2. Materials and Methods

2.1. W-Model Framework for Aircraft Component Modifications

The classical V-Model has served as the foundational framework for aerospace systems engineering, providing structured guidance from initial concept development through certification and entry into operational service. However, this traditional approach terminates upon aircraft delivery, creating a significant gap in addressing reliability degradation and performance issues that emerge during the operational lifecycle. To address this limitation, this study introduces the W-model framework as a comprehensive lifecycle management approach that seamlessly integrates systematic component modification processes with established aerospace development practices (

Figure 1).

The W-model represents a paradigm shift from the linear, terminating structure of the classical V-Model to a continuous, iterative lifecycle framework that acknowledges the dynamic nature of aircraft operations and the need for ongoing reliability improvements. The framework derives its name from the characteristic “W” shape formed by connecting initial aircraft development, operational service, and systematic modification cycles into a unified process architecture.

The conceptual foundation of the W-model rests on three fundamental principles:

Lifecycle continuity recognizes that aircraft development does not conclude upon certification but extends throughout the operational life, requiring systematic processes for addressing emerging reliability challenges.

Data-driven decision-making emphasizes the use of quantitative operational data and statistical analysis to identify modification needs, prioritize interventions, and validate improvements.

Process integration ensures that modification activities maintain the same level of rigor, traceability, and regulatory compliance as initial development processes.

Unlike reactive, ad hoc approaches to component modifications, the W-model provides a proactive framework that anticipates reliability degradation and establishes systematic pathways for continuous improvement. This approach transforms reliability issues from operational problems into engineering opportunities, enabling airlines and manufacturers to optimize component performance throughout the aircraft lifecycle.

The W-model framework (

Figure 1) comprises three integrated segments that collectively address the complete aircraft lifecycle from initial concept through continuous operational improvement.

Left segment: Initial aircraft development encompasses the traditional aerospace development process, including concept development, requirements engineering, system architecture definition, and system design and development. This segment follows established V-Model principles, culminating in system integration, verification and validation, and certification activities that enable aircraft entry into operational service.

Central segment: Operations and maintenance serve as the operational bridge between initial development and ongoing improvement activities. This segment encompasses in-service data collection, performance monitoring, maintenance execution, and operational experience accumulation. The operations and maintenance phase generates the empirical data foundation that drives subsequent modification decisions and provides validation of implemented improvements.

Right segment: The component modification cycle introduces a systematic six-phase process specifically designed for developing and implementing component-level modifications based on operational experience. This segment mirrors the rigor and structure of initial development while addressing the unique challenges of post-certification improvements.

The W-model architecture ensures seamless transitions between segments through formal data interfaces, process handoffs, and feedback mechanisms. Operational data flows from the central segment to initiate modification activities, while certified improvements return to enhance operational performance, creating a continuous cycle of reliability growth.

The component modification cycle represents the core innovation of the W-model framework, providing systematic processes for translating operational experience into engineering improvements. The six phases are structured to maintain consistency with aerospace engineering practices while addressing the specific requirements of modification development.

Phase 1. Reliability monitoring establishes systematic collection and tracking of component performance data from operational service. This phase employs statistical process control, trend analysis, and failure pattern recognition to identify components exhibiting degraded reliability performance. Key activities include mean time between failures (MTBF) tracking, failure mode documentation, dispatch reliability analysis, and maintenance cost assessment. The phase outputs include comprehensive reliability databases, performance trend reports, and preliminary identification of components requiring further analysis.

Phase 2. Reliability analysis and candidate selection provides the critical analytical foundation for modification decisions through systematic evaluation of reliability data and component prioritization. This phase applies advanced statistical methods, root cause analysis, and multi-criteria decision analysis to select modification candidates that offer the greatest potential for reliability improvement and operational benefit. Activities include failure mode and effects analysis (FMEA), fault tree analysis (FTA), economic impact assessment, and technical feasibility evaluation. The phase culminates in a formal decision gate that authorizes progression to preliminary design activities for selected components.

Phase 3. Preliminary design review (PDR) validates the technical feasibility and regulatory acceptability of proposed modifications through structured engineering evaluation. The PDR assesses modification concepts against safety requirements, certification constraints, and integration considerations. Review activities include conceptual design evaluation, safety impact assessment, regulatory pathway analysis, and resource requirement definition. Successful PDR completion authorizes advancement to detailed development activities.

Phase 4. Detailed development encompasses comprehensive engineering of the modification, including component design, interface definition, manufacturing process development, and integration planning. This phase applies established aerospace engineering tools and methodologies, including computer-aided design (CAD), finite element analysis (FEA), computational fluid dynamics (CFD), and simulation modeling. Development activities emphasize maintainability, manufacturability, and lifecycle cost optimization while ensuring compatibility with existing aircraft systems.

Phase 5. Critical design review (CDR) provides final validation of the completed modification design before transition to manufacturing and qualification testing. The CDR evaluates technical maturity, safety compliance, manufacturing readiness, and certification pathway confirmation. Review activities include detailed design verification, risk assessment validation, interface compatibility confirmation, and qualification test planning. CDR approval authorizes prototype development and formal qualification activities.

Phase 6. Certification of modification ensures regulatory compliance and airworthiness approval through systematic demonstration of modification performance and safety. Certification activities include qualification testing, compliance verification, documentation preparation, and interaction with regulatory authorities. The phase concludes with issuance of appropriate approvals, such as supplemental-type certificates (STCs) or engineering orders, authorizing operational implementation of the modification.

The W-model framework establishes quantitative criteria for initiating and prioritizing modification programs, ensuring that limited engineering resources are allocated to components offering the greatest potential for reliability improvement and operational benefit.

The primary decision triggers include reliability performance thresholds where component MTBF falls below acceptable levels, the failure rate increases exceed statistical control limits, or maintenance costs reach economically unsustainable levels.

Secondary evaluation criteria encompass safety impact assessment, fleet-wide applicability analysis, modification complexity evaluation, and certification pathway feasibility. These criteria ensure that modification investments deliver measurable returns while maintaining technical and regulatory viability.

The framework incorporates resource allocation mechanisms that balance modification priorities against available engineering capacity, budget constraints, and operational scheduling requirements. Portfolio management approaches enable the simultaneous development of multiple modifications while maintaining program coordination and resource optimization.

Through the systematic application of these decision criteria and resource allocation mechanisms, the W-model framework enables organizations to maximize the effectiveness of their reliability improvement investments while maintaining the safety and quality standards essential to commercial aviation operations.

2.2. Reliability-Centered Modification Methodology

The RCMM defines a structured process for translating operational reliability insights into certified design improvements. Within the W-model framework (

Figure 1), the RCMM forms the right-hand V, providing a sequence of phases that mirror the rigor of the initial development cycle while focusing on targeted enhancements for in-service components. Each phase is described below.

The RCMM formalizes the post-certification improvement cycle, transforming operational data into structured redesign actions validated through engineering rigor and regulatory compliance. This methodology ensures that reliability improvements are not ad hoc but systematically integrated into the product lifecycle, in alignment with the W-model framework.

Table 1 summarizes the key characteristics of each phase.

2.3. Data Sources and Diagnostic Methodologies

The effectiveness of the proposed W-model and the RCMM depends on the quality and depth of operational data and the diagnostic methods applied to them. Throughout the operational life of an aircraft, data are gathered from multiple complementary sources. Aircraft health monitoring systems and built-in test equipment provide continuous streams of fault codes, usage parameters, and environmental data. Maintenance information systems record scheduled and unscheduled activities, including removals, replacements, and corrective actions. Service bulletins and airworthiness directives issued by original equipment manufacturers (OEMs) and regulators supply information on known issues and recommended modifications, while operator reliability reports summarize key metrics such MTBF and dispatch reliability on a periodic basis. Additional insights come from laboratory and shop findings, such as tear-down inspections and non-destructive evaluation results, which reveal detailed wear patterns and failure modes.

As part of the implementation of the Aviation Technical Support as a Service (ATSaaS) concept [

37,

38], harmonization of heterogeneous operational data sources, especially across different airlines, was a critical preparatory step to ensure consistent and meaningful reliability analysis. Maintenance logs, fault codes, and failure reports varied significantly in structure, terminology, and detail depending on operator-specific maintenance information systems and reporting standards. To address this, the following multi-stage data harmonization pipeline was implemented:

Aircraft maintenance reports were first aligned to a common terminology using ATA Chapter classification as the base taxonomy. Disparate operator-specific terms were mapped to standardized failure modes, part descriptions, and maintenance actions.

All data sources were transformed into a unified tabular format where each row corresponded to a maintenance event linked to a specific component serial number, aircraft tail number, and timestamp. Free-text fields were processed using natural language techniques to extract structured attributes such as failure symptoms, corrective actions, and environmental context.

Fault codes and maintenance action codes were normalized across fleets using translation tables developed in collaboration with MRO data experts. Equivalent codes from different reporting systems (e.g., MEL vs. ACMS logs) were reconciled to enable cross-comparative analysis.

Inconsistent, incomplete, or ambiguous records were flagged for manual review. Only entries with high-confidence mappings and complete temporal and component metadata were retained for analysis to ensure statistical validity.

This harmonized dataset enabled the calculation of reliability metrics across aircraft and operators, forming the foundation for subsequent candidate selection, modification justification, and validation analysis in the reliability-centered modification methodology (RCMM) process.

To ensure reliability and consistency, all collected data undergo pre-processing and cleaning before analysis. This includes filtering out duplicate or irrelevant fault reports, normalizing timestamps and operational cycles, mapping part numbers to specific system configurations, and applying thresholding rules to distinguish minor anomalies from significant events.

Once pre-processed, the operational and maintenance data are subjected to a structured suite of diagnostic analyses that combine classical reliability theory with fault modeling techniques.

First, statistical reliability modeling is performed to extract time-to-failure distributions and calculate key performance indicators such as failure rate , quantifying the frequency of failures over time; reliability function , representing the probability that the component performs without failure up to time ; and Weibull parameters , used to model the shape and scale of the degradation pattern and to infer the prevailing failure mode (e.g., infant mortality, random, or wear-out). These outputs provide the quantitative basis for identifying degradation trends and assessing component aging behavior.

In parallel, failure mode and effects analysis (FMEA) is applied to systematically identify all potential failure modes of the component, assess their causes and effects, and prioritize them using criticality rankings (e.g., RPN scores). This ensures that both frequent and high-impact failure modes are addressed.

Additionally, fault tree analysis (FTA) is conducted to map out the logical pathways through which lower-level failures propagate to cause system-level faults. This technique supports the identification of critical subsystems, potential single points of failure, and failure propagation mechanisms.

Together, these methods form a complementary diagnostic toolkit that transforms raw data into actionable insights, supporting decision-making within the W-model lifecycle modification framework.

Trend and pattern analyses are applied to time-series data for MTBF and mean time between removals (MTBR) values to detect early signs of performance deterioration, and cross-fleet comparisons are performed to benchmark reliability metrics across aircraft operating in different environments or duty cycles.

The results of these analyses feed directly into the phase of reliability analysis and candidate selection. Components that exceed predefined thresholds, such as a failure rate above regulatory alert levels or a sustained decline in MTBF, are flagged for further engineering evaluation. This integrated approach ensures that the redesign efforts within the W-model focus on components with the highest potential for improvement, systematically transforming field observations into quantifiable reliability indicators and guiding data-driven decisions that lead to certified design enhancements.

2.4. Engineering and Analytical Approaches

Transforming operational insights into certified design improvements requires a carefully structured set of engineering and analytical activities (

Figure 2). Once candidate components have been identified through reliability analysis, the modification process begins with translating observed issues into refined technical requirements. Existing designs are reviewed to understand load paths, material characteristics, and operational constraints, and new requirements are formulated to mitigate the specific failure modes, such as improving fatigue strength, enhancing sealing performance, or reducing contamination.

These requirements are then evaluated using computational tools. Finite element modeling is employed to simulate stresses, thermal loads, and vibration responses under representative operating conditions. Computational fluid dynamics and thermal analyses are used where necessary to study environmental effects and optimize geometry or materials. Insights from these simulations inform iterative improvements before any physical prototyping takes place.

In parallel, design documentation is updated. Three-dimensional CAD models, interface control documents, and system architecture diagrams are revised to incorporate the proposed modifications. Peer reviews and cross-disciplinary assessments are conducted to confirm that the modifications comply with certification requirements and do not introduce unintended interactions with adjacent systems. Verification plans and test procedures are then prepared, defining load spectra, environmental conditions, and acceptance criteria for qualification.

Prototype components are fabricated and subjected to accelerated life tests, vibration endurance evaluations, or environmental exposure cycles. The outcomes of these tests are compared with analytical predictions, and discrepancies are used to refine both the design and the models. This iterative process ensures that the proposed modification achieves its targeted reliability improvement while maintaining airworthiness standards.

The final step involves documentation and certification of modification. All analyses, test results, and design updates are compiled into certification packages that comply with regulatory frameworks such as EASA Part-21 or FAA supplemental-type certificate processes. Once approved, the modification is formally released to operational service, completing the reliability-centered improvement cycle within the W-model framework.

2.5. Mathematical Framework of This Study

To support the decision-making process within the W-model, a quantitative mathematical framework was applied to analyze operational data, predict reliability growth, and define thresholds for initiating and validating modifications. This framework links observed failure data with reliability models and feeds into the engineering activities described in previous sections.

The starting point of the analysis is the computation of primary reliability indicators from operational data. MTBF and MTBR are calculated as [

39,

40]

These values are continuously updated from aircraft health monitoring records and maintenance reports to reflect the current performance of each component.

Failure rate

trends are evaluated using time-dependent failure intensity functions. For a given component, the instantaneous failure rate is expressed as

where

is the reliability function representing the probability of survival beyond time

. A consistently increasing

over successive monitoring intervals is a key trigger for entering the RCMM cycle.

For deeper statistical modeling, the time-to-failure data are fitted to a Weibull distribution [

41]

where the shape parameter

indicates the failure mode (with

representing early-life failures,

a constant failure rate, and

a wear-out process) and the scale parameter

defines the characteristic life. Shifts in

and

between baseline and modified designs are used to quantify expected reliability improvements.

To further evaluate the robustness of reliability modeling within the W-model framework, a series of sensitivity and distributional goodness-of-fit analyses were conducted.

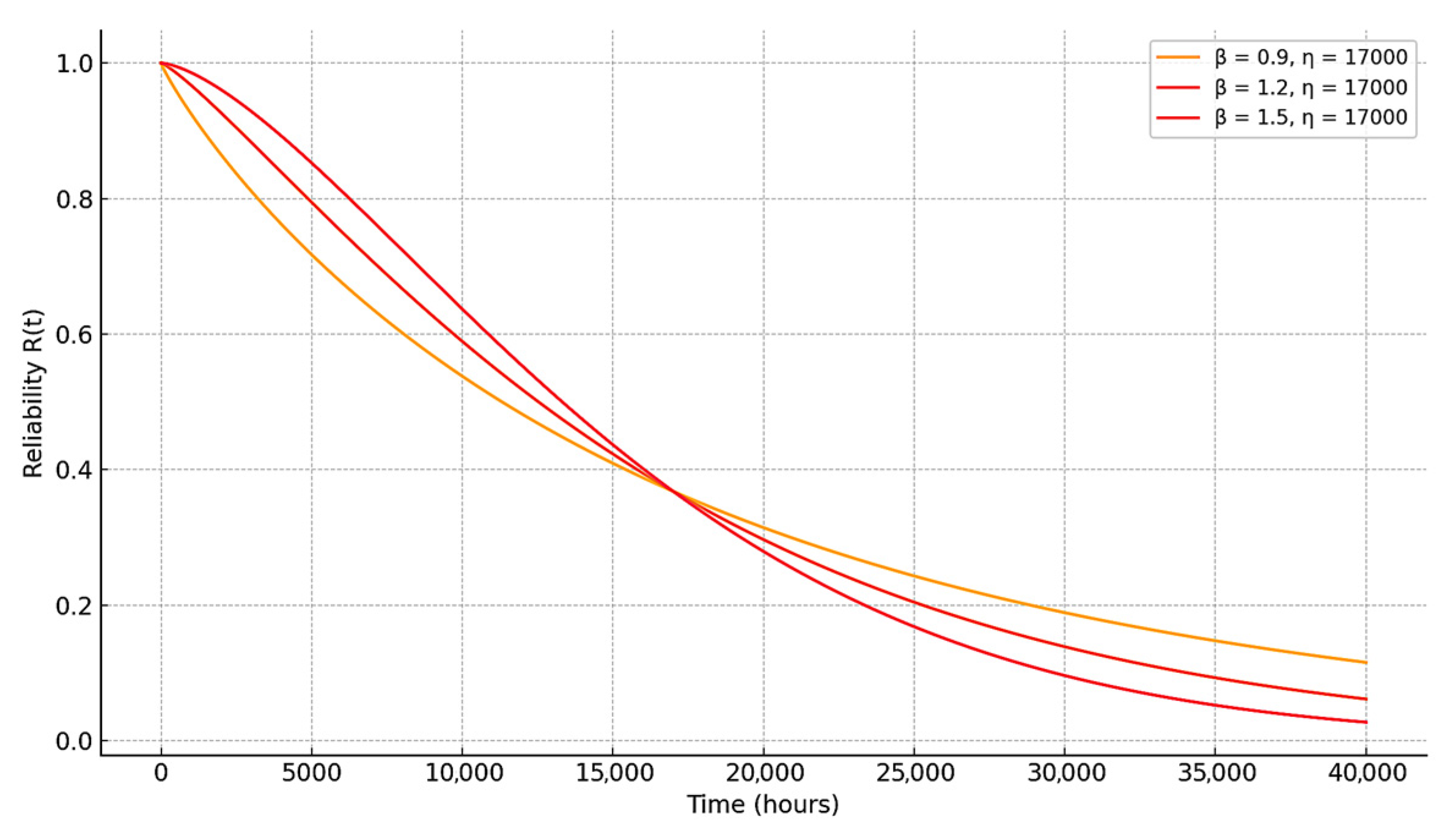

Figure 3 presents the sensitivity of the reliability function

to variations in the shape parameter

, holding the scale parameter

constant at 17,000 h. As shown, when

, the component behavior reflects an infant mortality regime, where reliability deteriorates rapidly with time. In contrast, values

correspond to wear-out behavior, yielding more stable and predictable reliability profiles. This highlights the importance of accurate shape parameter estimation, especially when making modification entry decisions based on increasing failure rates.

.

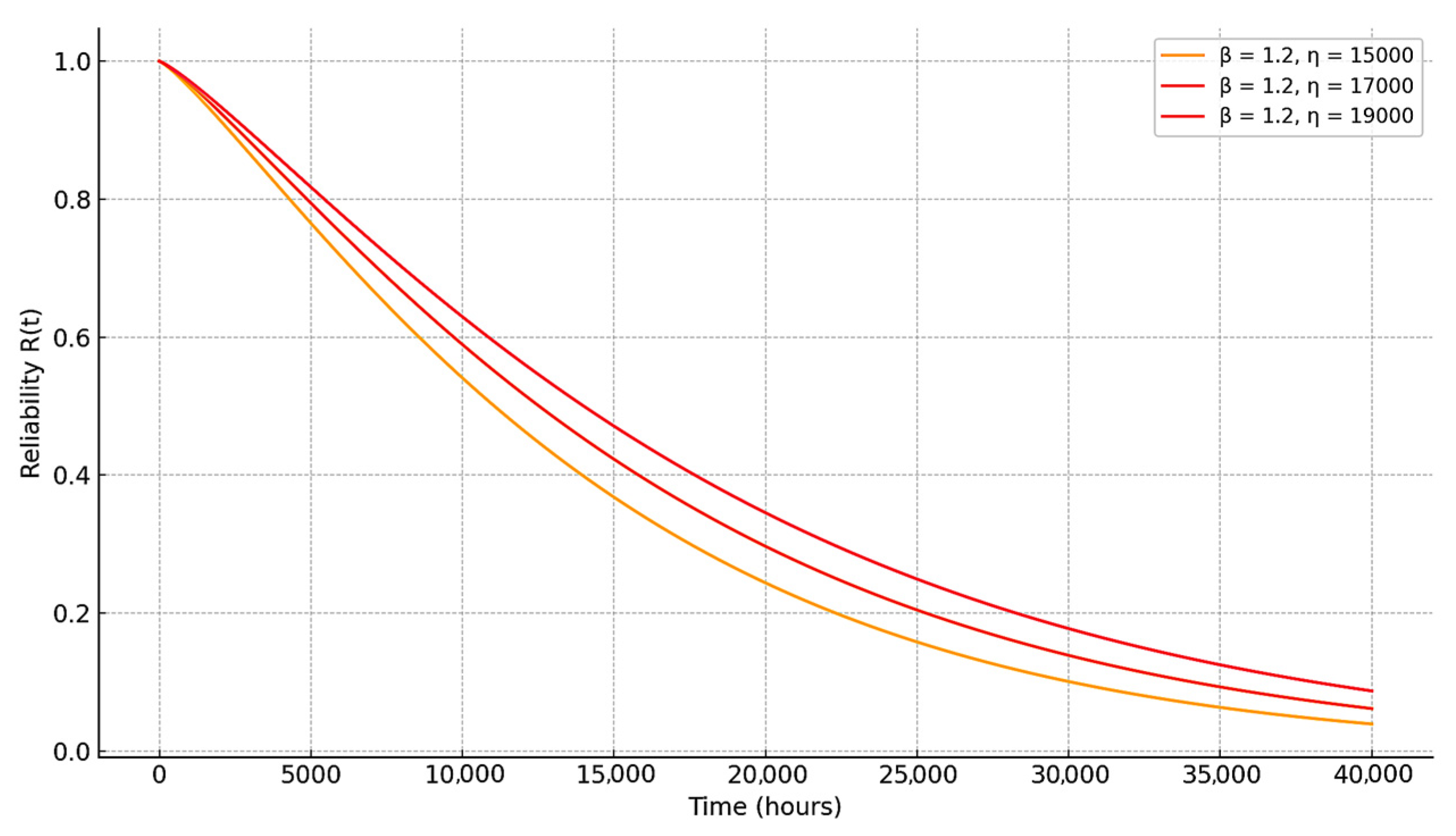

Figure 4 illustrates the sensitivity of

to variations in the scale parameter

, while keeping

. Here, changes in

shift the reliability curve horizontally but do not significantly alter its slope or failure dynamics. This confirms that while affects expected lifetime, reliability sensitivity is more strongly governed by

.

.

To justify the selection of the Weibull distribution, time-to-failure data were also fitted to exponential, lognormal, and gamma distributions.

Figure 5 presents a comparison of Anderson–Darling (AD) statistics across these distributional models. The Weibull distribution yielded the lowest AD value, indicating the best empirical fit. Notably, the exponential model (a special case of Weibull with

) underrepresented early-life failure rates, while the lognormal distribution overfit the upper tail of the data, potentially leading to inflated MTBF estimates. These findings support the adoption of the two-parameter Weibull model as a theoretically justified and empirically validated foundation for reliability-centered decision-making in the W-model process.

A decision criterion for candidate selection is defined as

ensuring that only components with significant reliability gaps proceed to redesign. The anticipated benefit of a modification is evaluated by estimating the projected improvement factor

with

where

is derived from simulation results and preliminary testing.

The framework also captures the iterative nature of reliability improvement within the W-model. After each modification cycle, the reliability function is updated as

where

is the reliability function of a component after the

cycle (the probability that it operates without failure up to time

),

is the additional reliability contributed by the modification compared to the previous design. It quantifies how much higher the probability of survival becomes across time

, and

denotes the iteration index of the modification process. This formulation allows reliability growth to be tracked over successive cycles and provides quantitative justification for engineering decisions and certification submissions.

The integration of these mathematical formulations into the RCMM process allows the W-model not only to structure workflow stages but also to enable data-driven thresholds, predictions, and validations, ensuring that modifications are supported by robust analytical evidence before approval and implementation.

3. Results

3.1. Case Study Context and Implementation

To demonstrate the practical application of the W-model and the RCMM, a case study was conducted on a flight-critical component within the pneumatic system of aircraft. The pneumatic bypass valve was selected as the illustrative case study for several reasons directly aligned with the goals of the W-model framework. First, the component is classified as flight-critical within the aircraft’s environmental control and pneumatic systems, meaning its failures have a direct operational impact, typically triggering aircraft maintenance actions, dispatch delays, or bleed system degradation. Second, its operational reliability is influenced by a combination of mechanical wear, vibration exposure, and contamination, making it an ideal candidate for data-driven reliability analysis and engineering redesign.

Third, this component has a relatively high frequency of unscheduled removals and has historically exhibited variability in MTBF across fleet usage profiles, thus providing a rich dataset for statistical modeling. Importantly, it also represents a component where modifications can be executed at the subassembly level (e.g., actuator or sealing redesign) without requiring full system requalification, making it practical for a lifecycle modification case within current certification pathways. These characteristics make the bypass valve a representative and technically appropriate target for validating the structured RCMM embedded in the W-model.

The bypass valve assembly includes a torque motor mounted on the valve body. This torque motor is a critical control element that modulates the valve position based on electronic commands from the environmental control system. Field observations indicated that this actuator section was particularly susceptible to vibration-assisted wear and contamination, making it a key focus of the reliability-centered modification effort.

Operational data revealed a marked decline in MTBF once the component exceeded approximately 15,000 service hours. Fault reports indicated recurrent issues such as internal leakage, erratic actuation, and contamination accumulation, prompting repeated unscheduled removals and replacements.

Following the RCMM process, the first step involved comprehensive reliability analysis and candidate selection. Maintenance logs, teardown inspections, and operator reliability reports were reviewed to isolate the subcomponents most frequently associated with failures. Statistical analysis identified the actuator assembly and associated sealing interfaces as primary contributors to reduced operational life. This analysis provided a clear justification for entering the PDR phase.

During the PDR, engineering teams proposed several design concepts aimed at addressing contamination ingress and improving construction in terms of reliability. These included redesigning the actuator’s screen construction, selecting alternative sealing materials, and incorporating improved surface coatings to mitigate wear. Finite element modeling was used to assess any reliability issues in the modified configuration, and computational simulations predicted a significant reduction in contamination pathways.

With promising analytical results, the project progressed to detailed development. Updated CAD models and interface control documents were generated to reflect the proposed construction and material changes. Prototype components were fabricated and subjected to accelerated life testing, vibration endurance testing, and environmental exposure trials. These tests validated the expected improvements, showing enhanced sealing performance and reduced contamination levels in critical regions.

The critical design review confirmed that the revised design met all functional and reliability requirements without introducing new risks or integration issues. Documentation of test results updated instructions for continued airworthiness (ICA), and revised maintenance procedures were prepared and submitted to regulatory authorities. Certification was achieved through the issuance of a minor modification approval, authorizing the modified component for operational use.

To ensure the validity of the observed improvements and support a meaningful evaluation of the W-model, a structured comparative design was implemented using a quasi-experimental, longitudinal approach. Two clearly defined populations were used for comparison:

Baseline group (control): 18 aircraft equipped with the original version of the pneumatic bypass valve, observed continuously during the 36-month pre-modification and transition period.

Modified group (treatment): 18 aircraft receiving the redesigned valve beginning at month 12, with subsequent performance monitored using identical metrics.

The control variables across both groups included aircraft type, operating environment, flight profiles, maintenance schedules, and installation position, which were held constant to isolate the effect of the valve modification itself.

Maintenance practices and failure-reporting standards were harmonized through the implementation of the ATSaaS framework [

37,

38], ensuring consistency in data acquisition and analysis.

While the real-world aviation environment does not permit randomized control trials, this structured deployment and data separation allowed for baseline comparisons and the direct attribution of performance shifts to the intervention defined by the W-model methodology.

The use of empirical indicators (e.g., MTBF trends, failure severity rankings, and FMEA updates) over a consistent observational window ensures that the reported gains reflect genuine engineering improvements rather than artifacts of uncontrolled variability.

3.2. Reliability Performance Analysis

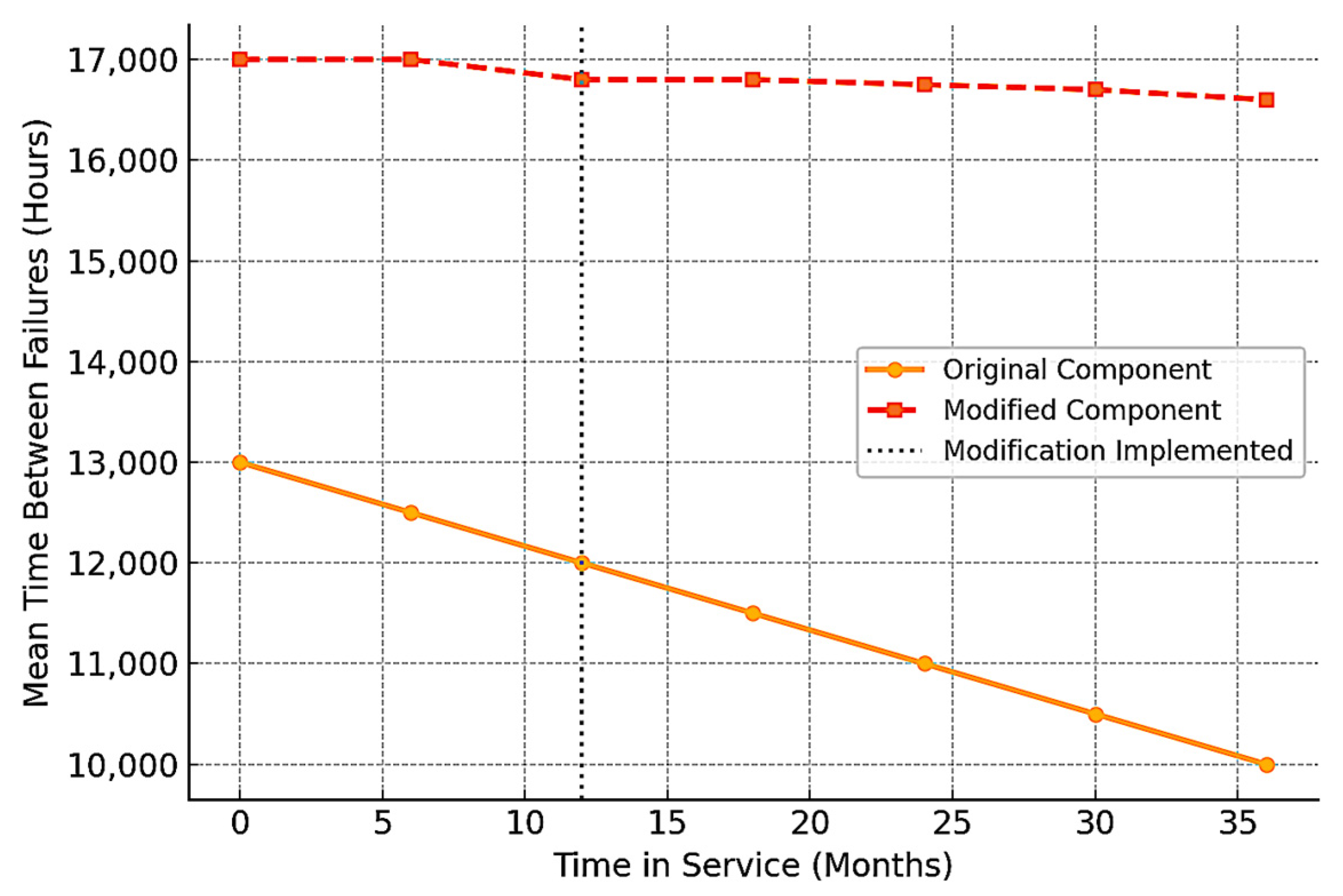

Reliability indicators derived from the operational dataset demonstrate a clear improvement in performance following the implementation of the modification. Prior to redesign, the bypass valve exhibited a downward trend in MTBF, with values averaging 12,500 h and decreasing steadily as the components aged in service. MTBR followed a similar pattern, reflecting the increasing frequency of unscheduled maintenance actions. Failure rate calculations based on field data indicated a growing intensity function, confirming that the component was operating in an early wear-out phase.

After redesign and certification under the RCMM process, updated fleet monitoring revealed substantial reliability growth. The MTBF increased to 17,000 h, representing an improvement of approximately 36%, while MTBR rose to 15,200 h, corresponding to a reduction in unscheduled removals of more than 40%. The calculated failure rate decreased significantly, confirming a transition to a more stable operating regime with a lower probability of in-service failure.

Table 2 summarizes key reliability indicators derived from operational data before and after the modification was introduced. The modified component shows a marked improvement in MTBF and MTBR, a reduced failure rate, and fewer unscheduled removals per 1 000 flight hours. These metrics quantitatively demonstrate the reliability growth achieved through the RCMM process.

Figure 6 illustrates the evolution of MTBF for the bypass valve over a 36-month observation period. The original component (solid line) shows a gradual decline in MTBF, indicating growing reliability issues in service, while the modified component (dashed line) maintains a consistently higher MTBF following implementation at month 12. The vertical reference line marks the introduction of the modification, highlighting the resulting upward shift in reliability performance.

3.3. Statistical Modeling of Failures

To further characterize the reliability improvement achieved through the modification, time-to-failure data from both the original and modified components were analyzed using a Weibull statistical model. This modeling approach allows the failure behavior to be represented by two parameters: the shape parameter , which indicates the predominant failure mode, and the scale parameter , which represents the characteristic life of the component.

Analysis of the pre-modification data revealed a shape parameter , signifying a failure distribution dominated by early-life or infant mortality events. The corresponding scale parameter was consistent with the observed MTBF of approximately 12,500 h. In contrast, data collected after implementation of the redesigned component showed a marked change in failure characteristics. The shape parameter increased to a value slightly greater than one, indicating a transition to a more stable, wear-out dominated regime, while the scale parameter increased in line with the observed improvement in MTBF and MTBR.

Figure 7 presents the Weibull probability plot comparing both datasets. The original component’s data points (shown in red) exhibit a shallower slope, consistent with early-life failures, whereas the modified component’s data (shown in blue) align with a steeper slope and a higher characteristic life. These results confirm that the RCMM process not only improved the average reliability metrics but also fundamentally altered the failure behavior of the component, reducing susceptibility to early-life failures and extending the overall operational life span.

3.4. Design Change Impact

The reliability improvements observed in the modified bypass valve can be directly attributed to a series of targeted engineering changes, developed in response to the failure modes identified during the reliability analysis and candidate selection phase. Each design adjustment was based on data-driven insights, modeled analytically, and validated through laboratory testing, in full alignment with the RCMM process.

One of the most significant contributors to failure in the original design was the construction of the actuator screen. Modeling of the actuator performance showed that excessive exhaust screen contamination causes the valve to adopt an un-commanded, fully open position, which follows incorrect valve performance and unscheduled removals. The screen was redesigned to improve construction in terms of reliability, improved material interfaces, and reinforced boundary conditions, resulting in a measurable reduction in contamination level.

Another major failure driver of the bypass valve was contamination ingress leading to seal degradation and internal leakage. To address this, the sealing system was upgraded with a higher-grade elastomer resistant to environmental exposure and particle infiltration. Additionally, a tighter tolerance sealing groove and refined surface finish were introduced to enhance contact pressure without increasing friction. These changes significantly improved sealing performance, as confirmed through bench testing under high-vibration and high-contamination scenarios.

A third change involved the application of anti-corrosion coatings on critical internal surfaces. Corrosion pitting had been identified in teardown inspections as a precursor to leakage and valve actuation delays. By adding a certified protective coating to exposed metallic surfaces, the design team extended the corrosion resistance and reduced long-term wear.

Table 3 summarizes these key design changes, their corresponding failure modes in the original configuration, and the intended impacts of the redesign. Together, these interventions not only addressed the dominant sources of failure but also simplified maintenance procedures and reduced the frequency of unscheduled removals. This illustrates the core principle of the W-model—using operational feedback to guide targeted, certifiable design improvements that extend component life and enhance reliability in service.

3.5. Verification and Bench Testing

Following the completion of the detailed design phase, the modified bypass valve underwent an extensive series of verification and bench testing activities to ensure that the predicted reliability improvements were achieved under controlled yet representative operating conditions. These tests were designed to replicate the dominant stressors identified during the reliability analysis and to provide objective evidence of performance prior to fleet implementation.

Accelerated life testing was carried out to simulate extended service cycles within a condensed timeframe. Test rigs subjected the redesigned valve to repeated actuation under varying pressure differentials and temperature profiles, replicating the operational envelope experienced during normal flight cycles. These tests demonstrated a marked extension in endurance, with the modified design completing test cycles equivalent to over 20,000 operational hours without evidence of the leakage or wear patterns observed in the original configuration.

In addition to life testing, vibration endurance testing was performed to assess the valve’s performance under high-frequency loads typical of its installation environment. The redesigned actuator screen and improved sealing interfaces maintained integrity throughout vibration profiles exceeding the baseline certification requirements, confirming that the stress reductions predicted by simulation translated into real-world robustness.

Environmental exposure tests further validated the new materials and coatings. Components were exposed to high humidity, salt fog, and particulate contamination to verify corrosion resistance and sealing performance. The enhanced elastomer and anti-corrosion coating-maintained functionality without degradation, meeting the criteria defined in the preliminary design review.

Results from all test campaigns were consolidated into verification reports and compared with the analytical predictions. The close alignment between simulated and observed outcomes provided strong confidence in the validity of the engineering models. These findings were formally reviewed during the critical design review and incorporated into the certification documentation package, providing regulators with a comprehensive evidence base for approval.

3.6. Certification and Operational Rollout

The final stage of the W-model process involved formal certification of the redesigned bypass valve and its subsequent integration into the operational fleet. Following successful completion of verification and bench testing, all engineering data, analysis reports, and test results were compiled into a comprehensive certification dossier. This documentation included updated drawings and interface control documents, detailed verification plans and qualification results, and revised instructions for ICA. The dossier was prepared in accordance with applicable regulatory frameworks, including EASA Part-21 and corresponding FAA supplemental type certificate procedures, to demonstrate that the modified component met all relevant airworthiness and safety standards.

The certification process involved close collaboration with regulatory authorities, who reviewed the modification evidence to ensure that the design changes did not introduce new risks and that all requirements were met or exceeded. Upon satisfactory evaluation, an STC was granted, authorizing the modified valve for use across the operator’s fleet. This milestone marked the formal closure of the reliability-centered modification loop, transitioning the component from development into operational service.

Following certification, the modified bypass valves were progressively introduced into the fleet as part of scheduled maintenance intervals. An initial operational evaluation phase was conducted to monitor performance in real-world conditions. Reliability indicators such as MTBF and failure rate were tracked for the first 12 months after rollout, and results confirmed the improvements observed during laboratory testing. No unexpected failure modes were detected, and maintenance crews reported fewer unscheduled removals and reduced troubleshooting time, further validating the effectiveness of the design changes.

The lifecycle modification process described in this study was subject to formal airworthiness review and certification procedures in accordance with applicable internal and regulatory standards. Specifically, the engineering change underwent the following:

Preliminary design review (PDR), where the failure analysis results, reliability projections, and preliminary design concepts were evaluated by the design authority.

Critical design review (CDR), during which the complete reliability model, redesign documentation, FMEA/fault tree updates, and MTBF trend data were reviewed by an interdisciplinary panel that included safety, certification, and engineering representatives.

Implementation readiness review (IRR), validating the qualification test results and confirming readiness for in-service deployment.

All analyses and supporting evidence such as the updated reliability block diagrams, test reports, and engineering change documentation, were compiled into the certification documentation package, in accordance with the operator’s Design Organization Approval (DOA) and aligned with EASA Part 21 Subpart J procedures.

While detailed certification records are proprietary and not included in full for confidentiality reasons, the procedures followed are fully traceable to standard industry practice. The successful operational rollout, with demonstrated MTBF improvement and stable post-modification performance over 24 months, validated the acceptability of the modifications within the safety management framework.

This successful certification and operational rollout demonstrate the practical value of the W-model framework. By integrating operational data, structured engineering analysis, and rigorous verification into a closed-loop process, the methodology delivered measurable improvements in component reliability while maintaining compliance with stringent aviation safety requirements.

4. Discussion

4.1. Significance of the W-Model Framework

The introduction of the W-model represents more than an incremental adjustment to established systems-engineering practice; it provides a structured paradigm for continuous improvement throughout the operational lifecycle of an aircraft system. By adding a second V-shaped loop for reliability-centered modifications, the framework formally integrates feedback from operational service into the design and certification process. This contrasts with traditional approaches, where in-service issues are often addressed through ad hoc redesigns or isolated engineering changes without the rigor of a full validation cycle.

In the seminal work [

42], Thomas Kuhn introduced the concept of a “paradigm shift” to describe a fundamental change in the basic concepts and experimental practices of a scientific discipline. He argued that scientific progress is not purely cumulative but undergoes periodic revolutions in which one framework is replaced by another that is incommensurable with it. This concept has since been extended beyond science to fields like engineering, management, and technology innovation.

The claim that the W-model constitutes a paradigm shift is theoretically grounded in three key distinctions from the traditional V-model and existing post-certification practices:

Extension of lifecycle scope (structural shift): The classical V-model, while foundational to systems engineering, concludes at certification, thus treating the operational phase as external to the design lifecycle. The W-model redefines this boundary by structurally integrating operational service and post-certification modification into the same formal lifecycle framework. This shift reconfigures the aircraft system lifecycle from a linear to a cyclical (iterative) paradigm—representing a structural departure from the classical model.

Transformation of feedback into certified engineering (processual shift): In existing practice, in-service modifications are typically ad hoc, driven by non-standardized engineering change orders or service bulletins. The W-model introduces a rigorously defined reliability-centered modification methodology that applies formal verification, validation, and certification steps to post-certification changes—mirroring the pre-certification process but for the operational phase. This standardization of reactive changes into proactive, certifiable engineering processes represents a fundamental shift in how reliability improvement is operationalized.

Integration of data-driven decision logic (cognitive and analytical shift): The W-model incorporates operational data analysis (e.g., statistical reliability modeling, Weibull analysis, decision thresholds) as formal triggers for initiating design modifications. It embeds analytical models into lifecycle management as decision-making instruments, rather than relying solely on human intuition or heuristics. This marks a cognitive transformation of post-certification engineering from judgment-based to analytics-driven, enabling predictive and strategic reliability enhancement.

The combination of these shifts satisfies Kuhn’s original notion of a paradigm shift as a change in the underlying assumptions, tools, and workflows that define a scientific or engineering domain. In our case, the W-model redefines aerospace component lifecycle management by accomplishing the following:

Embedding operational service within the formal development lifecycle.

Providing a certifiable structure for in-service redesigns.

Transforming empirical data into engineering decisions within a closed-loop framework.

The W-model’s significance lies in its ability to maintain the traceability and compliance strengths of the classical V-Model while extending its scope beyond initial certification. By embedding phases such as reliability monitoring, candidate selection, and iterative design reviews, the W-model ensures that each modification is justified by data, validated through analysis and testing, and approved through standard certification pathways. This creates a closed-loop process that not only corrects existing reliability issues but also builds a documented history of design evolution, supporting regulatory audits and future engineering work.

For industry stakeholders, the framework offers practical benefits. Operators and MROs gain a systematic method to channel operational insights into actionable design improvements, reducing unscheduled maintenance and associated costs. OEMs benefit from structured feedback that guides product updates and strengthens customer trust. Regulators are presented with clear, evidence-based documentation that simplifies the approval of modifications. In this way, the W-model transforms operational experience into a strategic asset, fostering a culture of continual reliability growth within the aerospace sector.

4.2. Comparison with Existing Approaches

When compared with existing approaches to post-certification improvements, the W-model offers a distinctive balance of structure, traceability, and adaptability. In traditional practice, the classical V-Model concludes with certification and entry into service. Subsequent design changes are often managed through isolated service bulletins, engineering change orders, or maintenance task updates without the benefit of a full lifecycle framework. While these measures can resolve specific issues, they are typically reactive, lack standardized feedback loops, and may not capture long-term reliability growth across the fleet.

In contrast, the W-model embeds a second, mirrored development cycle dedicated to in-service modifications. This allows for the same level of rigor applied during initial development—requirement management, design reviews, verification, and certification—to be consistently applied to redesign activities. Unlike informal approaches, the W-model ensures that operational data directly drive the identification of redesign candidates and that every modification is systematically validated before rollout.

The W-model also differs from iterative improvement cycles commonly used in other industries, such as Plan–Do–Check–Act loops [

43] or lean Six Sigma processes [

44]. While those frameworks emphasize continuous improvement, they often lack the aviation-specific regulatory structure and documentation traceability required for certifiable modifications. Similarly, digital-twin-enabled maintenance approaches provide powerful predictive insights but typically focus on condition monitoring rather than defining how those insights feed into certified design changes. By integrating operational analytics with a formal engineering and certification process, the W-model fills this gap, offering a comprehensive methodology that is both data-driven and compliant with airworthiness standards.

Compared with existing approaches, the W-model provides a formalized, closed-loop structure that bridges the gap between operational experience and certified design improvement, setting it apart as a practical and regulatory-aligned solution for achieving sustained reliability growth.

4.3. Practical Implications for Industry

The implementation of the W-model has clear practical implications for a wide range of aviation stakeholders. For operators and maintenance organizations, the framework provides a structured pathway to convert operational data into actionable design improvements. By incorporating phases such as reliability monitoring, candidate selection, and formalized design reviews, maintenance teams can prioritize redesign efforts based on quantified impact, reducing unscheduled removals and improving fleet availability. This translates directly into lower lifecycle costs, fewer operational disruptions, and optimized spare-part inventories.

For OEMs, the W-model offers a transparent mechanism to integrate field feedback into product evolution. Instead of relying solely on periodic service bulletins or ad hoc corrective actions, OEMs can employ the model to track reliability trends across fleets, assess design alternatives using robust engineering methods, and deliver modifications that are already validated for regulatory acceptance. This proactive approach strengthens customer confidence and enhances competitiveness in a market increasingly driven by performance-based contracts.

From a regulatory perspective, the W-model simplifies the oversight of design changes by providing a clear and traceable workflow that mirrors the rigor of initial certification processes. The explicit documentation of requirements, analyses, test results, and compliance evidence at each step of the modification cycle supports faster and more consistent approvals. It also aligns with emerging industry initiatives focused on continuous airworthiness management and digitalization of maintenance records.

The W-model encourages a cultural shift in industry practices—from reactive problem solving to a proactive, data-driven improvement cycle.

4.4. Limitations of This Study

While the case study demonstrates the feasibility and benefits of the proposed W-model and RCMM framework, several limitations should be acknowledged. First, the analysis was focused on a single component, the pneumatic system bypass valve, within a specific fleet and operational context. Although the results show clear reliability improvements, caution should be exercised when generalizing these findings to other components or aircraft systems without further validation.

Second, the reliability analysis relied on historical operational data collected from a limited number of aircraft and a finite observation period. Variability in operational environments, maintenance practices, or reporting accuracy could influence the reliability indicators and may not fully represent broader fleet behavior. Expanding the dataset across different operators and longer service periods would provide a more comprehensive assessment.

Third, the statistical modeling and simulations were based on certain simplifying assumptions, such as constant operating conditions and idealized material properties. Real-world factors such as supply chain constraints, human factors in maintenance execution, or unforeseen environmental stresses may introduce additional complexities not captured in the current model.

Finally, while the RCMM process was integrated within the regulatory framework and successfully resulted in certification, this study did not address potential organizational challenges, such as resource allocation, workforce training, or change management requirements for widespread adoption. These factors could affect implementation timelines and overall effectiveness in practice.

Recognizing these limitations highlights opportunities for further research and refinement of the W-model, ensuring that future studies can build on this work to strengthen its applicability and robustness across a broader spectrum of aerospace components and operational scenarios.

4.5. Future Research Directions

The development and successful application of the W-model in this study open several promising avenues for further research. A natural extension is to broaden the scope of case studies beyond the pneumatic system to other aircraft subsystems, such as avionics modules, environmental control components, or structural elements. Applying the W-model to a wider variety of systems would help to validate its generalizability and uncover component-specific considerations in reliability-centered modification cycles.

Another important direction involves deeper integration with digital technologies. The use of digital twins and real-time health monitoring systems could enhance the feedback loop by providing continuous, high-fidelity operational data. Embedding machine learning or advanced analytics within the RCMM framework could enable predictive detection of emerging failure trends and automate candidate selection processes, further improving responsiveness and reducing human bias in decision-making.

Future studies may also explore the economic dimension of the W-model. Incorporating cost–benefit analyses into the modification cycle would allow stakeholders to prioritize redesigns not only by technical necessity but also by lifecycle cost savings and return on investment. This could lead to decision support tools that balance safety, reliability, and financial considerations in a unified framework.

Organizational aspects warrant further study too. Implementing the W-model across large fleets or multinational operators will require changes in training, workflow management, and cross-disciplinary collaboration. Examining these human and organizational factors will ensure that technical improvements are matched by operational readiness, enabling the aerospace industry to fully realize the benefits of continuous reliability growth.

5. Conclusions

This study has proposed the W-model framework as a comprehensive solution for integrating operational reliability data with formal design improvement processes in aerospace engineering. By extending the classical V-Model beyond initial certification, the framework addresses the critical gap where post-certification modifications are typically managed through ad hoc approaches lacking structured validation.

The implementation of the RCMM demonstrated significant measurable improvements in component reliability. The pneumatic system bypass valve case study achieved a 36% increase in MTBF (from 12,500 to 17,000 h), 41% improvement in MTBR (to 15,200 h), and 43% reduction in unscheduled removals. Weibull statistical analysis revealed that modifications fundamentally altered failure behavior, transitioning from early-life failure patterns to stable, wear-out-dominated performance.

The W-model transforms operational experience from isolated issues into a strategic asset for continuous reliability growth. For operators, it provides reduced lifecycle costs and improved fleet availability. OEMs benefit from proactive product evolution based on field data, while regulators gain simplified oversight through clear, traceable documentation that mirrors initial certification rigor.

This research provides the first comprehensive framework formally integrating operational feedback with certified design improvement processes. The mathematical framework enables quantitative reliability assessment and objective modification prioritization. This study demonstrates effective integration of advanced engineering analysis with operational data analytics to guide targeted design improvements.

Future research should expand the methodology to other aircraft subsystems, integrate emerging technologies such as machine learning and digital twins, and develop comprehensive economic models for cost–benefit optimization.

The W-model framework represents a new advancement in aerospace lifecycle management, providing systematic continuous reliability improvement while maintaining regulatory compliance. By transforming operational data into actionable engineering improvements, it enables the aerospace industry to realize the full potential of accumulated service experience.