Experimental Investigation of the Hydrodynamic Characteristics of Longline Aquaculture Facilities under Current and Wave Conditions

Abstract

1. Introduction

2. Materials and Methods

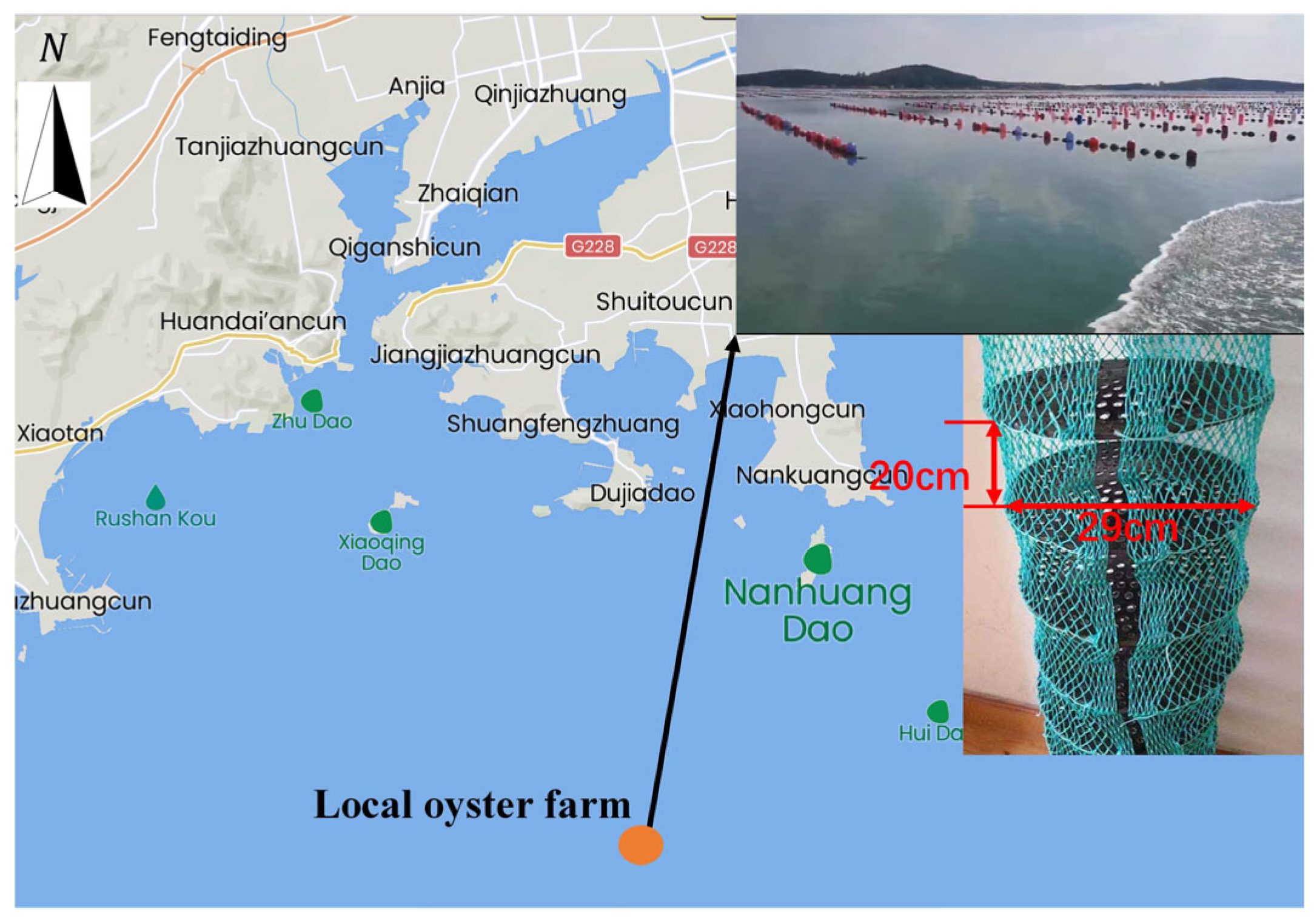

2.1. Prototype Configurations of a Longline Aquaculture Facility with Lantern Nets

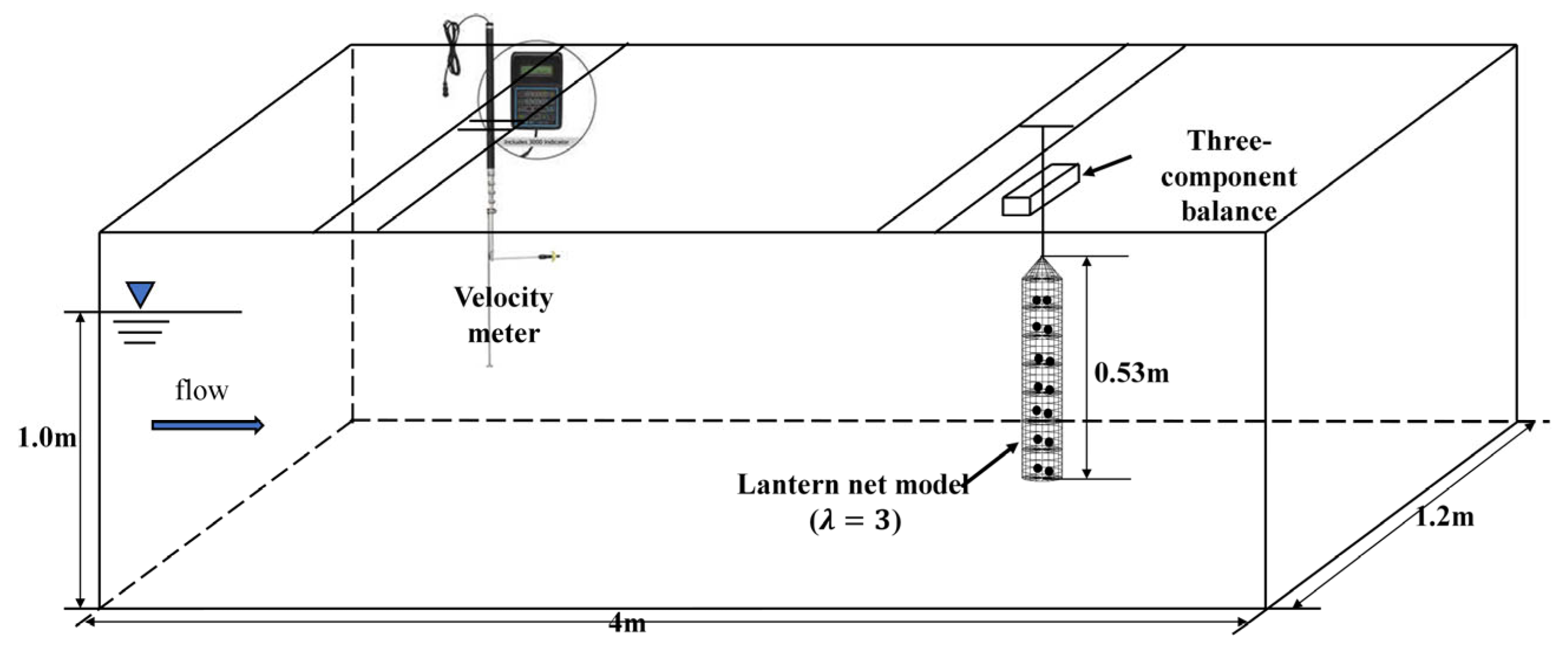

2.2. Flume Tank Experiment to Investigate the Drag Characteristics of the Lantern Net

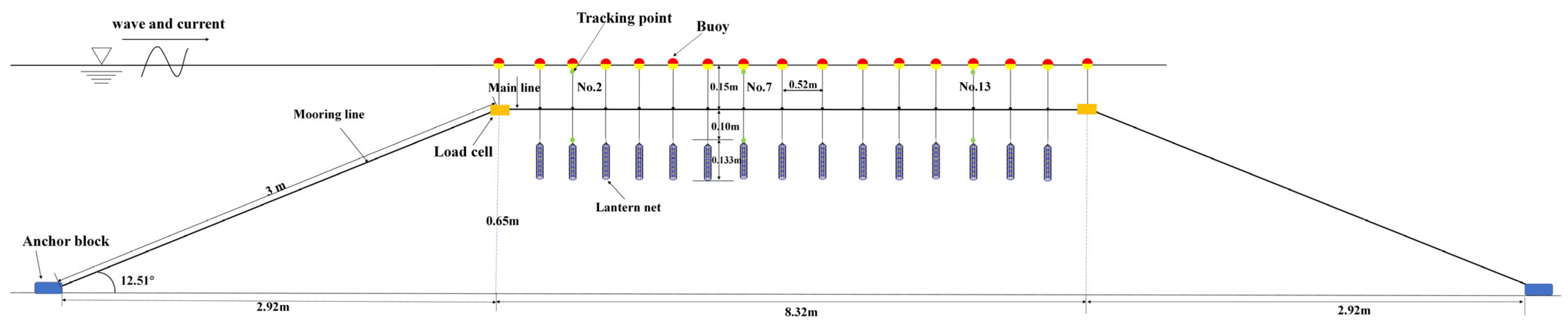

2.3. Wave/current-Tank Experiment to Investigate the Hydrodynamics of the Longline Aquaculture Facility with Lantern Nets

3. Results

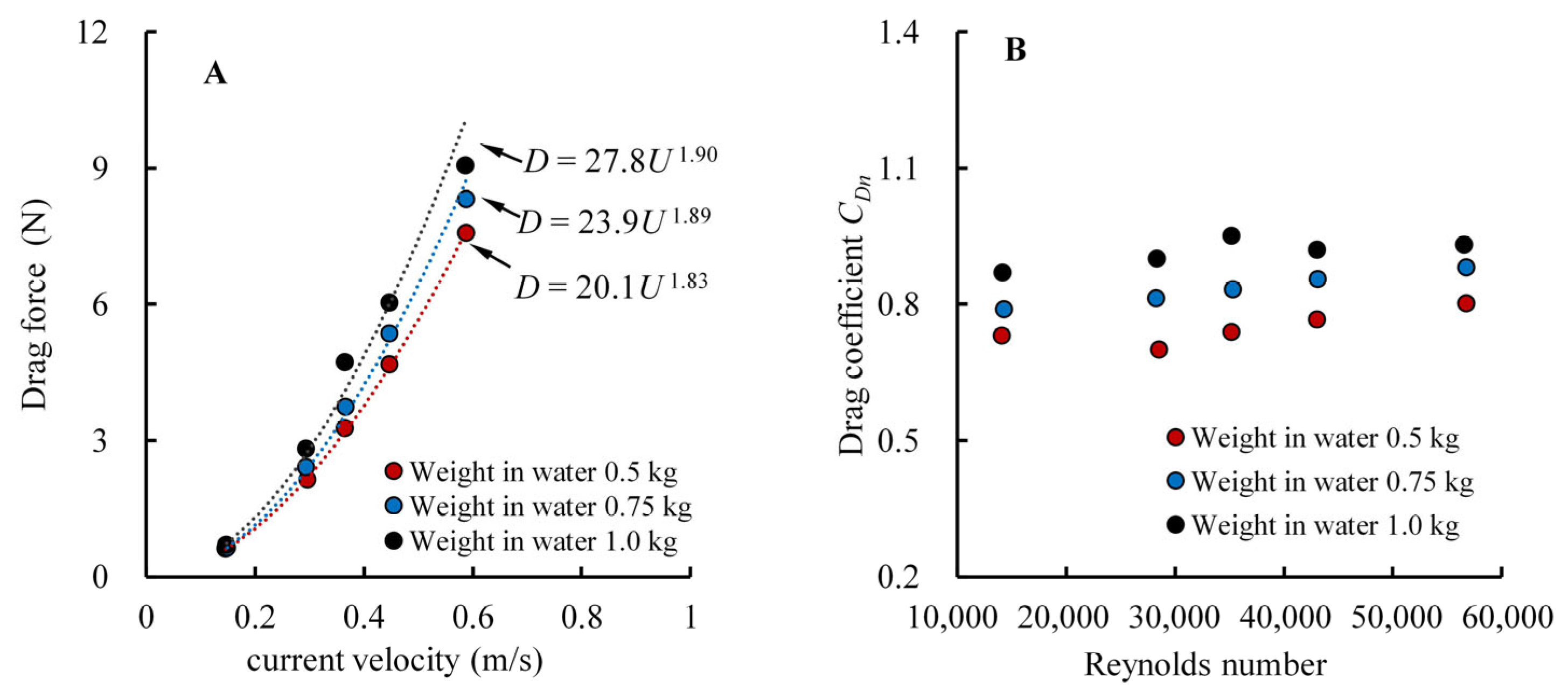

3.1. Drag force of the Lantern Net in Currents

3.2. Mooring Line Tension of the Longline Aquaculture Facility in Currents

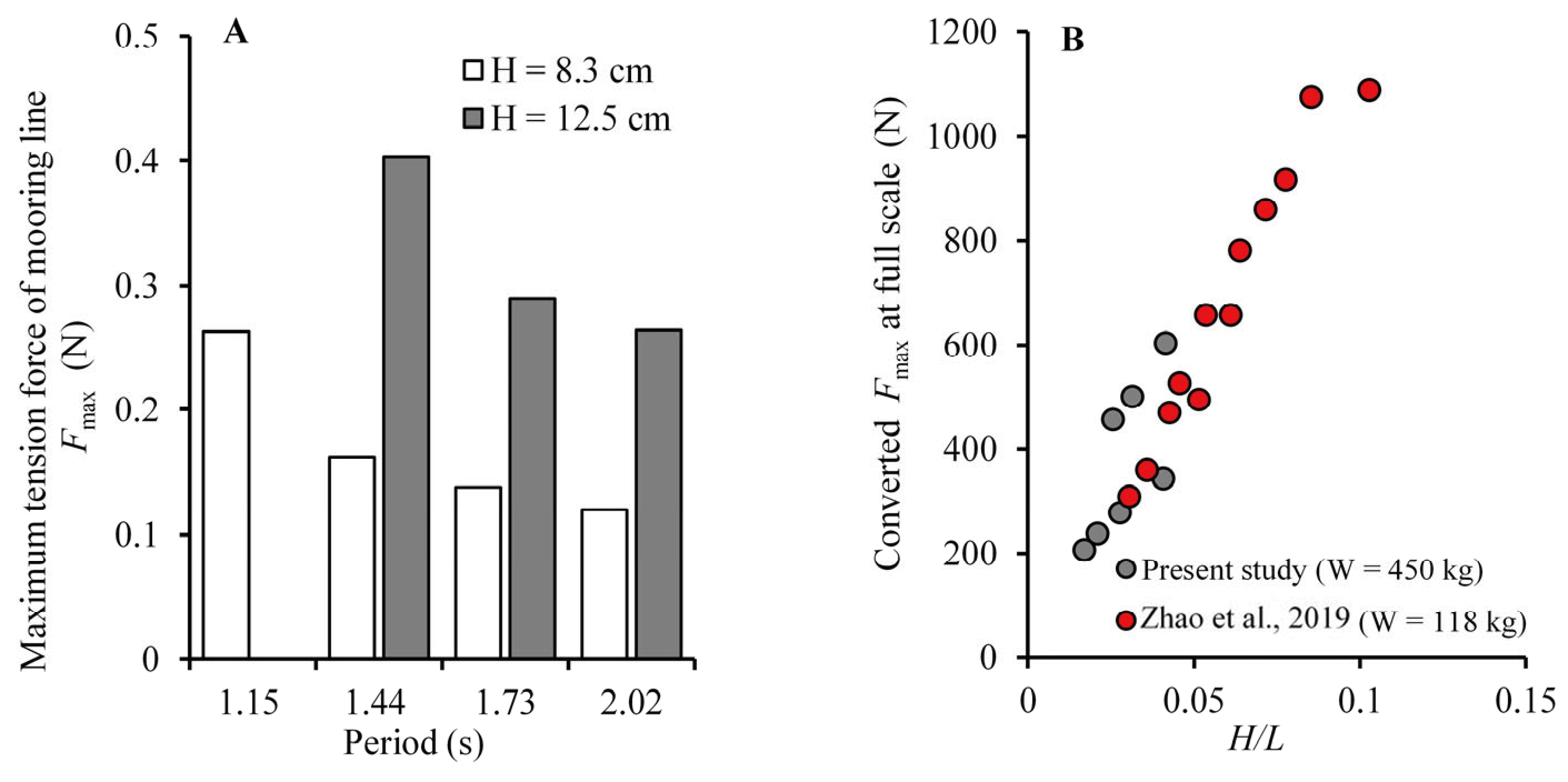

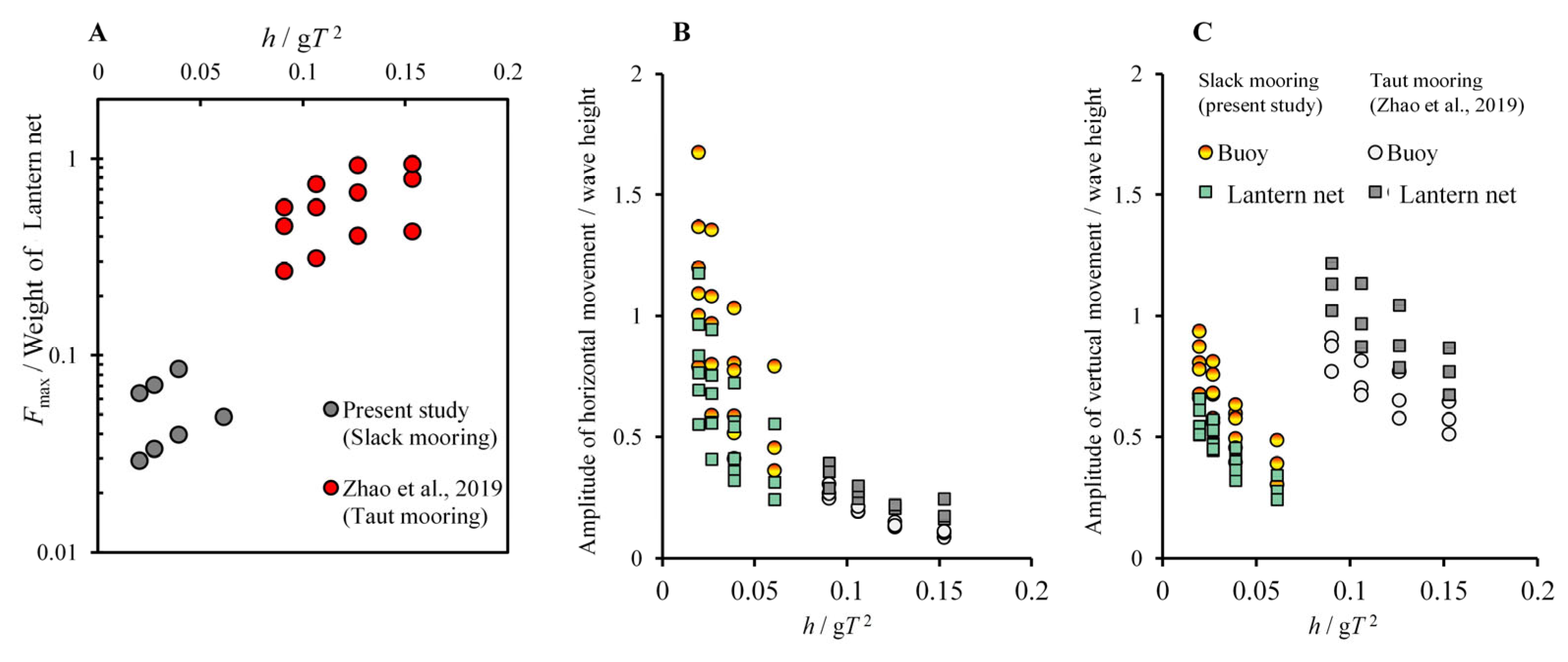

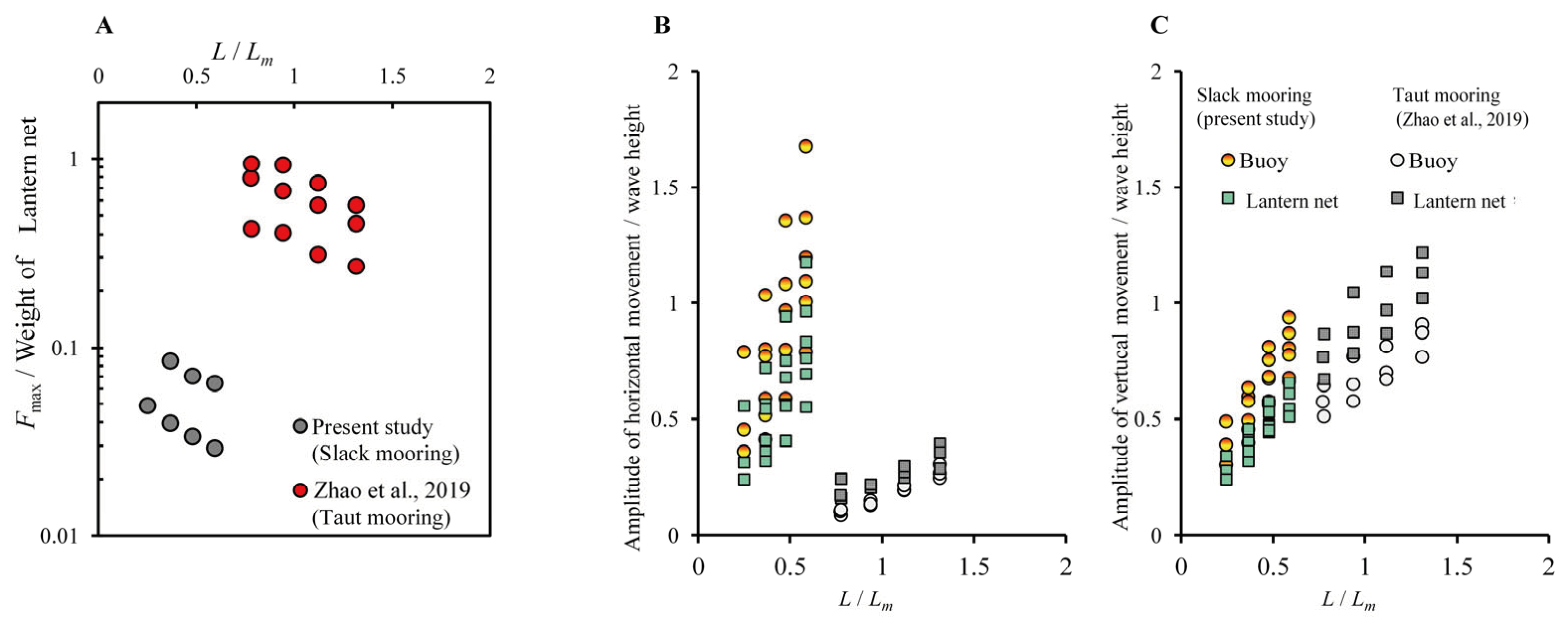

3.3. Maximum Tension of the Mooring Line of the Longline Aquaculture Facility under the Wave Conditions

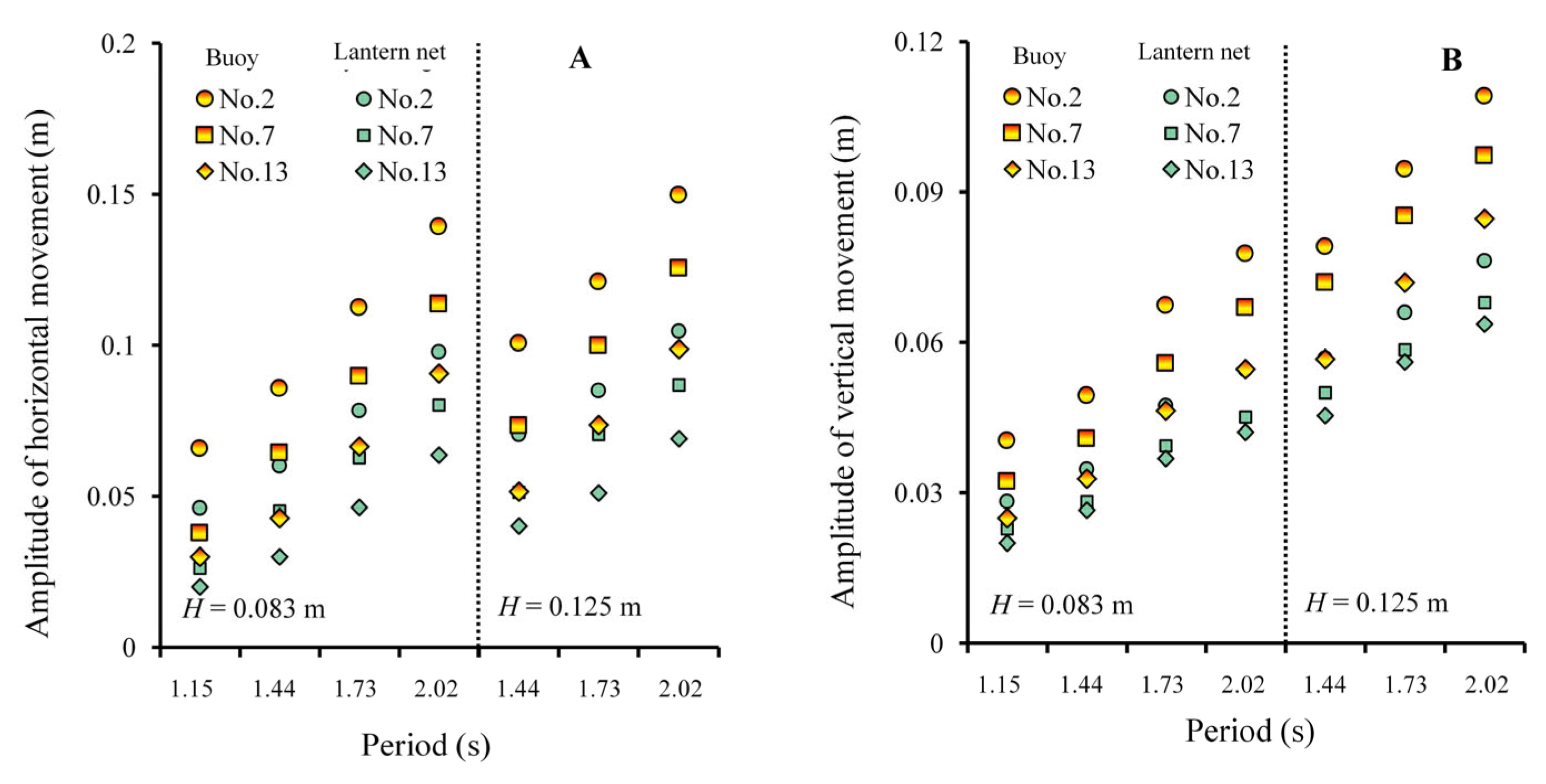

3.4. Dynamic Motion of the Longline Aquaculture Facility in Waves

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hosomi, R.; Yoshida, M.; Fukunaga, K. Seafood consumption and components for health. Glob. J. Health Sci. 2012, 4, 72–86. [Google Scholar] [CrossRef]

- Golden, C.D.; Koehn, J.Z.; Shepon, A.; Passarelli, S.; Free, C.M.; Viana, D.F.; Matthey, H.; Eurich, J.G.; Gephart, J.A.; Fluet-Chouinard, E.; et al. Aquatic foods to nourish nations. Nature 2021, 598, 315–320. [Google Scholar] [CrossRef]

- Knysh, A.; Tsukrov, I.; Chambers, M.; Swift, M.R.; Sullivan, C.; Drach, A. Numerical modeling of submerged mussel longlines with protective sleeves. Aquac. Eng. 2020, 88, 102027. [Google Scholar] [CrossRef]

- Landmann, J.; Fröhling, L.; Gieschen, R.; Buck, B.H.; Heasman, K.; Scott, N.; Smeaton, M.; Goseberg, N.; Hildebrandt, A. Drag and inertia coefficients of live and surrogate shellfish dropper lines under steady and oscillatory flow. Ocean Eng. 2021, 235, 109377. [Google Scholar] [CrossRef]

- China Agriculture Press. Bureau of Fisheries of the Ministry of Agriculture: China Fishery Statistical Yearbook 2020; China Agriculture Press: Beijing, China, 2020. [Google Scholar]

- Buck, B.H. Experimental trials on the feasibility of offshore seed production of the mussel Mytilus edulis in the German Bight: Installation, technical requirements and environmental conditions. Helgol. Mar. Res. 2007, 61, 87–101. [Google Scholar] [CrossRef]

- Cheney, D.; Langan, R.; Heasman, K.; Friedman, B.; Davis, J. Shellfish Culture in the Open Ocean: Lessons Learned for Offshore Expansion. Mar. Technol. Soc. J. 2010, 44, 55–67. [Google Scholar] [CrossRef]

- Nguyen, N.Q.; Thiagarajan, K.; Auger, J. Integrity assessment of an oyster farm mooring system through in-situ measurements and extreme environment modeling. Ocean Eng. 2019, 172, 641–659. [Google Scholar] [CrossRef]

- Stevens, C.; Plew, D.; Hartstein, N.; Fredriksson, D. The physics of open-water shellfish aquaculture. Aquac. Eng. 2008, 38, 145–160. [Google Scholar] [CrossRef]

- Ferreira, J.G.; Saurel, C.; Lencart e Silva, J.D.; Nunes, J.P.; Vazquez, F. Modelling of interactions between inshore and offshore aquaculture. Aquaculture 2014, 426–427, 154–164. [Google Scholar] [CrossRef]

- Gagnon, M.; Bergeron, P. Observations of the loading and motion of a submerged mussel longline at an open ocean site. Aquac. Eng. 2017, 78, 114–129. [Google Scholar] [CrossRef]

- South, P.M.; Delorme, N.J.; Skelton, B.M.; Floerl, O.; Jeffs, A.G. The loss of seed mussels in longline aquaculture. Rev. Aquac. 2021, 14, 440–455. [Google Scholar] [CrossRef]

- Mascorda Cabre, L.; Hosegood, P.; Attrill, M.J.; Bridger, D.; Sheehan, E.V. Offshore longline mussel farms: A review of oceanographic and ecological interactions to inform future research needs, policy and management. Rev. Aquac. 2021, 13, 1864–1887. [Google Scholar] [CrossRef]

- Zhao, Y.-P.; Yang, H.; Bi, C.-W.; Chen, Q.-P.; Dong, G.-H.; Cui, Y. Hydrodynamic responses of longline aquaculture facility with lantern nets in waves. Aquac. Eng. 2019, 86, 101996. [Google Scholar] [CrossRef]

- López, J.; Hurtado, C.F.; Gomez, A.; Zamora, V.; Queirolo, D.; Gutierrez, A. Stress analysis of a submersible longline culture system through dynamic simulation. Lat. Am. J. Aquat. 2017, 45, 25–32. [Google Scholar] [CrossRef]

- Plew, D.R.; Stevens, C.L.; Spigel, R.H.; Hartstein, N.D. Hydrodynamic Implications of Large Offshore Mussel Farms. IEEE J. Ocean. Eng. 2005, 30, 95–108. [Google Scholar] [CrossRef]

- Stevens, C.L.; Plew, D.R.; Smith, M.J.; Fredriksson, D.W. Hydrodynamic Forcing of Long-Line Mussel Farms: Observations. J. Waterw. Port Coast. Ocean. Eng. 2007, 133, 192–199. [Google Scholar] [CrossRef]

- Raman-Nair, W.; Colbourne, B. Dynamics of a mussel longline system. Aquac. Eng. 2003, 27, 191–212. [Google Scholar] [CrossRef]

- Magoon, C.; Vining, R. Introduction to Shellfish Aquaculture in the Puget Sound Region; Washington Department of Natural Resources Handbook: Olympia, WA, USA, 1980. [Google Scholar]

- Homziak, J.; Veal, C.D.; Hayes, D. Design and Construction of Aquaculture of Facilities in Dredged Material Containment Area; Technical Report EL-93-11; U.S. Army Engineer Waterways Experiment Station: Vicksburg, MS, USA, 1993. [Google Scholar]

- Matsubara, Y.; Noda, H.; Hirao, A. Dynamic Behaviour of the Submerged Buoy-Cable System by Ocean Waves. Coast. Eng. Jpn. 1985, 28, 235–241. [Google Scholar] [CrossRef]

- Cheng, W.; Sun, Z.; Liang, S.; Liu, B. Numerical model of an aquaculture structure under oscillatory flow. Aquac. Eng. 2020, 89, 102054. [Google Scholar] [CrossRef]

- Feng, D.; Meng, A.; Wang, P.; Yao, Y.; Gui, F. Effect of design configuration on structural response of longline aquaculture in waves. Appl. Ocean Res. 2021, 107, 102489. [Google Scholar] [CrossRef]

- Cheng, W.-W.; Xu, Y.-Y.; Mu, P. Experimental and numerical investigation of the dynamic responses of longline aquacultural structures under waves. Ocean Eng. 2023, 276, 114234. [Google Scholar] [CrossRef]

- Yao, G.-Q.; Ma, Z.-X.; Ding, B.-C.; Wang, J.-Y. Statistical analysis of annual ultimate values of waves in the Yellow Sea and the Bohai Sea. China Harb. Eng. 1992, 4, 31–37. [Google Scholar]

- Zhang, X.-Z.; Kong, Y.-W. Research on offshore significant wave height based on satellite observation data. Technol. Ind. Across Straits 2017, 1, 80–81. [Google Scholar] [CrossRef]

- Qiu, W.-B.; Li, G.-Y.; Xu, J.-C.; Hu, Y.-Q.; Wang, Y.-D.; Shi, H.-Y. Spatial and temporal variation characteristics of the waves in the Yellow Sea and Bohai Sea. Mar. Sci. 2021, 45, 1–8. [Google Scholar] [CrossRef]

- Kapetsky, J.; Aguilar-Manjarrez, J.; Jenness, J. A Global Assessment of Offshore Mariculture Potential from a Spatial Perspective; FAO Fisheries and Aquaculture Technical Paper NO. 549; Fisheries and Aquaculture Management Division: Rome, Italy, 2013. [Google Scholar]

- Ryan, J. Farming the deep blue. In Bord Iascaigh Mhara Technical Report; BIM: Dublin, Ireland, 2004; Available online: http://www.bim.ie/media/bim/content/downloads/Farming,the,Deep,Blue.pdf (accessed on 2 February 2023).

- You, X.; Kumazawa, T.; Ito, S.; Hattori, R.; Yu, H.; Shiode, D.; Hu, F. Sediment recognition by warp tension monitoring of bottom otter trawling and applying the self-organizing map algorithm. Ocean Eng. 2021, 236, 109455. [Google Scholar] [CrossRef]

- Lin, J.; Li, C.; Zhang, S. Hydrodynamic effect of a large offshore mussel suspended aquaculture farm. Aquaculture 2016, 451, 147–155. [Google Scholar] [CrossRef]

- Zhan, J.M.; Jia, X.P.; Li, Y.S.; Sun, M.G.; Guo, G.X.; Hu, Y.Z. Analystical and experimental investigation of drag on nets of fish cages. Aquac. Eng. 2006, 1, 91–101. [Google Scholar] [CrossRef]

- Zhao, Y.P.; Bi, C.W.; Dong, G.H.; Gui, F.K.; Cui, Y.; Xu, T.J. Numerical simulation of the flow field inside and around gravity cages. Aquac. Eng. 2013, 52, 1–13. [Google Scholar] [CrossRef]

- Bi, C.W.; Zhao, Y.P.; Dong, G.H.; Zheng, Y.X.; Gui, F.K. A numerical analysis on the hydrodynamic characteristics of net cages using coupled fluid–structure interaction model. Aquac. Eng. 2014, 59, 1–12. [Google Scholar] [CrossRef]

- Mjåtveit, M.A.; Cheng, H.; Ong, M.C.; Lee, J. Comparative study of circular and square gravity-based fish cages with different dimensions under pure current conditions. Aquac. Eng. 2022, 96, 102223. [Google Scholar] [CrossRef]

- Cheng, H.; Li, L.; Ong, M.C. Comparative study of five commonly used gravity type fish cages under pure current conditions. Ocean Eng. 2022, 250, 110977. [Google Scholar] [CrossRef]

| Components | Parameters | Prototype | Model of 1/12 |

|---|---|---|---|

| Lantern net | Material | Polyethylene | Polyethylene |

| Diameter | 0.29 m | 2.42 cm | |

| Height | 1.6 m | 13.3 cm | |

| Length for each layer | 0.2 m | 1.67 cm | |

| Mass of lantern net (weight in water) | 9 kg | 27.8 g | |

| Net mesh | Material | Polyethylene | Polyethylene |

| Diameter | 0.002 m | 0.1 cm | |

| Length | 0.02 m | 0.3 cm | |

| Main line | Material | Polyethylene | Polyethylene |

| Diameter | 0.026 m | 0.22 cm | |

| Length | 100 m | 833 cm | |

| Mooring line | Material | Polyethylene | Polyethylene |

| Diameter | 0.026 m | 0.22 cm | |

| Length | 36 m | 300 cm | |

| Buoy | Material | polyethylene | polyethylene |

| Diameter | 0.2 m | 5.1 cm | |

| Buoyancy | 16.5 kgf * | 9.2 gf * | |

| Tether line 1 | Material | Polyethylene | Polyethylene |

| Diameter | 0.009 m | 0.05 cm | |

| Length | 1.8 m | 15 cm | |

| Tether line 2 | Material | Polyethylene | Polyethylene |

| Diameter | 0.006 m | 0.08 cm | |

| Length | 1.2 m | 10 cm |

| Wave Height H (m) | Periods T (s) | Wavelength L (m) | |

|---|---|---|---|

| 1 | 0.083 | 1.15 | 2.07 |

| 2 | 1.44 | 3.05 | |

| 3 | 1.73 | 3.98 | |

| 4 | 2.02 | 4.91 | |

| 5 | 0.125 | 1.44 | 3.05 |

| 6 | 1.73 | 3.98 | |

| 7 | 2.02 | 4.91 |

| Component | Lantern Net | Buoy |

|---|---|---|

| Projected area | 3.19 × 10−3 m2 | 2.04 × 10−3 m2 |

| Number | 15 | 17 |

| Drag coefficient | 0.8 ± 0.1 | 0.5 |

| Current velocity (m/s) | Inclined angle (deg.) | Ratio of submerged volume |

| 0.149 | 10 | 0.26 |

| 0.223 | 18 | 0.29 |

| 0.297 | 23.7 | 0.32 |

| 0.371 | 30.7 | 0.35 |

| 0.446 | 36.7 | 0.38 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Xie, J.; Luo, Y.; Wang, X.; Guo, G.; You, X. Experimental Investigation of the Hydrodynamic Characteristics of Longline Aquaculture Facilities under Current and Wave Conditions. Fishes 2023, 8, 204. https://doi.org/10.3390/fishes8040204

Wang X, Xie J, Luo Y, Wang X, Guo G, You X. Experimental Investigation of the Hydrodynamic Characteristics of Longline Aquaculture Facilities under Current and Wave Conditions. Fishes. 2023; 8(4):204. https://doi.org/10.3390/fishes8040204

Chicago/Turabian StyleWang, Xinxin, Junyi Xie, Yan Luo, Xiao Wang, Gaobo Guo, and Xinxing You. 2023. "Experimental Investigation of the Hydrodynamic Characteristics of Longline Aquaculture Facilities under Current and Wave Conditions" Fishes 8, no. 4: 204. https://doi.org/10.3390/fishes8040204

APA StyleWang, X., Xie, J., Luo, Y., Wang, X., Guo, G., & You, X. (2023). Experimental Investigation of the Hydrodynamic Characteristics of Longline Aquaculture Facilities under Current and Wave Conditions. Fishes, 8(4), 204. https://doi.org/10.3390/fishes8040204