Heat Transfer Performance Enhancement of Gravity Heat Pipes by Growing AAO Nanotubes on Inner Wall Surface

Abstract

1. Introduction

2. Research Method

2.1. Growth of AAO Nanotubes

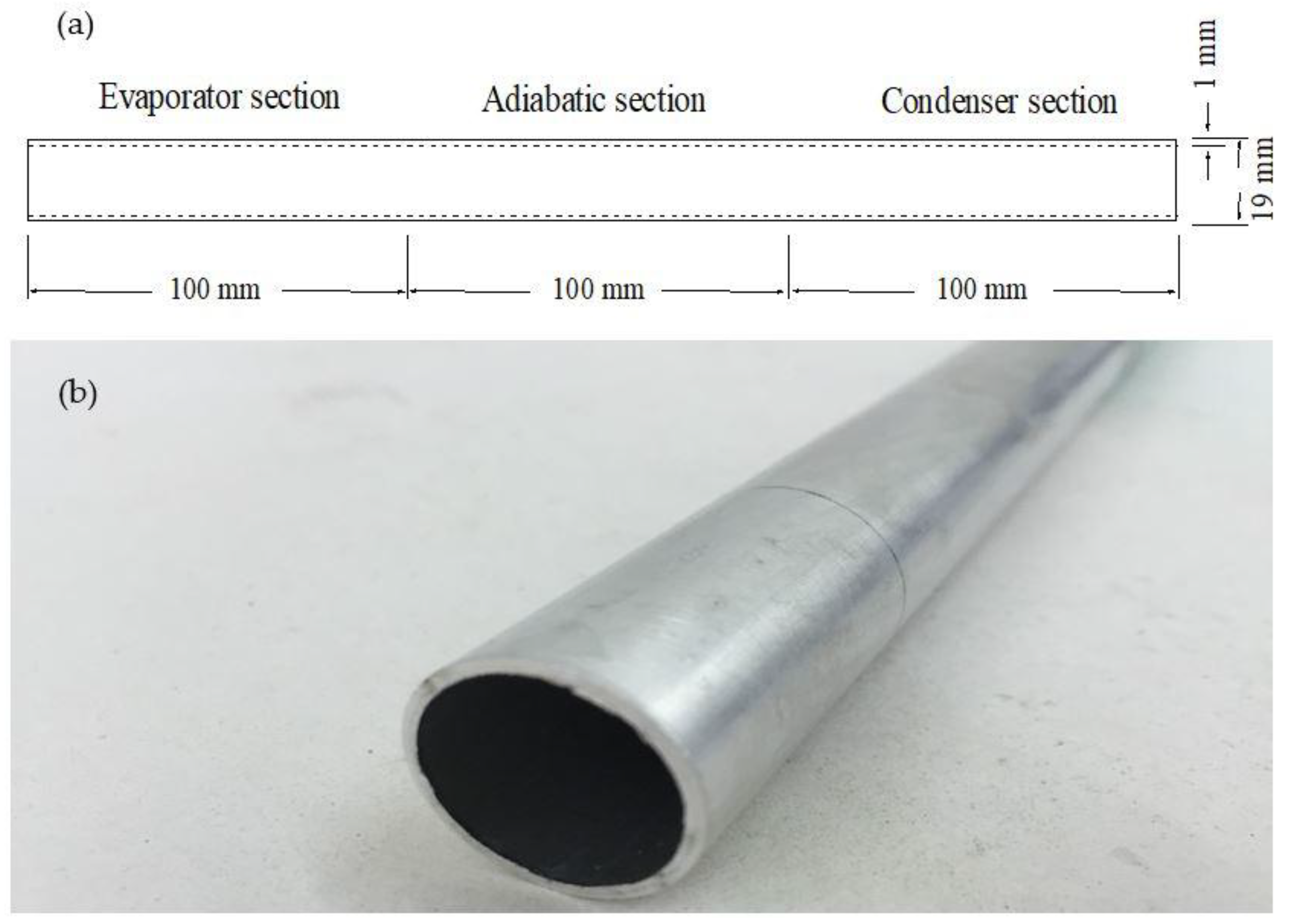

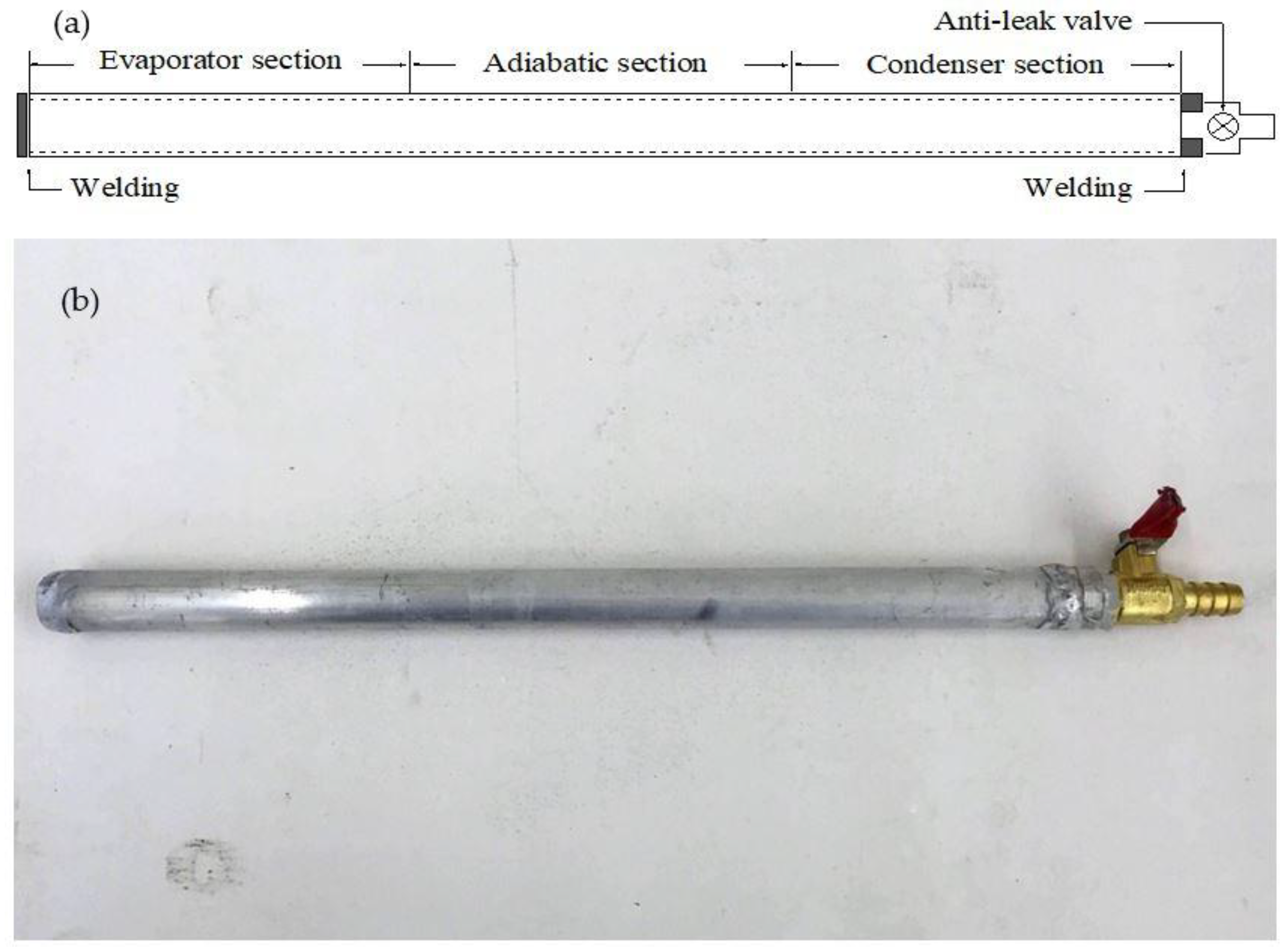

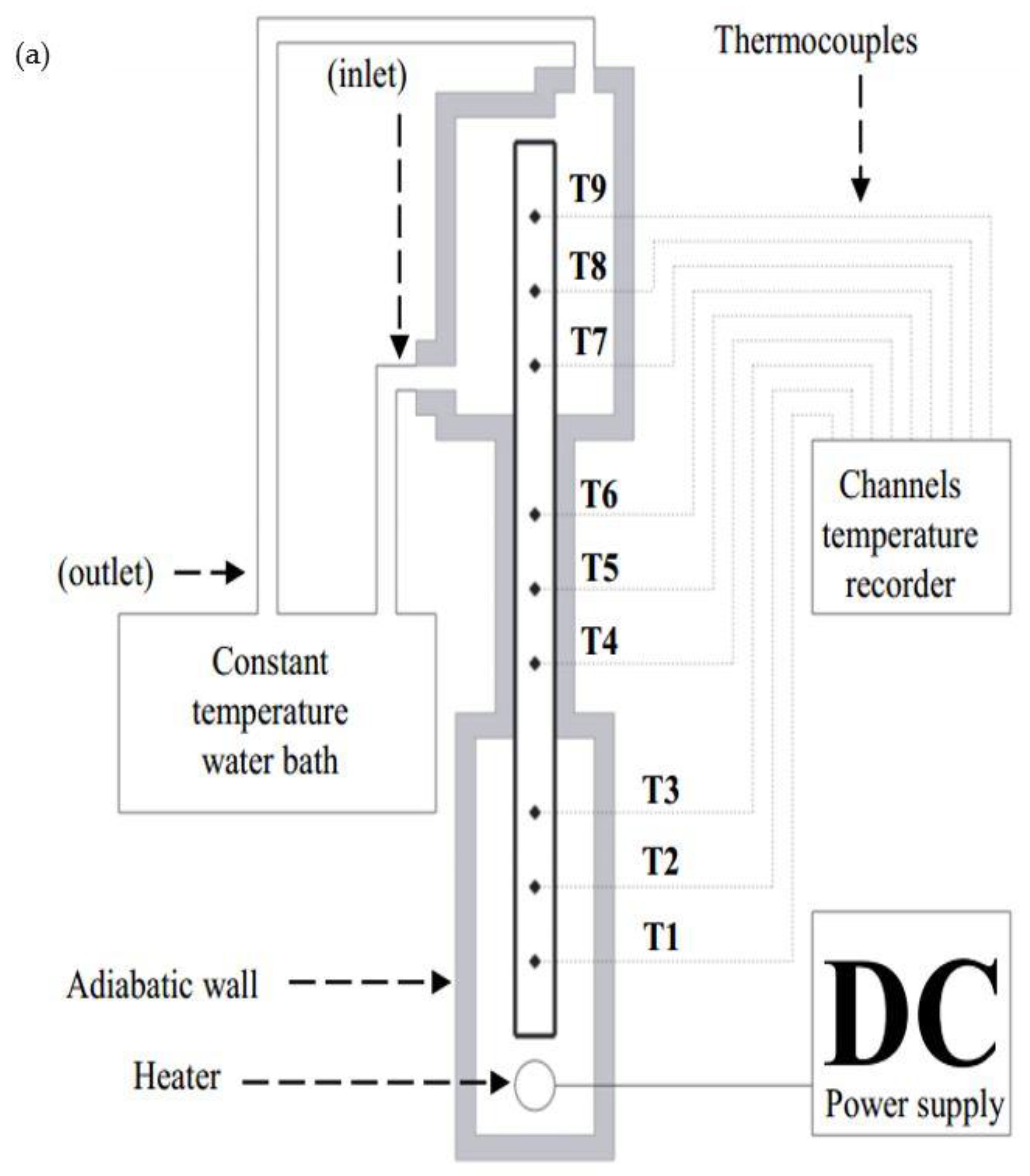

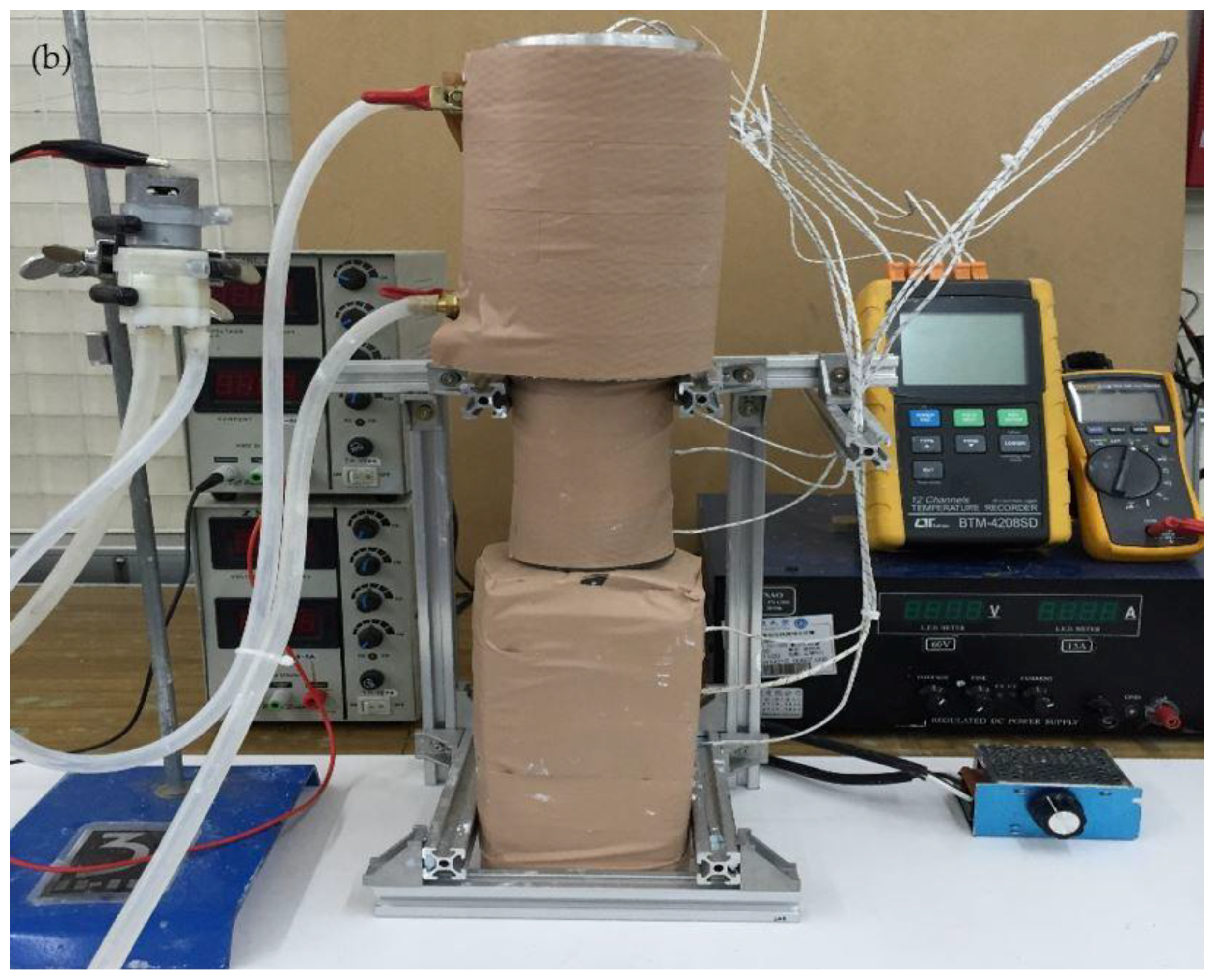

2.2. Experimental Design and Setup

2.2.1. Anodic Oxidation Treatment

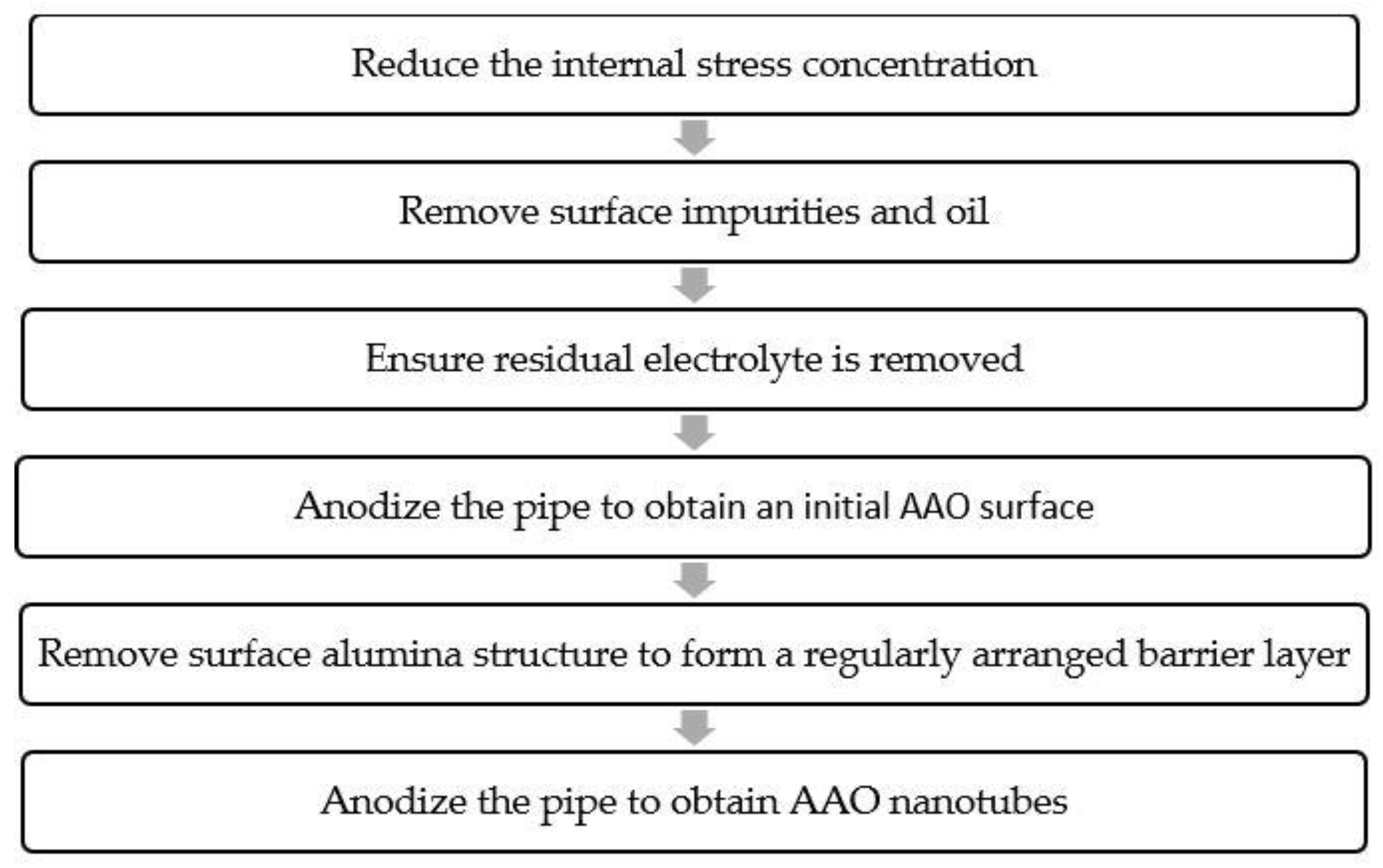

- An open-ended hollow aluminum alloy pipe was annealed at 450 °C for 3 h to reduce the internal stress concentration.

- A first mechanical polishing was performed on the pipe using #600, #1200, and #2000 sandpapers, sequentially; then, a second mechanical polishing was performed using a polishing fleece with 0.1 µm alumina powder to make the inner wall surface of evaporator section smoother. The pipe was then immersed in acetone (CH3COCH3) and ethanol (C2H6O), respectively, washed for 30 min using an ultrasonic cleaner, and rinsed with deionized (DI) water to remove surface impurities and oil.

- The pipe was connected to the anode, a copper bar was connected to the cathode, and both were then immersed in an electrolytic solution (2:1:1 ratio of phosphoric acid (H3PO4), sulfuric acid (H2SO4) and DI water) and subjected to electrolytic polishing at a current of 15 A to ensure that any scratches left after mechanical polishing were removed. After 90 s of polishing, the pipe was taken out and allowed to cool to room temperature. The same chemical polishing process was completed three times. It should be noted here that a PET insulation tape was attached to the outer wall of the pipe to block the chemical polishing on the outside of the pipe. Finally, the pipe was rinsed with DI water to ensure residual electrolyte is removed.

- The pipe was reconnected to the anode, a 0.25-inch-diameter copper bar was placed in the center of the pipe and connected to the cathode, and both were then immersed in an oxalic acid (H2C2O4) electrolyte with a concentration of 0.3 M. A particular anodizing voltage was applied to the first anodizing treatment step at a working temperature of 5 °C. It should be noted here that a micropump and a magnet stirrer are used to ensure that the concentration of electrolyte during the treatment is relatively uniform. The treatment time was maintained at 2 h, and, after the treatment was completed, the residual electrolyte was removed by rinsing with DI water to obtain an initial AAO surface.

- The anodized pipe was then immersed in undiluted phosphoric acid (H3PO4) for surface removal with the help of an ultrasonic bath. After 2 h surface removal, a regularly arranged barrier layer on surface was left. Acetone and ethanol were again used, respectively, to ultrasonically wash the pipe for 30 min, and DI water was then used to remove the residual phosphoric acid on the surface. The AAO barrier layer could serve as a basis for further generation of AAO nanotubes.

- The second anodizing treatment was performed on the pipe with the AAO barrier layer in the previous manner to obtain AAO nanotubes on the inner wall surface of the evaporator section of the heat pipe. In this treatment stage, the length of AAO nanotubes increased with the treatment time.

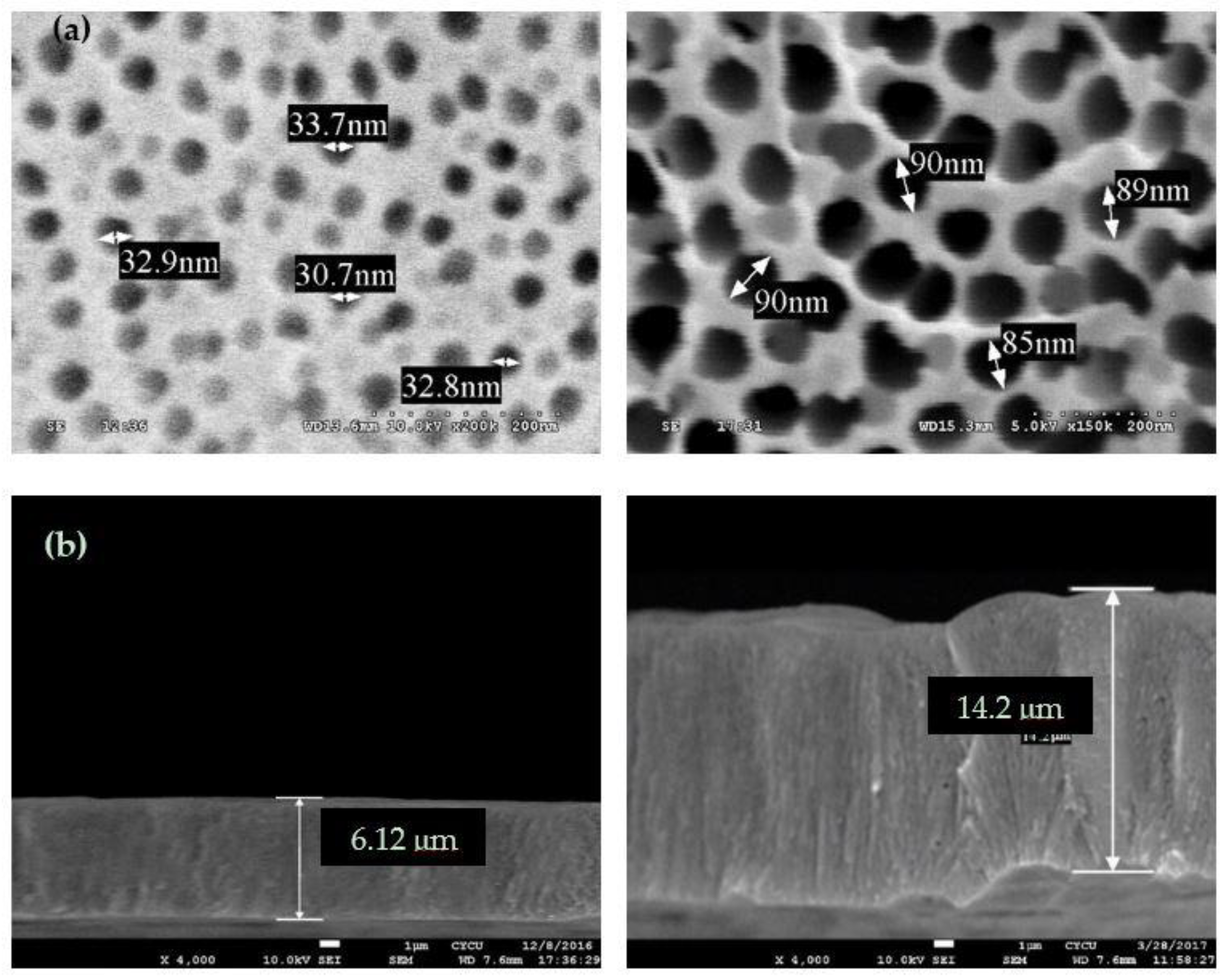

- In our experiments, the anodizing voltage applied was in the range of 20–50 V, and the treatment time consumed was in the range of 3–9 h. The average diameter and length of the AAO nanotubes measured by scanning electron microscope (SEM) imaging method are almost proportional to the anodizing voltage and the treatment time, respectively, as shown in Equations (1) and (2). Figure 3 shows the SEM images of AAO nanotube surfaces obtained at particular anodizing voltages (20 V and 50 V) and particular treatment times (3 h and 7 h).

2.2.2. Processing and Performance Test

3. Results and Discussion

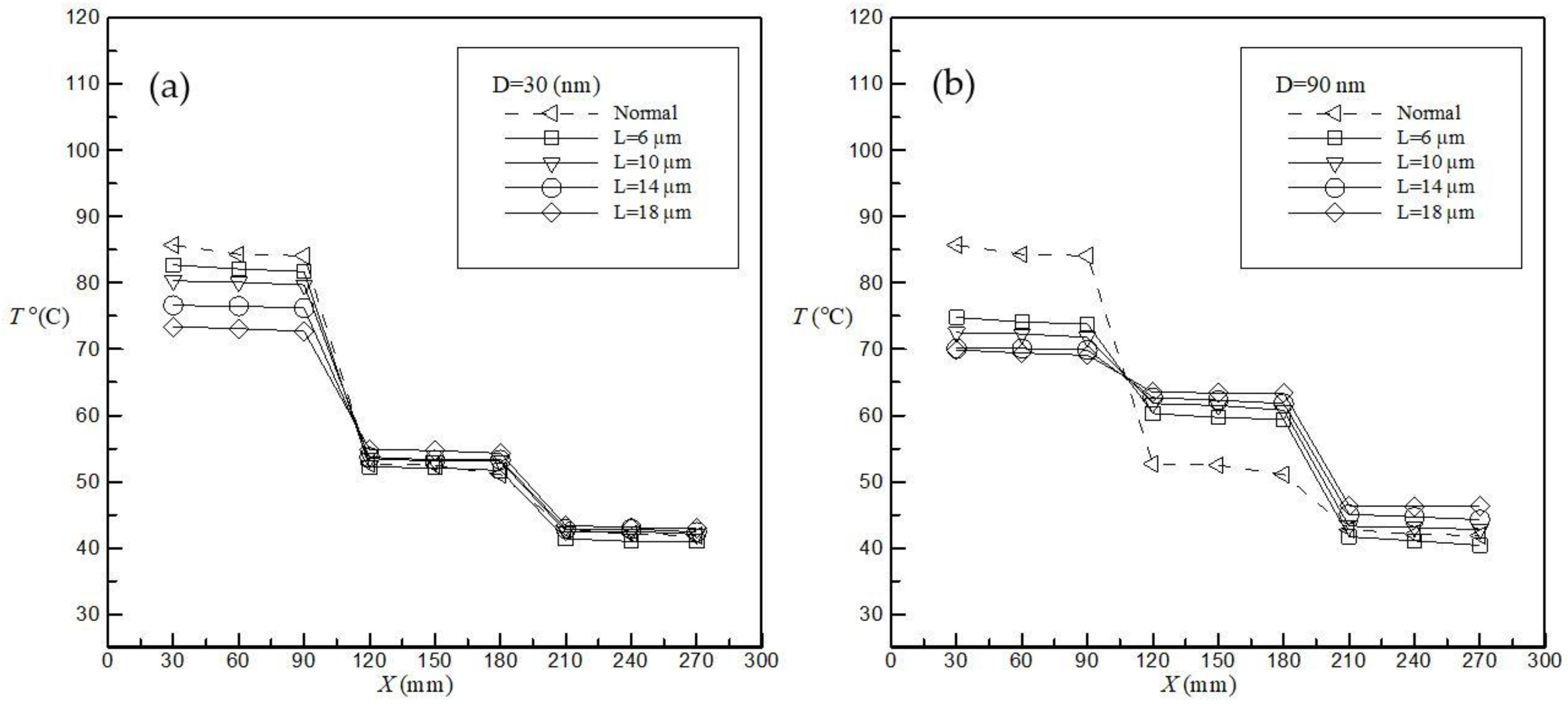

3.1. Temperature Distributions

3.2. Thermal Resistance versus Nanotube Size

3.3. Occurrence of Dry-Out Phenomenon

4. Conclusions

- Increasing the AAO nanotube length and diameter could result in reduced temperature variation between the evaporator section and the condenser section. The maximum percentage decrease in temperature difference between the evaporator section and the condenser section compared to the unprocessed heat pipe is 46.12%.

- Increasing the AAO nanotube length and diameter could lead to the reduction of the overall thermal resistance. The maximum percentage decrease in overall thermal resistance compared to the unprocessed heat pipe is 58.68%.

- The dry-out occurrence can be delayed due to the growth of the AAO nanotube length, but it cannot be not affected by the increase in diameter. The maximum applicable input heat power to avoid dry-out occurrence can be increased up to about 40%, compared to the unprocessed heat pipe.

Author Contributions

Funding

Conflicts of Interest

References

- Shabgard, H.; Allen, M.J.; Sharifi, N.; Benn, S.P.; Faghri, A.; Bergman, T.L. Heat pipe heat exchangers and heat sinks: Opportunities, challenges, applications, analysis, and state of the art. Int. J. Heat Mass Transf. 2015, 89, 138–158. [Google Scholar] [CrossRef]

- Xue, H.S.; Fan, J.R.; Hu, Y.C.; Hong, R.H.; Cen, K.F. The interface effect of carbon nanotube suspension on the thermal performance of a two-phase closed thermosyphon. J. Appl. Phys. 2006, 100, 104909. [Google Scholar] [CrossRef]

- Liu, Z.H.; Yang, X.F.; Guo, G.L. Effect of nanoparticles in nanofluid on thermal performance in a miniature thermosyphon. J. Appl. Phys. 2007, 102, 013526. [Google Scholar] [CrossRef]

- Khandekar, S.; Joshi, Y.M.; Mehta, B. Thermal performance of closed two-phase thermosyphon using nanofluids. Int. J. Therm. Sci. 2008, 47, 659–667. [Google Scholar] [CrossRef]

- Noie, S.H.; Heris, S.Z.; Kahani, M.; Nowee, S.M. Heat transfer enhancement using Al2O3/water nanofluid in a two-phase closed thermosyphon. Int. J. Heat Fluid Flow 2009, 30, 700–705. [Google Scholar] [CrossRef]

- Paramatthanuwat, T.; Boothaisong, S.; Rittidech, S.; Booddachan, K. Heat transfer characteristics of a two-phase closed thermosyphon using de ionized water mixed with silver nano. Heat Mass Transf. 2010, 46, 281–285. [Google Scholar] [CrossRef]

- Teng, T.P.; Hsu, H.G.; Mo, H.E.; Chen, C.C. Thermal efficiency of heat pipe with alumina nanofluid. J. Alloys Compd. 2010, 504, S380–S384. [Google Scholar] [CrossRef]

- Huminic, G.; Huminic, A.; Morjan, I.; Dumitrache, F. Dumitrache, Experimental study of the thermal performance of thermosyphon heat pipe using iron oxide nanoparticles. Int. J. Heat Mass Transf. 2011, 54, 656–661. [Google Scholar] [CrossRef]

- Yang, X.F.; Liu, Z.H. Application of functionalized nanofluid in thermosyphon. Nanoscale Res. Lett. 2011, 6, 494. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.J.; Wang, P.Y.; Liu, Z.H. Application of water-based SiO2 functionalized nanofluid in a loop thermosiphon. Int. J. Heat Mass Transf. 2013, 56, 59–68. [Google Scholar] [CrossRef]

- Kamyar, A.; Ong, K.S.; Saidur, R. Effects of nanofluids on heat transfer characteristics of a two-phase closed thermosyphon. Int. J. Heat Mass Transf. 2013, 65, 610–618. [Google Scholar] [CrossRef]

- Buschmann, M.H.; Franzke, U. Improvement of thermosyphon performance by employing nanofluid. Int. J. Refrig.-Rev. Int. Froid 2014, 40, 416–428. [Google Scholar] [CrossRef]

- Asirvatham, L.G.; Wongwises, S.; Babu, J. Heat transfer performance of a glass thermosyphon using graphene-acetone nanofluid. Heat Transf.-Trans. ASME 2015, 137, 111502. [Google Scholar] [CrossRef]

- Zhao, S.; Xu, G.; Wang, N.; Zhang, X. Experimental study on the thermal start-up performance of the graphene/water nanofluid-enhanced solar gravity heat pipe. Nanomaterials 2018, 8, 72. [Google Scholar] [CrossRef] [PubMed]

- Solomon, A.B.; Ramachandran, K.; Pillai, B.C. Thermal performance of a heat pipe with nanoparticles coated wick. Appl. Therm. Eng. 2012, 36, 106–112. [Google Scholar] [CrossRef]

- Solomon, A.B.; Mathew, A.; Ramachandran, K.; Pillai, B.C.; Karthikeyan, V.K. Thermal performance of anodized two phase closed thermosyphon (TPCT). Exp. Therm. Fluid Sci. 2013, 48, 49–57. [Google Scholar] [CrossRef]

- Singh, R.R.; Selladurai, V.; Ponkarthik, P.K.; Solomon, A.B. Effect of anodization on the heat transfer performance of flat thermosyphon. Exp. Therm. Fluid Sci. 2015, 68, 574–581. [Google Scholar] [CrossRef]

- Solomon, A.B.; Daniel, V.A.; Ramachandran, K.; Pillai, B.C.; Singh, R.R.; Sharifpur, M.; Meyer, J.P. Performance enhancement of a two-phase closed thermosiphon with a thin porous copper coating. Int. J. Heat Mass Transf. 2017, 82, 9–19. [Google Scholar] [CrossRef]

- Tharayil, T.; Asirvatham, L.G.; Rajesh, S.; Wongwises, S. Effect of nanoparticle coating on the performance of a miniature loop heat pipe for electronics cooling applications. J. Heat Transf.-Trans. ASME 2018, 140, 022401. [Google Scholar] [CrossRef]

- Li, A.P.; Muller, F.; Birner, A.; Nielsch, K.; Gosele, U. Hexagonal pore arrays with a 50–420 nm interpore distance formed by self-organization in anodic alumina. J. Appl. Phys. 1998, 84, 6023–6026. [Google Scholar] [CrossRef]

- Thompson, G.E.; Wood, G.C. Porous anodic film formation on aluminium. Nature 1981, 290, 230–232. [Google Scholar] [CrossRef]

- Chien, Y.-C.; Weng, H.C. A brief note on the magnetowetting of magnetic nanofluids on AAO surfaces. Nanomaterials 2018, 8, 118. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Weng, H.C.; Yang, M.-H. Heat Transfer Performance Enhancement of Gravity Heat Pipes by Growing AAO Nanotubes on Inner Wall Surface. Inventions 2018, 3, 42. https://doi.org/10.3390/inventions3030042

Weng HC, Yang M-H. Heat Transfer Performance Enhancement of Gravity Heat Pipes by Growing AAO Nanotubes on Inner Wall Surface. Inventions. 2018; 3(3):42. https://doi.org/10.3390/inventions3030042

Chicago/Turabian StyleWeng, Huei Chu, and Meng-Hsueh Yang. 2018. "Heat Transfer Performance Enhancement of Gravity Heat Pipes by Growing AAO Nanotubes on Inner Wall Surface" Inventions 3, no. 3: 42. https://doi.org/10.3390/inventions3030042

APA StyleWeng, H. C., & Yang, M.-H. (2018). Heat Transfer Performance Enhancement of Gravity Heat Pipes by Growing AAO Nanotubes on Inner Wall Surface. Inventions, 3(3), 42. https://doi.org/10.3390/inventions3030042