Abstract

Maintaining well integrity is essential in the oil and gas industry to prevent environmental hazards, operational risks, and economic losses. Cement bond log (CBL) tools are essential in evaluating cement bonding and ensuring wellbore stability. This study presents a patent landscape review of CBL technologies, based on 3473 patent documents from the Lens.org database. After eliminating duplicates and irrelevant entries, 167 granted patents were selected for in-depth analysis. These were categorized by technology type (wave, electrical, radiation, neutron, and other tools) and by material focus (formation, casing, cement, and borehole fluid). The findings reveal a dominant focus on formation evaluation (59.9%) and a growing reliance on wave-based (22.2%) and other advanced tools (25.1%), indicating a shift toward high-precision diagnostics. Geographically, 75% of granted patents were filed through the U.S. Patent and Trademark Office, and 97.6% were held by companies, underscoring the dominance of corporate innovation and the minimal presence of academia and individuals. The review also identifies notable patents that reflect significant technical innovations and discusses their role in advancing diagnostic capabilities. These insights emphasize the need for broader collaboration and targeted research to advance well integrity technologies in line with industry goals for operational performance and safety.

1. Introduction

Natural gas is one of the discoveries that have transformed the modern energy landscape, significantly affecting the global economy and various aspects of human development [1,2]. With the increasing demand for fossil fuel-based energy, the oil and gas industry has rapidly expanded and invested heavily in well logging technologies to enhance operational safety and optimize drilling efficiency [3], hence the rapid advancements in well-logging technologies.

However, maintaining well integrity—the structural soundness of the well to prevent leaks or failures—remains a persistent challenge throughout the different phases of a well’s life cycle, including during drilling, production, and abandonment [3]. Failures in well integrity can lead to catastrophic consequences including surface explosions, environmental contamination, and significant economic losses [4]. Globally, more than 7% of the 380,000 oil and gas wells have reported integrity issues in the past decade alone [5], emphasizing the urgent need for technological innovation in well integrity management [6].

To address these challenges, the industry relies on cement bond logs (CBLs), a key-cased hole logging technology used to evaluate the bond between the casing and cement, which plays a critical role in ensuring zonal isolation and structural integrity. The integrity of the wellbore is especially important for safe hydrocarbon production and prevention of gas leakage, particularly in low-permeability or hydrate-bearing formations where collapse and fracturing risks are heightened [7,8]. Among the various integrity checks, the evaluation of the cement–formation bond is arguably the most critical, as it helps prevent the formation of leak paths to the surrounding environment. Introduced in the early 1960s, the first acoustic cement bond logs used sound waves to evaluate the bonding between cement and casing. Since then, they have since become a fundamental tool for evaluating well integrity [9]. Over the decades, technological advancements such as ultrasonic imaging and distributed acoustic sensing have significantly improved the resolution and diagnostic capabilities of cement bond logging tools. These innovations have helped address several limitations of earlier tools, particularly in detecting small channels or defects. Nevertheless, some persistent issues remain, including the difficulty in detecting micro-annuli, assessing decentralized casing structures, and ensuring accurate interpretation of data in complex well environments [10].

While numerous academic and industry studies have focused on the physical mechanisms and operational deployment of CBL tools, relatively few have analyzed innovation trends through the perspective of patent activity [11]. The objective of this systematic review is to analyze global innovation trends in CBL technologies by examining granted patents from the past 20 years, categorized by technology type, material focus, geographic distribution, and applicant profile, in order to identify patterns of technological development and gaps in the current innovation landscape. Patents are a very rich source of technical knowledge, especially in this highly commercializable area, and provide a window into the direction and focus of technological development within an industry. As such, this study is unique in presenting a systematic patent analysis of cement bond logging technologies, using the Lens.org database. From an initial dataset of 3473 patents, a total of 167 granted patents were selected for detailed analysis, covering a 20-year period from 2004 to 2024. These patents were categorized by technology type and by the materials evaluated. The study also examines the geographical distribution of patents, identifies leading inventors and organizations, and highlights the dominance of corporate players over academic institutions. By analyzing patent trends over time and across categories, the research uncovers areas of concentrated innovation as well as gaps, such as the under-representation of patents focused solely on cement or borehole fluids, and the need for more multi-functional tools. This patent-based approach contributes to a deeper understanding of how CBL technologies have evolved, where future innovations are most needed, and how the industry can respond to ongoing well integrity challenges through cross-sector collaboration.

The remainder of this paper is organized as follows. Section 2 outlines the historical development of well-logging technologies, and the relevance of patents in innovation. Section 3 describes the methodology for selecting and analyzing patents, with findings, including trends by technology, material, geography, and applicant type, given in Section 4. Section 5 highlights key technological advancements across waves, electrical, radiation, and neutron tools. Finally, the paper concludes with reflections on innovation gaps and recommendations for future research and broader academic participation.

2. Technical Background

2.1. The Importance of Well Integrity: Historical Failures and Lessons Learned

The first discovery of natural gas occurred in Oil City, Pennsylvania, in 1859 [12] during a period when safety standards were virtually non-existent. Over time, numerous incidents have underscored the critical importance of maintaining well integrity. A notable case is the Piper Alpha disaster in the North Sea during the 1990s, where a series of procedural, structural, and cultural failures led to the ignition of condensate vapor and catastrophic explosions [13]. Other examples include over 50 wells emitting gas in California’s Santa Fe Springs Oilfield [14], and a 26.2% surface casing vent flow among 15,003 wells drilled in the Gulf of Mexico between 1973 and 2003 [15]. Norway also reported integrity failures in abandoned wells between 1970 and 2011 [16], while China’s Kenxi reservoir recorded a 31.3% failure rate between 1978 and 1999 [17]. In Canada, 22% of wells monitored from 1987 to 1993 exhibited surface casing vent flow and gas migration [18], and similar issues have been observed in the UK Continental Shelf and Malacca Strait. A global survey reported that 7% of 380,000 wells in Canada, China, the Netherlands, Offshore Norway, the UK, and the US experienced well integrity failure [5].

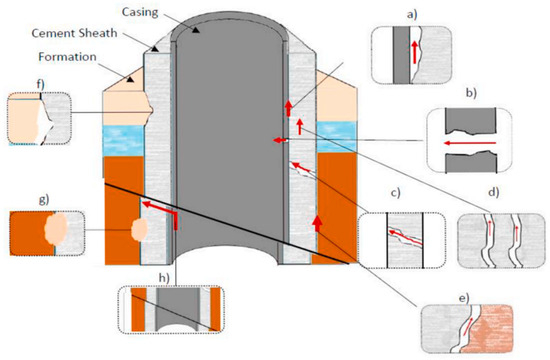

Such failures are primarily attributed to structural deficiencies, often resulting in cement degradation and leakage pathways (Figure 1) [19,20]. Experts widely agree that “poor cement design” is a primary contributor [21,22,23,24]. Research has explored the influence of geometric and material properties [25,26,27,28], and numerical simulations have investigated stress conditions and failure mechanisms [29,30,31,32,33,34], revealing that under triaxial stress during pressurization, the cement–shale interface may fail to ensure zonal isolation [35], and potentially allowing inter-zonal fluid migration and compromising hydrocarbon containment.

Figure 1.

Well integrity failures and leakage pathways (indicated by the red arrow) [36] (a) Leakage pathways created along the micro-annuli at the cement sheath interfaces with the casing, (b) Leakage pathways due to mechanical failure of the casing or corrosion, (c) Leakage pathways due to cement mechanical failure, (d) Poor bonding due to the development of channels in the cement, (e) Leakage pathways created along the micro-annuli at the cement sheath interfaces with the formation, (f) An unsatisfactory annular cementing job when cement does not fill the annulus entirely, (g) Poor bonding due to the existence of mud cake, and (h) The creation of shear failure zone in the formation and casing above the reservoir.

2.2. Technological Developments in Well Integrity Evaluation

To address these risks, various cement evaluation tools have been developed over the decades. Among the most widely used are cement bond logs (CBL) and Variable Density Logs (VDL), which transmit acoustic signals through the casing and cement to evaluate cement integrity. CBLs evaluate bond quality by analyzing signal amplitude whilst VDLs provide more detailed insights into cement density, aiding in potential leak detection. Additional tools, such as Ultrasonic Casing Imagers (UCIs), utilize high-frequency sound waves to analyze the casing condition, with corrosion logs used to assess the extent of corrosion in the well’s casing [37,38,39].

These technologies form the basis of this study’s analysis, by categorizing technologies based on function, application and material. Despite these advancements, progress in cement evaluation technologies has been relatively slow since the pioneering acoustic methods introduced by Grosmangin et al. (1961) [40] and Anderson and Walker (1961) [41]. Even with modern tools, achieving complete assurance in cement performance remains elusive [42].

Acoustic logging techniques, including sonic and ultrasonic tools, remain the most widely used tools for cement evaluation [40,43,44]. However, they are not without limitations. Minor defects such as micro annuli, small gaps in the cement bond, can escape without detection even with the available advanced tools [45]. These undetected, albeit physically minor flaws may compromise well integrity by allowing fluid migration between formations. Furthermore, CBL and VDL tools struggle with detecting micro-defects and are less reliable in evaluating decentralized or misaligned wellbores. Recent studies have emphasized how decentralization and micro-annuli can lead to incorrect assessments of cement quality [46]. These persistent limitations point to the need for complementary methods, such as pressure-based or fluid communication testing, to ensure effective zonal isolation and reduce the risk of hydrocarbon migration.

2.3. Patents as a Window into Technological Innovation

Patents are legal documents that grant inventors exclusive rights to their inventions, typically for a period of 20 years, during which others may not manufacture or commercialize the invention without explicit permission from the inventor. In exchange for these rights, inventors must publicly disclose the technical details of their inventions [47]. Unlike academic journals, which focus on disseminating knowledge without legal protection [48], patents serve both as protective mechanisms and as detailed technical documents that encourage competitive advancement in technology.

Each patent includes several key sections: abstract, background, detailed description, drawings, and most importantly, the claims, which define the novelty and legal boundaries of the invention. For researchers, these claims offer insights into how new tools differ from prior art and what specific innovations are being protected.

In the context of well integrity, patents offer a record of technological evolution and help reveal industry needs over time. As well integrity is crucial for preventing operational failures and environmental hazards [4,13], patent analysis provides a strategic tool for understanding how technologies have evolved to address these challenges.

2.4. Scope and Relevance of Patent Analysis in This Study

Patent analysis offers multiple benefits. First, it helps establish technological trends by tracking innovation focus, such as the transition from sonic to ultrasonic tools [49] for more precise evaluations, or the development of integrated monitoring systems that minimize human error [42]. By examining the patent families (i.e., the same invention filed across multiple jurisdictions), researchers can also identify regional leaders and track the geographic diffusion of key technologies. This analysis further reveals innovation gaps—such as the limited development of tools capable of evaluating multiple materials (cement, formation, casing, borehole fluid) simultaneously.

Second, patent analysis offers insight into the competitive landscape. Identifying the leading inventors, companies, and institutions behind well integrity innovations helps to understand which entities are investing heavily in specific technological areas [13]. For example, companies specializing in downhole tools often dominate patent activity, reflecting their commercial stakes and strategic focus.

Third, patents often disclose the technical challenges being addressed by inventors. These include environmental conditions such as high temperature and pressure, tool durability issues, and limitations in detecting fine-scale defects [44]. By studying these challenges as described in the patents, researchers can identify the design goals of current tools and the shortcomings that future innovations must address.

In essence, patents serve not only to protect intellectual property but also to provide a transparent view of technological development. They are a rich source of technical knowledge on how well-logging technologies—particularly CBL and VDL tools—have evolved. Analyzing these documents helps identify both current capabilities and future research directions.

3. Methodology

3.1. Patent Review Process

This research investigates technological innovations in cement bond logs by conducting structured patent analysis. Patents serve as a valuable source of information, by offering insights into technological progress whilst protecting inventors’ rights. For this study, Lens.org was selected as the primary and sole information source due to its extensive access to over 165 million global patent documents from 96 different jurisdictions, including major patent offices such as USPTO, EPO, WIPO, CNIPA and others. One of its key strengths lies in its built-in multilingual support, which provides automatic English translations for non-English patent filings, such as those from China, Japan, and Korea, thereby reducing language-related barriers and improving coverage of innovation activity in non-English-speaking regions. As a freely accessible platform, it promotes equitable research access across both developed and developing countries, supporting transparency and reproducibility. Moreover, the platform also integrates academic literature and offers exportable data formats (e.g., CSV), facilitating both quantitative and qualitative analysis [50]. These features make it particularly well-suited for conducting global innovation assessments while ensuring methodological openness and accessibility.

The analysis involved identifying key innovation trends, leading inventors, and the geographical distribution of patent activity. Patent filings can reveal which regions lead in particular technologies and how these innovations evolve over time. This is especially important in evaluating the development of cement bond log (CBL) tools [51]. The search spanned from the earliest available records to the most recent filings, allowing for a comprehensive overview of technological evolution. Full-text patent documents, including titles, abstracts, and claims, were reviewed to identify patents directly relevant to cement bond logging technologies [52].

Table 1 summarizes the keywords used in the patent search across technological, process, and application categories, whilst Table 2 lists the relevant International Patent Classification (IPC) codes used to refine the search.

Table 1.

Keywords of patents that are used in search in LENS database.

Table 2.

International patent classification and the description used in the search [53].

The keywords and IPC codes were chosen to ensure the search captured patents directly relevant to CBL technologies. For example, the “Cased-hole log” and “Cement bond log” terms represent the core diagnostic tools for evaluating cement integrity, while keywords such as “Evaluation” and “Bonding” target specific assessment processes. The IPC codes selected provide focused coverage of technological and material aspects central to cement bond logging. Other IPC codes were excluded for being either too broad or unrelated to the study’s focus. Although G01V3 is relevant to well-logging technologies, it was excluded in favor of the broader coverage provided by E21B47 and G01V1. These keywords were developed through an iterative process involving domain-specific terminology and expert validation. To ensure comprehensive coverage, the final keyword set was benchmarked against known patents encompassing key sensing technologies—such as sonic, ultrasonic, gamma-ray, neutron, and resistivity tools. The search strategy incorporated a two-stage filtering process: initial automated retrieval using keywords and IPC codes, followed by manual screening to retain only those patents directly related to cement bond log tools.

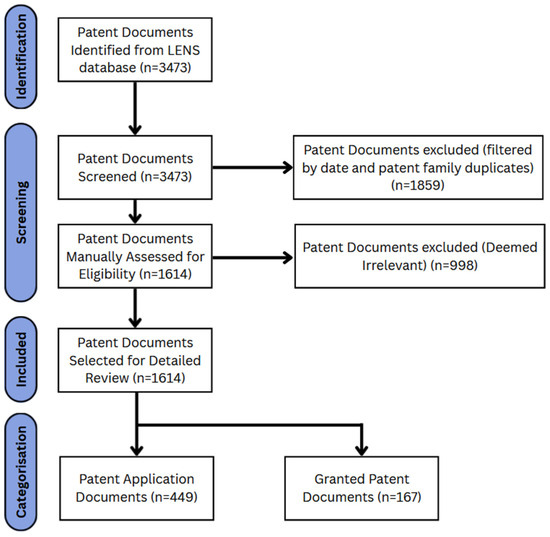

To ensure transparency and methodological rigor, this analysis was conducted in full compliance with the Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA) guidelines [11], adapted for the analysis of patent literature. The PRISMA framework guided the structured identification, screening, eligibility assessment, and inclusion of patent documents relevant to cement bond log (CBL) technologies. A PRISMA flow diagram is provided in Figure 2 to illustrate the selection process. To maintain data quality, duplicate patents within the same patent family were removed, ensuring each invention was counted only once. Additionally, time-series analysis was applied to identify innovation peaks and technological shifts over time. Patent citation analysis was also performed to trace the influence of earlier patents on subsequent developments [54]. This systematic review was not prospectively registered in a public review database.

Figure 2.

Patent search review in flow chart using PRISMA statement [55].

As illustrated in Figure 2, the search process began by retrieving 3473 patent documents from the Lens.org database using relevant keywords and IPC codes. The search was conducted on 12 September 2024 and covered filings from 1 September 2004 to 1 September 2024, ensuring a 20-year window focused on modern innovations and avoiding outdated technologies. To eliminate redundancies, a deduplication process was performed based on patent family groupings, accounting for multiple filings of the same invention across multiple jurisdictions, and thereby, reducing the dataset to 1614 unique patent documents. Subsequently, a manual screening process was conducted to assess relevance to CBL technologies, with a total of 999 irrelevant patents excluded due to misclassification and irrelevance. This results in 616 relevant patents, comprising 167 granted patents and 449 published patent applications.

While both granted and published patents were considered for bibliometric analysis, such as filing trends and geographical distribution, only the 167 granted patents were subjected to detailed technology updates. This distinction is essential, as granted patents represent legally approved inventions and offer a stable reference for analyzing technological maturity and industry priorities, whilst patent applications are still pending examinations and are subject to amendments prior to grant or even rejection. Accordingly, this study prioritizes granted patents for its core analysis.

3.2. Patent Analysis

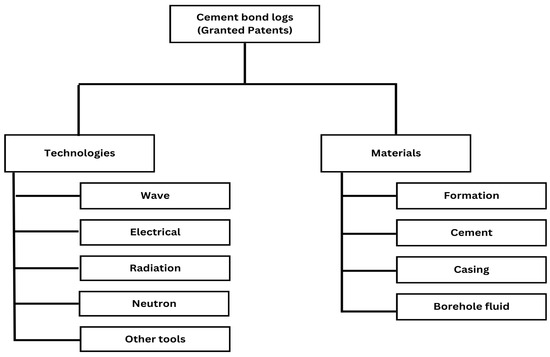

To understand innovation trends in cement bond logging, the 167 granted patents were systematically analyzed and classified into two primary dimensions: technologies and materials. This dual classification framework allows us to evaluate how different diagnostic tools (technologies) are applied to assess specific well components (materials), all of which contribute to maintaining well integrity. Figure 3 presents a visual overview of this classification, showing the distribution of granted patents across the five technology categories and four material types. This mapping provides a comprehensive picture of how innovation is occurring within and across these categories.

Figure 3.

Categorization of patents in the cement bond logs (granted patents) using patent analysis.

3.2.1. Technologies

The technologies category encompasses diagnostic tools that are designed to evaluate well integrity. These tools are essential for detecting potential leakage paths and weak bonds that could compromise the safety and reliability of oil and gas wells. The analysis shows that while traditional technologies such as wave-based and electrical tools remain foundational, there is growing interest in more advanced or hybrid systems, as shown in Figure 3.

- Wave-Based Tools

Acoustic technologies include sonic, ultrasonic, lamb wave and general acoustic technologies. These tools can transmit sound waves through the wellbore to identify the weak bonds of the well structure. Many patents focus on using these tools to evaluate the formation while some patents also emphasize their use in evaluating cement and ensuring the well is being sealed [56].

- Electrical Tools

Electrical tools encompass resistivity and electromagnetic measurement systems. These tools assess the electrical properties of materials in the wellbore to detect formation characteristics and the presence of borehole fluids. Electrical tools help identify zones where the well structure may be compromised due to poor bonding or material degradation.

- Radiation Tools

Radiation-based technologies are Gamma-ray, X-ray tools, Density tools and Other Nuclear technologies that measure the density and the composition of formation and cement. They are used to provide details about cement or formation that are correctly bonded and stable by using radiation.

- Neutron

Neutron technologies are tools that can measure the hydrogen content which help in determining borehole fluid (fluid saturation) and formation(porosity). These tools are important in how the cement isolates the wellbore from the surrounding formation to ensure no leakage occurs.

- Other Tools

This category encompasses logging systems that could not be clearly assigned to wave-based, electrical, radiation-based, or neutron-based technologies. These may include general-purpose tools, diagnostic platforms with unspecified sensing mechanisms, or hybrid systems described without sufficient detail for precise classification. Technologies that incorporate computational methods, data fusion, or analytics are included here only if the underlying sensing approach is not explicitly defined. If the sensing basis is stated, the tool is categorized accordingly under its appropriate class. This approach ensures consistency and minimizes subjectivity in classification.

To aid comparison and support interpretation of the patent landscape, Table 3 summarizes the key attributes of each technology type, including their typical advantages, limitations, applicable deployment conditions, and a concise description of their sensing approach.

Table 3.

Summary of advantages, disadvantages, and applicable conditions for the five core cement bond log (CBL) technologies.

3.2.2. Materials

The materials category mostly focuses on the components involved in well drilling construction that are evaluated by the above technologies. This innovation in evaluating these materials helps to ensure well integrity.

- Cement

Cement is located between the casing and the formation to seal the well. Patents in this category usually focus on improving the cement’s durability, resistance, and bond capabilities which are critical to maintaining well integrity.

- Casing

The casing provides structural support and prevents fluid migration. Strengthening the casing is essential to enhance the ability to bond with the cement to prevent well leaks.

- Formation

Formation plays a significant role in how cement is bonded to the surrounding rocks. Innovation in cement bonding helps to improve the bond between cement and surrounding rocks(formation) which can maintain well integrity and prevent fluid migration.

- Borehole Fluids

Borehole fluids are also important because they directly affect the signal clarity, and they also affect the cement’s ability to bond with the casing and the surrounding formation. Hence, managing the fluids is crucial in proper cement setting and optimizing the bond process.

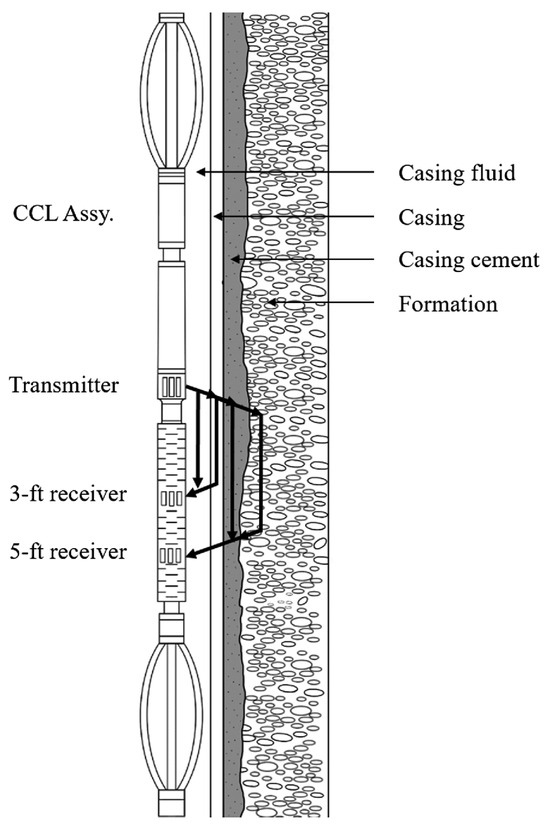

Figure 4 illustrates the arrangement of key well components: borehole fluid, casing, formation, and cement, and how various diagnostic tools interact with these materials. This visual representation complements Table 4, which categorizes the materials evaluated by cement bond logging technologies, summarizing their roles and common diagnostic targets. Together, these elements highlight the relationship between technologies and materials, emphasizing how innovations in diagnostic tools are essential for assessing material integrity and mitigating future well integrity failures.

Figure 4.

The relationship between the key components of the well, including the casing (casing fluid), cement (casing cement), formation, and borehole fluid (casing fluid) [57].

Table 4.

Summary of material categories evaluated by cement bond logging technologies.

4. Results and Discussions

4.1. Bibliographic Studies

A total of 616 patents were selected for a comprehensive review of innovations related to cement bond logs. Among these, 448 (72.9%) are patent applications, while 167 (27.1%) are granted patents. This distribution indicates that a substantial portion of technologies in this domain remain under examination, suggesting that many innovations are still in development. The high number of pending applications implies that new technologies may emerge once these patents are approved, reflecting a dynamic and evolving field.

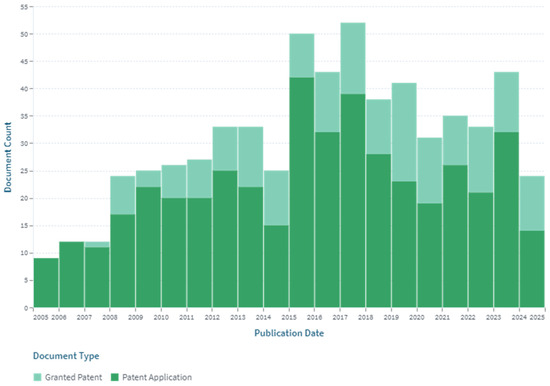

Figure 5 shows the number of patent documents categorized by their publication year. In this figure, the light green bars represent granted patents that were published in a given year and later approved, while the dark green bars represent patent applications published but not yet granted. The data for 2024 are partial, reflecting only documents published up to the search date of 12 September 2024. This visual differentiation highlights the varying stages of innovation—granted patents have passed formal examination and been awarded legal protection, whereas applications are still under review. Patent activity was relatively low between 2005 and 2008, but began to increase steadily from 2009, especially for granted patents. The highest number of pending applications occurred in 2015, with 42 filings, while only 8 patents were granted that year. This discrepancy may be attributed to delays in the examination process at patent offices, which can prolong approval times. The highest peak in granted patents occurred in 2019, with 19 patents, marking a significant year for innovation in well integrity technologies during the review period of 1 September 2004 to 1 September 2024.

Figure 5.

Number of patent documents according to their publication year.

Overall, the predominance of patent applications over granted patents reflects an ongoing commitment to research and development in cement bond logging. While many technologies are still awaiting formal protection, the granted patents represent mature innovations that have successfully met legal and technical criteria. This trend underscores the industry’s strong focus on advancing tools to improve well integrity evaluation.

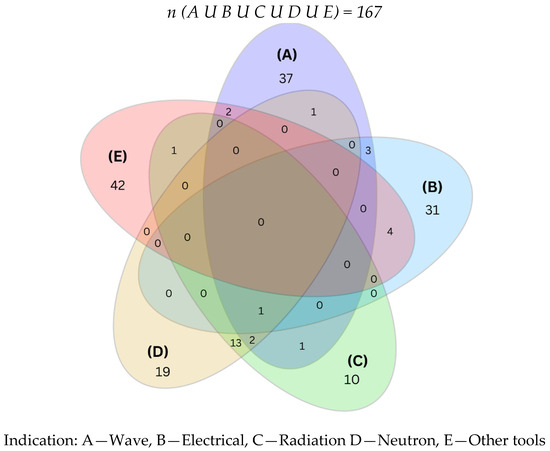

The Venn diagram in Figure 6 illustrates the distribution of the 167 granted patents across five technology categories related to cement bond logs: Wave (A), Electrical (B), Radiation (C), Neutron (D), and Other Tools (E). Each of these technologies plays an important role in the evaluation of well integrity, as previously introduced in Figure 3. Among the 167 patents, the largest number—42 patents (25.1%)—falls under the Other Tools (E) category. This category includes tools that are either unspecified or advanced well-logging systems not classifiable under traditional categories. The size of this group suggests a rising demand for specialized and adaptable systems capable of addressing complex well integrity challenges. Following this, Wave-based technologies (A)—which include sonic and ultrasonic tools—account for 37 patents (22.2%), reaffirming their central role in acoustic-based evaluation. Electrical tools (B), which include resistivity and electromagnetic systems, make up 31 patents (18.6%). Neutron-based tools (D), used primarily to assess porosity and hydrogen content, comprise 19 patents (11.4%). Finally, Radiation tools (C), such as gamma-ray and X-ray instruments, represent the smallest share, with 10 patents (6.0%).

Figure 6.

Venn diagram of technology categories for granted patents from 1 September 2004 to 1 September 2024.

The Venn diagram also reveals that many tools integrate multiple technologies, indicating a trend toward multi-functional systems that provide more comprehensive evaluations. In total, 28 patents (16.8%) exhibit overlaps between technology categories, representing inventions that incorporate two or more diagnostic approaches for well integrity assessment. The most frequent overlap occurs between Radiation and Neutron tools (C ∩ D), comprising 13 patents (7.8%). These tools often work in tandem to analyze formation density and porosity, providing critical insights into subsurface conditions. Another notable overlap is between Electrical and Other Tools (B ∩ E), which account for 4 patents (2.4%), followed by Wave and Electrical tools (A ∩ B) with 3 patents (1.8%), and Wave and Other Tools (A ∩ E) with 2 patents (1.2%). These combinations reflect the development of hybrid logging tools aimed at improving the accuracy and depth of integrity evaluations. Other overlaps include Wave and Radiation tools (A ∩ C), Wave and Neutron tools (A ∩ D), and Radiation and Other Tools (C ∩ E) found with 1 patent (0.6%) paired for comprehensive evaluation.

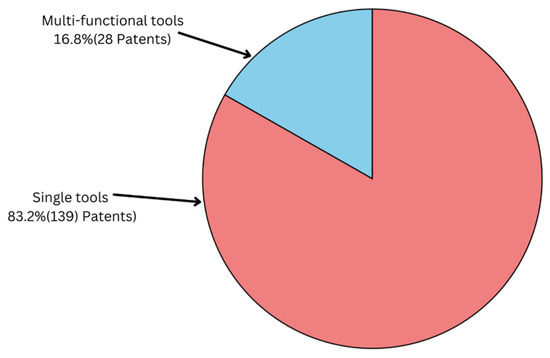

Moreover, two patents (1.2%) integrate three technologies simultaneously—Wave, Radiation, and Neutron (A ∩ C ∩ D)—demonstrating a more sophisticated approach to well evaluation. One patent (0.6%) includes a rare integration of four technologies: Wave, Electrical, Radiation, and Neutron (A ∩ B ∩ C ∩ D), offering a holistic solution for integrity assessment. Such multi-functional tools are designed to reduce costs while increasing accuracy, particularly beneficial in harsh environments like deep or offshore wells. Figure 7 illustrates the comparison between multi-functional and single-function tools. A total of 28 patents demonstrates the integration of multiple technologies, while the remaining 145 patents are categorized as non-overlapping—each using only one technology type.

Figure 7.

The number of granted patents in technology categories with single tools and multi-functional tools.

While wave-based tools remain a dominant technology, the increasing number of patents that integrate multiple diagnostic approaches highlights a significant industry shift toward more versatile, high-performance well-logging tools.

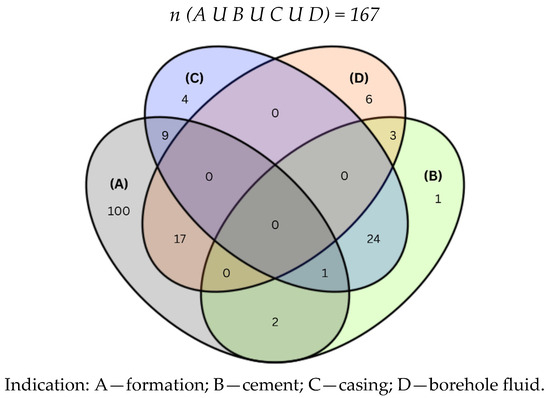

Figure 8 presents a Venn diagram showing the distribution of 167 granted patents across four material categories relevant to cement bond log evaluations: formation, cement, casing, and borehole fluid. These categories represent the primary well components assessed using various cement bond log technologies. The analysis reveals that a significant majority of these patents—100 out of 167, or 59.9%—are focused on evaluating formation. This trend reflects the industry’s strong emphasis on formation evaluation as a critical aspect of maintaining well stability and zonal isolation. In contrast, the other material categories are represented by a considerably smaller number of patents. Borehole fluid appears in only 6 patents (3.6%), casing in 4 patents (2.4%), and cement in just a single patent (0.6%). The remarkably low number of patents focusing solely on cement may suggest that cement evaluation is often conducted in conjunction with other materials, particularly casing and formation, rather than as an independent objective. Such a pattern points to a potential underrepresentation of standalone cement-focused technologies in the current innovation landscape. This outcome stems from a deliberate classification choice made during the review process. Since many modern well integrity tools assess multiple material interfaces, such as cement, casing, and formation, within a single system, patents were classified under “multi-material” unless they demonstrated a clear emphasis on cement. This method helps to avoid inflating counts in single-material categories and ensures each patent is categorized according to its primary diagnostic objective.

Figure 8.

Venn diagram of materials categories for granted patents from 1 September 2004 to 1 September 2024.

The Venn diagram in Figure 8 also highlights several overlaps between material categories, indicating the presence of tools designed to evaluate multiple well components simultaneously. The most frequent overlap, involving 24 patents or 14.4%, is between cement and casing. This suggests that many tools aim to ensure the quality of the cement-to-casing bond, which is crucial for the structural integrity and sealing capability of the well. The second most common overlap involves formation and borehole fluid, found in 17 patents (10.2%), highlighting the importance of evaluating the interaction between rock structures and fluid presence, particularly during drilling and completion phases. Other notable overlaps include nine patents (5.4%) that assess both formation and casing, demonstrating a focus on the interface between geological structures and mechanical well components. A smaller number of patents evaluate combinations such as formation and cement (2 patents, or 1.2%) and cement and borehole fluid (3 patents, or 1.8%), indicating that certain material pairings are considered relevant for specific evaluation goals. Interestingly, only one patent (0.6%) addresses the simultaneous evaluation of three components—formation, cement, and casing—while no patents were found that evaluate all four materials together. This absence suggests an opportunity for innovation in developing fully integrated tools capable of simultaneously assessing formation, cement, casing, and borehole fluid.

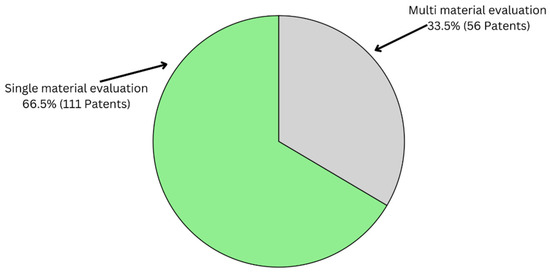

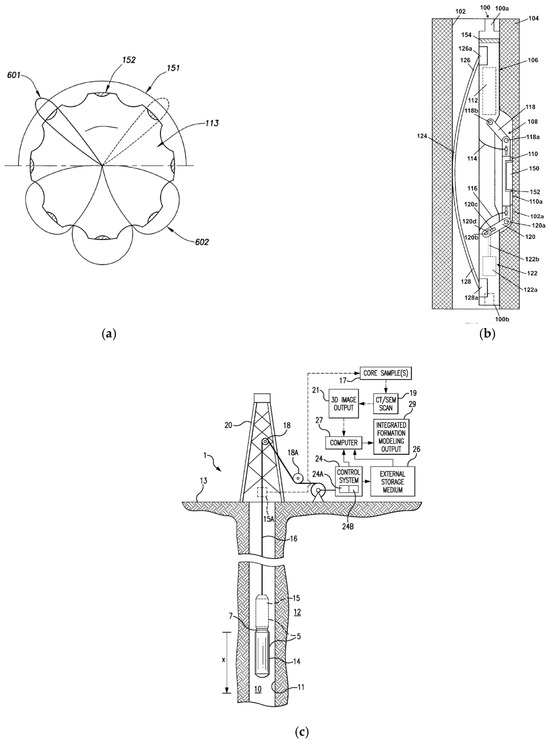

To better understand how many tools evaluate single versus multiple materials, Figure 9 compares the number of patents with single-material and multi-material focus. Out of the 167 granted patents, 56 (33.5%) are designed to assess more than one material, while the remaining 111 patents (66.5%) focus on evaluating only one component. This indicates that although most tools are specialized, there is a growing interest in multi-functional systems capable of offering a more comprehensive view of well integrity. It is important to note that the material classification is independent of the number of technologies integrated within a tool. While some tools categorized under multi-functional technologies combine several sensing methods, their material focus is determined solely by the well components explicitly targeted for evaluation within the patent. This ensures that a tool assessing only formation, even if multi-functional technologically, is counted under the single-material category for formation.

Figure 9.

Number of granted patents in materials category that have single material evaluation and multi-material evaluation.

This analysis shows that formation evaluation is the dominant focus among granted patents, reflecting the industry’s recognition of its importance in securing well stability. Cement, casing, and borehole fluids are comparatively underrepresented as standalone targets, which suggests that they are often assessed alongside other components. The relatively small number of patents addressing multiple materials points to a technological gap in fully integrated evaluation systems—highlighting an area for future innovation in cement bond logging technologies.

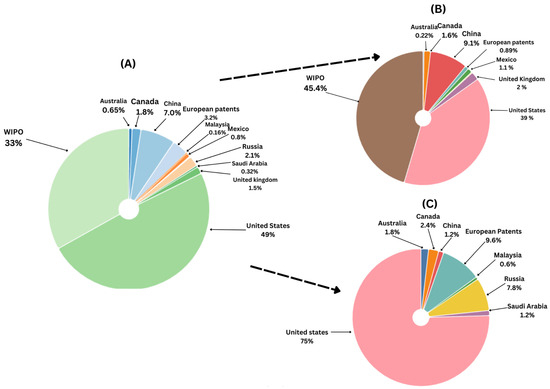

Figure 10 presents three charts that illustrate the distribution of patent activity across countries based on primary filing jurisdiction rather than the nationality or corporate headquarters of applicants. Any patent initially filed through the United States Patent and Trademark Office (USPTO), for instance, is attributed to the United States, regardless of whether the applicant is a domestic or foreign entity. This approach reflects where legal protection was first sought, offering insight into regional filing preferences and strategies. These charts cover (A) published patents, including both granted and pending applications; (B) patent applications only; and (C) granted patents. Chart A shows that the United States has the highest number of published patents related to cement bond logs, with 309 patents (50%), followed by the World Intellectual Property Organization (WIPO), which accounts for 204 patents (33%). Although WIPO is not a country, it plays a crucial role in facilitating international patent applications under the Patent Cooperation Treaty (PCT). Through this system, inventors can file a single application that is recognized in multiple countries, serving as a gateway for global protection before entering national or regional phases [44]. In addition to the United States and WIPO, other notable contributors include China (7.0%), Canada (1.8%), and European patents (3.2%). European patents are granted by the European Patent Office (EPO) and can be validated in multiple European countries such as Germany, France, and Italy under a unified system [58]. These figures highlight the regions where innovation in cement bond log technologies is actively being pursued and disclosed.

Figure 10.

(A) Published patents based on countries, (B) patent applications based on countries, (C) granted patents based on countries.

Chart B focuses on patent applications that are still under review and not yet granted. WIPO holds the largest share of these applications, with 204 filings (45%), which indicates that many international submissions remain in the preliminary phase, pending examination by national patent offices. The United States follows with 177 applications (39%), a proportion that aligns with its overall leadership in published patent volume. This divergence between high WIPO application volume and lower numbers in granted patents is expected, as WIPO itself does not grant patents. Instead, it acts as an initial international filing platform through the PCT system. Applications must then enter national phases, where they undergo substantive examination. Therefore, the WIPO numbers reflect the early stages of patent life cycles, while granted patent data—such as that from the USPTO—represents technologies that have passed formal scrutiny and received legal protection.

Chart C narrows the focus to granted patents, offering insight into technologies that have successfully passed legal and technical scrutiny. The United States leads again, with 126 granted patents (75%), reinforcing its central role in cement bond log innovation. This figure includes all patents for which the USPTO served as the primary filing office, regardless of the applicant’s country of origin. As a result, both domestic applicants and foreign entities choosing to file through the USPTO are reflected under the U.S. category, ensuring consistency across all charts when analyzing jurisdictional trends. Following the United States, European patents accounts for 9.6% and Russia 7.8%. Other countries contribute smaller shares, including Canada (2.4%), Australia (1.8%), China (1.2%), and Saudi Arabia (1.2%). These results indicate that while international contributions exist, the United States remains the dominant source of legally recognized inventions in this field.

Together, the three charts in Figure 10 provide a clear overview of the global distribution of patent activity related to cement bond logs. The data highlight the technological leadership of the United States, the strategic importance of WIPO as a filing route for international protection, and the procedural realities that lead to discrepancies between application volumes and granted patent counts. These trends suggest both a strong pipeline of emerging innovations and a need to support broader global engagement in patent prosecution, especially in underrepresented regions.

The limited participation of certain countries in patent filings may reflect several underlying factors. First, resource constraints, including limited funding for R&D and restricted access to proprietary subsurface data, can hinder the capacity of organizations in developing countries to pursue patentable innovations in well-logging technologies. Second, national innovation agendas may prioritize different areas of the energy sector, such as renewable energy development or upstream exploration, resulting in lower investment in downhole diagnostic tools like cement bond logs. Third, smaller or less mature oil and gas markets may rely on imported technologies rather than developing domestic solutions, reducing the incentive to file patents locally. Finally, the procedural complexity and cost of patent prosecution, especially under the PCT system, can deter participation from entities with fewer legal and administrative resources. These factors together may explain the regional imbalances observed in Figure 10 and highlight the need for targeted support to expand global engagement in oilfield technology innovation.

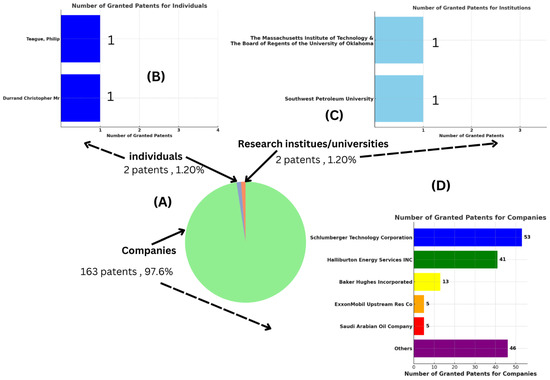

Figure 11 presents the distribution of granted patents in the field of cement bond logs according to the type of applicants. As shown in Figure 11A, the vast majority of granted patents—163 out of 167 (97.6%)—are owned by companies, reflecting a dominant role of industry in driving innovation in this domain. Figure 11D further details the leading corporate applicants, with Schlumberger Technology Corporation holding the highest number of granted patents at 53, followed by Halliburton Energy Services Inc. with 41 patents, and Baker Hughes Incorporated with 13 patents. These figures underscore the competitive engagement of major oilfield service providers in developing proprietary well-logging technologies.

Figure 11.

(A) Categories of applicants of granted patents, (B) individual applicants of granted patents, (C) countries of university applicants of granted patents, and (D) company applicants of granted patent.

By contrast, universities and research institutes collectively hold only 2 patents (1.2%), as illustrated in Figure 11C. Among them, Southwest Petroleum University is listed as the owner of U.S. Patent 11965412B1 [59], while a collaboration between the Massachusetts Institute of Technology and The Board of Regents of the University of Oklahoma holds U.S. Patent 8380437B2 [60]. Similarly, only 2 patents (1.2%) are owned by individual inventors, as shown in Figure 11B. These include Durrand Christopher with U.S. Patent 8061443B2 [61], and Teague Philip, who owns EP Patent 3685196B1 [62].

This overwhelming dominance of company-owned patents suggests that innovation in cement bond log technologies is largely industry-driven. The complexity, cost, and long development timelines associated with such technologies likely require substantial institutional resources and sustained investment—factors that are typically within the reach of large corporations rather than individuals or academic institutions. From a commercial perspective, companies are motivated to secure patent protection not only to safeguard their investments but also to prevent competitors from replicating their inventions. The relatively limited participation of universities and individual inventors highlights a potential gap in academic engagement and independent contributions to this field. Bridging this gap could be facilitated through increased collaboration between academia and industry, which would allow for knowledge sharing, interdisciplinary innovation, and broader participation in the development of new evaluation tools for well integrity. By fostering such partnerships, the sector could benefit from fresh perspectives and research capabilities that complement the industrial expertise and infrastructure of corporate entities.

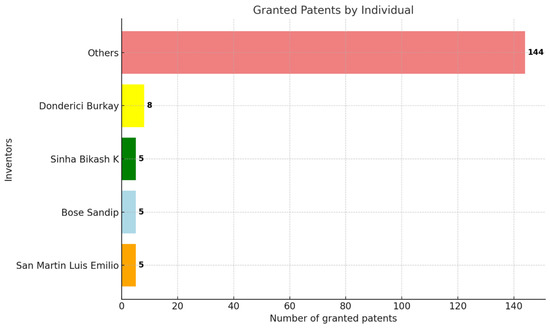

Figure 12 shifts the focus to the inventors listed in the granted patents. In patent documentation, inventors are those who initially contribute to the development and submission of the invention, while the owners—often the companies—are the legal rights holders once the patent is granted. As shown in Figure 12, the leading inventors include Donderici Burkay, who is credited with 8 patents, followed by Sinha Bikash K, Rose Sandip, and San Martin Luis Emilio, each with 5 patents. These inventors are part of the 144 total patents attributed to named individuals, even though the ownership lies with their employers.

Figure 12.

Inventors of granted patents.

This structure reflects the collaborative, team-based approach typical of corporate R&D environments. Companies invest in and retain technical experts to drive continuous innovation, particularly in the highly specialized and competitive area of well logging. The presence of prolific inventors within corporate teams indicates a systematic effort to harness in-house expertise to maintain technological leadership and address industry-specific challenges in well integrity assessment.

Table 5 presents the annual distribution of granted patents related to cement bond log technologies across different technology categories from 2005 to 2024. The table highlights both the total number of patents granted each year and the specific categories to which they belong, providing insights into the evolution of innovation in this field over time. In the early years, between 2006 and 2009, patent activity was relatively low. For instance, only one patent (0.6%) was granted in 2007, while nine patents (5.39%) were granted in 2008. Most of the patents granted during this early period fell under the Other Tools category, with five patents (11.9%), and included two multi-functional tools (7.14%). The minimal presence of radiation- and neutron-based tools during this time suggests that innovation in these specific technologies had not yet gained momentum. A notable increase in patent activity began around 2010, with a consistent upward trend that peaked in 2019, when 18 patents (10.78%) were granted—the highest annual count in the dataset. That year marked a significant rise in innovation, particularly in wave-based tools, which accounted for six granted patents (16.21%), and in multi-functional tools, with three patents (10.71%). These numbers reflect an intensified focus among inventors on developing tools that combine acoustic sensing capabilities or integrate multiple diagnostic methods to address the increasing complexity of well-integrity challenges.

Table 5.

Number of granted patents under technology categories on each published year.

Throughout the 20-year period, the most active category has been Other Tools, which represents 42 granted patents (25.15%). This group typically includes tools that fall outside conventional classifications or involve integrated, smart, or adaptive logging systems. The sustained patent activity in this category indicates an ongoing search for novel solutions that go beyond traditional single-mode evaluation tools. The Wave-based category follows closely, with 37 granted patents (22.16%), underscoring the continuing relevance of sonic and ultrasonic techniques in wellbore evaluation. These tools remain a cornerstone of cement bond log assessments due to their ability to detect micro-defects and assess bonding quality between casing, cement, and formation. Electrical tools account for 31 patents (18.56%) over the review period, indicating steady interest in the use of resistivity and electromagnetic methods, especially in formation evaluation. This may reflect the perceived accuracy and adaptability of electrical tools in identifying formation properties and evaluating the presence of borehole fluids.

The year-by-year breakdown in Table 5 highlights not only the overall growth in patent activity but also the shifting focus of innovation toward more versatile, accurate, and integrated logging tools. The continued emergence of wave-based and multi-functional tools demonstrates a strong industry drive to improve diagnostic precision and operational efficiency in well integrity assessments

Table 6 presents an overview of granted patents categorized by material type—formation, cement, casing, borehole fluid, and multi-material evaluations—from 2005 to 2024. This breakdown offers insights into which well components are most frequently targeted by innovation in cement bond log technologies over time.

Table 6.

Shows an overview of granted patents in the materials category per year from 2005 to 2024.

Across the 20-year span, formation emerges as the most frequently addressed material, with 100 patents (60%) out of 167. This strong focus indicates the industry’s sustained interest in evaluating formation conditions to ensure structural stability and zonal isolation. The highest number of formation-related patents was recorded in 2019, with 11 patents (11%), coinciding with the overall peak in granted patents across all categories. This suggests that formation evaluation was a key driver of technological innovation during that year. The multi-material category accounts for 56 patents (33.53%), highlighting a growing trend toward integrated evaluation tools capable of assessing multiple components simultaneously. These tools offer operational efficiency by reducing the need for multiple passes or separate tools, and are particularly valuable in complex well environments. The multi-material category shows consistent activity across the years, with notable peaks in 2019 (6 patents), 2022 (7 patents), and 2023 (6 patents), reflecting ongoing efforts to improve the comprehensiveness and cost-effectiveness of well logging solutions. In contrast, the number of patents focused solely on cement and casing remains low. Only one patent (0.60%) was granted for cement in 2015, while casing is addressed in just four patents (2.40%) over the entire period. This low representation may be explained by the fact that cement and casing evaluations are often conducted in conjunction with formation assessments, and are therefore classified under the multi-material category rather than as standalone evaluations. The borehole fluid category also remains relatively underrepresented, with only six patents (3.60%). The data suggests that while formation remains the dominant focus, there is a clear and rising interest in multi-functional tools that can assess various material interactions in a single run. This evolution aligns with industry needs for more integrated, efficient, and accurate diagnostic solutions. Meanwhile, the limited number of patents addressing cement, casing, or borehole fluid independently may indicate an area where further dedicated innovation could be beneficial, particularly if such components are treated as distinct challenges rather than components bundled into composite evaluations.

Taking together with the insights from Table 5, which focused on technological categories, Table 6 helps map the progression of innovation across both tool types and evaluation targets. These trends are useful in identifying where current research and development are concentrated and in highlighting opportunities for future technological advancements in cement bond log design.

4.2. Technology Updates

The technology updates highlight innovations in cement bond logging technologies through analysis of the 167 granted patents. To provide clarity and depth, the updates are organized based on the underlying technological approach: wave-based, electrical, radiation-based, neutron-based, other specialized tools, and multi-functional systems, with each category reflecting a distinct trajectory of technological development, showcasing how specific sensing mechanisms and tool configurations have evolved to address challenges in well integrity evaluation. The number of patents discussed in each category is proportional to the volume of patents captured, while also taking into account the diversity of innovation, industry relevance, and representativeness. Specifically, selected patents span a balance of early foundational inventions, recently granted patents, highly cited patents, and patents with large family sizes. Although some categories, such as multi-functional tools, contain fewer patents overall, they receive focused attention due to their rising prominence in integrated well-logging solutions. This structured approach offers a balanced and meaningful perspective on technological evolution across the spectrum of CBL innovations.

4.2.1. Wave Technology

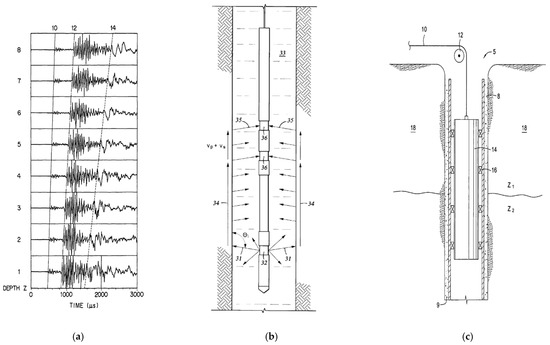

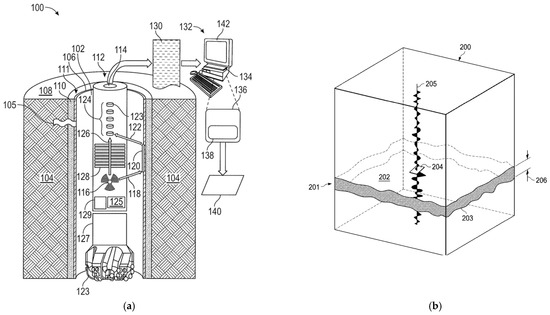

One of the earliest advancements in wave-based technology for cement bond logging is documented in US Patent 7337068 B2, granted in February 2008 [63]. This invention utilizes acoustic waves to detect anomalies in the cement bond and casing structure. As illustrated in Figure 13a, acoustic signals are transmitted through the wellbore, and their reflections are captured over time to produce a waveform. These waveforms reveal how sound waves behave at various depths and interfaces within the well, allowing engineers to identify weak cement bonds by observing disruptions or irregularities in the reflected signal. A smoother waveform typically indicates a stronger bond, while distortions suggest poor bonding or voids. Since this tool evaluates both casing and cement, it falls under the multi-material category as well as wave technology, and it marked a significant step forward in improving early detection of well integrity issues.

Figure 13.

(a) Global Classification of Sonic Logs, patent (US 7337068 B2) [63], (b) System and Method for Detection of Near-Wellbore Alteration Using Acoustic Data, patent (US 7516015 B2) [64], and (c) Use of The Lamb Wave in Cement Bond Logs, patent (US 7663969 B2) [65].

A subsequent innovation in this category is described in US Patent 7516015 B2, granted in April 2009 [64]. This patent introduced a method for assessing the strength of cement bonds using acoustic data, as shown in Figure 13b. The system operates by transmitting labeled acoustic signals (such as signal 31 in the diagram) through the wellbore to measure how waves propagate through different materials—cement, casing, and formation. The speed and behavior of wave transmission provide insights into material properties and bonding conditions. The faster and more stable the wave propagation, the more accurate and timely the diagnosis of subsurface defects. This real-time data enables engineers to identify cracks or debonded zones early, reducing the risk of serious failures. Notably, this patent has 16 citations, making it one of the most highly referenced wave-based patents, which reflects its importance in shaping future research and technological development in the industry.

Another key contribution to wave technology is US Patent 7663969 B2, issued in February 2010 [65]. This patent presents an advanced method that combines both acoustic and Lamb waves to evaluate bonding between the cement, casing, and formation. Lamb waves are particularly effective for detecting defects in thin layers, making them ideal for inspecting surface-level imperfections at the casing–cement interface. As shown in Figure 13c, the tool emits acoustic and Lamb wave signals within the wellbore, and the reflected signals from key zones—denoted as Z1 and Z2—are analyzed to determine the bond quality. Like the earlier patent US 7516015 B2 [64], this tool offers real-time feedback, but it improves upon previous designs by enhancing precision in identifying small-scale defects in critical bonding areas. The ability to detect such surface flaws is essential for preventing long-term structural failure.

While these three early patents laid the foundation for wave technology in cement bond logging, subsequent patents—some with the highest family counts—indicate the widespread international adoption and ongoing refinement of these core principles. These innovations demonstrate the importance of wave-based tools in delivering accurate, real-time diagnostics essential to ensuring well integrity in increasingly complex drilling environments.

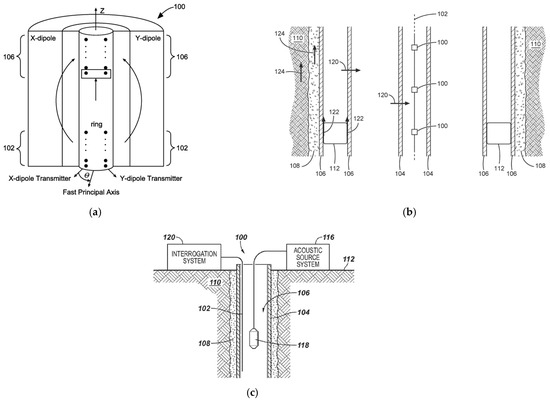

Furthermore, US Patent 9348052 B2, granted in May 2016, represents one of the most widely recognized innovations in wave technology, holding the highest extended family count in this category with 23 related filings [66]. This means that the core invention has either been granted or filed in 23 different jurisdictions, reflecting both its commercial value and international adoption. As illustrated in Figure 14a, this technology utilizes X-dipole and Y-dipole transmitters to emit directional acoustic waves capable of detecting micro-cracks, weak cement bonds, and defects in the casing. A key component of this tool is a ring structure, which enables the capture of acoustic wave propagation in multiple directions. This feature enhances the ability to detect defects with greater precision and provides real-time diagnostic data on cement bond and formation conditions. The widespread family filings highlight the tool’s reliability and acceptance as a trusted method for detecting micro-defects, thus playing a vital role in preserving well integrity.

Figure 14.

(a) Analytic Estimation Apparatus, Methods, and Systems, patent (US 9348052 B2) [66], (b) Acoustic Array Signal Processing for Flow detection, patent (US 11208884 B2) [67], and (c) Methods for Locating a Cement Sheath in a Cased Wellbore, patent (US 9546548 B2) [68].

The second-highest family count in the wave technology category is held by US Patent 11208884 B2, granted on 28 December 2021, which has an extended family size of 16 [67]. This patent introduces an advanced acoustic array signal processing system for monitoring fluid movement and detecting cracks in the cement–casing bond. As shown in Figure 14b, the system includes acoustic sensors (labeled 100) installed within the wellbore to track fluid dynamics and identify potential defects (labeled 120) in the surrounding cement layer (108). These sensors can detect early signs of fluid leaks (124) before they escalate into more serious integrity issues. The innovation is capable of capturing high-resolution acoustic data, which offers clear and detailed imaging of defects, making it easier for engineers to identify minor anomalies. Its elevated family count underscores the operational relevance and practical reliability of this approach in the field.

Another key patent in wave-based acoustic monitoring is US Patent 9546548 B2, granted on 17 January 2017, which stands out for having the highest citation count, with 24 citations by subsequent patents [68]. This indicates the foundational impact of this invention on later developments within the field. The system utilizes high-resolution acoustic wave technology to detect cracks and discontinuities within the cement and casing. As illustrated in Figure 14c, an acoustic source (118) is lowered into the wellbore to emit waves that pass through surrounding materials, including the casing (104) and cement (108). The returning signals are captured by an interrogation system (120), which processes and converts them into actionable data. An acoustic source controller (116) is used to manage wave generation, ensuring accurate and consistent signal transmission. This method offers real-time, high-fidelity data acquisition, making it especially effective in deep or complex wells where traditional monitoring techniques may lack sensitivity. Its high citation count reflects the patent’s significant influence, as it has served as a technological reference point for subsequent innovations in acoustic well integrity assessment.

Together, these patents represent the most impactful and widely adopted contributions to wave-based cement bond log technologies. Their high family counts and citation metrics indicate both global applicability and scientific relevance, reinforcing the importance of acoustic systems in advancing real-time, high-precision well evaluation.

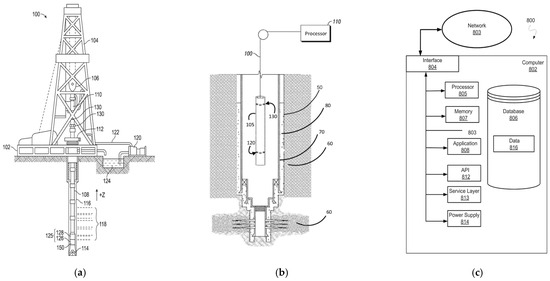

The most recent advancement in wave-based cement bond log technology is described in US Patent 11994642 B2, granted in May 2024 [69]. This patent introduces a cutting-edge acoustic system designed to enhance the detection of flaws in the cement and casing of oil and gas wells. As illustrated in Figure 15a, the system deploys wireline acoustic tools into the wellbore to transmit and receive acoustic signals. These signals travel through the well structure and reflect off interfaces, allowing engineers to detect anomalies in the cement, casing, and even the surrounding formation. The surface equipment (130) processes these returning signals in real time to identify issues such as fluid leaks. The integration of real-time, high-resolution data acquisition with acoustic sensing enables faster and more accurate decision-making by field engineers, significantly reducing the risk of well integrity failure. What sets this technology apart from earlier systems is its ability to combine precision acoustic monitoring with real-time evaluation, making it especially valuable in complex and high-risk well environments.

Figure 15.

(a) Method and Apparatus for Geophysical Formation Evaluation Measurements Behind Casing, patent (US 11994642 B2) [69], (b) Guided Mode Beamforming for Probing Open-Hole Formations Using Acoustic Waves, patent (US 11899153 B2) [70], and (c) Tight Reservoir Fluid Characterization by Using Sonic Slowness Well Logs, patent (US 11892590 B2) [71].

Another recent innovation is described in US Patent 11899153 B2, granted in February 2024 [70]. This patent introduces an advanced guided-mode beamforming technology, aimed at improving downhole data acquisition and signal clarity. As depicted in Figure 15b, a wireline acoustic tool (50) is lowered into the wellbore and equipped with one or more transmitters that emit acoustic signals toward the casing (70) and cement (80). The reflected signals are captured by a receiver array, which identifies defects or fluid leaks within the well structure. A key component of this system is the controller (110), which dynamically adjusts the amplification levels and timing of signal processing to optimize performance based on the downhole conditions. This targeted, adaptive approach allows the tool to focus acoustic energy on specific materials, yielding more accurate and real-time data. Compared to older methods, this system delivers superior precision, particularly in challenging or high-pressure environments where detailed evaluations are critical.

The third recent patent in this category is US Patent 11892590 B2, granted in February 2024 [71], which introduces an advanced sonic slowness-based system for evaluating fluid types in tight reservoirs. Unlike previous methods focused solely on structural integrity, this technology leverages compressional (P-wave) and shear wave (S-wave) velocity measurements to analyze subsurface rock and fluid properties. As shown in Figure 15c, the system is built around a robust computing framework (802) that processes real-time acoustic data captured by sonic tools. The processor (805) handles computational tasks, while the database (806) stores measurement data. The application module (808) uses this input to predict the type of fluid—such as gas, oil, or water—present in the formation. A key feature is the integration of networked data acquisition (803), which enables simultaneous monitoring from multiple well locations. This real-time, distributed sensing architecture enhances engineers’ ability to make timely and accurate decisions, especially in geologically complex environments. The combination of sonic evaluation and real-time computation represents a substantial step forward in fluid diagnostics for modern reservoir management.

These three recent patents demonstrate the ongoing innovation in wave-based technologies for well integrity evaluation. They reflect a shift toward real-time, high-resolution, and computationally integrated systems, which enhance the precision, speed, and scope of cement and formation monitoring in modern well environments.

4.2.2. Electrical Technology

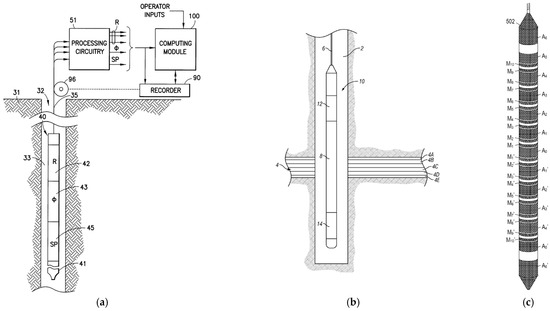

One of the earliest granted patents under the electrical category is US Patent 7555390 B2, issued in June 2009 [72]. This patent introduces a multipass resistivity logging system that allows for repeated measurements at different radial depths within the borehole. The key advantage of this system is its ability to collect time-lapse resistivity data, enabling engineers to better understand fluid saturations, filtrate losses, and formation properties as drilling progresses. As illustrated in Figure 16a, the tool (labeled 40) travels through the borehole (33), collecting resistivity measurements which are then transmitted to a processing circuitry (51) and a computing module (100). These components work together to analyze the data and estimate properties such as water and oil saturation in the formation. By logging resistivity across multiple passes, this tool enhances the resolution and accuracy of formation evaluation and supports better-informed decisions in wellbore management.

Figure 16.

(a) Petrophysical Interpretation of Multipass Array Resistivity Data Obtained While Drilling, patent (US 7555390 B2) [72], (b) Processing of Multi-Component Induction Measurements in a Biaxially Anisotropic Formation, patent (US 8112227 B2) [73], and (c) Multi-Array Laterolog Tools and Methods with Differential Voltage Measurements, patent (US 9547100 B2) [74].

Another significant innovation in this category is US Patent 8112227 B2, granted in February 2012 and owned by Baker Hughes Incorporated [73]. This patent holds the highest extended family count (32) among electrical tools, and has been cited by 20 other patents, making it both widely adopted and influential. As shown in Figure 16b, the system features a resistivity logging tool (labeled 2) designed to measure electrical properties across biaxially anisotropic formations. The surrounding earth layers are denoted as 4A, 4B, 4C, etc., indicating distinct formation zones. Central to the invention is an induction mandrel unit (8) that houses transmitter and receiver coils. These coils are used to induce and detect electromagnetic fields in the formation, allowing the system to estimate anisotropy and resistivity in complex geological structures. The patent’s high family count reflects its international relevance, and its extensive citation record affirms its foundational role in the advancement of modern electrical logging technologies.

The third notable invention is US Patent 9547100 B2, titled “Multi-Array Laterolog Tools and Methods with Differential Voltage Measurements,” granted in January 2017 [74]. This patent introduces a multi-array laterolog resistivity tool, which is designed to acquire resistivity measurements from multiple depths simultaneously. As depicted in Figure 16c, the system utilizes a combination of center, guard, and monitor electrodes to emit and collect a series of electrical currents for differential voltage analysis. These currents are modulated across different frequencies, improving measurement stability and resolution. A key advantage of this tool is its ability to function during drilling operations, making it particularly valuable for real-time formation evaluation. The patent’s extended family size of 22 reflects its widespread acceptance and the tool’s utility in diverse drilling environments.

In addition to resistivity and induction tools, US Patent 9273548 B2, granted in March 2016, represents a notable innovation in electromagnetic-based formation evaluation [75]. Titled “Fiberoptic Systems and Methods for Detecting EM Signals,” this patent holds the highest citation count in the electrical category, having been cited by 20 other patents. The system transmits electromagnetic energy into the formation, which induces electrical currents in conductive rock materials. These currents generate resistive heating, which is detected using fiberoptic sensors integrated into the tool. The inclusion of fiberoptic detection enhances the resolution and accuracy of the system by measuring the thermal response associated with current flow. This dual-sensing approach—combining EM field measurements and fiberoptic thermal sensing—enables more detailed formation characterization, improving engineers’ understanding of subsurface conditions and fluid pathways. Its high citation count reflects its significance as a foundational reference in the evolution of downhole EM sensing technologies.

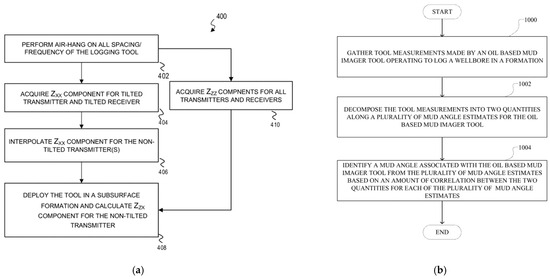

Continuing the trend of advancement, US Patent 11953639B2, granted in April 2024, introduces a novel calibration system for resistivity logging tools [76]. As shown in Figure 17a, the calibration procedure begins by positioning the tool in open air to collect baseline measurements. The tool then acquires data from various angles and distances to fine-tune its performance before being deployed downhole. Once placed in the underground environment, the tool uses the calibration data to continuously self-adjust during logging operations. This approach improves the accuracy and reliability of resistivity readings, particularly under harsh or variable conditions, and helps reduce measurement errors in real time.

Figure 17.

(a) Cross-Component Response Interpolation for Coaxially Oriented Antennas in an Electromagnetic Tool, patent (US 11953639 B2) [76], and (b) Mud Angle Determination for Electromagnetic Imager Tools, patent (SA 5224402 B1) [77].

The second latest innovation in this category is described in Saudi Arabia Patent 5224402 B1, granted in March 2024 [77]. This patent presents a system that uses electromagnetic imaging tools to determine the mud angle, which refers to the orientation of drilling mud relative to the wellbore. As depicted in Figure 17b, the tool collects EM measurement data from within the well and compares it across a range of angular positions. It then identifies the angle that best fits the observed data, thereby providing engineers with more accurate imaging of subsurface formations and fluid-mud interactions. This technology is particularly valuable for geosteering and wellbore stability assessment in real time.

Together, these electrical technology patents illustrate the progression of resistivity- and electromagnetic-based tools in cement bond logging. Each system offers increasing sophistication in data acquisition, signal processing, and formation interpretation, enabling engineers to assess material properties, monitor well conditions in real time, and enhance decision-making accuracy—particularly in complex or anisotropic geological environments.

4.2.3. Radiation Technology

Radiation-based tools, particularly those employing gamma-ray techniques, have long been recognized as crucial instruments for evaluating casing and cement integrity in oil and gas wells. These technologies are valued for their non-invasive capabilities, providing engineers with critical information without disturbing the well infrastructure.

The earliest innovation in this category is RU Patent 2309437 C2, titled “Device for Examining Cement Ring Behind Casing String in Wells and Main Pipelines”, published in October 2007 [78]. This patent introduces a system using a gamma-radiation source and detector to assess the quality of the cement ring behind casing strings. The tool tracks the interaction of gamma rays with the cement and records the reflected signals to identify any voids or weak bonds. This technique ensures accurate cement evaluation and has become widely used in geophysical well research. The principle is conceptually similar to that of US Patent 9546548 B2, which also analyzes radiation reflections to assess bonding integrity.

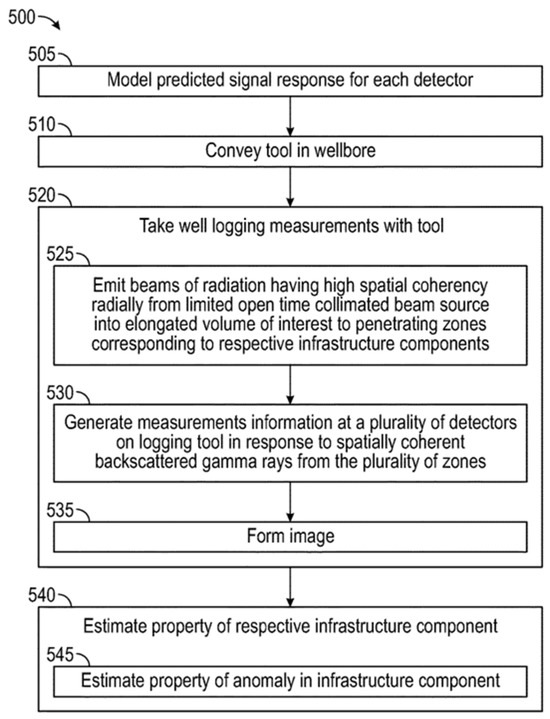

US Patent 10185052 B2, granted in January 2019, holds the highest extended family size among radiation-based tools, with 11 related patents filed internationally [79]. This patent presents a gamma-ray backscatter tool for evaluating both casing and cement conditions. As shown in Figure 18, the tool emits radiation beams that penetrate the surrounding layers and uses multiple detectors to capture backscattered gamma rays. The resulting data allows for detailed, layer-specific analysis of material placement and bonding. The tool’s non-invasive design ensures it can safely collect subsurface data without damaging the wellbore—a major advantage in high-pressure or aging wells.

Figure 18.

Constrained Backscatter Gamma Ray Casing and Cement Inspection Tool, patent (US 10185052 B2) [79].

US Patent 7925483 B2, granted in April 2011, has received the highest citation count among radiation technologies, cited by 25 other patents [80]. This system utilizes natural gamma-ray logging to evaluate geological formations within the wellbore. By measuring ambient radiation, it can distinguish between formation layers, bed boundaries, and other subsurface features. The tool is also capable of generating 3D visualizations of the borehole environment, offering a more complete understanding of geological structures. Although this system also integrates electrical tools, its primary innovation centers on gamma-ray detection and its role in formation characterization.

The most recent advancement is represented by US Patent 11384630 B2, granted in July 2022, which has the highest family size of 18 for radiation tools [81]. This patent introduces a novel approach for verifying gravel pack and cement placement using natural low-level gamma radiation. Gravel packs are critical for preventing sand ingress in production wells, and the ability to confirm their correct installation is essential for well integrity. The system involves lowering a gamma-ray detector into the well to compare real-time data with historical reference measurements. Additionally, Monte Carlo simulations are used to model various gravel pack geometries, significantly improving the accuracy of material placement assessment. This tool enhances confidence in wellbore sealing and contributes to leak prevention during oil extraction.

Together, these radiation-based technologies showcase a clear trajectory of innovation, evolving from early gamma-ray detectors to advanced simulation-integrated systems. Each development emphasizes improved precision, reliability, and operational safety, reinforcing the vital role of radiation logging in modern well integrity evaluation.

4.2.4. Neutron Technology

Neutron-based tools play an essential role in well logging, particularly in assessing fluid movement, formation porosity, and gas saturation. These tools operate by emitting neutrons into the wellbore and surrounding formation. As the neutrons interact with various atoms, they induce nuclear reactions that produce secondary gamma rays, which can then be analyzed to infer important subsurface properties.

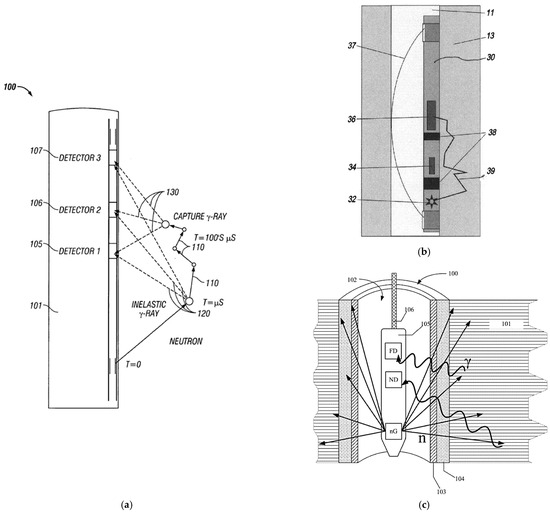

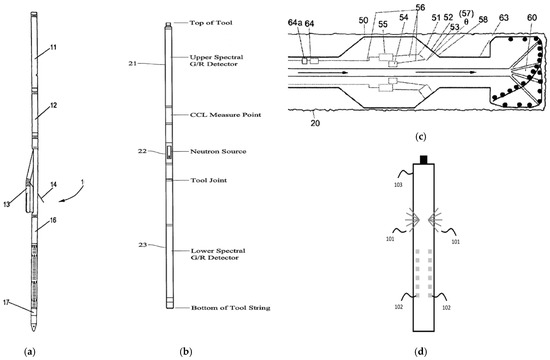

The earliest invention in this category is US Patent 7705292 B2, granted in April 2010 [82]. This patent introduces a system that uses a pulsed neutron generator to measure mud flow velocity and other downhole parameters. The tool emits neutrons into the borehole fluid, which in turn causes the fluid to emit gamma rays. These gamma rays are detected at set distances from the neutron source, allowing the system to calculate how long the fluid takes to travel between detectors. This transit time enables the tool to determine both the flow rate of the borehole fluid and estimate the porosity of the surrounding rock. The key innovation lies in the activation of borehole fluid through neutron bombardment, followed by gamma-ray detection, yielding valuable real-time insight into dynamic fluid behaviors within the well.

The first Russian patent listed in this section, RU Patent 2411551 C2, was granted in 2011 and holds the highest extended family count in the neutron category, with 21 related filings [83]. This system applies pulse neutron logging to evaluate gas saturation and pressure within the formation. Like US 7705292 B2, this tool uses a pulsed neutron source, but its objective differs—it is primarily concerned with formation analysis rather than borehole fluid. As shown in Figure 19a, the tool includes a neutron source (101) and three gamma-ray detectors (105, 106, 107) positioned at different distances to measure the time-based gamma-ray emissions from neutron interactions with surrounding media. The tool also employs a Monte Carlo simulation framework to model gas saturation without depending on high-speed neutron transport data. This simulation capability, paired with real-time acquisition, provides more robust and accurate formation evaluation. The broad international patent family highlights the widespread applicability and influence of this technology.