Wire-Based Solid-State Propellant Management System for Small Form-Factor Space Propulsion

Abstract

1. Introduction

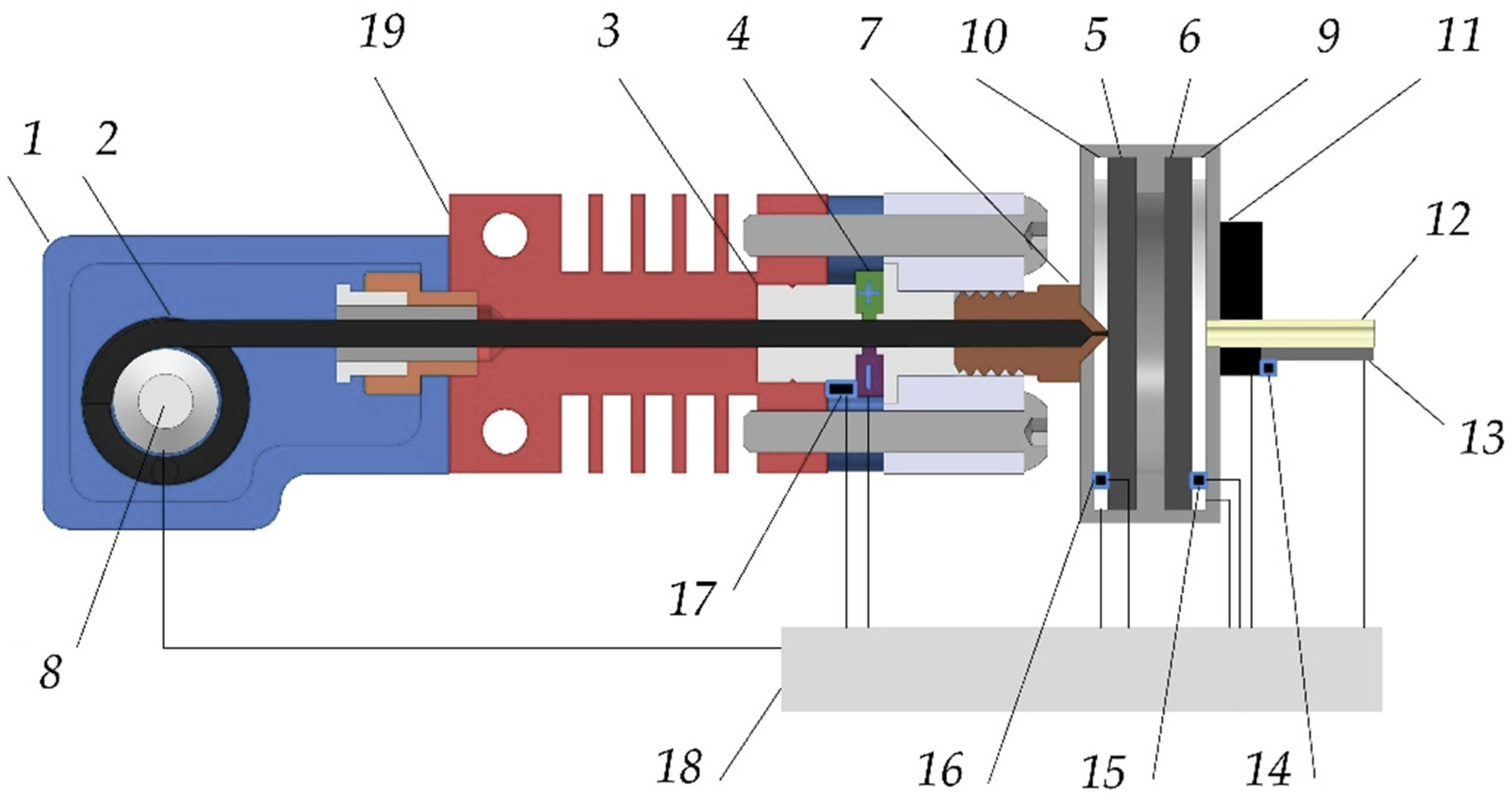

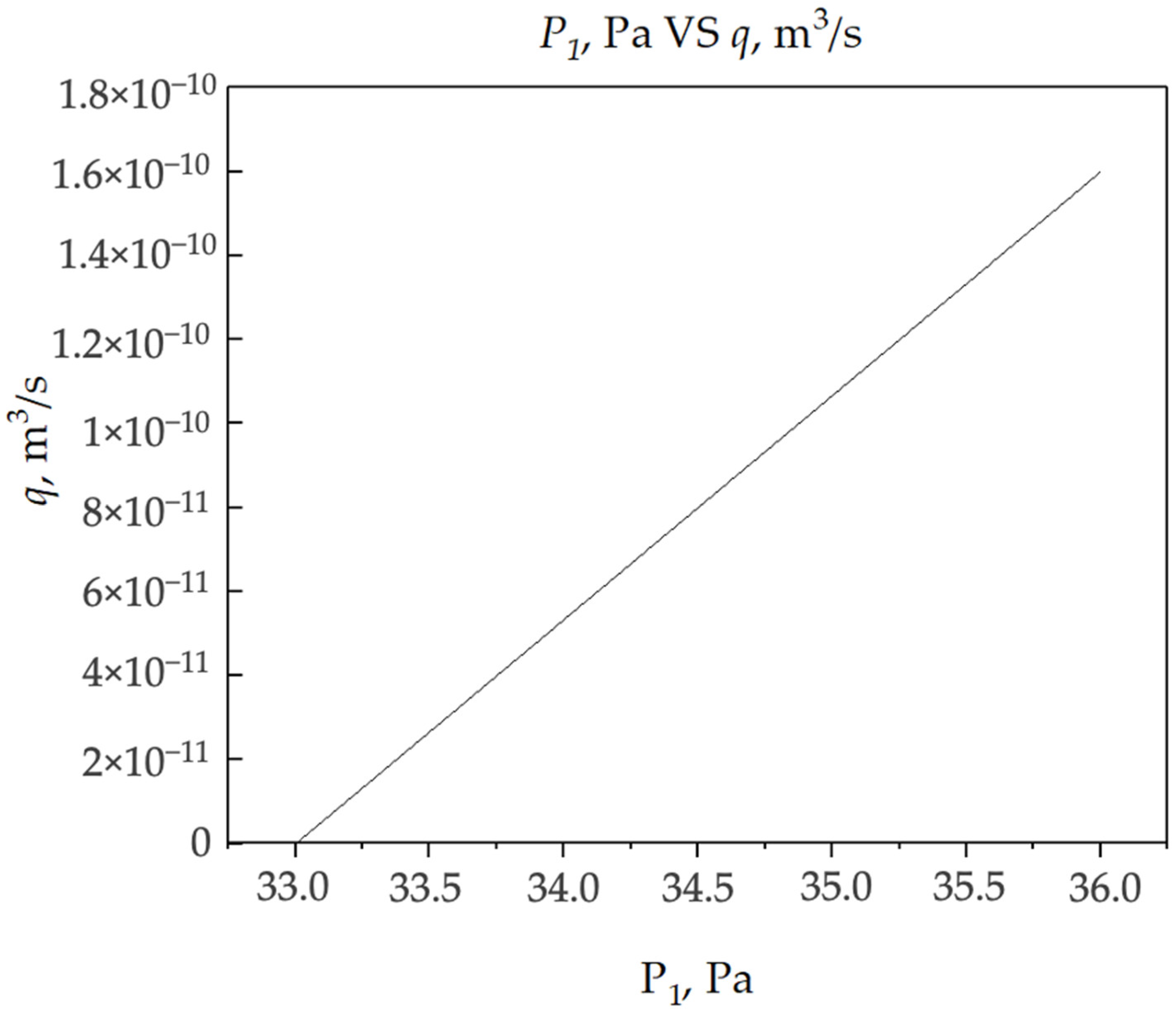

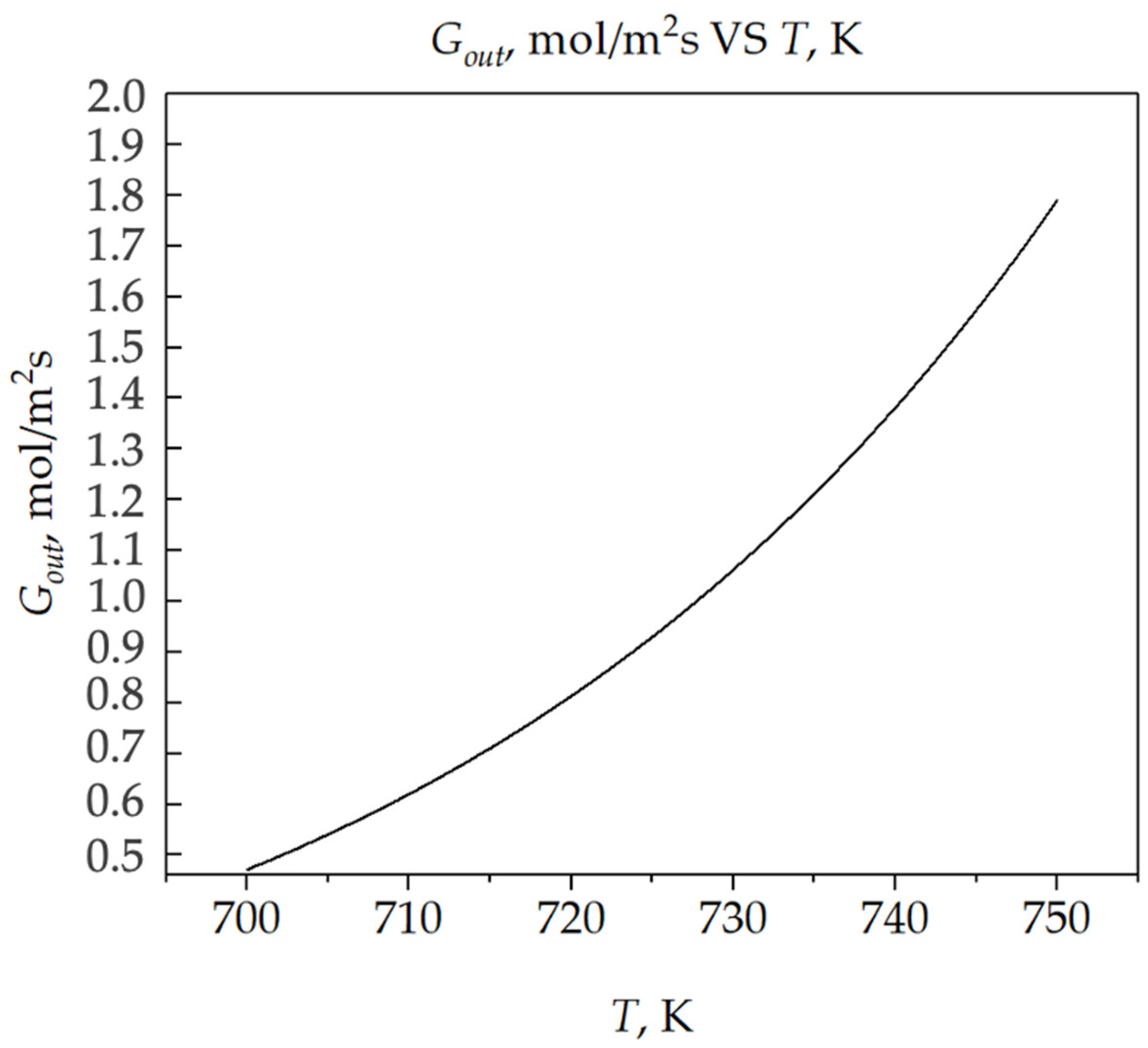

2. Materials and Methods

2.1. Comparative Analysis of Propellant Management Systems

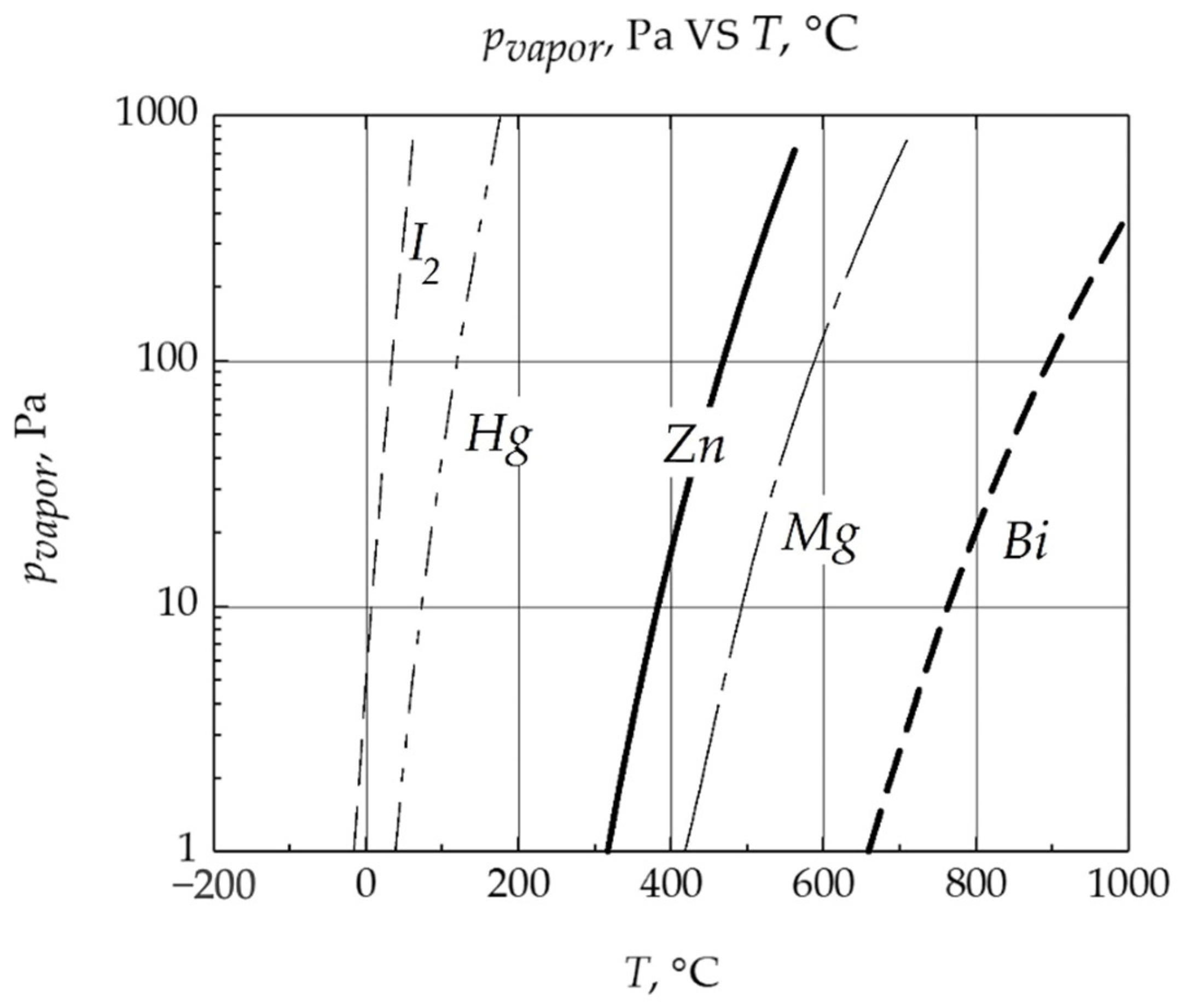

2.2. Comparative Analysis of Fluid- and Solid-State Propellants

3. Results

4. Discussion

4.1. Advantages of Proposed System over Current Solutions

4.2. Prospective Use of Proposed System

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Alnaqbi, S.; Darfilal, D.; Swei, S.S.M. Propulsion Technologies for CubeSats. Aerospace 2024, 11, 502. [Google Scholar] [CrossRef]

- Ponti, F. Advancing Iodine Thruster Technology: Insights and Objectives of Project BOOST. J. Electr. Propuls. 2025, 4, 41. [Google Scholar] [CrossRef]

- Levchenko, I.; Baranov, O.; Keidar, M.; Riccardi, C.; Roman, H.E.; Xu, S.; Alexander, K. Additive Technologies and Materials for the Next-Generation CubeSats and Small Satellites. Adv. Funct. Mater. 2024, 34, 2407602. [Google Scholar] [CrossRef]

- Shumeiko, A.; Telekh, V.; Ryzhkov, S. Thrust-Vectoring Schemes for Electric Propulsion Systems: A Review. Chin. Chin. Chin. Chin. J. Aeronaut. 2025, 38, 103401. [Google Scholar] [CrossRef]

- O’Reilly, D.; Herdrich, G.; Kavanagh, D.F. Electric Propulsion Methods for Small Satellites: A Review. Aerospace 2021, 8, 22. [Google Scholar] [CrossRef]

- Savelev, P.O.; Pashaev, A.D.; Shumeiko, A.I. Modeling of Processes in Porous Thermal Throttles for Iodine Flow Control for Space Applications. Results Eng. 2024, 24, 103463. [Google Scholar] [CrossRef]

- Rafalskyi, D.; Martínez, J.M.; Habl, L.; Rossi, E.Z.; Proynov, P.; Boré, A.; Baret, T.; Poyet, A.; Lafleur, T.; Dudin, S.; et al. In-Orbit Demonstration of an Iodine Electric Propulsion System. Nature 2021, 599, 411–415. [Google Scholar] [CrossRef]

- Bellomo, N.; Magarotto, M.; Manente, M.; Trezzolani, F.; Mantellato, R.; Cappellini, L.; Paulon, D.; Selmo, A.; Scalzi, D.; Minute, M.; et al. Design and In-Orbit Demonstration of REGULUS, an Iodine Electric Propulsion System. CEAS Space J. 2022, 14, 79–90. [Google Scholar] [CrossRef]

- Levchenko, I.; Goebel, D.M.; Bazaka, K. Electric Propulsion of Spacecraft. Phys. Today 2022, 75, 38–44. [Google Scholar] [CrossRef]

- Levchenko, I.; Baranov, O.; Pedrini, D.; Riccardi, C.; Roman, H.E.; Xu, S.; Lev, D.; Bazaka, K. Diversity of Physical Processes: Challenges and Opportunities for Space Electric Propulsion. Appl. Sci. 2022, 12, 11143. [Google Scholar] [CrossRef]

- Shumeiko, A.I.; Telekh, V.D.; Ryzhkov, S.V. Probe Diagnostics and Optical Emission Spectroscopy of Wave Plasma Source Exhaust. Symmetry 2022, 14, 1983. [Google Scholar] [CrossRef]

- Shumeiko, A.I.; Telekh, V.D.; Mayorova, V.I. Development of a Novel Wave Plasma Propulsion Module with Six-Directional Thrust Vectoring Capability. Acta Astronaut. 2022, 191, 431–437. [Google Scholar] [CrossRef]

- Takahashi, K.; Charles, C.; Boswell, R.W. Detection of High Energy Electrons in a Cusp-Field Magnetic Nozzle Radio Frequency Plasma Thruster. AIP Adv. 2025, 15, 075203. [Google Scholar] [CrossRef]

- Andrews, S.; Andriulli, R.; Souhair, N.; Magarotto, M.; Ponti, F. Axial-Radial Plasma Transport and Performance of a Plasma Thruster Magnetic Nozzle under Bohm’s Anomalous Diffusion Scaling. Plasma Sources Sci. Technol. 2025, 30, 015013. [Google Scholar] [CrossRef]

- Andreescu, A.M.T.; Crunteanu, D.E.; Teodorescu, M.V.; Danescu, S.N.; Stoicescu, A.; Cancescu, A.; Paraschiv, A. Operating Characteristics of a Wave-Driven Plasma Thruster for Cutting-Edge Low Earth Orbit Constellations. Inventions 2024, 9, 107. [Google Scholar] [CrossRef]

- Shumeiko, A.I.; Telekh, V.D. Direct Thrust Measurements of 2U-Sized Bi-Directional Wave Plasma Thruster. AIP Adv. 2023, 13, 085113. [Google Scholar] [CrossRef]

- Shumeiko, A.I.; Telekh, V.D.; Ryzhkov, S.V. Starting Modes of Bi-Directional Plasma Thruster Utilizing Krypton. Symmetry 2023, 15, 1705. [Google Scholar] [CrossRef]

- Andronov, A.A.; Shumeiko, A.I.; Pashaev, A.D.; Tsygankov, P.A.; Kovalev, S.V.; Telekh, V.D. Plume Characterization of Electrodeless Plasma Thruster with Configurable Exhaust. Symmetry 2025, 17, 661. [Google Scholar] [CrossRef]

- Andrews, S.; Andriulli, R.; Souhair, N.; Magarotto, M.; Ponti, F. Cathode-Less RF Plasma Thruster Design and Optimisation for an Atmosphere-Breathing Electric Propulsion (ABEP) System. Acta Astronaut. 2024, 225, 833–844. [Google Scholar] [CrossRef]

- van Lynden, W.; Andriulli, R.; Souhair, N.; Ponti, F.; Magarotto, M. Coupling of Fluid and Particle-In-Cell Simulations of Ambipolar Plasma Thrusters. Aerospace 2024, 11, 880. [Google Scholar] [CrossRef]

- Shumeiko, A.I.; Telekh, V.D. Helicon Engine in Outboard Air as a Successful Solution for Maintaining Small Space Vehicle in Orbits Up to 200 km. In Proceedings of the AIP Conference, Moscow, Russia, 28 January–1 February 2019; AIP Publishing LLC.: Melville, NY, USA, 2019; p. 170019. [Google Scholar]

- Yamasaki, J.; Yokota, S.; Shimamura, K. Hall thruster performances using low cost propellant. In Proceedings of the AIAA Propulsion and Energy 2019 Forum, Indianapolis, IN, USA, 19–22 August 2019; p. 3999. [Google Scholar] [CrossRef]

- Martínez, J.; Rafalskyi, D. Design and development of iodine flow control systems for miniaturized propulsion systems. CEAS Space J. 2022, 14, 91–107. [Google Scholar] [CrossRef]

- Benavides, G.F.; Kamhawi, H.; Mackey, J.; Haag, T.; Costa, G. Iodine Hall-effect electric propulsion system research, development, and system durability demonstration. In Proceedings of the 2018 Joint Propulsion Conference, Cincinnati, OH, USA, 9–11 July 2018; p. 4422. [Google Scholar]

- Tsay, M.; Frongillo, J.; Zwahlen, J.; Paritsky, L. Maturation of iodine fueled BIT-3 RF ion thruster and RF neutralizer. In Proceedings of the 52nd AIAA/SAE/ASEE Joint Propulsion Conference, Salt Lake City, UT, USA, 25–27 July 2016; p. 4544. [Google Scholar] [CrossRef]

- Foust, J. Cubesat Launched on Artemis 1 Trying to Fix Propulsion System. SpaceNews.com. Available online: https://spacenews.com/cubesat-launched-on-artemis-1-trying-to-fix-propulsion-system/ (accessed on 16 August 2025).

- Yaginuma, K.; Asakawa, J.; Nakagawa, Y.; Tsuruda, Y.; Koizumi, H.; Kakihara, K.; Yanagida, K.; Murata, Y.; Ikura, M.; Matsushita, S.; et al. AQT-D: CubeSat demonstration of a water propulsion system deployed from ISS. Trans. Jpn. Soc. Aeronaut. Space Sci. Aerosp. Technol. Jpn. 2020, 18, 141–148. [Google Scholar] [CrossRef]

- Bruno, T.J.; Svoronos, P.D. CRC Handbook of Fundamental Spectroscopic Correlation Charts; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Grishin, S.D.; Leskov, L.V.; Kozlov, N.P. Electric Rocket Engines; Nauka: Moscow, Russia, 1975. [Google Scholar]

- Szabo, J.; Robin, M.; Paintal, S.; Pote, B.; Hruby, V. High density Hall thruster propellant investigations. In Proceedings of the 48th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Atlanta, GA, USA, 30 July–1 August; 2012. [Google Scholar] [CrossRef]

- Lide, D.R. CRC Handbook of Chemistry and Physics: A Ready-Reference Book of Chemical and Physical Data; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Younglove, B. Tables of Industrial Gas Container Contents and Density for Oxygen, Argon, Nitrogen, Helium, and Hydrogen; National Bureau of Standards: Washington, DC, USA, 1985. [Google Scholar]

- Stull, D.R. Vapor pressure of pure substances. Organic and inorganic compounds. Ind. Eng. Chem. 1947, 39, 517–540. [Google Scholar] [CrossRef]

- Teng, Y.; Li, Z.; Chen, C. Pre-Darcy Flows in Low-Permeability Porous Media. Hydrogeol. J. 2024, 32, 1957–1977. [Google Scholar] [CrossRef]

- Koutsoyiannis, D. Clausius–Clapeyron Equation and Saturation Vapour Pressure: Simple Theory Reconciled with Practice. Eur. J. Phys. 2012, 33, 295. [Google Scholar] [CrossRef]

- Szabo, J.J., Jr.; Pote, B.; Paintal, S.; Robin, M.; Hruby, V. Iodine Fueled Plasma Generator System. Patent No. US8610356B2, 17 December 2013. [Google Scholar]

- Alekseevich, B.A.; Aleksandrovich, K.S.; Georgievich, O.V.; Alekseevich, S.A.; Aleksandrovich, S.P. Iodine Storage and Supply System. Patent No. RU2557789C2, 27 July 2015. [Google Scholar]

- Olegovich, S.P.; Dzhamaldinovich, P.A.; Ivanovich, S.A. System for Storage and Supply of Working Medium with Possibility of Fast Flow Control. Patent No. RU2828141C1, 7 October 2024. [Google Scholar]

| Parameter | Pressurized Fluid-State PSSS | Liquid- and Solid-State PSSS | |

|---|---|---|---|

| Propellant type | Noble gases (Kr, Xe, Ar) | Solids (I2, Zn, Mg, Bi, Hg, Cs) or liquids (H2O, NH3) | |

| Aggregation state | Gaseous- or liquid-state substances | Liquid- and solid-state substances | |

| Storage conditions | Pressures in range from 100 kPa to dozens MPa, temperatures in range from −60 °C to 60 °C | Pressures in range of 1 to 100 kPa, temperatures in range of −60 °C to 103 °C | |

| Mass flow and pressure management system | High-pressure valves and throttles with given flow area | Low-pressure valves, thermal throttles in form of porous filters and tubes with given flow cross-section that includes heating system | |

| Storage density, (g/cm3) | <2 | Up to 10 | |

| Dimensions | Dry mass and volume up to 90% of whole propulsion system | Dry mass and volume no more than 50% of whole propulsion system | |

| Risks | Propellant tanks | Depressurization | Chemical destruction |

| Feedthrough lines | Depressurization, clogging due to system or propellant impurities (metal swarf) | Channel blockage due to deposited propellant accumulation [26] | |

| Satellite systems and components | None | Deposition of propellant on systems and components of satellite | |

| Applicability for CubeSats | Limited due to mass and volume | Versatile, depending on choice of propellant | |

| Thermal control | Propellant preparation | Not required | Required for sublimation |

| Tanks | Not required except for Xe | Required during operations | |

| Lines | Nor required | Required during operations | |

| Some flight application examples on small satellites, thruster name (propellant) | BDEPT (Kr) [4] | NPT-30 (I2) [7] Regulus (I2) [8] BIT-3 (I2) [25] AQT-D (H2O) [27] | |

| Propellant | Storage Density, (g/cm3) | Potential Ionization, (eV) | Temperature, (K) at Which Pressure of 1000 (Pa) Is Reached | Molar Mass, (g/mol) | Notes on Safety and Operating Conditions |

|---|---|---|---|---|---|

| I2 | 4.9 | 9.3 | 341.68 | 127 | 1 |

| Zn | 7.1 | 9.4 | 448 | 65 | 2 |

| Mg | 1.74 | 7.7 | 698 | 24 | 2 |

| Bi | 9.78 | 7.3 | 1052 | 209 | 2 |

| Cs | 1.93 | 3.9 | 350 | 132 | 1,3 |

| Kr | 0.5 | 14 | - | 83 | - |

| Xe | 1.6 | 12.1 | - | 131 | 4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Savelev, P.O.; Shumeiko, A.I.; Telekh, V.D. Wire-Based Solid-State Propellant Management System for Small Form-Factor Space Propulsion. Inventions 2025, 10, 75. https://doi.org/10.3390/inventions10050075

Savelev PO, Shumeiko AI, Telekh VD. Wire-Based Solid-State Propellant Management System for Small Form-Factor Space Propulsion. Inventions. 2025; 10(5):75. https://doi.org/10.3390/inventions10050075

Chicago/Turabian StyleSavelev, Pavel O., Andrei I. Shumeiko, and Victor D. Telekh. 2025. "Wire-Based Solid-State Propellant Management System for Small Form-Factor Space Propulsion" Inventions 10, no. 5: 75. https://doi.org/10.3390/inventions10050075

APA StyleSavelev, P. O., Shumeiko, A. I., & Telekh, V. D. (2025). Wire-Based Solid-State Propellant Management System for Small Form-Factor Space Propulsion. Inventions, 10(5), 75. https://doi.org/10.3390/inventions10050075