Fast-Gated 16 × 1 SPAD Array for Non-Line-of-Sight Imaging Applications

Abstract

1. Introduction

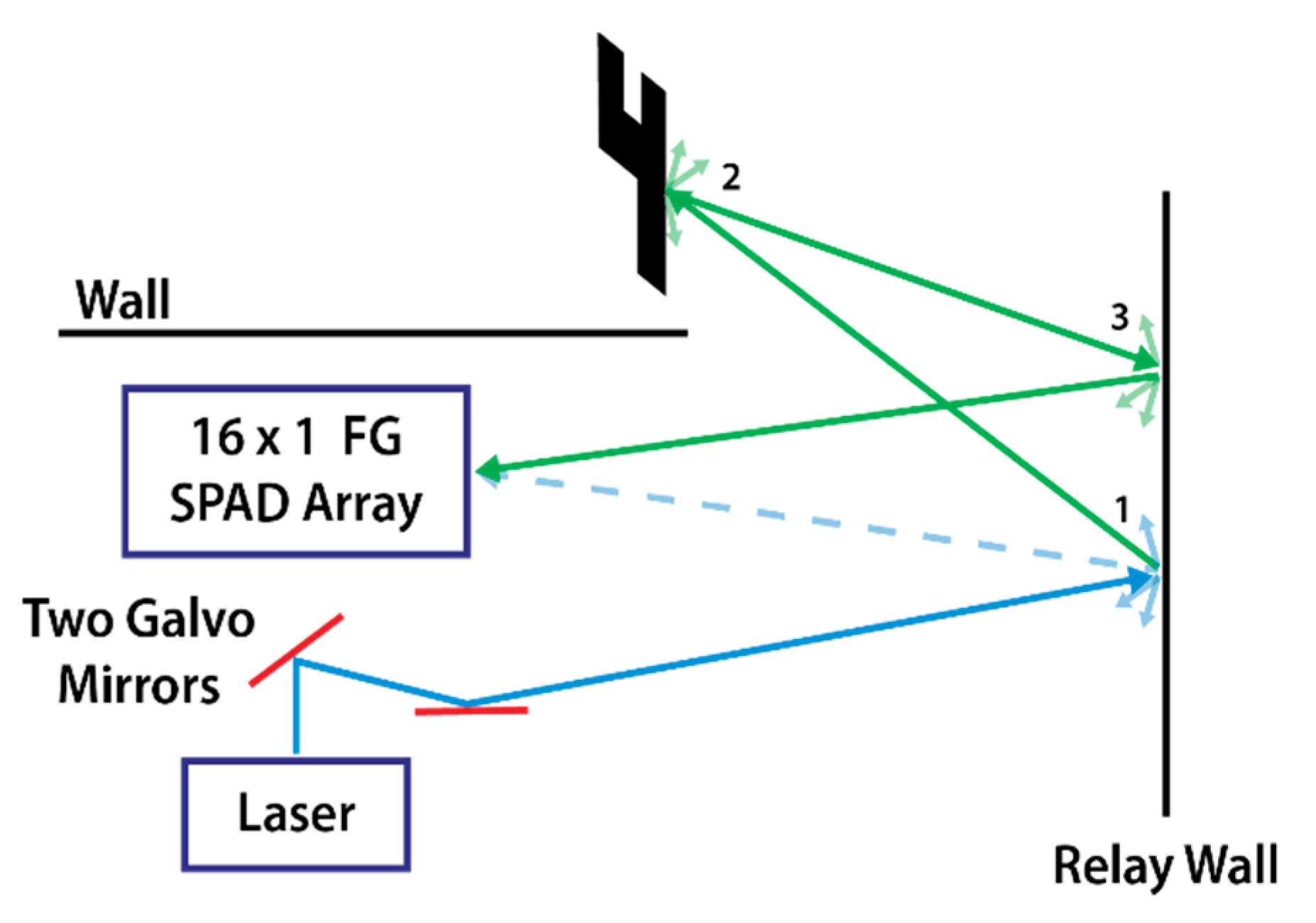

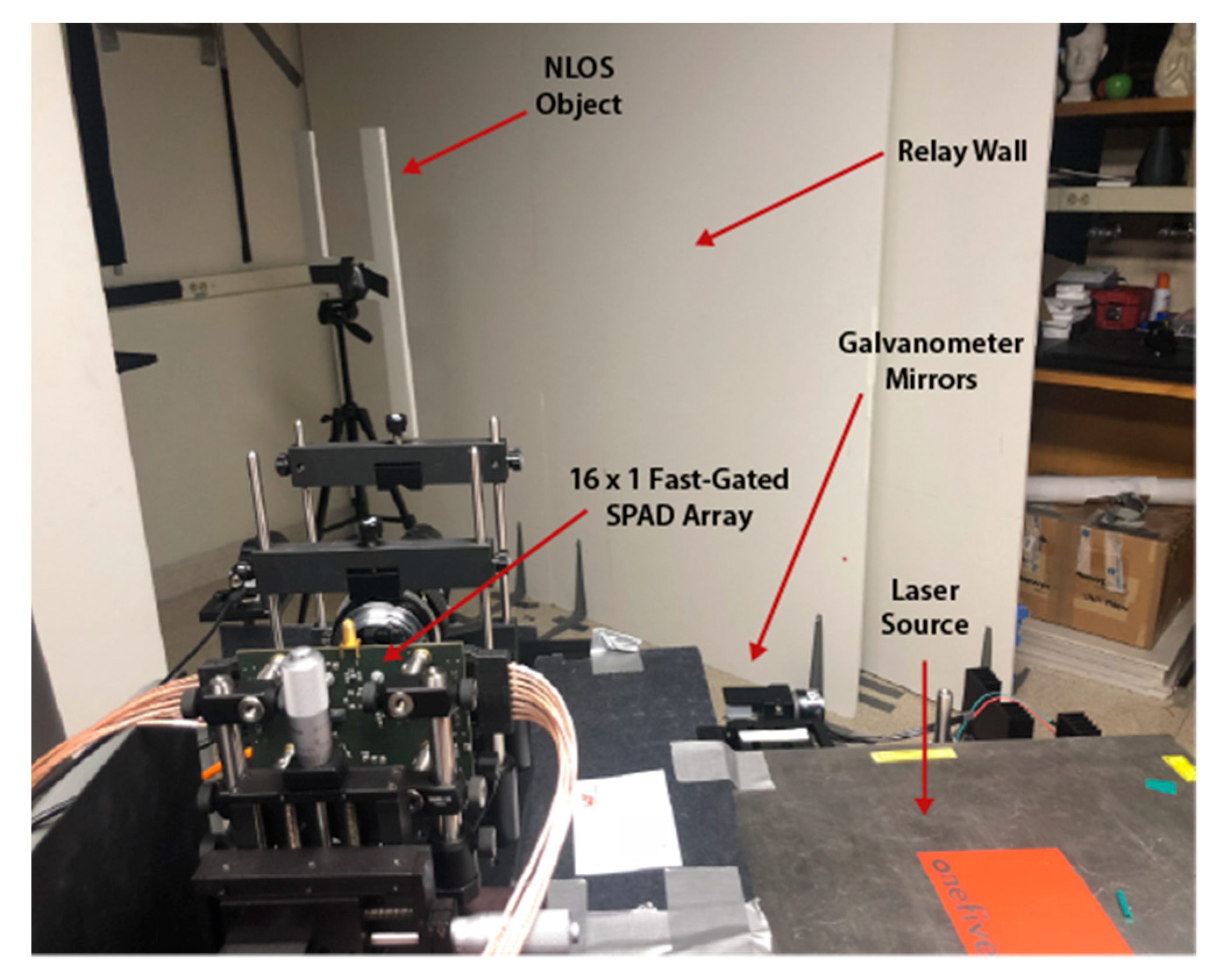

2. Non-Line-of-Sight Imaging

2.1. NLOS Systems and Reconstruction Techniques: State-of-the-Art

2.2. Improvements in NLOS Reconstruction: The Phasor-Field Method

3. Instrument Design

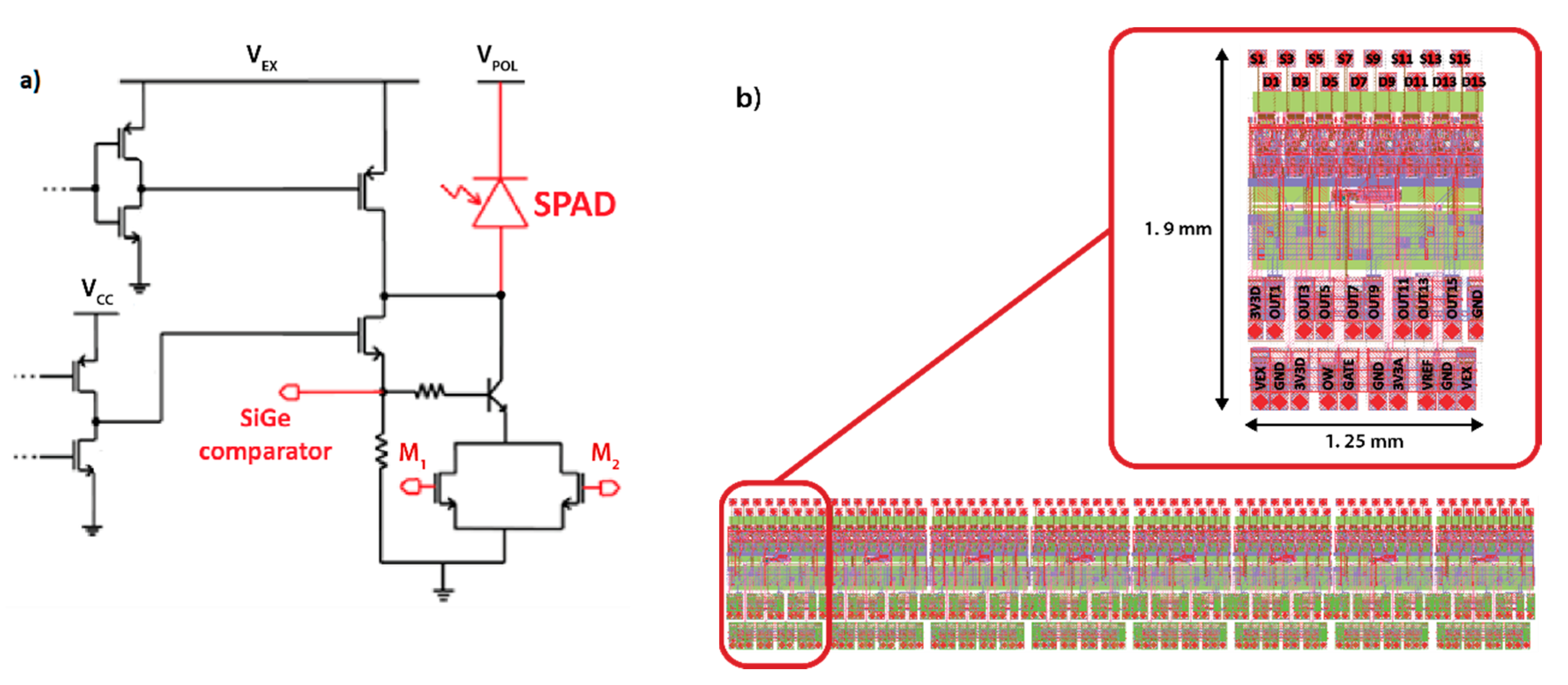

3.1. Fast-Gating AQC Array

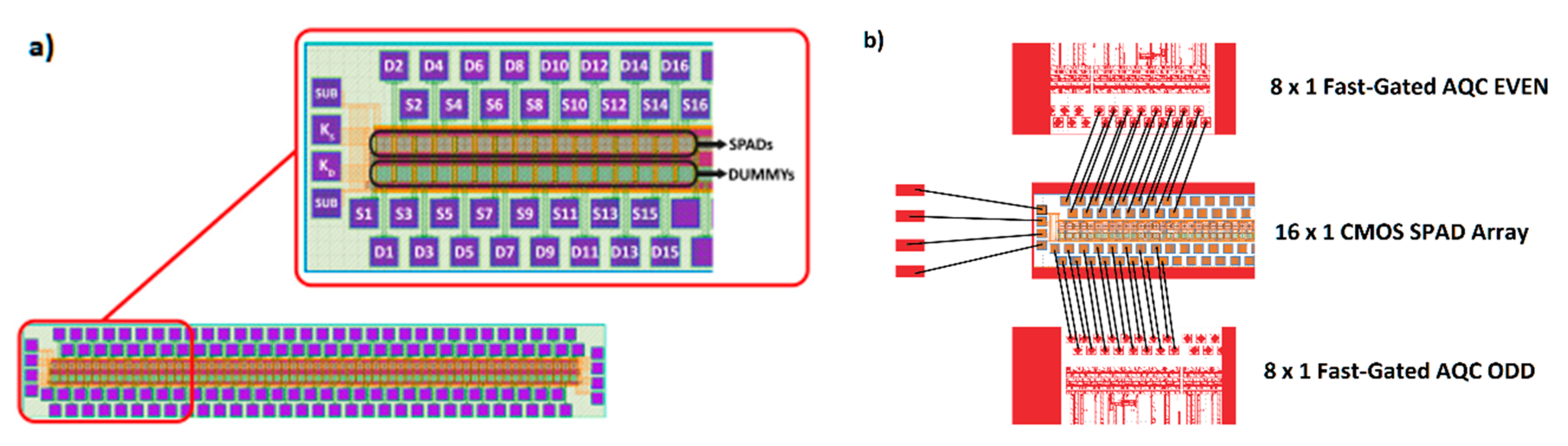

3.2. CMOS SPAD Array

3.3. System Description

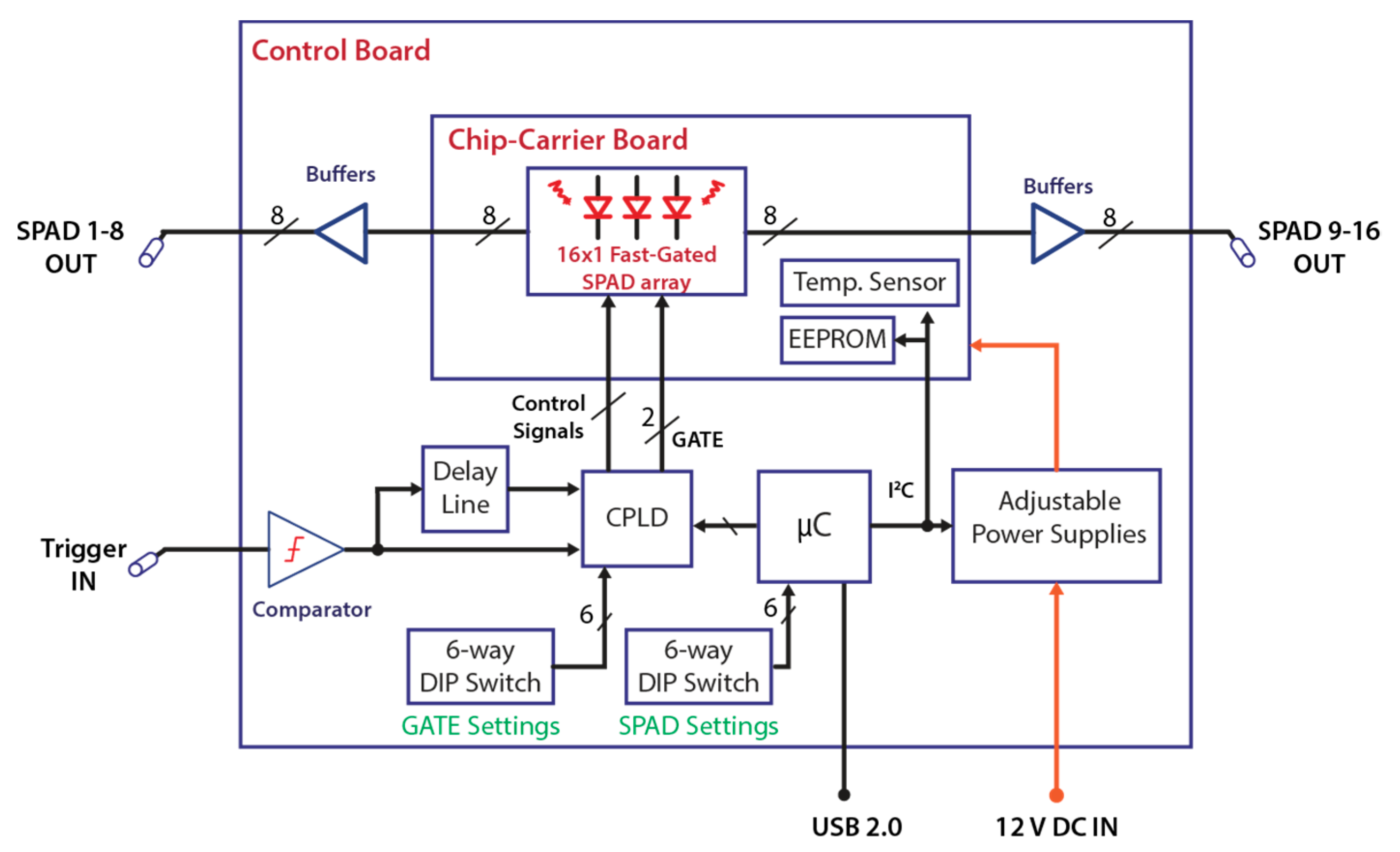

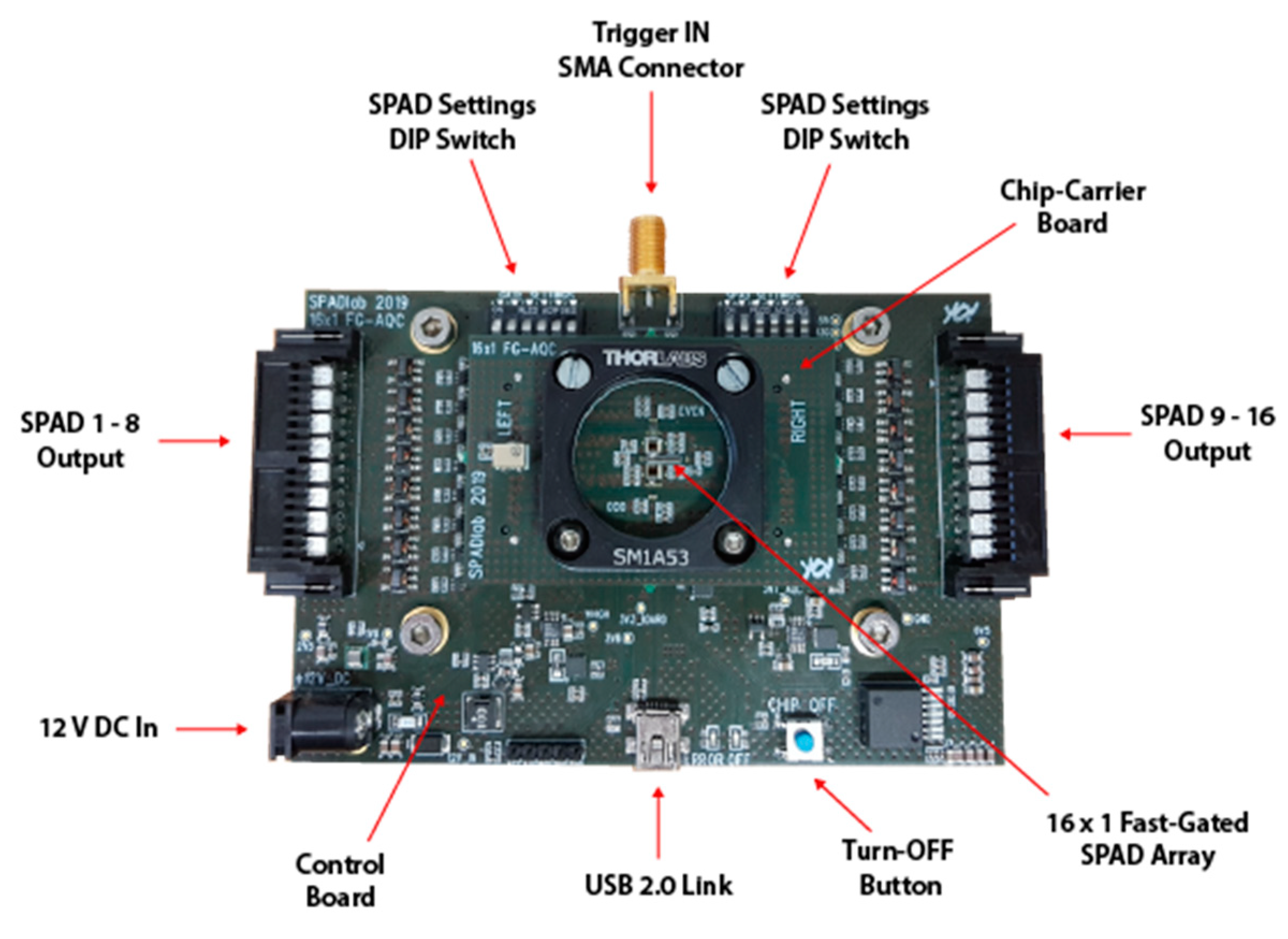

- A chip-carrier board hosts the 16 × 1 SPAD array and the two 8 × 1 fast-gating AQC arrays. The three ASIC are wire bonded directly on the PCB.

- A control board hosts the chip-carrier board and its ancillary electronics, a microcontroller and a Complex Programmable Logic Device (CPLD) for system operation and timing signals.

3.3.1. Chip-Carrier Board

3.3.2. Control Board

4. Experimental Characterization

4.1. Fast-Gating AQC Array–Design Issues

- Small size of the output buffer for the photon out signal (see OUTi pads in Figure 2b), leading to a weak driving current of the output pads, thus increasing the overall timing jitter of the detector. To limit its impact, the digital section of the ASIC is biased above 3.5 V in order to increase the output buffer driving capability (absolute maximum rating for this technology is 3.9 V) and reduce the overall timing jitter.

- Issue in the circuitry driving the degeneration MOS transistors in the SPAD pulser circuit (see M1 and M2 Figure 2a) resulting in having such transistors always OFF with the nominal 3.3 V power supply, leading to no effect of the reset BJT, and thus in a slow (longer than 1 ns) OFF-ON SPAD transition. A minimum 3.6 V power supply was found necessary in order to effectively overcome this limitation. The final power supply was set to 3.7 V for both the analog and digital sections of the ASIC, as this configuration proved best gating performance. All the measurement results provided in the following sections are obtained using a 3.7 V power supply.

- Too high resistance of metal rails for power supply of the SPAD pulser circuit (VEX in Figure 2a) and ground reference. The high resistance (estimated > 1.5 Ω for VEX rail) and the high peak current during SPAD transitions (estimated > 1 A) result in a strong electrical crosstalk within the AQC ASIC, affecting detector response linearity. Additionally, power consumption at the VEX power supply (higher that what expected after ASIC postlayout simulations) is proportional to the applied gate ON-time, maybe due to cross-conductance. This problem leads to high operating temperature for both the AQC arrays and the SPAD array, with an estimated SPAD operating temperature that may exceed 60°C, with non-negligible impact on detector DCR.

4.2. Optical Crosstalk

4.3. Electroluminescence

4.4. Detection Linearity in Gated Operation

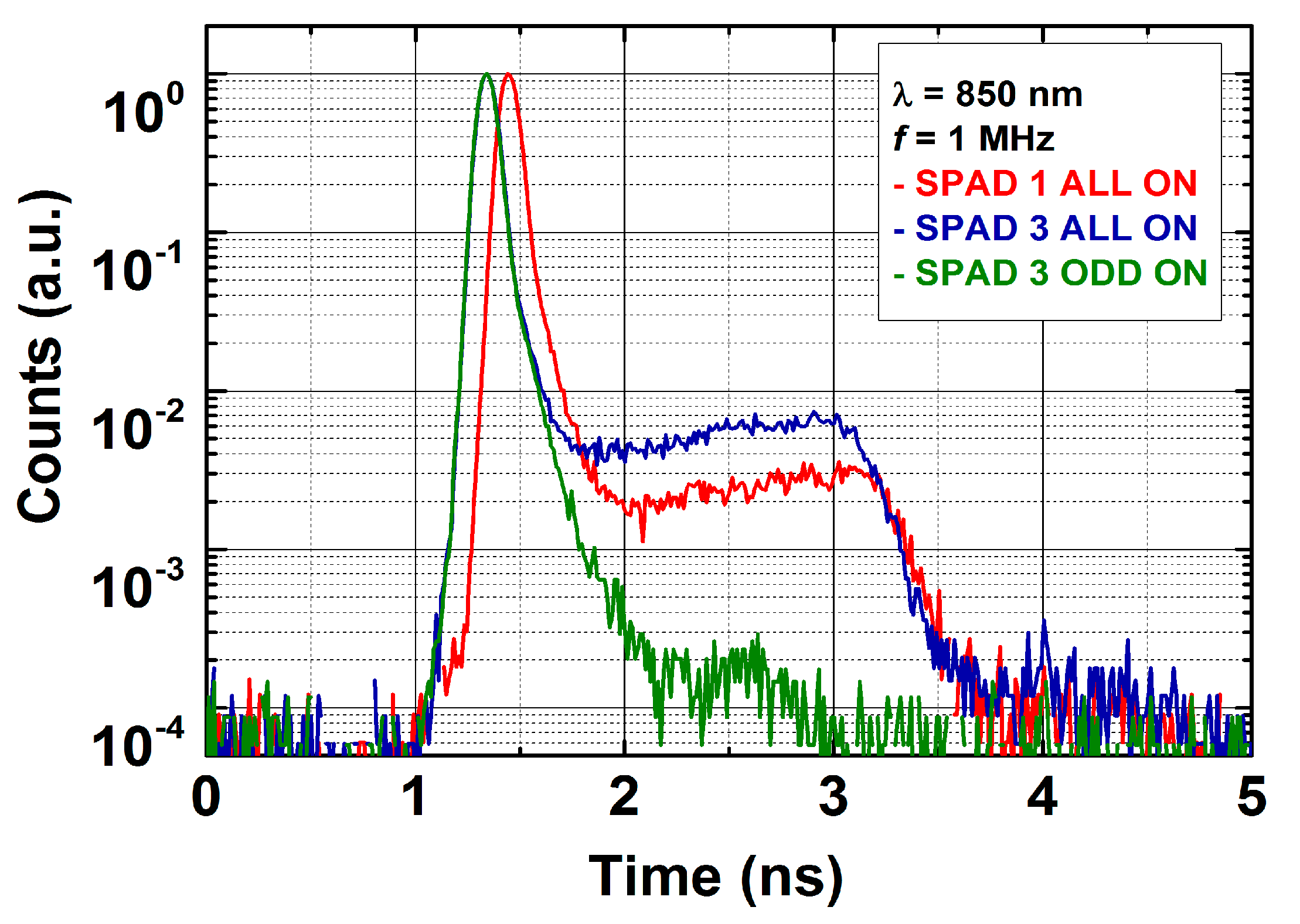

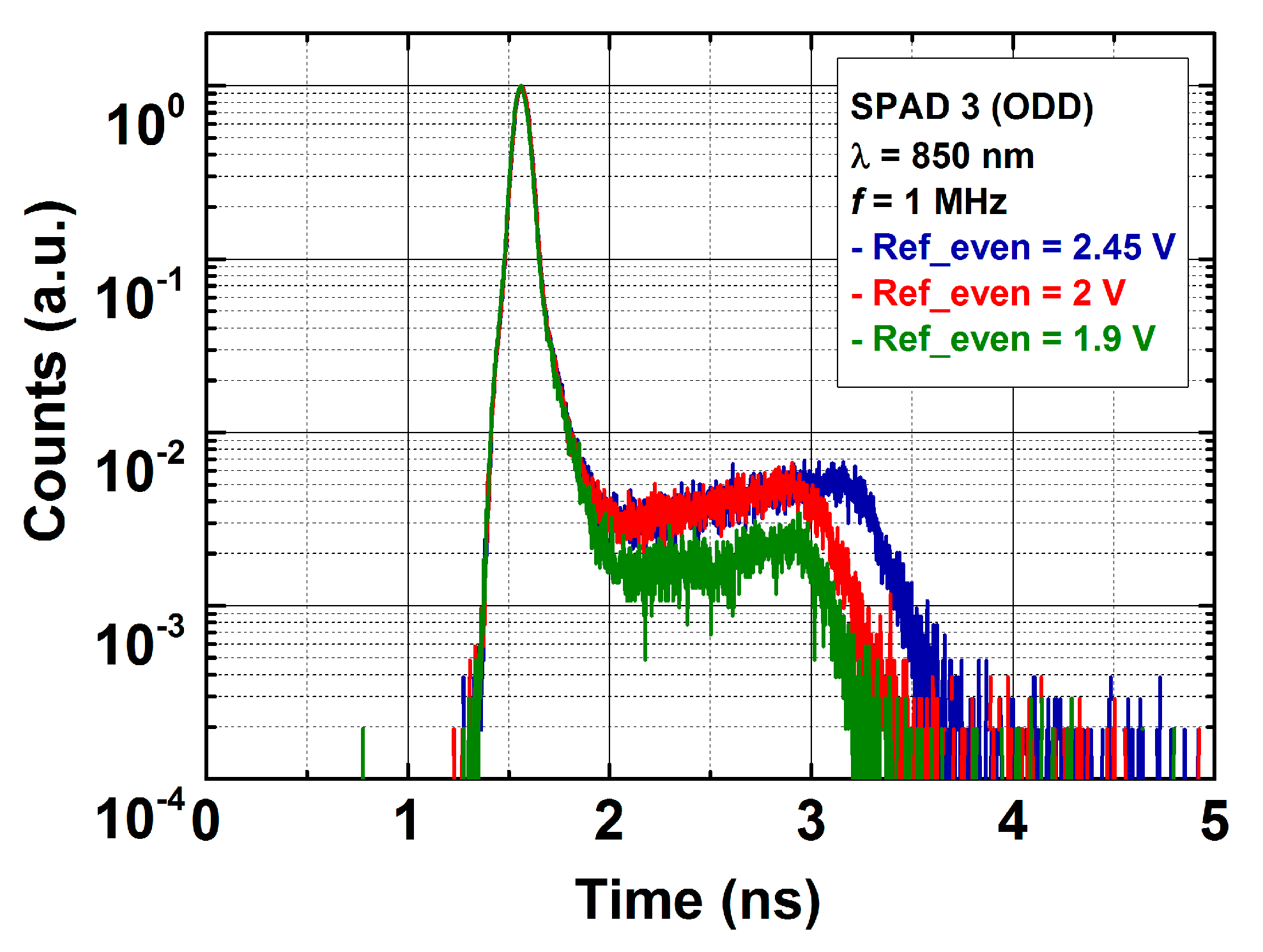

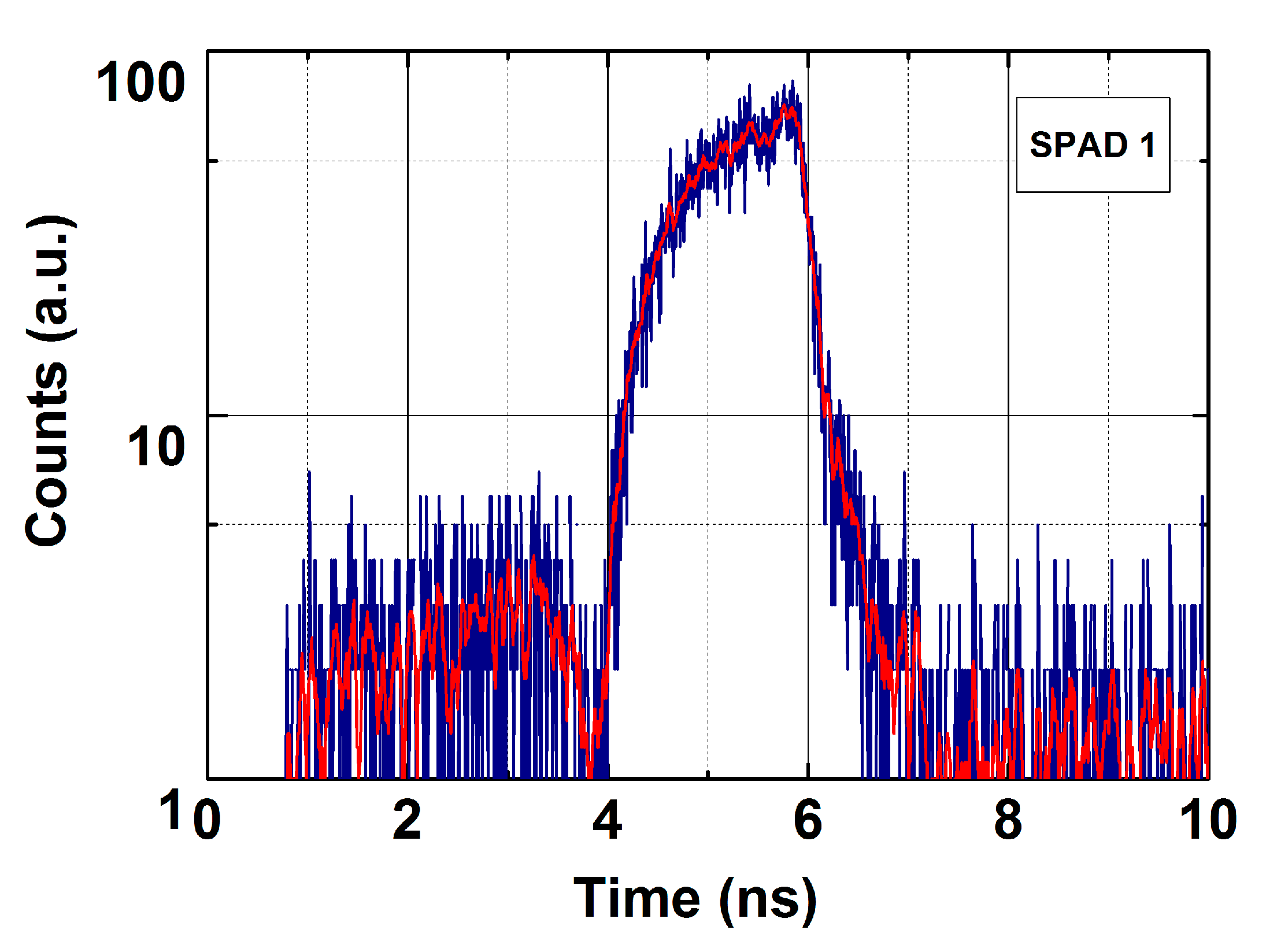

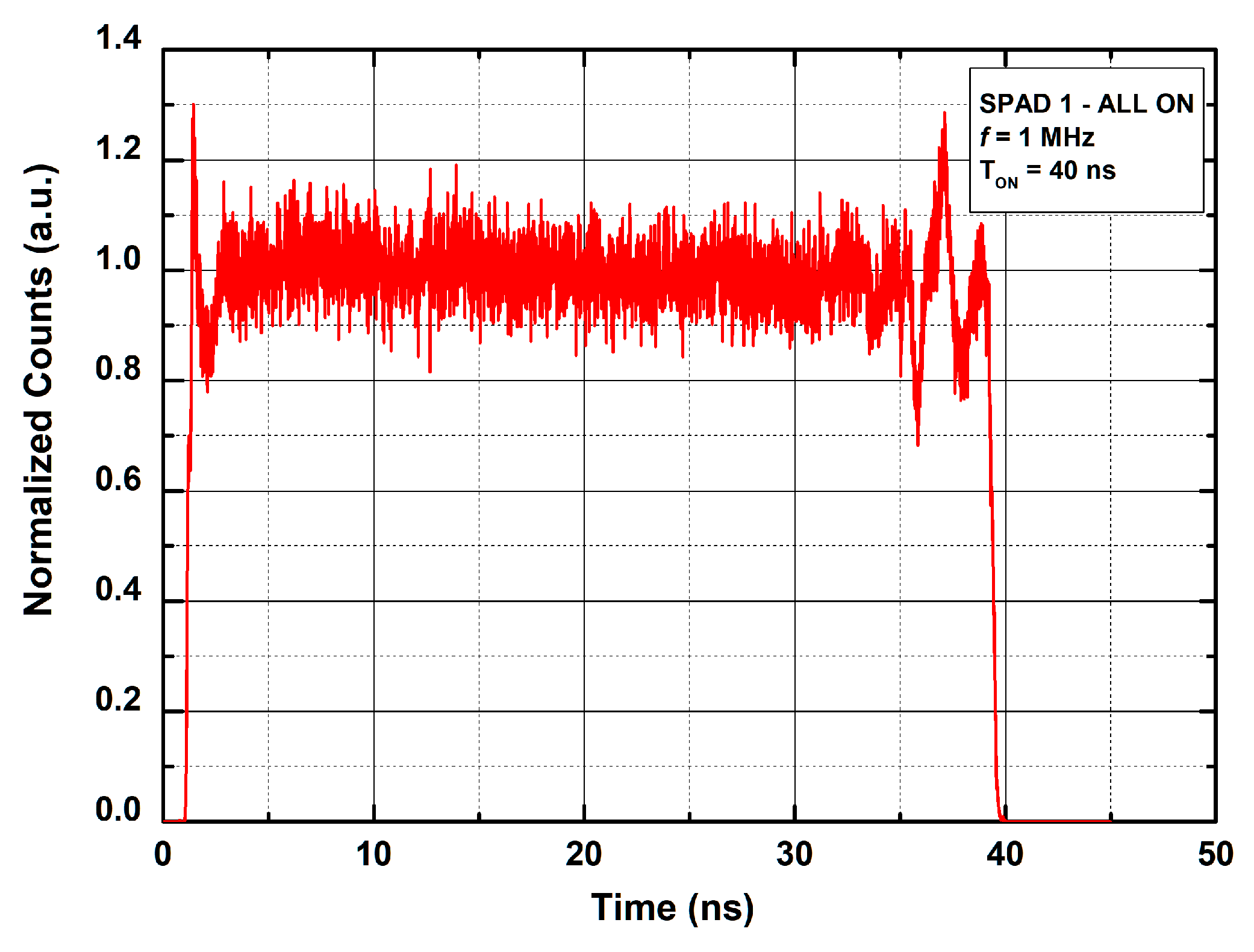

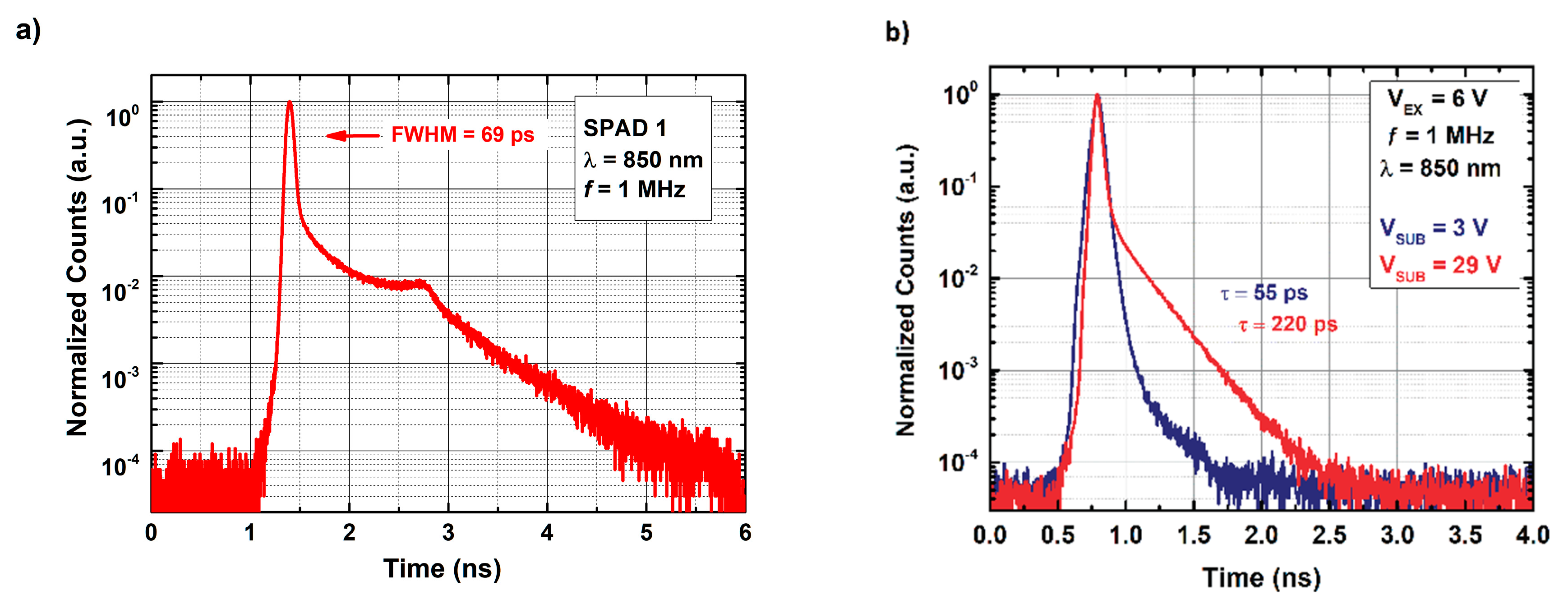

4.5. Single-Photon Timing Resolution

5. NLOS Preliminary Measurement

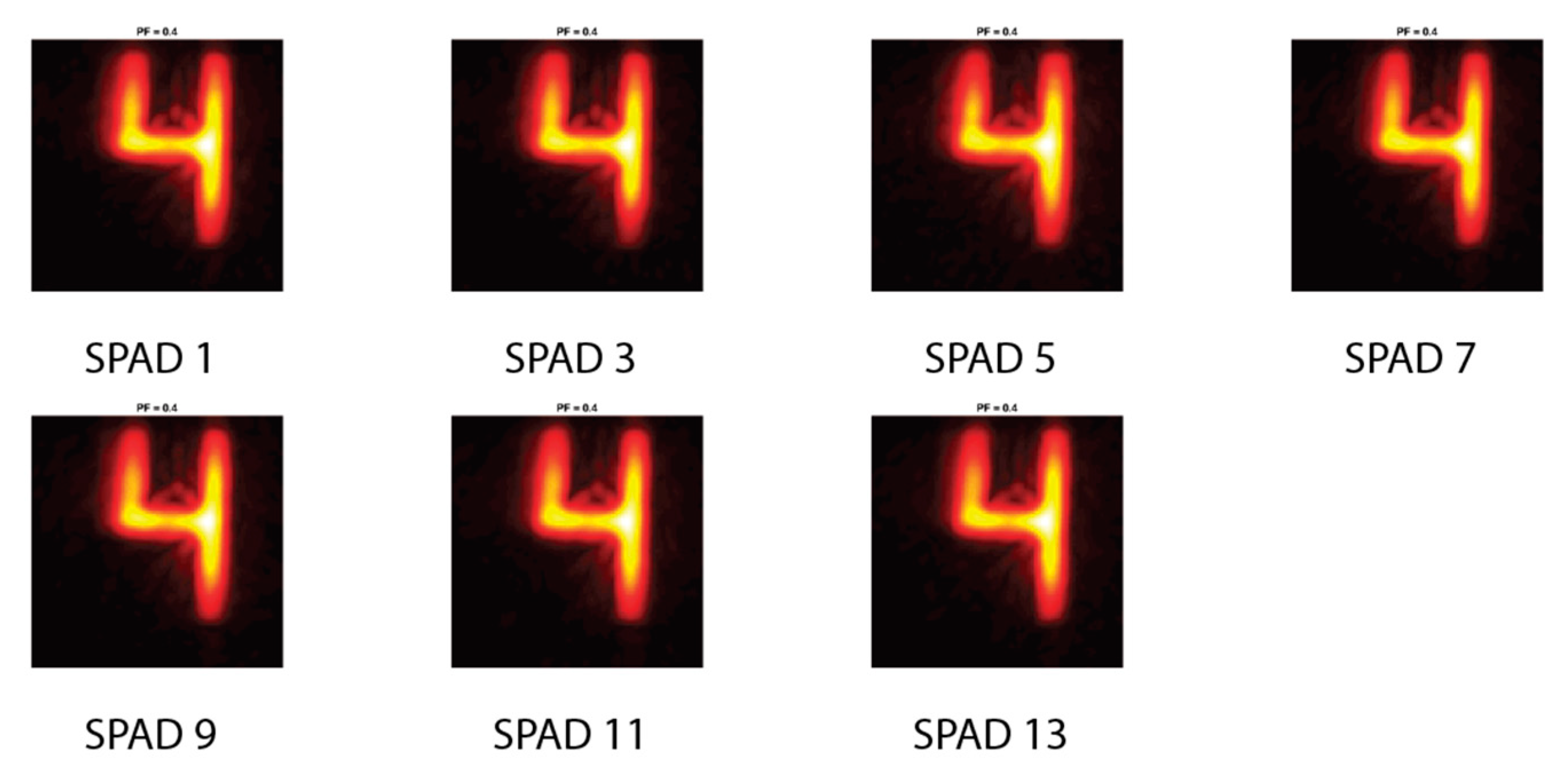

Reconstruction of the Hidden Object

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bruschini, C.; Homulle, H.; Antolovic, I.M.; Burri, S.; Charbon, E. Single-photon avalanche diode imagers in biophotonics: Review and outlook. Light Sci. Appl. 2019, 8, 1–28. [Google Scholar] [CrossRef] [PubMed]

- Puszka, A.; Di Sieno, L.; Dalla Mora, A.; Pifferi, A.; Contini, D.; Planat-Chrétien, A.; Koenig, A.; Boso, G.; Tosi, A.; Hervé, L.; et al. Spatial resolution in depth for time-resolved diffuse optical tomography using short source-detector separations. Biomed. Opt. Express 2015, 6, 1–10. [Google Scholar] [CrossRef] [PubMed]

- del Bianco, S.; Martelli, F.; Zaccanti, G. Penetration depth of light re-emitted by a diffusive medium: Theoretical and experimental investigation. Phys. Med. Biol. 2002, 47, 4131–4144. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Eraerds, P.; Walenta, N.; Barreiro, C.; Thew, R.; Zbinden, H. 2.23 GHz gating InGaAs/InP single-photon avalanche diode for quantum key distribution. Adv. Photon Count. Tech. 2010, 7681, 76810Z. [Google Scholar]

- Castello, M.; Tortarolo, G.; Hernández, I.C.; Bianchini, P.; Buttafava, M.; Boso, G.; Tosi, A.; Diaspro, A.; Vicidomini, G. Gated-STED microscopy with subnanosecond pulsed fiber laser for reducing photobleaching. Microsc. Res. Tech. 2016, 79, 785–791. [Google Scholar] [CrossRef]

- Gariepy, G.; Krstaji, N.; Henderson, R.; Li, C.; Thomson, R.R.; Buller, G.S.; Heshmat, B.; Raskar, R.; Leach, J.; Faccio, D. Single-photon sensitive light-in-flight imaging. Nat. Commun. 2015, 6, 6021. [Google Scholar] [CrossRef]

- Buttafava, M.; Zeman, J.; Tosi, A.; Eliceiri, K.; Velten, A. Non-line-of-sight imaging using a time-gated single photon avalanche diode. Opt. Express 2015, 23, 20997–21011. [Google Scholar] [CrossRef]

- Ralston, T.; Charvat, G.; Peabody, J. Real-time through-wall imaging using an ultrawideband multiple input multiple-output (MIMO) phased array radar system. In Proceedings of the IEEE International Symposium on Phased Array Systems and Technology, Waltham, MA, USA, 12–15 October 2010; pp. 551–558. [Google Scholar]

- Chakraborty, B.; Li, Y.; Zhang, J.; Trueblood, T.; Suppappola, A.P.; Morrell, D. Multipath exploitation with adaptive waveform design for tracking in urban terrain. In Proceedings of the IEEE International Conference on Acoustics Speech and Signal Processing, Dallas, TX, USA, 14–19 March 2010; pp. 3894–3897. [Google Scholar]

- Sume, A.; Gustafsson, M.; Herberthson, M.; Janis, A.; Nilsson, S.; Rahm, J.; Orbom, A. Radar Detection of Moving Targets Behind Corners. IEEE Trans. Geosci. Remote Sens. 2011, 49, 2259–2267. [Google Scholar] [CrossRef]

- Sen, P.; Chen, B.; Garg, G.; Marschner, S.R.; Horowitz, M.; Levoy, M.; Lensch, H.P.A. Dual Photography. ACM Trans. Graph. 2005, 24, 745–755. [Google Scholar] [CrossRef]

- Repasi, E.; Lutzmann, P.; Steinvall, O.; Elmqvist, M.; Ghler, B.; Anstett, G. Advanced short-wavelength infrared range-gated imaging for ground applications in monostatic and bistatic configurations. Appl. Opt. 2009, 48, 5956–5969. [Google Scholar] [CrossRef]

- Hebden, J.C.; Kruger, R.A.; Wong, K.S. Time resolved imaging through a highly scattering medium. Appl. Opt. 1991, 30, 788–794. [Google Scholar] [CrossRef]

- Velten, A.; Wu, D.; Jarabo, A.; Masia, B.; Barsi, C.; Joshi, C.; Lawson, E.; Bawendi, M.; Gutierrez, D.; Raskar, R. Femto-photography: Capturing and Visualizing the Propagation of Light. ACM Trans. Graph. 2013, 32, 44. [Google Scholar] [CrossRef]

- Heide, F.; Hullin, M.B.; Gregson, J.; Heidrich, W. Low-budget Transient Imaging Using Photonic Mixer Devices. ACM Trans. Graph. 2013, 32, 45. [Google Scholar] [CrossRef]

- Heide, F.; Xiao, L.; Heidrich, W.; Hullin, M.B. Diffuse Mirrors: 3D Reconstruction from Diffuse Indirect Illumination Using Inexpensive Time-of-Flight Sensors. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Columbus, OH, USA, 24–27 June 2014; pp. 3222–3229. [Google Scholar]

- Kirmani, A.; Hutchison, T.; Davis, J.; Raskar, R. Looking Around the Corner using Ultrafast Transient Imaging. Int. J. Comput. Vis. 2011, 95, 13–28. [Google Scholar] [CrossRef]

- Velten, A.; Willwacher, T.; Gupta, O.; Veeraraghavan, A.; Bawendi, M.G.; Raskar, R. Recovering three-dimensional shape around a corner using ultrafast time-of-flight imaging. Nat. Commun. 2012, 3, 745. [Google Scholar] [CrossRef] [PubMed]

- Gupta, O.; Willwacher, T.; Velten, A.; Veeraraghavan, A.; Raskar, R. Reconstruction of hidden 3D shapes using diffuse reflections. Opt. Express 2012, 20, 19096–19108. [Google Scholar] [CrossRef]

- Laurenzis, M.; Velten, A. Nonline-of-sight laser gated viewing of scattered photons. Opt. Eng. 2014, 53, 023102. [Google Scholar] [CrossRef]

- Gariepy, G.; Tonolini, F.; Henderson, R.; Leach, J.; Faccio, D. Tracking hidden objects with a single-photon camera. arXiv 2015, arXiv:1503.01699. [Google Scholar]

- Buttafava, M.; Boso, G.; Ruggeri, A.; Mora, A.D.; Tosi, A. Time-gated single-photon detection module with 110 ps transition time and up to 80 MHz repetition rate. Rev. Sci. Instrum. 2014, 85, 083114. [Google Scholar] [CrossRef]

- Micro Photon Devices s.r.l. FastGated SPAD. Available online: http://www.micro-photon-devices.com/MPD/media/Datasheet/FastGatedSPAD.pdf (accessed on 27 August 2019).

- O’Toole, M.; Lindell, D.B.; Wetzstein, G. Confocal non-line-of-sight imaging based on the light-cone transform. Nature 2018, 555, 338–341. [Google Scholar] [CrossRef]

- Lindell, D.B.; Wetzstein, G.; O’Toole, M. Wave-based non-line-of-sight imaging using fast fk migration. ACM Trans. Graph. (TOG) 2019, 38, 1–13. [Google Scholar] [CrossRef]

- Chan, S.; Warburton, R.E.; Gariepy, G.; Leach, J.; Faccio, D. Non-line-of-sight tracking of people at long range. Opt. Express 2017, 25, 10109–10117. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Guillén, I.; La Manna, M.; Nam, J.H.; Reza, S.A.; Le, T.H.; Gutierrez, D.; Jarabo, A.; Velten, A. Virtual Wave Optics for Non-Line-of-Sight Imaging. arXiv 2018, arXiv:1810.07535. [Google Scholar]

- Arellano, V.; Gutierrez, D.; Jarabo, A. Fast back-projection for non-line of sight reconstruction. Opt. Express 2017, 25, 11574–11583. [Google Scholar] [CrossRef]

- Ruggeri, A.; Ciccarella, P.; Villa, F.; Zappa, F.; Tosi, A. Integrated Circuit for Subnanosecond Gating of InGaAs/InP SPAD. IEEE J. Quantum Electron. 2015, 51, 1–7. [Google Scholar] [CrossRef]

- Villa, F.; Bronzi, D.; Zou, Y.; Scarcella, C.; Boso, G.; Tisa, S.; Tosi, A.; Zappa, F.; Durini, D.; Weyers, S.; et al. CMOS SPADs with up to 500 μm diameter and 55% detection efficiency at 420 nm. J. Mod. Opt. 2014, 61, 102–115. [Google Scholar] [CrossRef]

- Lacaita, A.; Zappa, F.; Bigliardi, S.; Manfredi, M. On the Bremsstrahlung Origin of Hot-Carrier-Induced Photons in Silicon Devices. IEEE Trans. Electron Devices 1993, 40, 577–582. [Google Scholar] [CrossRef]

- Nakamura, Y.; Okumura, A.; Tajima, H.; Yamane, N.; Zenin, A. Characterization of SiPM Optical Crosstalk and Its Dependence on the Protection-Window Thickness. In Proceedings of the 5th International Workshop on New Photon-Detectors (PD18), Tokyo, Japan, 27–29 November 2018. [Google Scholar]

- Rech, I.; Ingargiola, A.; Spinelli, R.; Labanca, I.; Marangoni, S.; Ghioni, M.; Cova, S. Optical crosstalk in single photon avalanche diode arrays: A new complete model. Opt. Express 2008, 16, 8381–8394. [Google Scholar] [CrossRef]

- Micro Photon Devices s.r.l. PDM Series. Available online: http://www.micro-photon-devices.com/MPD/media/Datasheet/PDM.pdf (accessed on 12 September 2019).

- Picoquant Gmbh, Hydraharp 400 Datasheet. Available online: https://www.picoquant.com/images/uploads/downloads/10-hydraharp400.pdf (accessed on 25 September 2019).

| ODD SPAD # | SPTR a [ps] | DCR b [kcps] | EVEN SPAD # | SPTR a [ps] | DCR b [kcps] |

|---|---|---|---|---|---|

| 1 | 42 | 76 | 2 | 51 | 64 |

| 3 | 44 | 65.6 | 4 | 47 | 66.6 |

| 5 | 44 | 66 | 6 | 47 | 66.4 |

| 7 | 42 | 66 | 8 | 49 | 66.4 |

| 9 | 44 | 59.6 | 10 | 52 | 60 |

| 11 | 38 | 72 | 12 | 46 | 60.6 |

| 13 | 41 | 60 | 14 | 45 | 61 |

| 15 | 40 | 60.4 | 16 | 41 | 56.2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Renna, M.; Nam, J.H.; Buttafava, M.; Villa, F.; Velten, A.; Tosi, A. Fast-Gated 16 × 1 SPAD Array for Non-Line-of-Sight Imaging Applications. Instruments 2020, 4, 14. https://doi.org/10.3390/instruments4020014

Renna M, Nam JH, Buttafava M, Villa F, Velten A, Tosi A. Fast-Gated 16 × 1 SPAD Array for Non-Line-of-Sight Imaging Applications. Instruments. 2020; 4(2):14. https://doi.org/10.3390/instruments4020014

Chicago/Turabian StyleRenna, Marco, Ji Hyun Nam, Mauro Buttafava, Federica Villa, Andreas Velten, and Alberto Tosi. 2020. "Fast-Gated 16 × 1 SPAD Array for Non-Line-of-Sight Imaging Applications" Instruments 4, no. 2: 14. https://doi.org/10.3390/instruments4020014

APA StyleRenna, M., Nam, J. H., Buttafava, M., Villa, F., Velten, A., & Tosi, A. (2020). Fast-Gated 16 × 1 SPAD Array for Non-Line-of-Sight Imaging Applications. Instruments, 4(2), 14. https://doi.org/10.3390/instruments4020014