3-D Printable Polymer Pelletizer Chopper for Fused Granular Fabrication-Based Additive Manufacturing

Abstract

1. Introduction

2. Materials and Methods

2.1. Designs

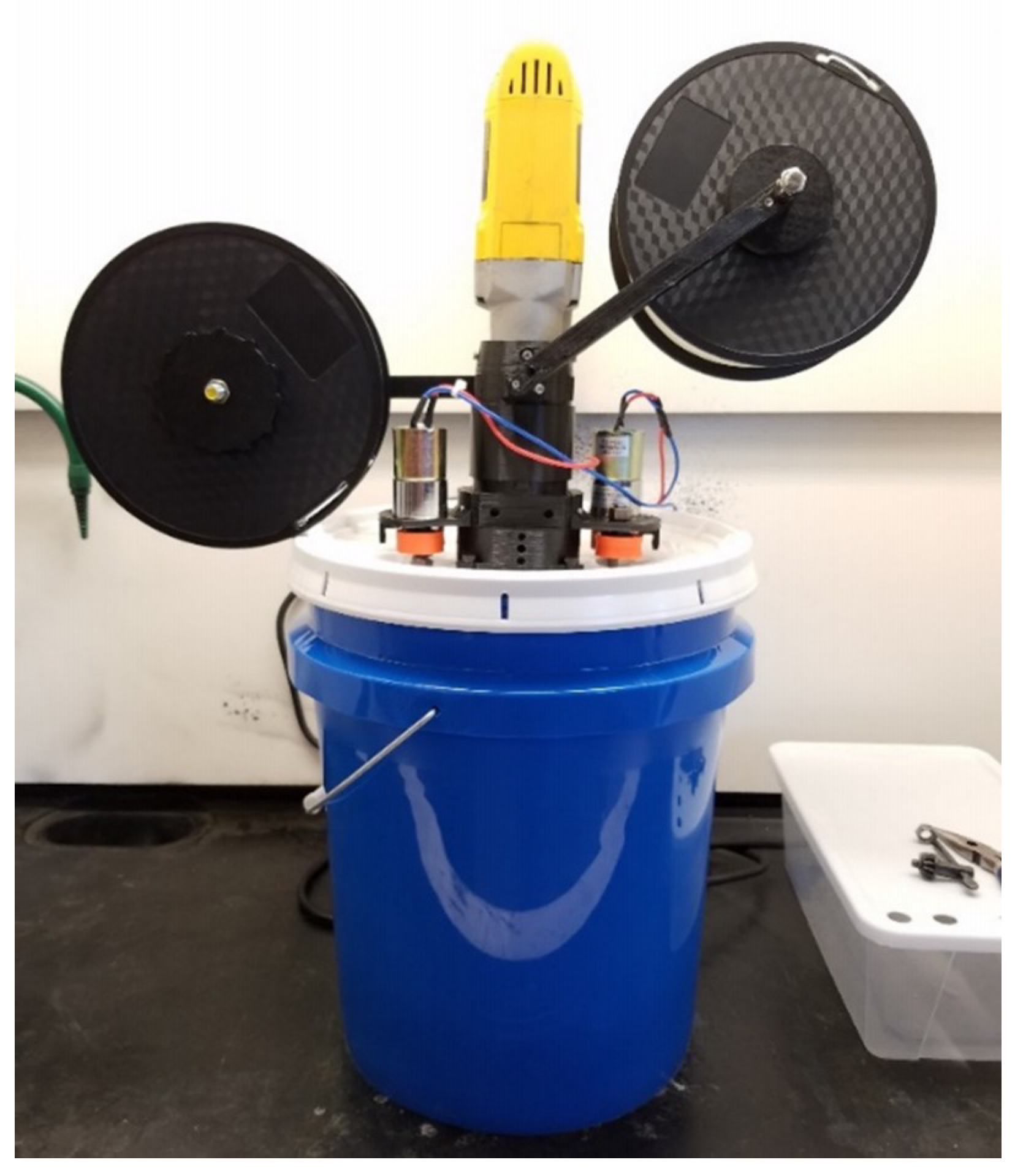

2.1.1. Mechanical

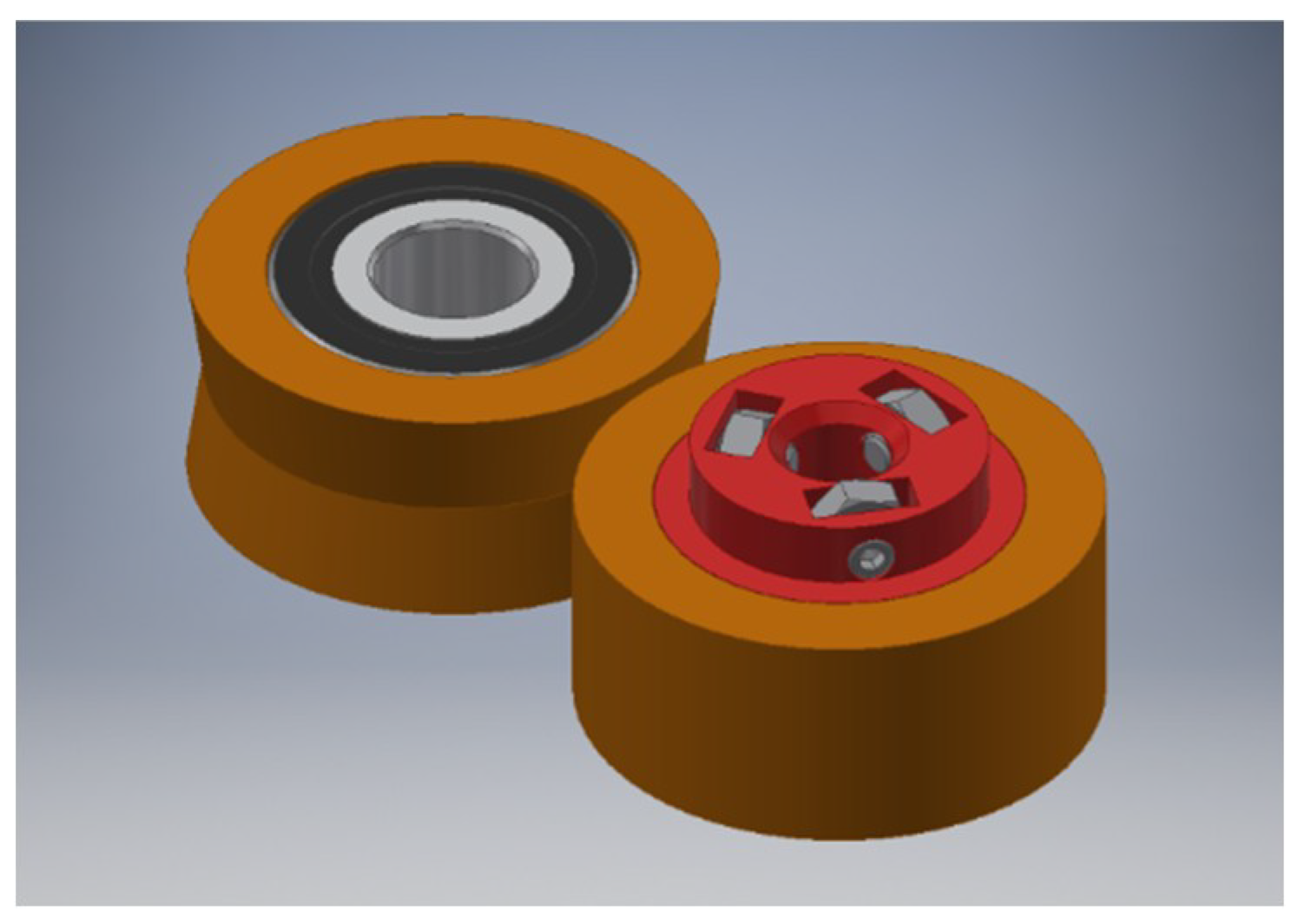

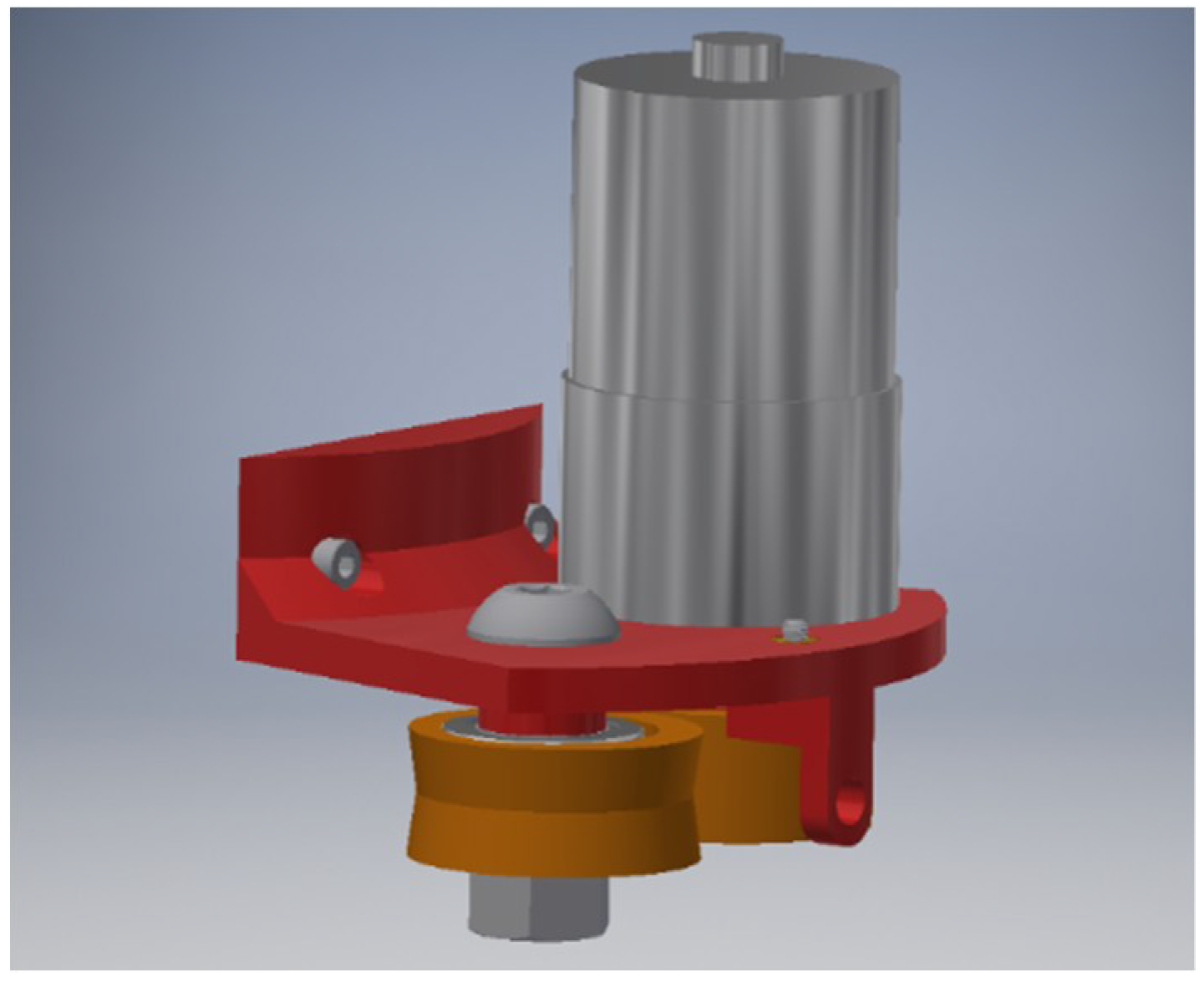

- Subassembly preparation for grabbing wheels.

- Glue Ninjaflex wheels to double stack of bearings

- Glue Ninjaflex wheels to printed motor wheel

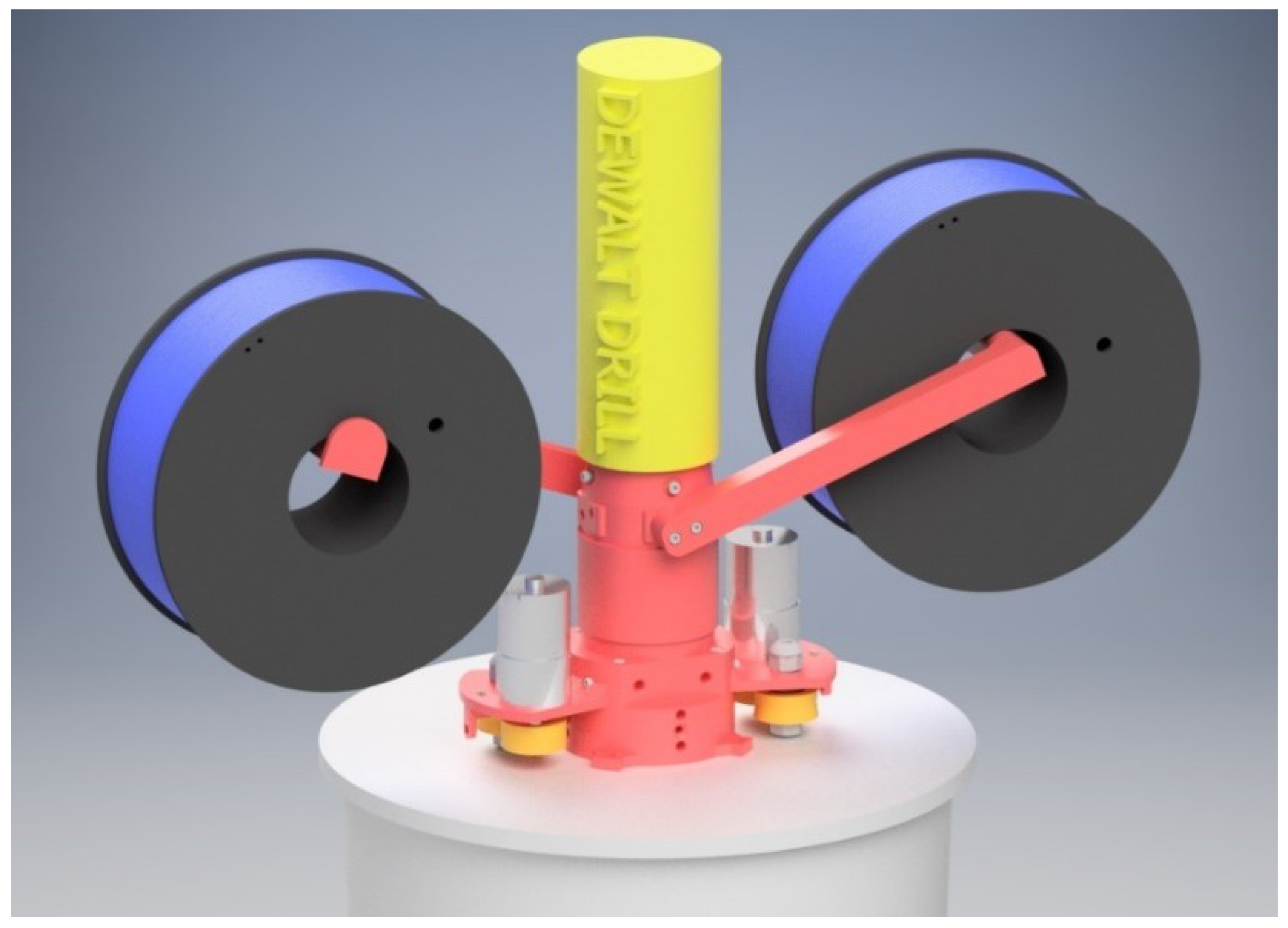

- Place M3 nuts and M3 grub screws into printed motor wheel as shown in Figure 2.

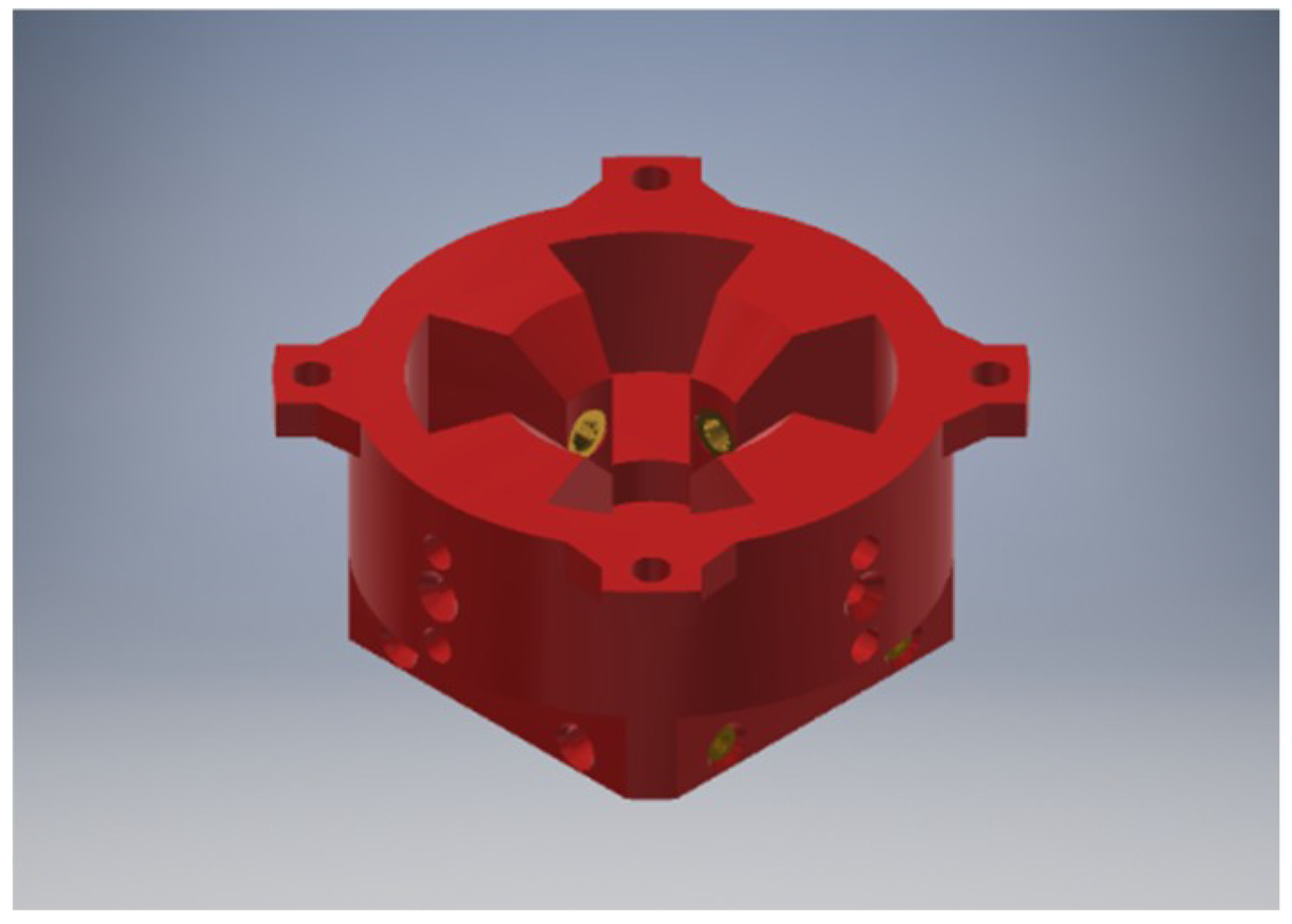

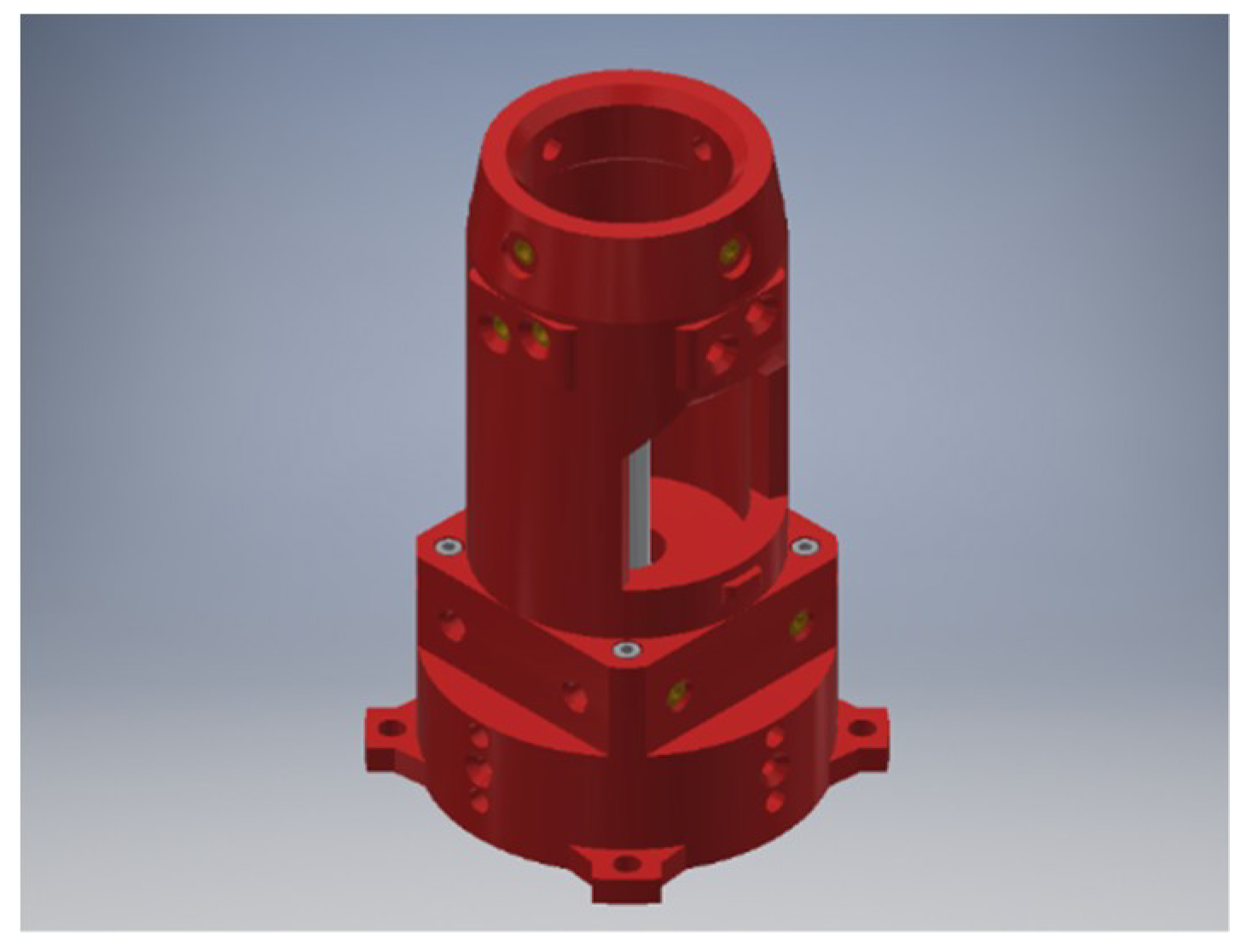

- Base Layer

- Start with the base part facing down (Figure 3), insert an M5 heat insert into the holes you plan on using.

- Flip the base over and insert M3 heat inserts into the sides and top. Only insert where needed (e.g., one motor only needs one side, four motors need all sides).

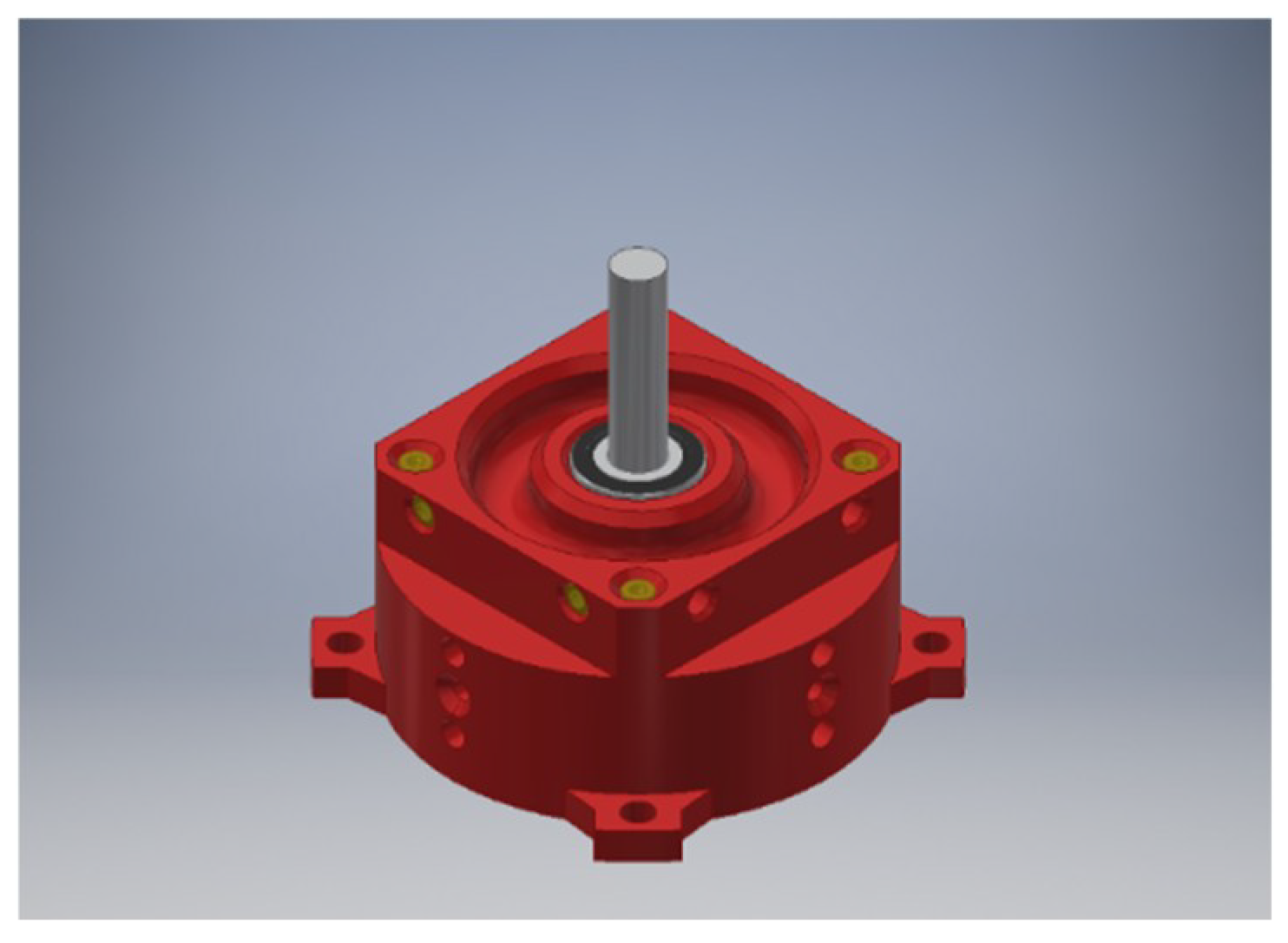

- Once complete (Figure 4), insert bearing into the top as shown, then insert Forstner bit through the bottom.

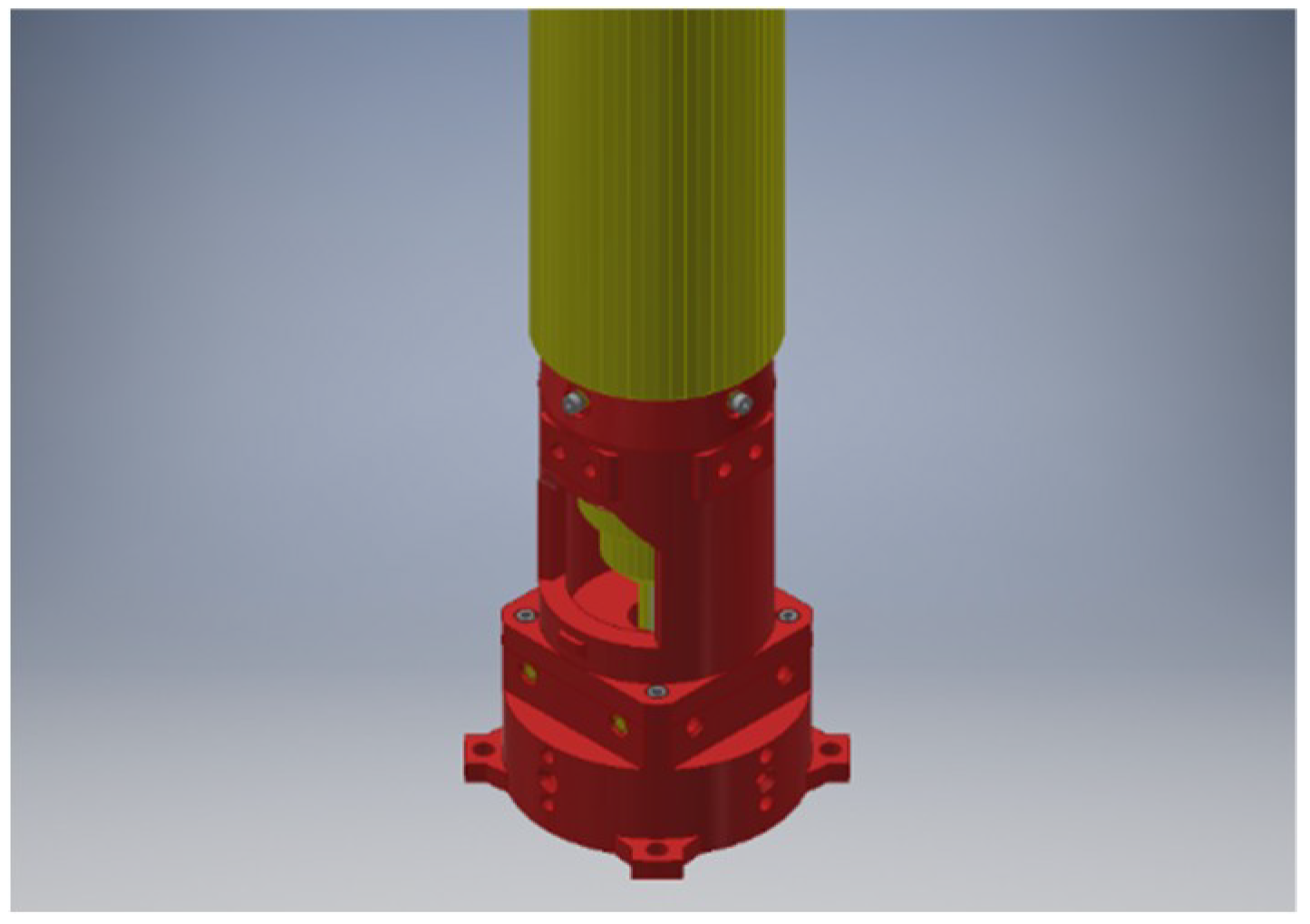

- Middle Layer

- Place the middle section on top of base, secure using M3 × 10 mm screws.

- Insert the M3 heat set inserts into the top four holes as well as the angled holes for the spool holders (only need to insert into sides being used).

- Make sure the Forstner bit goes through both the middle and the base, as in Figure 5.

- Put drill motor in through the top and use the included chuck key to tighten it onto Forstner bit (Figure 6).

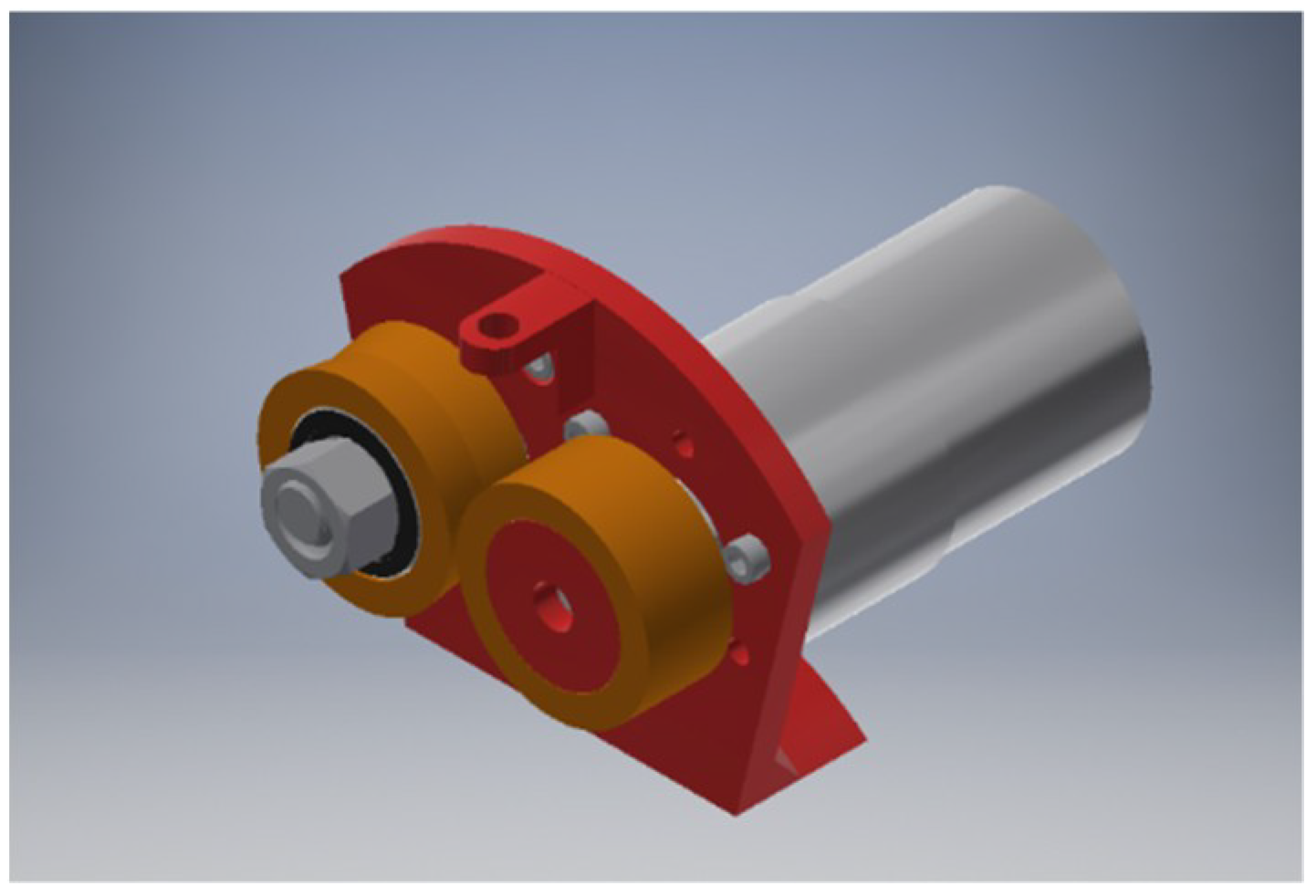

- Filament Drivers

- Screw the motor into the bracket using M3 × 10 mm screws, then place the printed motor wheel onto the shaft.

- Screw in the filament guide using an M3 × 10 mm screw and heat set insert, as shown in Figure 7.

- Assemble the idler wheel with the following sequence: bolt head, bracket, printed spacer, NinjaFlex wheel, and nut.

- Secure filament driver assembly onto the rest of the main assembly, as shown in Figure 8.

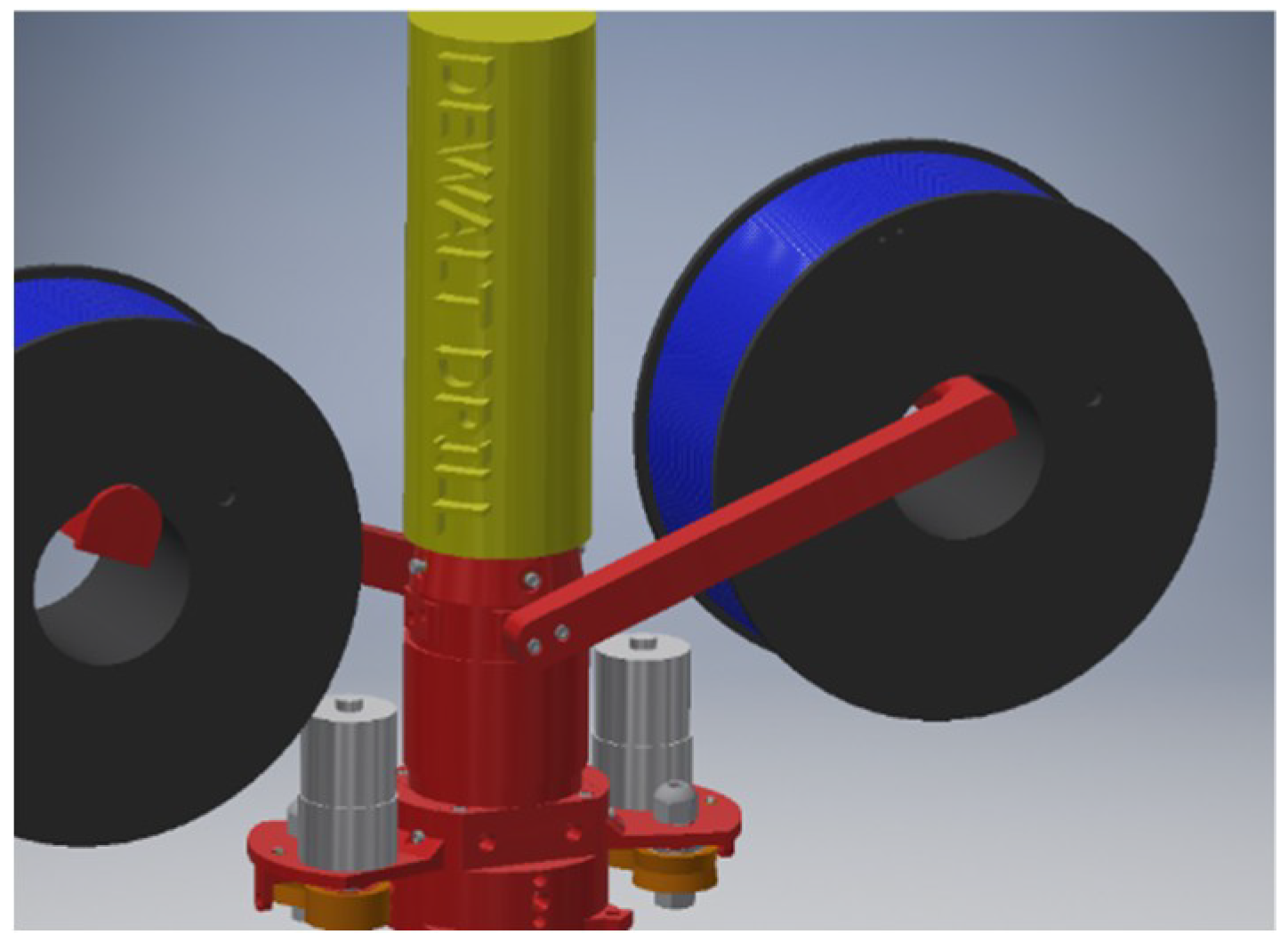

- Spool Holder

- Use the M3 × 10 mm bolts to attach the spool holder arms (Figure 9).

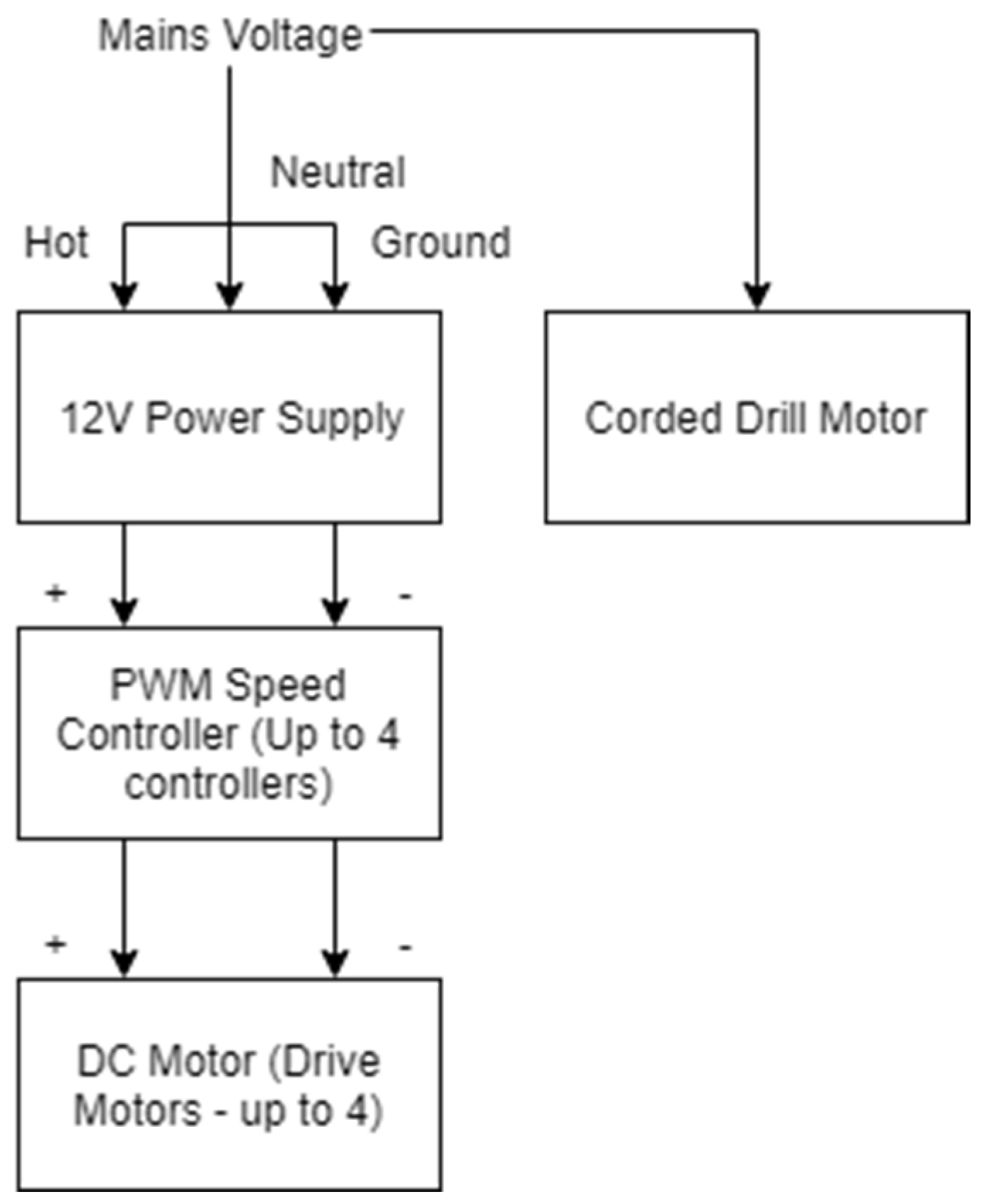

2.1.2. Electrical

2.2. Materials

2.3. System Performance Quantification

2.4. FPF 3-D Printing

2.5. Pellets as Recyclebot Feedstock

3. Results

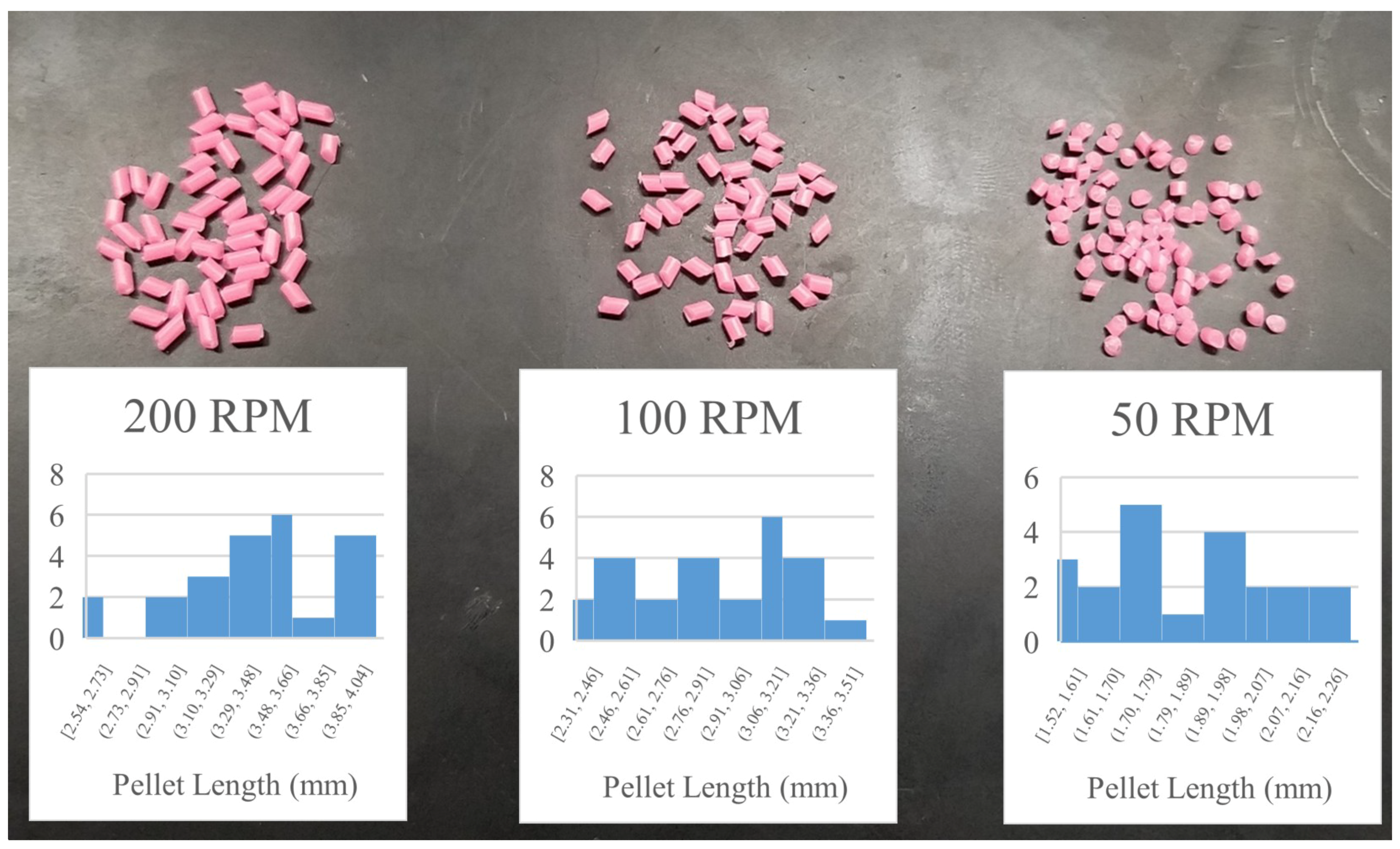

3.1. Pellet Manufacturing

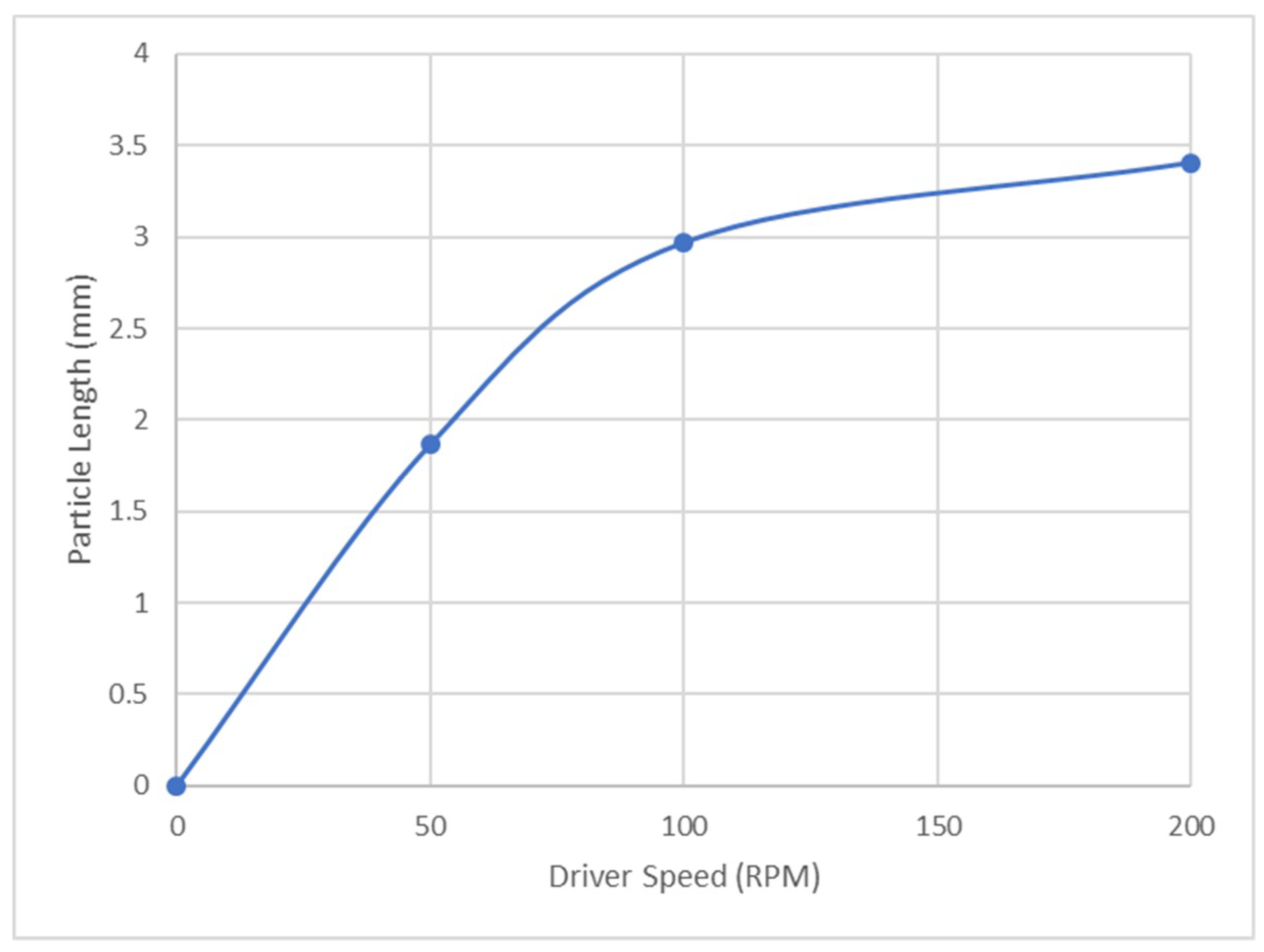

3.1.1. Pellets for FGF

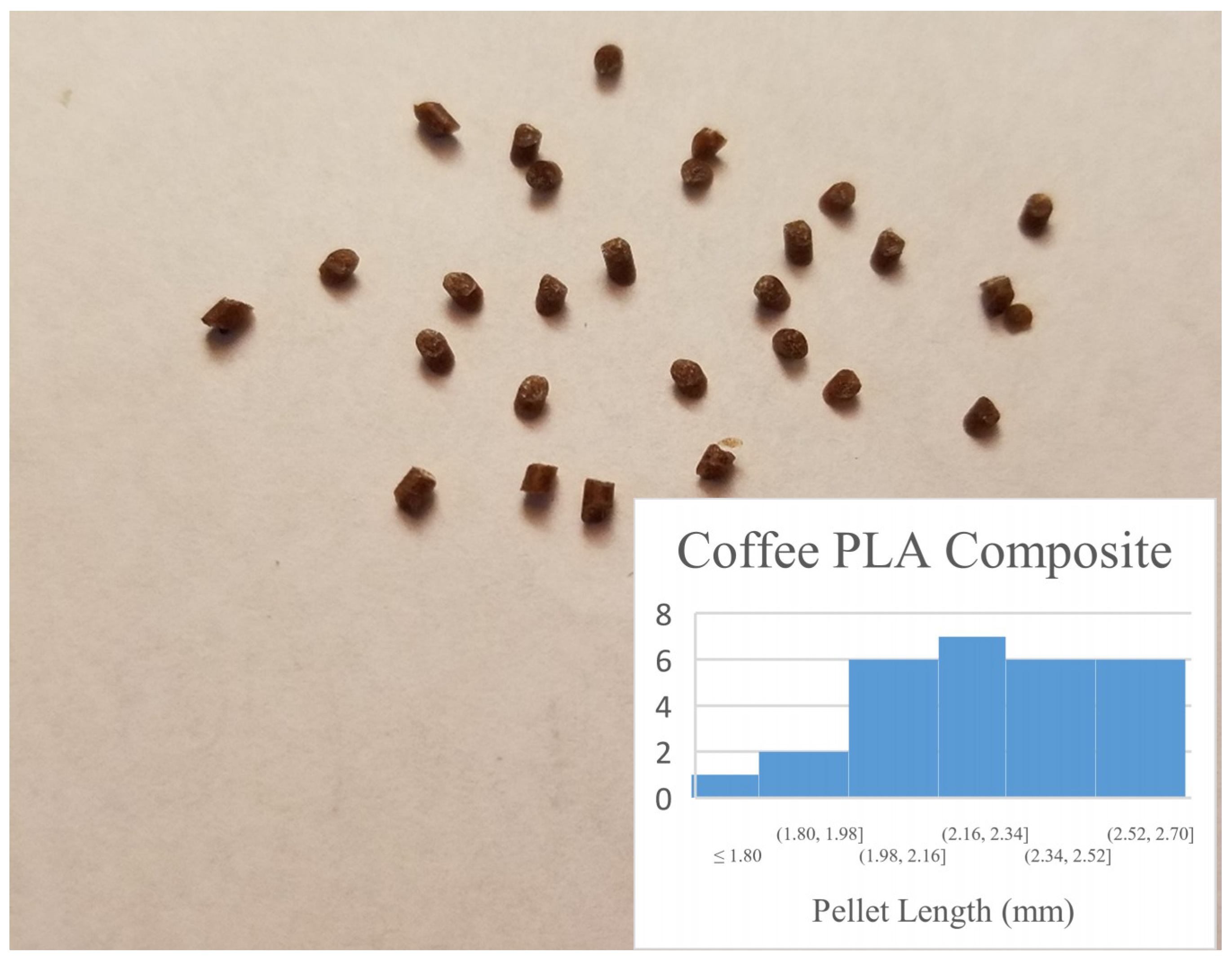

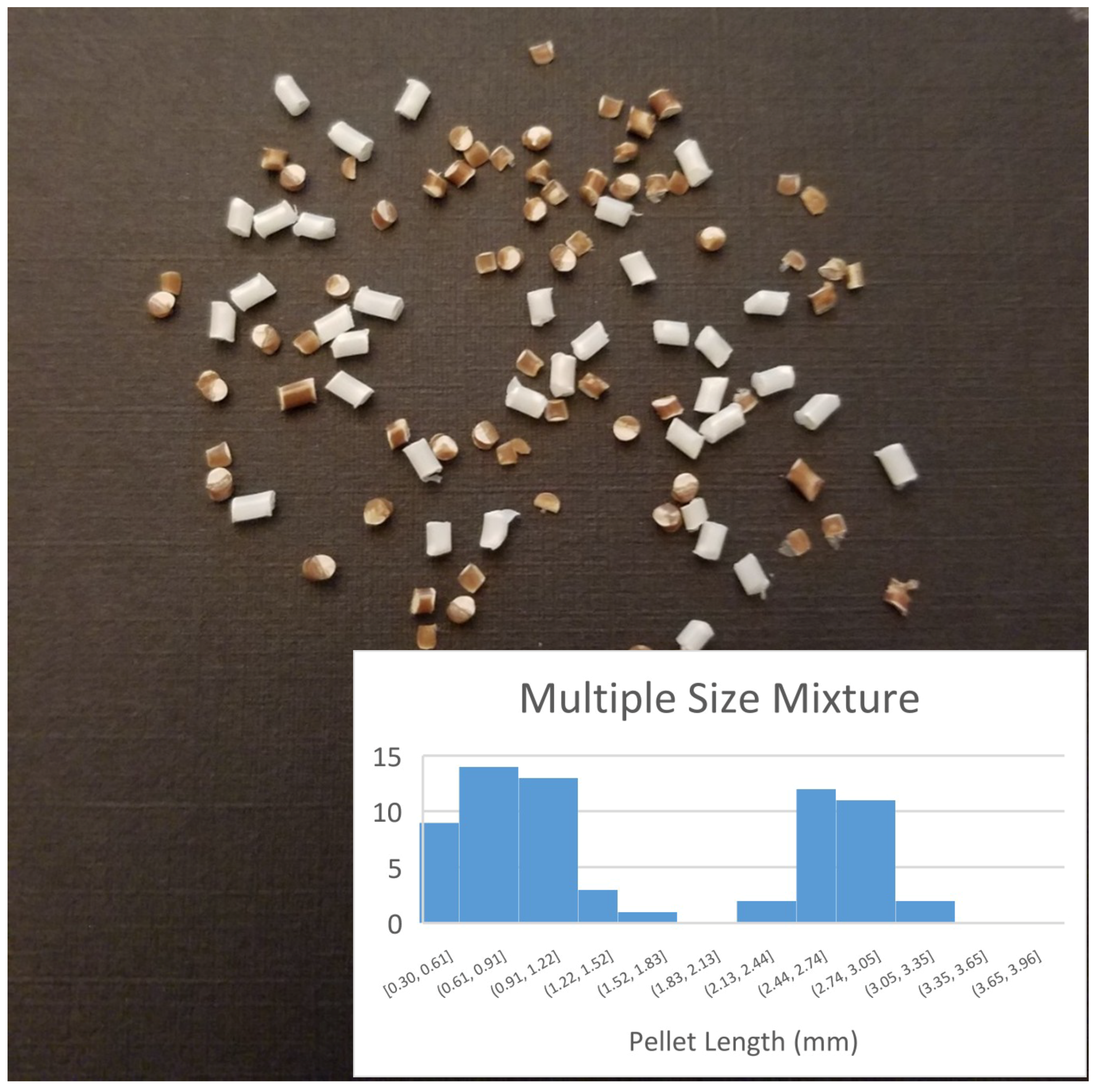

3.1.2. Pellets for Recyclebot

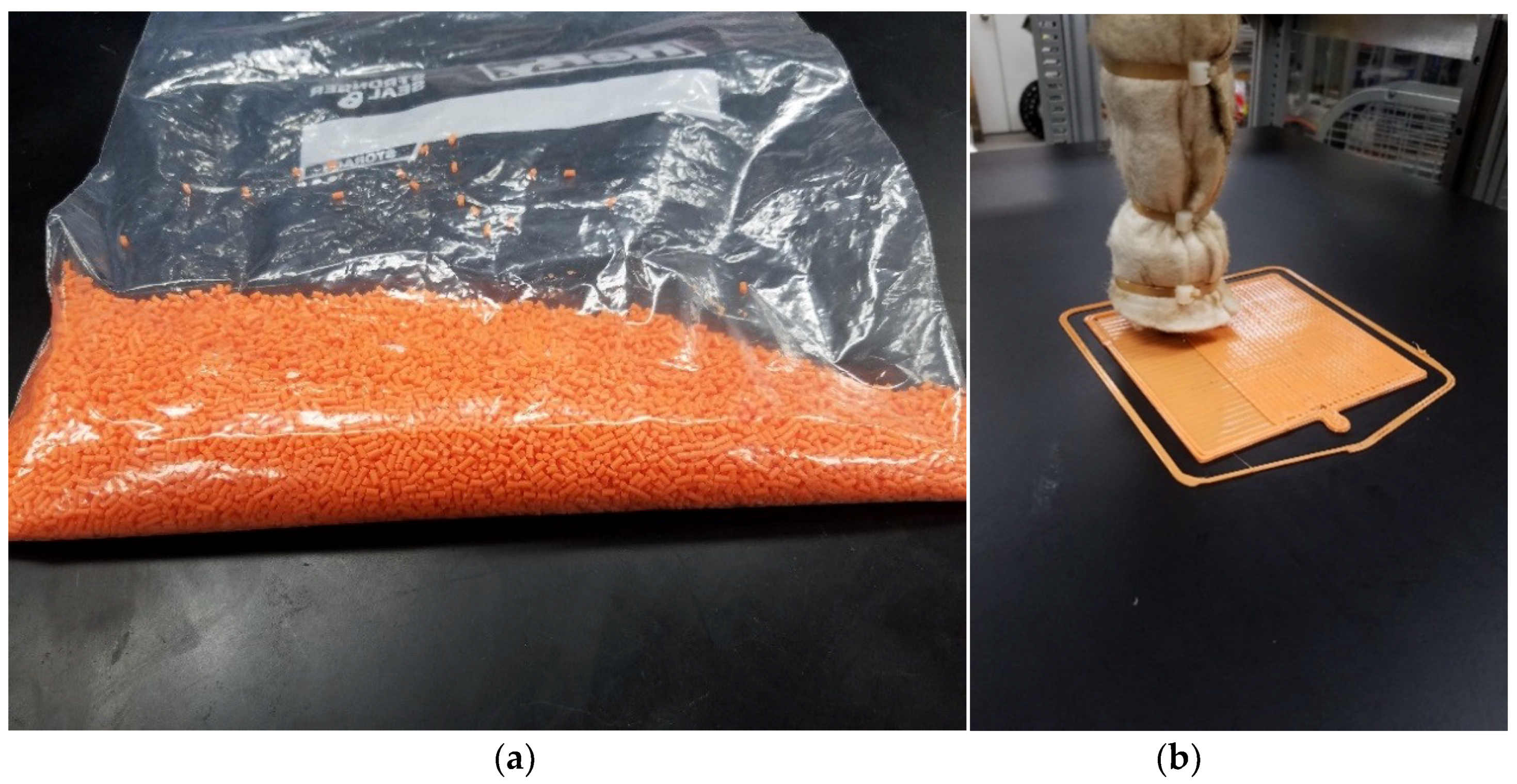

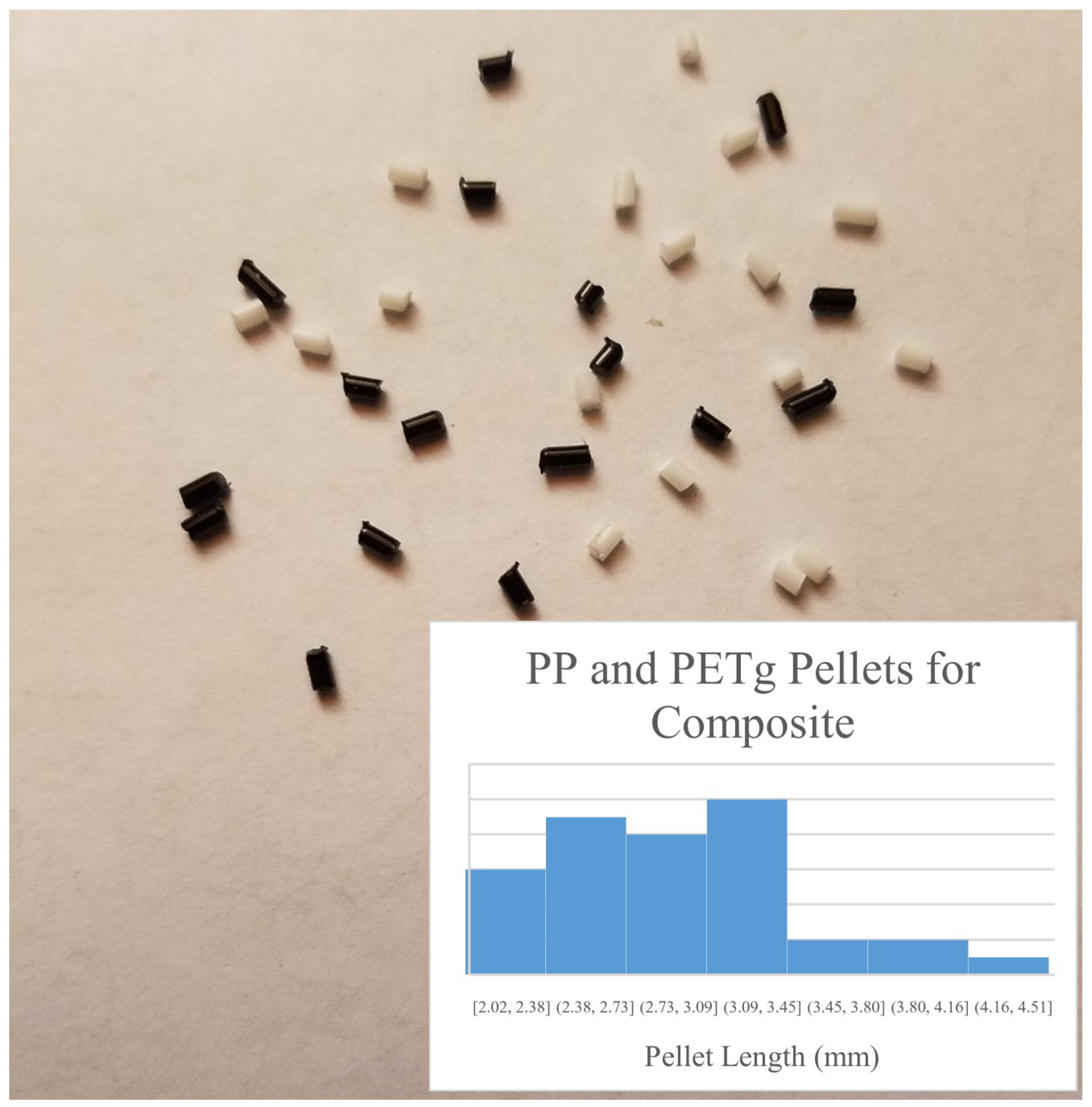

3.2. Fractional Control of Color and Composite Mixing

4. Discussion

4.1. Pellet Manufacturing

4.1.1. Pellets for Fused Granular Fabrication

4.1.2. Pellets for Recyclebot Filament Manufacturing

4.2. Fractional Control of Color and Composite Mixing

4.3. Applications

4.4. Future Work

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Sells, E.; Bailard, S.; Smith, Z.; Bowyer, A.; Olliver, V. RepRap: The replicating rapid prototyper-maximizing customizability by breeding the means of production. In Proceedings of the World Conference on Mass Customization and Personalization, Cambridge, MA, USA, 7–10 October 2007. [Google Scholar]

- Jones, R.; Haufe, P.; Sells, E.; Iravani, P.; Olliver, V.; Palmer, C.; Bowyer, A. RepRap-the replicating rapid prototyper. Robotica 2011, 29, 177–191. [Google Scholar] [CrossRef]

- Bowyer, A. 3D printing and humanity’s first imperfect replicator. 3D Print. Addit. Manuf. 2014, 1, 4–5. [Google Scholar] [CrossRef]

- Scan, B. How to Make (almost) Anything. The Economist, 2005. Available online: http://www.economist.com/node/4031304 (accessed on 2 November 2018).

- Gershenfeld, N. How to Make Almost Anything: The Digital Fabrication Revolution. 2012. Available online: http://cba.mit.edu/docs/papers/12.09.FA.pdf (accessed on 2 November 2018).

- Markillie, P. A Third Industrial Revolution. The Economist, 2012. Available online: http://www.economist.com/node/21552901 (accessed on 2 November 2018).

- Gwamuri, J.; Wittbrodt, B.; Anzalone, N.; Pearce, J. Reversing the trend of large scale and centralization in manufacturing: The case of distributed manufacturing of customizable 3-D-printable self-adjustable glasses. Challeng. Sustain. 2014, 2, 30–40. [Google Scholar] [CrossRef]

- Wittbrodt, B.; Laureto, J.; Tymrak, B.; Pearce, J. Distributed manufacturing with 3-D printing: A case study of recreational vehicle solar photovoltaic mounting systems. J. Frugal Innov. 2015, 1, 1–7. [Google Scholar] [CrossRef]

- Woern, A.L.; Pearce, J.M. Distributed manufacturing of flexible products: Technical feasibility and economic viability. Technologies 2017, 5, 71. [Google Scholar] [CrossRef]

- Petersen, E.E.; Kidd, R.W.; Pearce, J.M. Impact of DIY home manufacturing with 3D printing on the toy and game market. Technologies 2017, 5, 45. [Google Scholar] [CrossRef]

- Petersen, E.E.; Pearce, J. Emergence of home manufacturing in the developed world: Return on investment for Open-Source 3-D printers. Technologies 2017, 5, 7. [Google Scholar] [CrossRef]

- Wittbrodt, B.T.; Glover, A.G.; Laureto, J.; Anzalone, G.C.; Oppliger, D.; Irwin, J.L.; Pearce, J.M. Life-cycle economic analysis of distributed manufacturing with open-source 3-D printers. Mechatronics 2013, 23, 713–726. [Google Scholar] [CrossRef]

- Anderson, P.; Sherman, C.A. A discussion of new business models for 3D printing. Int. J. Technol. Market. 2007, 2, 280–294. [Google Scholar] [CrossRef]

- Laplume, A.; Anzalone, G.; Pearce, J. Open-source, self-replicating 3-D printer factory for small-business manufacturing. Int. J. Adv. Manuf. Technol. 2015, 85, 633–642. [Google Scholar] [CrossRef]

- Laplume, A.; Petersen, B.; Pearce, J. Global value chains from a 3D printing perspective. J. Int. Bus. Stud. 2016, 47, 595–609. [Google Scholar] [CrossRef]

- Pearce, J. Quantifying the value of open source hardware development. Mod. Econ. 2015, 6, 1–11. [Google Scholar] [CrossRef]

- Pearce, J.M. Return on investment for open source scientific hardware development. Sci. Public Policy 2016, 43, 192–195. [Google Scholar] [CrossRef]

- Babak, K. Wohlers Report 2016: 3D Printing and Additive Manufacturing State of the Industry Annual Worldwide Progress Reports; Wohlers Associates Inc.: Fort Collins, CO, USA, 2016. [Google Scholar]

- Horne, R. RepRap Development and Further Adventures in DIY 3D Printing: No More Filament?—Quest for a Universal Pellet Extruder for 3D Printing. Reprap Development and Further Adventures in DIY 3D Printing 2014. Available online: https://richrap.blogspot.com/2014/12/no-more-filament-quest-for-universal.html (accessed on 2 November 2018).

- Universal Pellet Extruder. Available online: http://upe3d.blogspot.com/ (accessed on 2 November 2018).

- Braanker, G.B.; Duwel, J.E.P.; Flohil, J.J.; Tokaya, G.E. Developing a Plastics Recycling Add-on for the RepRap 3D-Printer; Delft University of Technology: Delft, The Netherlands, 2010. [Google Scholar]

- The PartDaddy—Large Format Delta 3D Printer—Custom. Available online: https://www.seemecnc.com/products/partdaddy-large-format-delta-3d-printer (accessed on 9 July 2018).

- Cheetah Pro Large Format 3D Printer by Hans Fouche. Available online: http://www.fouche3dprinting.com (accessed on 9 July 2018).

- Introducing David. Available online: http://sculptify.com/david (accessed on 9 July 2018).

- Erecto-Struder 24v, ErectorBot Store. Available online: http://www.erectorbot.com/store/product_info.php?cPath=23&products_id=65 (accessed on 9 July 2018).

- Gigabot X: Large-Scale, Recycled Plastic Pellet 3D Printer. Available online: https://www.kickstarter.com/projects/re3d/gigabot-x-your-direct-pellet-extrusion-3d-printer (accessed on 9 July 2018).

- Giberti, H.; Sbaglia, L.; Silvestri, M. Mechatronic design for an extrusion-based additive manufacturing machine. Machines 2017, 5, 29. [Google Scholar] [CrossRef]

- Liu, X.; Chi, B.; Jiao, Z.; Tan, J.; Liu, F.; Yang, W. A large-scale double-stage-screw 3D printer for fused deposition of plastic pellets. J. Appl. Polym. Sci. 2017, 134, 45147. [Google Scholar] [CrossRef]

- Volpato, N.; Kretschek, D.; Foggiatto, J.A.; da Silva Cruz, C.G. Experimental analysis of an extrusion system for additive manufacturing based on polymer pellets. Int. J. Adv. Manuf. Technol. 2015, 81, 1519–1531. [Google Scholar] [CrossRef]

- Woern, A.; Byard, D.; Oakley, R.; Fiedler, M.; Snabes, S.; Pearce, J.; Woern, A.L.; Byard, D.J.; Oakley, R.B.; Fiedler, M.J.; et al. Fused particle fabrication 3-D printing: Recycled materials’ optimization and mechanical properties. Materials 2018, 11, 1413. [Google Scholar] [CrossRef] [PubMed]

- Byard, D.J.; Woern, A.L.; Oakley, R.B.; Fiedler, M.J.; Snabes, S.L.; Pearce, J.M. Green Fab Lab Applications of Large-Area Waste Polymer-based Additive Manufacturing. Unpublished work. 2018. [Google Scholar]

- Beaudoin, A. JMS-1704: Multihead 3D Printer. Ph.D. Thesis, Worcester Polytechnic Institute, Worcester, MA, USA, 2016. [Google Scholar]

- Wang, Z.; Liu, R.; Sparks, T.; Liou, F. Large-scale deposition system by an industrial robot (I): Design of fused pellet modeling system and extrusion process analysis. 3D Print. Addit. Manuf. 2016, 3, 39–47. [Google Scholar] [CrossRef]

- Kumar, N.; Jain, P.K.; Tandon, P.; Pandey, P.M. Additive manufacturing of flexible electrically conductive polymer composites via CNC-assisted fused layer modeling process. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 175. [Google Scholar] [CrossRef]

- Kumar, N.; Jain, P.K.; Tandon, P.; Pandey, P.M. Extrusion-based additive manufacturing process for producing flexible parts. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 143. [Google Scholar] [CrossRef]

- Whyman, S.; Arif, K.M.; Potgieter, J. Design and development of an extrusion system for 3D printing biopolymer pellets. Int. J. Adv. Manuf. Technol. 2018, 96, 3417–3428. [Google Scholar] [CrossRef]

- Pearce, J.M. A novel approach to obviousness: An algorithm for identifying prior art concerning 3-D printing materials. World Patent Inf. 2015, 42, 13–18. [Google Scholar] [CrossRef]

- Barbosa, F. Thingiverse.com High Speed Filament Pelletizer by Fred_barbosa. Available online: https://www.thingiverse.com/thing:397524 (accessed on 1 November 2018).

- Hada, W. Thingiverse.com 3D Filament Pelletizer Powered by Drill by Wahada. Available online: https://www.thingiverse.com/thing:288465 (accessed on 1 November 2018).

- Scott, C. Shred-Buddy 3D Recycler Turns Your Old Filament, Bottles, and Even Fishing Line into Brand New 3D Printing Material. Available online: https://3dprint.com/144236/shred-buddy-3d-recycler/ (accessed on 20 November 2018).

- Filament Pelletizer (Page 1)—Filastruder—SoliForum—3D Printing Community. Available online: http://www.soliforum.com/topic/5159/filament-pelletizer/ (accessed on 1 November 2018).

- Gibb, A. Building Open Source Hardware: DIY Manufacturing for Hackers and Makers; Pearson Education: London, UK, 2014; ISBN 978-0-321-90604-5. [Google Scholar]

- Oberloier, S.; Pearce, J.M. General design procedure for free and open-source hardware for scientific equipment. Designs 2017, 2, 2. [Google Scholar] [CrossRef]

- 3-D Printable Polymer Pelletizer Chopper. Open Science Framework, 2018. Available online: https://osf.io/6t4dn/ (accessed on 2 November 2018).

- FIJI Is Just ImageJ. Available online: https://fiji.sc/ (accessed on 9 July 2018).

- Re:3D. Available online: https://github.com/Gigabot-Labs/Pellet-Extruder (accessed on 21 July 2018).

- re:3D | Life-Sized Affordable 3D Printing. Available online: https://re3d.org/ (accessed on 9 July 2018).

- Slic3r-G-Code Generator for 3D Printers. Available online: http://slic3r.org (accessed on 10 July 2018).

- Marlin Firmware. Available online: http://marlinfw.org (accessed on 10 July 2018).

- Woern, A.L.; McCaslin, J.R.; Pringle, A.M.; Pearce, J.M. RepRapable Recyclebot: Open source 3-D printable extruder for converting plastic to 3-D printing filament. HardwareX 2018, 4, e00026. [Google Scholar] [CrossRef]

- Recyclebot. Appropedia. Available online: http://www.appropedia.org/Recyclebot (accessed on 19 December 2017).

- Baechler, C.; DeVuono, M.; Pearce, J.M. Distributed recycling of waste polymer into RepRap feedstock. Rapid Protot. J. 2013, 19, 118–125. [Google Scholar] [CrossRef]

- Pringle, A.M.; Rudnicki, M.; Pearce, J. Wood furniture waste-based recycled 3-D printing filament. For. Prod. J. 2018, 68, 86–95. [Google Scholar] [CrossRef]

- Zander, N.E.; Gillan, M.; Burckhard, Z.; Gardea, F. Recycled polypropylene blends as novel 3D printing materials. Addit. Manuf. 2018. [Google Scholar] [CrossRef]

- Zhong, S.; Pearce, J.M. Tightening the loop on the circular economy: Coupled distributed recycling and manufacturing with recyclebot and RepRap 3-D printing. Resour. Conserv. Recycl. 2018, 128, 48–58. [Google Scholar] [CrossRef]

- Cruz Sanchez, F.; Lanza, S.; Boudaoud, H.; Hoppe, S.; Camargo, M. Polymer Recycling and Additive Manufacturing in an Open Source context: Optimization of processes and methods. In Proceedings of the 2015 Annual International Solid Freeform Fabrication Symposium-An Additive Manufacturing Conference, Austin, TX, USA, 10–12 August 2015; pp. 10–12. [Google Scholar]

- Cruz Sanchez, F.A.C.; Boudaoud, H.; Hoppe, S.; Camargo, M. Polymer recycling in an open-source additive manufacturing context: Mechanical issues. Addit. Manuf. 2017, 17, 87–105. [Google Scholar] [CrossRef]

- Oblak, P.; Gonzalez-Gutierrez, J.; Zupančič, B.; Aulova, A.; Emri, I. Processability and mechanical properties of extensively recycled high density polyethylene. Polym. Degrad. Stabil. 2015, 114. [Google Scholar] [CrossRef]

- Hyung Lee, J.; Sub Lim, K.; Gyu Hahm, W.; Hun Kim, S. Properties of recycled and virgin poly(ethylene terephthalate) blend fibers. Appl. Polym. Sci. 2012, 128, 2. [Google Scholar] [CrossRef]

- Anderson, I. Mechanical properties of specimens 3D printed with virgin and recycled polylactic acid. 3D Print. Addit. Manuf. 2017, 4, 110–115. [Google Scholar] [CrossRef]

- McDonough, W.; Braungart, M. Cradle to Cradle: Remaking the Way We Make Things; Farrar, Straus and Giroux: New York, NY, USA, 2010; ISBN 978-1-4299-7384-7. [Google Scholar]

- Kreiger, M.; Anzalone, G.C.; Mulder, M.L.; Glover, A.; Pearce, J.M. Distributed recycling of post-consumer plastic waste in rural areas. MRS Online Proc. 2013, 1492, 91–96. [Google Scholar] [CrossRef]

- Kreiger, M.A.; Mulder, M.L.; Glover, A.G.; Pearce, J.M. Life cycle analysis of distributed recycling of post-consumer high density polyethylene for 3-D printing filament. J. Clean. Prod. 2014, 70, 90–96. [Google Scholar] [CrossRef]

- Zhong, S.; Rakhe, P.; Pearce, J.M. Energy payback time of a solar photovoltaic powered waste plastic recyclebot system. Recycling 2017, 2, 10. [Google Scholar] [CrossRef]

- Pakkanen, J.; Manfredi, D.; Minetola, P.; Iuliano, L. About the Use of Recycled or Biodegradable Filaments for Sustainability of 3D Printing. In Sustainable Design and Manufacturing; Smart Innovation, Systems and Technologies; Springer: Cham, Switzerland, 2017; pp. 776–785. [Google Scholar]

- Chong, S.; Pan, G.-T.; Khalid, M.; Yang, T.C.-K.; Hung, S.-T.; Huang, C.-M. Physical characterization and pre-assessment of recycled high-density polyethylene as 3D printing material. J. Polym. Environ. 2017, 25, 136–145. [Google Scholar] [CrossRef]

- Mohammed, M.I.; Mohan, M.; Das, A.; Johnson, M.D.; Badwal, P.S.; McLean, D.; Gibson, I. A low carbon footprint approach to the reconstitution of plastics into 3D-printer filament for enhanced waste reduction. KnE Eng. 2017, 2, 234–241. [Google Scholar] [CrossRef]

- Mohammed, M.I.; Das, A.; Gomez-Kervin, E.; Wilson, D.; Gibson, I. EcoPrinting: Investigating the use of 100% recycled Acrylonitrile Butadiene Styrene (ABS) for Additive Manufacturing. Solid Freeform Fabrication 2017. In Proceedings of the 28th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 7–9 August 2017. [Google Scholar]

- Tian, X.; Liu, T.; Wang, Q.; Dilmurat, A.; Li, D.; Ziegmann, G. Recycling and remanufacturing of 3D printed continuous carbon fiber reinforced PLA composites. J. Clean. Prod. 2017, 142, 1609–1618. [Google Scholar] [CrossRef]

- OSHE Granulator MKII, Open Science Framework. Available online: https://osf.io/auswp/ (accessed on 10 July 2018).

- Baden, T.; Chagas, A.M.; Gage, G.; Marzullo, T.; Prieto-Godino, L.L.; Euler, T. Open labware: 3-D printing your own lab equipment. PLoS Biol. 2015, 13, e1002086. [Google Scholar] [CrossRef] [PubMed]

- Winters, B.J.; Shepler, D. 3D printable optomechanical cage system with enclosure. HardwareX 2018, 3, 62–81. [Google Scholar] [CrossRef]

- Hietanen, I.; Heikkinen, I.T.S.; Savin, H.; Pearce, J.M. Approaches to open source 3-D printable probe positioners and micromanipulators for probe stations. HardwareX 2018, 4, e00042. [Google Scholar] [CrossRef]

- Bellon, J.A.; Pino, M.J.; Wilke, N. Low-cost equipment for electroformation of Giant Unilamellar Vesicles. HardwareX 2018, 4, e00037. [Google Scholar] [CrossRef]

- Pearce, J.M. Expanding the Consumer Bill of Rights for material ingredients. Mater. Today 2018, 21, 197–198. [Google Scholar] [CrossRef]

- Hunt, E.J.; Zhang, C.; Anzalone, N.; Pearce, J.M. Polymer recycling codes for distributed manufacturing with 3-D printers. Resour. Conserv. Recycl. 2015, 97, 24–30. [Google Scholar] [CrossRef]

- Stevenson, K. The Other Reason for 3D Printing Pellets. Fabbaloo. Available online: http://www.fabbaloo.com/blog/2018/5/10/the-other-reason-for-3d-printing-pellets (accessed on 9 July 2018).

| Part | Quantity | Price |

|---|---|---|

| Drill motor | 1 | $99.00 |

| PLA filament ~400 g | 1 | $10.00 |

| NinjaFlex filament ~20 g | 1 | $1.60 |

| 12-V DC motor 200 rpm | 1 | $14.99 |

| Caster bearings | 3 | $2.99 |

| Speed controller | 1 | $8.45 |

| Power supply | 1 | $15.84 |

| 1′′ Forstner bit | 1 | $11.75 |

| 18 AWG hookup wire pack | 1 | $14.99 |

| 3/8′′-16 × 1.25” in bolt | 1 | $0.32 |

| 3/8′′-16 regular hex nut | 1 | $0.05 |

| M3 hex nut | 3 | $0.03 |

| M3 grub screw | 3 | $0.29 |

| M3 heat insert | 20 | $2.46 |

| M5 heat insert | 4 | $0.91 |

| M3 × 10 screw | 25 | $1.36 |

| Total | $185.03 |

| Description | Use |

|---|---|

| 5-gallon bucket or tote | Pellet collection |

| Three-dimensional (3-D) printer | Part manufacturing |

| Zip ties | Wire management |

| Super glue | Mounting Ninjaflex to bearings |

| Wire strippers (10–18 AWG) | Stripping motor, controller wires |

| Electronic solder | Soldering wires to motor |

| Soldering iron | Heat set inserts and wire soldering |

| Heat shrink tubing | For covering solder joints on motor |

| Adjustable wrenches | Tightening 3/8′′ nuts |

| Micro screwdriver set | Screwing wires into terminals |

| Allen wrench set (hex key) | For M3 bolts and M3 grub screws |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Woern, A.L.; Pearce, J.M. 3-D Printable Polymer Pelletizer Chopper for Fused Granular Fabrication-Based Additive Manufacturing. Inventions 2018, 3, 78. https://doi.org/10.3390/inventions3040078

Woern AL, Pearce JM. 3-D Printable Polymer Pelletizer Chopper for Fused Granular Fabrication-Based Additive Manufacturing. Inventions. 2018; 3(4):78. https://doi.org/10.3390/inventions3040078

Chicago/Turabian StyleWoern, Aubrey L., and Joshua M. Pearce. 2018. "3-D Printable Polymer Pelletizer Chopper for Fused Granular Fabrication-Based Additive Manufacturing" Inventions 3, no. 4: 78. https://doi.org/10.3390/inventions3040078

APA StyleWoern, A. L., & Pearce, J. M. (2018). 3-D Printable Polymer Pelletizer Chopper for Fused Granular Fabrication-Based Additive Manufacturing. Inventions, 3(4), 78. https://doi.org/10.3390/inventions3040078