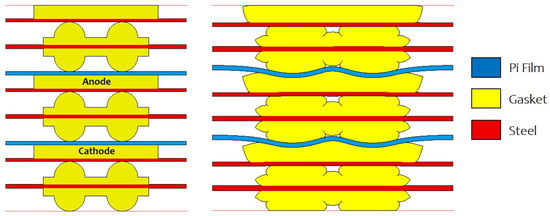

Proton-exchange membrane fuel cells (PEMFCs) are a type of hydrogen fuel cell that produces only water vapour as a byproduct. However, hydrogen fuel cells face several challenges, including the high cost of materials and the need for a reliable and efficient method of storing and generating hydrogen. Their applications range from transportation to stationary power generation to portable devices [1,2]. Research in PEMFCs and hydrogen fuel cells has focused on improving their performance, durability, and cost-effectiveness [3]. It involves developing new fuel cell materials and improving the design of fuel cell stacks. Furthermore, researchers are investigating more efficient and cost-effective ways to produce hydrogen, such as using renewable energy sources [4]. Fuel cells typically consist of three main components: an anode, a cathode, and an electrolyte membrane. Electrons flow through the cathode (the negative electrode of the cell), and oxygen is reduced to form water. The anode is the positive electrode, where hydrogen ions are oxidised to form protons and electrons. The membrane electrolyte acts as a barrier between the cathode and anode, allowing ions to pass through while preventing electrons from flowing in the wrong direction. Together, these components generate electricity through the chemical reaction of hydrogen and oxygen [5]. The assembled PEMFC can be seen in Figure 1.

Figure 1.

A breakdown of the PEMFC compartment.

The gasket material used in hydrogen fuel cells is crucial to guaranteeing safe and effective operation. To stop the leaking of hydrogen gas and other fluids, it is in charge of sealing the various components of the fuel cell. Elastomers, polymers, and ceramics—materials that can tolerate high temperatures and pressures in fuel cells—are commonly used to create the gasket. The gasket must also withstand the corrosive effects of hydrogen and other chemicals in the fuel cell environment. The durability and functionality of the fuel cell system depend on the gasket’s installation and maintenance procedures. Silicone rubber, ethylene propylene diene monomer (EPDM), and polytetrafluoroethylene (PTFE) are typical gasket materials for fuel cell stacks [6]. These gasket materials and sealants are ideal for applications involving hydrogen fuel cells due to their outstanding chemical and physical characteristics. Fluoroelastomers and PTFE are known for their chemical and high-temperature resistance, and EPDM and silicon rubber are recognised for their flexibility and durability [7].

Most accelerated ageing methods for hydrogen fuel cells involve exposing them to high temperatures, high humidity, and sulfuric acid. It enables manufacturers and researchers to test the fuel cells’ toughness and lifetime before using them in practical applications by simulating the harsh circumstances that the cells could encounter during routine operation. To replicate the sulphur impurities that could be present in the hydrogen fuel utilised in the cells, sulphuric acid is added to the testing environment. The test results can assist researchers in identifying and resolving any design or component problems that might contribute to the fuel cells’ rapid degradation [8,9,10]. The performance and toughness of the bipolar plates of a hydrogen fuel cell are assessed under contact pressure. To simulate the operational circumstances of the fuel cell, a specific force is applied to the contact region between the bipolar plate and the membrane electrode assembly (MEA) during the test. A mechanical press or load cell applies pressure to the material before and after the trial, and the fuel cell’s electrical output is monitored. The test findings can be used to assess the bipolar plate material’s quality, the MEA’s dependability, and the fuel cell’s overall performance [10,11,12]. To maintain its seal, the material must also resist deterioration and brittleness over time. The performance of these materials in a hydrogen fuel cell environment can be assessed using tensile testing, which can also help identify the optimum material for a particular application [13,14,15,16,17]. The outcomes of the tests can also be used to compare various gasket materials and choose the best choice for the system. It is crucial to consider the possibility of degradation owing to the challenging operating conditions of the fuel cell when selecting a gasket material for a hydrogen fuel cell. High pressures and temperatures are encountered while operating hydrogen fuel cells, as well as severe chemicals and gases. Choosing a gasket material that can resist these circumstances without deteriorating over time is crucial. PEMFCs have shown great promise as clean and efficient energy conversion devices for various applications. The performance and durability of PEMFCs depend on the integrity of their components, with gasket materials being critical for maintaining the fuel cell’s sealing efficiency.

Despite their prevalent use, a comprehensive comparative study between LSR and EPDM as PEMFC gasket materials is lacking in the current literature. This research addresses this knowledge gap and provides valuable insights into materials’ mechanical behaviour and performance under realistic operating conditions. The study will extract strain functions by employing experimental data and advanced FEA to understand how each material responds to different contact pressures and von Mises stress, ensuring accurate predictions of their behaviour during fuel cell operation. In [18], the study investigates the degradation of silicone rubber, EPDM, and a developed EPDM-2 compound as gasket materials in PEMFCs. The study compares the changes in properties and structure of a silicone rubber gasket caused by actual fuel cell use and accelerated ageing in acidic solutions. The results show that acid hydrolysis is the primary mechanism of silicone rubber degradation and that TFA solutions have a more aggressive effect on silicone rubber than sulphuric acid and Nafion solutions. EPDM 2 compound showed good performance with a low compression set value, making it a potential replacement for silicone rubber in PEMFCs. In [19], the study investigates the degradation of silicone rubber gaskets used in PEMFCs. The researchers found that the gaskets’ hardness increases and weight decreases with increasing temperature cycles, leading to cracks on the surface and changes in surface chemistry due to de-crosslinking and chain scission. The results highlight the importance of proper gasket materials in maintaining the electrochemical performance of PEMFCs over their long-term operation. A study examined how silicone rubbers of varying hardnesses degraded in various water solutions at 80 °C. As a result of extended exposure to acidic aqueous solutions, silicone rubbers decomposed more severely, according to the results. The study also found that weight loss measurements alone may not accurately characterise degradation and that strong acids led to significant cracking and void formation [20]. For optimal performance, the elastomeric gasket materials for PEM fuel cells are exposed to harsh environments and must have physical and chemical stability. In [21], the study investigates the chemical degradation of five materials in a simulated fuel cell solution using a dynamic mechanical analysis (DMA), analysing storage, loss modulus, and tan to determine glass transition temperature and other properties over 63 weeks. In [22], the study examines the stress-strain distribution of the sealing system in single-cell and multi-cell constructions at various operating temperatures using the steel-strip PEMFC model. Temperature and other parameters impact the sealing performance and mechanical behaviour of PEMFCs, as shown by the analysis of the impacts of compression ratio, fluid pressure, dislocation, and dimension on these two aspects. In [23], the study investigates using multilayered EPDM seal materials in PEM fuel cells for sustained long-term operation. The study finds that multilayered vulcanizates have higher hardness, better sealing capacity, and dimensional stability than blended materials, with nearly the same gas permeability. Ageing tests show that while mechanical properties decline with time, multilayered vulcanizates perform better than blended ones. In [24], the study analyses the impact of rubber material selection on the sealing performance of compression packers in multi-stage fractured horizontal wells. Constitutive experiments were conducted, and finite element models were established to study the influence of rubber materials and casing thickness on sealing performance under various setting pressures. The results show that the sealing performance decreases as the set pressure increases, and the B75 material was found to have the best sealing performance. This research provides essential information for designing compression packers and has significant implications for successfully implementing horizontal multi-stage fracturing. In [25], the study investigates the chemical degradation of five elastomeric gasket materials in a simulated and aggressive accelerated fuel cell solution for up to 63 weeks. Using optical microscopy, weight loss monitoring, atomic absorption spectrometer analysis, and ATR-FTIR spectroscopy, the study reveals that CR and LSR are not as stable as the other three materials, and FSR appears to be the most stable. A paper examines the change in properties and structure of silicone rubber gaskets used in a fuel cell stack. In [26], the study compares the effects of actual fuel cell use on accelerated ageing under elevated temperatures and acidic conditions. Results show that acid hydrolysis is the leading cause of degradation and that accelerated ageing tests accurately reflect the conditions of a fuel cell environment. The long-term chemical and mechanical stability of gaskets in PEM fuel cells is critical. In [27], the study investigated using silicone rubber specimens subjected to different compression loads and simulated environments. The weight change, morphological changes, and surface chemistry were studied using optical microscopy, ATR-FTIR, and XPS. The results showed significant changes in surface morphology, surface chemistry, and mechanical properties due to exposure to the simulated environments and compression loads over time. The acid concentration and compression load significantly impacted the silicone rubber material’s degradation [28]. In [29], the study uses hyperelastic models to evaluate the sealing effect of a flat rubber ring (FRR) in a roller bit. The Yeoh-revised model, based on single-axis compression stress, predicts Mises stress more accurately than the Yeoh model. The study demonstrates that the Yeoh-revised model better predicts the FRR’s sealing effect and Mises stress distribution, aiding in FRR structure optimisation for improved longevity in roller bits. The model achieves the highest R2 value of 0.9771, effectively addressing FRR’s soft property and contributing to more precise stress calculations. In [30], the study investigates the dynamic friction process of rubber seals in pneumatic servo systems, considering the influence of geometric errors. Rubber seals’ friction force and contact area were studied using a self-made friction test platform. A numerical model using finite element simulation revealed the impact of machining errors (roundness and straightness) on friction characteristics. The synergistic effects of roundness and straightness in rubber seal friction behaviour were explored, contributing to the accurate prediction of cylinder dynamic mechanical properties. In [31], the study investigates the influence of rubber hardness on tissue paper embossing, considering different configurations of rubber plates with varying hardness. The mechanical properties, softness, and bulk of the tissue products were evaluated. A finite element model replicating experimental results supports the use of rubber rolls with low hardness internally and high hardness externally. Optimising rubber roll hardness and configuration in embossing operations can enhance the critical properties of tissue paper products, providing valuable insights for the industry. In [32], the study presents a comparative analysis of 16 hyperelastic models for neoprene gaskets under uniaxial tensile loading. The selection of an appropriate model is essential for accurately predicting gasket behaviour when limited experimental data is available. The research provides insights into the most suitable hyperelastic constitutive model, ensuring both accuracy and safety margin for neoprene gasket applications, mitigating the risks associated with leakages, and enhancing overall safety in industrial and domestic appliances. LSR and EPDM are popular for PEMFC gaskets due to their excellent chemical resistance, elasticity, and compatibility with the fuel cell environment [33,34]. The contributions of this study are highlighted below:

- The study addresses the research gap by providing a comprehensive and direct comparison between two widely used gasket materials, LSR and EPDM, specifically in PEMFC applications.

- The study generates experimental data for LSR and EPDM gasket materials under tensile tests (uniaxial and biaxial) and ageing tests. This experimental data is essential for validating the subsequent Finite Element Analysis (FEA) models using contact pressure and von Mises stress and enhancing the accuracy and reliability of the study’s findings.

- By employing advanced FEA using the Marc software, the study extracts strain functions for both LSR and EPDM gaskets. This approach is significant as it enables researchers to understand how each material responds to different contact pressures and von Mises stress, providing valuable information on their mechanical behaviour and deformation characteristics.

- The study’s focus is on evaluating the contact pressure distribution and Von Mises stress distribution for LSR and EPDM gaskets. These analyses shed light on each material’s sealing efficiency and mechanical stability under varying tensile and ageing tests, directly addressing the research gap concerning the structural integrity and long-term reliability of PEMFC gasket materials.

- The study aims to assess the accuracy of various hyperelastic models, such as Ogden, Gent, Mooney-Rivlin, Yeoh, Neo-Hookean, and Arruda-Boyce, in representing the mechanical behaviour of LSR and EPDM gasket materials. By evaluating these models and their predictions against experimental and FEA data, this research will provide valuable insights into the most appropriate hyperelastic model for accurately simulating the behaviour of gaskets in PEMFC applications.

2. Materials and Methods

PEMFC gasket material is crucial in fuel cell technology and serves as a seal between the different layers of the fuel cell stack, allowing the flow of hydrogen and oxygen while preventing leaks. The theoretical background of PEMFC gasket material revolves around its ability to withstand high temperatures, provide excellent chemical stability and high electrical conductivity, and exhibit high compression resilience. Additionally, it should have low gas permeability to maintain a high level of performance. The choice of material depends on various factors, including fuel cell operating conditions, compatibility with the other components, and cost [35,36,37,38,39].

2.1. Overview of Gasket Material Selection

Gasket materials are critical in sealing, insulation, and vibration reduction in various automotive, aerospace, and industrial equipment applications. Selecting a suitable gasket material depends on several factors, such as temperature, pressure, fluid compatibility, and chemical resistance. The most common gasket materials include EPDM, FKM, LSR, and VMQ. EPDM is a synthetic rubber known for its excellent weather, ozone, and ageing resistance. It is suitable for various applications and can handle temperatures ranging from −60 °C to 150 °C. EPDM is also compatible with water, steam, and various automotive fluids. EPDM gaskets are widely used in automotive applications such as radiator hoses, coolant systems, and washer systems [40,41,42,43,44]. LSR is a silicone rubber produced in liquid form and cured to form a solid rubber. LSR offers excellent weather and ageing resistance, a low compression set, and high tear resistance. It can handle temperatures from −60 °C to 200 °C and is suitable for applications requiring high-temperature stability, chemical resistance, and low toxicity [45,46,47,48,49,50,51,52]. FKM (Fluoroelastomer) is a synthetic rubber known for its excellent chemical and heat resistance. It can handle temperatures up to 200 °C and is suitable for aggressive chemical environments. FKM gaskets are widely used in fuel systems, chemical processing, and automotive engine seals. VMQ (Viton-A) is a fluoroelastomer known for its excellent chemical and heat resistance. It can handle temperatures up to 204 °C and is suitable for aggressive chemical environments. VMQ gaskets are widely used in fuel systems, chemical processing, and automotive engine seals [53,54,55,56,57]. Selecting the suitable gasket material depends on the specific application requirements, such as temperature, pressure, fluid compatibility, and chemical resistance. EPDM, FKM, LSR, and VMQ are some of the most common gasket materials and offer unique benefits and limitations. A comprehensive material selection process that considers each material’s specific application requirements and the benefits and regulations is necessary to ensure optimal performance.

2.2. Overview of Hyper-Elastic Constitutive Models

Hyperelastic constitutive models mathematically represent the stress-strain relationship of rubber-like materials. These models are crucial in designing and analysing many technical applications because they forecast how rubber-like materials behave under various loading circumstances. Ogden, Yeoh, Mooney Rivlin, Neo Hookean, Arruda Boyce, and Gent are some of the most commonly used hyperelastic constitutive models [58]. A well-known hyperelastic constitutive model designed to simulate the mechanical behaviour of rubbery materials is Ogden’s (1984) model. The right Cauchy-Green deformation tensor’s first and second invariants are assumed to be functions of the material’s strain energy density in this model. The Yeoh (1993) model is a more intricate hyperelastic constitutive model created to represent rubber-like materials’ nonlinear and anisotropic behaviour. The first and second invariants of the right Cauchy-Green deformation tensor and the first invariant of the deviatoric tensor are assumed to be functions of the strain energy density of the material in this model. A two-parameter hyperelastic constitutive model called the Mooney Rivlin (1940) model was created to simulate the mechanical behaviour of rubber-like materials. The right Cauchy-Green deformation tensor’s first and second invariants are assumed to be a function of the material’s strain energy density in this model [59,60]. A one-parameter hyperelastic constitutive model called the Neo-Hookean (1949) model was created to simulate the mechanical behaviour of rubber-like materials. The deviatoric component of the right Cauchy-Green deformation tensor is assumed to be proportional to the strain energy density of the material in this model. An eight-parameter hyperelastic constitutive model called the Arruda Boyce (1993) model was created to simulate the mechanical behaviour of rubber-like materials. The first and second invariants of the right Cauchy-Green deformation tensor and the first invariant of the deviatoric tensor are assumed to be functions of the strain energy density of the material in this model. A three-parameter hyperelastic constitutive model called the Gent (1995) model was created to represent the mechanical behaviour of rubber-like materials accurately. The first and second invariants of the right Cauchy-Green deformation tensor and the first invariant of the deviatoric tensor, [61], are assumed to be functions of the strain energy density of the material in this model. These hyperelastic constitutive models offer different levels of complexity and precision to represent the mechanical behaviour of rubber-like materials. The engineering application’s unique needs and the accuracy of predicting how the rubber-like material will behave will determine the best model [62,63,64,65,66]. Hyperelastic models describe the stress-strain behaviour of materials that exhibit large deformations while preserving their elastic behaviour. The respective equations and parameters are highlighted in Equations (1)–(6).

- Neo-Hookean model parameters:

- represents the strain energy density.

- is the shear modulus (also known as the material’s Lamé parameter), which characterises the material’s resistance to shear deformation.

- is the bulk modulus, which characterises the material’s resistance to volume change.

- is the first invariant of the modified deformation tensor.

- J is the volume ratio of the deformed state to the undeformed state, known as the Jacobian.

Mooney Rivlin model parameters:

represents the strain energy density.

and : Material constants

: is the first invariant of the deformation tensor

: is the second invariant of the deformation tensor

Ogden model parameters:

: represents the strain energy density

: are material constants associated with each term in the model

: are hyperparameters that determine the form of the strain energy density function. The choice of these parameters influences the model’s ability to fit experimental data

N: is the number of terms in the model

: is the first invariant of the deformation tensor raised to the power

Yeoh model parameters:

: represents the strain energy density

: are material constants associated with each term in the model. These constants determine the strength and shape of each term in the polynomial expansion

N: Order of the polynomial expansion

: is the first invariant of the deformation tensor

Gent model parameters:

represents the strain energy density.

is the shear modulus, which characterizes the material’s resistance to shear deformation.

is a hyperparameter that determines the form of the strain energy density function and influences the material’s behaviour.

: is the first invariant of the deformation tensor raised to the power

Arruda and Boyce model parameters:

represents the strain energy density.

are material constants associated with each term in the model.

are hyperparameters that determine the form of the strain energy density function. The choice of these parameters influences the model’s ability to fit experimental data.

is the first invariant of the modified deformation tensor, raised to the power

N is the number of terms in the model.

B is another material constant, typically associated with incompressibility.

J is the volume ratio of the deformed state to the undeformed state, known as the Jacobian.

The Neo-Hookean model is apt for nearly incompressible materials like silicone rubber and soft biological tissues. It relies on two material constants, the shear modulus and bulk modulus , and assumes minimal volume change. However, it’s not suitable for highly compressible materials. The Mooney-Rivlin model is more straightforward yet effective for moderately nonlinear rubber-like materials. Material constants and are obtained through curve fitting, matching experimental data. The Ogden model offers versatility as it can be tailored to various rubber-like materials. It incorporates material constants and that can be adjusted via curve fitting. The Yeoh model is flexible, allowing constant material adjustments to suit different rubber materials. Its complexity can be fine-tuned by altering the number of terms N. The gent model provides a versatile representation of materials with hyperelastic and near-incompressible characteristics. Material constants and are determined through curve fitting. It’s well-suited for modelling biological tissues, elastomers, and soft materials displaying nonlinear behaviour under large deformations. The Arruda-Boyce model is a simplified representation suitable for rubber-like materials. It involves adjusting material constants and through curve fitting to match specific material properties.

2.3. Proposed Gasket Material FEA Model

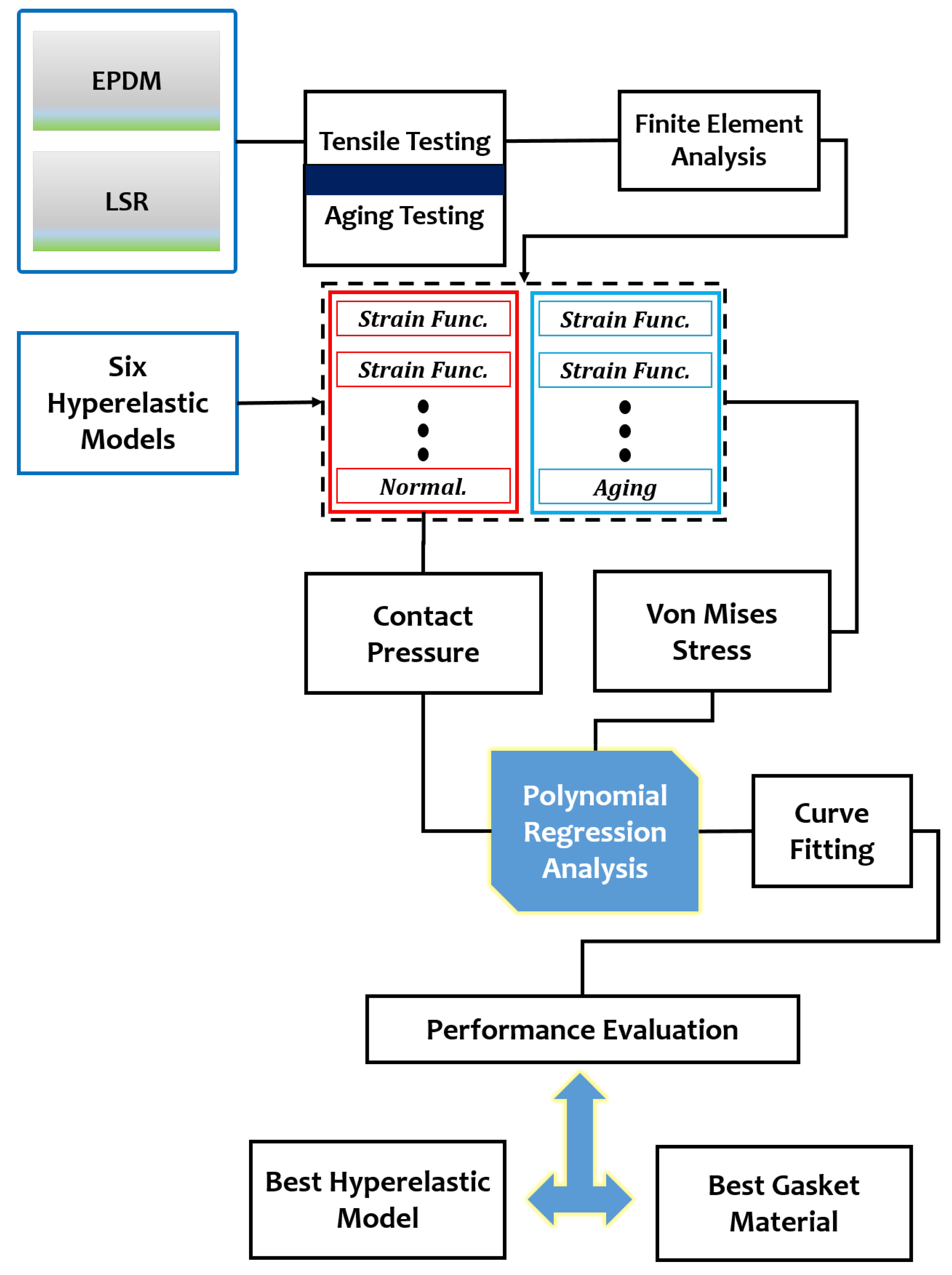

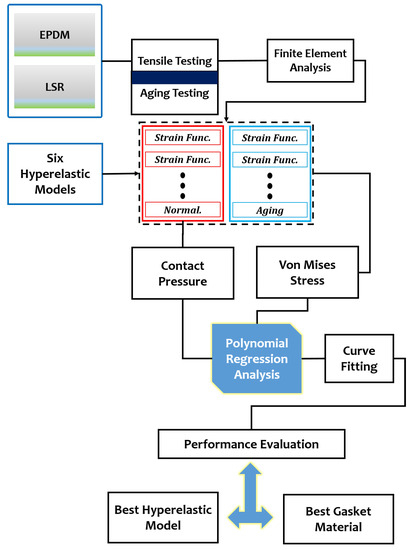

Selecting the suitable gasket material is crucial to ensuring the reliable and efficient performance of a Proton-Exchange Membrane Fuel Cell (PEMFC). Following these steps, you can create a PEMFC gasket material selection framework to help you select the best gasket material for your specific fuel cell application. During FEA simulations, contact pressure and von Mises stress are calculated based on the component’s material properties, loads, and geometric characteristics. The results of these simulations can be used to make informed design decisions and improve the performance and reliability of the component. Figure 2 explains the breakdown process for the gasket materials and the decision-making paradigm. The proposed FEA model involves creating a comprehensive simulation of the gasket assembly, considering material behaviour, contact interactions, and loading conditions. The results, including contact pressure and von Mises stress distributions, provide insights into gasket performance, stress distribution, and potential failure modes, guiding design decisions and ensuring reliable sealing systems. The proposed FEA model involves creating a comprehensive simulation of the gasket assembly, considering material behaviour, contact interactions, and loading conditions. The results, including contact pressure and von Mises stress distributions, provide insights into gasket performance, stress distribution, and potential failure modes, guiding design decisions and ensuring reliable sealing systems. The proposed FEA model steps are highlighted as follows:

Figure 2.

PEMFC Gasket Material Framework.

- Geometry and Mesh Generation: Create a detailed 3D geometry of the gasket and its sealing components. Generate a finite element mesh for the entire assembly, including the gasket, mating surfaces, and bolts or fasteners.

- Material Properties: Define the material properties of the gasket using a suitable hyperelastic model (e.g., Neo-Hookean, Mooney-Rivlin, etc.). Input the material parameters derived from experimental data.

- Boundary Conditions: Apply appropriate boundary conditions to simulate the actual operating conditions of the gasket assembly.

- Contact Modelling: Define the contact interactions between the gasket and the mating surfaces. This step is crucial to accurately simulate how the gasket deforms and interacts with the surrounding components. Choose an appropriate contact algorithm, such as penalty-based or augmented Lagrange, and specify friction coefficients if friction plays a role in sealing.

- Load Application: Apply loads or pressures that mimic the operational conditions of the gasket. These loads might include internal or external forces, thermal expansion, mechanical loading, or a combination.

- Analysis and Solution: Perform a nonlinear static analysis to simulate the deformation and stress distribution in the gasket and the surrounding components. Solve the FEA problem iteratively, considering the nonlinearities introduced by the hyperelastic material behaviour and contact interactions.

- Results Interpretation: Extract and analyse the results, which include:

- Displacements and deformations of the gasket and other components.

- Strains and stresses, including von Mises stress, throughout the assembly.

- Contact pressures at the gasket’s sealing surface.

- Focus on areas of interest, such as the gasket-contacting regions and regions prone to stress concentrations.

- Validation and Comparison: Validate the FEA model by comparing the predicted results to experimental data or known analytical solutions. Assess the model’s accuracy and reliability in capturing the behaviour of the gasket assembly under different loading conditions.

2.4. Experimental Testing for the Gasket Materials

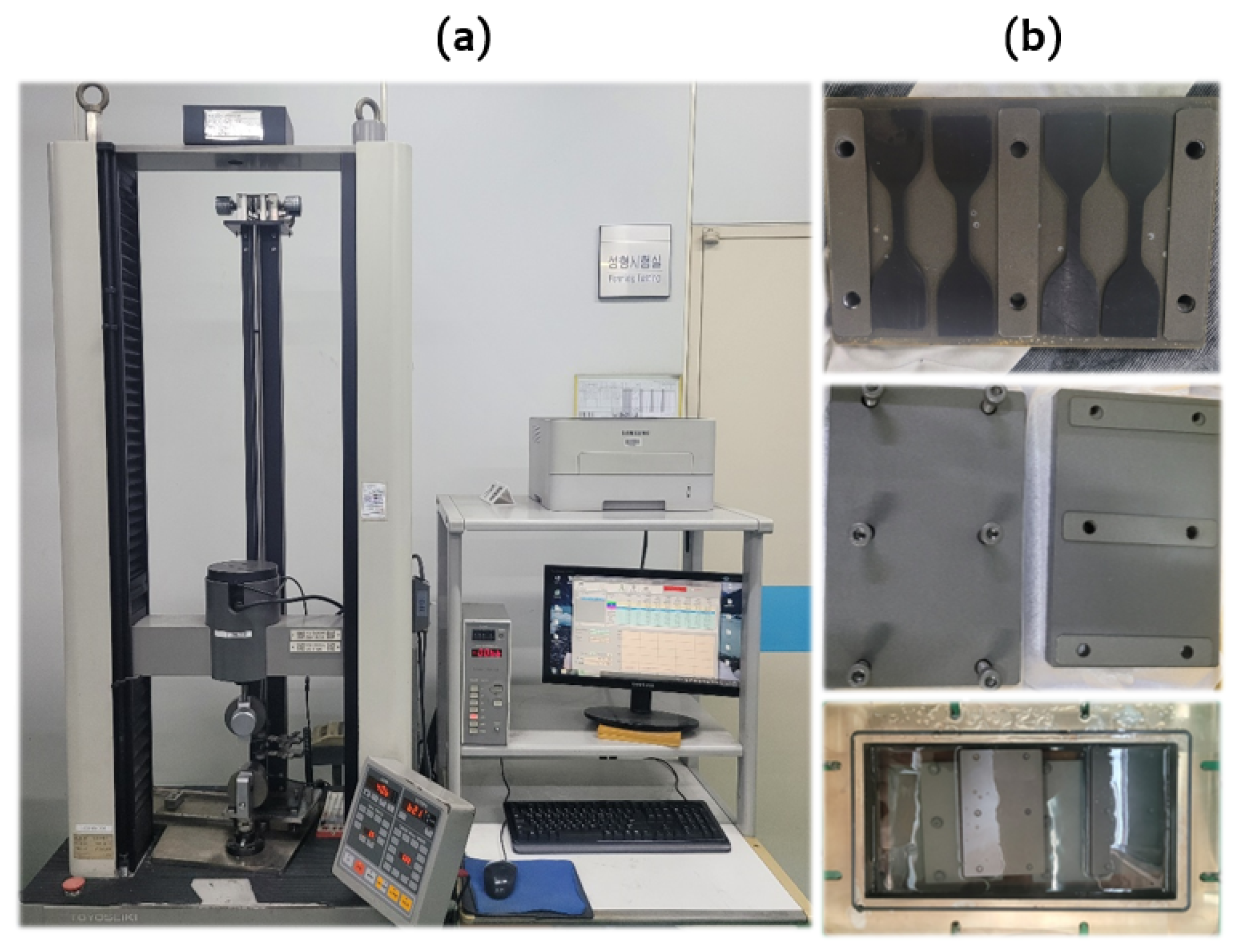

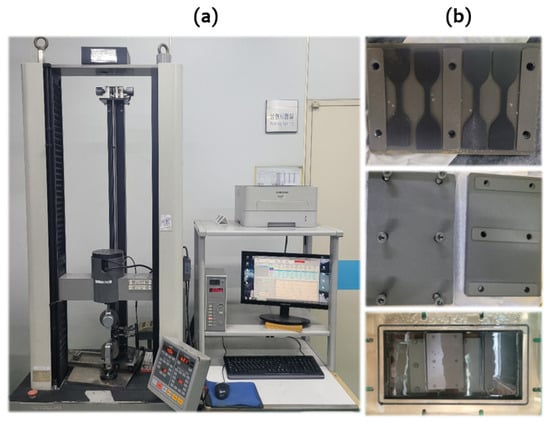

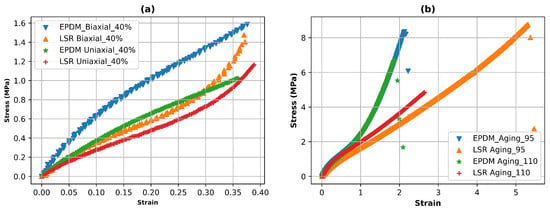

Biaxial and uniaxial testing determine the mechanical properties of materials, such as strength, stiffness, and ductility. The primary difference between the two tests is the direction of the applied force. Uniaxial testing involves applying a single force to the tested material in one direction. In contrast, biaxial testing uses two forces in different directions simultaneously. The testing result can reveal necessary information about the material’s behaviour and properties. Generally, uniaxial testing provides a more superficial, straightforward analysis of a material’s behaviour under tension or compression. When conducting an experimental study to choose the best material, it is essential to consider the application’s specific requirements. For example, if the material is subjected to complex loads in multiple directions, biaxial testing may provide more accurate information about its behaviour in real-world applications. Conversely, uniaxial testing may be sufficient if the material is only subjected to unidirectional forces. On one hand, Figure 3a shows the experimental procedure capturing the uniaxial and biaxial testing. The testing was conducted using the LLOYD material testing equipment produced by AMETEK Sensors, Tests, and Calibration (STC). On the other hand, Figure 3b represents the ageing experimental procedure using the sulfuric solution immersed for 3000 h, equivalent to 125 days.

Figure 3.

PEMFC Gasket Experiment (a) Tensile Testing (b) Ageing Testing.

Interestingly, for the ageing procedure, the gasket material was cut into appropriate sizes and shaped suitable for testing, ensuring that the samples were free from defects or contamination. A sulfuric acid solution was prepared with a concentration relevant to the operational conditions of the PEMFC. The solution matched the typical sulfuric acid concentration in the fuel cell environment. This concentration is usually in the range of 30% to 85% sulfuric acid by weight. The ageing chamber or exposure apparatus was set up where the gasket material samples would contact the sulfuric acid solution. The ageing temperature and the duration for which the samples will be exposed to sulphuric acid were determined. The temperature and ageing time was pegged to 95 °C to 110 °C to represent the expected operating conditions of the PEMFC. The gasket material samples were immersed in the sulfuric acid solution within the ageing chamber. It was ensured that the gasket samples were fully submerged and not exposed to air during ageing. The ageing conditions were carefully monitored to maintain the desired temperature and acid concentration. Based on the ageing time, the gasket samples were removed periodically from the chamber at predefined intervals to assess changes in the material properties over time.

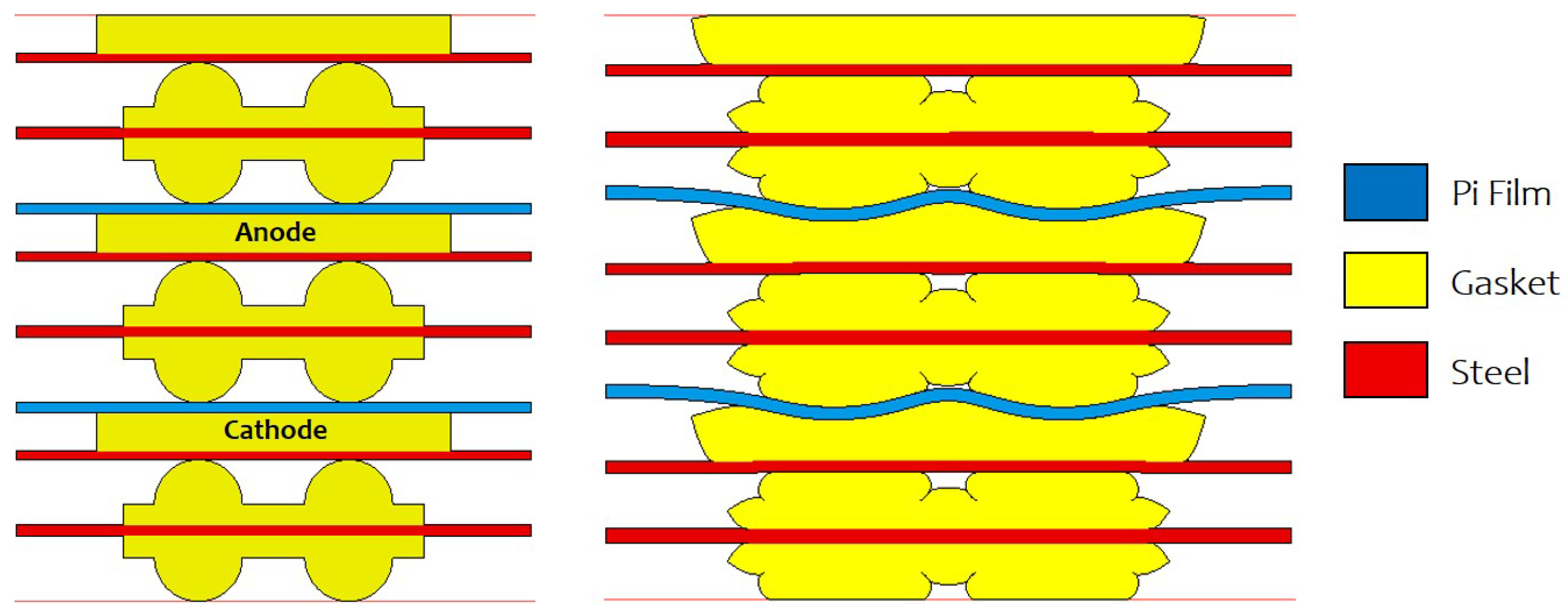

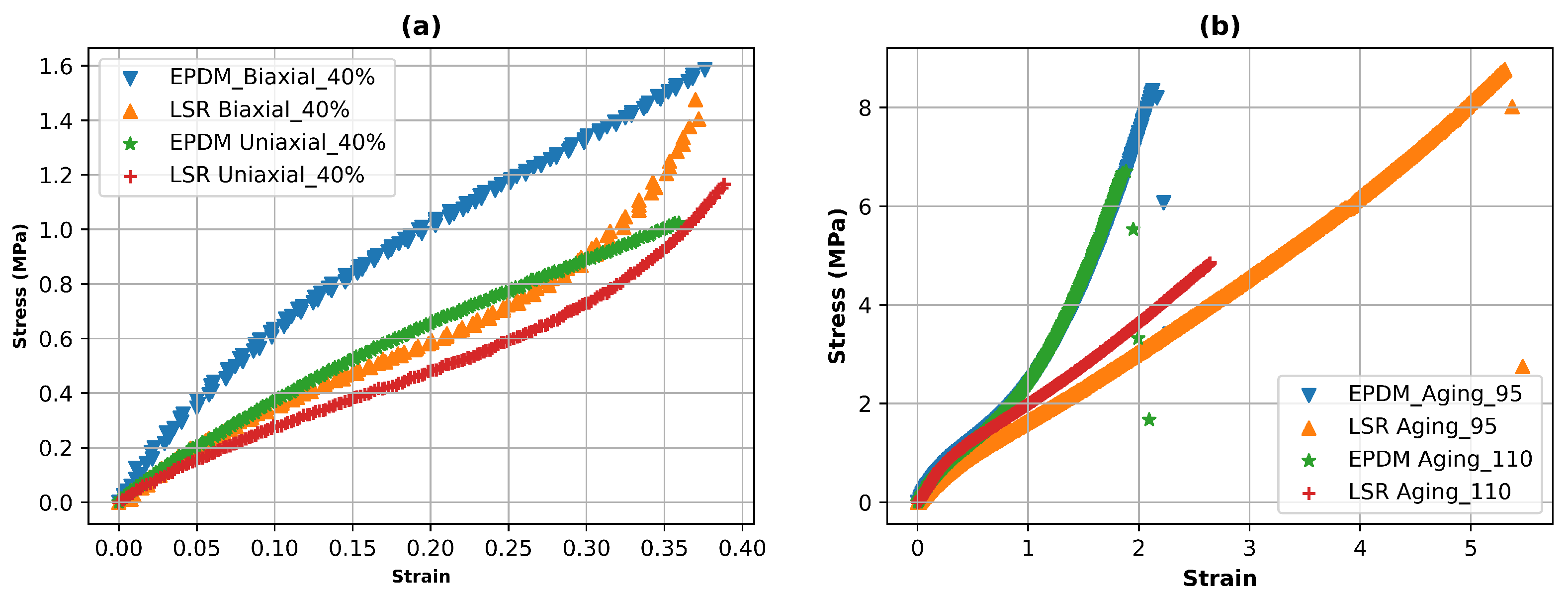

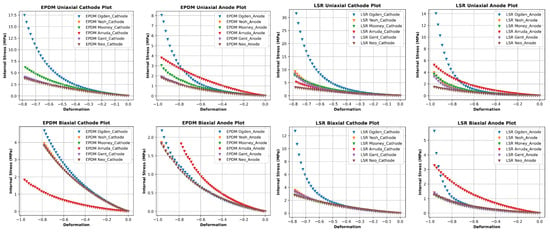

Figure 4 shows the cross-section of the gasket material comprising the anode, cathode, pi film, and steel, with their labels showing, respectively, as assembled in the figure. Ultimately, the best material choice will depend on various factors, including the specific properties required for the application, the cost and availability of different materials, and the results of any experimental testing. In this study, we have carried out the experimental tensile using both biaxial and uniaxial techniques to have a comprehensive paradigm for selecting the best gasket material. As can be seen from Figure 5a, it consists of four plots under the tensile condition, namely EPDM Biaxial (blue colour), LSR Biaxial (orange colour), EPDM Uniaxial (green colour), and LSR Uniaxial (red colour), respectively. Interestingly, another set of gasket samples was exposed to compression testing at varying temperatures, and the resulting data is plotted and shown in Figure 5b.

Figure 4.

A cross-section/schematic of the experimental procedure under gasket tensile testing.

Figure 5.

(a) Stress-Strain curve under biaxial and uniaxial tensile testing at 40% displacement. (b) Stress-Strain curve under ageing technique.

3. Results and Discussion

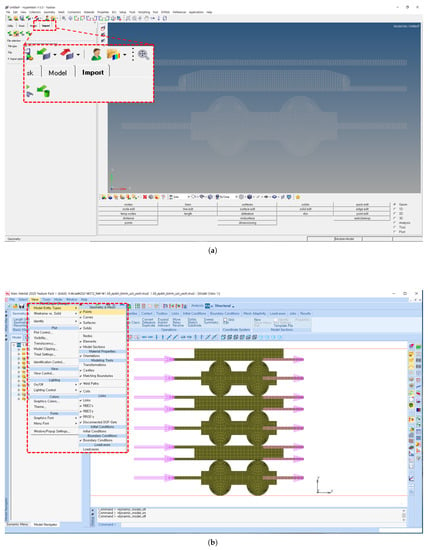

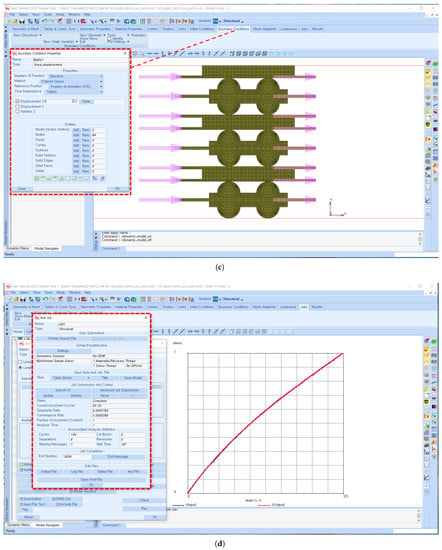

3.1. Gasket Material FEA Modelling Characterization

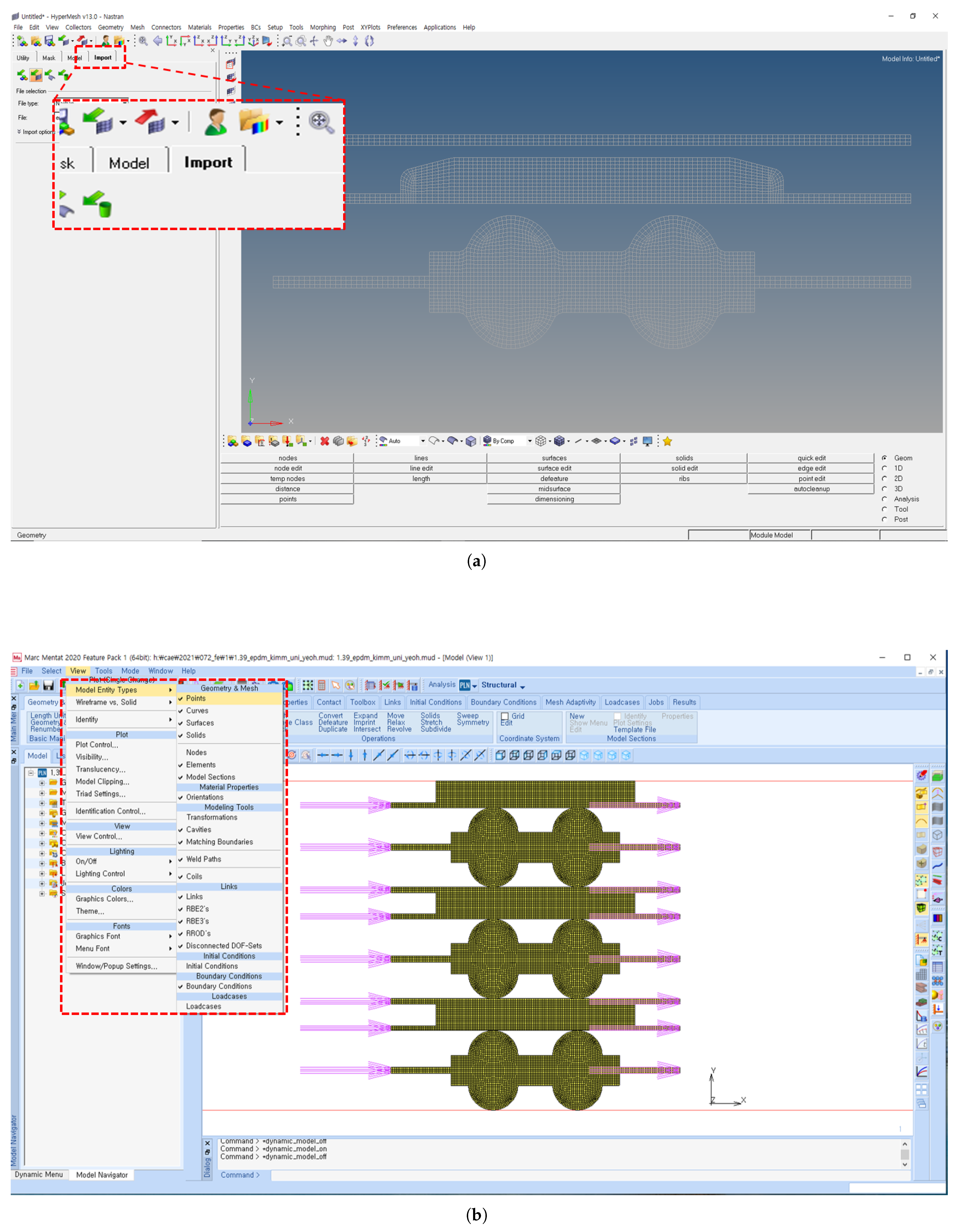

Modelling and characterization of gasket materials can be achieved using contact pressure and Von Mises stress. The utilisation of the MARC program involves a structured sequence of steps to conduct FEA modelling. This process encompasses several crucial stages, including defining element types, establishing geometric properties, inputting material property values, configuring contact interactions, specifying boundary conditions, setting up load cases, and configuring job parameters. Upon completing these steps, the analysis generates insightful results that are pivotal for understanding the behaviour of rubber components. The primary focus is on critical parameters such as von Mises stress, contact pressure, and deformation. These parameters play a pivotal role in assessing the structural integrity and performance of the components under scrutiny. Contour bands are employed to comprehend the distribution of these numerical values across the analysed model. These bands offer a visual representation of the parameter variation, allowing for the identification of peak values in distinct regions like the anode gasket, cathode gasket, and plate. The evaluation of contact pressure is particularly noteworthy because it is treated as a vector quantity. The analysis allows for generating load characteristic graphs. These graphs further aid in comprehending load-bearing trends and stress variations under different conditions. This study details a comprehensive methodology for employing the MARC program in FEA modelling. By systematically following the outlined steps, valuable insights into the mechanical behaviour of the gasket components are gained, highlighting critical parameters such as von Mises stress, contact pressure, and deformation. The utilisation of contour bands and load characteristic graphs enhances the clarity and depth of the analysis, facilitating a robust understanding of component performance. Following the illustration of the FEA individual process comprising contact pressure and Von Mises stress as shown in Figure 6, the resulting modelling parameters for each hyperelastic model are summarised in Table 1 and Table 2 for the EPDM and LSR gasket material, respectively. The two gasket materials under study, namely EPDM and LSR, were subjected to both contact pressure and von Mises stress. In contrast, the respective material parameters were recorded for each of the hyperelastic models, namely: Mooney Rivlin(3), Yeoh(3), Ogden(6), Neo Hookean(1), Arruda Boyce(2), and Gent(2), with their respective number of parameters in the bracket.

Figure 6.

The FEA process description (a) by importing the CAD file in Hypermesh, and exporting the mesh after specifying the drag in Hypermesh, (b) importing the mesh files into MARC, and Setting Geometry & Mesh Model-entity types for models, (c) specifying the boundary conditions, and selecting strain energy function, (d) The curve of the graph is fitted through experimental data, and Turning the interpretation around to check the interpretation results.

Table 1.

Hyperelastic Model Parameter Values for the selected RLM under dual tensile conditions.

Table 2.

Hyperelastic Model Parameter Values for the selected RLM under ageing conditions.

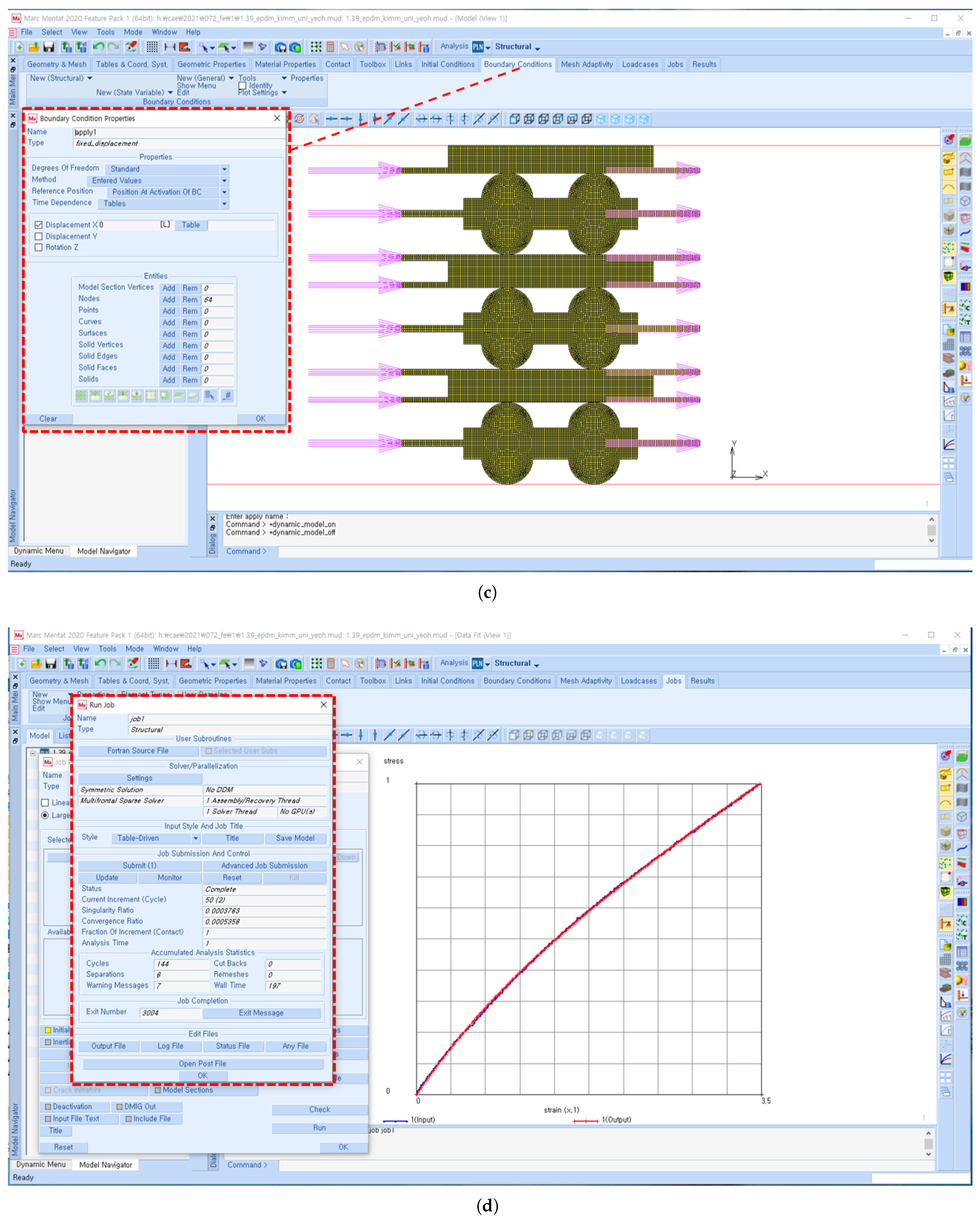

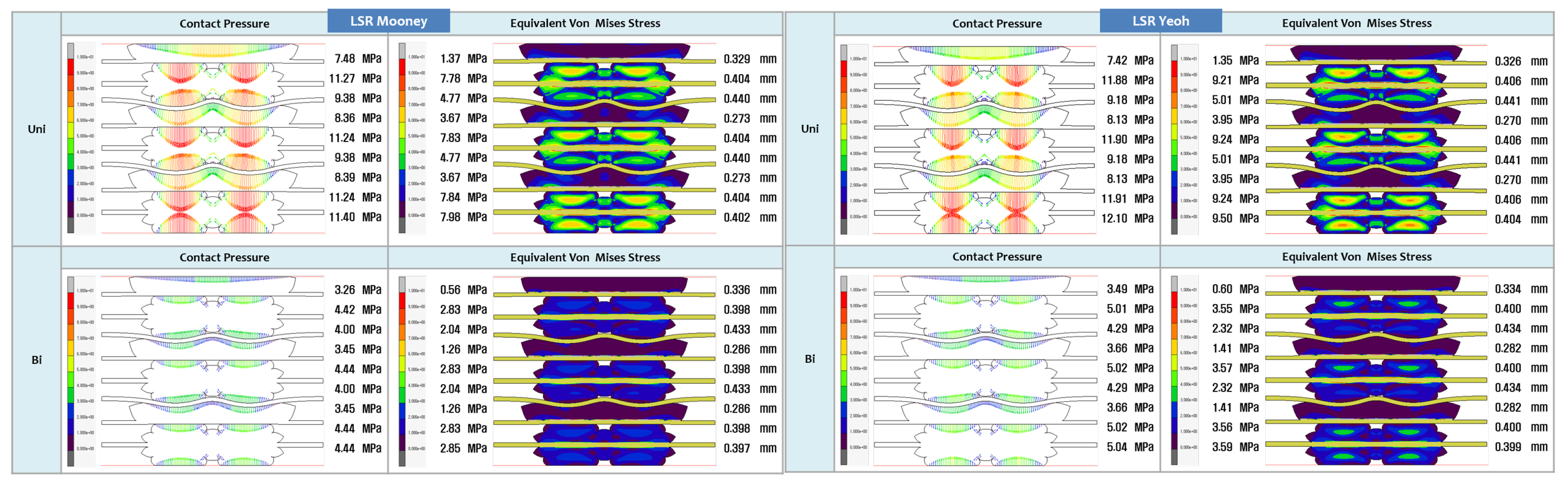

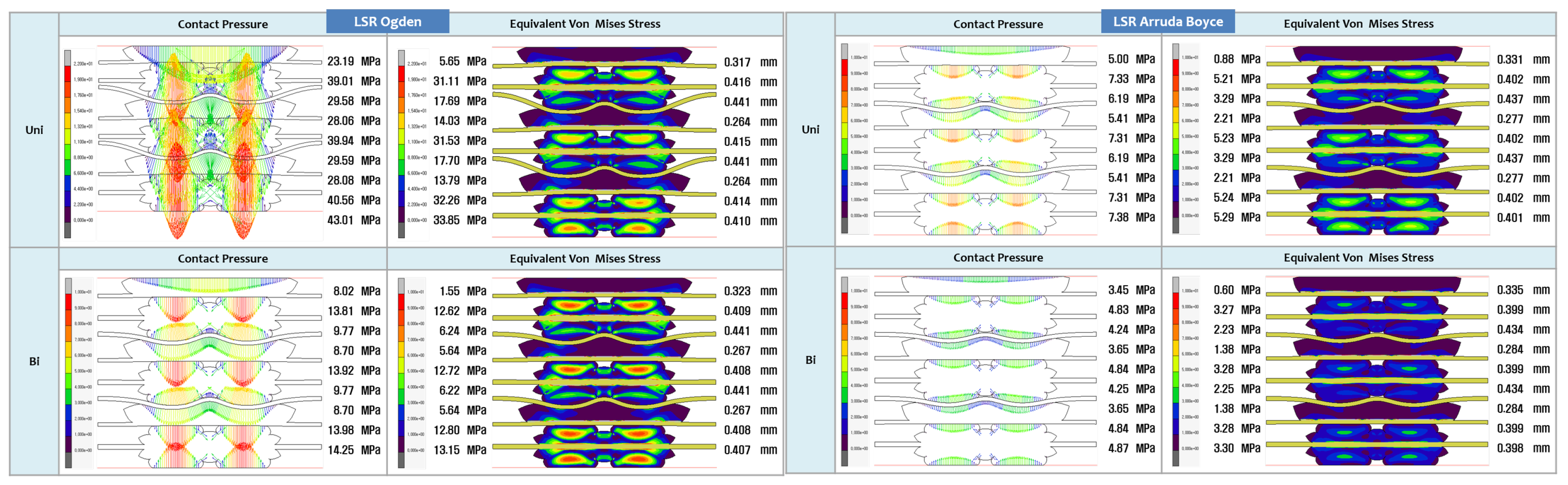

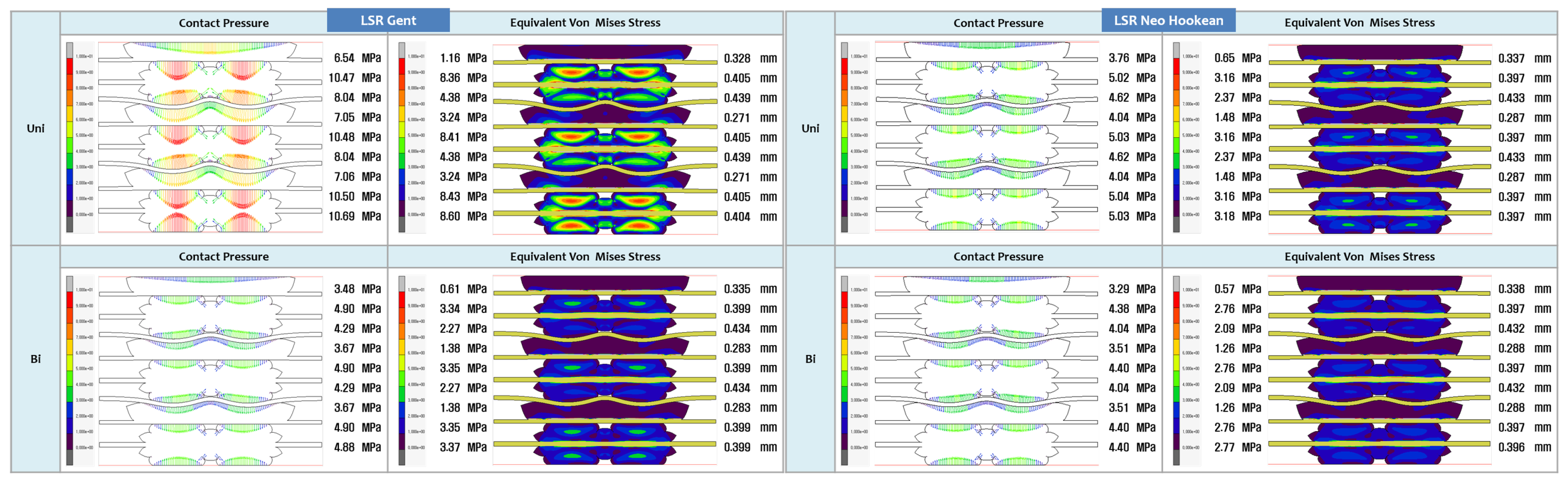

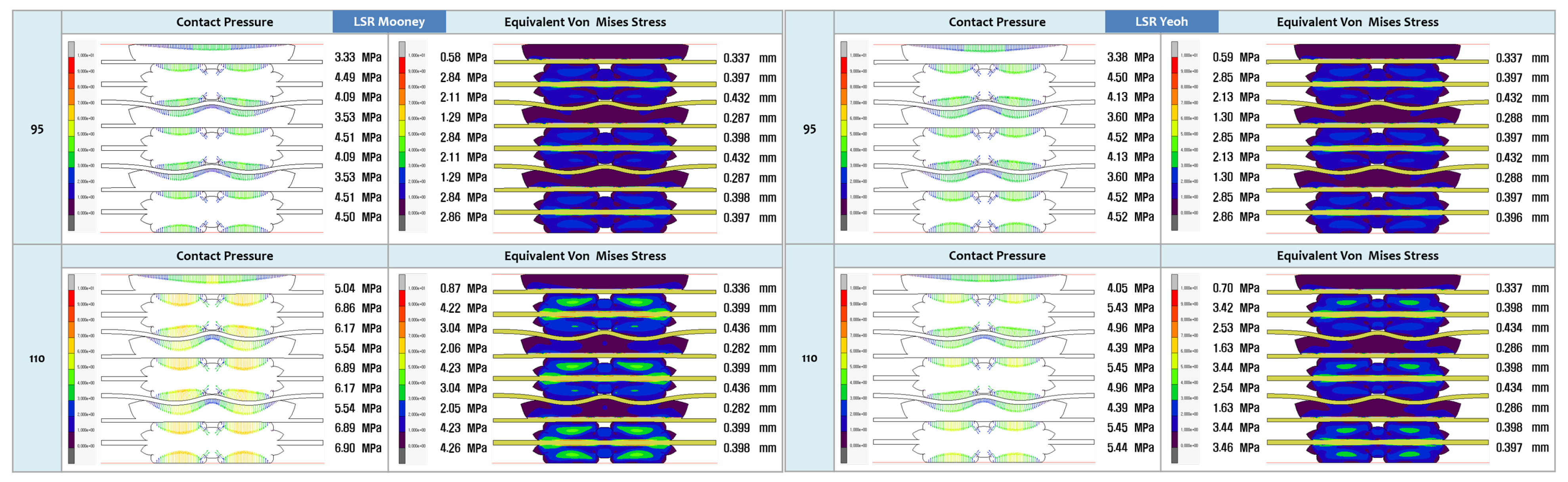

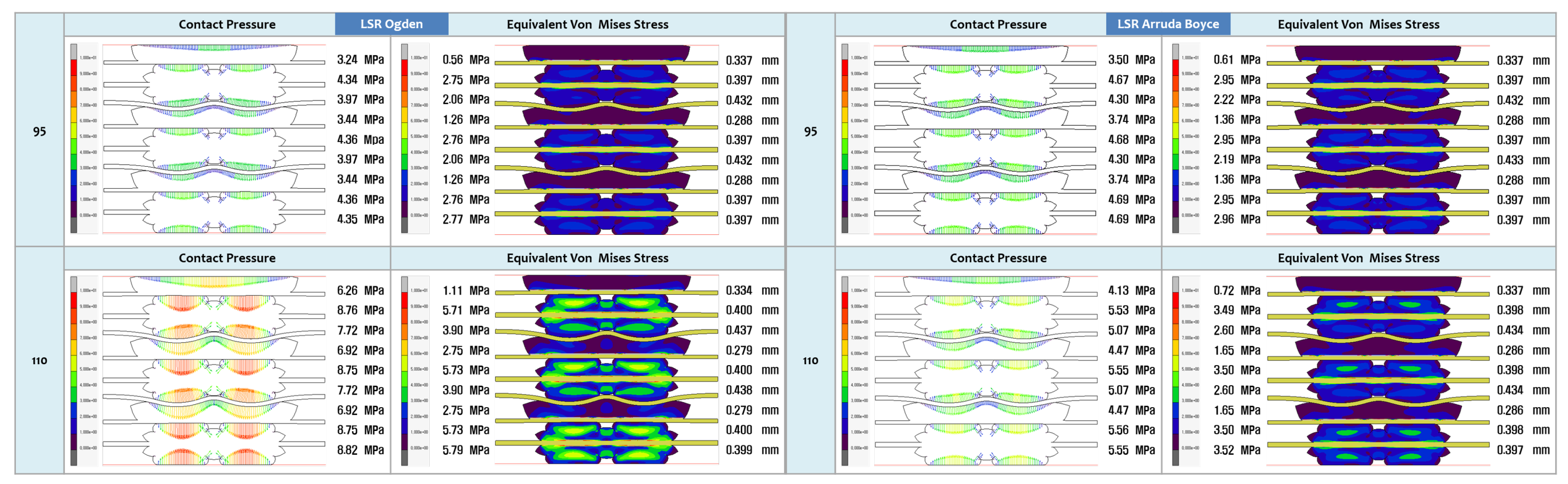

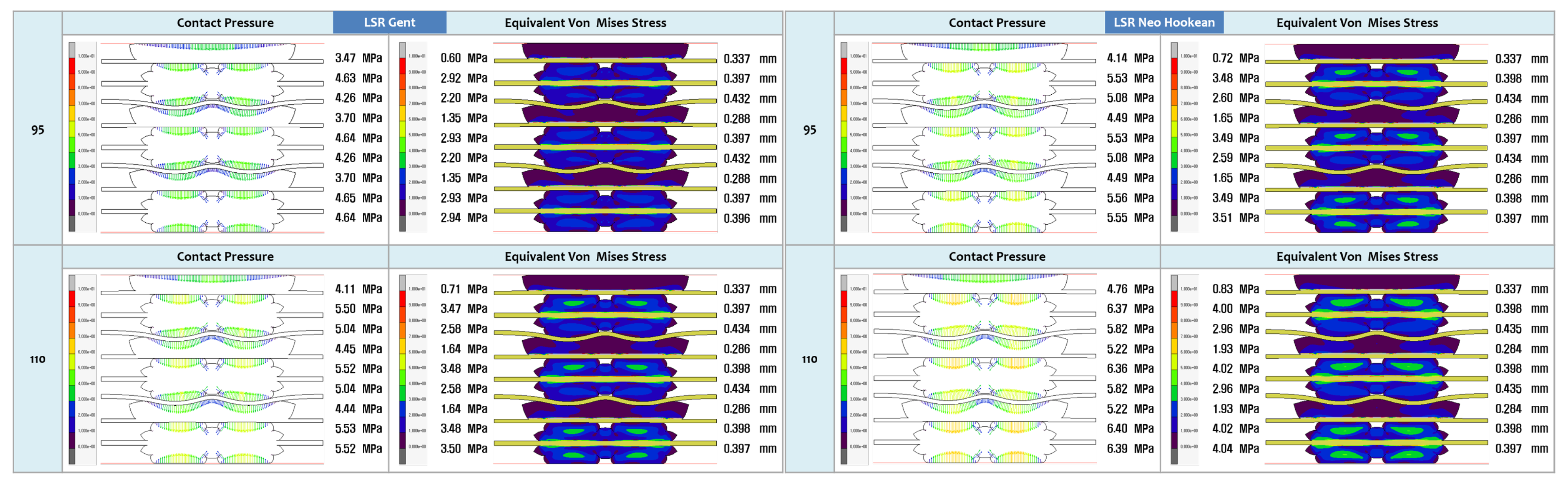

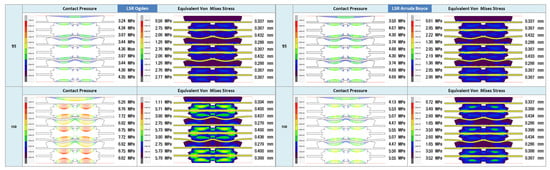

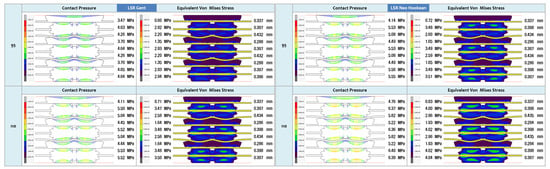

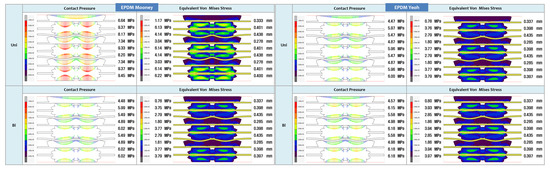

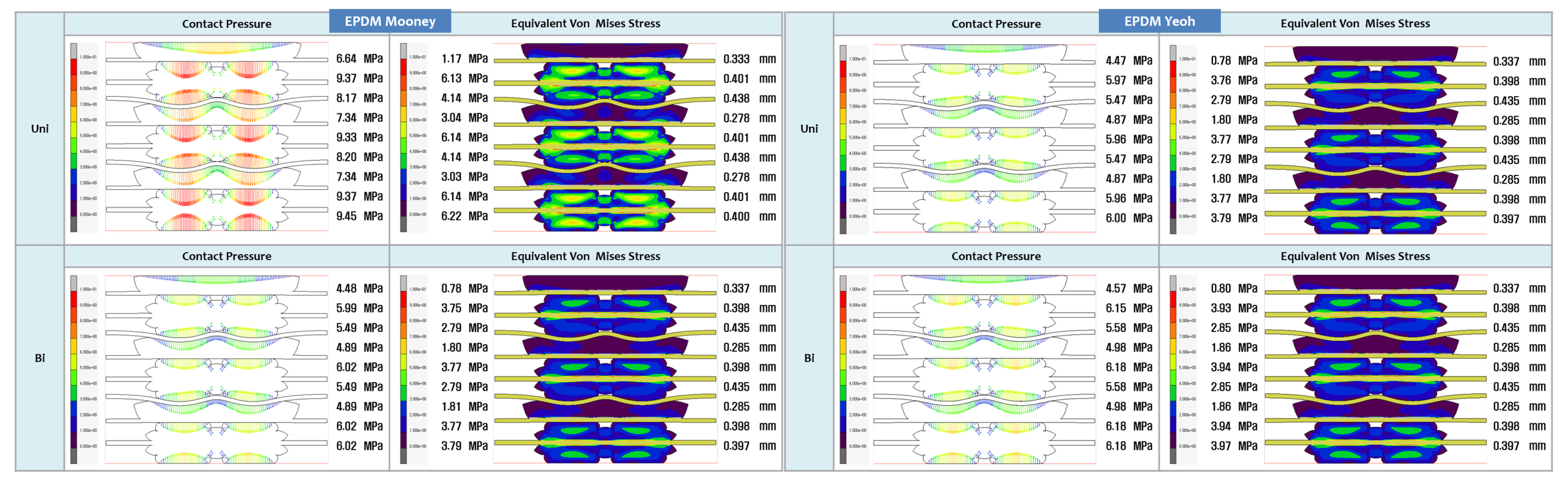

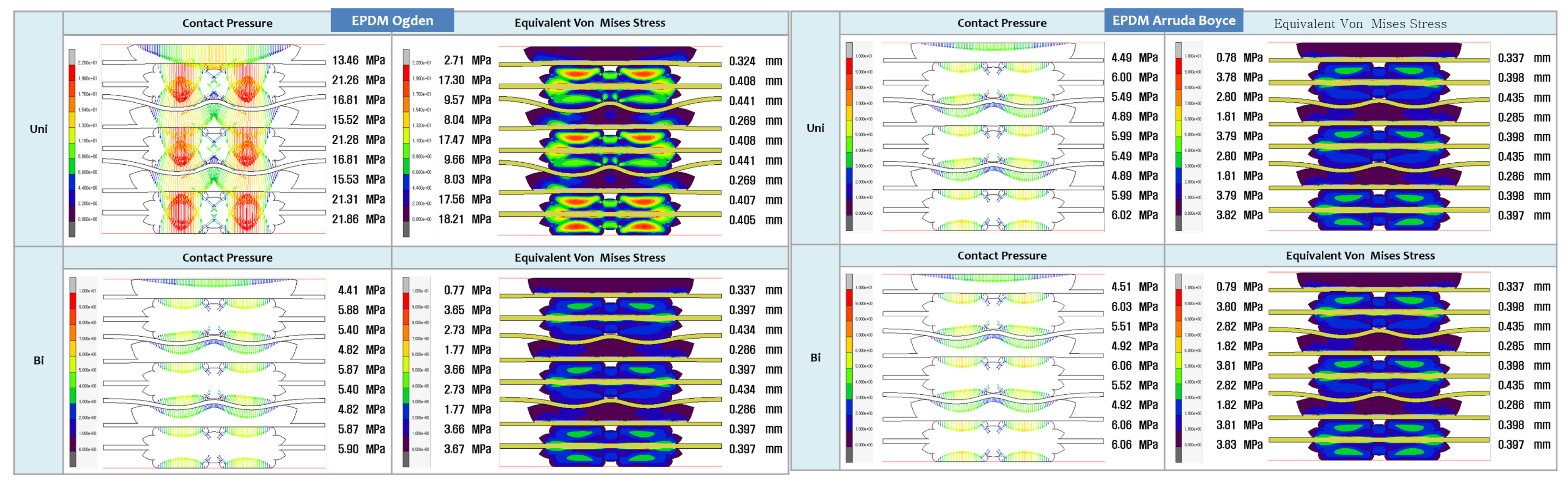

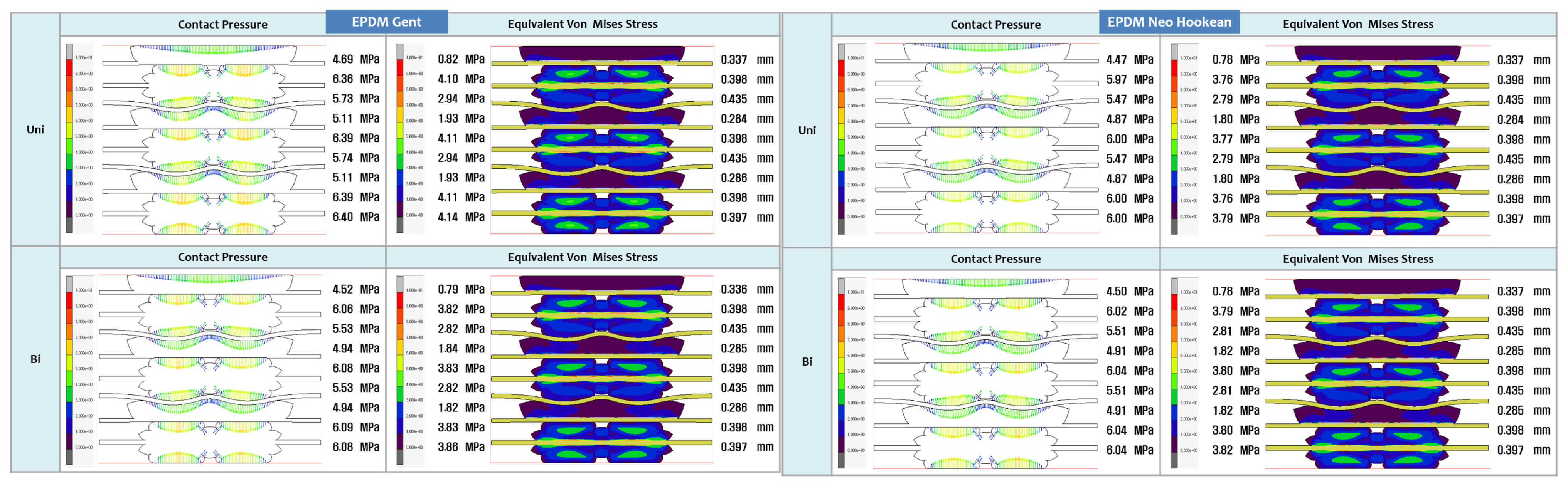

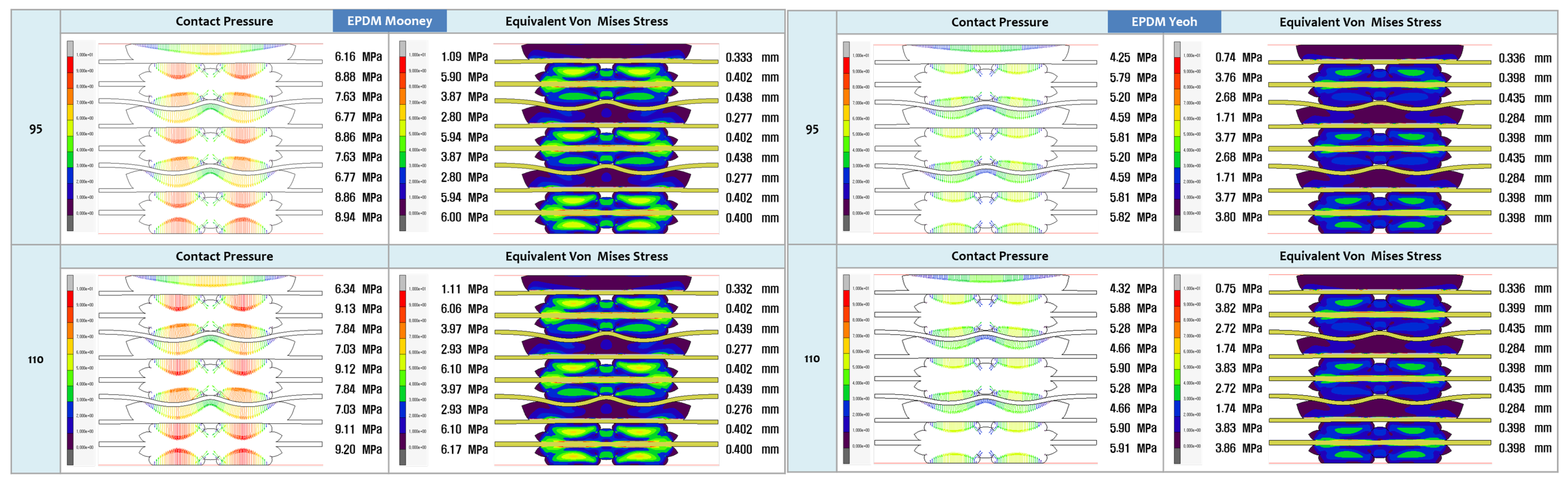

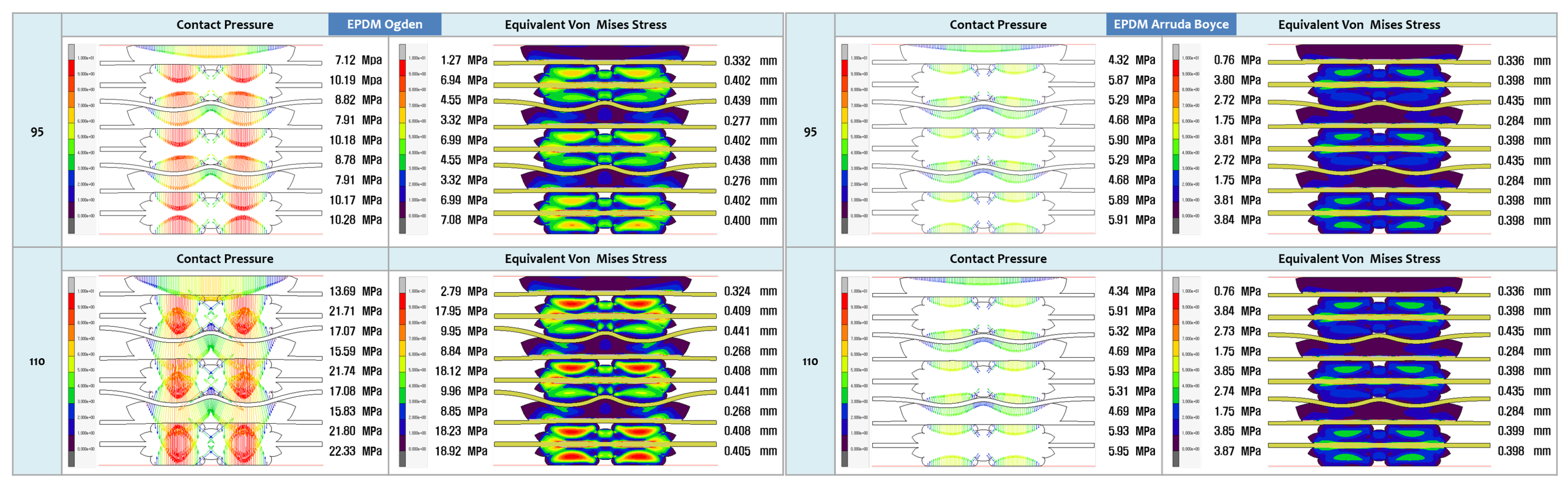

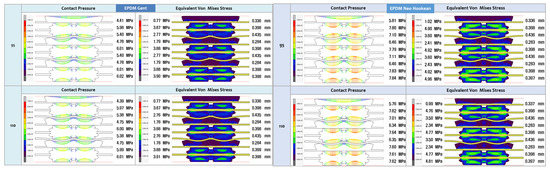

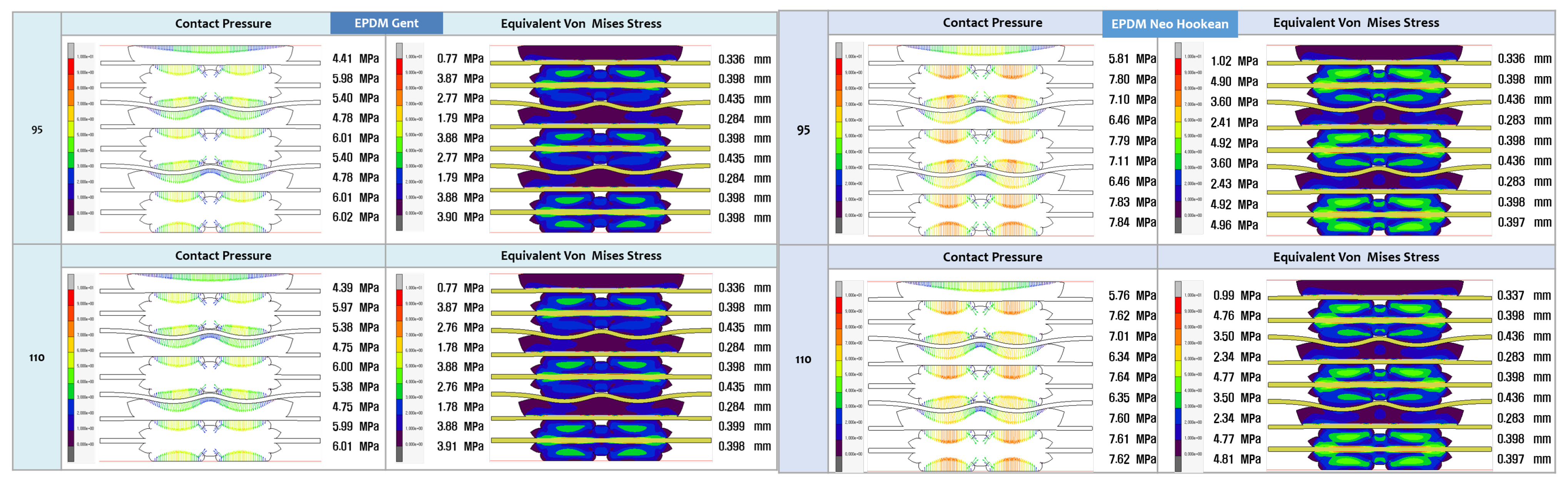

3.2. FEA Modelling Visualization

Contact pressure heatmap visualisation depicts the distribution of forces exerted between contacting surfaces within a simulated structure. MARC software achieves this by assigning colours to different pressure levels. The warmer red and orange denote higher pressures in the resulting heatmap, while cooler colours like blue and green represent lower pressures. This visualisation aids in identifying regions of concentrated force transmission, potential stress concentrations, and contact separation or sliding areas. The von Mises stress heatmap portrays the distribution of equivalent stress levels, combining different types of stresses to assess a material’s potential for yielding or failure. By employing colour gradients, this visualisation method offers insight into stress concentrations, critical areas of deformation, and potential failure points. Warmer colours signify higher stress levels, while cooler ones represent lower ones.

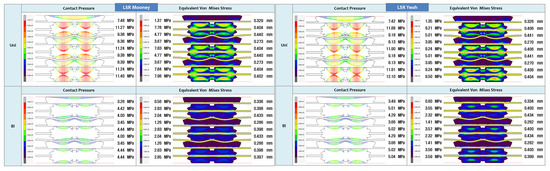

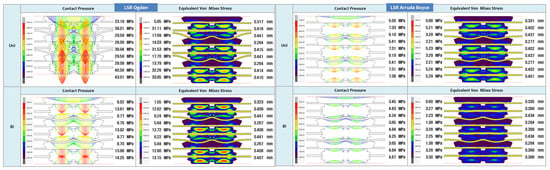

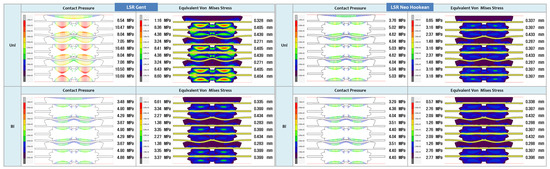

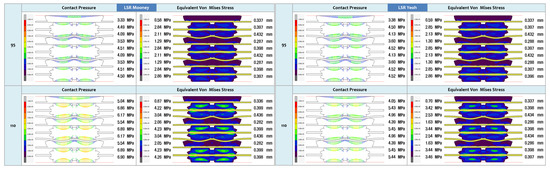

The resulting visualisation following the FEA modelling was designed to capture the contact pressure (left) with its varying contact pressure (MPa) and displacement, and the Von Mises stress (right) with its varying internal deformation (MPa) and displacement (mm). With precedence to the original hyper mesh, Figure 7, Figure 8 and Figure 9 show the modelling visualisation for the LSR gasket material. In contrast, Figure A1, Figure A2, and Figure A3 (Appendix A) show the modelling visualisation for the EPDM gasket material under tensile conditions (Uniaxial and Biaxial). Under the ageing conditions with varying temperatures and working conditions, Figure 10, Figure 11 and Figure 12 show the FEA visualisation for the EPDM material under ageing conditions, while Figure A4, Figure A5 and Figure A6 show the FEA visualisation for the LSR material under ageing conditions. In summary, the FEA modelling visualisation notably shows high contact pressure heatmap mostly under uniaxial tensile testing compared with the biaxial tensile testing conditions. Also, there were significant concentrations looking at the Mooney Rivlin and Ogden models for both the contact pressure and Von Mises stress as shown in Figure A1 and Figure A2, respectively, under the EPDM materials. However, in the LSR materials, there was more concentration for Mooney Rivlin, Yeoh, and Ogden, as shown in Figure 7 and Figure 8. Interestingly, under the ageing condition, it can be noted from the FEA visualisation that under EPDM material, the Mooney Rivlin and Ogden Model had a substantial concentration for both the 95 °C and 110 °C analyses for the PEMFC. Figure A4 and Figure A5 give better representation for the analysis. However, under the LSR material for the ageing condition, there was little or no concentration at both temperature ranges and also at each of the six hyperelastic models. This further prompts the need to access the resulting modelling data from the FEA for further assessment in order to aid the PEMFC gasket material selection framework between EPDM and LSR, respectively.

Figure 7.

Contact Pressure and Von Mises Stress modelling visualization considering Mooney Rivlin and Yeoh Parameters under tensile conditions for PEMFC LSR gasket material.

Figure 8.

Contact Pressure and Von Mises Stress modelling visualization considering Ogden and Arruda Boyce Parameters under tensile conditions for PEMFC LSR gasket material.

Figure 9.

Contact Pressure and Von Mises Stress modelling visualization considering Gent and Neo Hookean Parameters under tensile conditions for PEMFC LSR gasket material.

Figure 10.

Contact Pressure and Von Mises Stress modelling visualization considering Mooney and Yeoh parameters under ageing conditions for PEMFC LSR gasket materials.

Figure 11.

Contact Pressure and Von Mises Stress modelling visualization considering for Ogden and Arruda Boyce Parameters under ageing conditions PEMFC LSR gasket materials.

Figure 12.

Contact Pressure and Von Mises Stress modelling visualization considering Gent and Neo Hookean Parameters under ageing conditions for PEMFC LSR gasket materials.

3.3. FEA Modelling Output and Curve Fitting Assessment

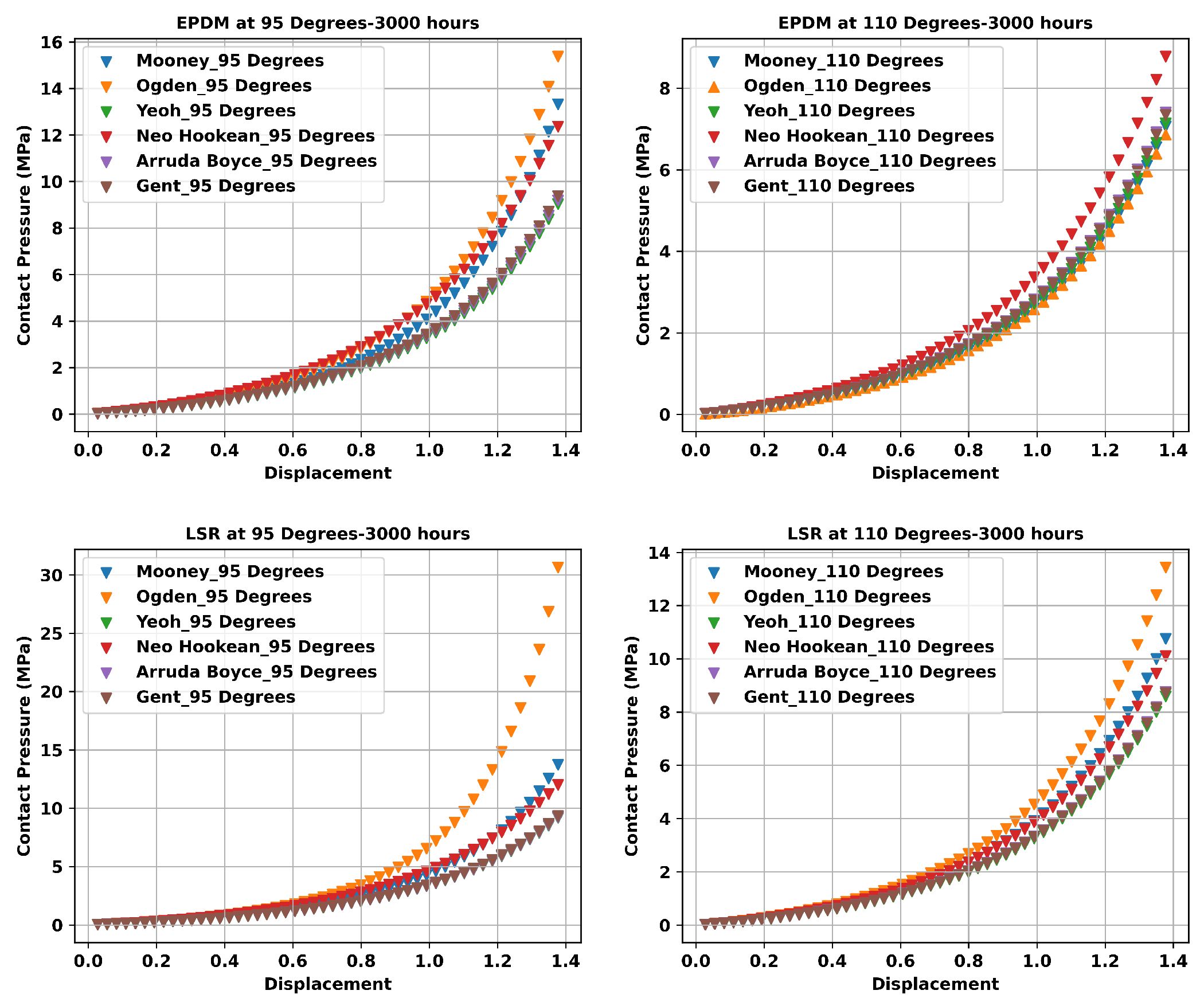

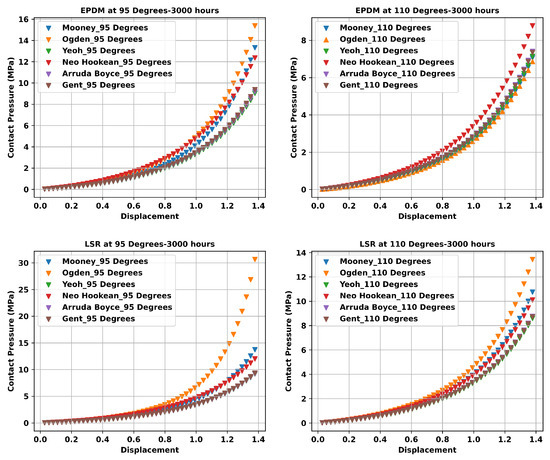

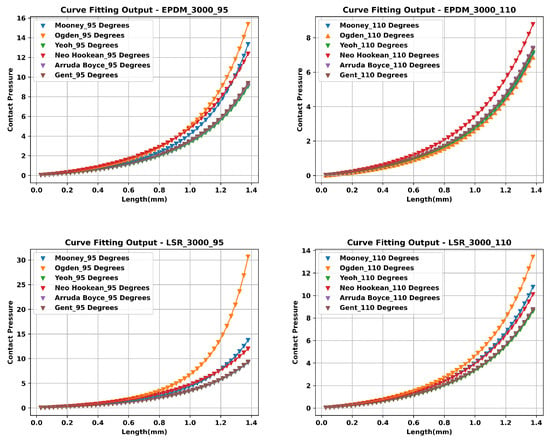

From Figure 13, the corresponding output from the finite element analysis under ageing conditions for the LSR and EPDM materials is shown. The respective hyperelastic models, namely Mooney Rivlin, Ogden, Yeoh, Neo Hookean, Arruda Boyce, and Gent, are used for modelling the gasket materials (LSR and EPDM) at varying temperatures and working hours (3000).

Figure 13.

Contact Pressure output data from FEA modelling considering the multi-hyperelastic models for EPDM and LSR gasket materials.

The resulting plot in Figure 13 shows an almost similar trend for their respective outputs. The assessment of the contact pressure of a material typically involves measuring the pressure distribution between two contacting surfaces. It is often completed using pressure-sensitive films or sensors, which can be placed between the surfaces to be measured. Contact pressure assessment is essential in many applications where two materials are in contact, such as manufacturing processes, collaborative design, and biomechanical analysis. The contact pressure between two materials can affect the wear and deformation of the materials and can also impact the overall system’s performance.

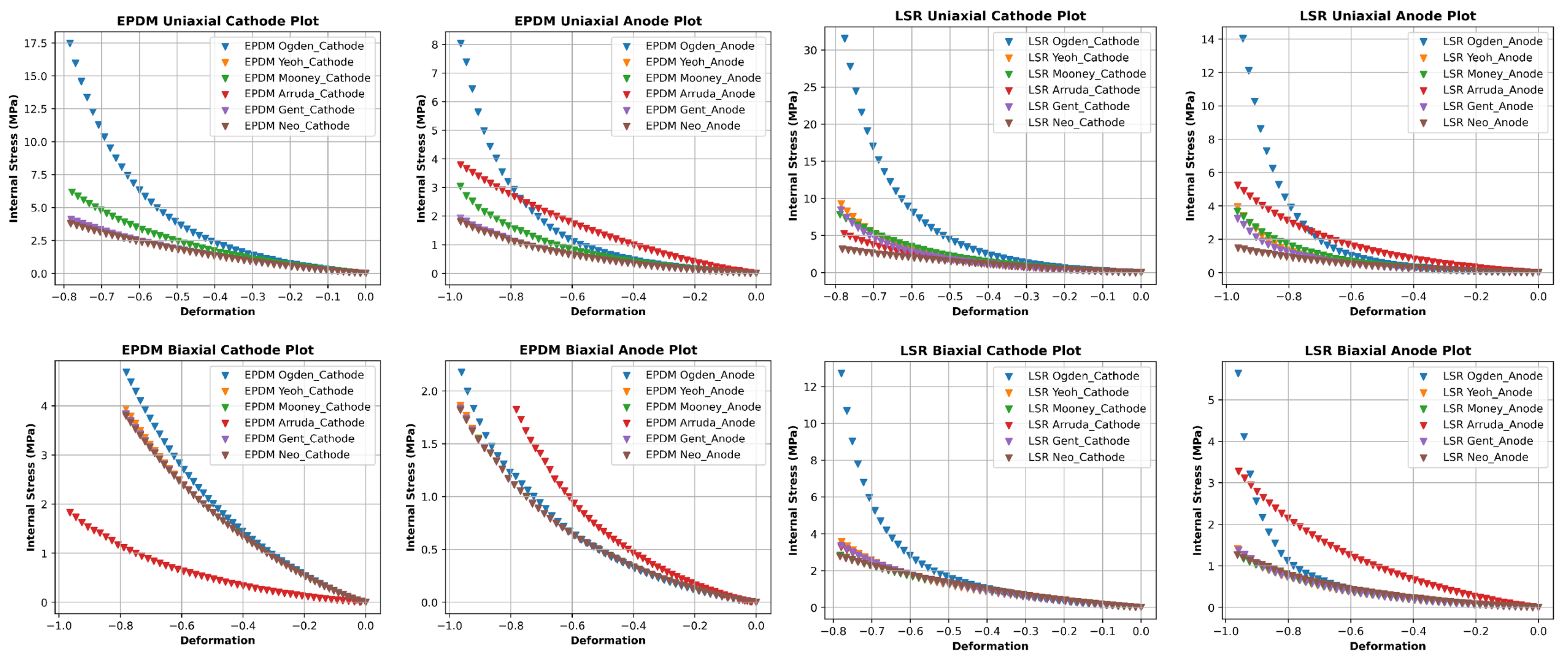

The FEA modelling output from the MARC program provides insights into the behaviour of materials during a uniaxial testing process. Through computational simulations, FEA predicted how the gasket material responds to applied forces, helping to understand its mechanical properties. The output includes stress and strain distributions across the specimen, indicating high-stress concentrations or deformation regions. Additionally, FEA yields information on load-displacement curves, enabling the characterization of material elasticity, yield point, and ultimate strength. It also reveals critical points, such as fracture initiation and propagation. The simulation aids in identifying potential failure modes and validating experimental results. By offering a comprehensive view of the material’s response to uniaxial loading, FEA modelling enhances our comprehension of material behaviour and assists in designing reliable structures across various industries. Figure 14 shows the visualisation of the von Mises stress output at 40% displacement for the FEA modelling.

Figure 14.

Von Mises Stress output considering the multi-hyperelastic models at 40% displacement for EPDM and LSR PEMFC gasket material.

3.4. Proposed Non-Linear Regression Analysis

Curve fitting is finding a mathematical function (curve) that closely matches a set of observed data points. The objective is to create a mathematical model that describes the relationship between the independent variable (input) and the dependent variable (output) as accurately as possible. The curve-fitting process consists of adjusting the parameters (coefficients) of the chosen function to minimise the difference between the predicted values generated by the position and the actual observed data points. It is typically achieved through an optimisation algorithm that seeks to find the best-fitting curve. In this study, curve fitting aims to validate the Finite Element Analysis (FEA) model’s accuracy in predicting the behaviour of the two selected gasket materials. By fitting a polynomial regression model to the FEA data, you create a mathematical representation of how the FEA results relate to the experimental data. Once the polynomial regression model was fitted, its predictions were compared with the experimental data. This comparison allows you to assess how well the FEA model aligns with real-world observations. It is a critical step in verifying the FEA model’s reliability and identifying areas for adjustments or improvements. Depending on the nature of the data and the problem at hand, various types of functions can be chosen for curve fitting. In the case of polynomial regression, polynomial functions were used. It is a type of regression analysis in which the relationship between the dependent variable and one or more independent variables is modelled as an nth-degree polynomial. The polynomial function can be expressed as:

- where y is the dependent variable,

- x is the independent variable and

- a0, a1, a2, ⋯ are the coefficients that need to be estimated.

Polynomial regression can capture complex nonlinear relationships between variables and fit a curve to the data with high accuracy. However, higher-degree polynomials can lead to overfitting, which can reduce the model’s generalisation ability. The choice of polynomial regression for this study is borne out of the nature of the data and the research question at hand. The latter (exponential regression) is also a great technique for modelling and the curve-fitting process. It is essential to evaluate the performance of the models using appropriate metrics and interpret the results.

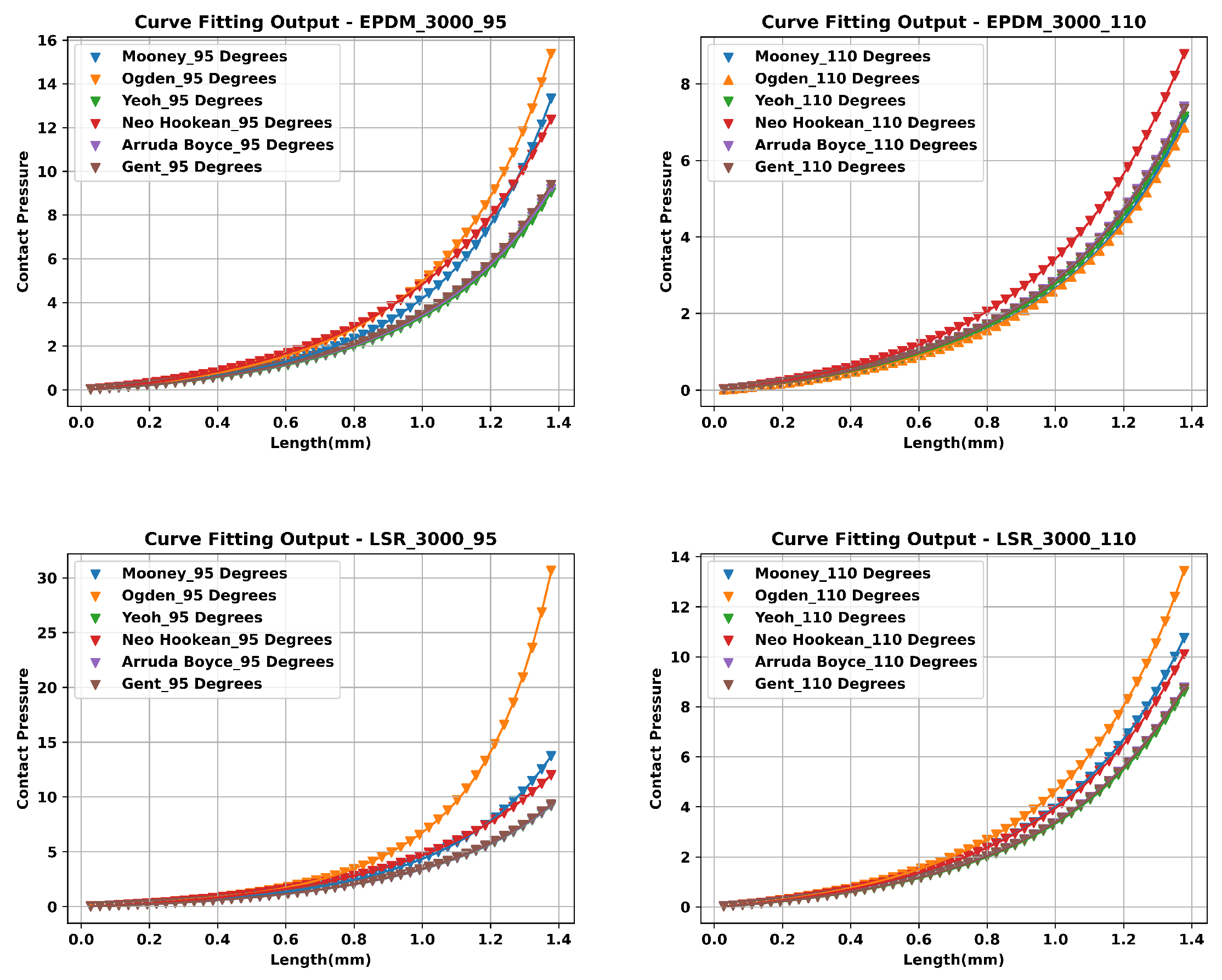

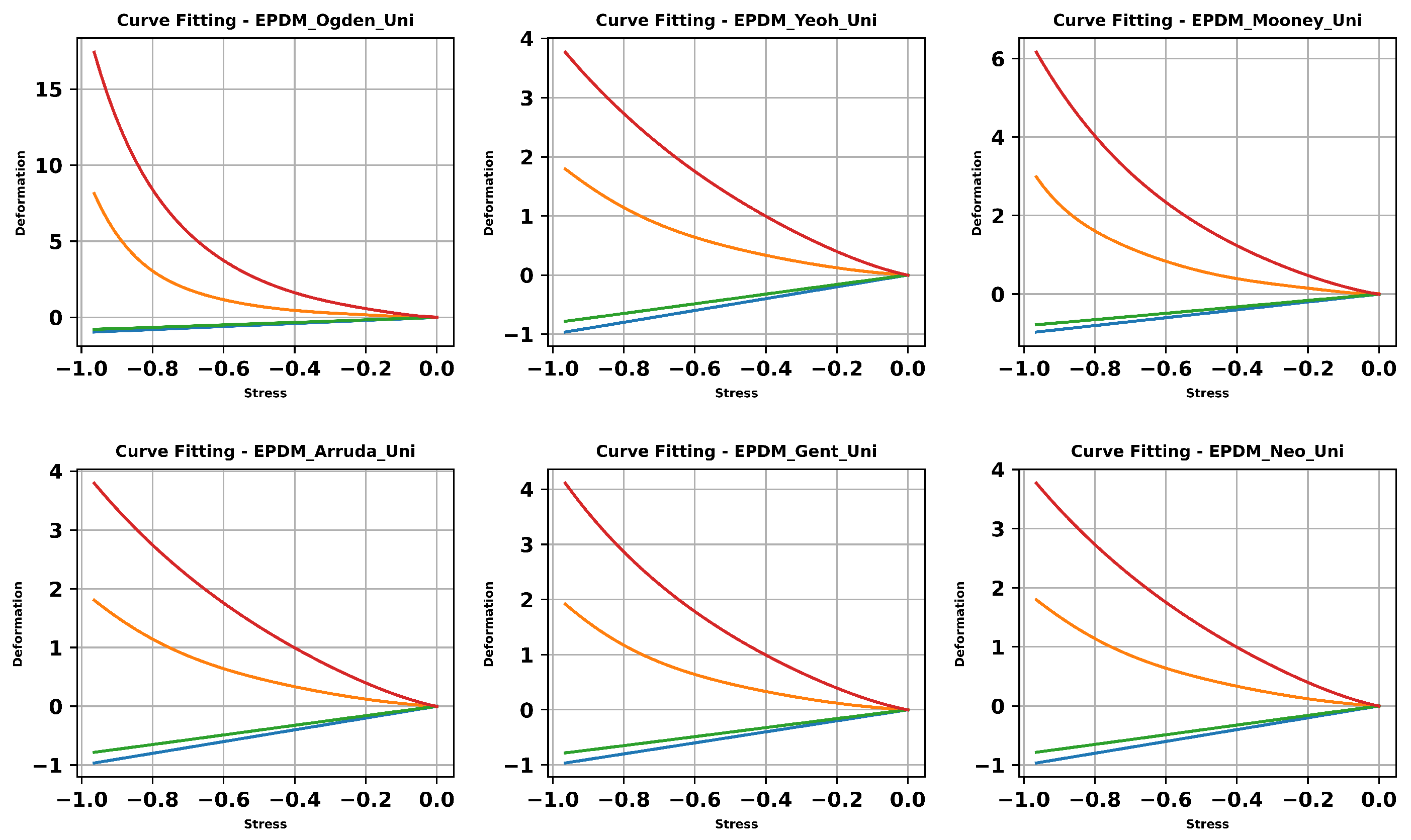

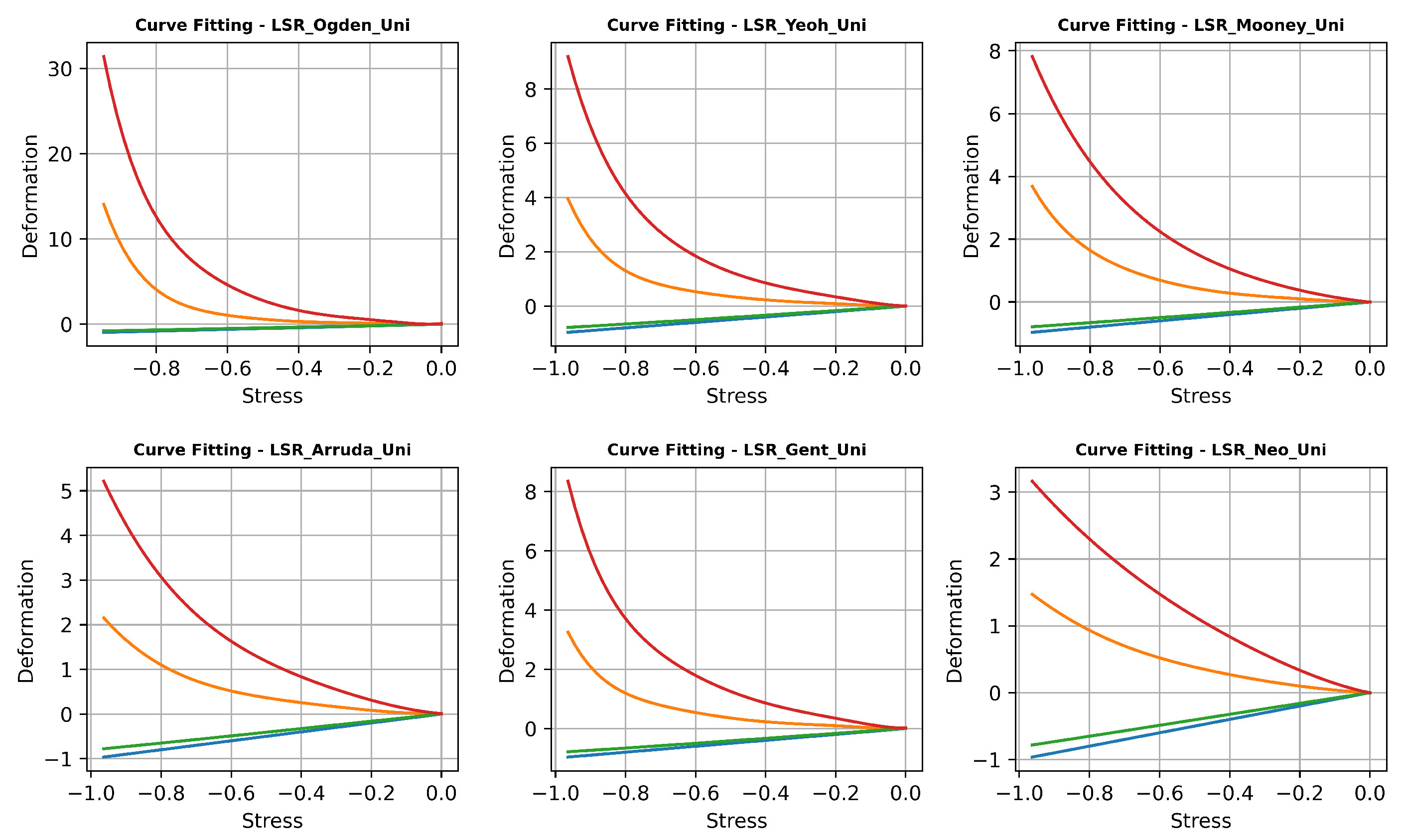

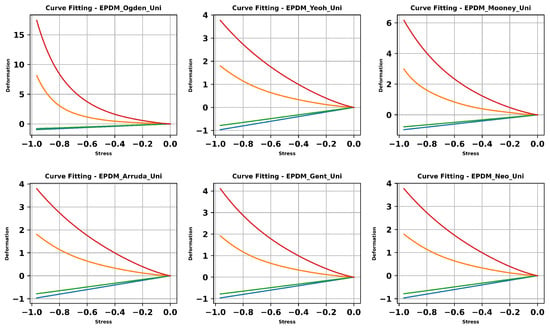

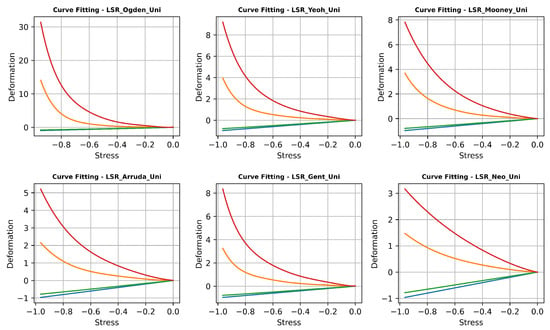

Figure 15 serves as the curve fitting assessment for the data output from the ageing conditions with 3000 working hours and varying temperature ranges of 95 °C and 110 °C, which falls in line with the working temperature of a typical PEMFC system (60–120 °C). The outputs of the hyperelastic models—contact pressure and Von Mises stress data—should ideally be equal to the real modelling data; however, because of the underlying assumptions of each model, miscalculations are unavoidable. A relationship (linear, quadratic, and/or polynomial) between the model outputs and the contact pressure and Von Mises data allows for evaluating the respective models’ curve similarity with the real contact pressure and Von Mises data. Figure 16 and Figure 17 show the curve fitting assessment plot using a combination of polynomial and linear regression for the EPDM and LSR materials, respectively, under the tensile condition (Uniaxial). We decided to proceed only with the uniaxial dataset because there were not enough meaningful concentrations across selected hyperelastic models for the two materials (EPDM and LSR), hence the need to proceed mainly with the uniaxial dataset.

Figure 15.

Curve fitting assessment from multi-hyperelastic models under ageing conditions for PEMFC EPDM and LSR PEMFC gasket materials.

Figure 16.

Curve fitting assessment from multi-hyperelastic models under tensile conditions for PEMFC EPDM gasket material.

Figure 17.

Curve fitting assessment from multi-hyperelastic models under tensile conditions for PEMFC LSR gasket material.

3.5. Non-Linear Regression Performance Metrics

Regression metrics are used to evaluate the performance of a regression model, which predicts a continuous numerical output variable based on one or more input variables. These metrics help evaluate a regression model’s performance and select the best model for a particular problem. MSE measures the average of the squared differences between the predicted values and the actual values. It quantifies the overall magnitude of errors in the model’s predictions. Lower MSE values indicate better model performance, representing more minor prediction errors. It is a standard metric for assessing the goodness of fit. RMSE is the square root of the MSE. It estimates the standard deviation of the model’s prediction errors. Like MSE, lower RMSE values signify more accurate predictions. RMSE is favoured for its ease of interpretation. It’s in the same units as the dependent variable and thus provides a more intuitive understanding of prediction errors. R-squared measures the proportion of the variance in the dependent variable (output) that can be explained by the independent variable(s) model. It ranges from 0 to 1, with higher values indicating a better fit. R-squared is valuable for assessing how well the model explains the variability in the data. An R-squared of 1 means the model perfectly predicts the data, while lower values suggest the model explains less variance. MAPE calculates the average percentage difference between predicted and actual values. It provides insight into the magnitude of errors as a percentage of the actual values. MAPE is particularly useful when assessing the accuracy of models in situations where errors are expressed as percentages. Lower MAPE values indicate better predictive accuracy, and it is commonly used in forecasting. In curve fitting or regression analysis, these metrics help assess how well the model fits the observed data. Researchers and analysts use these metrics to gauge the model’s predictive power and ability to generalise to new data. Lower MSE, RMSE, and MAPE, along with a higher R-squared, typically indicate a more accurate and reliable model. However, the choice of the most appropriate metric depends on the data’s specific characteristics and the analysis’s goals. Some standard regression metrics and their mathematical expressions are shown in Equations (8)–(12):

The Mean Squared Error (MSE) measures the average squared difference between the predicted and actual values. It is given by:

where n is the number of samples, is the actual value, and is the predicted value.

Root Mean Squared Error (RMSE): This is the square root of the MSE and provides the average error in the same units as the output variable. It is given by:

The averageabsolute difference between the predicted and real values is measured by mean absolute error (MAE). It is given by:

R-Squared (): This measures the proportion of variance in the output variable that the model explains. It ranges from 0 to 1, with higher values indicating a better fit. It is given by:

where is the mean of the output variable.

Mean Absolute Percentage Error (MAPE) measures the average percentage difference between the predicted and actual values. It is given by:

where is the actual value.

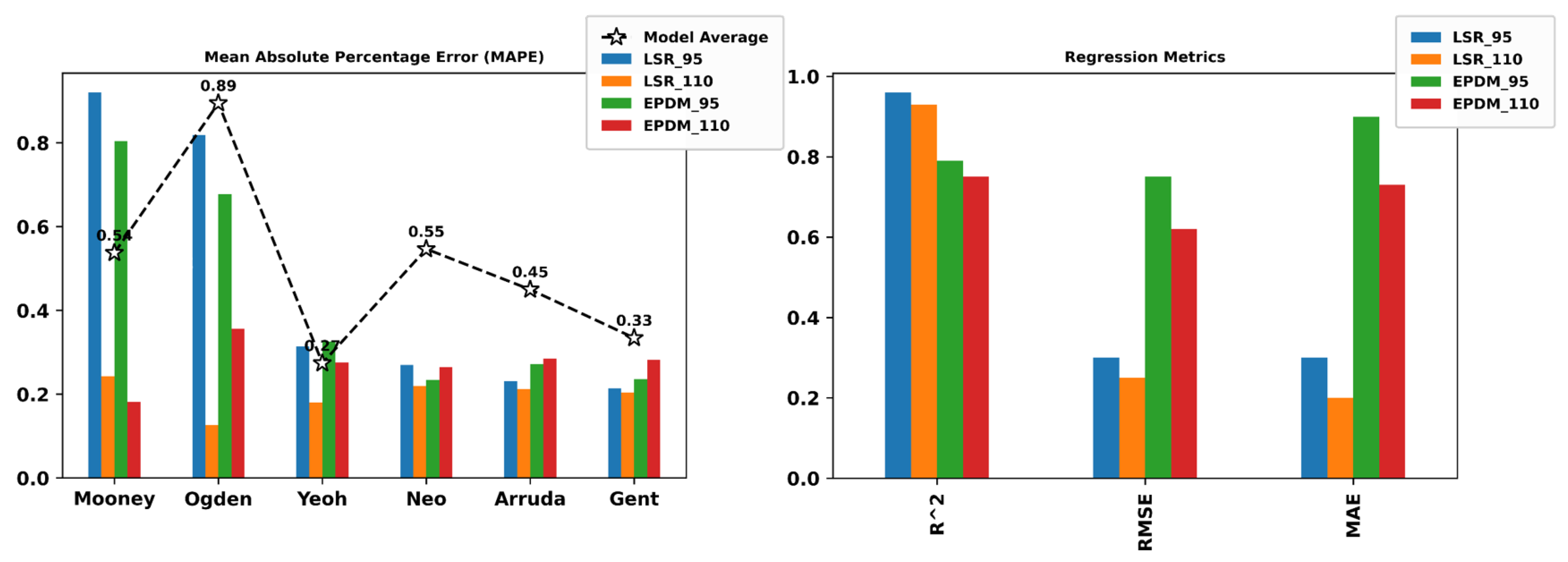

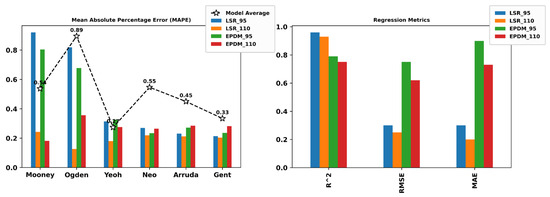

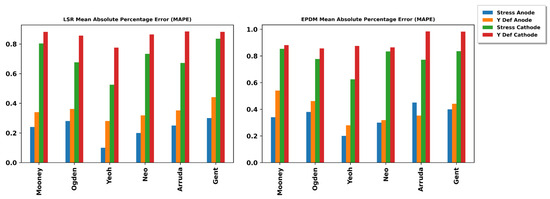

Figure 18 shows the regression assessment plot considering the ageing conditions deployed on the PEMFC gasket material (EPDM and LSR). On the left is a plot showing the performance of the six hyperelastic models for the EPDM and LSR gasket materials candidates using the MAPE metrics. The lowest model average of the six hyperelastic models is the Gent model with 0.23% modelling error, with the Ogden model having the highest MAPE of 1.49%. Considering other metrics (R2, RMSE, and MAE) to select the best material considering the ageing conditions of varying temperatures of 95 and 110 °C. It can be noted from the bar plot that the LSR at 95 °C had the highest value of R2, with the least being the EPDM at 110 °C, giving superiority to the LSR material over the EPDM. The root means square error (RMSE) showed the LSR material was better than the EPDM material, with an average least value of 0.3% and 0.5%, respectively. Likewise, the mean absolute error (MAE) showed the LSR gasket material had the lowest average value of 0.25% compared with the average value of EPDM gasket material at 0.75%. Overall, the LSR gasket material had better performance compared with the EPDM under ageing conditions.

Figure 18.

Regression metrics for EPDM and LSR PEMFC gasket materials considering ageing conditions.

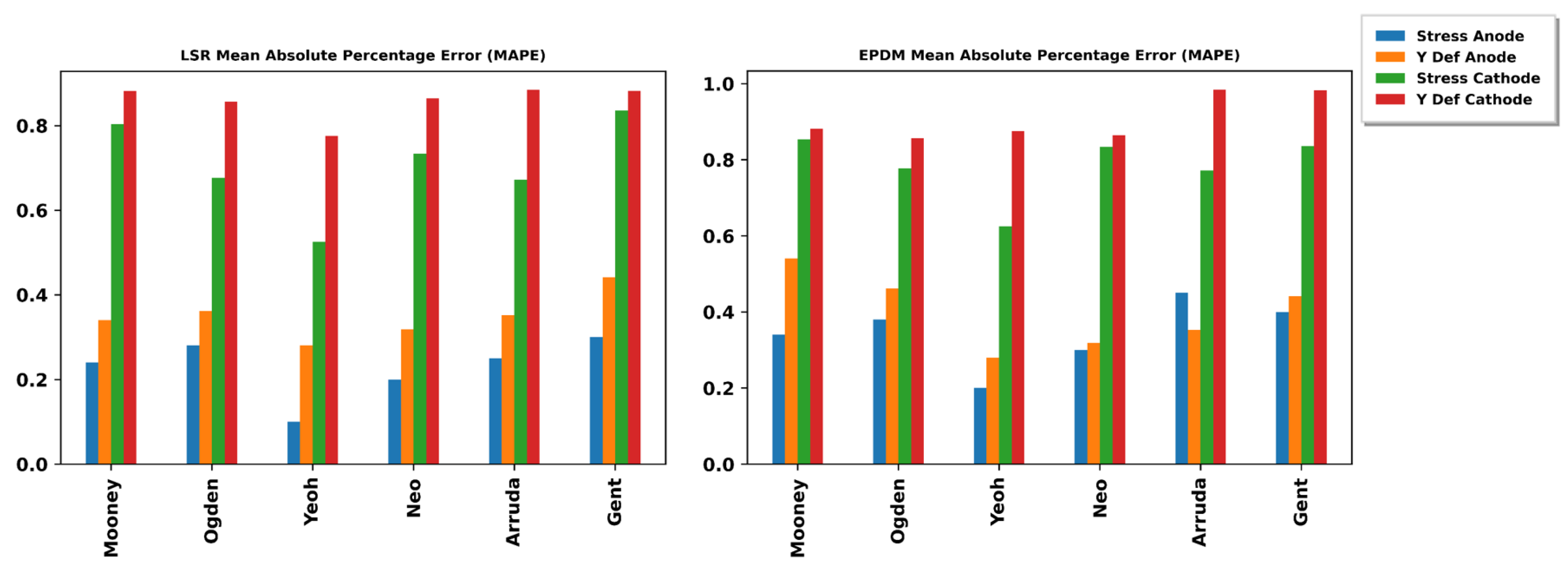

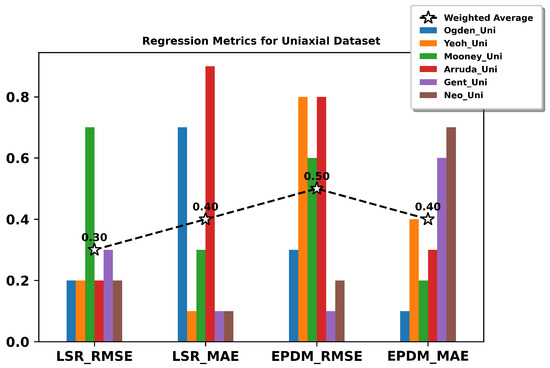

Subsequently, we tried to check the performance metrics of the EPDM and LSR materials, considering uniaxial tensile conditions. Figure 19 and Figure 20 give insight into the regression metrics analysis under uniaxial tensile conditions for the PEMFC gasket materials. The LSR MAPE metrics show anode superiority over the cathode area of the gasket. Subsequently, the Yeoh model had the lowest MAPE result at both the cathode and anode areas, with the Gent model showing the highest percentage of modelling error. The EPDM MAPE metrics similarly took the same route, with the result of the anode on the lower end compared with the cathode’s higher percentage error. The LSR material had the least RMSE value of 0.30% compared with the EPDM material, which had an RMSE value of 0.50%. However, under the MAE assessment, both PEMFC gasket materials under consideration had the same average value of 0.40%, considering the tensile conditions. It should be noted that, from the above analysis, the EPDM can also be regarded as a suitable material for gasket application in PEMFC, even though the LSR gasket material had a slight edge in performance. Overall, the LSR gasket material is a suitable gasket material in terms of the decision framework analysis considering both the ageing and tensile conditions, which is enough paradigm for choosing the right material.

Figure 19.

MAPE Metrics for EPDM and LSR PEMFC gasket materials considering tensile conditions.

Figure 20.

RMSE and MAE metrics for EPDM and LSR PEMFC gasket materials considering tensile conditions.

4. Conclusions

In conclusion, this research paper examined the influence of contact pressure and von Mises stress on PEMFC gasket materials (EPDM and LSR) using finite element analysis to aid decision-making and select the best material. Experimental tensile testing, ageing testing, and FEA modelling using hyperelastic models were carried out to analyse the materials’ contact pressure and von Mises stress. An exploratory data analysis was conducted on the resulting data, and a non-linear regression analysis was performed to create a decision framework for the PEMFC gasket material selection. This study showed that EPDM and LSR have suitable mechanical properties for PEMFC gasket applications. However, the FEA analysis revealed that LSR is more resistant to von Mises stress than EPDM, making it the better choice for higher-pressure applications. The exploratory data analysis showed a correlation between the hyperelastic models and the von Mises stress, with the Mooney Rivlin and Yeoh models exhibiting the highest correlation coefficients. The non-linear regression analysis resulted in a decision framework for selecting the appropriate material based on the required contact pressure and von Misses stress. The study compared the performance of LSR and EPDM gasket materials under ageing conditions using RMSE and MAE assessments. The results showed that the LSR gasket material outperformed the EPDM material in both RMSE and MAE assessments. The LSR material had the lowest RMSE value of 0.30%, indicating a lower prediction percentage error compared with the EPDM material, which had an RMSE value of 0.50%. Additionally, the LSR gasket material had a significantly lower average MAE value of 0.25% compared with the EPDM material, with an average MAE value of 0.75%. Furthermore, under the tensile testing procedure, the modelling and curve fitting results through the MAPE, RMSE, and MAE showed that the Yeoh model is a suitable hyperelastic model for better prediction using the von Misses stress, and the LSR had the least error at both the anode and cathode areas, respectively. Similarly, the ageing modelling and curve fitting results put the Yeoh model above the other hyperelastic models with the least average percentage error and a computational cost of 0.27 s. These findings suggest that LSR could be a better material for PEMFC gaskets under ageing conditions and could potentially improve the performance and durability of fuel cells. The decision framework created in this study can aid in selecting the most appropriate gasket material for specific applications, enhancing the safety and reliability of fuel cells in electric vehicles. Further research could investigate the long-term effects of using LSR gasket materials in fuel cells to validate these results.

Author Contributions

Conceptualization, S.-H.P. and A.B.K.; methodology, S.-H.P. and A.B.K.; software, S.-H.P., W.J.J., A.B.K. and J.-W.H.; validation, S.-H.P. and A.B.K.; formal analysis, S.-H.P. and A.B.K.; investigation, S.-H.P. and A.B.K.; data curation, S.-H.P. and W.J.J.; writing—original draft preparation, S.-H.P. and A.B.K.; writing—review and editing, A.B.K.; visualization, S.-H.P., W.J.J. and A.B.K.; resources and supervision, J.-W.H.; project administration, J.-W.H.; funding acquisition, J.-W.H. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Technology Innovation Program (or Industrial Strategic Technology Development Program-Material Parts Technology Development) (k-g012000998304, Development of Silicone-Based Elastomer with Excellent Acid Resistance and Application Technology for Fuel Cell Stack Gasket) funded by the Ministry of Trade, Industry and Energy (Motie, Korea).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to laboratory regulations.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| ATIR-FTIR | Attenuated Total Reflectance Fourier Transform Infrared Spectroscopy |

| CR | Cluoropene Rubber |

| DMA | Dynamic Mechanical Analysis |

| EPDM | Ethylene Propylene Diene Monomer |

| FEA | Finite Element Analysis |

| FEP | Fluorinated Ethylene Propylene |

| LSR | Liquid Silicon Rubber |

| MAE | Mean Absolute Error |

| MAPE | Mean Absolute Percentage Error |

| MEA | Membrane Electrode Assembly |

| MSE | Mean Square Error |

| NBR | Nitrite Butadiene Rubber |

| PEMFC | Proton-exchange membrane fuel cell |

| PFSA | Perfluoro Sulfonic Acid |

| PTFE | Polytetrafluoroethylene |

| R2 | R-Squared |

| RMSE | Root Mean Square Error |

| STC | Sensors, Test and Calibration |

| TFA | Trifluoroacetic acid |

| VMQ | Silicone Rubber Vinyl Methyl |

| XPS | X-ray Photoelectron Spectroscopy |

Appendix A

Figure A1.

Contact Pressure and Von Mises Stress modelling visualization considering Mooney Rivlin and Yeoh Parameters under tensile conditions for PEMFC EPDM gasket material.

Figure A1.

Contact Pressure and Von Mises Stress modelling visualization considering Mooney Rivlin and Yeoh Parameters under tensile conditions for PEMFC EPDM gasket material.

Figure A2.

Contact Pressure and Von Mises Stress modelling visualization considering Ogden and Arruda Boyce Parameters under tensile conditions for PEMFC EPDM gasket material.

Figure A2.

Contact Pressure and Von Mises Stress modelling visualization considering Ogden and Arruda Boyce Parameters under tensile conditions for PEMFC EPDM gasket material.

Figure A3.

Contact Pressure and Von Mises Stress modelling visualization considering Gent and Neo Hookean Parameters under tensile conditions for PEMFC EPDM gasket material.

Figure A3.

Contact Pressure and Von Mises Stress modelling visualization considering Gent and Neo Hookean Parameters under tensile conditions for PEMFC EPDM gasket material.

Figure A4.

Contact Pressure and Von Mises Stress modelling visualization considering Mooney and Yeoh Parameters under ageing conditions for PEMFC EPDM material.

Figure A4.

Contact Pressure and Von Mises Stress modelling visualization considering Mooney and Yeoh Parameters under ageing conditions for PEMFC EPDM material.

Figure A5.

Contact Pressure and Von Mises Stress modelling visualization considering Ogden and Arruda Boyce Parameters under ageing conditions for PEMFC EPDM materials.

Figure A5.

Contact Pressure and Von Mises Stress modelling visualization considering Ogden and Arruda Boyce Parameters under ageing conditions for PEMFC EPDM materials.

Figure A6.

Contact Pressure and Von Mises Stress modelling visualization considering Gent and Neo Hookean Parameters under ageing conditions for PEMFC EPDM materials.

Figure A6.

Contact Pressure and Von Mises Stress modelling visualization considering Gent and Neo Hookean Parameters under ageing conditions for PEMFC EPDM materials.

References

- Singla, M.K.; Nijhawan, P.; Oberoi, A.S. Hydrogen fuel and fuel cell technology for cleaner future: A review. Environ. Sci. Pollut. Res. 2021, 28, 15607–15626. [Google Scholar] [CrossRef] [PubMed]

- Manoharan, Y.; Hosseini, S.E.; Butler, B.; Alzhahrani, H.; Senior, B.T.F.; Ashuri, T.; Krohn, J. Hydrogen Fuel Cell Vehicles; Current Status and Future Prospect. Appl. Sci. 2019, 9, 2296. [Google Scholar] [CrossRef]

- John, M.T.; Peter, P.E.; Peter, J.D.; Gari, P.O. Decarbonising energy: The developing international activity in hydrogen technologies and fuel cells. J. Energy Chem. 2020, 51, 405–415. [Google Scholar] [CrossRef]

- Jamil, A.; Rafiq, S.; Iqbal, T.; Khan, H.A.A.; Khan, H.M.; Azeem, B.; Mustafa, M.Z.; Hanbazazah, A.S. Current status and future perspectives of proton exchange membranes for hydrogen fuel cells. Chemosphere 2022, 303 Pt 3, 135204. [Google Scholar] [CrossRef]

- Pourrahmani, H.; Siavashi, M.; Yavarinasab, A.; Matian, M.; Chitgar, N.; Wang, L.; Van herle, J. A Review on the Long-Term Performance of Proton Exchange Membrane Fuel Cells: From Degradation Modeling to the Effects of Bipolar Plates, Sealings, and Contaminants. Energies 2022, 15, 5081. [Google Scholar] [CrossRef]

- Olabi, A.G.; Wilberforce, T.; Alanazi, A.; Vichare, P.; Sayed, E.T.; Maghrabie, H.M.; Elsaid, K.; Abdelkareem, M.A. Novel Trends in Proton Exchange Membrane Fuel Cells. Energies 2022, 15, 4949. [Google Scholar] [CrossRef]

- Vikas, K.; Poornesh, K.; Koorata, U.S.; Pranav, P.; Soney, C.G. Review on physical and chemical properties of low and high-temperature polymer electrolyte membrane fuel cell (PEFC) sealants. Polym. Degrad. Stab. 2022, 205, 110151. [Google Scholar] [CrossRef]

- Yiqing, W.; Tahrizi, A.; Yilin, W.; Ying, C.; Eric, D.W.; Mark, H.E.; Kenneth, G.R.; Yong, W.; Feng, G.; Unmesh, M.; et al. A comparative study between real-world and laboratory accelerated ageing of Cu/SSZ-13 SCR catalysts. Appl. Catal. B Environ. 2022, 318, 121807. [Google Scholar] [CrossRef]

- Mohamed, O.A.; Al Khattab, R. Fresh Properties and Sulfuric Acid Resistance of Sustainable Mortar Using Alkali-Activated GGBS/Fly Ash Binder. Polymers 2022, 14, 591. [Google Scholar] [CrossRef]

- Winter, L.; Lampke, T. Influence of Hydrothermal Sealing on the High Cycle Fatigue Behavior of the Anodized 6082 Aluminum Alloy. Coatings 2022, 12, 1070. [Google Scholar] [CrossRef]

- Yang, D.; Tan, Y.; Li, B.; Ming, P.; Xiao, Q.; Zhang, C. A Review of the Transition Region of Membrane Electrode Assembly of Proton Exchange Membrane Fuel Cells: Design, Degradation, and Mitigation. Membranes 2022, 12, 306. [Google Scholar] [CrossRef] [PubMed]

- Ke, S.; Yimin, W.; Yuhang, D.; Hongjie, X.; Philip, M.; Tobias, S.; Katharina, B.; Christopher, E.; Hannes, W.W.; Jens, S.; et al. Assembly techniques for proton exchange membrane fuel cell stack: A literature review. Renew. Sustain. Energy Rev. 2022, 153, 111777. [Google Scholar] [CrossRef]

- Kim, J.H.; Lee, Y.K.; Kim, D.H. Mechanical properties of gasket elastomers for sealing applications. J. Appl. Polym. Sci. 2016, 133, 43873. [Google Scholar] [CrossRef]

- Kurniawan, A.; Shim, Y. Tensile behaviour of silicone rubber gaskets under different temperature conditions. J. Appl. Polym. Sci. 2017, 134, 44635. [Google Scholar] [CrossRef]

- Kang, J.; Lee, C.; Kim, J. Tensile and compression properties of soft rubber gaskets used in automotive applications. Polym. Test. 2015, 42, 42–47. [Google Scholar] [CrossRef]

- Wang, X.; Li, X. Influence of filler type on the mechanical properties of nitrile rubber gaskets for sealing applications. J. Appl. Polym. Sci. 2017, 134, 45217. [Google Scholar] [CrossRef]

- Chen, J.; Yang, J.; Li, Y. Tensile properties and stress relaxation behaviour of silicone rubber gaskets for automotive applications. Polym. Test. 2015, 47, 90–95. [Google Scholar] [CrossRef]

- Pehlivan-Davis, S. Polymer Electrolyte Membrane (PEM) Fuel Cell Seals Durability. Ph.D. Thesis, Loughborough University, Loughborough, UK, 2016. Available online: https://hdl.handle.net/2134/21749 (accessed on 8 April 2023).

- Wu, F.; Chen, B.; Yan, Y.; Chen, Y.; Pan, M. Degradation of Silicone Rubbers as Sealing Materials for Proton Exchange Membrane Fuel Cells under Temperature Cycling. Polymers 2018, 10, 522. [Google Scholar] [CrossRef]

- Feng, J.; Zhang, Q.; Tu, Z.; Tu, W.; Wan, Z.; Pan, M.; Zhang, H. Degradation of silicone rubbers with different hardness in various aqueous solutions. Polym. Degrad. Stab. 2014, 109, 122–128. [Google Scholar] [CrossRef]

- Lin, C.W.; Chien, C.H.; Tan, J.; Chao, Y.J.; Van Zee, J.W. Dynamic mechanical characteristics of five elastomeric gasket materials aged in a simulated and accelerated PEM fuel cell environment. Int. J. Hydrogen Energy 2011, 36, 6756–6767. [Google Scholar] [CrossRef]

- Zhang, J.; Hu, Y. Sealing performance and mechanical behaviour of PEMFCs sealing system based on thermodynamic coupling. Int. J. Hydrogen Energy 2020, 45, 23480–23489. [Google Scholar] [CrossRef]

- Shen, L.; Xia, L.; Han, T.; Wu, H.; Guo, S. Improvement of hardness and compression set properties of EPDM seals with alternating multilayered structure for PEM fuel cells. Int. J. Hydrog. Energy 2016, 41, 23164–23172. [Google Scholar] [CrossRef]

- Hu, G.; Zhang, P.; Wang, G.; Zhang, M.; Li, M. The influence of rubber material on sealing performance of packing element in compression packer. J. Nat. Gas Sci. Eng. 2017, 38, 120–138. [Google Scholar] [CrossRef]

- Lin, C.W.; Chien, C.H.; Tan, J.; Chao, Y.J.; Van Zee, J.W. Chemical degradation of five elastomeric seal materials in a simulated and accelerated PEM fuel cell environment. J. Power Sources 2011, 196, 1955–1966. [Google Scholar] [CrossRef]

- Pehlivan-Davis, S.; Clarke, J.; Armour, S. Comparison of accelerated ageing of silicone rubber gasket material with ageing in a fuel cell environment. J. Appl. Polym. Sci. 2013, 129, 1446–1454. [Google Scholar] [CrossRef]

- Wang, Z.; Tan, J.; Wang, Y.; Liu, Z.; Feng, Q. Chemical and mechanical degradation of silicone rubber under two compression loads in simulated proton-exchange membrane fuel-cell environments. J. Appl. Polym. Sci. 2019, 136, 47855. [Google Scholar] [CrossRef]

- Chang, H.; Wan, Z.; Chen, X.; Wan, J.; Luo, L.; Zhang, H.; Tu, Z. Temperature and humidity effect on ageing of silicone rubbers as sealing materials for proton exchange membrane fuel cell applications. Appl. Therm. Eng. 2016, 104, 472–478. [Google Scholar] [CrossRef]

- Zhou, W.; Wang, C.; Fan, P.; Kuang, Y.; Dong, Z. The Sealing Effect Improvement Prediction of Flat Rubber Ring in Roller Bit Based on Yeoh-Revised Model. Materials 2022, 15, 5529. [Google Scholar] [CrossRef]

- Lin, A.; Wu, J.; Li, H.; Li, Z.; Su, B.; Wang, Y. Effect of Geometric Error on Friction Behavior of Cylinder Seals. Polymers 2021, 13, 3438. [Google Scholar] [CrossRef]

- Vieira, J.C.; Mendes, A.d.O.; Ribeiro, M.L.; Vieira, A.C.; Carta, A.M.; Fiadeiro, P.T.; Costa, A.P. FEM Analysis Validation of Rubber Hardness Impact on Mechanical and Softness Properties of Embossed Industrial Base Tissue Papers. Polymers 2022, 14, 2485. [Google Scholar] [CrossRef]

- Latif, R.F.; Khan, N.S. Comparative Analysis of Various Hyperelastic Models for Neoprene Gasket at Ranging Strains. In Proceedings of the 2019 16th International Bhurban Conference on Applied Sciences and Technology (IBCAST), Islamabad, Pakistan, 8–12 January 2019; pp. 179–188. [Google Scholar] [CrossRef]

- Cheon, K.-M.; Akpudo, U.E.; Kareem, A.B.; Nwabufo, O.C.; Jeon, H.-R.; Hur, J.-W. An FEA-Assisted Decision-Making Framework for PEMFC Gasket Material Selection. Energies 2022, 15, 2580. [Google Scholar] [CrossRef]

- Olayinka, A.; Emblom, W.J. Surface roughness of AISI 1010 and AISI 304 of PEMFC bipolar plates with microscale hydroformed capillary channels. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2022, 236, 1332–1340. [Google Scholar] [CrossRef]

- Kim, Y.K.; Kim, Y.H.; Kim, J.Y. Development of silicone-based gasket material for PEMFCs. J. Power Sources 2018, 284, 289–298. [Google Scholar] [CrossRef]

- Hu, Y.; Zhang, Y.; Wang, J.; Liu, Q. A review on proton exchange membrane fuel cell (PEMFC) gasket materials. J. Power Sources 2016, 308, 101–119. [Google Scholar] [CrossRef]

- Haque, M.E.; Danquah, M.K. A review on the design, selection and optimization of gasket materials for proton exchange membrane fuel cell (PEMFC). Renew. Sustain. Energy Rev. 2015, 47, 766–776. [Google Scholar] [CrossRef]

- Rau, N.; Spiess, W. Fluorinated Ethylene Propylene (FEP) gaskets for proton exchange membrane fuel cells (PEMFCs): An overview. J. Appl. Polym. Sci. 2016, 133, 43189. [Google Scholar]

- Lee, H.J.; Kim, J.Y. Performance comparison of silicone and fluoropolymer gaskets for proton exchange membrane fuel cells (PEMFCs). J. Power Sources 2018, 389, 157–166. [Google Scholar] [CrossRef]

- Baker, J.M.; Kim, Y. Dynamic mechanical analysis of an EPDM rubber. J. Appl. Polym. Sci. 2013, 130, 378–384. [Google Scholar] [CrossRef]

- Dubey, N.C.; Bose, S.K. Studies on the thermal and mechanical properties of EPDM and its composites. Polym. Compos. 2015, 36, 631–637. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, J.; Han, X. Preparation and properties of EPDM/organic silica hybrid nanocomposites. J. Appl. Polym. Sci. 2015, 132, 42076. [Google Scholar] [CrossRef]

- Hiltunen, M.; Nurminen, J.; Ahola, S. Effect of filler type and content on the properties of EPDM rubber compounds. Rubber Chem. Technol. 2015, 88, 564–576. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, Y.; Han, X. Synthesis and properties of EPDM/organoclay nanocomposites. J. Appl. Polym. Sci. 2013, 128, 4117–4123. [Google Scholar] [CrossRef]

- Fang, Y.; Xu, L.; Du, Y. Recent advances in liquid silicone rubber (LSR) materials and applications. J. Appl. Polym. Sci. 2020, 137, 48180. [Google Scholar] [CrossRef]

- Kim, J.H.; Lee, H.J.; Kim, K.H. Preparation and mechanical properties of liquid silicone rubber/silicone rubber composite materials. J. Appl. Polym. Sci. 2019, 136, 47758. [Google Scholar] [CrossRef]

- Chiu, H.W.; Li, J.H. Application of liquid silicone rubber (LSR) materials in medical and healthcare products. Polymers 2020, 12, 1019. [Google Scholar]

- Li, L.; Li, Q.; Li, H.; Qiu, Q. A review of liquid silicone rubber (LSR) material and its processing technologies. Polymers 2019, 11, 2288. [Google Scholar]

- Sun, X.; Li, C.; Li, S.; Zhang, X. Properties and applications of liquid silicone rubber (LSR) in 3D printing. Polymers 2020, 12, 1866. [Google Scholar]

- Chen, X.; Lin, T. The research progress of liquid silicone rubber (LSR) materials in the field of soft-touch consumer electronics. J. Appl. Polym. Sci. 2019, 136, 48005. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, Y.; Liu, Y. Study on the thermal stability and mechanical properties of liquid silicone rubber (LSR) under high-temperature conditions. J. Appl. Polym. Sci. 2019, 136, 46936. [Google Scholar] [CrossRef]

- Liu, X.; Wang, L.; Lu, J. The research progress of liquid silicone rubber (LSR) materials in the field of aerospace. J. Appl. Polym. Sci. 2019, 136, 46580. [Google Scholar] [CrossRef]

- Kang, S.K.; Kim, Y.J.; Jeong, J.S. Characterization of FKM and VQM elastomers used in various sealing applications. J. Appl. Polym. Sci. 2019, 136, 46699. [Google Scholar] [CrossRef]

- Lee, J.Y.; Lee, Y.J. Performance comparison of FKM and VQM elastomers in high-temperature sealing applications. J. Polym. Eng. 2017, 37, 831–839. [Google Scholar] [CrossRef]

- Kim, H.J.; Lee, S.H. Evaluation of mechanical and dynamic mechanical properties of FKM and VQM elastomers. J. Elastomers Plast. 2015, 47, 165–173. [Google Scholar]

- Zhang, J.; Liu, Y.; Chen, X. FKM and VQM elastomers as dynamic seal materials: A review. J. Polym. Eng. 2019, 39, 901–913. [Google Scholar]

- Oh, J.H.; Kim, J.H. Chemical and thermal stability of FKM and VQM elastomers in high-temperature applications. J. Polym. Sci. Technol. 2017, 27, 145–152. [Google Scholar] [CrossRef]

- Murea, C.M. Updated Lagrangian for Compressible Hyperelastic Material with Frictionless Contact. Appl. Mech. 2022, 3, 533–543. [Google Scholar] [CrossRef]

- Ogden, R.; Saccomandi, G.; Sgura, I. Fitting hyperelastic models to experimental data. Comput. Mech. 2004, 34, 484–502. [Google Scholar] [CrossRef]

- Kim, B.; Lee, S.B.; Lee, J.; Cho, S.; Park, H.; Yeom, S.; Park, S.H. A comparison among Neo-Hookean model, Mooney-Rivlin model, and Ogden model for chloroprene rubber. Int. J. Precis. Eng. Manuf. 2012, 13, 759–764. [Google Scholar] [CrossRef]

- Khaniki, H.B.; Ghayesh, M.H.; Chin, R.; Amabili, M. A review on the nonlinear dynamics of hyperelastic structures. Nonlinear Dyn. 2022, 110, 963–994. [Google Scholar] [CrossRef]

- Li, H.; Li, J.; Niu, S. A viscoelastic constitutive model for gasket materials under dynamic loading. J. Appl. Mech. Tech. Phys. 2019, 60, 763–771. [Google Scholar]

- Wang, X.; Su, J.; Hu, X. A constitutive model for gasket material based on the logarithmic strain rate. J. Appl. Mech. Tech. Phys. 2017, 58, 244–252. [Google Scholar]

- Chen, X.; Liu, Y. Constitutive models for gasket materials considering the nonlinear behaviour of fibre-reinforced rubber composites. Int. J. Non-Linear Mech. 2015, 77, 16–25. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, H. A new hyperelastic constitutive model for gasket materials under large deformation. J. Mech. 2017, 33, 797–807. [Google Scholar] [CrossRef]

- Li, J.; Li, H.; Niu, S. An improved constitutive model for gasket materials considering the nonlinear behaviour of rubber composites. Int. J. Mech. Mater. Des. 2018, 14, 53–65. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).