Abstract

Onshore farming for premium aquaculture is under scrutiny and criticism partially due to possible causes of adverse environmental impacts on other resource users and the surrounding environment. The best alternative to preventing or minimizing these impacts is to utilize open seawater by large submersible cage culture. The current operation in Taiwan has demonstrated that the culture operation is technically feasible but economically demanding because of high capital and operating costs. Therefore, this study conducted an economic analysis of the expansion of large submersible cage culture by selecting two premium species of snubnose pompano (Trachinotus anak) and cobia (Rachycentron canadum) and examined the profitability of large submersible cage culture investment. This study found that the current operation of four-unit cages highlighted a negative net present value and internal rate of return with a payback period of over ten and six years, respectively. Large submersible cage culture can be financially profitable when its operation unit expands from 8 to 24 units. Increasing unit cages to eight incurred a gross margin of 17.09%, BCR 1.21, with a payback period of 5.36 years. Expanding the operation to 24-unit cages was a potentially lucrative investment with a gross margin of 18.51%, BCR 1.23, PI 2.15, internal rate of return of 20.84%, and a payback period of 3.55 years. Sensitivity analyses revealed that market price and survival rate significantly impact the profitability of large submersible cage culture. Finally, it is suggested that producers could invest in 8-unit cages and maintaining the survival rate of snubnose pompano and cobia at 80% and 40%, respectively.

1. Introduction

Onshore farming for premium aquaculture is under scrutiny and criticism partially because they are believed to generate adverse environmental impacts on other resource users and the surrounding environment. Taiwan is located in the subtropical zone, surrounded by the sea on all sides, with a coastline of 1961 km. It has a high degree of marine biodiversity and a climate and environment suitable for the development of fisheries. Most of Taiwan’s aquaculture areas are in offshore and coastal areas, with aquaculture and fisheries covering an area of 44,000 hectares, and cage net aquaculture only accounting for about 30 hectares.

The major development of Taiwan’s cage culture occurred in 1988. Mostly in the littoral areas of Penghu and Pingtung, the peak yield was more than 5000 MT [1,2]. However, the culture facility and culture management techniques are immature. In recent years, the yield remains at about 2500 MT, accounting for about 1% of Taiwan’s culture fishery production [3]. There are merely 11 farmers at present. According to geographical location, two to three typhoons pass through Taiwan annually, and the China coastal current moves south in the winter. Therefore, the net cages are mostly concentrated in the Penghu basin or inshore waters of Pingtung to avoid the attack of typhoons and facilitate routine culture management operations [4,5,6,7]. However, the Penghu basin is not deep enough, and the water flows slowly. The culture waste cannot all be taken away by the ocean current or tides. Over the years, the sea areas became polluted gradually, inducing many fish diseases. Due to typhoons or heavy rainfall, the land-based pollution source is often brought into the Pingtung Sea area, thereby causing harm to net cages and the cultured organisms. Many environmental organizations worldwide criticize that the pollution source induced by inshore culture fishery is hazardous [5,8,9].

In recent years, cage culture has been progressively moved to wider waters in many countries. Open sea areas have deeper waters and stronger ocean currents, which could prevent environmental pollution and fish diseases. They are more friendly to the culture environment and favorable for sustainable operation [10,11,12,13]. Therefore, the government of Taiwan investigated the aquatic characteristics, tidal current, ocean waves, hydrology, water quality, coastal current of the sea areas around Taiwan, the constraints of the existing industrial equipment, the probability of addressing acquisition, and waterways in 2016. They selected a water depth of 40~70 m with an annual mean wave height under 0.1 m and an annual average flow velocity lower than 0.3 m/s to plan the possible areas for developing net cages in the open sea. This attempt aimed to assist the farmers in Pingtung area to build a demonstration field of large-sized net cages with a circumference of 100 m and a net depth of 15 m between 2017 and 2019 (Figure 1). The goal was to divert Taiwan’s cage culture industry to the large-scale and scale-up culture enterprise type.

Figure 1.

Cage aquaculture 3 km offshore from Haikou Port, Checheng Township, Pingtung. The purple circle and the ref circle in this figure locate our cages.

The tested annual output of offshore large net cage cultured snubnose pompano is 200 tons/cage year. The cage culture is a high-risk and high-profit capital concentrated industry. For farmers to be offshore, upsizing and scaling-up will certainly increase capital expenditure and operating costs. The culture management model and challenges are also different from traditional inshore culture. Therefore, comprehensive evaluation and planning are required before investment [1,14,15,16].

The technical, economic, and legal feasibility should be considered in the investment in culture fishery [17]. Taiwan is actively involved in research, development, and discussions at the technical and legal levels. From the economic perspective, this study adopted the cost-effective method and sensitivity analyses to analyze the economic feasibility and investment potential of developing offshore cage culture in Taiwan. It also evaluated the appropriate production scale of initial investment to provide integrated information on industrial transformation and trade investment in cage culture in Taiwan.

2. Materials and Methods

2.1. Study

All data in this study were collected from the research site based on the sea area of the Haikou Offshore Demonstration Field in Checheng Township, Pingtung County, Taiwan (Figure 1). This study selected two species, snubnose pompano (Trachinotus anak) and cobia (Rachycentron canadum). The analytic data were divided into preliminary data and secondary data. The questionnaire for the preliminary data was designed according to the variables influencing the production benefit of cage culture, including economic, biological, and technical variables. Farmers, scholars, and experts of cage culture were interviewed on-site in May 2020 to find out about the farmers’ business processes, considerations in production, and risk management in the cage culture industry. The secondary data were derived from the market statistics on the global information network of fishery products of the Fisheries Agency from 2015 to 2019. Quote the exchange rate published by the Bank of Taiwan on 15 July 2022. This study evaluated the selling price range and occurrence probability according to the market prices of snubnose pompano and cobia for the past five years.

2.2. Offshore Cage Aquaculture Facility

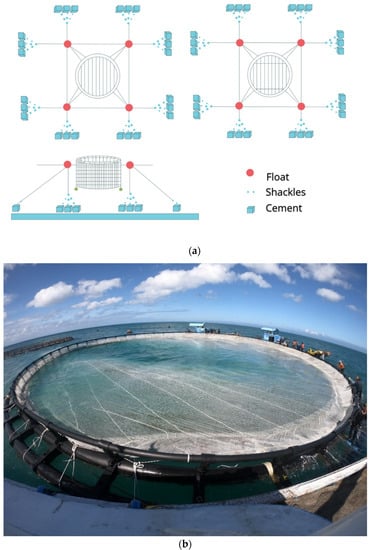

A basic schematic of the offshore cage aquaculture facility is summarized in Figure 2, and Table 1 summarizes its general specifications.

Figure 2.

(a) Schematic of the components and construction of the circular cage net; (b) the real-world cage.

Table 1.

Submerged circular cage net system specifications and construction costs.

2.3. Cost–Benefit Analysis

The cost–benefit analysis adopted in this study was based on previous studies [17,18]. The experiment selected five economic indicators: benefit–cost ratio (BCR), profitability, net present value (NPV), internal rate of return (IRR), and cost recovered years. It set a 10-year term of investment for simulated evaluation of investing in different target species in cage culture. The BCR was used for evaluating culture productivity in culture economics [2,19,20,21,22,23]. The cost was divided into operating expense (OPEX) and depreciation cost (DC) in the cost–benefit analysis operation. The OPEX referred to the expenses required in the cage culture process, such as the costs of fries, water and electricity, personnel, and feed. It excluded the initial investment in construction. The DC referred to the acquisition cost of hardware facilities, such as net cage systems and automated equipment. The depreciation period of each equipment is not consistent, and the depreciation amount amortized each year has little impact on the overall calculation. This study excludes the depreciation expense and does not recognize it. The cost–benefit ratio and profitability were calculated based on net revenue. The NPV, IRR, and cost recovered years were calculated using cash flow (CF) [24]. The discount rate is calculated by using the Weighted Average Cost of Capital (WACC) as the determined discount rate, for which the loan interest rate of 6% is the summary of the interest rates reported by the Credit Department of the 283 Agricultural Associations in Taiwan in August 2020. The average basic lending rate in the table and the expected return on investment of shareholders are 10%. Based on this, the discount rate of this study is calculated to be 10%.

As with all economic analyses, assumptions need to be made to simplify the study and maintain the focus of the analysis on the appropriate areas. With four cages as a unit, the assumptions used in this study were developed using the actual data from cages. Different constructs, i.e., 4, 8, 16, 20, 24 cages, are included in our assumptions. Taking a group of four-unit cages as an example, the construction cost of matching aquaculture production equipment is 15.96 million NTD (Table 2). All income, operating costs, and biological data were based on data obtained during the ten years of operation of the offshore cage aquaculture. The cost of equipment attaching to different cage constructs is assumed to be the same in our experiments. When the number of cages reaches sixteen units, to improve operation efficiency and ship transportation capacity, an additional CT-5 fishing boat is required (20 million NTD), and the rest of the equipment configuration is unchanged.

Table 2.

Cost–benefit analysis of 4 cages during ten-year production.

2.4. Operational Scale of Cage Culture

Economic models were developed in this study to assess and compare the effects of the operational scale of cage culture on profitability for hypothetical 8, 16, 20, and 24 cages aquaculture. The economic analysis techniques used were based on 4 cages aquaculture. The data obtained from 4 cages were sound, and assumptions were developed for these larger-scale facilities. Based on the market price analysis results for the 4 cages aquaculture, income data were applied to these models to determine the long-term income projections for 8, 16, 20, and 24 cages. Most operating costs for 8, 16, 20, and 24 cages were developed based on costs incurred for 4 cages, with additional expert opinion provided by breeding experts who actually operate the cage culture as to how these costs may change at different scales.

2.5. Analysis of Key Variables Affecting Offshore Cage Aquaculture Profitability

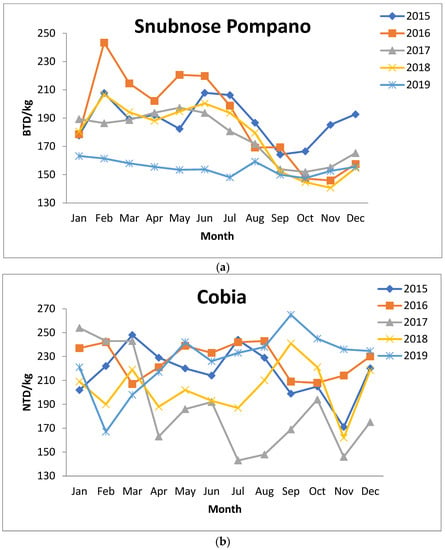

A sensitivity analysis was conducted to highlight areas where improvement of the offshore cage aquaculture may have the greatest performance and economic impact. The survival rate and farm price were addressed by comparing the financial performance in a variable range. The farm price used for sensitivity analysis was derived from the highest occurrence over a period of five years (Figure 3).

Figure 3.

Fish market price in Taiwan from 2015 to 2019: (a) Snubnose pompano (b) Cobia.

3. Result

Table 1, Table 2 and Table 3 show the cage aquaculture specifications and its construction costs. The total investment for 4 cages is NTD 159.550 million. The cages are a significant proportion of the investment (NTD 72 million), and the workboat is the second largest investment. Table 4 shows the summary production variables of snubnose pompano (Trachinotus anak) and cobia (Rachycentron canadum) in 4 cages. Table 2 shows the expenditure and financial performance of both species. Feed is the main expense of production, and fry is the second largest expense. The net revenue of snubnose pompano was NTD 20.1 million and cobia was NTD 28.6 million. The gross margin of snubnose pompano and cobia was 14.94% and 20.82%, respectively. The cost–benefit ratios of both species were 1.18 and 1.26, but snubnose pompano incurred a profit index of 0.98. This indicates that the project is not feasible for investment. In addition, both species incurred a negative NPV, showing the producers to have suffered a loss in both species. Snubnose pompano’s producers also incurred a negative IRR, and the payback period was 10.04 years.

Table 3.

Initial investment for cage aquaculture.

Table 4.

Basic production parameter of cage aquaculture (4 cages).

Table 5 shows the scenario of increasing the cages’ units for raising both species. Capital expenditure for 8 units is NTD 231.5 million. This cost increased with increasing cages’ units. Total expense for 24 units was NTD 539.5 million, which was 3.3 times higher compared to 4 units. There was an additional CT-3 and CT-5 workboat from 16- to 24-unit cages’ operation. Increasing the cages’ units also affected production costs. The operation cost of subnose pompano doubled from 8 to 24 units, increasing significantly. The feed cost remained the main expense. In cobia farming, feed is also the main expense, and fry is the second-largest expense covering 95% of the production cost.

Table 5.

Investment, production cost, and revenue of snubnose pompano and cobia production in different number of cages.

The profitability measure highlighted that the gross margin increased from 8 units, but gross margin and BCR almost remained similar from 16 to 24 units (Table 6). NPV increased significantly with increasing cages’ units, and the IRR also followed a similar trend. Additionally, increasing the cages’ units decreased the payback period. The 24 units showed a payback period of 3.55 years. The gross margin of cobia farming in 24 units was 24.54%, and the benefit–cost ratio was 1.33. NPV also increased as the cages’ units increased. The 24 units gained the highest IRR (30.19%) and the lowest payback period (2.69 years).

Table 6.

Summary of financial indicators of snubnose pompano and cobia production in different number of cages.

Table 6 shows that when the scale of the cages’ units was increased every four units, the fish fry and feed expenditure of the snubnose pompano and cobia increased with an increase in the number of fish. Other expenses decreased with the increase in the number of cage units. The unit production cost of snubnose pompano fell from 155 NTD/kg (4 units) to 149 NTD/kg (24 units). Additionally, the unit production cost of cobia dropped from 167 NTD/kg (4 units) to 159 NTD/kg (24 units).

This study analyzed the sensitivity based on the survival rate and the market price. The simulation comprised of three survival rate scenarios and four market price ranges (Table 7). When the price of snubnose pompano remained unchanged at 181 NTD/kg and the survival rate was 70%, producers incurred a gross profit margin of 13.81%, BCR of 1.16, profitability index of 1.26, negative NPV (−67,061), IRR of 5.21%, and a payback period of 7.03 years. Increasing the survival rate to 90%, producers incurred NPV NTD of 195.7 million and a payback period of 2.24 years. The financial and economic indicators showed that increasing survival rates led to an economically feasible investment. A similar trend was also revealed in cobia farming, whereby increasing the survival rate to 50% led to an economically feasible investment.

Table 7.

Sensitivity analysis of snubnose pompano and cobia at different farm prices and survival rates.

4. Discussion

The analysis of 4 cages on snubnose pompano and cobia found that the investment forecast was not economically viable. After the 10-year projection, the investment incurred a negative NPV of –NTD 56,696 and –NTD 22,126, respectively (Table 6). The current investment highlights that such losses are difficult to accept the investment in 4 cages.

According to profit indicators, snubnose cobias and pompanos are unprofitable. All indicators were negative, with an investment payback period for snubnose pompano over ten years and cobia over six years. These results are contrary to an economic analysis of cobia on a large production scale in Brazil [25]. Cobia farming in Brazil by an installation of twenty-four 1607 m3 cages, a total volume of 38,568 m3 unit cages, stocking density of 3 fish/m3, yield of 316,358 kg/year, and selling price of 8.62 USD/kg, incurred a positive NPV of USD 297,615 and a payback period of 3.88 years. The feed cost is the main expense (64.43%) and is more sensitive to FCR, selling price, and productivity fluctuation. The operation expense in Brazil and Taiwan is almost similar. The main reason for the high discrepancy in profitability is due to the high initial investment in Taiwan. Producers in Taiwan have invested in several supporting infrastructures, such as workboats, repair bases, primary processing refrigeration equipment, and heavy machinery equipment. Moreover, the different market prices also reveal the gap in profit incurred. The selling price in Brazil is 8.62 USD/kg and in Taiwan is 7.3 USD/kg. The high selling price in Brazil means producers incur a better profit performance.

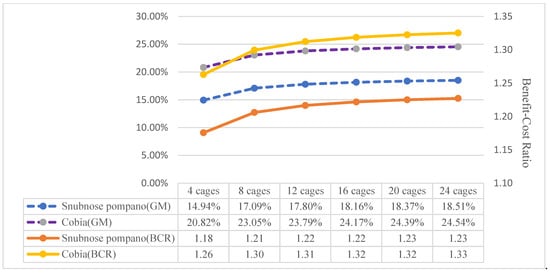

The operational scale of cage culture can be discussed due to the development of economic models for hypothetical 8 to 24 cage investment. In contrast to the non-viability of 4 cage investment, the hypothetical 8 cages for snubnose pompano farming appeared marginally viable, with a positive NPV of NTD 3.631 million. The hypothetical 16 cages incurred a gross margin of 18.16%, BCR of 1.22, and a payback period of 4.06 years. Further increasing the unit cages to 20 units gained a gross margin of 18.37%, NPV of NTD 164.612 million, IRR of 19.21%, and payback period of 3.75 years. The data highlight the importance of the potential for economic viability at higher output levels. The hypothetical 20-unit cage investment demonstrates the importance of the operational scale of cage culture for economic viability (Table 6). The results also indicate that the 24 cage was economically viable with a gross margin of 18.51%, BCR of 1.23, PI of 2.15, IRR of 20.84%, and a payback period of 3.55 years. Investment in 8 or more units not only showed better financial performance than the 4 cages, but also appeared to be a potentially lucrative investment opportunity (Figure 4). The financial indicator in cobia farming suggests a similar trend: increasing cages’ units increases the profit gained by producers. The economic analysis of large cage culture in [17] demonstrated that the profit indicators of more than 8 cages are positive. The profitability is gradually improved with the increased number, and 16-unit cages are recommended due to their reasonable investment and easiness to manage. For 16 cages, cobia’s total annual breeding cost is NTD 493.903 million, with a BCR of 1.32, an NPV of NTD 242.563 million, and an IRR of 25.66%. The breeding cost of snubnose pompano is NTD 555.792 million, with a BCR of 1.22, an NPV of NTD 104.285 million, and an IRR of 16.97%. The payback periods of the two species are less than four years and have sufficient profits. According to the recent management experience in cage aquaculture in Taiwan, 16-unit cages can be managed with the presented hypothetical manpower, operating vessels, and automated equipment. Moreover, risk management and environmental carrying capacity must be considered to facilitate environmentally sustainable operation. The previous study reported that cobia has the greatest potential among all candidate species for offshore cage culture in Taiwan [1]. Increasing the system size in cobia production would be more profitable. Cobia farming is highly profitable compared to other aquaculture species [26].

Figure 4.

Analysis of the optimal production scale of cage aquaculture.

The sensitivity analyses on investing in different units of cages found that increasing the sale price and survival rate are the two key variables that have the most significant effect on the profitability of large-scale submersible cage culture. The analyses also showed that the survival rate of 70% of snubnose pompano was profitable at a price of 191 to 211 NTD/kg. Moreover, the survival rate of 30% in cobia farming was profitable at a price of 211 to 231 NTD/kg. The analysis revealed that an increase in the survival rate to 80% of snubnose pompano contributed to better economic performance in 16 to 24 cages. Additionally, increasing the survival rate to 40% of cobia resulted in better financial indicators (Table 7). Another study found that a 16-unit cage was the optimal production scale based on cost–benefit analysis using PR, NPV, IRR, and payback period. As shown in Figure 4, the optimum production scale conditions were satisfied with the economic benefits of investment when 16-unit cages were constructed. The breakeven point for cobia was achieved at a survival rate of 50% and a purchasing price of 235 NTD/kg. In other words, at an average survival rate of 50%, dealers can still make profits if the purchasing price of cobias drops to 201 NTD/kg. At a purchasing price of 231 NTD/kg, it only takes a survival rate of 30% to make profits. Regarding investments in snubnose pompano, profits can still be made at an average survival rate of 90% if the price drops to 181 NTD/kg. At a purchasing price of 191 NTD/kg, it only takes a survival rate of 70% to break even.

The development of large cage culture also has a negative impact that is not well-regulated. The rapid development of offshore mariculture also brings environmental challenges and requests for carrying capacity management [27,28]. The environmental restrictions of sea cage culture prevent the accumulation of particulate pollutants at the sediment level through migration and transportation [29,30,31]. The accumulation of particulate matter is a cumulative process, and most of the particles are deposited around the fish farms. The results of [31] indicated that sea cage culture has a limited influence on seawater environmental quality, whereas higher pollution levels were predicted for the sediment. A high stocking density and excessively using commercial feed had a negative impact on the environment. In the form of uneaten feeding pellets and fish-released feces, particulate waste is considered the primary source of ecological impact on the benthic community [32,33]. The feed composition directly determines the number of pollutants generated by the cage, especially in the release of nitrogen and phosphorus [34,35,36,37]. Therefore, exploring the sea area by determining the carrying capacity is useful for sustainable environmental management of large submersible cage culture.

In recent years, the government of Taiwan has advocated developing agriculture as a business operation and encouraged agriculture and fishery to transform smallholder economy into the business management model and use strategic and technical operations for initial public offerings. The government also assists companies to enter the extensive capital market to effectively raise funds for their future development, debt refunding, and operating costs. The enterprises interested in such direction can establish internal audit, internal control, and sound auditing systems to manage the operational risks, identify corporate competitiveness, adjust the operating guidelines, and improve the financial structure. However, there are serious challenges to asset risk control and produce yield improvement in the evolutionary process of culture fishery. The industry’s biological assets and non-biological assets (net cage facilities) are on the sea, making it undesirable as compared to the onshore culture. The asset risk control is difficult, and the asset insurance (cultured species or facilities) is unavailable. The financial institutions are hesitant to approve the loan. To collect funds from the public, the pre-operation is complicated, the working liabilities are increased, and the required cost is high. It is very difficult for the enterprises without the scale of operation, sound financial statement, or stable profit.

Referring to the developed countries of cage culture, the automatic and intelligent big data system is an essential tool for mariculture industry upgrade. Developing the scale efficiency is necessary to implement the profit of mariculture. The scale efficiency decision-making aims at the optimum economic benefit, which should be presented by appropriate asset allocation or reasonable production conditions. Having a good culture sea area environment, appropriate culture sea area, and adequate working capital is the foremost step in the scale-up development of the cage culture industry. When the culture sea area is diverted to the unshaded deep-sea area far from the coast, the culture environment is closer to nature and a better culture management technique is required. Therefore, the countries where the marine cage culture develops rapidly are oriented to scale-up, automation, and big data intelligence, aiming to resist the worst sea conditions, high yield, and intelligent accurate management.

The findings of this study show that only the scale operation of cage culture has good economic feasibility, but the demand for funds is high. A stable and adequate flow of funds is an important factor in enterprise operation. The techniques of operations cannot be enhanced without funds. Furthermore, the biological culture management improvement or importing the automated and advanced equipment, professional teams, talent cultivation, brand operation, and marketing channels are closely related to enterprises’ activable and available funds. The FAO [38] presented opinions on the development of marine cage culture in Asia in a global outline and regional comments on cage culture. The cage culture industry in Asia has a promising future. The cobia is very promising to be a global product. Under the cultural influence, Asia cannot expand development by vertical integration as Norway or Chile do, but the enterprises can develop in a cooperative manner to exert effective industrial power. For developing large-scale disaster-resistant submersible cages with a circumference over 100 m and 3 km away from the coast in Taiwan, time- and labor-saving, safe, intelligent, and automated equipment should be used. These systems could be automatic sensing systems for hydrology and images, automatic bait-casting systems, automatic net-washing machines, automatic fish pumps, and automatic dead fish clearing. Only the large data-based AI decision-making system can increase the culture efficiency, reduce the culture cost, and effectively protect biological and nonbiological assets on the sea.

5. Conclusions

Taiwan’s onshore culture area is about 40,000 ha. The culture production is about 300,000 MT. In recent years, the Taiwan government has been dedicated to green energy. The green energy is estimated to be 25% of the total electricity generation of Taiwan in 2025. A part of land-based fishponds will evolve into fishery-electricity symbiosis, and 3000 ha of land for fishponds has been planned for developing solar energy. The culture fishery production will be influenced in the future. Taiwan’s culture fishery is mostly petty-farmer management, and the industry lacks international competitiveness. The net cages in the open sea are of capital-intensive industry, and the labor-intensive culture management should be changed into a technology-intensive management style. The application of various automated equipment contributes to the transformation of the traditional culture fishery of Taiwan. Taiwan is surrounded by seas, but the cage culture yield only accounts for 1%. This refers to the underutilization of sea resources. As the onshore culture area gradually decreases and the offshore area is polluted, Taiwan’s cage culture will certainly develop towards far and deep-sea areas. In 2016, the FAO conducted a survey on the coastal countries suitable for the development of cage net aquaculture in the world, and evaluated the conditions such as water depth, flow rate, and cost-effective sea area. In the countries suitable for the development of offshore cage net conditions, Taiwan ranked third, and the production base of offshore cage net aquaculture was quite similar, excellent and regarded as having great potential for development. Taiwan is surrounded by seas with a high degree of marine biodiversity, and the climate and environment are suitable for the development of fisheries. Taking advantage of the sea area to expand the area of marine cage net aquaculture can not only increase the share of marine aquaculture, but also reduce freshwater consumption and carbon emissions. The inevitable development trend of Taiwan’s aquaculture industry is to overcome the risks brought by strong winds, waves, and flow speed in the open sea through aquaculture-related equipment automation and intelligent technology, ocean energy power generation equipment, genetic breeding, feed processing, vaccine production, aquatic product processing, cold chain logistics, Internet of Things, and other industrial chains, in order to create rural economic development and increase employment. The findings of this paper have economic feasibility. Future investors need to carefully evaluate the levels of culture technique and operating management.

Author Contributions

Conceptualization, H.-Y.L. and C.-T.H.; methodology, H.-Y.L.; validation, H.-Y.L. and B.-Y.C.; formal analysis, H.-Y.L. and B.-Y.C.; investigation, H.-Y.L., B.-Y.C. and P.-L.H.; resources, Y.-L.H.; writing—original draft preparation, H.-Y.L., F.A. and B.-Y.C.; writing—review and editing, H.-Y.L., F.A. and B.-Y.C.; supervision, C.-T.H.; project administration, C.-T.H.; funding acquisition, C.-T.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by two government agencies. One is the Fisheries Agency, and the other is the Ministry of Science and Technology (MOST). The Fisheries Agency, Council of Aquaculture (FA.COV), grant numbers 105AS-14.3.1-FA-F2 and 106RR-2.2.4-1.3-FA-002. The Ministry of Science and Technology (MOST), grant number 110-2634-F-019-001. The funding sources had no involvement in the conduct of this study or submission for publication.

Institutional Review Board Statement

Not applicable.

Acknowledgments

The authors would like to thank the farmers, experts, and scholars and for participating in the interviews and for providing valuable information on cage culture farming.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Miao, S.; Tang, H.C. Bioeconomic analysis of improving management productivity regarding grouper Epinephelus malabaricus farming in Taiwan. Aquaculture 2002, 211, 151–169. [Google Scholar] [CrossRef]

- Jiang, B.; Guo, Q.K.; Li, Z.C.; Guo, Y.X.; Su, Y.L.; Li, W.; Liu, C.; Li, A.X. Biofouling of nets is a primary source of cryptocaryoniasis outbreaks in cage cultures. Aquaculture 2022, 550, 737892. [Google Scholar] [CrossRef]

- Fisheries Agency Fisheries. Statistical Yearbook-2020; Fisheries Agency Fisheries Council of Agriculture: Taipei, Taiwan, 2020.

- Huguenin, J.E. The design, operations and economics of cage culture system. Aquac. Eng. 1997, 16, 167–203. [Google Scholar] [CrossRef]

- Stickney, R.R. Impact of cage and net-pen culture on water quality and benthic communities. In Tomasco; Aquaculture and The Environment in the United States; Tomasso, J.R., Ed.; US Aquaculture Society: St Amant, LA, USA, 2002; pp. 105–118. [Google Scholar]

- Sarkar, U.K.; Mishal, P.; Borah, S.; Karnatak, G.; Chandra, G.; Kumari, S.; Das, B.K. Status, potential, prospects and issues of floodplain wetland fisheries in India: Synthesis and review for sustainable management. Rev. Fish. Sci. Aquac. 2021, 29, 1–32. [Google Scholar] [CrossRef]

- Mrityunjoy, K.; Debasish, P.; Ahmed, H.R. Optimization of stocking density for mono-sex Nile tilapia (Oreochromis niloticus) production in riverine cage culture in Bangladesh. Heliyon 2021, 7, e08334. [Google Scholar]

- Shainee, M.; Ellingsen, H.; Leira, B.J.; Fredheim, A. Design theory in offshore fish cage designing. Aquaculture 2013, 392, 134–141. [Google Scholar] [CrossRef]

- Noroi, G.; Glud, R.N.; Gaard, E.; Simonsen, K. Environmental impacts of coastal fish farming: Carbon and nitrogen budgets for trout farming in Kaldbaksfjøurdur (Faroe Island). Mar. Ecol. 2011, 431, 223–241. [Google Scholar]

- Kapetsky, J.; Aguiler-Manjarrez, J.; Jenness, J. A global assessment of offshore mariculture potential from a spatial perspective. In FAO Fisheries and Aquaculture Technical Paper; FAO: Rome, Italy, 2013. [Google Scholar]

- Kankainen, M.; Mikalsen, R. Offshore Fish Farm Investment and Competitiveness in the Baltic Sea; Aquabest Project 2; Finnish Game and Fisheries Research Institute: Helsinki, Finland, 2014. [Google Scholar]

- Bjelland, H.V.; Fore, M.; Lader, P.; Kristiansen, D.; Holmen, I.M.; Fredheim, A.; Grotli, E.I.; Fathi, D.E.; Oppedal, F.; Utne, I.B.; et al. Exposen aquaculture in Norway. In MTS/IEEE Washington; Insitute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2015. [Google Scholar]

- Holm, P.; Buck, B.H.; Langan, R. Introduction: New Approachs to Sustainable Offshore Food Production and the Development of Offshore Platforms. Aquaculture Perspective and Multi-Use Sites in the Open Ocean; Springer: Cham, Switzerland, 2017; pp. 1–20. [Google Scholar]

- Klinger, D.; Naylor, R. Searching for solutions in aquaculture: Charting a sustainable course. Annu. Rev. Environ. Resour. 2012, 37, 247–276. [Google Scholar] [CrossRef]

- Chowdhury, M.A.; Roy, N.C.; Chowdhury, A. Growth, yield and economic returns of striped catfish (Pangasianodon hypophthalmus) at different stocking densities under floodplain cage culture system. Egypt. J. Aquat. Res. 2020, 46, 91–95. [Google Scholar] [CrossRef]

- Weaver, T. Financial appraisal of operational offshore wind energy projects. Renew. Sustain. Energy 2012, 16, 5110–5120. [Google Scholar] [CrossRef]

- Huang, C.T.; Afero, F.; Hung, C.W.; Chen, B.Y.; Nan, F.H.; Chiang, W.S.; Tang, H.J.; Kang, C.K. Economic feasibility assessment of cage aquaculture in offshore wind power generation areas in Changhua County, Taiwan. Aquaculture 2022, 548, 737611. [Google Scholar] [CrossRef]

- Lipton, W.L.; Kim, D.H. Assessing the economic viability of offshore aquaculture in Korea: An evaluation based on rock bream, oplegnathus fasciatus, production. World Aquac. Soc. 2007, 38, 506–515. [Google Scholar] [CrossRef]

- Nguyen, P.V.; Huang, C.T.; Hsiao, Y.J.; Truong, K.H. Data envelopment analysis for production efficiency improvement: An empirical application on Brine shrimp Artemia franciscana culture in the Mekong Delta, Vietnam. Aquac. Res. 2020, 51, 2985–2996. [Google Scholar]

- Iliyasu, A.; Mohamed, Z.A. Evaluating contextual factors affecting the technical efficiency of freshwater pond culture systems in Peninsular Malaysia: A two-stage DEA approach. Aquac. Rep. 2016, 3, 12–17. [Google Scholar] [CrossRef][Green Version]

- Huang, C.T.; Nguyen, P.V.; Chen, Y.T.; Liang, T.T.; Nan, F.H.; Liu, P.C. Improving productivity management of commercial abalone Haliotis diversicolor supertexta and Haliotis discus hannai aquaculture in Taiwan: A bioeconomic analysis. Aquaculture 2019, 512, 734323. [Google Scholar] [CrossRef]

- Nogueira, M.C.F.; Henriques, M.B. Large-scale versus family-sized system production: Economic feasibility of cultivating Kappaphycus alvarezii along the southeastern coast of Brazil. J. Appl. Phycol. 2020, 32, 1893–1905. [Google Scholar] [CrossRef]

- Ahmad, T.; Zhang, D.D. Renewable energy integration/techno-economic feasibility analysis, cost/benefit impact on islanded and grid-connected operations: A case study. Renew. Energy 2021, 180, 83–108. [Google Scholar] [CrossRef]

- Castilho-Barrosa, L.; Owatari, M.S.; Mouriño, J.L.P.; Silva, B.C.; Seiffert, W.Q. Economic feasibility of tilapia culture in southern Brazil: A small-scale farm model. Aquaculture 2020, 515, 734551. [Google Scholar] [CrossRef]

- Bezerra, T.R.Q.; Ernesto, C.D.; Luiz, F.A.; Maia, F.; Artur, N.R.; Santiago, H.; Ronaldo, O.C. Economic analysis of cobia (Rachycentron canadum) cage culture in large-and small-scale production systems in Brazil. Aquac. Int. 2015, 24, 609–622. [Google Scholar] [CrossRef]

- Petersen, E.H.; Luan, T.D.; Chinh, D.T.M.; Tuan, V.A.; Binh, T.Q.; Truc, L.V.; Glenncros, B.D. Bioecomic of cobia, Rachycentron canadum, culture in Vietnam. Aquac. Econ.Manag. 2014, 18, 28–44. [Google Scholar] [CrossRef]

- Papageorgiou, N.; Kalantzi, I.; Karakassis, I. Effects of fish farming on the biological and geochemical properties of muddy and sandy sediments in the Mediterranean sea. Mar. Environ. 2010, 69, 326–336. [Google Scholar] [CrossRef] [PubMed]

- Riera, R.; Pérez, Ó.; Cromey, C.; Rodríguez, M.; Ramos, E.; Alvarez, O.; Dominguez, J.; Monterroso, Ó.; Tuya, F. MACAROMOD: A tool to model particulate waste dispersion and benthic impact from offshore sea-cage aquaculture in the Macaronesian region. Ecol. Model. 2017, 361, 122–134. [Google Scholar] [CrossRef]

- Zhang, J.H.; Hansen, P.K.; Fang, J.G.; Wang, W.; Jiang, Z.J. Assessment of the local environmental impact of intensive marine shellfish and seaweed farming—Application of the MOM system in the Sungo Bay, China. Aquaculture 2009, 287, 304–310. [Google Scholar] [CrossRef]

- Holmer, M. Environmental issues of fish farming in offshore waters: Perspectives, concerns and research needs. Aquac. Environ. Interact. 2010, 1, 57–70. [Google Scholar] [CrossRef]

- Zhao, Y.X.; Zhang, J.H.; Liu, Y.; Sun, K.; Zhang, C.; Wu, W.G.; Teng, F. Numerical assessment of the environmental impacts of deep sea cage culture in the Yellow Sea, China. Sci. Total Environ. 2020, 706, 135752. [Google Scholar] [CrossRef]

- Riera, R.; Monterroso, Ó.; Rodríguez, M.; Ramos, E. Biotic indexes reveal the impact of harbour enlargement on benthic fauna. Chem. Ecol. 2011, 27, 311–326. [Google Scholar] [CrossRef]

- Riera, R.; Pérez, Ó.; Rodríguez, M.; Ramos, E.; Monterroso, Ó.; Sacramento, A. Are assemblages of the fireworm Hermodice carunculata enhanced in sediments beneath offshore fish cages? Acta Oceanol. Sin. 2014, 33, 108–111. [Google Scholar] [CrossRef]

- Cai, H.; Sun, Y. Management of marine cage aquaculture environmental carrying capacity method based on dry feed conversion rate. Environ. Sci. Pollut. Res. 2007, 14, 463–469. [Google Scholar]

- Cromey, C.J.; Nickell, T.D.; Treasurer, J.; Black, K.D.; Inall, M. Modelling the impact of cod (Gadusmorhua L.) farming in the marine environment–CODMOD. Aquaculture 2009, 289, 42–53. [Google Scholar] [CrossRef]

- Cromey, C.J.; Thetmeyer, H.; Lampadariou, N.; Black, K.D.; Kögeler, J.; Karakassis, I. MERAMOD: Predicting the deposition and benthic impact of aquaculture in the eastern Mediterranean sea. Aquac. Environ. Interact. 2012, 2, 157–176. [Google Scholar] [CrossRef]

- Cai, H.; Ross, L.G.; Telfer, T.C.; Wu, C.; Zhu, A.; Zhao, S.; Xu, M. Modelling the nitrogen loadings from large yellow croaker (Larimichthyscrocea) cage aquaculture. Environ. Sci. Pollut. Res. 2016, 23, 7529–7542. [Google Scholar] [CrossRef] [PubMed]

- Halwart, M.; Soto, D.; Arthur, J.R. (Eds.) Cage Aquaculture Regional Reviews and Global Overview; Food and Agriculture Organization (FAO): Rome, Italy, 2007; Volume 498, pp. 42–45. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).