1. Introduction

Delaying the aircraft stall to achieve higher (maximum lift coefficient) has been of much interest in using various types of boundary-layer control (BLC) in recent decades. As well as minimizing air vehicle drag by delaying the transition from laminar to turbulent flow, BLCs are used to delay the flow separation of high angles of attack lifting sur-faces that experience a strong adverse pressure gradient.

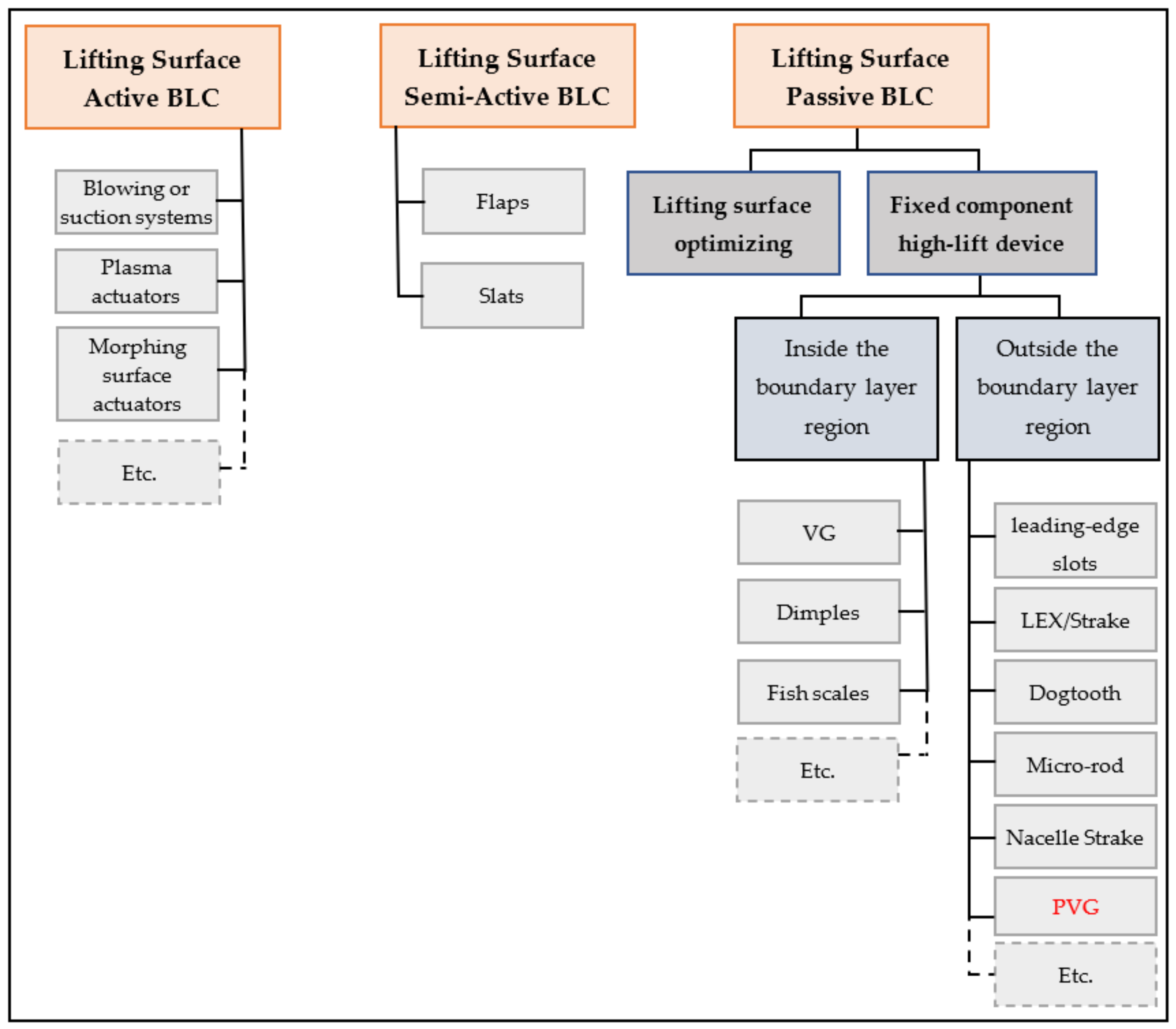

There are three types of BLC including active, semi-active, and passive. The active BLC includes blowing/suction systems, morphing surface actuators, plasma actuators, etc. In blowing/suction systems, low-energy layers are sucked in, or high-energy flows are blown [

1]. Plasma actuators are an example of this type of BLC. In these actuators, the induced velocity energizes the low-energy boundary layers [

2]. In morphing surface actuators, piezoelectric actuators excite the turbulent boundary layer. One of the biggest disadvantages of active methods is the need for a secondary source of energy. In addition, active flow control generally imposes additional weight and maintenance costs [

3]. There are numerous review articles to find out the pros and cons of different types of active BLC (e.g., [

1,

2,

3]). The semi-active BLC includes a movable type of flap and slat. These BLCs are active at some points of the flight envelope, such as takeoff, landing, and sometimes maneuver points, and will be inactive at other points of the flight envelope.

The last type of lifting surface BLC is the passive method. One way of the passive BLC method is to optimize the shape of the lifting surface to delay the flow separation. Other methods use fixed-component high-lift devices, which are classified into two types depending on their location, either in the boundary layer region or outside.

Figure 1 shows lifting surface BLC categories.

To compare any lifting surface BLC or investigate a new idea, it is necessary to examine all effects in a multidisciplinary approach.

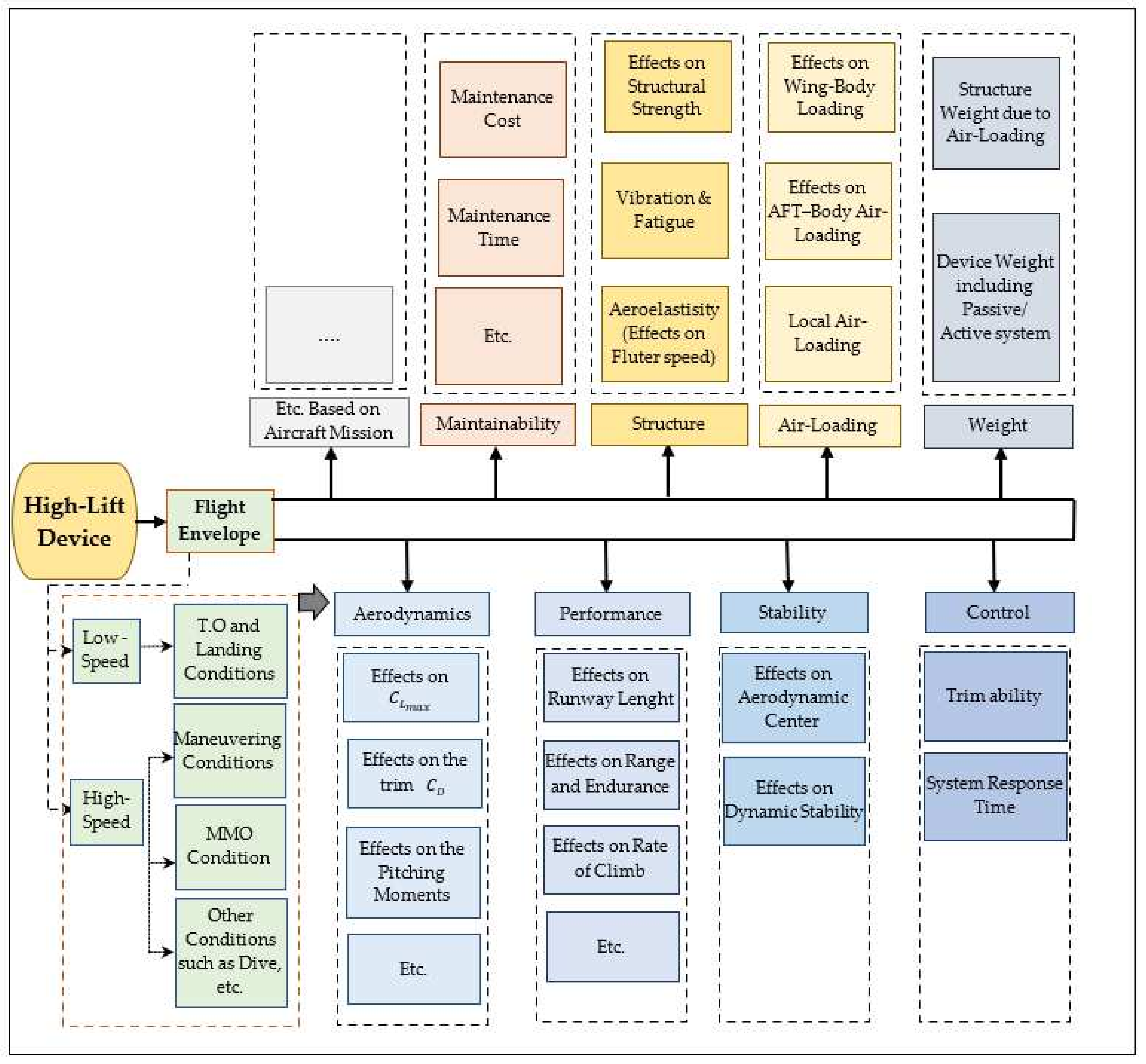

Figure 2 depicts various fields necessary to include in a comprehensive review. These fields all originate from the mission and flight envelope of an aircraft. They can include aerodynamics, performance, stability and control, air loading, structure, system weight imposed on the aircraft, system reliability, and maintainability, etc.

In the aerodynamic analysis of a high-lift device, in addition, to achieve an increase in at low speeds during takeoff and landing, the aircraft drag change at high speeds at cruise, maneuver, MMO, etc., points is also important. In addition, a change in the (pitching moment coefficient at zero angle of attack) of an aircraft can change the balanced loading and also impose a trim drag. Furthermore, it can affect the air loading of the wing and rear body as well as the controllability of the aircraft. In addition, a change in the (pitching moment coefficient versus angle of attack) slope can change the aerodynamic center of the aircraft and thus its stability. Additionally, the weight of the system imposed on the aircraft should be reasonable, along with increasing the .

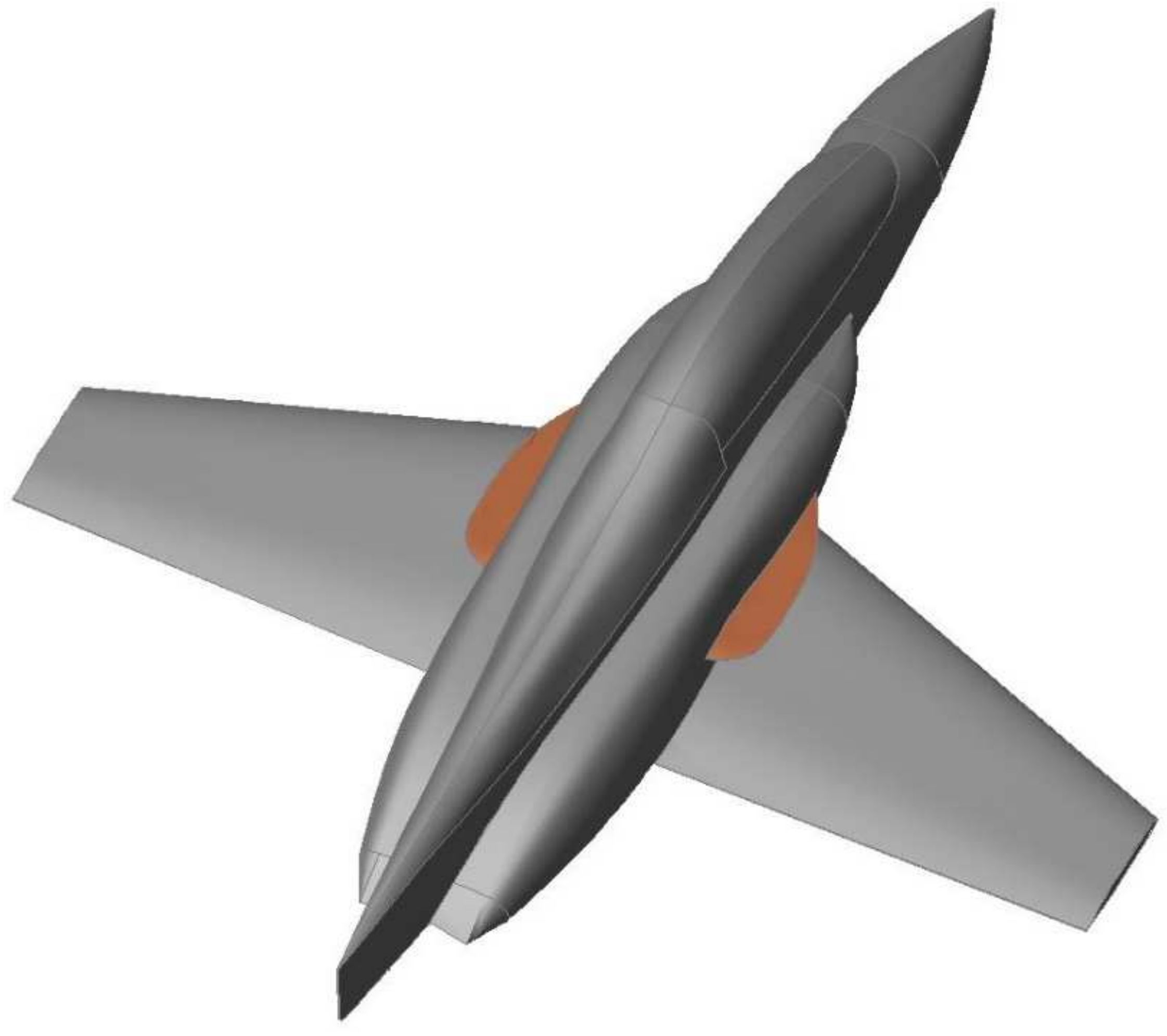

During some research on designing an advanced low-wing training jet, the authors came up with an innovative design to delay the aircraft stall. This is a powerful vortex generator, which is attached to the body and is located at the top of the wing (

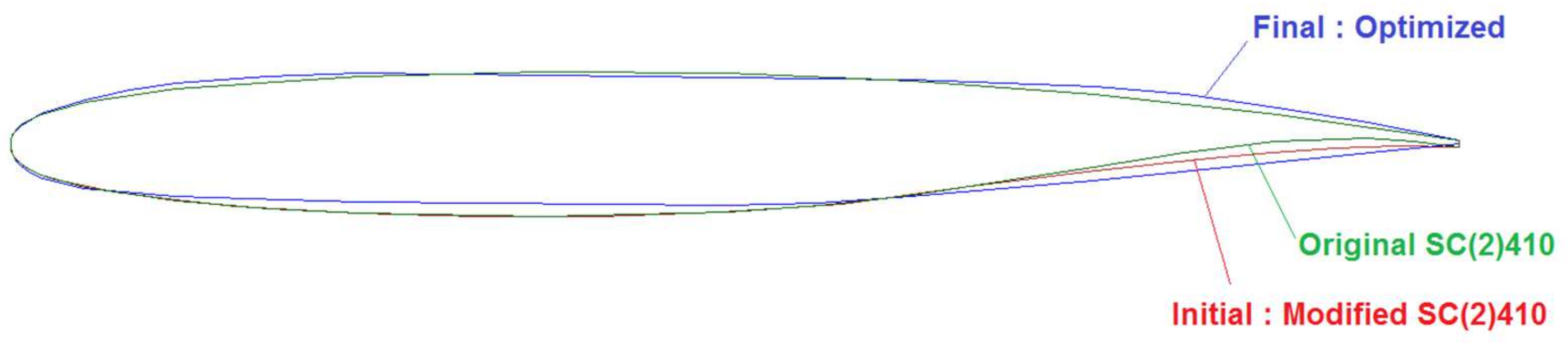

Figure 2). PVG is a fixed component high-lift device and, unlike small conventional vortex generators, locates outside the boundary layer region. The performance and advantages of this new aerodynamic surface compared to other high-lift devices are discussed in this article. According to the location of PVG, this device can be used in combination with other BLC methods (except Leading-Edge Extension (LEX)). In this research, the effect of PVG along with semi-active BLC, i.e., several types of leading-edge and trailing-edge flaps, are investigated. Additionally, the combination of PVG with the lifting surface optimization method is also presented at the same time. To evaluate the concept of PVG in a more realistic manner, the wing airfoil is optimized in three-point optimization, including takeoff condition, maneuver point, and cruise condition, using the adjoint method.

The adjoint method has been well-developed in recent decades [

4,

5,

6]. The computational cost of this method is independent of the number of design variables. Hence, the low computational cost is an advantage of this method over other gradient-based methods. This method involves two different approaches, including continuous and discrete. The second approach results in more precise gradients [

5], so it has been implemented in this work. To accelerate the optimization process, a 2D all-speed flow and adjoint solver based on a viscous unstructured finite volume method is developed [

7,

8]. To do this, the 3D conditions of the aircraft are reduced to 2D conditions using conventional methods.

As stated before, it is possible to use PVG together with other high-lift devices. However, in the case of LEX, it is not reasonable to use it at the same time. LEX, an aerodynamic surface, has been proposed to delay the aircraft stall [

9,

10,

11]. Like PVG, it prevents flow separation by creating a vortex flow over a wide area of the wing. Therefore, there is a possibility of interference between these vortex flows. Herein, it is necessary to make a comparison between the performance of LEX and PVG.

Generally, the position of a LEX in the front region of a wing moves forward the aerodynamic center, and therefore, the static stability of an aircraft decreases. As an example, the wind tunnel tests of the F-16 model show that installing a LEX shifts the aerodynamic center from approximately 7.2 to 3 percent of

(mean aerodynamic chord) in the linear region of the lift curve [

11]. To compensate for the LEX effect, either the aircraft gravity center must move forward, or an artificial stability system (such as stability augmentation system (SAS) or fly-by-wire (FBW)) should be used. The requirements impose complexity and cost. As it is shown in the results, PVG does not move the aerodynamic center of the aircraft, and as a result, the static stability of the aircraft does not change. In contrast to this advantage, PVG in this research is proposed for installation on low-wing aircraft, which is a limitation compared to LEX. For the use of PVG in high-wing aircraft, other innovative designs are required, which are beyond the scope of this work.

Other methods, such as using dogtooth or vortex generators (VGs), delay the separation in the local area of the wing and have local effects. LEX, dogtooth, and VGs are sometimes used together to delay separation in the fuller part of the wing.

VGs alone have been investigated in several previous reports, and good review articles have been published in this field [

1]. In a three-element high-lift airfoil at M = 0.2 and Re = 5 × 10

6, 10% lift increase and in RAE 5243 transonic airfoil at M = 0.67 and Re = 19 × 10

6, 20% lift increase were reported [

1]. It should be emphasized that these data are for the airfoil alone, and the effectiveness of the results will be reduced in an aircraft in the presence of a fuselage. However, it seems that the combination of PVG with conventional VGs leads to synergy in the results, which is another research.

Another device in the passive control of the boundary layer is the nacelle strake. This device compensates for the negative effect of turbofan engine nacelles on the wing flow field. It increases the

value by about 5.5% in the high lift configuration [

12]. This device is installed in the front of a wing, and its functionality is similar to conventional strake (LEX). The position, size, and effects of this device are significantly different from the proposed PVG device shown in the results.

In addition to the above methods, other passive techniques such as dimples [

13,

14,

15], fish scales [

15], and micro-rod [

16] have been introduced to delay the flow separation in recent years. As long as these different techniques are not investigated in a single platform or practically used in an operational aircraft, it is not possible to state accurately their advantages and disadvantages. In the dimple and fish scale devices, different results have been reported. The differences can be due to their shape, position, size, and arrangement, as well as the analysis conditions. To examine them completely, according to

Figure 2, it is necessary to consider various issues such as their effect on the pitching moment, control and stability, buffeting, the strength of the structure, etc. Furthermore, the effect of combining the use of dimple and fish scales with PVG on aerodynamic coefficients needs an additional study. In the micro-rod device, it prevents severe stalling and creates a delay of about 2 degrees in the stall point [

16]. Again, it seems that in the practical use of this device, as well as the leading-edge slot device, one should pay attention to its effects on the aircraft cruise condition and structure vibration.

In this work, the introduced method was examined by itself. Only a general comparison is made with the LEX and Nacelle strake techniques as methods that have been applied in various aircrafts.

In the results section, PVG is implemented on a sample of an advanced low-wing training jet. In order to reduce the complexity and the volume of computing mesh, the results are provided for the wing-body configuration.

According to

Figure 2, in presenting PVG as a new fixed component high-lift device, extensive issues should be checked. In the first step, in addition to the main issue of increasing the

of the aircraft in takeoff/landing conditions at low-speed flows, the effects of PVG on aerodynamic coefficients are investigated in two conditions of high-speed flows, namely MMO and a maneuvering point. In the next step, according to

Figure 1, the combination of PVG as a fixed component high-lift device with the method of lifting surface optimization is conducted in order to achieve better results. For this purpose, using the adjoint method, the wing airfoil is optimized in the same three points of takeoff/ landing condition, MMO condition, and the maneuvering point. To check the optimization effects in the presence of PVG, a comparison between results in the same three points is presented. In the final step, again according to

Figure 1, the combination of PVG as a passive BLC with a semi-passive BLC is investigated. In other words, the effect of PVG on several combinations of the leading-edge flap and trailing-edge flap is investigated. Moreover, a conceptual consideration of the other issues raised in

Figure 2 is conducted.

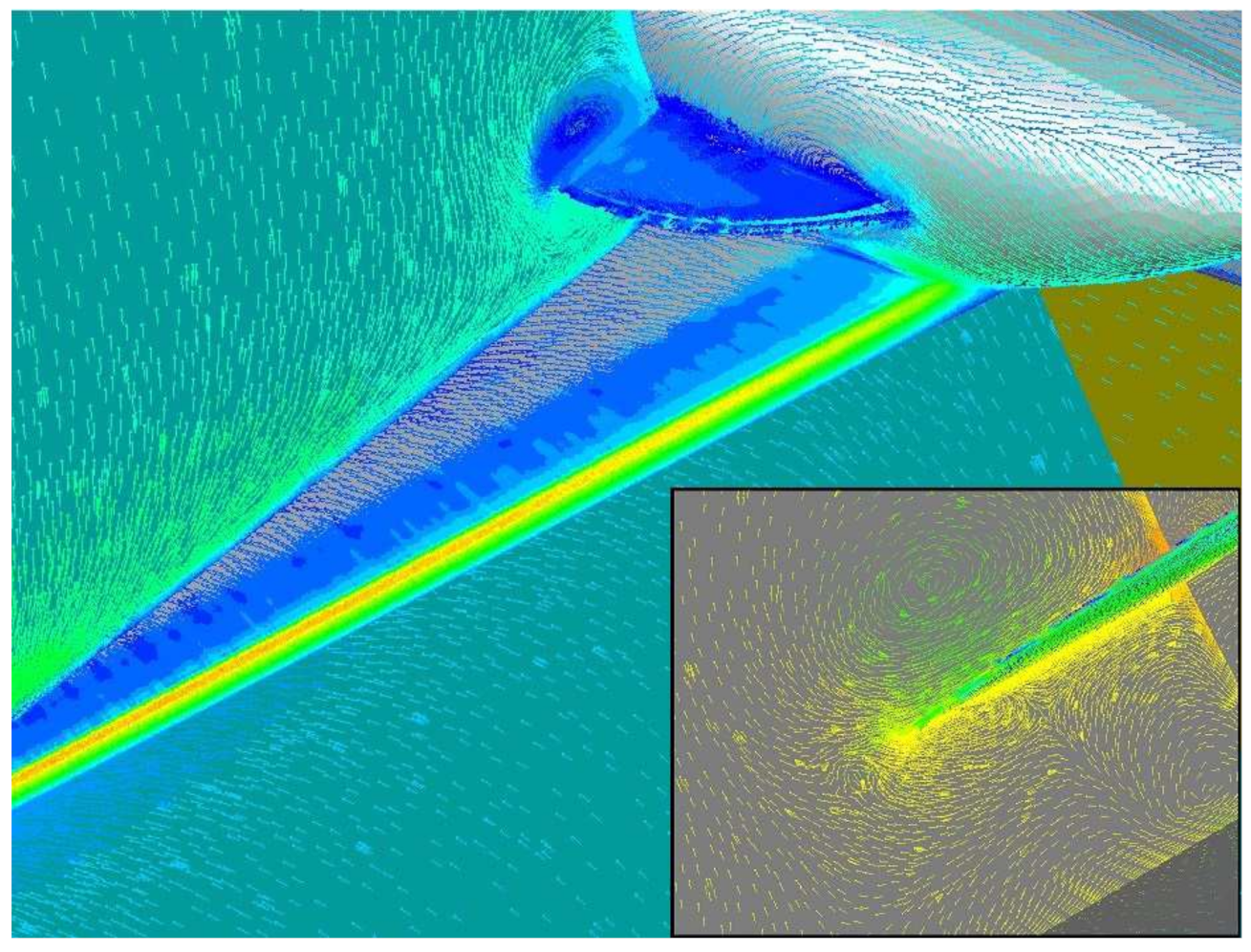

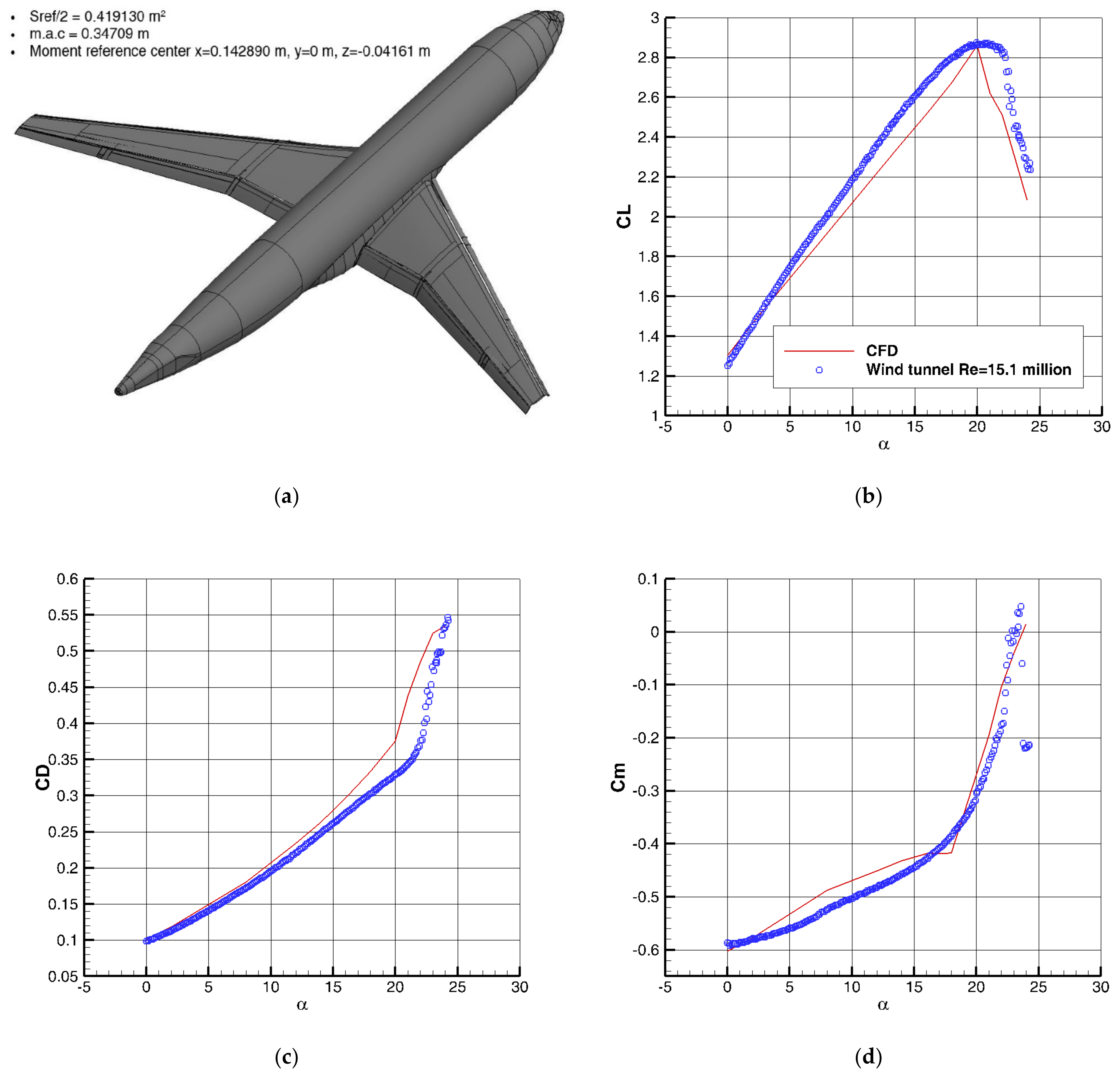

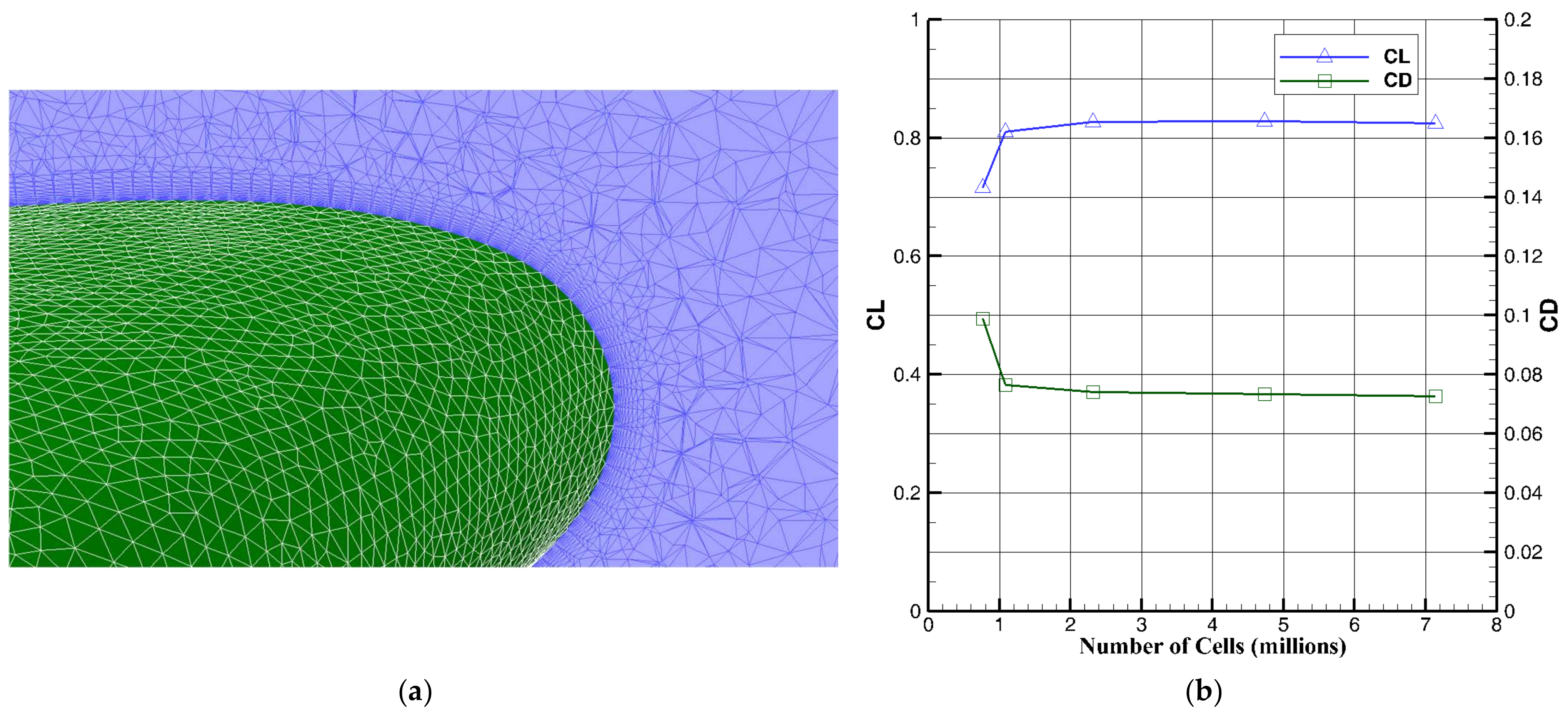

To validate the 3D numerical results, two CFD (computational fluid dynamic) test cases have been selected at low-speed (DLR-F11) [

17] and high-speed (AGARD B) [

18,

19,

20].

7. Conclusions

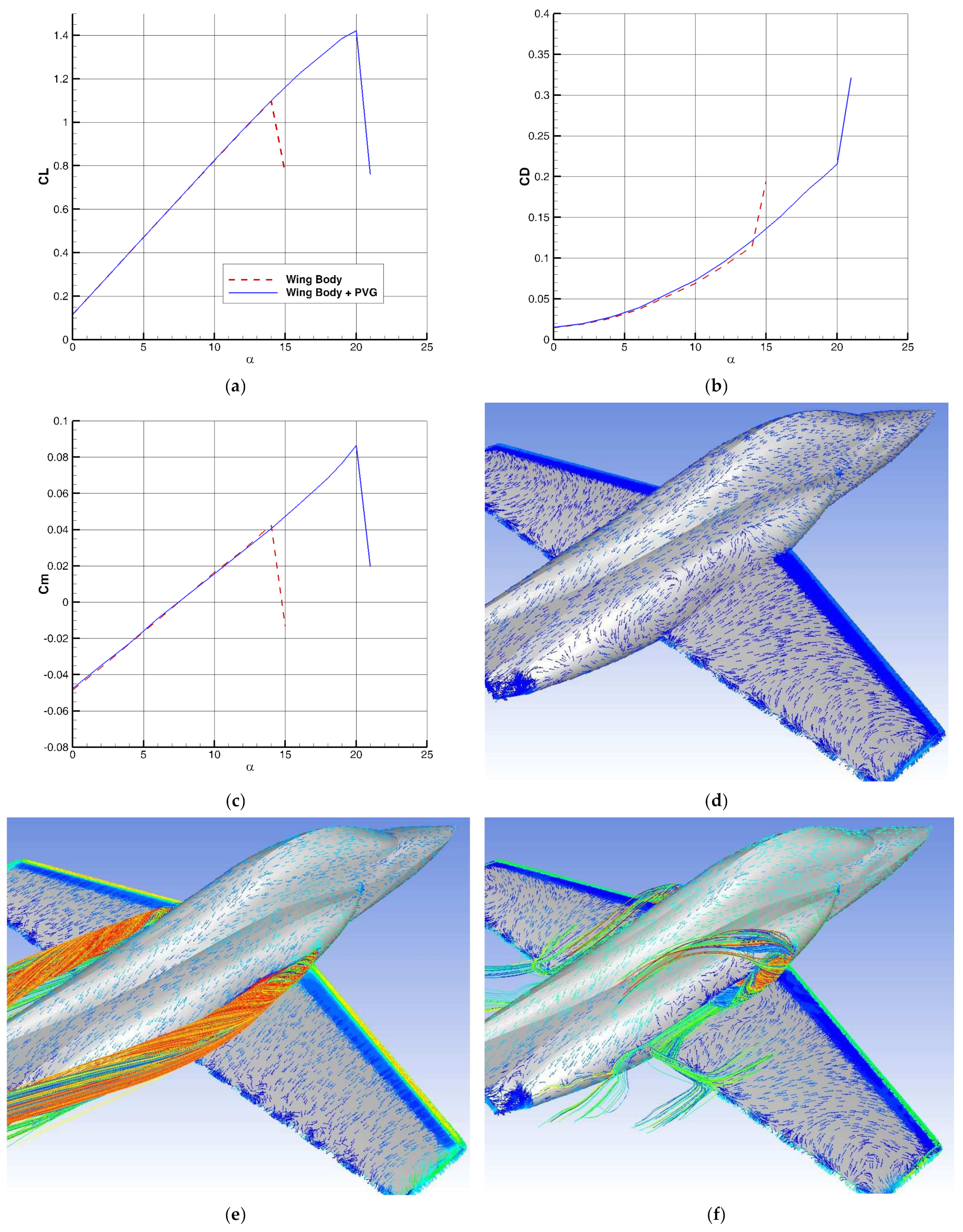

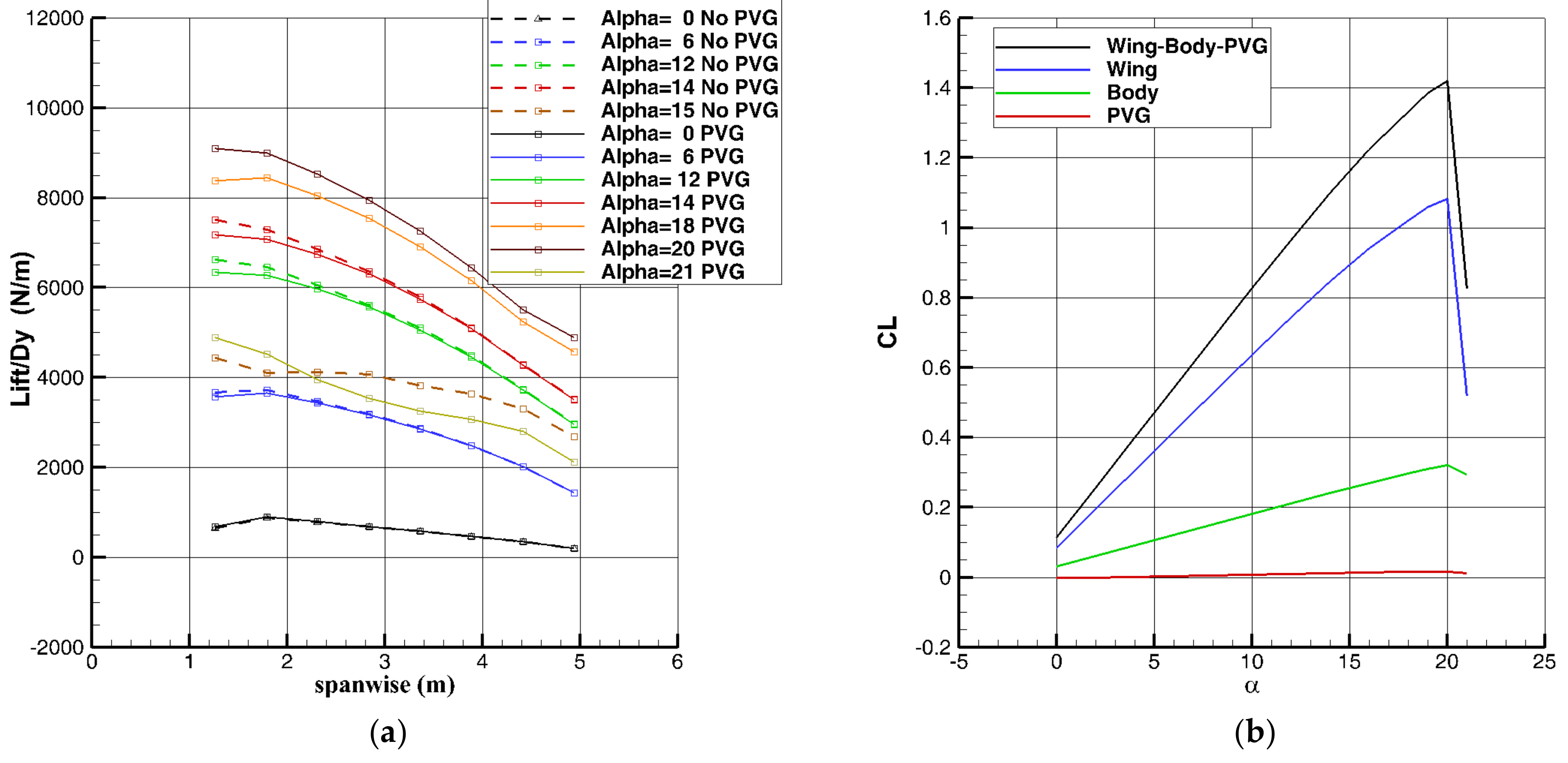

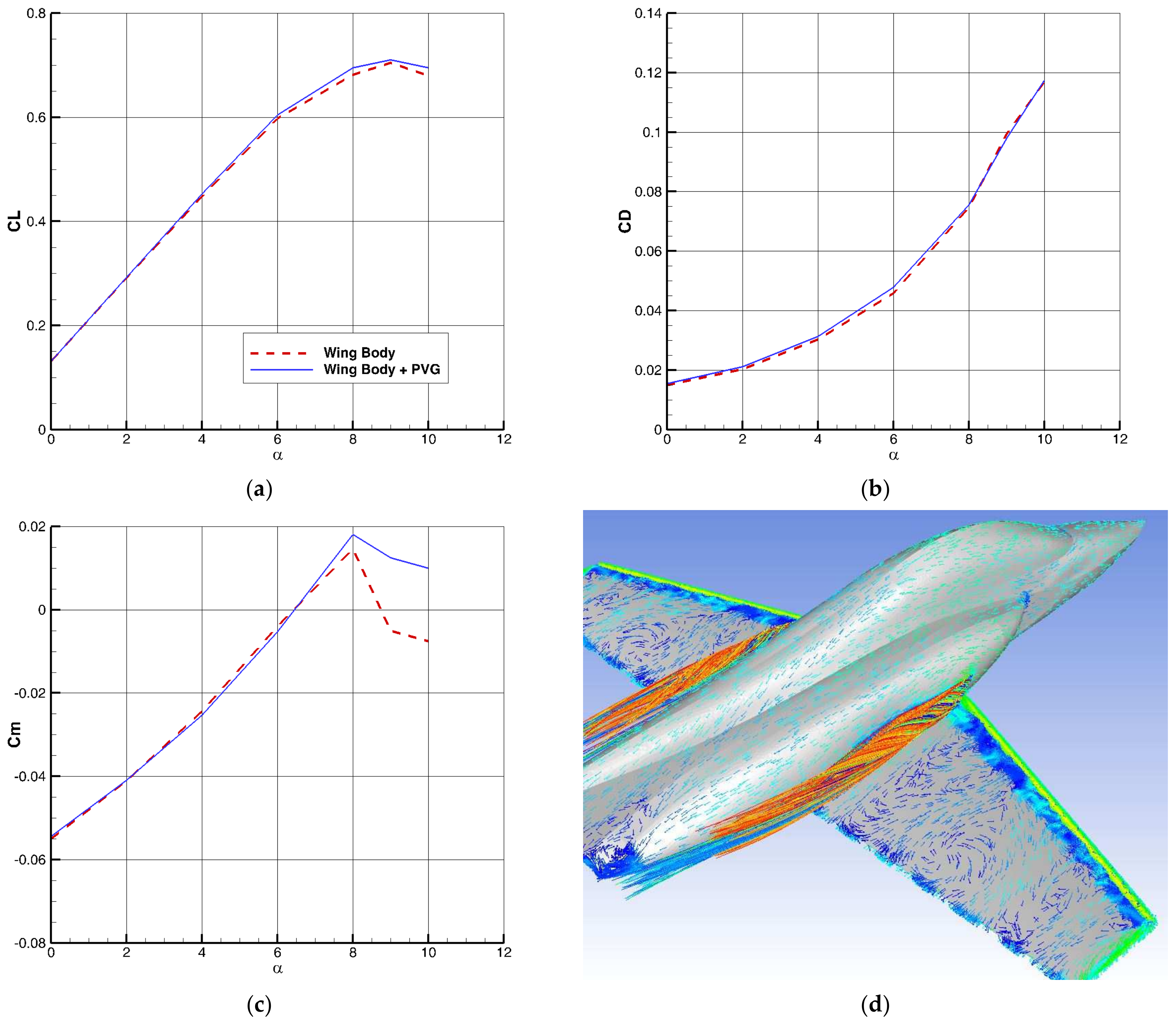

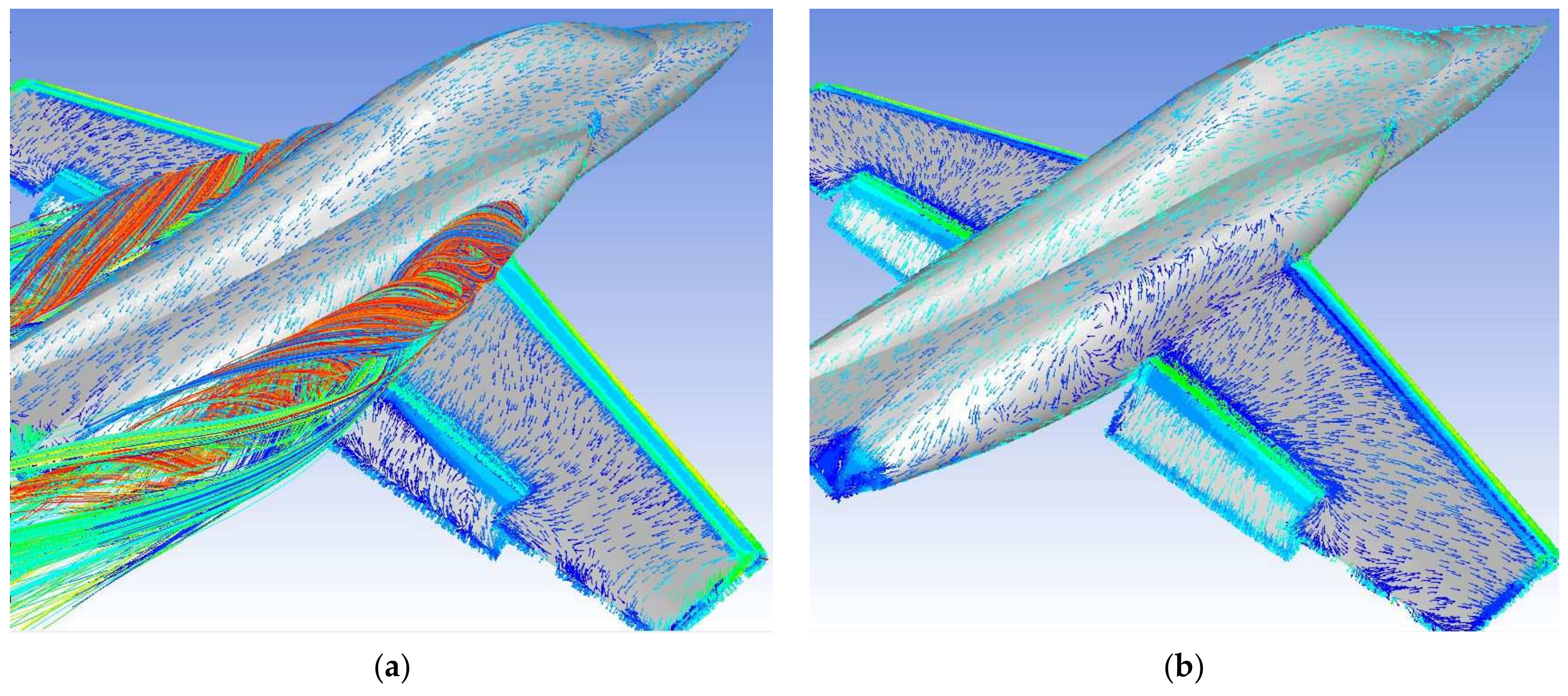

In this research, a new aerodynamic surface called PVG was introduced. Like the LEX and nacelle/body strake, this surface creates a strong vortex on the wing and delays the flow separation, but unlike the LEX, it does not change the stability and aerodynamic center of the aircraft. The results of this study were analyzed on a low-wing advanced training jet. In the clean configuration, the of the wing-body increases from 1.12 to 1.42 due to the six-degree stall delay in the presence of the PVG. Additionally, PVG does not show an inappropriate effect on aerodynamic coefficients at high speeds.

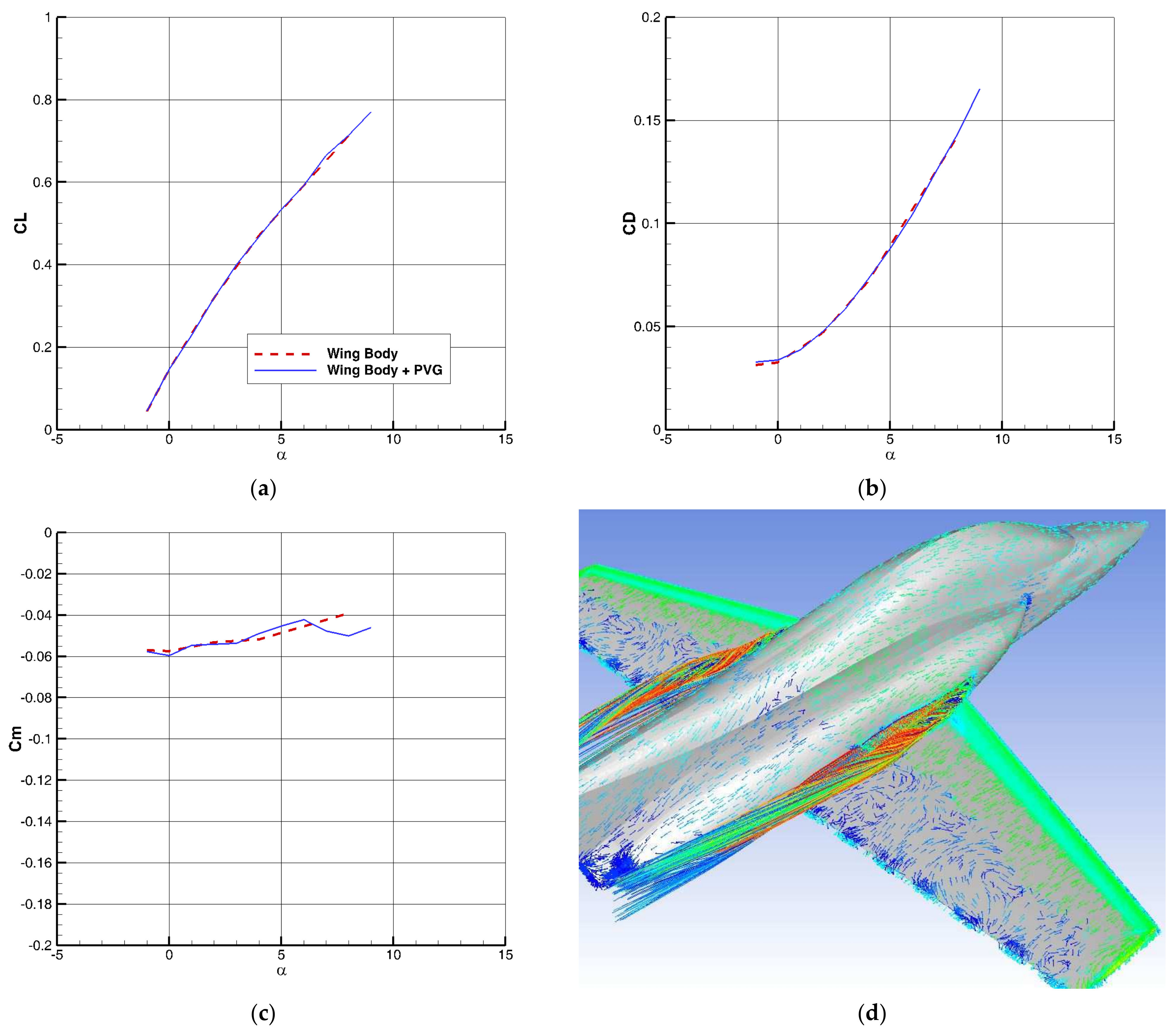

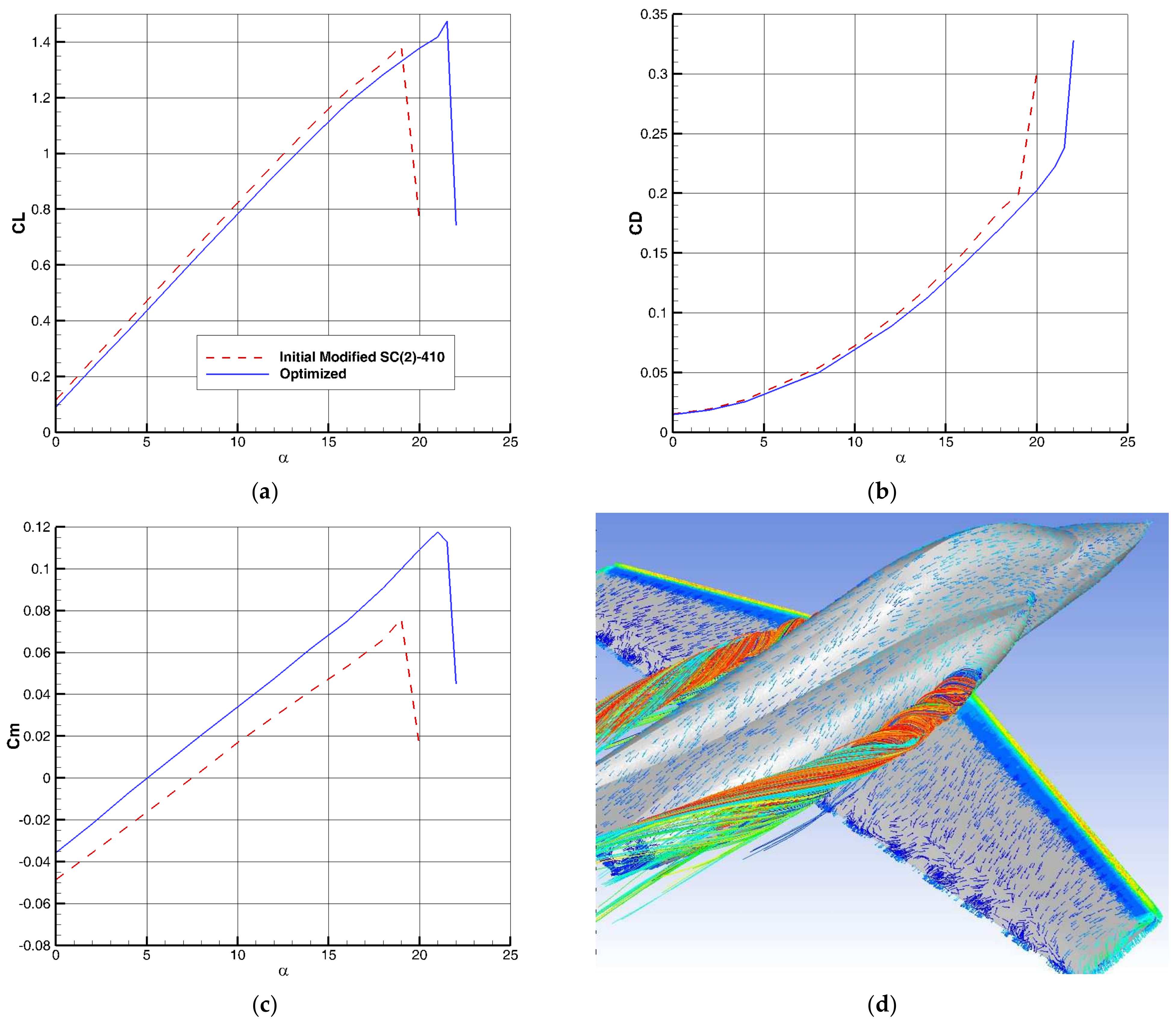

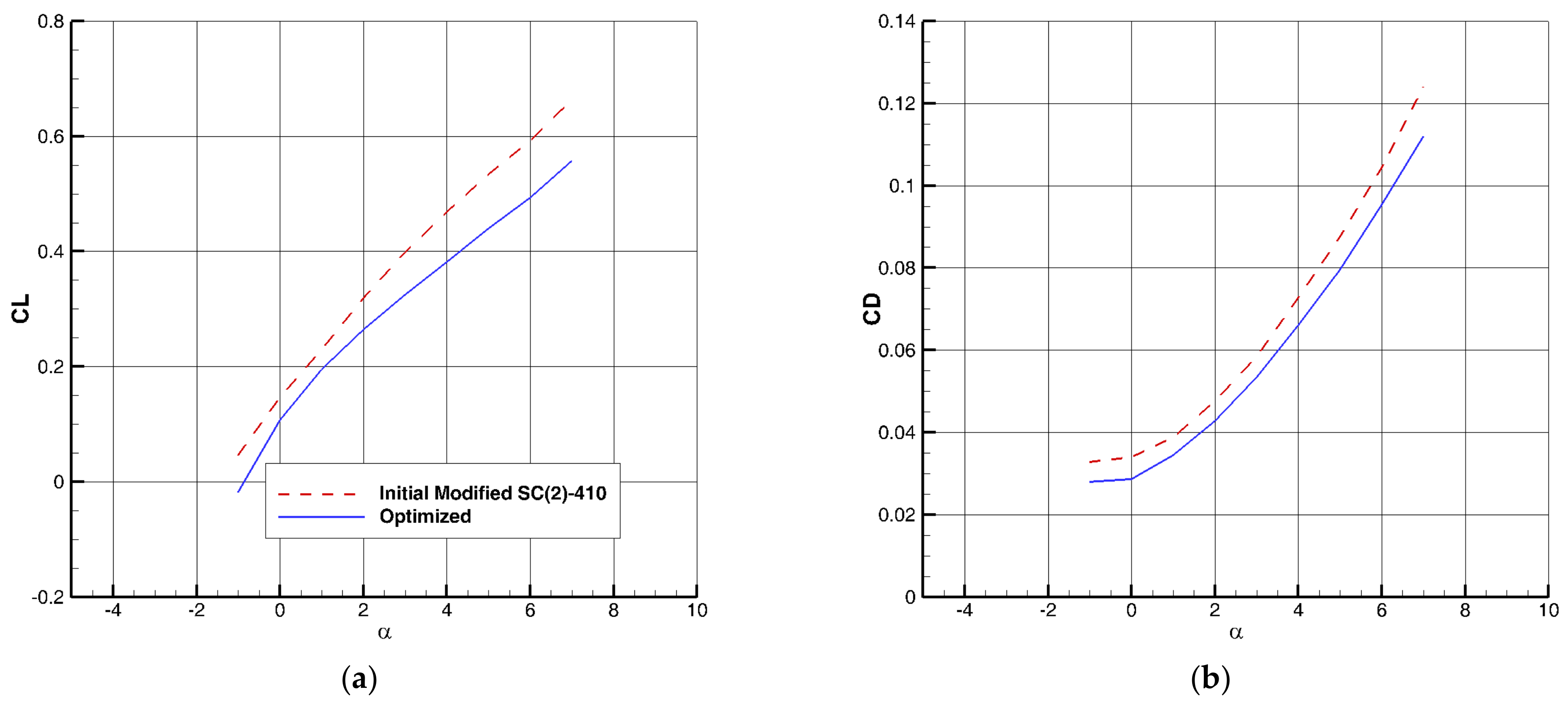

The optimization of the lifting surface as a passive BLC, using the adjoint method, causes further improvement in the value of so that this value increases from 1.42 to 1.48. The changes in the behavior of aerodynamic coefficients at high speeds are small.

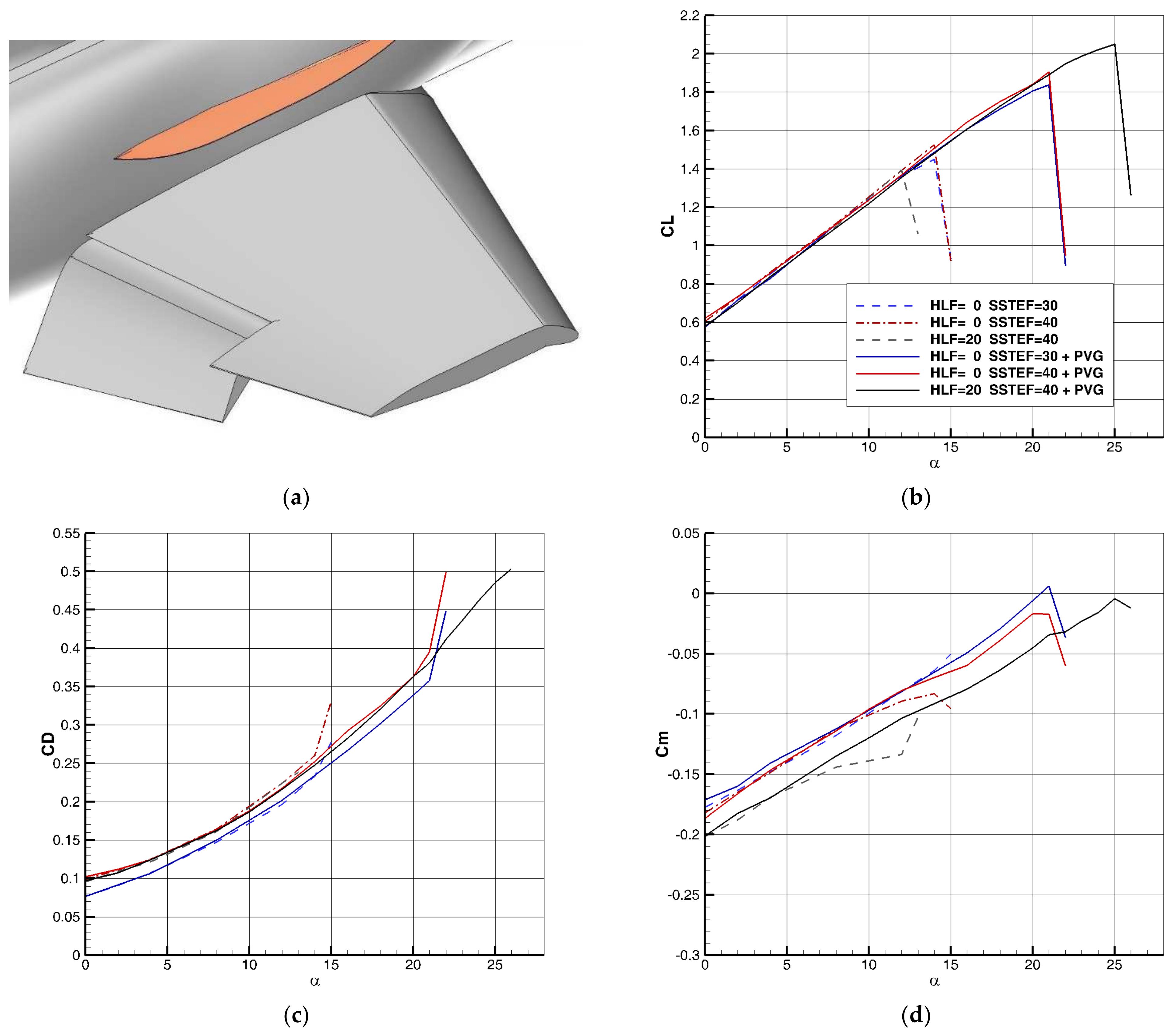

In the case of the hinged flaps of the leading edge and trailing edge ( and ), the value of increased from 1.21 to 1.8. Additionally, a significant increase in the value of is observed in the cases of single-slotted flaps of the trailing edge. In the case of and , the value of increases from 1.4 to 2.05 due to delay in the stall angle. According to the results, the efficiency of PVG is much higher than that of the nacelle strake. This is due to the proposed size and position of PVG, which makes it a powerful vortex generator. The new position also ensures that the aerodynamic center of the aircraft does not move.

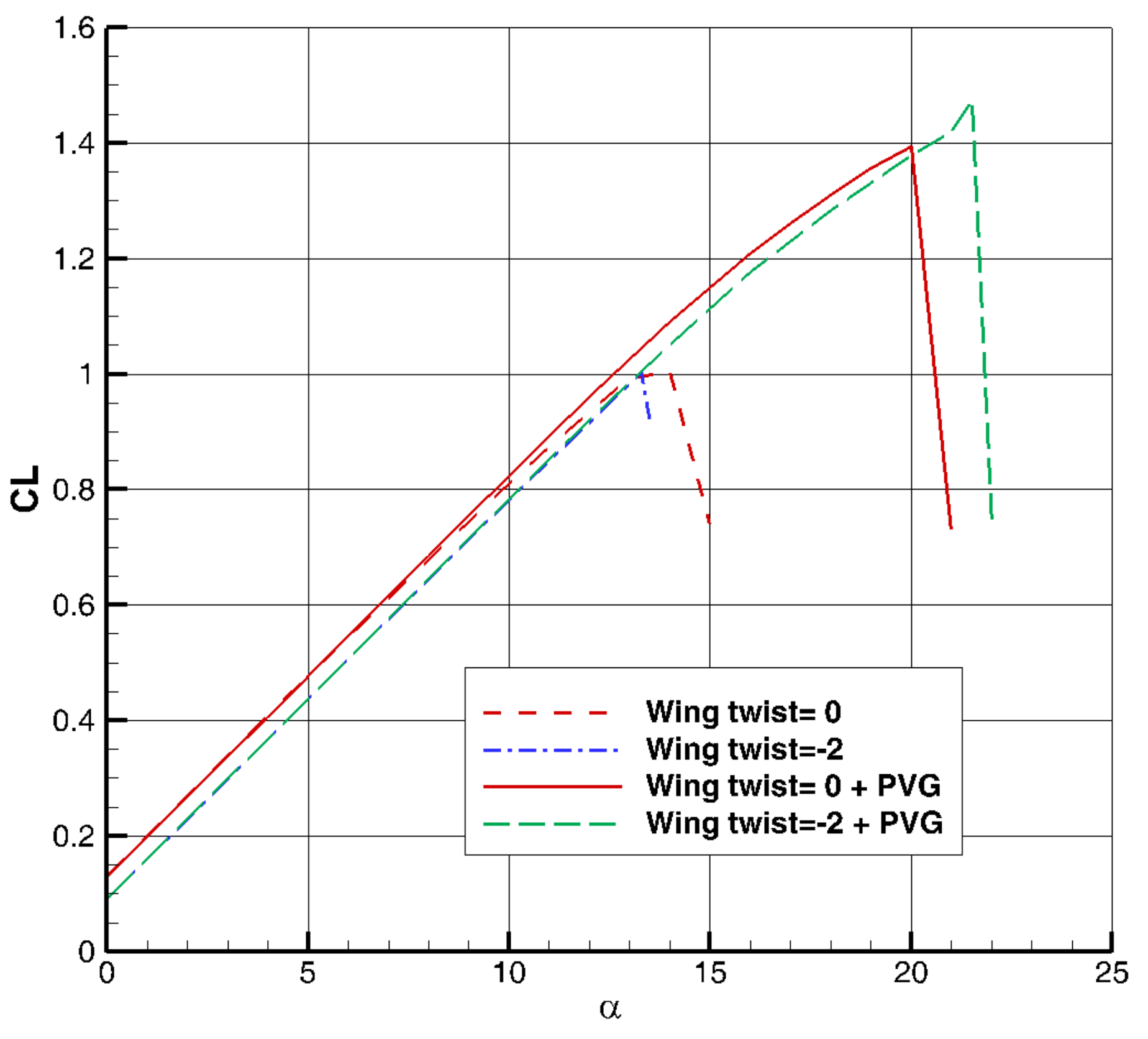

One of the characteristics of PVG, which was identified by investigating the effect of wing twist on PVG efficiency, is that the vortex generated by this aerodynamic surface affects the inner region of the wing more than its outer region. Therefore, the negative twist in the wing increases the effect of PVG.

According to the requirements of

Figure 2, acceptance of a new device depends on various issues. The above-obtained results are in the fields of aerodynamics, performance, stability, control, and air-loading. They show that applying a PVG on a low-wing aircraft with a speed range up to high subsonic Mach numbers improves the performance of the aircraft at low speeds without improper effects at high speeds. Additionally, due to the low contribution of lift force related to the PVG itself, there is not much aerodynamic load on it. For example, the estimation of the presented aircraft at sea level in M = 0.87 shows that the maximum load on the PVG is about 110 kg. Therefore, the structure required for PVG is simple and light and is negligible compared to the weight of the aircraft. This simple structure does not have a considerable negative effect on the maintainability of the aircraft.

Since the PVG aerodynamic surface is introduced for the first time in this work, more research is needed to optimize its effects as well as its possible applications. The additional works are suggested for the future as follows:

Complementary research on PVG effects in full aircraft configuration, including horizontal and vertical tails;

Research on combining PVG with other passive devices such as VGs, dimples, fish scales, etc.;

PVG shape optimization using the adjoint method or other optimization methods;

Investigations on PVG with the variable angle of incidence;

The possibility of use of PVG in low-wing business jets to increase T.O weight.