1. Introduction

Artificial roughened surfaces are widely adopted for passive heat transfer enhancements (HTE). These passive HTE measures are widely applied for the channel flows with applications to heat exchangers, internal cooling of gas turbine blades, proton exchange membrane fuel cells and the radiators in central heating systems, and for solar energy harvest. Among the various types of artificial roughness, surface ribs are commonly deployed along a heat transfer passage to promote the convective heat transfer rates. With such HTE elements, many symmetric channels such as square, rectangular, and circular channels are adopted to generate the heat transfer enhancements over all the channel walls. But other occasions require asymmetric HTE properties such as the radiators installed for harvesting solar energy and embedded under floor for one-side heating. For asymmetric HTE applications, the HTE benefits bargained with the augmented pressure drops are preferable to induce the higher HTE properties over the selective channel wall. The channel with an asymmetric sectional shape such as a parallelogram channel is often signified by different heat transfer properties on its channel walls. As the parallelogram coolant channels were used as the internal cooling passages of a gas turbine rotor blade, Chang et al. [

1,

2] explored the endwall heat transfer performance of the rotating parallelogram channels enhanced by 45° ribs without [

1] and with dimples [

2]. With the enhanced sectional vortices by the asymmetric parallelogram channel geometries, the heat transfer properties for the parallelogram channel were superior to those developed in the similar square channel [

3]. Without rotation, the particle image velocimetry (PIV) flow measurements for the twin-pass smooth parallelogram channel with a 45° included an angle at Reynolds number of 10,000 [

4] that disclosed the strongly asymmetric secondary flows in the smooth-walled parallelogram channel, which was in contrary to the sectional flow pattern generated in the square channel [

5]. With the pair of slant sidewalls, the coolant stream through the parallelogram channel was directed toward the front endwall to cause about 24.5–23.4% Nusselt number elevations from its opposite back endwall [

4]. For laminar flows through the parallelogram channels, the friction coefficients and Nusselt numbers were increased monotonically by increasing the channel width-to-height ratio for all the include angles of the parallelograms [

6]. Further HTE elevations attempted by the present study for the asymmetric applications are proposed by fitting the detached transverse S-ribs along the parallelogram channel.

Since the 1980s, a vast amount of research has been devoted to inventions of various types of ribs to acquire satisfactory HTE properties for channel flows. The Han group [

7,

8] was one of the pioneer research teams to study the thermo-hydraulic characteristics of the ribbed channels. The periodically broken boundary layers, flow reattachments, turbulence augmentations along with the rib-induced secondary flows generated considerable HTE benefits [

7,

8]. Zhao and Tao [

9] adopted the naphthalene sublimation method to measure the Sherwood numbers of the ducted flows enhanced by the ribs with an identical rib pitch-to-height (P/e) ratio of 10 and a rib-height to channel hydraulic diameter (e/d) ratio of 0.05, with different attack angles of 45°, 60°, 90°, −45° (135°), and −60° (120°) along the two straight legs of the twin-pass square channels [

9]. Relative to the Sherwood numbers detected from the similar smooth channel, the area-averaged Sherwood number ratios for the ribbed channels with the attack angle of 60° were the highest, followed by the case of 45°; while the ribs with the attack angles of 90° and −45° exhibited the lowest HTE ratios [

9]. Mochizuki et al. [

10] experimentally examined the combined effects of sharp a 180° turn and rib arrangements on the pressure-drop and heat-transfer performance of the twin-pass square channels. The ribs with the identical P/e and e/d ratios but different attack angles between 30°–90° with an interval of 15° were installed along the two straight legs of the twin-pass channels. Acting together by the secondary flows induced by the sharp turn and the ribs, the various rib arrangements incurred considerable differences in the pressure-drop and heat-transfer properties over the entire channels [

10]. Ekkad and Han [

11] adopted the transient liquid crystal method to detect the full-filed Nusselt number distributions for the twin-pass square channels with 90° parallel, 60° parallel, 60° V, and 60° broken V ribs of identical P/e and e/d ratios at Reynolds numbers of 6000–60,000. The heat transfer levels in the second leg were nearly 2–3 times higher than those developed in the first leg due to the sharp turn effect for the smooth twin-pass channels [

11]. With the ribbed twin-pass channels, the 60° parallel, 60° V and 60° broken V ribs generated the similar HTE benefits for the first leg [

11]. On the endwalls of the sharp bend and the second leg, the 60° parallel ribs exhibited the higher HTE ratios among this comparative group [

11]. Ekkad et al. [

12] also used the transient liquid crystal method to measure the detailed endwall Nusselt number distributions for the straight and tapered twin-pass channels with smooth walls and roughed by 90° ribs. In general, the HTE ratios attributed to the 90° ribs for both the straight and tapered channels were similar [

12]. Downstream to the sharp bend, the tapered channel showed slightly higher HTE ratios than those found in the straight channel [

12]. Wang and Sunden [

13] measured the friction coefficients and heat transfer rates using liquid crystal thermography for a set of square channels enhanced by the transverse ribs with various shapes on one channel endwall. With the fixed e/d ratio of 0.1, the P/e ratios of these ribs were varied from 8 to 15 at the tested Reynolds numbers between 8000 and 20,000. The trapezoidal rib with decreasing height in the flow direction generated the highest HTE effect; whereas the local low heat transfer spots in the region just behind the ribs were also suppressed. Egger et al. [

14] developed the transient infrared thermography method to measure the detailed endwall Nusselt number distributions for the twin-pass channel. The inlet and outlet legs of the twin-pass channel were enhanced by 45° ribs and had the trapezoidal and nearly rectangular cross-sections, respectively. With the rib induced secondary flows, the regional heat transfer elevations behind the ribs by directing core flows towards the rib floor were reported. On the bend endwall, the Nusselt number distribution was mainly characterized by the streamline curvature.

The other forms of ribs are installed between two channel sidewalls to formulate a number of small gaps between the detached ribs and the heat transfer walls. These detached ribs introduce accelerating flows through the gaps to burst boundary layers for generating HTE benefits. The argumentations of heat-transfer and pressure-drop coefficients induced by the various types of detached ribs [

15,

16,

17,

18] were compared with those induced by the attached ribs in [

19]. For the compatible detached and attached ribs [

15,

16,

17,

18], the HTE ratios raised by the detached ribs were elevated from those induced by the attached ribs [

19]. But the higher degrees of pressure drop augmentations were generated by the detached ribs with the similar thermal performance factors to those attributed to the attached ribs due to the higher HTE effectiveness for the detached ribs [

19]. Recently, novel methods [

20,

21,

22] were proposed to study the transport phenomena involving phase change activities for heat transfer augmentations. The two-dimensional numerical model of the falling film evaporation on horizontal tubes was studied [

20] with the dynamic characteristics of the film flow examined. The trade-off curve for the specific geometry was acquired to disclose the transition zone between the stable film and the drop-mode. Considering the lack of heat transfer geometry at the micro scale and the high computational cost for a numerical analysis of the compact cross-flow heat exchangers with complex finned geometries, an alternative design procedure was proposed to take the advantage of both numerical and analytical approaches [

21]. Such a multi-scale approach [

21] improved full-scale analysis accuracy and allowed for the investigation of various fin-effects on flow distributions, local heat transfer rates, and pressure losses. A new method for evaluating the overall performance of the countercurrent evaporative condensers using the hybrid experimental, numerical, or analytical approaches was proposed [

22]. The effect of the water flow rate on the cooling capacity of the cooling tower was successfully studied to demonstrate that a 50% increase of the sprayed water has led to a 14% performance improvement.

The present study invents the detached S-ribs as a passive HTE element. The hydro-thermal characteristics of the twin-pass parallelogram channel enhanced by the detached S-ribs arranged in the staggered manner along the inlet and outlet straight legs are experimentally examined. The detailed Nusselt number distributions over two opposite front and back endwalls of the twin-pass parallelogram channel that are measured using the steady-state infrared thermography method. The Fanning friction factors are measured from the pressure drops across the entire test channels at all the Reynolds numbers tested. At constant pumping power consumptions, the thermal performance factors (TPF) are evaluated. The heat-transfer, pressure-drop, and TPF data measured from the present test channel fitted with the detached transverse S-ribs are compared against those generated by the detached transverse straight ribs [

18] in the compatible twin-pass parallelogram channel. Two sets of empirical correlations evaluating the regionally averaged Nusselt numbers and Fanning friction factors for the present test channel are devised to assist the relevant applications.

2. Experimental Details

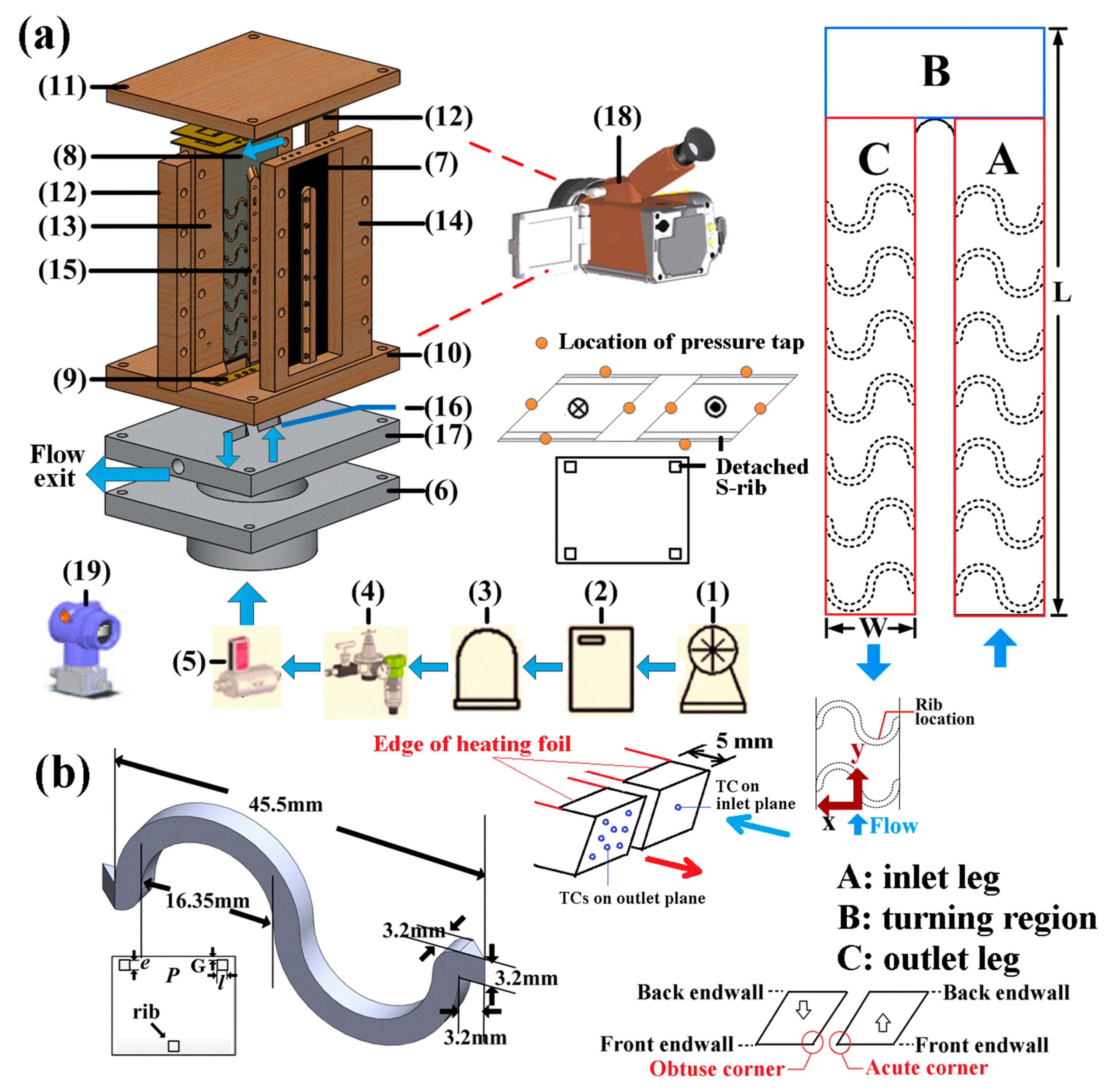

Figure 1a depicts the constructional details of the test module and the schematics of the test facility. Prior to entering the twin-pass test section, the airflow was supplied by the rotary type compressor (1) through the dehumidifier (2) from the air tank (3). The dry and cold air flowed through the needle valve (4) and the mass flow meter (5) at which the mass flow rate was constantly regulated to control the airflow at the targeted Reynolds number. Thus, the test coolant was dry air. The properties of the test coolant, such as viscosity, thermal conductivity, and specific heat, were evaluated by substituting the local fluid bulk temperature into the fluid property correlations determined from the tabulated data. In the cylindrical air plenum chamber (6) upstream the twin-pass test section, the honeycomb was installed to stratify the entry airflow.

For the parallelogram inlet or outlet leg of the present twin-pass channel, the channel width-to-height ratio (aspect ratio, AR = W/H) is 1. The two straight parallelogram inlet and outlet legs of 242 mm in length (L) are interconnected by the 180° sharp bend. The two inclined sidewalls of the sharp bend are extended from the two jointed inlet and outlet legs while the top sealed wall of the bend is flat. Thus, the twin-pass parallelogram flow pathway is formulated by two opposite 0.1 mm thick stainless steel heating foils, (7) and (8), two flat channel endwalls, two inclined channel outer sidewalls, a central divider with inclined facets, and the bend top wall. The heated stainless steel heating foil (7) subject to infrared scan is inlayed in the Teflon frame and painted black to enhance the emission. The opposite stainless steel heating foil (8) is installed on the 50 mm thick back wall for thermal insulation. The two stainless steel heating foils, (7) and (8), are sandwiched between the two pairs of copper plates (9) that connect with the electrical cables for feeding the adjustable heater powers to the test channel. The two pairs of copper plates (9) are embedded in the base plate (10). For electrical and thermal insulations, the channel base (10) and top (11) plates, the constituent channel walls (12)–(14) and the central divider are all made of Teflon.

The parallelogram section of the present twin-pass channel is composed by flat endwalls of 45.5 mm width (W) and inclined sidewalls at the included angle of 45°. As the twist action is applied to the bulk stream when the coolant travels from the cylindrical air plenum chamber into the parallelogram channel, the entry vortical flows are induced to generate the differential endwall heat transfer properties through the entire parallelogram inlet leg [

18]. In the outlet leg, the remaining vortical flows induced in the 180° sharp turn also cause asymmetric heat transfer properties on the two opposite endwalls of the parallelogram ribbed channel [

18]. Thus, the front and back endwalls for present twin-pass parallelogram channel are specified as shown by

Figure 1. The detailed Nusselt number distributions for both the front and back endwalls are measured.

The channel hydraulic diameter (d) of the parallelogram section is 32.17 mm. The distance between the apex of the round-edged central divider and the top wall of the sharp bend is 45.5 mm (1.41 d). The origin of present x-y coordinate system is located at the mid-location on the entry edge of the straight leg. The endwall regions of the inlet leg (IL), turning region (TR), and outlet leg (OL) are specified in

Figure 1a. Along the inlet or outlet legs, there are seven pairs of detached S-ribs installed adjacent to the two opposite flat endwalls with equal intervals at the rib pitch (P) to a height (e) ratio of 10. The y locations at which the S-ribs are installed for the inlet and outlet legs are identical. Each pair of opposite S-ribs in inlet or outlet leg is arranged in the staggered manner. As indicated in

Figure 1b, the cross section of the S-rib is square with the rib height (e) of 3.2 mm to provide the e/d ratio about 0.1. At the two ends of each S-rib, two tiny pins with the geometry matching the dents on the two inclined sidewalls are machined for installations. The high temperature silicone sealant is used to glue each S-rib on the two positioning dents at the two opposite channel sidewalls. The gap between each S-rib and the flat endwall is 1.22 mm, giving the rib gap (G) to rib height (e) ratio of 0.38.

The inlet fluid temperature is measured by the thermocouple in the air plenum chamber prior to the heating process. Thus, the measured fluid inlet temperature is treated as the inlet fluid bulk temperature (

Tb,in). With the non-uniform heat transfer coefficients generated by the particular flow field induced in the present twin-pass channel, the fluid temperatures become non-uniformly distributed over the flow exit plane. Eight thermocouples (16) are sandwiched between the base plate (10) and the exit flange (17) to detect the local fluid temperatures at the matrix spots arranged with equal intervals on the flow exit plane. The type of thermocouples used is K type. While the precision of the temperature readings is 0.01 K, the measurement uncertainty of the thermocouples is 0.3 K. As indicated in

Figure 1, these K-type thermocouples are installed on the flow inlet and outlet planes with upstream and downstream distances of 5 mm from the edges of the heating foils. The thermocouple measuring the fluid entry temperature is positioned at the central of the inlet plane. The eight thermocouples on the outlet plane are located with equal intervals as indicated by

Figure 1. All the thermocouple signals for fluid temperature measurements are transmitted to the computer via the Fluke Hydra2640-A data logger for on-line data monitoring and storage. The averaged value of the eight thermocouple readings is assumed as the measured exit fluid bulk temperature (

Tb,out). Having completed the post data processing, the calculated

Tb,out value is determined using the enthalpy balance method; which will be later illustrated. If the difference between the calculated and measured

Tb,out exceeds ±10%, the particular heat transfer test is re-performed. For measuring the detailed wall temperature distributions, the infrared thermography system with the precision of 0.1 K is adopted. The infrared camera (18) at the orientation parallel to the heated wall detects the wall temperature distribution at the scan rate of 60 frames per second.

The friction coefficients expressed as Fanning friction factors (f) are evaluated from the pressure drop measurements across the entire twin-pass test channel. There are four sets of pressure taps on the inner and outer inclined sidewalls as well as on the two opposite endwalls at the locations near the flow entry and exit. The micro-manometer (19) with the precision of 0.1 mm-H2O height connects with each set of pressure taps located at the flow entrance and exit to measure the Fanning friction factor of each constituent channel wall at each Reynolds number tested.

The steady state heat-transfer and pressure-drop measurements were carried out at Reynolds numbers of 5000, 7500, 10,000, 12,500, 15,000, and 20,000. When the successive wall temperature variations at the selective spots on the scanned heated endwall were less than 0.3 K, the steady state was assumed. The relevant raw data were then stored for the subsequent data processing to evaluate the Reynolds number, local Nusselt numbers and the Fanning friction factors.

The local Nusselt number at each steady state condition is calculated by Equation (1) as:

In Equation (1), h is the local convective heat transfer coefficient and

λ is the thermal conductivity of the coolant evaluated at the local fluid bulk temperature,

Tb. The local convective heat flux,

qf, is determined by subtracting the external heat loss flux from the supplied heat flux. To unravel the heat loss characteristics for the present test module, the heat loss calibration tests are performed using the test module with the thermal insulation fiber fully filled to block the airflow passage. When the supplied heater powers become balanced with the rates of external heat loss, the steady state wall-to-ambient temperature differences are acquired. The heat loss flux is then correlated into the function of wall-to-ambient temperature difference for evaluating local

qf. Using the measured coolant mass flow rate,

, and the convective heat flux,

qf, the streamwise increment of fluid bulk temperature, Δ

Tb, over a segmental streamwise length, Δy, is calculated using the enthalpy balance equation of:

where P

h is the peripheral heating length of the test channel over the Δy span and C

p is the constant pressure specific heat evaluated at local

Tb. Starting from the measured

Tb,in at the flow entry plane, the downstream

Tb values over the successive streamwise segments with the interval Δy are evaluated as:

Following the stepwise calculation routine using Equation (3), the calculated Tb,out at the flow exit plane is obtained and compared with the measured Tb,out.

The Fanning friction factors measured for each channel wall with the centerline length (L) are calculated by Equation (4).

The pressure drop, Δ

P, at each test Reynolds number is measured by the micro-manometer at the isothermal condition.

ρ and

Wm respectively stand for the fluid density and mean through flow velocity at the entrance of the test channel. The heat-transfer and pressure-drop references selected to account for the relative augmentations by the present test channel are determined from the Dittus–Boelter (

Nu∞) and Blasius (

f∞) correlations, respectively. The TPF, under the criterion of constant pumping power consumptions for the present test section are evaluated by Equation (5) as:

Under the criterion of constant pumping power consumption, TPF index was defined as (

St/

St∞)/(

f/

f∞)

1/3 [

23] where

St∞ and

f∞ are selected as the laminar or turbulent developed pipe-flow values. When the TPF values for a set of HTE measures compared at the same Reynolds (

Re) and Prandtl (

Pr) numbers, TPF is reduced to (

Nu/

Nu∞)/(

f/

f∞)

1/3. When the TPF value becomes unity, the heat transfer scenario caused by the particular set of HTE elements and the channel geometry is similar to that generated in the plain straight tube. When a TPF value is higher or less than unity, the efficiency of the HTE element is improved or impaired from the plain straight tube condition.

The experimental uncertainties for the measured Reynolds number, Nusselt number, and Fanning friction factor were estimated using the method reported in [

24]. The major sources attributed to the experimental uncertainties were the temperature measurements. The calibration report of present IR thermography system indicated the uncertainty of 0.4 K for the wall temperature measurements. The detailed descriptions for the calibration of the IR and the estimation of the emissivity coefficient of the heat transfer test module are previously reported [

25]. The accuracy of the fluid temperature measurements by present K-type thermocouples was 0.3 K. For the micro-manometer, the precision was 0.098 Pa. With the wall-to-fluid temperature differences between 48.3–95.2 °C and Δ

P in the range of 35–152 Pa, the maximum experimental uncertainties for the Reynolds number, Fanning friction factor, and Nusselt number were 3.2%, 7.6%, and 8.1%, respectively.

4. Conclusions

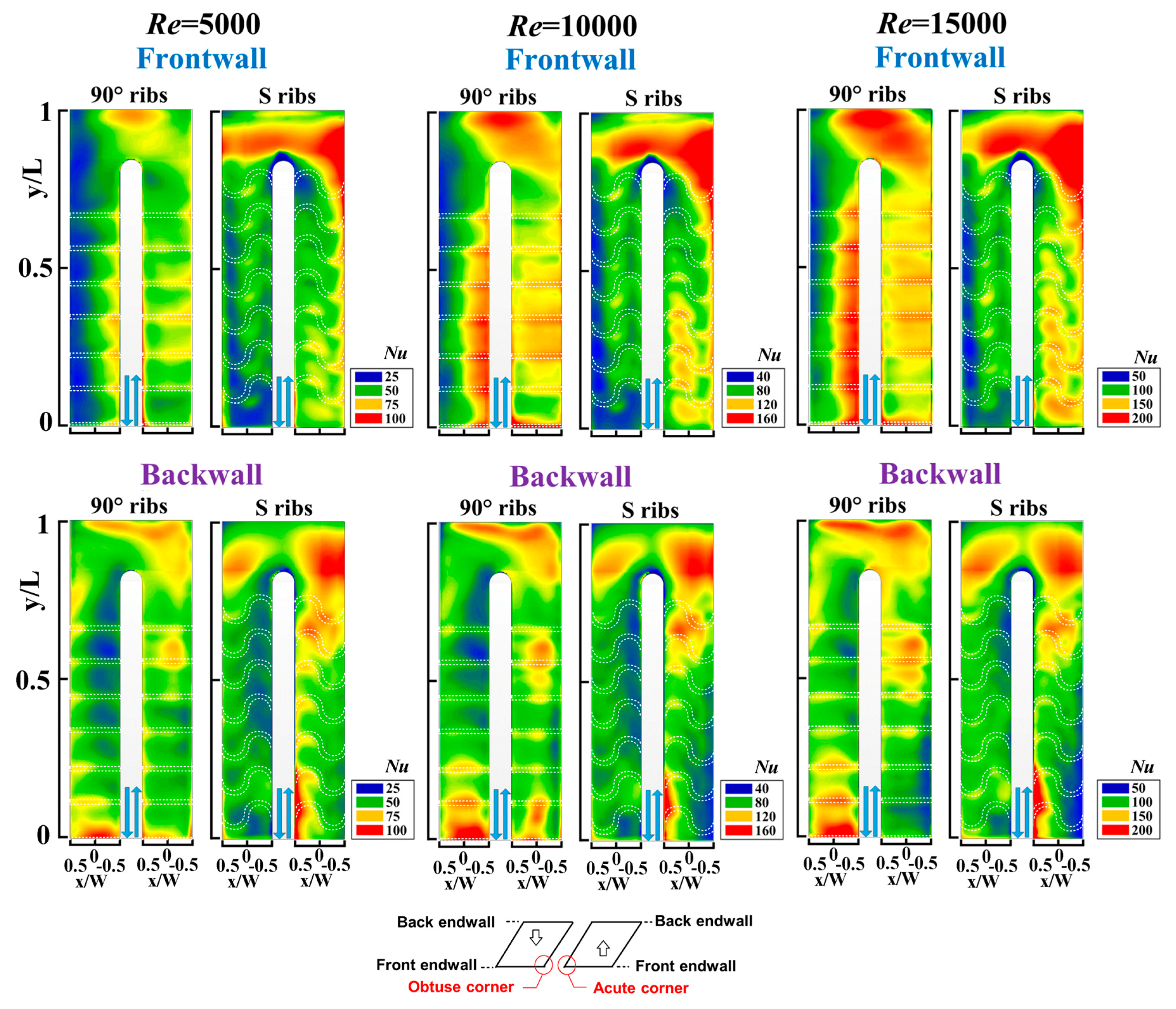

With the present detached S-ribs or the detached 90° ribs [

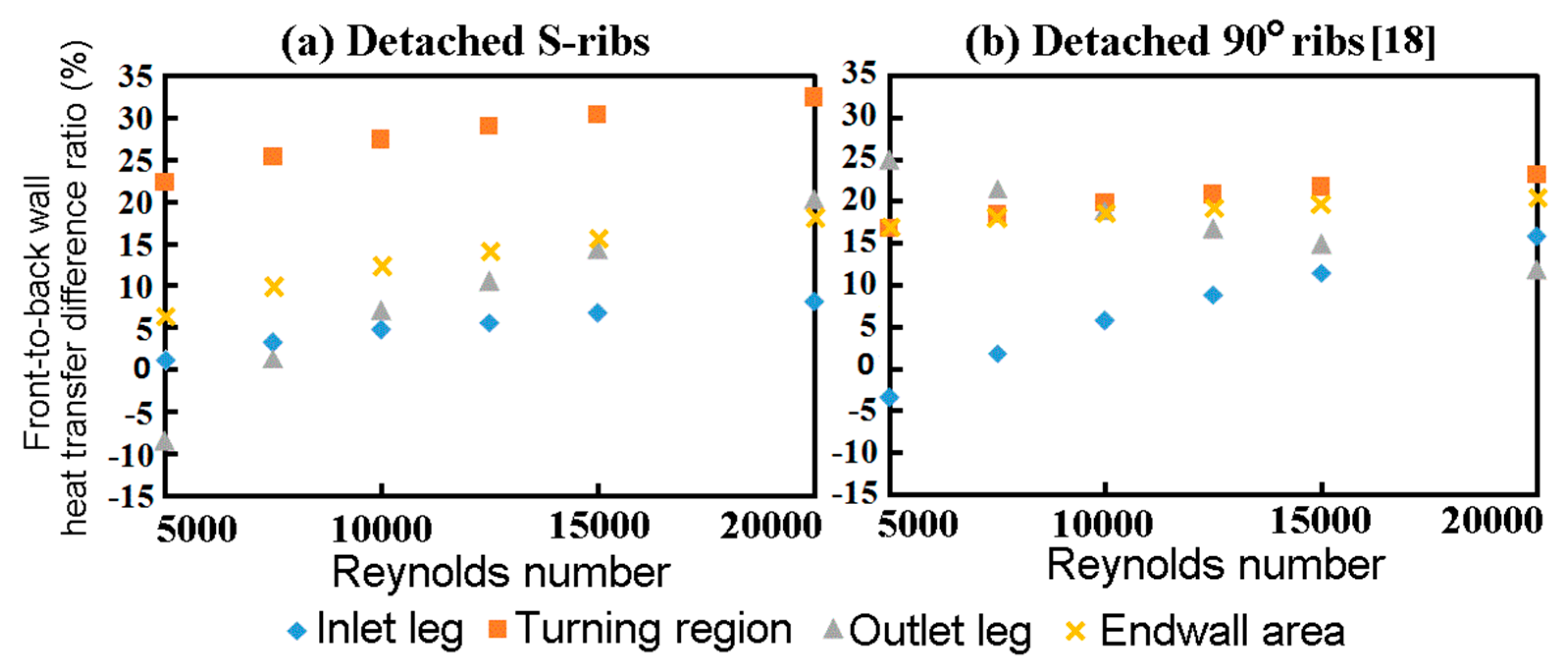

18] installed near the opposite endwalls of the twin-pass parallelogram channels, the heat transfer disparities between the front and back endwalls are generated. While the higher heat transfer rates generally emerge on the front endwall, the spanwise Nusselt number decays from the obtuse-corner edge toward the acute-corner edge are developed on both front and back endwalls along the inlet and outlet legs.

The front-to-back heat transfer disparities of the present twin-pass parallelogram channel with the detached S-ribs increase consistently as the Reynolds number increases. The present detached S-ribs are suitable for the high Reynolds number application that prefers the large front-to-back heat transfer differences.

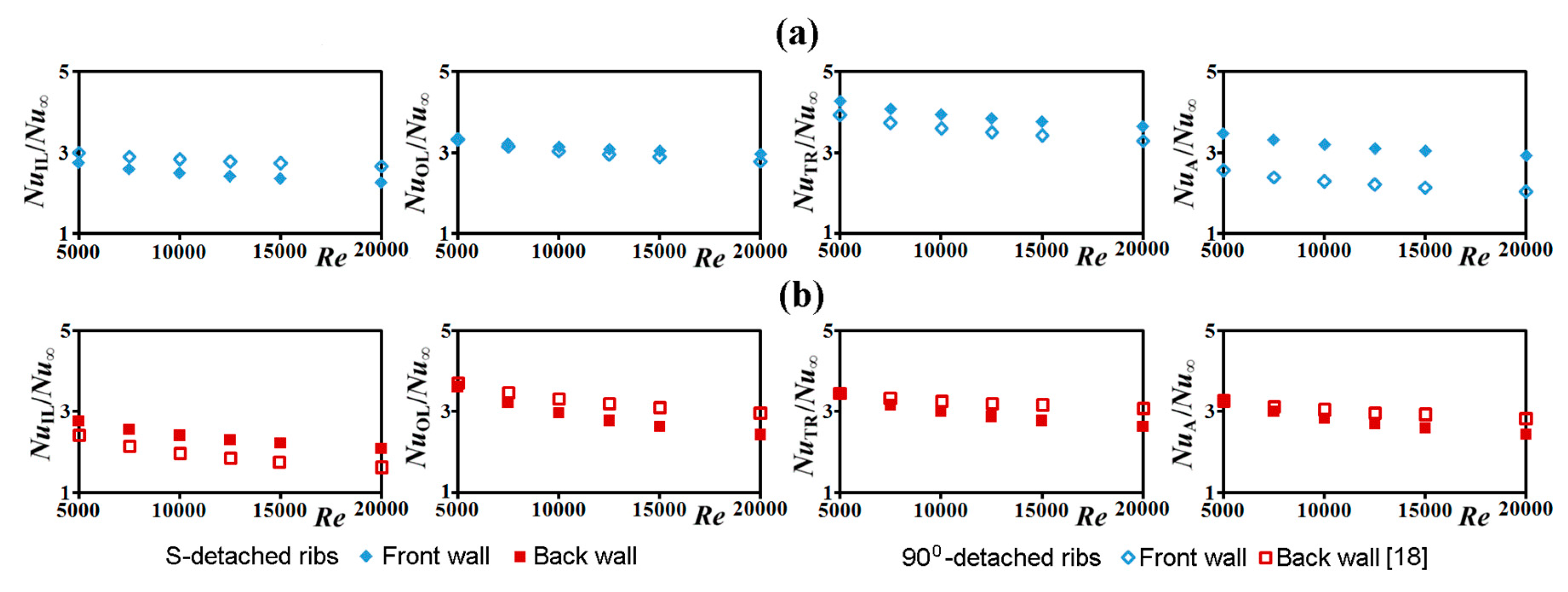

The higher degrees of overall heat transfer augmentation than those induced by the detached 90° ribs are generated by the present detached S-ribs. All the normalized Nu/Nu∞ ratios are decreased as the Reynolds number increases. Due to the flow structure induced by the present detached S-ribs in the twin-pass parallelogram channel, the NuIL/Nu∞, NuTR/Nu∞, NuOL/Nu∞, and NuA/Nu∞ ratios are in the respective ranges of 2.75–2.27, 4.28–3.65, 3.64–3.22, and 3.48–2.93 for the front wall and 2.76–2.09, 3.41–2.63, 3.62–2.42, and 3.18–2.38 for the back wall at 5000 ≤ Re ≤ 20,000.

In contrast to the

Re-driven

elevation caused by the detached 90° ribs due to the rib blockage effects, the

values for the present twin-pass parallelogram channel with the detached S-ribs are decreased as the Reynolds number increases, suggesting that the shearing actions among the fluids dominate the Fanning friction factors. The

/

f∞ ratios measured from the present test channel are in the range of 15.1–13 with 5000 ≤

Re ≤ 20,000; which are considerably higher than those elevated by the detached 90° ribs in the similar twin-pass parallelogram channel [

18].

The TPF values detected at 5000 ≤

Re ≤ 20,000 for the present twin-pass parallelogram channel with the detached S-ribs are all above than unity but decrease with the increase of the Reynolds number. While the higher degrees of heat transfer augmentations are induced by the present detached S-ribs in comparison with those elevated by the detached 90° ribs [

18], the larger

augmentations by the present detached S-ribs are lesser than the TPF values for the present twin-pass channel.

Two sets of empirical correlations evaluating the regionally averaged Nusselt numbers and the channel averaged Fanning friction factors are devised for the present twin-pass parallelogram channel with the detached S-ribs.