Experimental Study of a Tilt Single Slope Solar Still Integrated with Aluminum Condensate Plate

Abstract

:1. Introduction

2. Materials and Methods

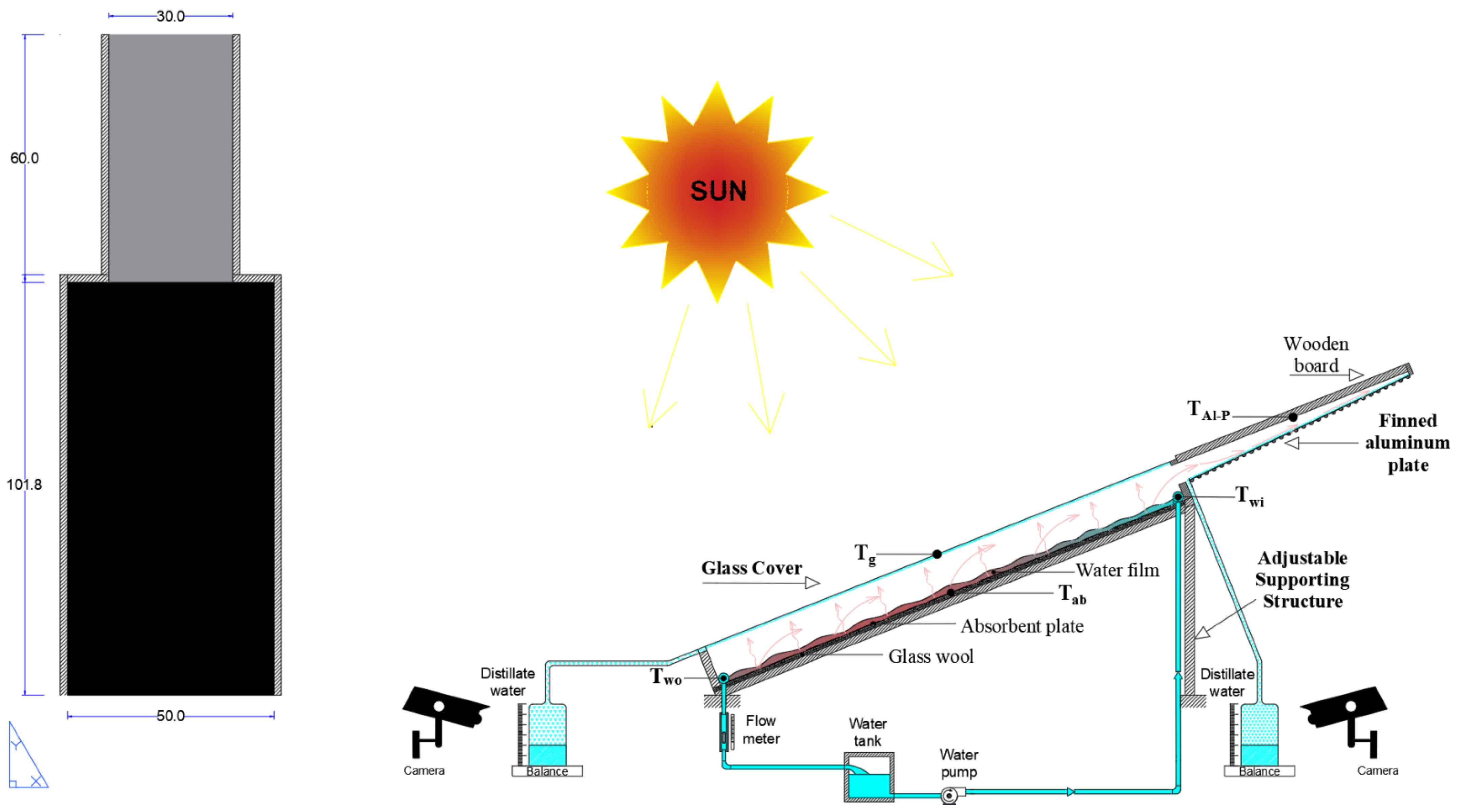

2.1. Experimental Setup

2.2. Experimental Method and Uncertainly Analysis

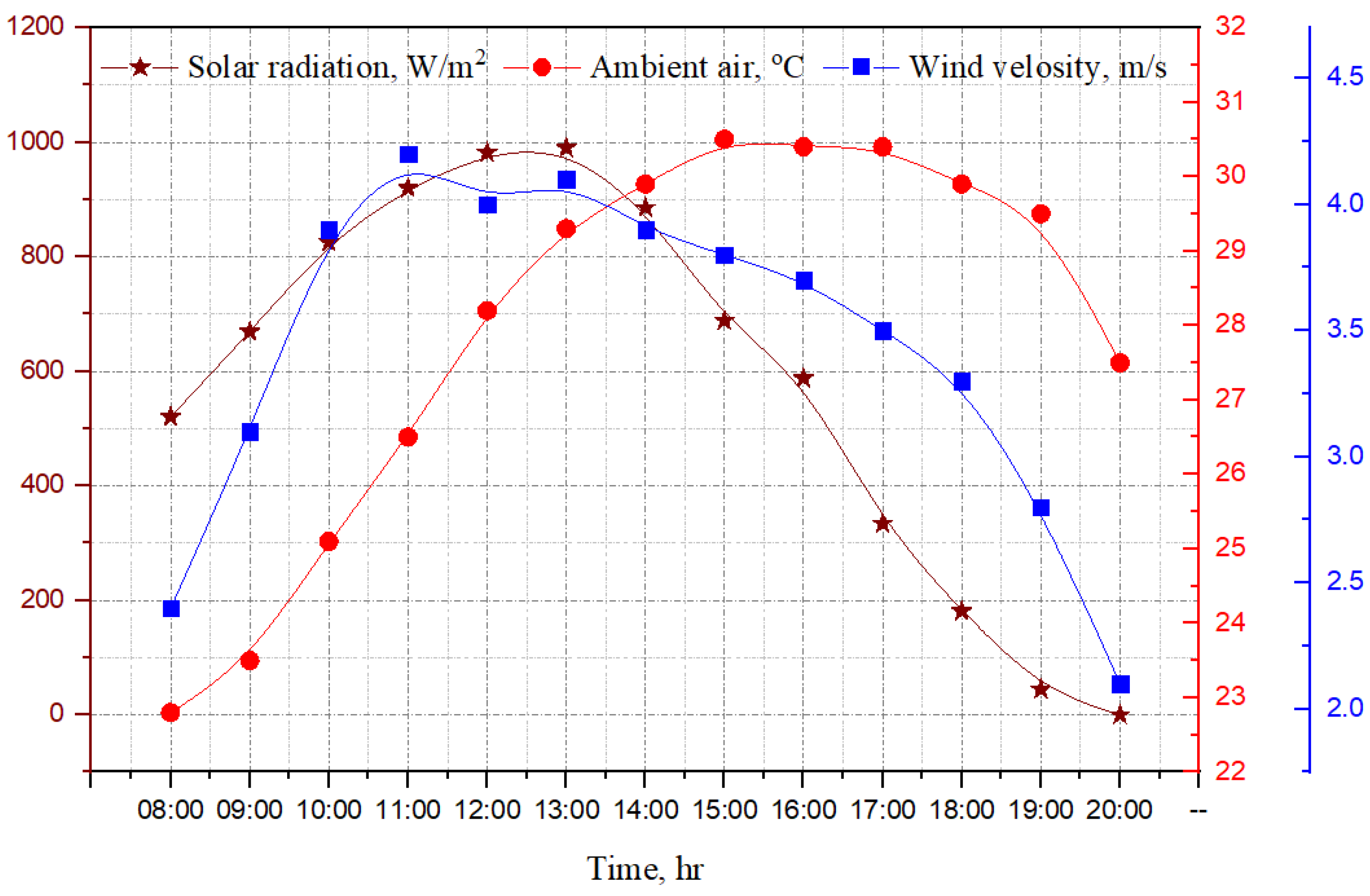

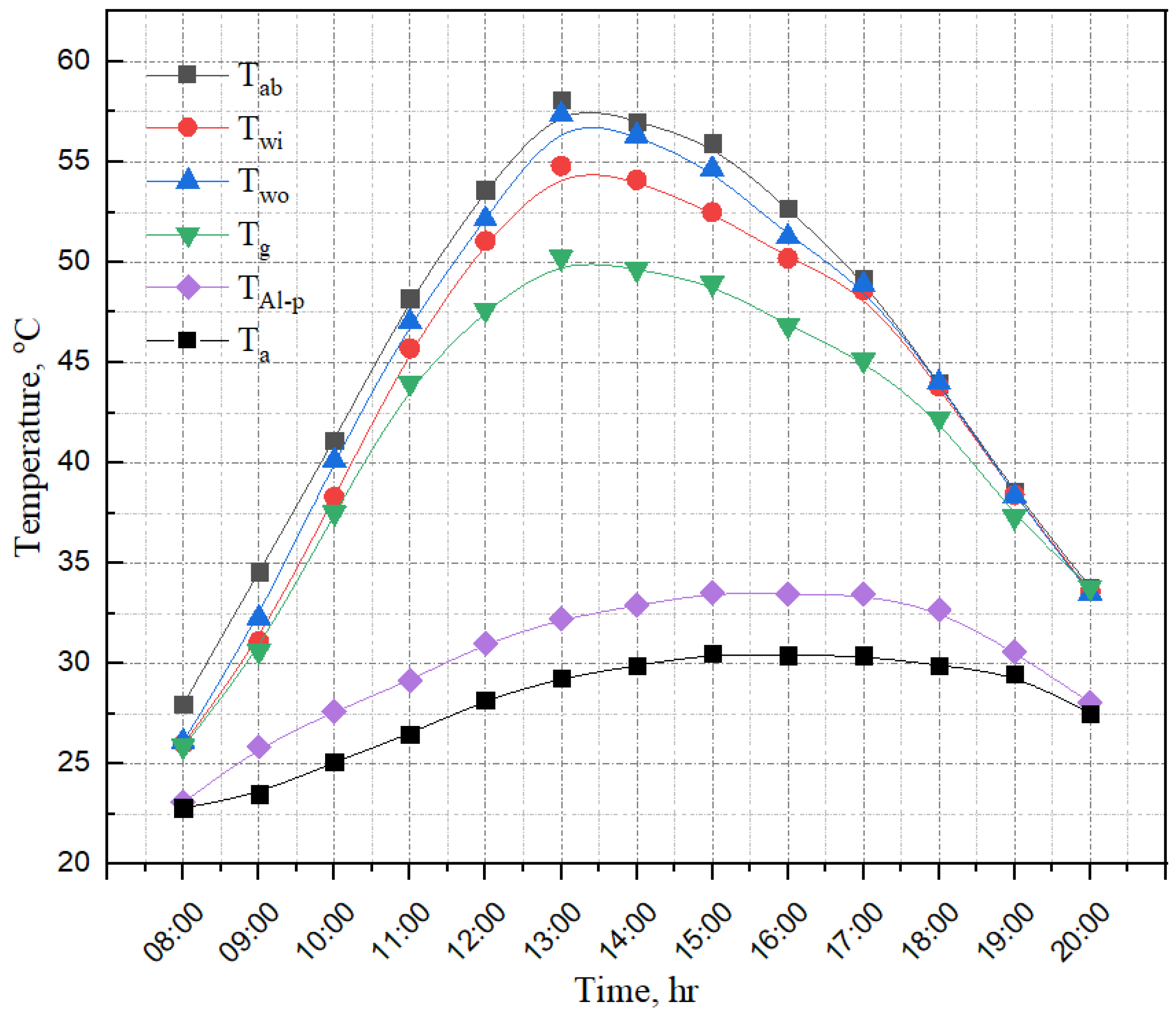

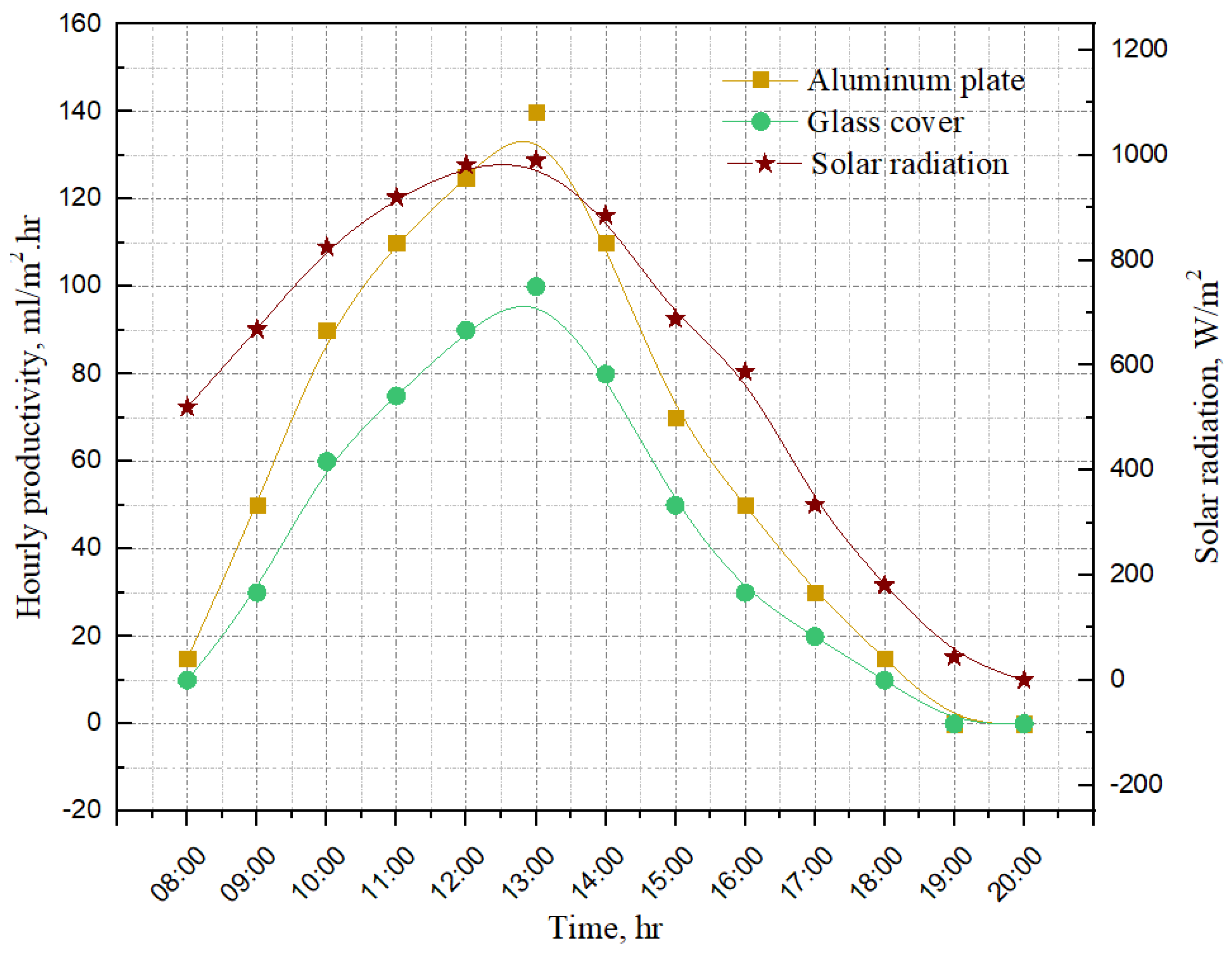

3. Results and Discussion

4. Analysis of Production Cost

5. Conclusions

- The suggested solar still is considered a pioneering attempt to produce freshwater water with a simple design and low cost, especially in remote and rural areas, by converting salt water into potable water (in areas where salt water is available) or extracting moisture from moist air (for areas with relatively high humidity).

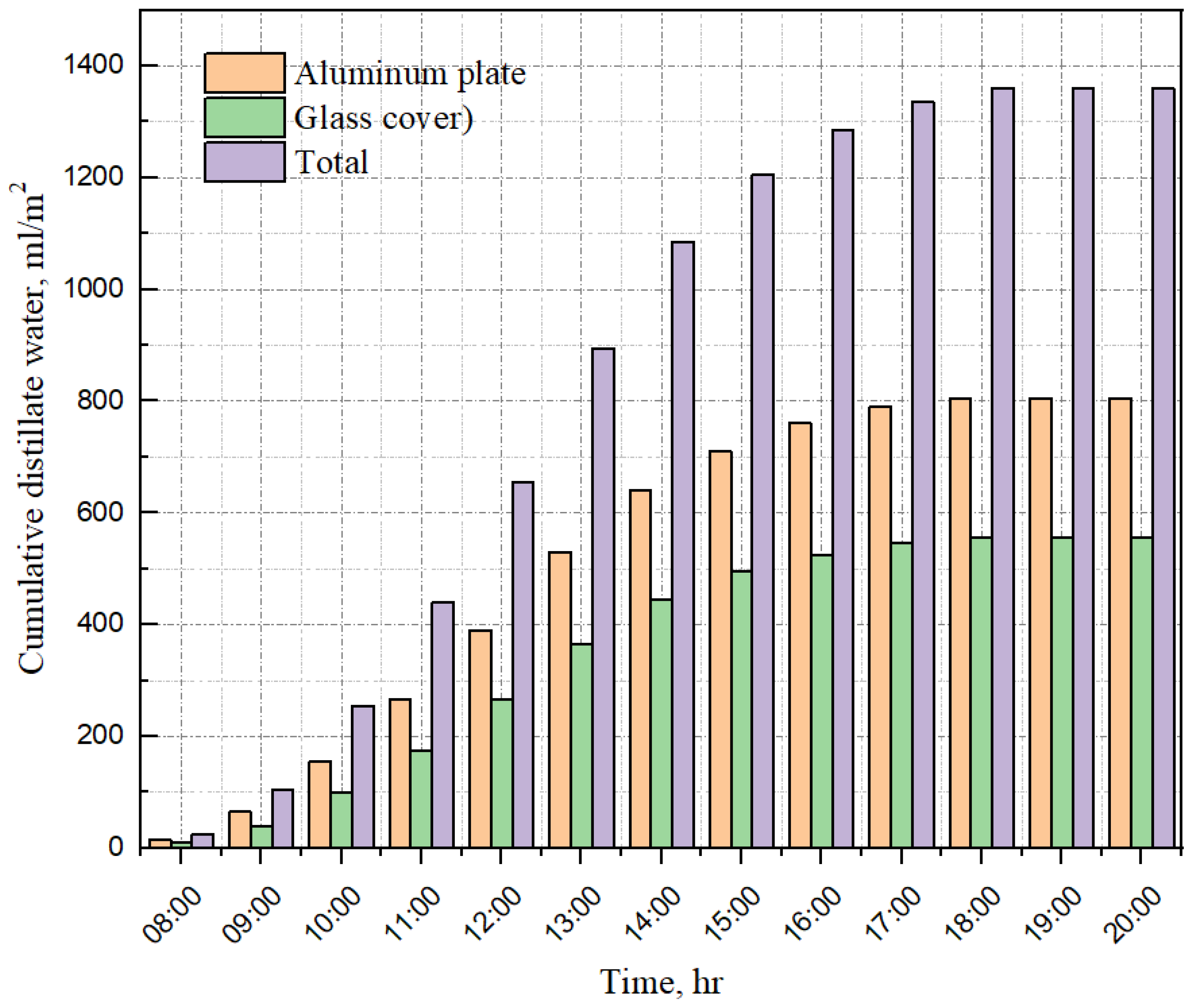

- The largest amount of water vapor condenses on the aluminum plate (about 46%), and the rest condenses on the glass cover. This means that the aluminum plate gave a significant effect in improving productivity.

- The system efficiency was generally low (the highest value was about 9.3 at 2:00 p.m.) due to the lower production rate relative to the solar energy absorbed by the absorber.

- In general, the estimated production cost of one liter of freshwater form suggested solar still is 0.063$. When compared with other studies, agreement was good with it in terms of the cost of production per liter of freshwater.

- In the future, it is proposed to implement this new form of solar still by adding the filament to the absorbent plate, and the suggested solar still area should be greater than .

Author Contributions

Funding

Conflicts of Interest

References

- Tiwari, G.N.; Singh, H.N.; Tripathi, R. Present status of solar distillation. Sol. Energy 2003, 75, 367–373. [Google Scholar] [CrossRef]

- Khawaji, A.D.; Kutubkhanah, I.K.; Wie, J.M. Advances in seawater desalination technologies. Desalination 2008, 221, 47–69. [Google Scholar] [CrossRef]

- García-Rodríguez, L. Seawater desalination driven by renewable energies: A review. Desalination 2002, 143, 103–113. [Google Scholar] [CrossRef]

- Muhammad-Sukki, F.; Munir, A.B.; Ramirez-Iniguez, R.; Abu-Bakar, S.H.; Mohd Yasin, S.H.; McMeekin, S.G.; Stewart, B.G. Solar photovoltaic in Malaysia: The way forward. Renew. Sustain. Energy Rev. 2012, 16, 5232–5244. [Google Scholar] [CrossRef]

- REN21. Renewables 2016 Global Status Report; REN21: Paris, France, 2016; ISBN 978-3-9818107-0-7. [Google Scholar]

- Ayoub, G.M.; Malaeb, L. Economic feasibility of a solar still desalination system with enhanced productivity. DES 2014, 335, 27–32. [Google Scholar] [CrossRef]

- Agrawal, A.; Rana, R.S.; Shrivastava, P.K.; Singh, R.P. A Short Review on Solar Water Distillation for. 2016, 27–36.

- Alwan, N.T.; Shcheklein, S.E.; Ali, O.M. Productivity of enhanced solar still under various environmental conditions in Yekaterinburg city, Russia. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Belgorod, Russia, 31 October–1 November 2020; Volume 791. [Google Scholar]

- Muftah, A.F.; Alghoul, M.A.; Fudholi, A.; Abdul-Majeed, M.M.; Sopian, K. Factors affecting basin type solar still productivity: A detailed review. Renew. Sustain. Energy Rev. 2014, 32, 430–447. [Google Scholar] [CrossRef]

- Alwan, N.T.; Shcheklein, S.E.; Ali, O.M. Evaluation of the productivity for new design single slope solar still at different saltwater depth. J. Phys. Conf. Ser. 2020, 1706. [Google Scholar] [CrossRef]

- Alwan, N.T.; Shcheklein, S.; Ali, O. Investigation of the coefficient of heat transfer and daily cumulative production in a single-slope solar distiller at different water depths. Energy Sources Part A Recover. Util. Environ. Eff. 2020, 1–18. [Google Scholar] [CrossRef]

- Sharma, M.; Tiwari, A.K.; Mishra, D.R. A review on desalination of water using single slope passive solar still. Int. J. Dev. Res. 2016, 6, 10002–10012. [Google Scholar]

- Alwan, N.T.; Shcheklein, S.E.; Ali, O.M. Experimental investigation of solar distillation system integrated with photoelectric diffusion-absorption refrigerator (DAR). Intern. Conf. Numer. Anal. Appl. Math. Icnaam 2020, 2290, 50023. [Google Scholar]

- Ahmed, H.M.; Ibrahim, G. Thermal Performance of a Conventional Solar Still with a Built-in Passive Condenser: Experimental studies. J. Adv. Sci. Eng. Res. 2017, 7, 1–12. [Google Scholar]

- Cooper, P.I. Some factors affecting the absorption of solar radiation in solar stills. Sol. Energy 1972, 13, 373–381. [Google Scholar] [CrossRef]

- Alwan, N.T.; Shcheklein, S.E.; Ali, O.M. A practical study of a rectangular basin solar distillation with single slope using paraffin wax (PCM) cells. Int. J. Energy Convers. 2019, 7, 162–170. [Google Scholar] [CrossRef]

- Deniz, E. An experimental and theoretical analysis of a vacuum tube solar collector-assisted solar distillation system. Energy Sources Part A Recover. Util. Environ. Eff. 2012, 34, 1637–1645. [Google Scholar] [CrossRef]

- Essa, F.A.; Abdullah, A.S.; Omara, Z.M. Rotating discs solar still: New mechanism of desalination. J. Clean. Prod. 2020, 275, 123200. [Google Scholar] [CrossRef]

- Alwan, N.T.; Shcheklein, S.E.E.; Ali, O.M. Case Studies in Thermal Engineering Experimental investigation of modified solar still integrated with solar collector. Case Stud. Therm. Eng. 2020, 19, 100614. [Google Scholar] [CrossRef]

- Naseer, T.A.; Shcheklein, S.E.; Ali, O.M. Effect of Hollow Drum Rotational Speed Variation on the Productivity of Modified Solar Still According to Yekaterinburg City, Russia. Appl. Sol. Energy (English Transl. Geliotekhnika) 2020, 56, 276–283. [Google Scholar] [CrossRef]

- Alwan, N.T.; Shcheklein, S.E.; Ali, O.M. Experimental investigations of single-slope solar still integrated with a hollow rotating cylinder. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Baghdad, Iraq, 16–17 December 2020; Volume 745. [Google Scholar]

- Alwan, N.T.; Shcheklein, S.E.; Ali, O.M. Materials Today: Proceedings Experimental analysis of thermal performance for flat plate solar water collector in the climate conditions of Yekaterinburg, Russia. Mater. Today Proc. 2021, 42, 2076–2083. [Google Scholar] [CrossRef]

- Fath, H.E.S.; El-Samanoudy, M.; Fahmy, K.; Hassabou, A. Thermal-economic analysis and comparison between pyramid-shaped and single-slope solar still configurations. Desalination 2003, 159, 69–79. [Google Scholar] [CrossRef]

- Shehata, A.I.; Kabeel, A.E.; Khairat Dawood, M.M.; Elharidi, A.M.; Abd_Elsalam, A.; Ramzy, K.; Mehanna, A. Enhancement of the productivity for single solar still with ultrasonic humidifier combined with evacuated solar collector: An experimental study. Energy Convers. Manag. 2020, 208, 112592. [Google Scholar] [CrossRef]

- Kabeel, A.E.; Hamed, A.M.; El-Agouz, S.A. Cost analysis of different solar still configurations. Energy 2010, 35, 2901–2908. [Google Scholar] [CrossRef]

- Kumar, S.; Tiwari, G.N. Life cycle cost analysis of single slope hybrid (PV/T) active solar still. Appl. Energy 2009, 86, 1995–2004. [Google Scholar] [CrossRef]

- Ali Samee, M.; Mirza, U.K.; Majeed, T.; Ahmad, N. Design and performance of a simple single basin solar still. Renew. Sustain. Energy Rev. 2007, 11, 543–549. [Google Scholar] [CrossRef]

| Equipment | The Accuracy | The Range | The Error Ratio % | Units |

|---|---|---|---|---|

| Data logger | −200–1370 | 0.3% | ||

| Thermocouple | −100–200 | 0.3% | ||

| Mercurial thermometer | 0–100 | 0.5% | ||

| Solar power meter | 0.1% | 0–2000 | 0.1% |

| Type Material | Quality | SSS ($) |

|---|---|---|

| MDF Wooden Board 1.8 cm thickness | 2 m2 | 14 |

| Glass cover 0.4 cm thickness | 0.5 m2 | 1.5 |

| Galvanized stainless sheet, 0.1 cm | 0.5 m2 | 2 |

| Alminum plate | 0.2 m2 | 5 |

| PV panel and accessories | 1 piece | 50 |

| Micro water pump | 1 piece | 2 |

| Spray paint heat-resistant | 2 pieces | 3 |

| Heat-resistant silicone glue | 2 pieces | 3 |

| Total cost | - | 80.5 |

| The Item | Suggested Solar Still | The Item | Suggested Solar Still |

|---|---|---|---|

| Life expectancy for solar still, n | 10 | The value of salvage (S), $ | 16.1 |

| Interest rate per year i,% | 12 | Annual salvage value (ASV), $ | 0.916 |

| manufacturing and installation capital cost (CS), $ | 80.5 | Annual maintenance cost (AMC), $ | 2.136 |

| Capital recovery factor (CRF), | 0.1769 | Annual cost (AC), $ | 15.459 |

| Sinking fund factor (SFF) | 0.0569 | Yearly yield from the solar still system (180 days), L | 244.8 |

| First annual cost (FAC), $ | 14.240 | , $ | 0.063 |

| Studies | Solar Water Distiller Type | The Location | Daily Productivity, | |

|---|---|---|---|---|

| [23] | The single slope solar distiller | Egypt | 8.39 | 0.035 |

| [26] | The single slope solar distiller | India | 1.91 | 0.14 |

| [27] | The single slope solar distiller | Pakistan | 3.25 | 0.063 |

| [16] | The single slope solar distiller | Iraq | 2.35 | 0.035 |

| [19] | The single slope solar distiller integrated with solar water collector | Russia | 5.5 | 0.0477 |

| Current study | A tilt single slope solar still integrated with aluminum condensate plate (ACP) | Russia | 1.36 | 0.063 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alwan, N.T.; Majeed, M.H.; Shcheklein, S.E.; Ali, O.M.; PraveenKumar, S. Experimental Study of a Tilt Single Slope Solar Still Integrated with Aluminum Condensate Plate. Inventions 2021, 6, 77. https://doi.org/10.3390/inventions6040077

Alwan NT, Majeed MH, Shcheklein SE, Ali OM, PraveenKumar S. Experimental Study of a Tilt Single Slope Solar Still Integrated with Aluminum Condensate Plate. Inventions. 2021; 6(4):77. https://doi.org/10.3390/inventions6040077

Chicago/Turabian StyleAlwan, Naseer T., Milia H. Majeed, Sergey E. Shcheklein, Obed M. Ali, and Seepana PraveenKumar. 2021. "Experimental Study of a Tilt Single Slope Solar Still Integrated with Aluminum Condensate Plate" Inventions 6, no. 4: 77. https://doi.org/10.3390/inventions6040077

APA StyleAlwan, N. T., Majeed, M. H., Shcheklein, S. E., Ali, O. M., & PraveenKumar, S. (2021). Experimental Study of a Tilt Single Slope Solar Still Integrated with Aluminum Condensate Plate. Inventions, 6(4), 77. https://doi.org/10.3390/inventions6040077