Characteristics and Performance of CAUTO (CAssino hUmanoid TOrso) Prototype

Abstract

:1. Introduction

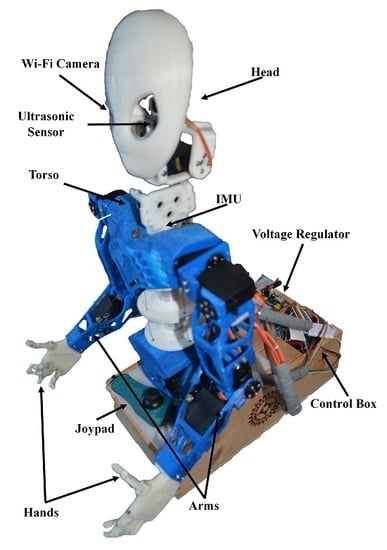

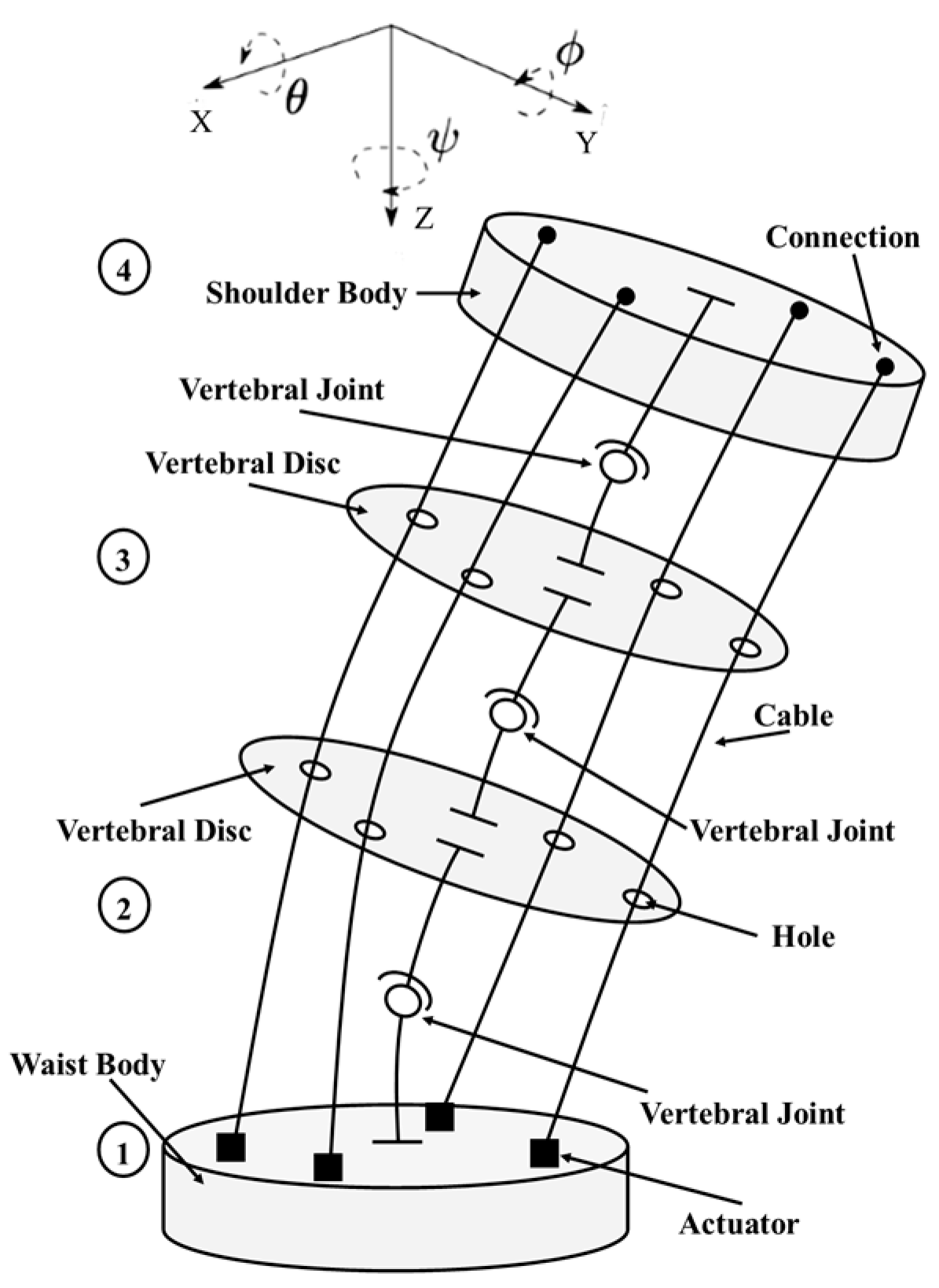

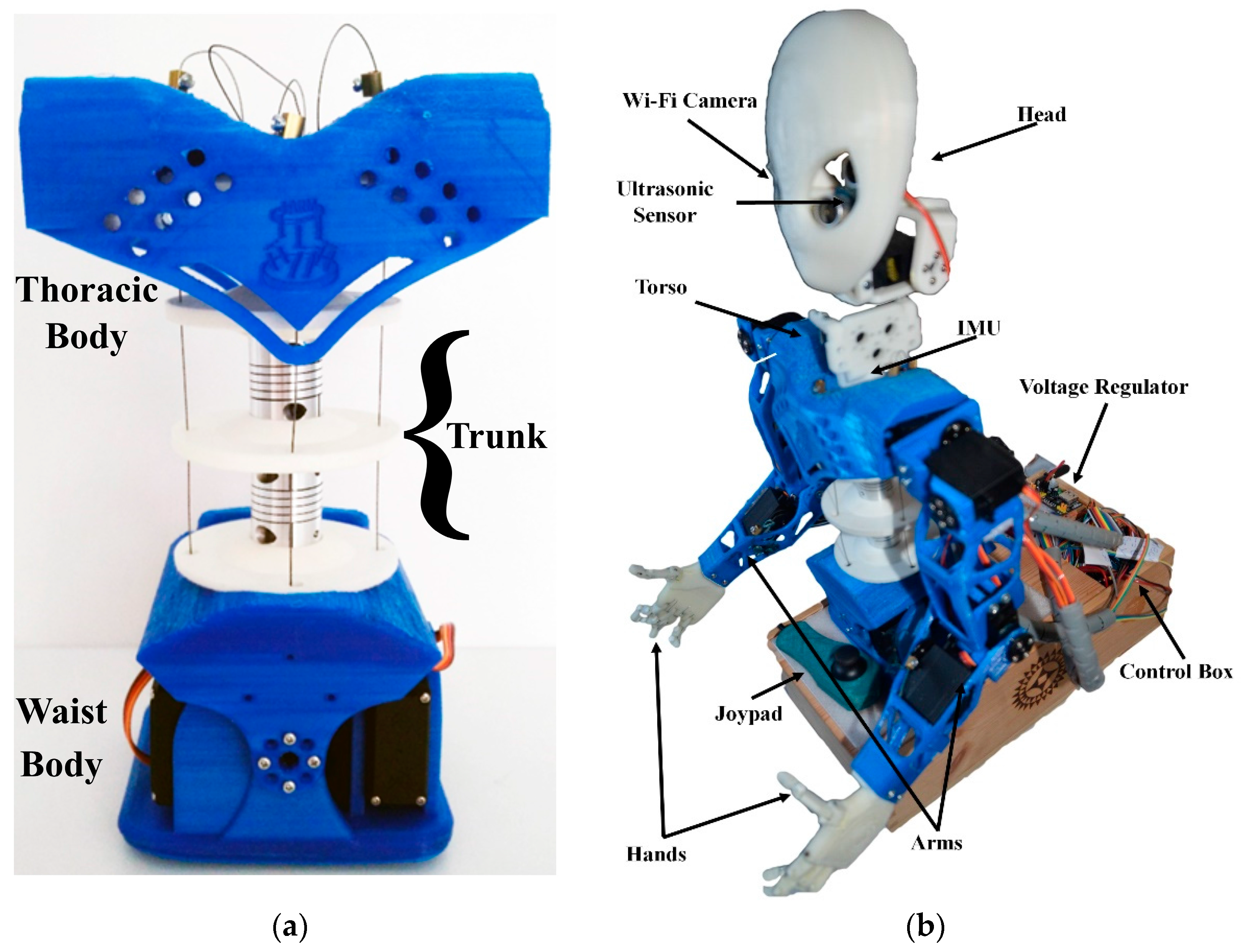

2. The CAssino hUmanoid TOrso (CAUTO) Design

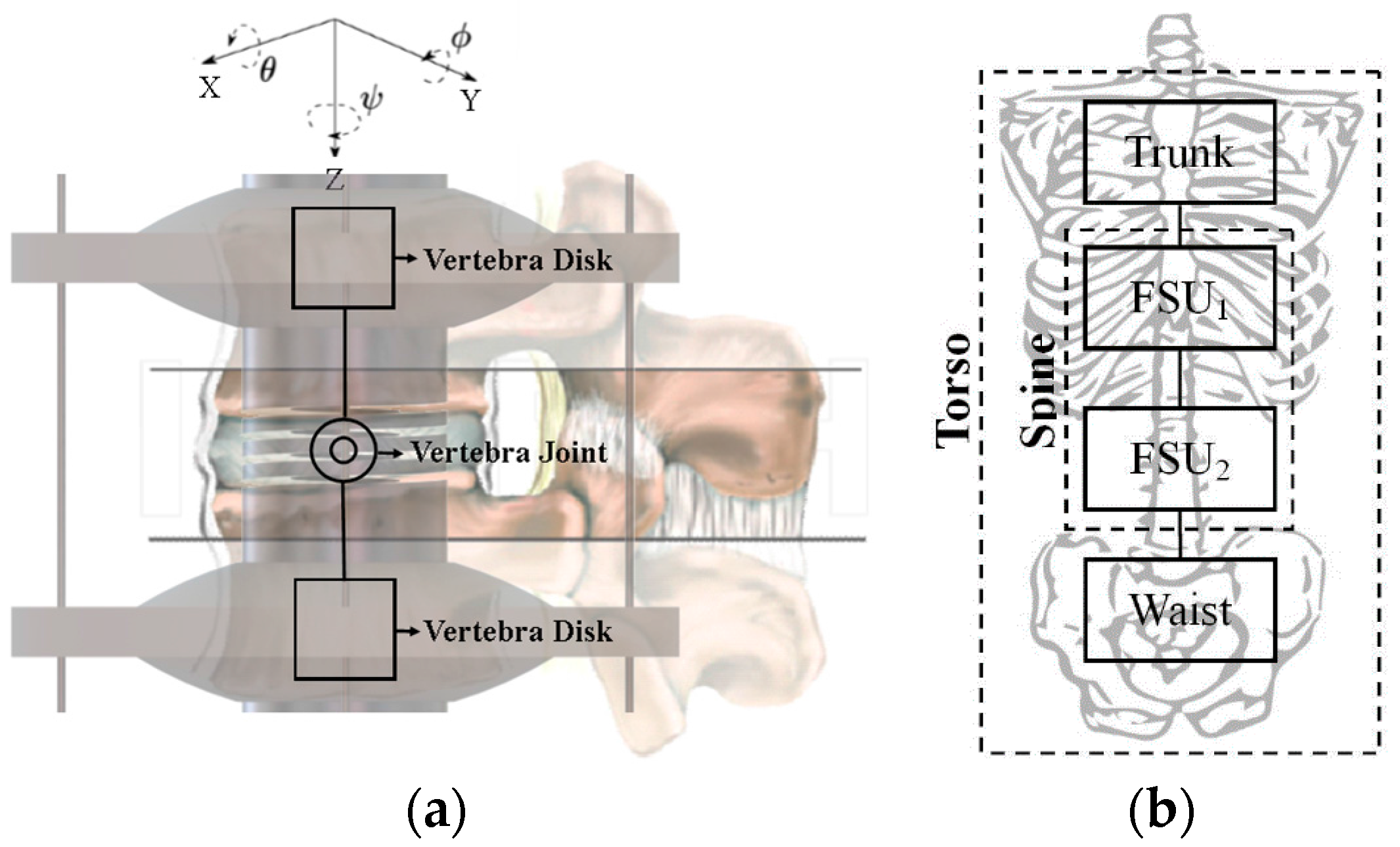

2.1. Kinematic Design and Requirements

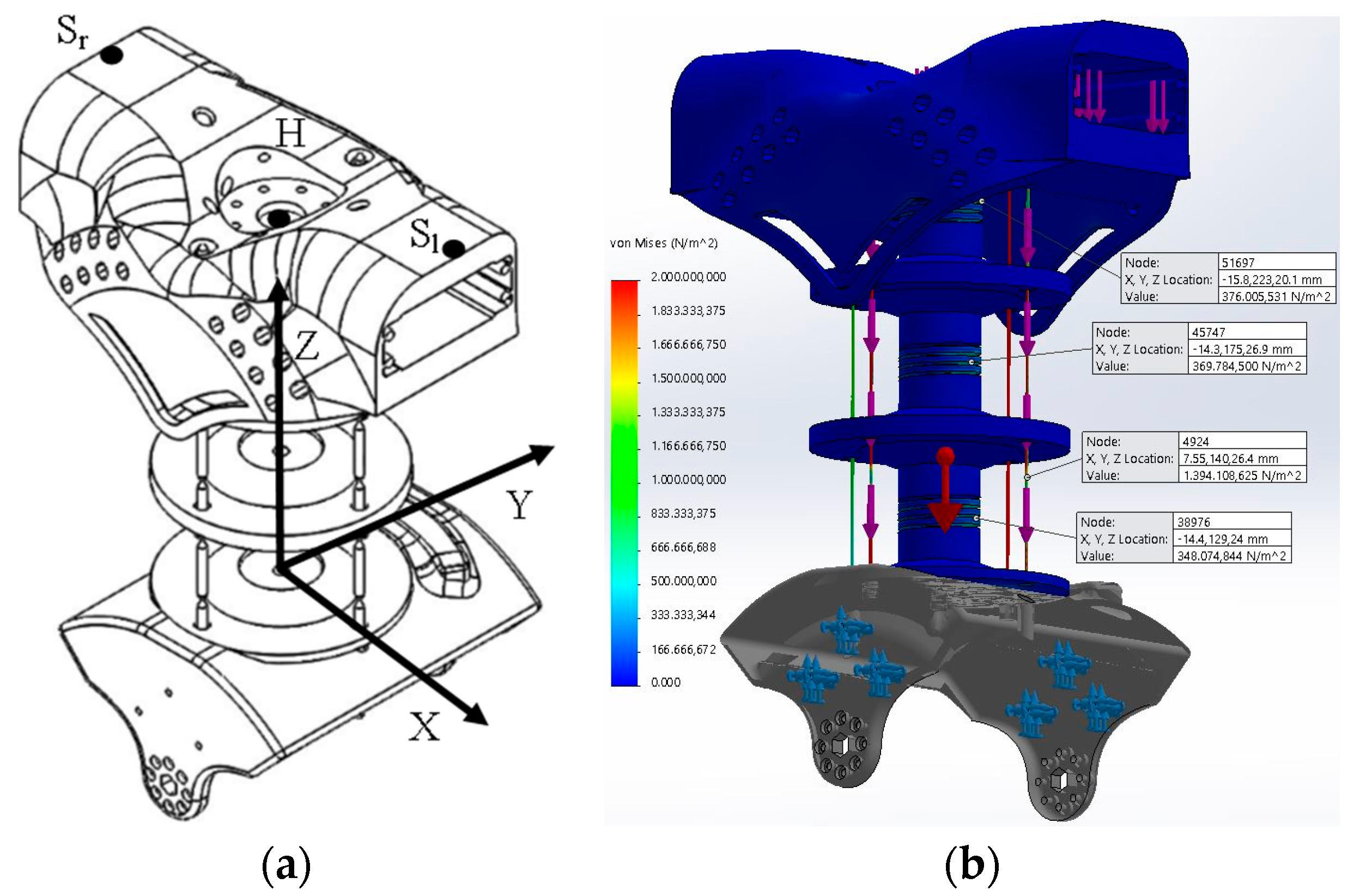

2.2. Mechanical Design

3. The Low-Cost Prototype

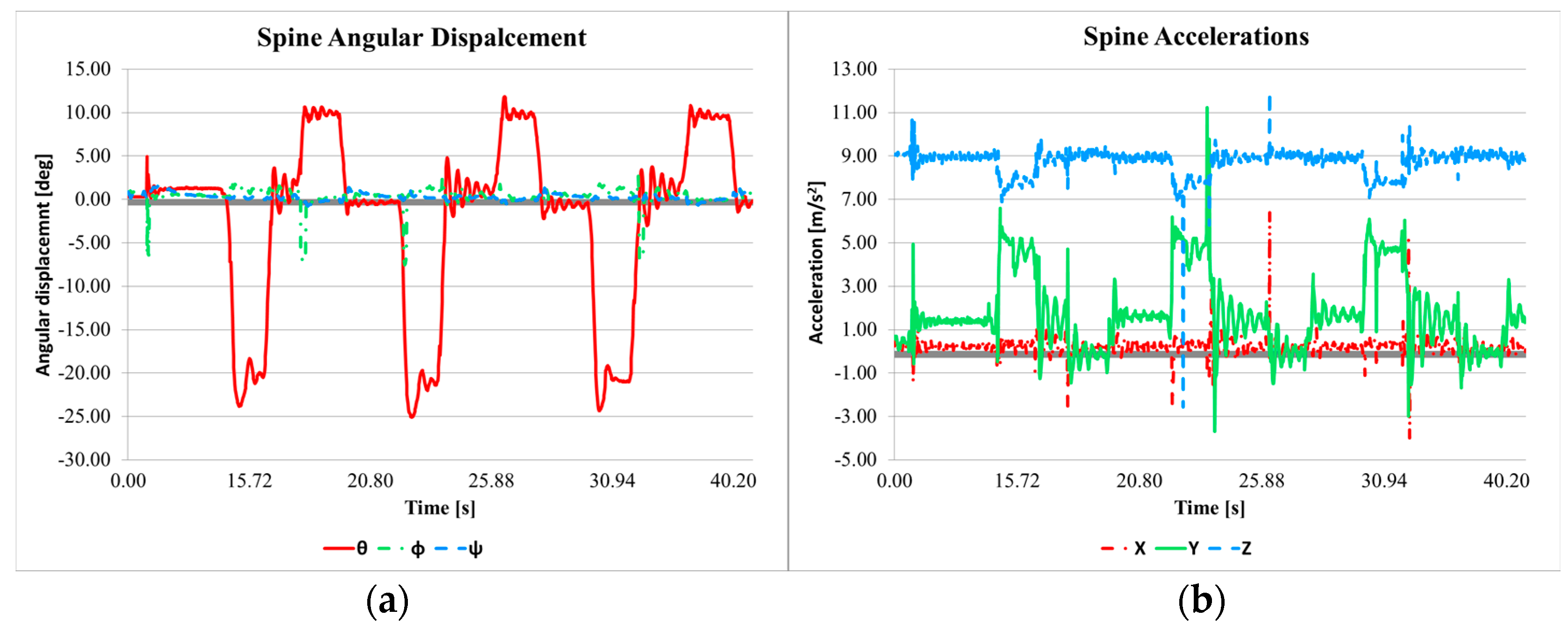

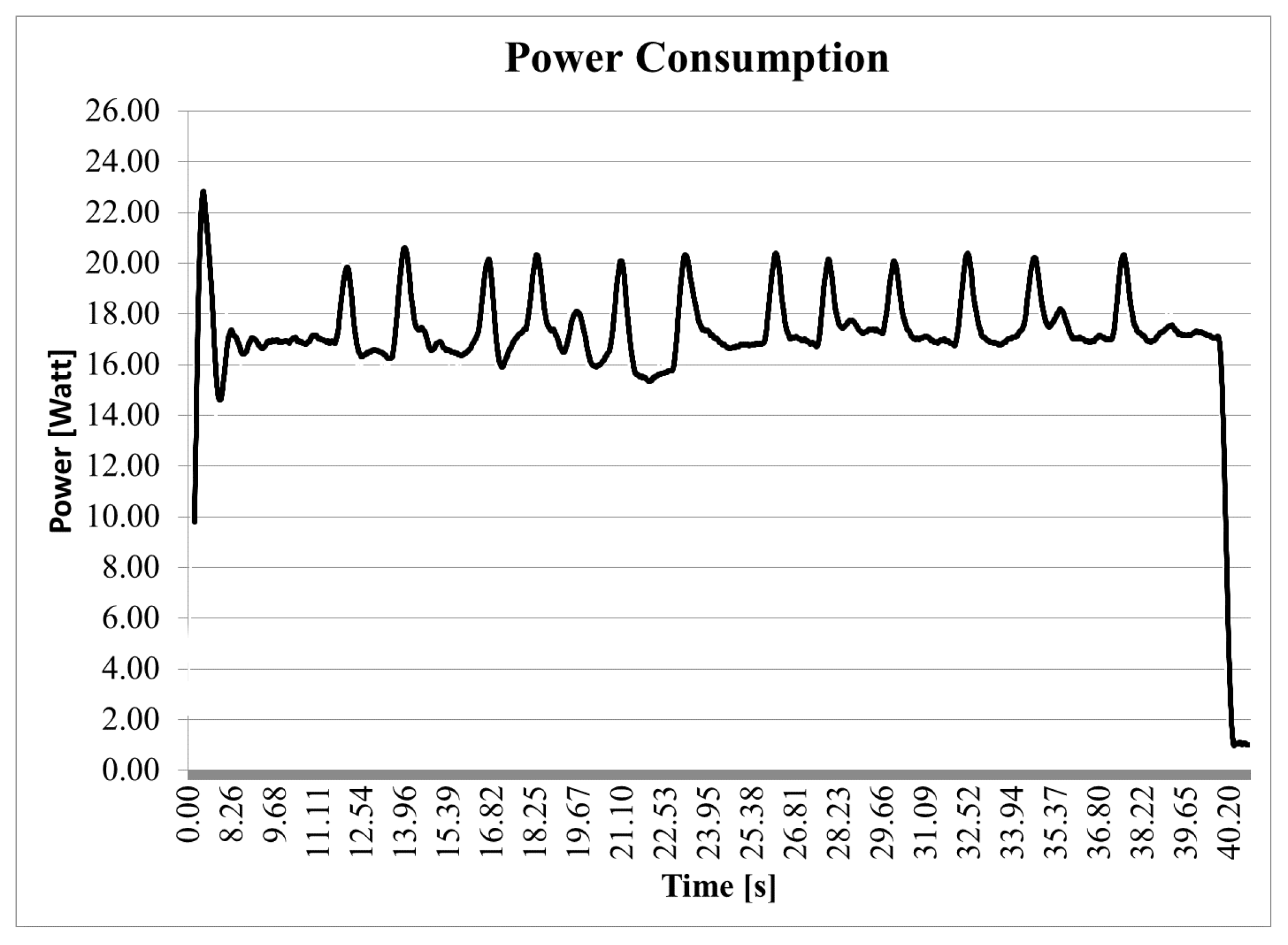

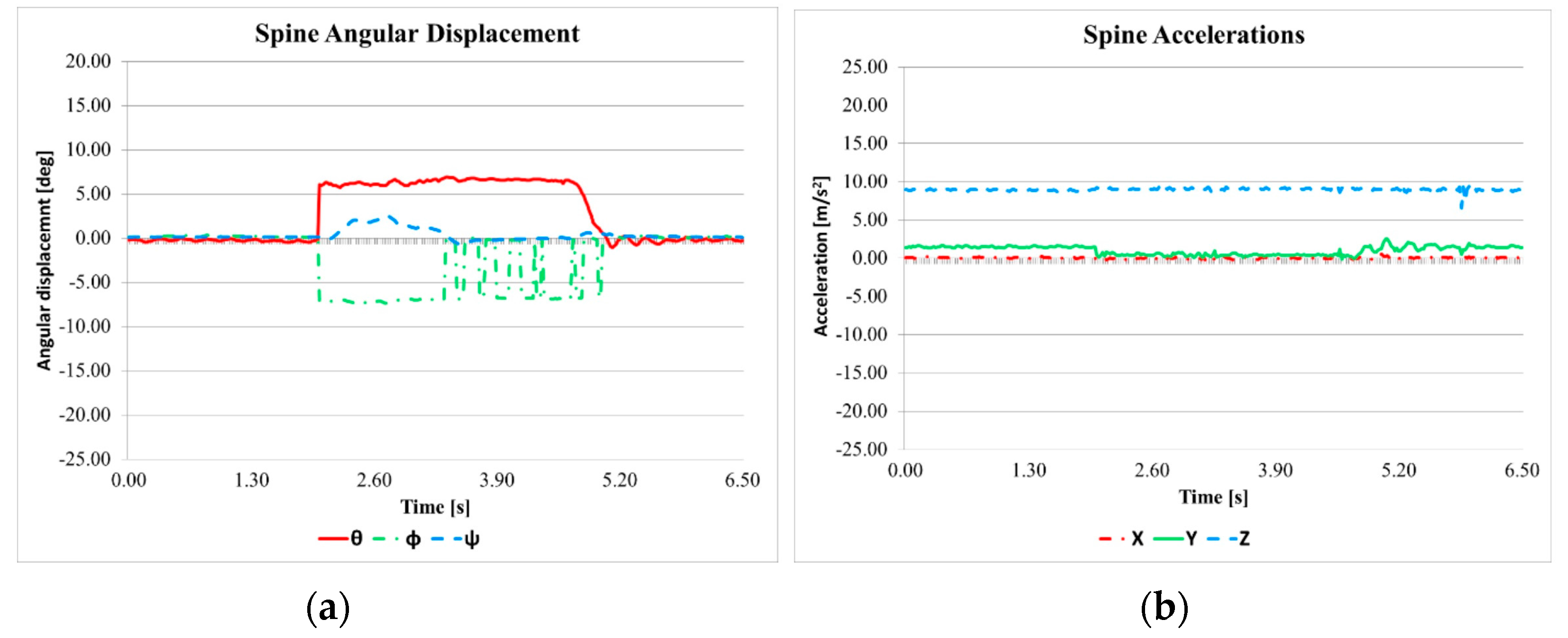

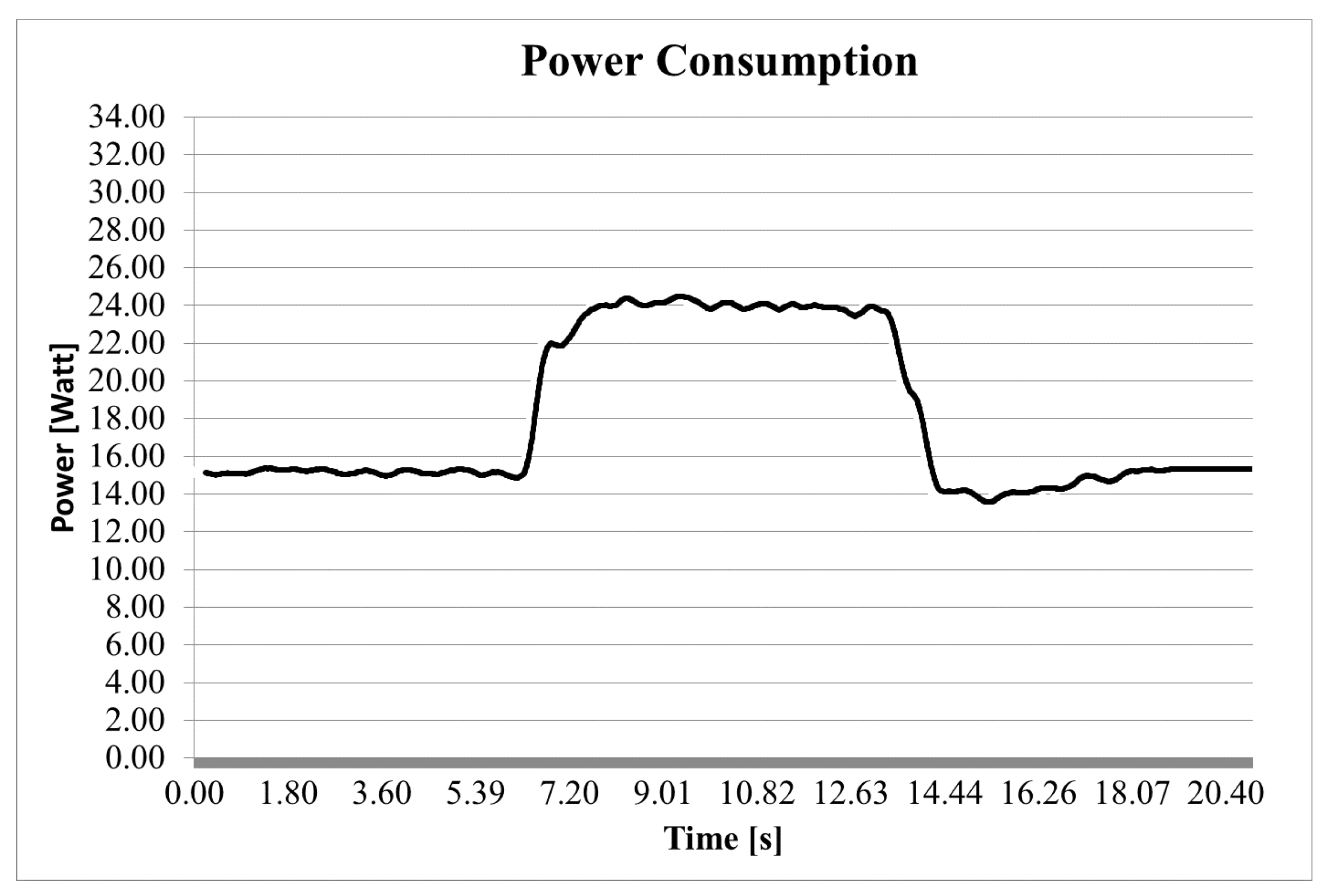

4. Experimental Tests for Performance Evaluation

4.1. Torso Behaviour in Bending

4.2. Torso Behaviour in Lifting Loads

5. Conclusions

Author Contributions

Conflicts of Interest

References

- Kemp, C.; Fitzpatrick, P.; Hirukawa, H.; Yokoi, K.; Harada, K.; Matsumoto, Y. Humanoid Robots. In Springer Handbook of Robotics; Siciliano, B., Khatib, O., Eds.; Springer: Berlin/Heidelberg, Germany, 2008; pp. 1307–1333. [Google Scholar]

- Hirose, M.; Ogawa, K. Honda humanoid robots development. Philos. Trans. R. Soc. 2007, 365, 11–19. [Google Scholar] [CrossRef] [PubMed]

- Ogura, Y.; Aikawa, H.; Shimomura, K.; Morishima, A.; Lim, H.O.; Takanishi, A. Development of a new humanoid robot WABIAN-2. In Proceedings of the ICRA 2006, 2006 IEEE International on Robotics and Automation, Orlando, FL, USA, 15–19 May 2006; pp. 76–81. [Google Scholar]

- Kaneko, K.; Kanehiro, F.; Morisawa, M.; Miura, K.; Nakaoka, S.; Kajita, S. Cybernetic Human HRP-4C. In Proceedings of the 9th IEEE/RAS International Conference on Humanoid Robots (Humanoids 2009), Paris, France, 7–10 December 2009; pp. 7–14. [Google Scholar]

- Zucker, M.; Joo, S.; Grey, M.X.; Rasmussen, C.; Huang, E.; Stilman, M.; Bobick, A. A General-purpose System for Teleoperation of the DRC-HUBO Humanoid Robot. J. Field Robot. 2015, 32, 336–351. [Google Scholar] [CrossRef]

- Mizuuchi, I.; Tajima, R.; Yoshikai, T.; Sato, D.; Nagashima, K.; Inaba, M.; Kuniyoshi, Y.; Inoue, H. The design and control of the flexible spine of a fully tendon-driven humanoid “Kenta”. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, Lausanne, Switzerland, 30 September–4 October 2002; pp. 2527–2532. [Google Scholar]

- Nori, F.; Jamone, L.; Sandini, G.; Metta, G. Accurate control of a human-like tendon-driven neck. In Proceedings of the 2007 7th IEEE-RAS International Conference on Humanoid Robots, Pittsburgh, PA, USA, 29 November–1 December 2007; pp. 371–378. [Google Scholar]

- Saladin, K.S. Human Anatomy; McGraw Hill Higher Education: New York, NY, USA, 2008. [Google Scholar]

- Ceccarelli, M. Fundamentals of Mechanics of Robotic Manipulation; Kluwer/Springer: Dordrecht, The Netherlands, 2004. [Google Scholar]

- Huston, R.L. Principle of Biomechanics; CRC Press: Boca Raton, FL, USA, 2009. [Google Scholar]

- Virginia, C. Bones and Muscles: An Illustrated Anatomy; Wolf Fly Press: New York, NY, USA, 1999. [Google Scholar]

- Cafolla, D.; Ceccarelli, M. Design and simulation of humanoid spine. In New Trends in Mechanism and Machine Science: From Fundamentals to Industrial Applications; Springer: Dordrecht, The Netherlands, 2014; pp. 285–594. [Google Scholar]

- Cafolla, D.; Cheng, I.; Ceccarelli, M. An experimental characterization of human torso motion. Front. Mech. Eng. 2015, 10, 311–325. [Google Scholar] [CrossRef]

- Cafolla, D.; Ceccarelli, M. Design and validation of a PKM Structure for a Humanoid Torso. In Proceedings of the 14th IFToMM World Congress, Taipei, Taiwan, 25–30 October 2015. paper OS13–122. [Google Scholar]

- Cafolla, D.; Ceccarelli, M. Experimental Inspiration and Rapid Prototyping of a novel Humanoid Torso. In Robotics and Mechatronics, Proceedings of the 4th IFToMM International Symposium on Robotics and Mechatronics, Poitiers, France, 23–25 June 2015; Springer: Dordrecht, The Netherlands, 2015; pp. 65–74. [Google Scholar]

- Cafolla, D.; Ceccarelli, M. Design and simulation of a cable-driven vertebra-based humanoid torso. Int. J. Hum. Robot. 2016, 13. [Google Scholar] [CrossRef]

- Cafolla, D.; Ceccarelli, M. Design and FEM analysis of a novel humanoid torso. In Multibody Mechatronic Systems; Springer: Dordrecht, The Netherlands, 2014; pp. 477–488. [Google Scholar]

- Ceccarelli, M.; Carbone, G.; Cafolla, D.; Wang, D.M.F. How to use 3D printing for feasibility check of mechanism design. In Advances in Robot Design and Intelligent Control; Springer International Publishing: Cham, Switzerland, 2015; pp. 307–315. [Google Scholar]

- Single Helix Beam Couplings, Flexible Couplings Catalog, Category #59; Huco: Hertford, UK, 2016.

- Servo Catalog, #MG995; TowerPro.: Singapore, 2016.

- ACS712 Current Sensor, Datasheet, ACS712-DS Rev. 15; Allegro MicroSystems, Inc.: Worcester, MA, USA, 2016.

- Digital Accelerometer, Document Number: D07925-0-5/09(0), Product #ADXL345; Analog Devices Inc.: Norwood, MA, USA, 2009.

- 3-Axis Gyroscope, Document Number: EB-ITG-3200-00-01.1, Product #ITG-3200; InvenSense: San Jose, CA, USA, 2010.

- 3-Axis Digital Compass, Document Number: 900405 Rev D, Product #HMC5883L; Honeywell: Morris Plains, NJ, USA, 2011.

- PING)))™ Ultrasonic Distance Sensor, Parallax Catalog #28015; Parallax: Rocklin, CA, USA, 2016.

- Ai-ball Mini Wifi Camera, Catalog Product #2; Thumbdrive: Singapore, 2016.

- Cafolla, D.; Ceccarelli, M. An experimental validation of a novel humanoid torso. J. Robot. Auton. Syst. 2017, 91, 299–313. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cafolla, D.; Ceccarelli, M. Characteristics and Performance of CAUTO (CAssino hUmanoid TOrso) Prototype. Inventions 2017, 2, 17. https://doi.org/10.3390/inventions2030017

Cafolla D, Ceccarelli M. Characteristics and Performance of CAUTO (CAssino hUmanoid TOrso) Prototype. Inventions. 2017; 2(3):17. https://doi.org/10.3390/inventions2030017

Chicago/Turabian StyleCafolla, Daniele, and Marco Ceccarelli. 2017. "Characteristics and Performance of CAUTO (CAssino hUmanoid TOrso) Prototype" Inventions 2, no. 3: 17. https://doi.org/10.3390/inventions2030017

APA StyleCafolla, D., & Ceccarelli, M. (2017). Characteristics and Performance of CAUTO (CAssino hUmanoid TOrso) Prototype. Inventions, 2(3), 17. https://doi.org/10.3390/inventions2030017