1. Introduction

Valuable minerals in iron ores mainly consist of iron oxide minerals, while gangue minerals are largely composed of quartz [

1,

2]. Elevating the concentration of valuable minerals to meet market specifications is a key focus of iron ore mineral processing facilities. Currently, the dominating approach for achieving this objective is through reverse flotation. When dealing with a low amount of low-quality iron ore or predominantly small particles, magnetic separators offer a viable solution. This is especially important when recovering materials from tailing dams or the reject slime generated during the beneficiation process [

3].

Wet High-Intensity Magnetic Separators (WHIMSs) exploit the contrasting magnetic properties between iron oxide minerals and quartz to facilitate efficient mineral concentration. By generating a robust magnetic field, these separators attract iron particles to metallic matrices while efficiently discarding quartz particles. Typically, WHIMS devices feature a continuously gyrating carousel of metallic matrices, continuously fed by a stream of water and mineral particles slated for concentration. Iron particles exhibit a higher affinity for attaching to the metallic matrices, while quartz particles are washed away by water. The material undergoes successive passages through a series of separators until the desired concentration level is achieved. This method proves particularly advantageous for large-scale, continuous production of iron ore, making a WHIMS the preferred separator in such operations.

The concentration performance of a WHIMS is subject to various operational factors. Some pertain to the incoming mineral-laden stream, including the concentration of iron and particle size distribution, while others are intrinsic to the device itself, such as the generated magnetic field intensity. The magnetic field, spanning from 1 to 2 Tesla in a WHIMS, is produced by an array of industrial coils connected to an electric energy AC-DC converter.

The tough conditions at a mineral processing facility, along with unreliable energy, create operational challenges that result in substantial wear and tear on the coils over time. As a result of this wear and tear, damages occur that not only reduce the strength of the magnetic field, but also cause a disruption in the even flow of current through the coil assembly. The deterioration leads to a decrease in the magnetic attraction between iron particles and metallic matrices, causing a significant drop in the efficiency of WHIMS separation. Detecting coil malfunction is crucial for maintaining optimal functionality and ensuring consistent and efficient magnetic separation processes within mineral processing operations.

In the present scenario, the maintenance plan for WHIMSs requires a production halt, as a human operator needs to be present to measure the magnetic field using a handheld Gaussmeter. This procedure poses significant challenges, especially for large-scale mining companies processing thousands of tons of minerals per hour. The large number of new devices makes the logistical complexities of this method even worse. Furthermore, the usual long intervals between successive measurements may permit prolonged periods of suboptimal equipment performance, translating directly into financial losses.

While some suggest using laboratory analysis of the reject flow concentration as an alternative for issue detection, this approach has inherent limitations. The results obtained using this method are often affected by masking effects caused by factors like changes in the input flow concentration. Moreover, laboratory analysis is constrained by costs, delays between sample collection and analysis results, and the need for human operators to work in safety-restricted environments [

4]. Laboratory analysis alone does not directly pinpoint the root cause of coil damage, making it difficult to identify and resolve issues affecting WHIMS performance. There is a pressing need for innovative strategies to address the drawbacks of the current maintenance approach. This will ensure timely intervention and sustained operational efficiency in large-scale mineral processing operations.

This paper introduces a simple yet powerful method for identifying reduced performance in WHIMSs due to low magnetic field generation. The proposed approach involves measuring the current within each set of coils that generates the magnetic field. The observable imbalance in current amplitude indicates a potential reduction in field strength for certain coils, along with an undesired surge in current for others. Such imbalances not only compromise the effectiveness of the WHIMS but may also lead to a faster degradation of the coil’s lifespan. This method’s real-time diagnostic capability, enabled by continuous current measurements, provides a proactive and responsive way to promptly identify and address issues. This enhances the operational longevity and efficiency of the WHIMS. The experiments were performed in an iron ore mineral processing company in Itabira, Minas Gerais, Brazil.

2. Motivation

Figure 1 illustrates the average iron concentration values for two output streams (concentrate and reject) across twenty-three magnetic separators (number of magnetic separators working at that time. For sake of simplicity, the tag numbers for the WHIMS in this paper do not correspond to the tag numbers in the facility) within the examined mineral processing facility. These averages were derived from a two-month evaluation period, during which samples were collected and analyzed in the laboratory every four hours. The incoming stream maintained a relatively stable iron concentration, averaging around 31%, with slow variations over time and a maximum deviation of less than 2%. While minor fluctuations were observed, they were not substantial enough to impact the interpretation of overall trends or justify a detailed plot of the input grade time series. The critical performance metric for this process is the percentage of iron ore present in the reject stream, which is expected to remain below 9.5%. However, fourteen out of the twenty-three magnetic separators failed to meet this prescribed threshold. The primary reason for such underperformance is attributed to inadequate magnetic field intensity.

It is important to emphasize that the magnetic separator only functions when a magnetic field is actively applied. There is no auxiliary or alternative separation mechanism in the WHIMS; the equipment is entirely dependent on the magnetic field to attract iron-bearing particles to the matrix. While other operational factors—such as feed rate, particle size distribution, or matrix condition—can affect overall performance, these are secondary in nature. The fundamental prerequisite for any separation to occur is the presence of a sufficiently strong and uniform magnetic field. Therefore, verifying whether the equipment is effectively generating this field is not just relevant—it is essential.

The insufficient magnetic field intensity stems from issues within the coils, exacerbating the situation. Moreover, when one coil experiences an increase in impedance to the electric current, it results in overcurrent flowing through the parallel coils within the same separator. This cascade effect not only leads to the failure of the affected coil but also accelerates the wear of the neighboring coils. We emphasize that the replacement cost for a single coil in such equipment can amount to USD 40,000.00 each. This figure solely represents the cost of the coil itself, excluding expenses related to service and the downtime incurred during the replacement process, resulting in significant financial implications for the operation.

Given the significant production losses and additional expenses incurred from replacing worn coils, it is critical to investigate methods for promptly detecting insufficient magnetic field intensity as it occurs. Despite extensive efforts in exploring marketing solutions, consulting with top magnetic sensor developers, and thoroughly reviewing the relevant literature, an effective solution still seems out of reach. This emphasizes the need for research and innovation in this important area to reduce the harmful effects of low magnetic field intensity on operational efficiency and cost-effectiveness in mineral processing facilities.

Although current measurement is a well-known technique in electrical engineering, its application to WHIMS diagnostics is both novel and impactful. Existing strategies for identifying performance loss in magnetic separators tend to rely on indirect or delayed feedback, such as product grade analysis or periodic field measurements. Our approach repositions a simple, cost-effective method within a new context—offering a direct and real-time diagnostic tool for detecting coil degradation, which has not been systematically addressed in prior WHIMS studies.

3. Literature Review

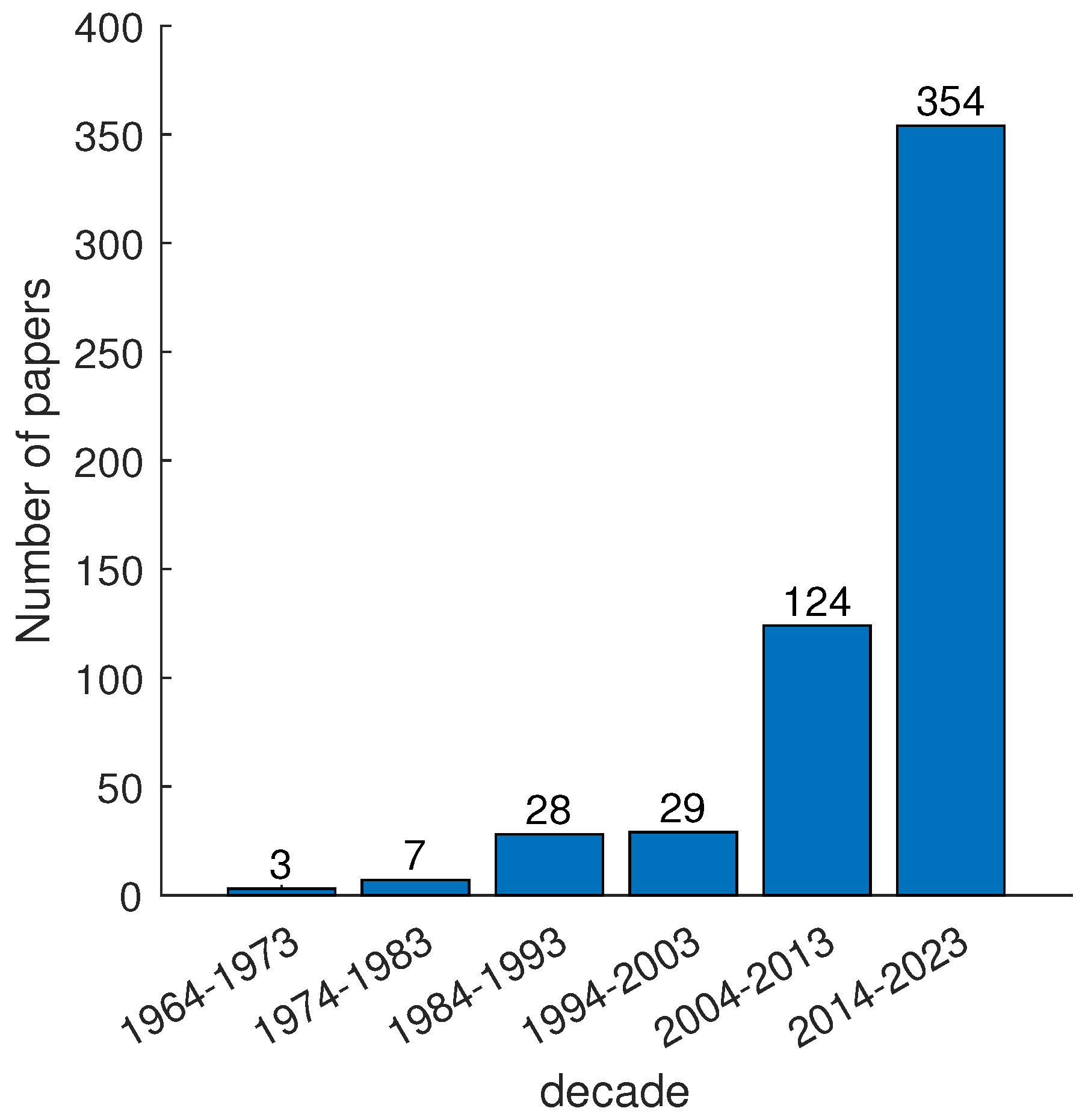

Given the importance of this topic in the mineral industrial sector, it is surprising that there are so few papers available on magnetic separators. However, it is evident that interest in this area is growing rapidly within scientific circles. For example,

Figure 2 visually illustrates the growing number of papers published using the term “Wet High-Intensity Magnetic Separator” in the Google Scholar search engine, highlighting the current trend and growing interest in this area of study.

Many studies on Wet High-Intensity Magnetic Separators (WHIMSs) assess their performance under varying operational conditions, such as changes in feed mineral characteristics. Angadi et al. [

5] investigated the factors affecting particle separation in WHIMSs, emphasizing the influence of magnetic field strength, particle size, and wash water rate on magnetic recovery, with regression models predicting yield and grade. da Rocha et al. [

3] focused on recovering iron from ore tailings in Minas Gerais, Brazil, achieving a 63% iron grade concentrate through optimized processing configurations, underscoring the importance of cleaning stages. Ribeiro and Ribeiro [

6] introduced mega-sized WHIMS technology, setting new world records for magnetic separators’ feed rates, with ongoing construction of concentration plants in Brazil for reclaiming low-grade iron ore tailings. Makhula [

7] explored the Longi LGS 500 WHIMS for South African iron ore, identifying significant effects of operating parameters on concentrate yield and iron grade, with the potential to produce a 55% Fe product. Furthermore, research efforts have delved into modeling and simulation of WHIMSs, as exemplified by [

8,

9]. Additionally, recent attention has been drawn to environmentally friendly approaches, leading to investigations and patents exploring the transition of WHIMSs to dry operation, as demonstrated by studies such as [

10,

11].

However, the majority of these studies assume ideal operational conditions, with the magnetic field set according to manufacturer specifications. It is remarkable that none of the reviewed papers delved into the issue of coil degradation over time or proposed efficient means of detecting it. This oversight shows a significant gap in the current literature on WHIMS performance and maintenance.

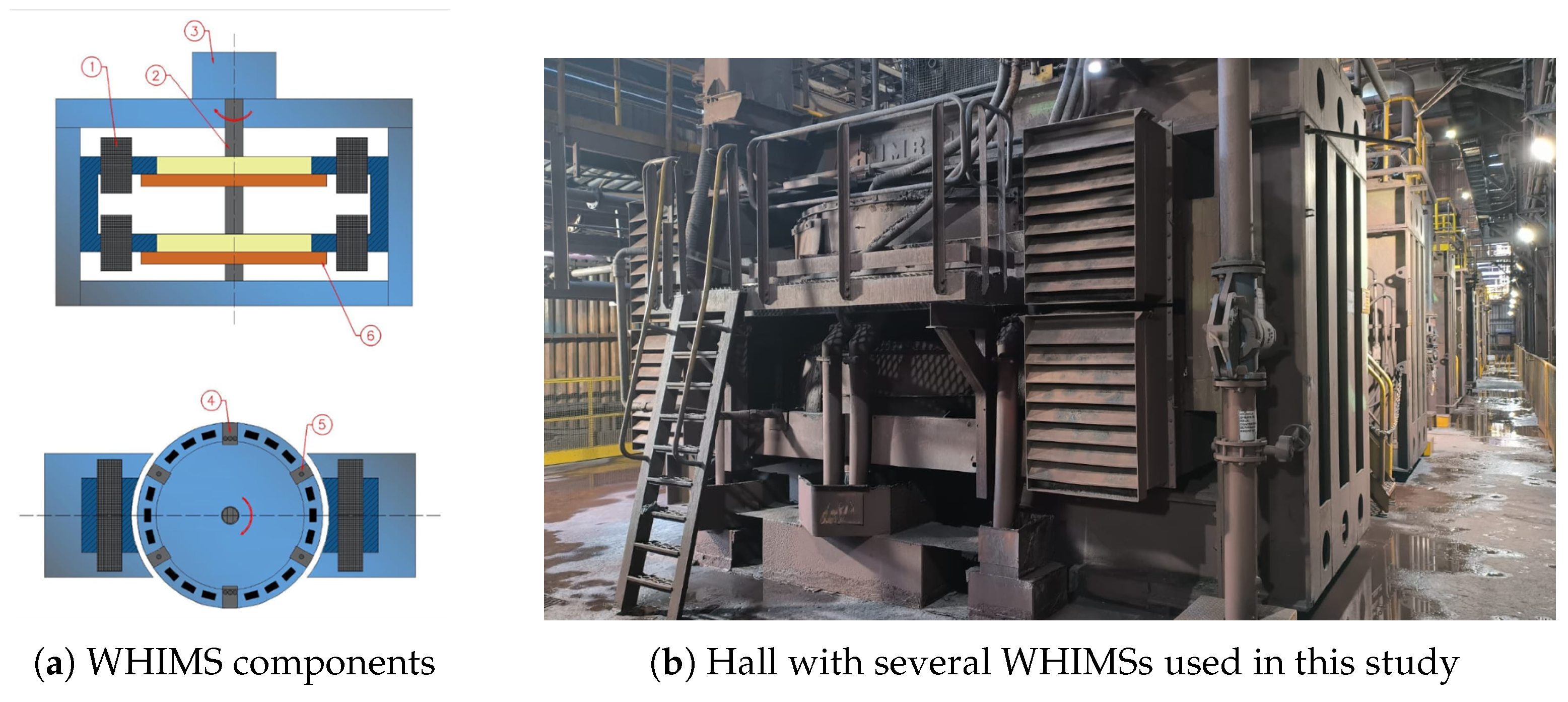

4. The WHIMS

Valuable minerals from ore streams are extracted using a specialized device called a Wet High-Intensity Magnetic Separator (WHIMS) in mineral processing facilities. The fundamental concept behind a WHIMS is to utilize the differences in magnetic characteristics of various minerals, using a strong magnetic field to extract and segregate paramagnetic and ferromagnetic particles from nonmagnetic ones. To achieve concentration, a rotating carousel of metallic matrices in the WHIMS is consistently fed with a mixture of water and mineral particles. The equipment used in this study was a Jones WHIMS model, manufactured by KHD Humboldt Wedag GmbH, which is widely adopted in industrial mineral processing for its high magnetic field intensity and multi-coil design. Each WHIMS unit is equipped with four independent coil sets, which are electrically powered in parallel via an AC-DC converter, resulting in a magnetic field that reaches 1 to 2 Tesla. As the material moves through the separator, the magnetic particles are attracted to the matrices due to the magnetic field, while the nonmagnetic particles are carried away by water.

Figure 3 shows the components of a typical WHIMS and a photo of the actual WHIMS group used in this study.

It is noteworthy that the material fed into the WHIMS typically goes through several preliminary processing stages. Typically, stages such as crushing, milling, and screening are integral parts of the beneficiation process. In our case, there is also the extra flotation stage. As a result, the material flow that enters the separator is already subjected to a strict concentration and particle size range. This pre-processing ensures that the material is well prepared for efficient separation within the WHIMS, optimizing its performance in concentrating valuable minerals from the ore stream.

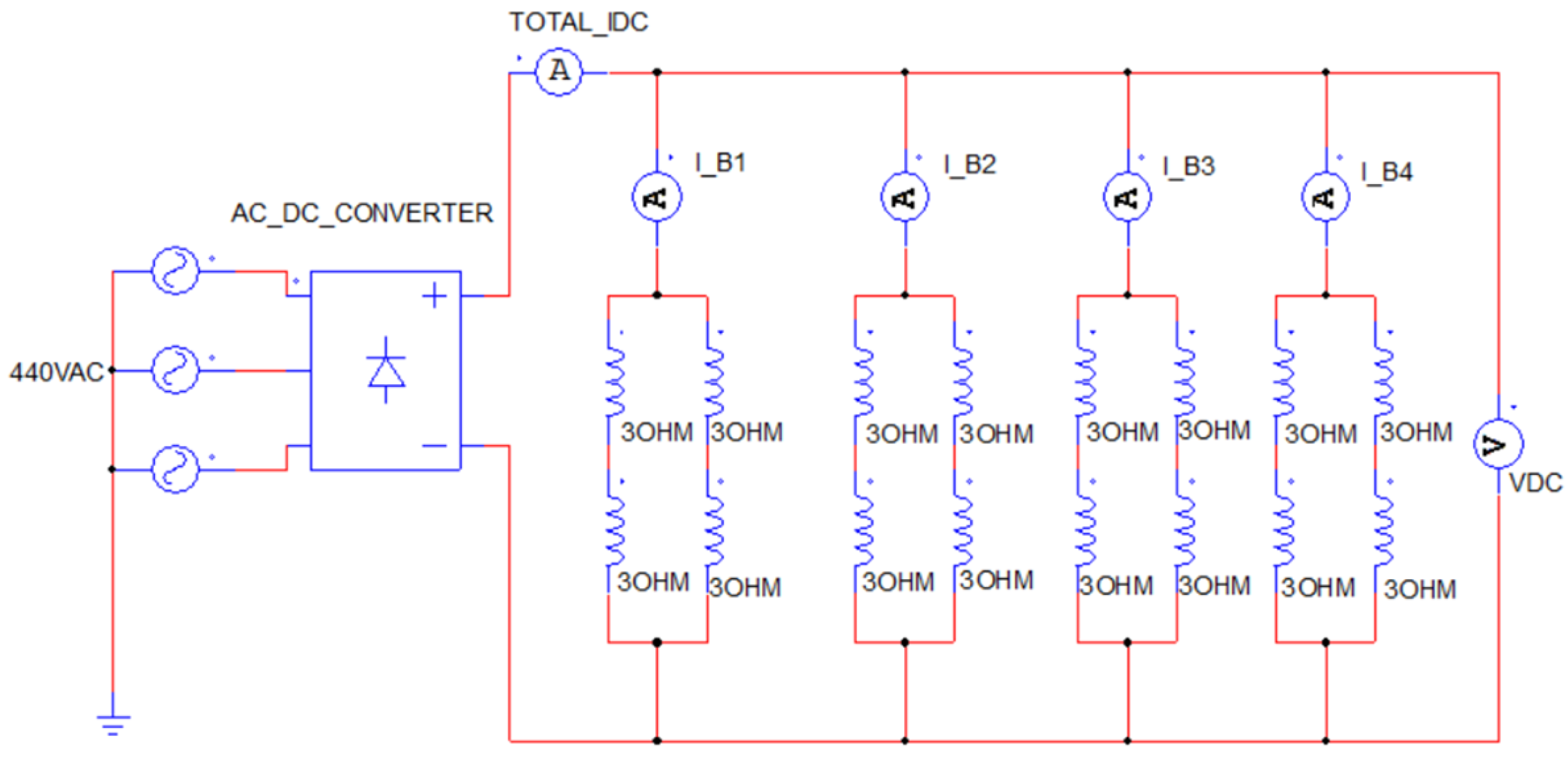

5. The Proposed Method

The proposed method aims to detect reductions in the intensity of the magnetic field provided by the WHIMS, with the key requirement being real-time measurement without the need for modifications to the equipment structure. Moreover, the method seeks to circumvent the costly use of laboratory analysis. To achieve this, the authors propose investigating the behavior of each set of coils in the WHIMS by measuring their currents. As depicted in

Figure 4, our approach involves incorporating an ammeter (denoted as

,

,

, and

, in the figure) into each of the four lines that power the coil sets, offering a particularly robust and straightforward implementation that avoids the need for structural alterations to the WHIMS, such as the installation of new sensors.

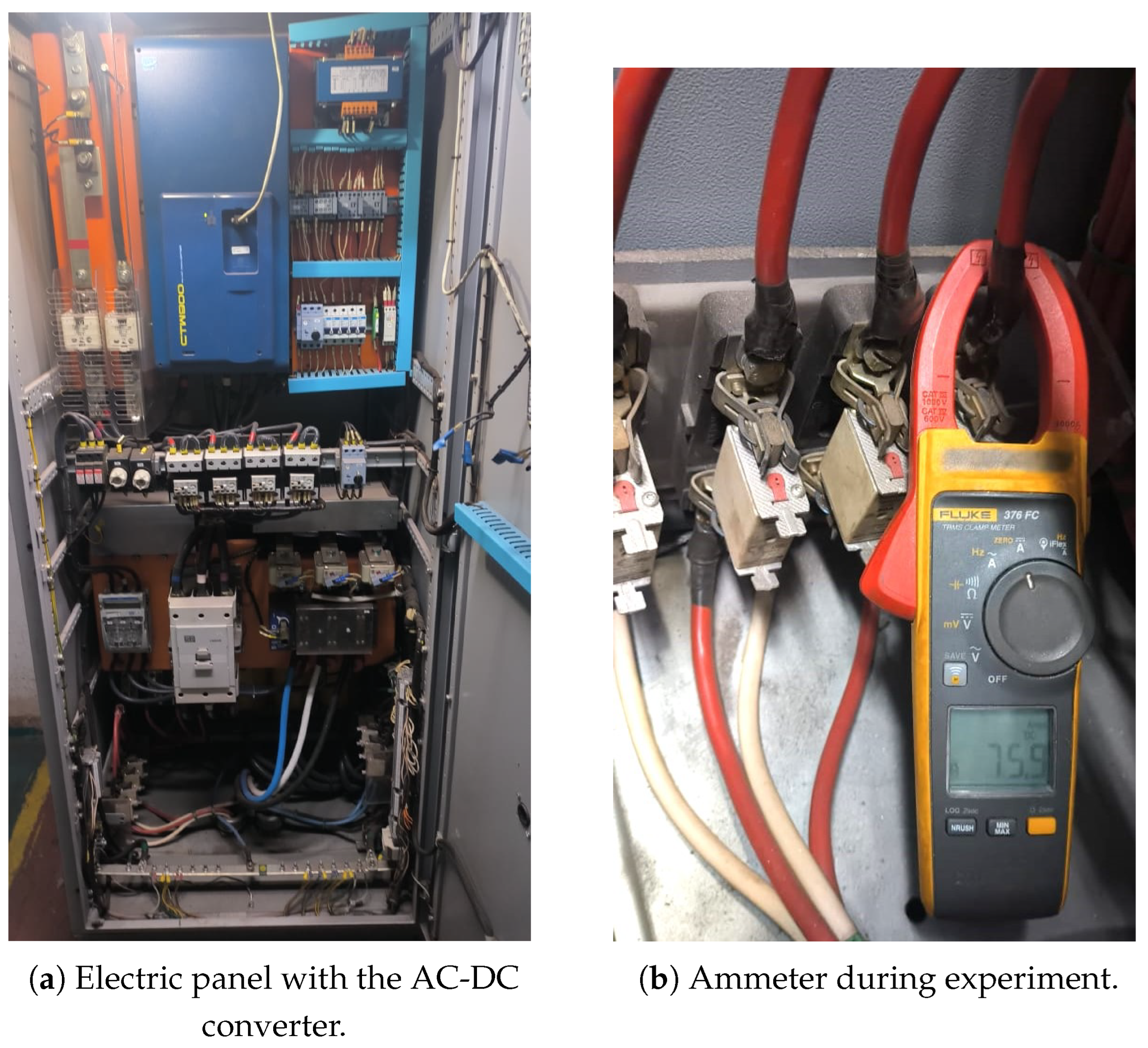

Figure 5 illustrates the electric panel featuring the AC-DC converter and the lines powering the coils. In this exploratory study, handheld ammeters are utilized, although future iterations may integrate fixed ammeters connected to a supervisory system.

6. Results and Discussion

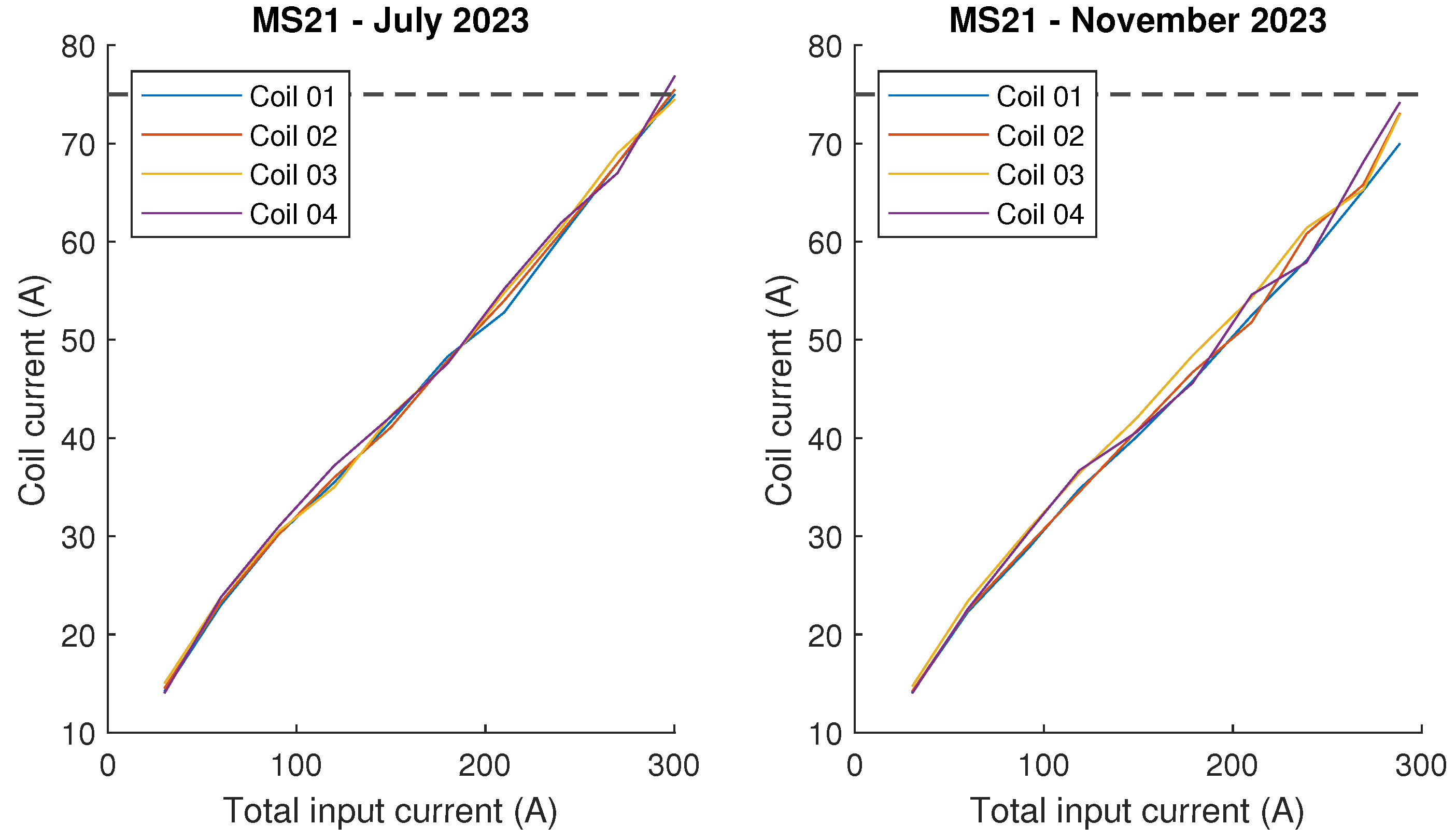

Given the operator’s ability to adjust the current set-point in the AC-DC converter, we opted to vary this total current and assess the corresponding current across the coil sets in each magnetic separator under study. The magnetic separators operated continuously during the experiments, processing material as usual. We conducted tests on six out of twenty-three magnetic separators, selected based on the accessibility and ease of manipulation of the electric panel. The experiments were conducted twice, once in July and again in November, using the same equipment without any intervening maintenance. Magnetic separators designated as MS08, MS18, MS21, and MS23 yielded expected results. For simplicity, we present in

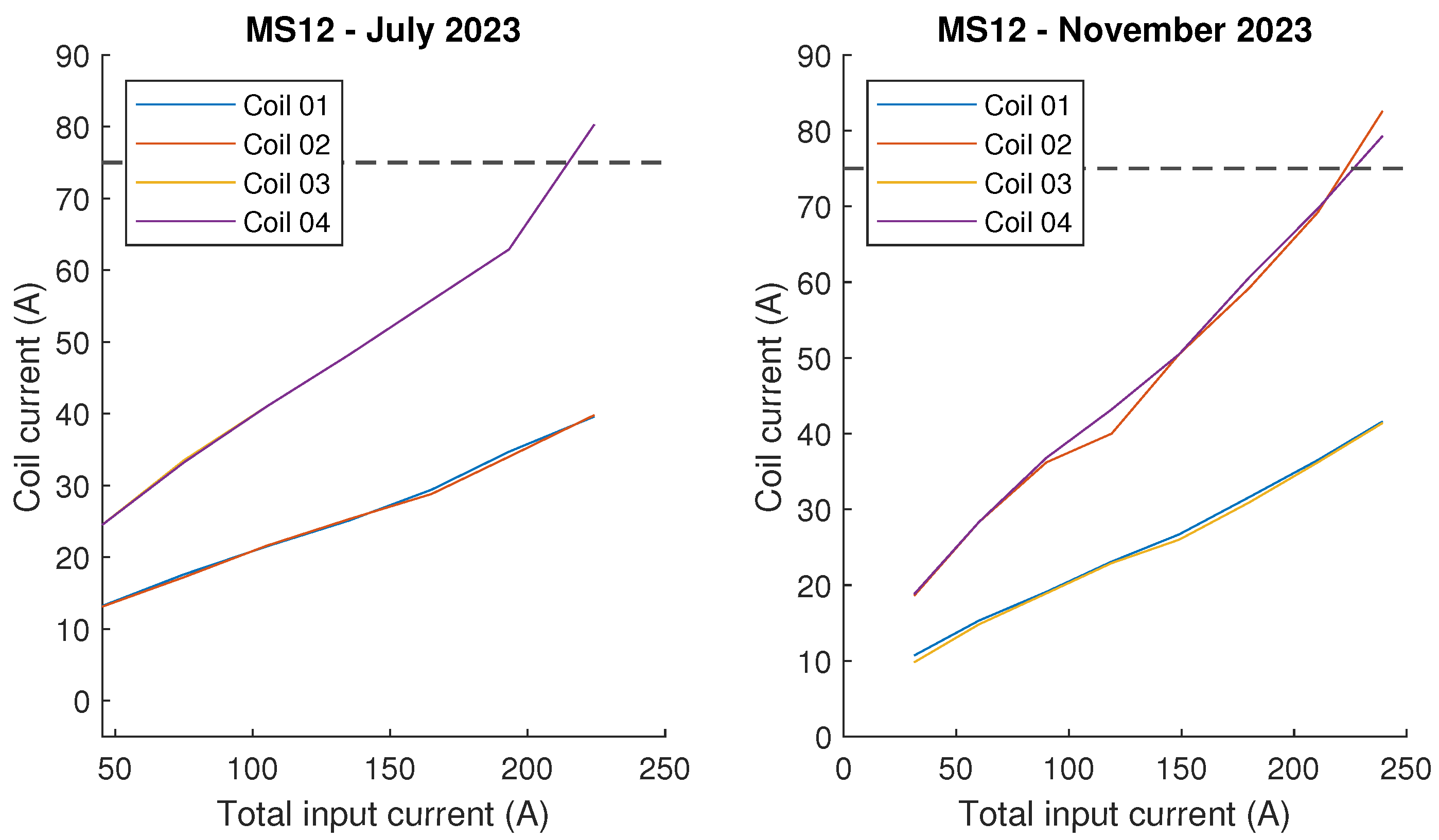

Figure 6 the results of a single successful case wherein all coils functioned properly—other curves exhibit identical patterns. Uncommon current behaviors were observed in only two instances, specifically for MS12 (

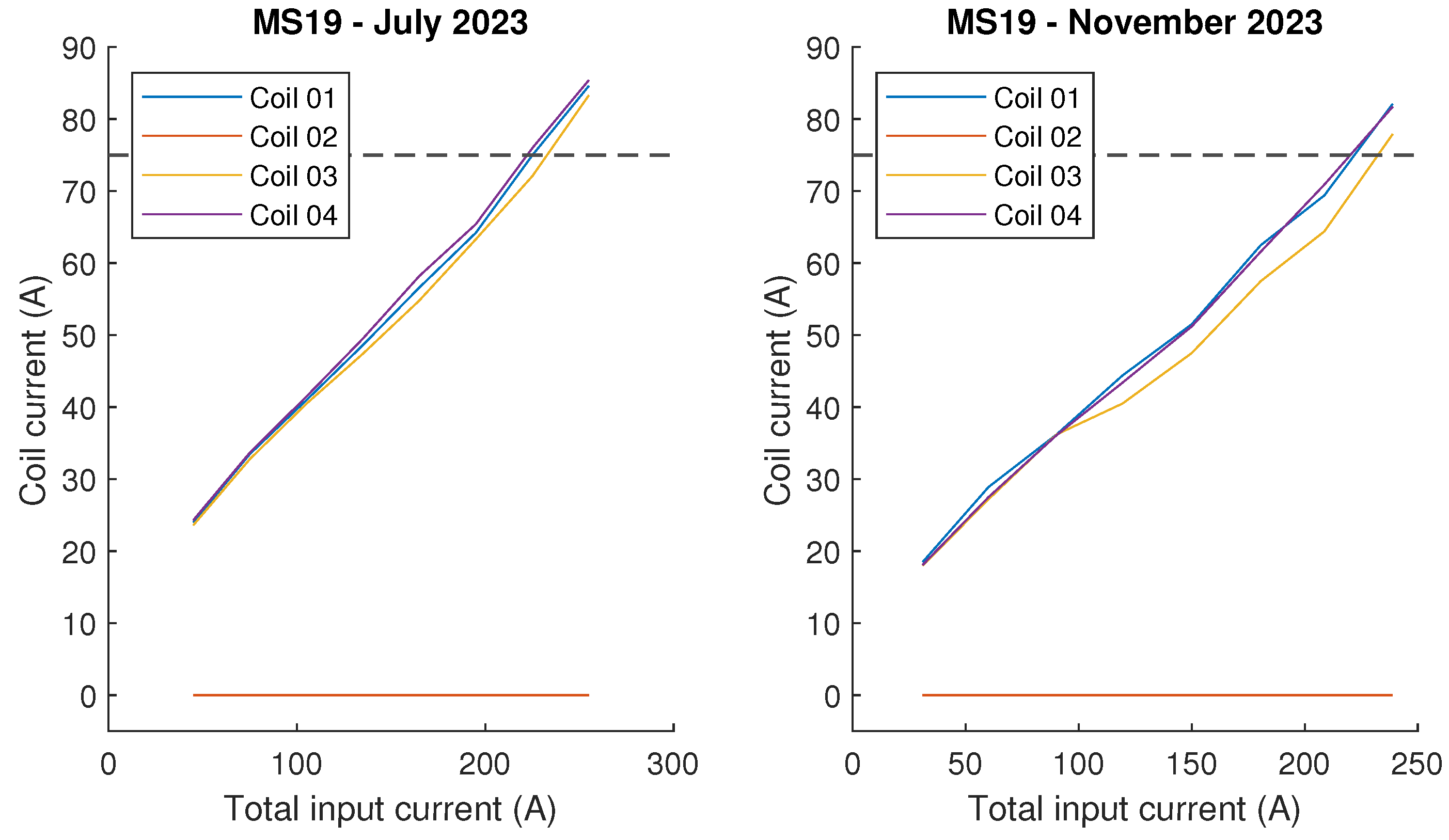

Figure 7) and MS19 (

Figure 8), which persisted consistently across both months.

As depicted in the graphs of

Figure 6, the current flowing through each set of coils exhibits a consistent amplitude across all four sets. This uniform distribution suggests that none of the sets is experiencing significant resistance to current flow. Furthermore, even under maximum input current conditions (300 A), the current through the coils remains within the factory-established limit of 75 A. However, it is worth noting that in November, the curves do not overlap as closely as they did previously. This discrepancy could indicate wear, although further research is needed to confirm this hypothesis.

Figure 7 and

Figure 8 depict the disparities in current flow across the coil sets in separators MS12 and MS19, respectively. In the case of MS12, variations in current values are evident between two sets of coils, whereas for MS19, no current flows through set number 2, indicating an open circuit path. Notably, in both instances, the reduction in current in certain sets results in higher current values in the remaining sets. While operators have the flexibility to adjust the current set-point in the converter, the total current is typically maintained at the maximum limit of 300 A. Consequently, it is evident in the case of MS19 and MS12 that individual coil currents exceed the factory limit of 75 A, potentially accelerating the wear of these coils.

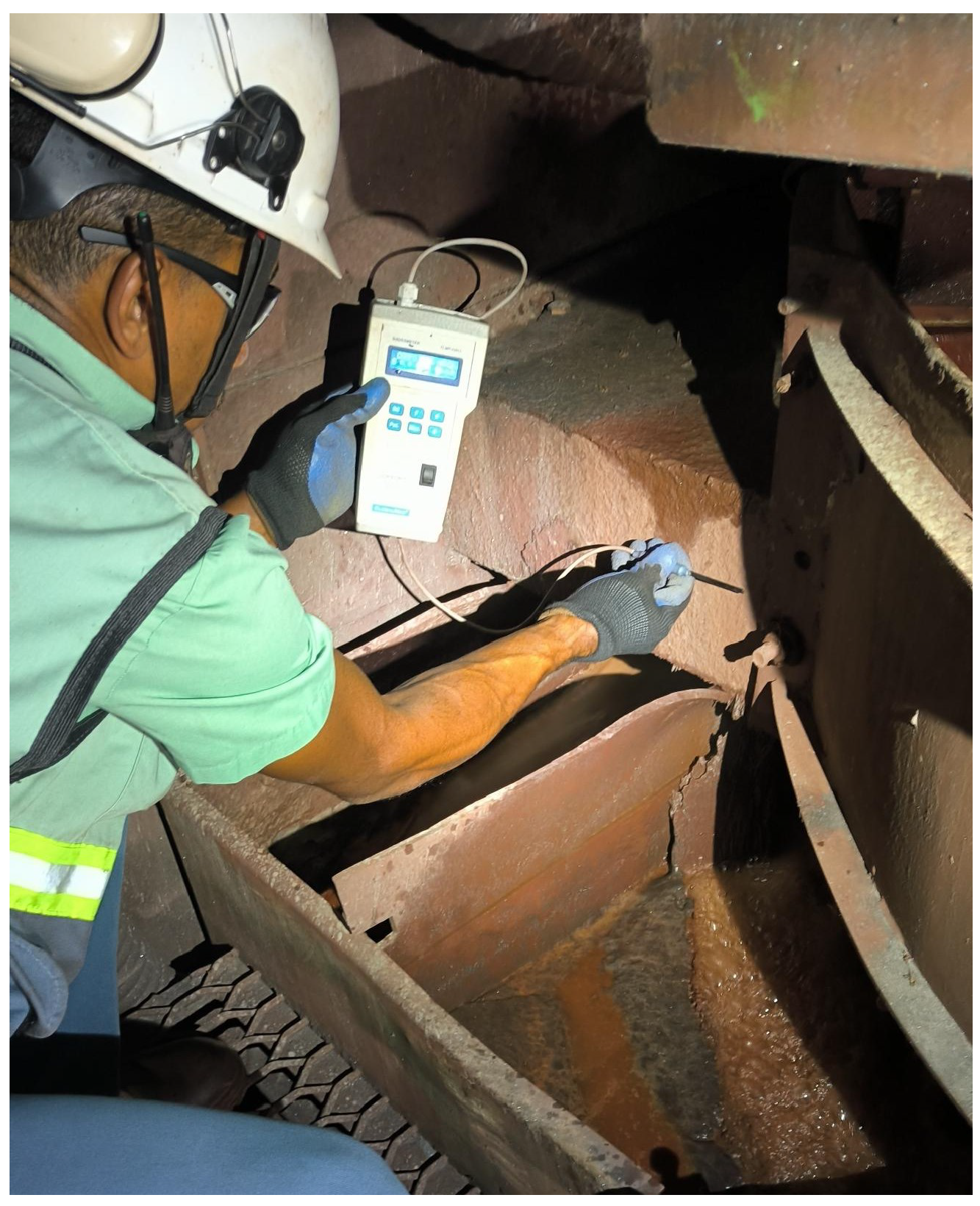

To verify whether variations in current flow through the coils correspond to differences in performance, we conducted magnetic field measurements in each of the studied WHIMSs. Typically, the manufacturer’s recommended procedure involves measuring the magnetic field within the carousel during interrupted production, aiming for a field intensity of 15,000 Gauss. However, to avoid production interruptions and obtain a more detailed assessment of the magnetic field from each set of coils, we devised an alternative approach. Illustrated in

Figure 9, we utilized a handheld Gaussmeter to measure the field intensity at each connection point between the set of coils and the metallic wall of the carousel. The results, presented in

Table 1, encompass the entire analysis of the magnetic separators. As anticipated, separators MS08, MS18, MS21, and MS23 exhibited no issues with their coils, yielding a consistent field intensity measurement of approximately 4100 Gauss. Conversely, MS12 and MS19 showed a notable reduction in field intensity. Notably, for MS19, where one set of coils exhibited an open-circuit condition, resulting in zero current flow through that coil set, the field intensity measured less than 15% of that of a regular set of coils, suggesting that the measurement may primarily reflect the field generated by the other three sets of coils.

7. Conclusions

In conclusion, our study emphasizes the importance of addressing coil degradation in Wet High-Intensity Magnetic Separators (WHIMSs) to maintain sustained operational efficiency in mineral processing facilities. By proposing a new and simple method to detect coil degradation through real-time monitoring of current measurements in coil sets, we provide a practical solution to quickly identify and address issues. Importantly, our method’s modifications occur outside the magnetic separator, specifically at the electric panel in the AC-DC converter, making it adaptable across various manufacturers. This flexibility makes it more useful in different operational environments. Our experimental analysis and statistical modeling show strong evidence of the significant effect of coil degradation on WHIMS efficiency, highlighting the need for proactive maintenance strategies. Our proposed method promises to revolutionize maintenance practices, ensuring improved operational longevity and efficiency in large-scale mineral processing operations.

Looking ahead, we aim to expand this work in two key directions. First, we plan to correlate coil current measurements with specific failure modes using machine learning techniques, as in [

13], and define threshold values that can reliably trigger maintenance actions. Second, we intend to perform a cost-effectiveness analysis to assess the return on investment of implementing the proposed monitoring system across multiple WHIMS units. This will include hardware costs, deployment scalability, and the potential reduction in operational losses due to early fault detection.

Author Contributions

Conceptualization, A.K.R.S.; Methodology, R.B.V.; Validation, R.B.V.; Formal analysis, R.B.V., A.K.R.S. and T.A.M.E.; Investigation, R.B.V.; Resources, R.B.V. and T.A.M.E.; Writing—original draft, R.B.V.; Writing—review & editing, T.A.M.E.; Supervision, A.K.R.S. and T.A.M.E.; Project administration, T.A.M.E.; Funding acquisition, T.A.M.E. All authors have read and agreed to the published version of the manuscript.

Funding

Thiago A. M. Euzébio and Alan K. Rêgo Segundo acknowledge the Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq) through grant 306394/2021-9 and 306720/2022-1, respectively. The APC was funded by Helmholtz-Zentrum Dresden-Rossendorf.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors acknowledge the Universidade Federal de Ouro Preto, Instituto Tecnológico Vale, CAPES, and FAPEMIG. We acknowledge also the comments and recommendations of the anonymous reviewers that have contributed to improve the quality of our work.

Conflicts of Interest

Author Ricardo B. Ventura was employed by the company Vale S.A. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Li, Y.; Li, S.; Zhao, X.; Pan, X.; Guo, P. Separation and purification of high-purity quartz from high-silicon iron ore tailing: An innovative strategy for comprehensive utilization of tailings resources. Process Saf. Environ. Prot. 2023, 169, 142–148. [Google Scholar] [CrossRef]

- Chen, K.; Liu, L.; Zuo, W.; Yin, W.; Sheng, Q.; Yao, J. Modeling the Liberation of Quartz in Low-Grade Iron Ores from Different Iron Deposits. Min. Metall. Explor. 2023, 40, 2495–2504. [Google Scholar] [CrossRef]

- da Rocha, R.B.; Reis, É.L.; Ribeiro, J.P. Wet High-Intensity Magnetic Separators (WHIMS) for recovering iron from tailings deposited in dams. Miner. Process. Extr. Metall. Rev. 2021, 42, 17–23. [Google Scholar] [CrossRef]

- Lott, G.D.; Da Silva, M.T.; Cota, L.P.; Guimarães, F.G.; Euzébio, T.A. Fuzzy Decision Support System for the Calibration of Laboratory-Scale Mill Press Parameters. IEEE Access 2021, 9, 24901–24912. [Google Scholar] [CrossRef]

- Angadi, S.I.; Jeon, H.S.; Mohanthy, A.; Prakash, S.; Das, B. Analysis of wet high-intensity magnetic separation of low-grade Indian iron ore using statistical technique. Sep. Sci. Technol. 2012, 47, 1129–1138. [Google Scholar] [CrossRef]

- Ribeiro, J.P.; Ribeiro, C.H.T. New mega-sized wet high intensity magnetic separator: A cost-effective solution to reclaim iron ore fines from tailing dams. Rem Rev. Esc. Minas 2013, 66, 529–533. [Google Scholar] [CrossRef]

- Makhula, M.J. Beneficiation of Fine Ores Using the Longi Wet High Magnetic Separator. Ph.D. Thesis, University of the Witwatersrand, Faculty of Engineering and the Built, Johannesburg, South Africa, 2014. [Google Scholar]

- Tucker, P. Modelling wet high intensity magnetic separation: A case study. Miner. Eng. 1994, 7, 1281–1300. [Google Scholar] [CrossRef]

- Rasool, R.; Lieberwirth, H. A continuum based numerical modelling approach for the simulation of WHIMS. Miner. Eng. 2018, 118, 97–105. [Google Scholar] [CrossRef]

- de Souza, L.C.O.; Lima, N.P.; Euzebio, T.A.M.; Pinto, T.V.B.; Silva, K.C. Method and System for Removing Iron Ore Particles Adhering by Magnetic Hysteresis to a Magnetic Matrix of a Vertical Magnetic Separator. U.S. Patent App. 18/037,049, 25 January 2024. [Google Scholar]

- Hu, Z.; Lu, D.; Wang, Y.; Zheng, X.; Zhang, Y. A novel pneumatic dry high-intensity magnetic separator for the beneficiation of fine-grained hematite. Powder Technol. 2024, 433, 119216. [Google Scholar] [CrossRef]

- Xiong, D.; Lu, L.; Holmes, R. Developments in the physical separation of iron ore: Magnetic separation. In Iron Ore; Elsevier: Amsterdam, The Netherlands, 2015; pp. 283–307. [Google Scholar]

- Matos, S.N.; Pinto, T.V.; Domingues, J.D.; Ranieri, C.M.; Albuquerque, K.S.; Moreira, V.S.; Souza, E.S.; Ueyama, J.; Euzébio, T.A.; Pessin, G. An Evaluation of Iron Ore Characteristics Through Machine Learning and 2D LiDAR Technology. IEEE Trans. Instrum. Meas. 2023, 73, 1–11. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).