Abstract

Friction, wear, and the consequent energy dissipation pose significant challenges in systems with moving components, spanning various domains, including nanoelectromechanical systems (NEMS/MEMS) and bio-MEMS (microrobots), hip prostheses (biomaterials), offshore wind and hydro turbines, space vehicles, solar mirrors for photovoltaics, triboelectric generators, etc. Nature-inspired bionic surfaces offer valuable examples of effective texturing strategies, encompassing various geometric and topological approaches tailored to mitigate frictional effects and related functionalities in various scenarios. By employing biomimetic surface modifications, for example, roughness tailoring, multifunctionality of the system can be generated to efficiently reduce friction and wear, enhance load-bearing capacity, improve self-adaptiveness in different environments, improve chemical interactions, facilitate biological interactions, etc. However, the full potential of bioinspired texturing remains untapped due to the limited mechanistic understanding of functional aspects in tribological/biotribological settings. The current review extends to surface engineering and provides a comprehensive and critical assessment of bioinspired texturing that exhibits sustainable synergy between tribology and biology. The successful evolving examples from nature for surface/tribological solutions that can efficiently solve complex tribological problems in both dry and lubricated contact situations are comprehensively discussed. The review encompasses four major wear conditions: sliding, solid-particle erosion, machining or cutting, and impact (energy absorbing). Furthermore, it explores how topographies and their design parameters can provide tailored responses (multifunctionality) under specified tribological conditions. Additionally, an interdisciplinary perspective on the future potential of bioinspired materials and structures with enhanced wear resistance is presented.

1. Introduction

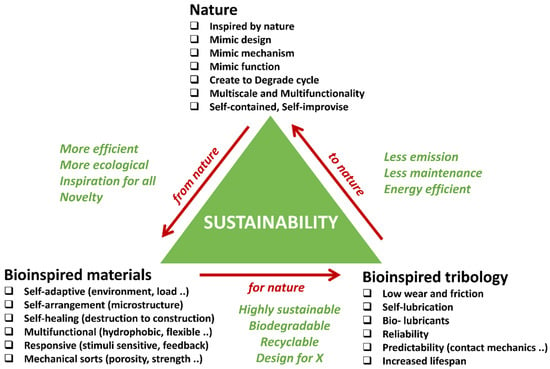

Sustainable development is closely linked to improvement in tribology (low friction, low wear, and enhanced lubrication), which has a significant and beneficial impact on both the environment and society [1]. Global energy consumption is increasing year on year, putting pressure on both resources and the environment. Notably, the repercussions of friction and wear extend beyond substantial energy and economic loss (approximately 23% of global energy loss and 1–2% of a nation’s GDP) and serve as a major source of CO2 emissions [2,3]. Crucially, tribological losses (material degradation), comprising high friction and wear inefficiencies, expenses related to part replacement and remanufacturing, and maintenance costs, affect virtually all moving elements, ranging from industrial machinery to the intricate mechanics of natural bone joints and artificial implants integrated into the human body [4]. Any effort aimed at curbing these losses yields a direct and positive impact, not only conserving energy but also fostering economic stability, and enhancing the well-being of both individuals and the environment. Consequently, it is entirely valid to assert that tribology, with its inherent capability to diminish friction and wear, characteristically contributes to the noble pursuit of a sustainable and human-centric world, and directly or indirectly contributes to Sustainable Development Goals 3, 6, 7, 8, 9, 11, 13, 14, and 15 [5]. Figure 1 shows the triangle of sustainability, revealing nature, bioinspired materials, and bioinspired tribology as its three corners.

Figure 1.

Sustainability triangle showing nature, materials, and tribology as its corners.

In this context, various methods can mitigate friction and its negative effects, such as wear. Those can be classified into (i) the mechanical approach (e.g., well-lubricated systems, novel composites, microstructural enhancements, and heat treatments, etc.) and (ii) the surface topography engineering approach (e.g., adjusting surface roughness or texture to reduce contact area). According to a model proposed by McFarlane and Tabor [6], friction force is the sum of two components: a mechanical contribution resulting from surface deformation and an adhesive contribution mainly influenced by surface energy. This model suggests that a minimum coefficient of friction (CoF) can be achieved at a critical value of real contact area [7]. Consequently, controlling surface topography can lead to CoF control. However, traditionally, the focus has been on mechanical approaches, overlooking the potential of engineered interfaces in friction control due to incomplete understanding of surface texturing (optimal choice and design of textures). Additionally, an innovative approach utilizes a combination of both approaches to enhance tribological properties and reduce friction and wear. The synergy may enable simultaneous tribological benefits, such as favorable effects of wear debris, continuous lubricant replenishment, formation of protective tribolayers or tribofilms, etc. [8,9].

Multifunctionality within tribological materials/surfaces represents a paradigm shift in engineering [10]. These materials not only mitigate wear and friction but also offer measurable benefits for efficient operation in specific applications. For instance, the wear rate of modern hip implants has been reduced by several orders of magnitude [11]. However, to enhance their longevity and minimize the necessity for revision surgeries, it is equally crucial for biomaterials to positively carry dynamic fluctuating high loads (during human movement), facilitate cell transfer and growth (biological interaction), and ensure seamless tribological integration within the human body (chemical interaction), even leveraging the positive effects of wear debris (e.g., hydroxyapatite-based biomaterials can generate wear debris that stimulates bone growth and integration around the implant, while optimized surface roughness/texture can lead to improved osteoconductivity or lubrication) [11,12,13,14]. Similarly, in the domain of photovoltaic (PV) solar cells, materials/surfaces are engineered to reduce wear (erosion) while simultaneously improving light absorption and self-cleaning properties [15]. This innovation can result in remarkable, up to 15%, enhancement in the overall efficiency and lifespan of solar panels [16]. In hydro-bearings and hydrofoils, meticulously designed surface textures that reduce drag lead to elevated energy conversion rates [17,18]. In certain instances, these materials have demonstrated substantial efficiency gains exceeding 20%, thereby translating into increased renewable energy production. In other cases, such as surgical instruments or soft robotics, it is advisable that the surface demonstrate higher friction or higher adhesion in order to improve the grip strength while accommodating high load transfer (pick up/drop) [19,20]. In space shuttles and satellites, the surfaces are designed to resist impact (wear) from space debris (meteors) while being lightweight, anti-weathering, etc. [21,22,23]. Space rover wheels are designed to navigate easily through harsh terrain, requiring enough flexibility while delivering tribological robustness [24]. Highly durable surfaces that demonstrate water-repellent properties, efficient water harvesting and spreading, or exceptional resistance to oils play a pivotal role in various applications [25,26,27]. These surfaces are essential for ensuring rapid lubricant dispersion, enabling rainwater harvesting systems, and powering nanogenerators, among other uses [28]. For instance, in the context of lubrication, surfaces with superoleophobic characteristics facilitate swift and uniform distribution of lubricants in machinery, reducing friction and wear. Moreover, surfaces engineered for efficient water spreading enable collection and storage of rainwater for various purposes while being resistant to enduring impact, erosion, etc. In summary, the creation of wear-resistant surfaces with specific functionalities, such as water harvesting and superoleophobic properties, has far-reaching implications across a range of applications, from industrial machinery to sustainable water management and energy harvesting technologies [29]. Frictional anisotropy is a critical tribological feature that spans from the molecular scale to the macroscale, characterized by directional asymmetry in friction response during sliding [30]. This feature is particularly valuable for microbots designed for friction-based locomotion, offering high maneuverability and precise targeting in confined three-dimensional (3D) spaces. Additionally, it ensures stress compatibility with soft living matter by limiting interface stresses [31]. As the demand grows for microbots in various applications like robotic assembly, drug delivery, lab-on-chip technology, sensing, microsurgery, and cancer treatment, there is a practical need to construct artificial prototypes [32]. These prototypes, exploiting geometric features to induce controllable anisotropic motion responses under external oscillating loads, serve as models for understanding and predicting the dynamics of future industrial microactuators [33]. For instance, in medical microbots navigating complex biological environments, anisotropic friction-based locomotion coupled with physical propulsion holds promise as an enabling technology for their development [34]. Table 1 shows the essential functional features required in key tribologically challenged fields.

Table 1.

Multifunctional features required in different tribological materials/situations [13,24,35,36,37,38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61].

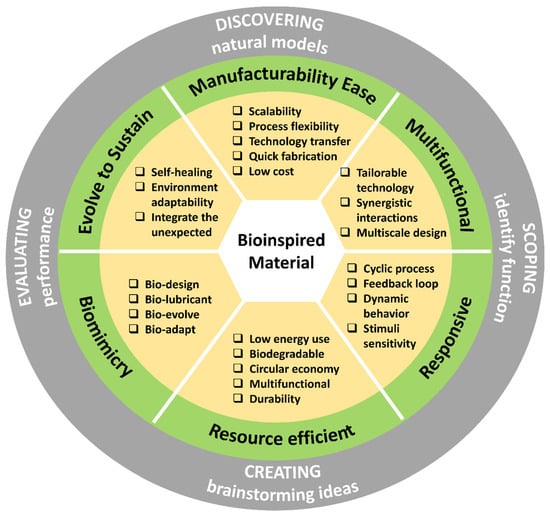

Recently, significant attention has been paid to the exploration of materials, surfaces, and architectures inspired by nature [25,26,62]. The fact that natural objects have survived the harshest conditions through multifaceted evolution inspires engineers to create or imitate the construction of similar structures. Nature-inspired materials are man-made materials that mimic the structure, properties, or functions of natural materials or living organisms and offer the potential for sustainable synergy between tribology and multifunctionality [63]. The properties of these materials and surfaces result from complex interplay between the surface structure and the morphology and physical and chemical properties. Moreover, many materials, surfaces, and devices with such designs provide multifunctionality. Various terms such as bioinspiration, biomimicry, biomimetics, nature inspiration, and nature mimicry are commonly used interchangeably by researchers [63]. Biomimetic materials imitate the evolutionarily developed structural features, leading to adapted architecture, especially in living species [64,65,66]. Often, the architectures exhibit a graded structure spanning multiple scales, including macro-, micro-, and nanoscales. For example, bone’s complex porous structure, characterized by complex ligament shapes and variations in density, allows it to achieve superior mechanical (stiffness, energy absorption, stress distribution, etc.) and biological characteristics (e.g., porosity leads to facilitating nutrient exchange and cell proliferation) compared to most man-made materials (biomaterials) [65].

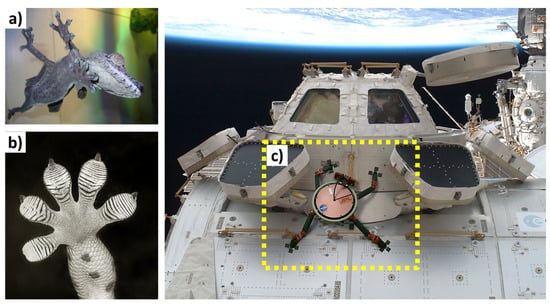

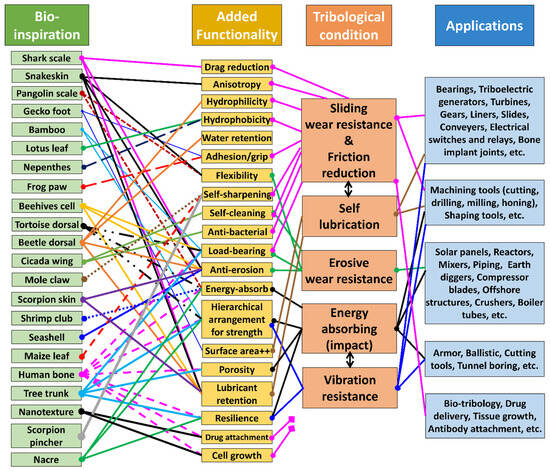

Friction and adhesion are common in nature. Notable examples involve leveraging nature-inspired surface textures found in animal scales and skins, such as those of sharks (for drag reduction and hydrophobicity), snakes (for erosion resistance), pangolins and turtles (for flexibility combined with erosion/abrasion resistance), and gecko feet (for improved adhesion) [24,63,67]. Some species feature adaptive systems that enable changes in color, pattern, or texture for defense, signaling, temperature regulation, or reproduction (also called the ‘chameleon mimetic system’) [68,69]. Nacre, an organic material found in mollusk shells, exhibits remarkable strength and resilience [70]. Spider silk, renowned for its exceptional mechanical properties and supercontraction abilities, holds great potential for various structural applications [71]. Examining beetle adhesion systems at the nanoscale has uncovered a diverse array of intricate multiscale architectures serving crucial functions like wing fixation, crawling, mating, and external protection, mainly utilized regarding locomotion for microrobots (anisotropic friction and earthworm-inspired) [30,34,72]. These adhesion systems utilize different mechanisms; some rely on liquid secretion (capillary force and lubrication), while others operate through direct interlocking of high-density microfibers or contact of mushroom-shaped hairy structures (van der Waals force) [70]. A comprehensive analysis of materials (structures) inspired by nature reveals their unique functionality, encompassing various domains of sustainable science [63]. Bioinspired structures combined with surface topography (or texturing) of these materials demonstrate promising outcomes in customizing friction, wear, and other captivating properties such as antifouling [73,74,75], self-lubrication [8,61,76], self-adaptation [77,78], hydrophobicity [27], self-cleaning [16,25,73], cell growth [12,79], drug delivery [80,81,82,83,84,85,86], antibacterial [79,87,88], color manipulation [68], anti-reflection [89], anisotropic friction in MEMS/NEMS/microrobots/microactuators [30,70,72], and enhanced adhesion [24,25,70,90]. Figure 2 shows various biological organisms (animals/plants) for inspiration regarding creating an efficient multifunctional tribological material.

Figure 2.

Bioinspired (nature) inspiration influencing various tribological conditions: (a) drag reduction in shark skin; (b) adhesion switch in gecko foot; (c) club of mantis shrimp; (d) flexibility of pangolin scales; (e) scorpion back; (f) drag reduction in penguin skin; (g) turtle shell; (h) fibered hierarchical layer of bamboo; (i) dung beetle back; (j) adhesion shift in sea horse tail; (k) friction anisotropy in snakeskin; (l) layered structure of Venus flower basket; (m) antibacterial cicada wings; (n) seashell; (o) hydrophobicity of lotus leaf; (p) trabecular bone network; (q) honeycomb cells; (r) adhesion manipulation in tree frog paw; (s) self-sharpening of maize leaf; and (t) hierarchical structure of softwood. Images reproduced with permission from The Biomimicry Institute, USA [91]. Reported areas of desired functionality concerning tribology are mentioned.

Achieving such complex nature-inspired geometries in materials or on their surface through conventional materials and technologies often proves challenging and expensive [92,93,94,95]. Historically, progress regarding materials (tribological) has primarily depended on modifying their chemical composition to alter their tribological and mechanical properties. Although this approach has yielded positive results, the journey from discovering new tribomaterial to its commercial availability has typically been time-consuming [92]. To this end, additive manufacturing (3D printing or laser surface texturing) offers promising prospects, especially in terms of generating complex bioinspired surfaces/materials and also allowing for faster fabrication and up-scaling production [94,95,96,97,98,99].

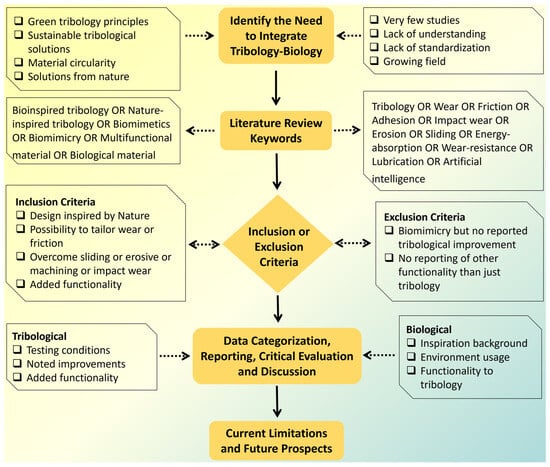

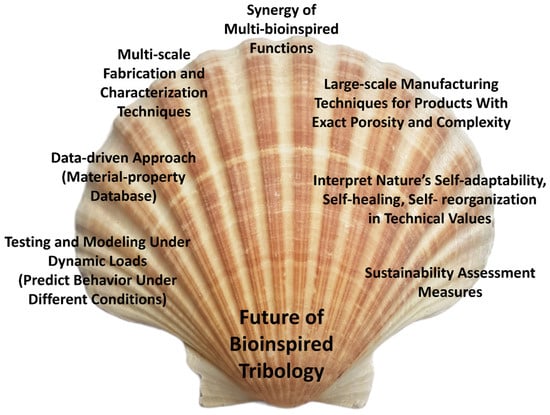

Any bottom-up approach to developing complex, multifunctional, and multiscale mimetics that can provide multiple robust functionalities requires a multidimensional strategy. The research in this multifaceted tribology domain is still at an early stage. The purpose of this review is to provide comprehensive information on the latest advances and future prospects in the field of “nature inspired” or “biologically inspired” tribological materials, with particular emphasis on their design, manufacturing processes, sources of inspiration, as well as friction and wear, performance, and other additional functions. The key focus is to establish a correlation between various tribological scenarios, bioinspired material characteristics, and their resilience to specific environmental conditions, aiming to formulate guidelines for the creation of bioinspired wear-resistant materials and systems. We have attempted to sum up relevant tribological information to a large extent. Nevertheless, due to some missing parameter specifications from the relevant reference publications that do not clearly and unambiguously characterize the physical conditions or tribological stress or the fact that tribological behavior is a system response and mere representation of some value such as force, rotational frequencies, etc., it is not in itself (alone) suitable for characterizing the stress level of the tribological system in question. Also, mixed or incorrect use of data/units for mass and forces should be avoided or carefully analyzed. For this, we recommend that readers defer to the relevant cited source(s). Figure 3 illustrates the research methodology framework for the current work.

Figure 3.

Research methodology framework. The arrow directions signify the flow direction of data.

2. Design and Fabrication Strategies for Bioinspired Tribological Surfaces

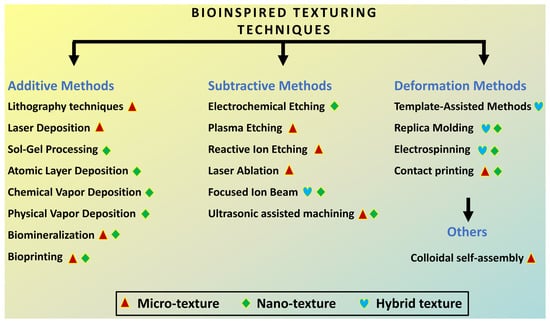

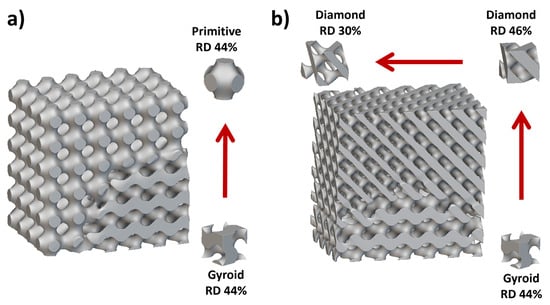

Bioinspired texturing techniques encompass a range of methods that mimic natural surface structures found in various biological systems. These techniques can be broadly classified into additive, subtractive, and deformation methods, each offering unique capabilities for creating surface textures with tailored properties and functionalities, benefiting a wide range of applications in tribology, biomedicine, materials science, and beyond. Figure 4 illustrates key texturing techniques as reported in the literature based on scales of textures and methods of fabrication.

Figure 4.

Bioinspired texturing techniques based on scales of textures and methods of fabrication.

Additive methods involve building up material to form desired textures. Lithography techniques, such as photolithography and electron-beam lithography, utilize masks or focused beams of light/electrons to selectively expose or remove material, creating precise patterns on surfaces [100,101,102]. Examples include microfluidic channels for lab-on-a-chip devices and photonic structures for optical applications.

Laser deposition involves using lasers to melt and deposit material onto a substrate, forming intricate structures layer by layer [97]. This technique is commonly used in additive manufacturing processes, including selective laser sintering and direct laser writing, to create complex 3D geometries with high resolution and accuracy [103].

Sol–gel processing involves the conversion of precursor solutions into solid materials through hydrolysis and condensation reactions [104,105]. By controlling the composition and processing conditions, sol–gel techniques can produce thin films, coatings, or bulk materials with tailored microstructures and properties. Applications include optical coatings, protective coatings for corrosion resistance, and biomedical implants.

Bioprinting utilizes CAD models to deposit biological materials, such as cells, growth factors, and biomaterials, layer by layer to create 3D structures. This technique is used in tissue engineering and regenerative medicine to fabricate customized scaffolds for tissue repair and organ transplantation [106,107].

Subtractive methods involve removing material to create textures on surfaces. Electrochemical etching utilizes electrochemical reactions to selectively dissolve material from a substrate, creating microscale or nanoscale features with high aspect ratios. This technique is widely used in semiconductor fabrication to pattern silicon wafers for microelectronics and MEMS devices [108].

Plasma etching involves using reactive plasma gases to remove material chemically or physically from a substrate, creating precise patterns through a process known as dry etching [108]. This technique is used in microfabrication processes to pattern semiconductor materials, polymers, and metals for electronic devices, sensors, and optical components.

Laser ablation utilizes high-power laser pulses to vaporize and remove material from a substrate, creating microscale or nanoscale features with high precision and resolution. This technique is used in materials processing, microfabrication, and surface modification applications, including micromachining, engraving, and thin-film patterning [84,109,110].

Ultrasonic-supported surface texturing is a specialized machining technique that utilizes ultrasonic vibrations to enhance the cutting action of the tool during surface texturing operations [111]. In this process, ultrasonic vibrations are applied to the cutting tool or workpiece, causing rapid small-scale movements that help to break up chips and improve material removal efficiency. This technique is particularly useful for creating microscale or nanoscale surface textures with precise control over texture depth, shape, and orientation.

Deformation methods alter surface textures through mechanical manipulation. Template-assisted methods involve using templates or molds with predefined patterns to transfer textures onto substrates through techniques such as nanoimprint lithography and soft lithography. Replica molding utilizes elastomeric molds to replicate surface textures from master molds onto different substrates, enabling large-scale production of biomimetic surfaces for various applications [34,100,112,113].

Electrospinning involves using an electric field to draw and elongate polymer solutions or melts into thin fibers, which are deposited onto a substrate to form textured surfaces with controlled fiber orientations and dimensions [114]. This technique is used in tissue engineering, filtration membranes, and functional textiles [115].

Contact printing utilizes patterned stamps or molds to transfer ink or functional materials onto substrates, creating textured surfaces with micrometer-scale or nanometer-scale features [116]. This technique is used in flexible electronics, sensors, and microfluidic devices for patterning conductive materials, biomolecules, and functional coatings.

Colloidal self-assembly involves the spontaneous organization of colloidal particles into ordered structures on a substrate through processes such as sedimentation, evaporation, or chemical interactions [117]. This technique is used in nanotechnology, photonic crystals, and surface engineering to create hierarchical structures with controlled properties for optical, electronic, and sensing applications.

3. Bioinspired Surfaces for Sliding Contacts

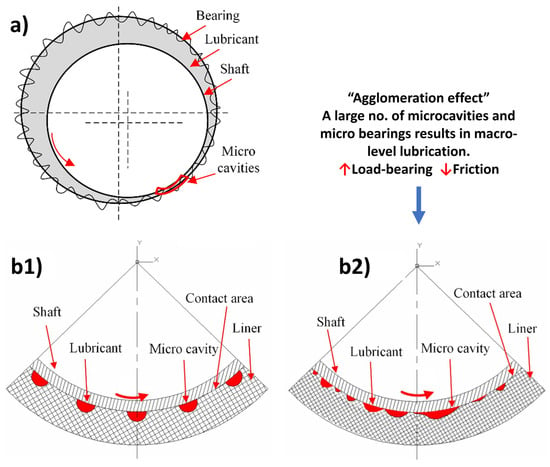

Sliding contacts bionic modifications and the bionic tribological surfaces thereof are designed to optimize lubrication (solid or liquid) and capture wear debris, such as in processes like honing cylinder liners. By creating bionic textures with controlled geometry, these surfaces retain lubricating oil and trap wear debris generated during rubbing. The material volume between the bionic textures acts as raised islands, cushioning the counterbody and reducing the actual contact area, thereby improving friction quality, and sometimes improving flexibility to accommodate sudden jerks. Properly structured cushioning islands can also reduce wear. The biotexturizing process often aims to adjust lubricating fluid film thickness, facilitating early separation between rubbing surfaces upon lubricant entry and reducing friction over a shorter distance [118]. It has been shown that biotextures can contribute to wear reduction by means of (i) enhancing hydrodynamic pressure to improve load carrying capacity and decrease shear–strain rate in the lubricant (hydrodynamic bearing effect), (ii) attracting more lubricant into the contact area (inlet suction effect), (iii) serving as a reservoir to store and supply lubricant to the interface (lubricant reservoir effect), (iv) capturing wear particles (debris-trapping effect), and (v) decreasing the actual contact area, thereby reducing friction [119,120]. It must be noted that Ra values (roughness) are commonly reported for surface texture analysis in most of the published work. However, it is important to note that Ra, owing to its double averaging, does not inherently convey significant information.

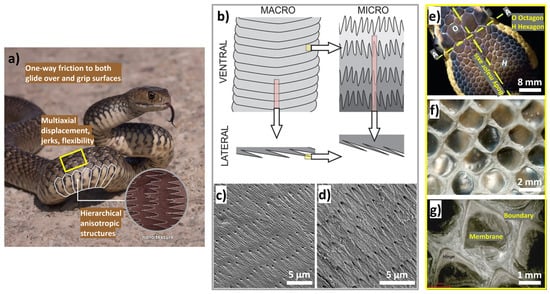

Additionally, certain bionic textures such as snake or shark skin/scales, maize leaf, etc., are known to exhibit frictional anisotropy, adding to their unique features. For example, in Figure 5, a typical snake slithering mechanism reveals varying topography across different areas of the snake’s skin. Pythons, known for constricting their prey before ingestion, must accommodate the prey’s volume and shape by stretching their jaws upon inhalation. This process can result in multi-axial displacements of the skin’s surface material [121]. To address this, the skin above line AA is composed of small patches of uniform octagonal shape connected by flexible strips. This design enables multi-axis stretching of the surface while potentially damping sudden jerks caused by prey resistance, as observed in the throat region. However, the frictional properties of the ventral surface (that touches the ground during slithering) of snakeskin vary widely, covering a broad range of values. Additionally, the degree of anisotropy, or directionality of friction, also varies within this range [122,123,124,125,126]. However, Filippov et al. [122] conducted a study comparing frictional experiments with anesthetized snakes on smooth and rough surfaces (with roughness values of Ra = 20 and 200 μm, respectively), revealing frictional anisotropy that diminished significantly on the smooth surface. They found that the macroscopic pattern of ventral scales contributes to frictional anisotropy at both macro- and microscales, with two hierarchical levels of structures, i.e., scales and denticles, playing a role. This explains why snakes experience decreased locomotory ability on smooth substrates and rely on a certain level of roughness for propulsion, in line with their numerical model’s predictions.

Figure 5.

Images showing (a) snake slithering mechanism. Adopted from The Biomimicry Institute, USA [91]; (b) hierarchical anisotropic structures on the ventral snake surface [122]; (c) SEM of western diamondback rattlesnake [122]; (d) SEM of black-necked spitting python [122]; (e) details of dorsal (back) scale structure of a python [121]; and (f,g) magnified image of a python dorsal [121].

Mühlberger et al. [127] utilized a combination of powder injection molding and ultraviolet light-assisted nanoimprint lithography to replicate the intricate features of a Python/Cobra (Naja nigrocollis). This approach enabled the direct copying of the biological surface and imprinting of unit textural features three times the length of the actual features of the snake. Pin-on-disc experiments comparing the friction behavior of textured and polished ceramic samples showed favorable results for the textured surfaces. Snakeskin textured samples exhibited a 30% lower COF than polished non-textured samples, particularly when sliding in the parallel direction. However, the study emphasized the importance of employing an efficient replication method to achieve the required fine size texturization. Samples with features similar in length to the original skin did not perform well due to the inadequacy of the replication technique used rather than the tribological inefficiency of the geometric features themselves. In an another study by Greiner et al. [126], they used laser texturing to create scale-like morphologies on 100Cr6 bearing steel pins, inspired by snake and sandfish skin, for testing in both lubricated and unlubricated tribological contacts. The wide scale-like surface structure significantly reduced friction forces by over 40% in unlubricated conditions, while, in lubricated conditions, it increased friction by more than three times. In an another study, Kumar et al. [128] investigated the impact of lotus leaf-inspired dimple texturing (diameter 500 µm, depth 8 µm) on the dry sliding performance of bearing steel, yielding several notable findings. Two different types of dimple shapes were produced, namely circular- and bi-triangular-shaped dimples. Further, to study the effect of dimple density, two different types of arrangements in dimples were created, i.e., in radial and spiral arrays. It was observed that a spiral array has a higher and more stable number of microdimples than a radial array under the same contact area, so the density of dimples becomes important. Hence, a higher effective number of microcavities was observed in the contact zone for the spiral array compared to the radial pattern, leading to increased wear particle entrapment. Moreover, increasing dimple density from 7% to 20% enhanced wear debris entrapment, consequently reducing wear. However, once the cavity is filled, the texture effect diminishes. Thirdly, bi-triangular dimples with lower density were more effective than circular shapes in reducing both friction and wear, with 20% density exhibiting optimal performance. Finally, in dry conditions, the textured samples displayed lower coefficients of friction compared to the untextured ones. Several other studies conducted on lotus leaf-inspired dimpled surfaces point to its friction-diminishing character due to debris entrapment and lubricant storage effects [124,129,130,131,132,133].

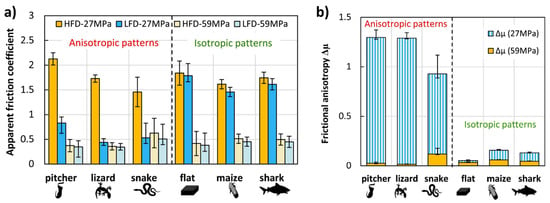

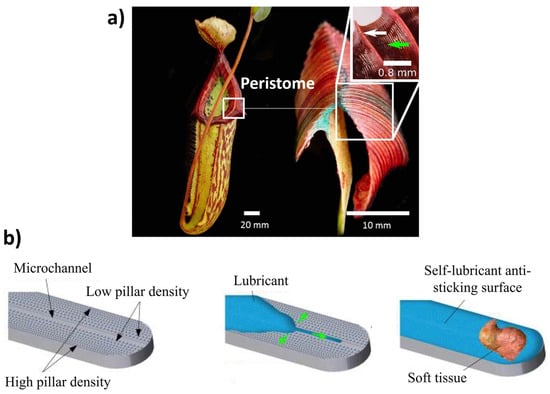

Han et al. [105] developed a novel bionic anti-adhesive electrode inspired by maize leaves, known for their anti-adhesive traits. The study investigated tissue adhesion effects on electrosurgical electrodes under high temperatures. Using the bionic anti-adhesive electrode, liver tissue was electrically cut in animal experiments. The results showed that the single bionic electrode had slightly better anti-adhesive properties, while the coupled electrode exhibited lower adhesion. The coupled electrode, coated with TiO2, gained superhydrophilic self-cleaning abilities. Later, Mzali et al. [134] studied the tribological behavior of five different surfaces’ patterns bioinspired from maize leaf skin, shark skin, snakeskin, pitcher’s structure, and lizard skin, with a focus on friction anisotropy and test conditions. Figure 6 depicts the apparent friction coefficient (CoF) evolution for various sliding cycles and contact pressures of 27 and 59 MPa [134]. Friction behavior significantly relies on surface texture and direction when interacting with anisotropic patterns. In the high-frictional direction (HFD), bioinspired patterns act as asperities, requiring substantial tangential load for deformation, correlating closely with plastic deformation and asperity sharpness. Asperities with sharper features induce higher plastic deformation, explaining the observed decrease in CoF (pitcher > lizard > snake). Conversely, in the low-frictional direction (LFD), the pattern effect is less pronounced, with an increase in pattern intensity resulting in higher absolute CoF values (0.8 to 0.4). When sliding in LFD, CoF decreases by 74%, 63%, and 61% for lizard, snake, and pitcher patterns, respectively. In contrast, isotropic patterns yield a large contact area (in relation to the apparent contact area), leading to relatively high CoF and increased adhesive wear. Increasing contact pressure reduces the friction coefficient, with a twofold pressure increase resulting in an 80% CoF drop. This phenomenon is attributed to frictional heat generation at the contact surface, affecting material strength and shear strength. In HFD, CoF ranges from 0.36 to 0.6, while, in LFD, CoF varies from 0.34 to 0.5. No significant difference in CoF between HFD and LFD is observed, indicating isotropic behavior among the tested specimens. However, at high contact pressures, flattening of surface asperities by the ball leads to early removal of high peaks, potentially reducing the microstructure’s impact on the friction coefficient. The anisotropic nature of friction evolution concerning bioinspired surface designs was reported by a few other authors [27,30,34,125,130,135,136].

Figure 6.

Images showing the progression of (a) CoF, i.e., µ, as function of the bioinspired surfaces for contact pressures and friction direction; and (b) direction-dependent CoF values of bioinspired surfaces for different contact pressure. The contact pressures were 27 MPa and 59 MPa. The friction directions are labeled as high friction direction (HFD) and low friction direction (LFD). Reproduced with permission from Ref. [134].

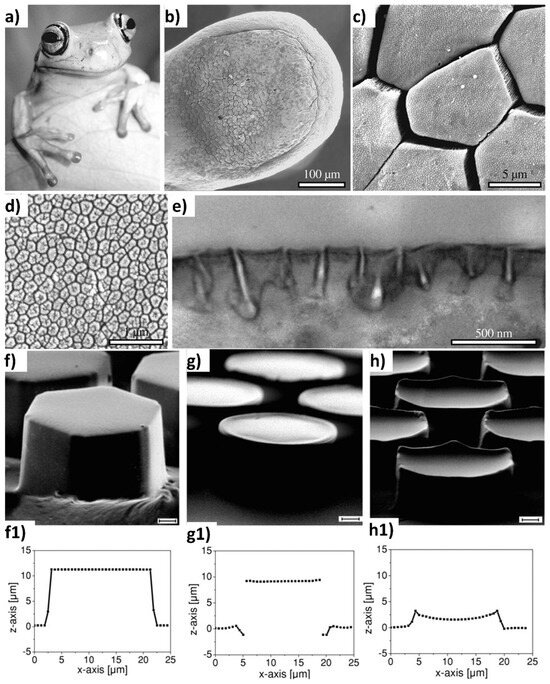

Furthermore, hexagonal textures exhibit noticeable anisotropy in various contact directions, influencing tribological properties. Nature’s diverse organisms, serving as models for texture design, showcase the remarkable effectiveness of hexagonal patterns. Many creatures feature hexagonal textures for specific functions: stability (e.g., insect compound eyes and honeycombs), adhesion (e.g., frog toes and clingfish), wear resistance (e.g., snake scales), lightweight structures (e.g., dragonfly wings), impact resistance (e.g., insect tentacles), and superhydrophobicity (e.g., bubble rafts and cicada toes), among others [137,138,139], for instance, the toe pads of tree frogs, characterized by hexagonal columnar epithelial cells separated by mucous-filled channels as shown in Figure 7 [140,141]. Tree frogs’ toe pads have garnered attention due to their ability to climb in humid environments without slipping. Similarly, hexagonal convex structures have been identified in the foot pads of katydids and bush crickets. Huang et al. and colleagues [132] engineered a surface structure inspired by tree frogs’ toe paw for wet sliding contacts, featuring elastic microdimple and -pillar patterns on polydimethylsiloxane elastomers (PDMS), to investigate its tribological performance. The friction behaviors of these patterned surfaces, lubricated with deionized water, were assessed. The results showed that the PDMS surface with microdimples exhibited reduced friction with increasing pattern area density. The area density of pillar patterns had a negligible impact on friction at low sliding speeds but became significant as sliding speed increased. The relationship between friction force and area density was approximately linear for pillar-patterned surfaces, possibly explaining the evolution of polygonal columnar structures in newts’ toe pads.

Figure 7.

Morphology of tree frog toe pads. (a) White’s tree frog (Litoria caerulea); SEMs of (b) toe pad, (c) epidermis with hexagonal epithelial cells, and (d) magnified view of the surface of a single hexagonal cell showing peg-like projections; (e) TEM of cross-section through cell surface. Reproduced with permission from Ref. [141]. SEM images depict arrays of hexagonal micropillars on PDMS surfaces, with diameters ranging from 15 to 19 μm. These pillars feature various tip shapes, (f,f1) flat tips, (g,g1) T-shaped tips with heights of 10 μm and channel widths of 3 and 5 μm, as well as (h,h1) concave tips with a height of 3 μm and a channel width of 5 μm. Scale bars in the images correspond to 2 μm; (f1,g1,h1) corresponding profiles of the pillars obtained with a confocal microscope are provided below. Reproduced with permission from Ref. [140].

Lu et al. [142] conducted a study inspired by Seashell to design Ni3Al matrix bioinspired shell-like composite surface structures with excellent tribological properties. Wear tests were conducted to evaluate the effects of surface texturing and solid lubricants, revealing that the presence of solid lubricants significantly reduced friction coefficients and wear losses. The SAC305 alloy promoted self-compensating lubrication behaviors due to its ability to form a lubricating film under dry friction sliding. The combination of theoretical models and experimental measurements established a contact and collision model for microprotrusions between friction pairs, highlighting the roles of soft and hard materials in mutual sliding. The SAC305 alloy, with high surface energy and low hardness, facilitated material transfer and self-compensating lubrication compared to the Ni3Al matrix.

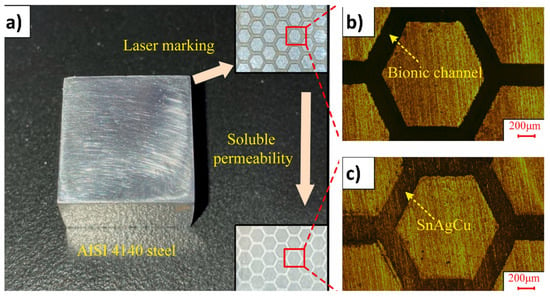

In a separate investigation focusing on the combined effects of texturing and solid lubricants, researchers drew inspiration from the strong adsorption observed at the interface, known as the contact interface, which arises from the synergistic interaction between mucous (acting as a solid lubricant) and the surface microstructure of the frog paw, Huang et al. [137] investigated the tribological properties of AISI 4140 steel improved by biomimetic hexagonal textures (Figure 8) and incorporation of solid lubricants (Ag, Sn, and Cu) and TiC, and their optimization thereof [138]. Introducing TiC and SnAgCu showed significant antifriction and wear resistance. Compared to Ag and Sn, the modified material exhibited around a 65% decrease in average COF and around a 42% decrease in wear depth in addition to achieving a steady frictional condition (reduced fluctuations). The multi-solid lubricants formed a lubricating film and enabled self-repairing behavior for surface defects, contributing to excellent antifriction and wear resistance. Nano-TiC particles were gradually enveloped by ductile SnAgCu during wear, transitioning the contact mode from sliding to rolling for antifriction effects. Moreover, rolling lubrication particles were captured by wear defects, facilitating self-repair. In another study, Wang et al. [143] designed dung beetle-inspired multi-bioinspired hierarchical textures featuring superhydrophobicity to enhance AISI 440C steel wear resistance in water lubrication. It was shown that multi-bioinspired hierarchical textures significantly improved wear resistance under low loads and high frequencies (values are provided in Table 2). Superhydrophobic micro/nanostructures played a crucial role in enhancing wear resistance, resulting in wear reduction rates higher than single bioinspired textures. The geometrical parameters notably affected the wear properties, with the wear rates decreasing by 64% and 50% for textured configurations. The combined effects of multiple texturing and superhydrophobic micro/nanostructures boosted wear resistance by increasing surface hardness and improving hydrodynamic pressure. Several others have reported superior tribological performance (reduction in CoF/wear rate/wear mechanisms, etc.) upon synergistic application of biotexturing and solid lubrication [61,76,144,145]. These structures can trap lubricants (wear debris may lead to rolling friction), reduce contact area, improve hydrodynamic pressure, and alter the contact interface, leading to improved wear resistance, reduced friction, and contributing to increased efficiency, durability, and reliability of mechanical systems, making them valuable tools in various industrial applications.

Figure 8.

Showing the process of creating (a) AISI 4140 bionic self-lubricating material involves marking the specimen; (b) after laser processing and (c) then infiltrating it with solid lubricants. Reproduced with permission from Ref. [138].

Table 2.

Results of different bioinspired structures under sliding wear conditions as reported in the literature. It is important to highlight that the absence of key tribotechnical parameters in many published findings prevents calculation of resulting tribological stress conditions. However, instances of tribocontact stress calculations have been observed assuming Hertzian contact and no wear to the counterbody in a few studies.

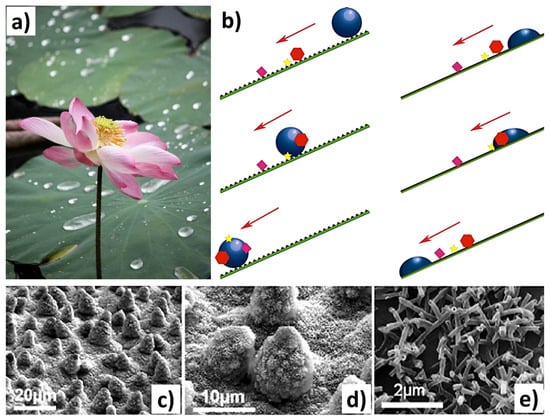

4. Bioinspired Surface Texturing of Biomaterials

Biomaterial surface modifications, regarding both chemical and topographic approaches inspired by nature, have been explored extensively [43]. Chemical modifications often involve the use of nature-derived compounds, such as biopolymers inspired by mussels, known for their exceptional biocompatibility and adhesive properties [155]. The current section addresses specific surface qualities targeted for reducing bacterial adhesion [88,156], improving cell adhesion, self-cleaning ability [25], including surface roughness, wettability [12], surface energy [147,157], biofouling resistance [113,158,159], and adhesion strength [100,160,161]. Utilizing natural surface topography for modifying these attributes offers advantages as it avoids the release of chemical compounds into the surrounding environment where such surfaces are employed [162]. This topographic alteration in biomaterial surfaces has the potential to reduce the reliance on antibiotics for treating implant-related infections, consequently mitigating the risk of antimicrobial resistance. Figure 9 shows the self-cleaning and hydrophobicity (water-repelling) properties of the lotus surface.

Figure 9.

Images showing (a) hydrophobicity and self-cleaning characteristics of the lotus leaf surface; (b) a schematic representation of droplet movement (red arrow) on an inclined nanostructured superhydrophobic surface, known as the lotus effect. As the droplet rolls off the surface, it collects contaminating particles, effectively cleaning it (left). In contrast, a smooth surface merely redistributes the particles with the moving droplet (right); and (c–e) SEM micrographs of lotus leaf surface at various magnifications. Reproduced with permission from Ref. [25].

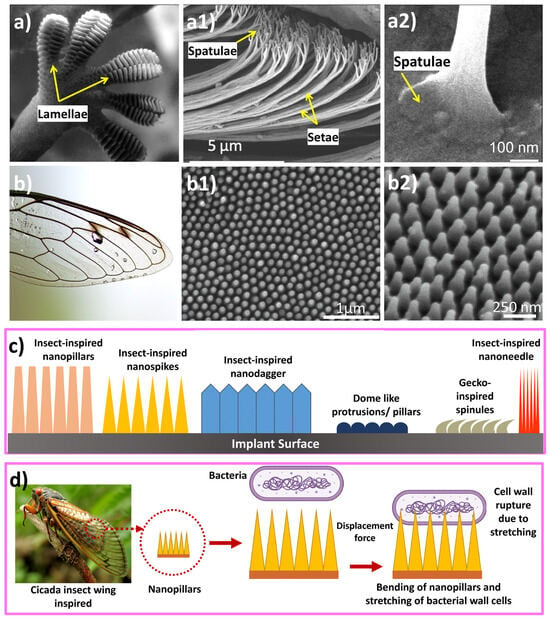

Another aspect is that bacteria can attach to the surface of a material through various mechanisms, resulting in the formation of biofilms when released into a biological environment [113]. To counteract this, various strategies have been devised to disrupt bacterial interactions with surfaces. Topographically textured surfaces offer a chemical-free approach to bacteria inactivation. The effectiveness of bacterial destruction depends on the interactions between bacterial cells and the surface’s texture features (mechanical response), such as pillars, columns, or rods, as shown in Figure 10c. Chopra et al. [79] reported that, when bacteria encounter nanopillars, they undergo a brief downward movement that causes their cell wall to rupture, resulting in lethal damage, as shown in Figure 10d. Bandara et al. [163] suggested a mechanism that involves a combination of strong adhesion forces and shear forces in a mixed short–tall nanopillars topography presence. When bacteria move across taller nanopillars, it causes the nanopillars to bend, which in turn stretches the bacterial cell wall, leading to its rupture. Other attributes like height, width, diameter, and spacing of these features significantly impact the bacterial response upon contact [43,161]. Even more fascinating are the physical alterations that involve creating micropatterns on surfaces to manipulate the hydration layer, rendering them either superhydrophobic or superhydrophilic [102,157,164]. This has given rise to technologies that mimic the texture of shark skin (also observed on lotus leaves) and replicate the superhydrophobic properties, leading to water repulsion and preventing the adhesion of contaminants, contributing to self-cleaning and antifouling properties such as the textures developed on surgical instruments (knife, etc.) [57,113,165,166]. Moreover, superhydrophilic biomaterials, which attract water strongly and facilitate rapid wetting and spreading of liquids across their surfaces, are particularly valued for their ability to promote crucial processes, such as cell adhesion, tissue growth, and fluid transport. Examples of applications include biomedical implants, tissue engineering scaffolds, and microfluidic devices, where the enhancement of these processes is essential for optimal functionality and performance [113,158,167]. Studies have revealed that the interplay between surface topography and various cell types impacts cell morphology, behavior, alignment, migration, and proliferation, among other traits [168,169]. These interactions ultimately alter the dynamics between cells and surfaces. Table 3 lists several bioinspired surface textures fabricated on biomaterials for their added functionality.

Figure 10.

Illustration of (a) a gecko foot showing lamellae; (a1,a2) SEM of setae and hairlike spinules’ structures on gecko toes [170]; (b) a cicada wing; (b1,b2) SEM showing nanopillar-like structure of cicada wing [171]; (c) schematic of different types of insect-inspired pillar-like nanotextures used towards fabricating antibacterial surfaces; and (d) schematic of bacterial killing/disrupting mechanism on a cicada wing-inspired nanopillar surface [79]. All images were reproduced with permission from respective publishers.

Table 3.

Results of various bioinspired topographies on biomaterials for sliding wear conditions, as reported in the literature.

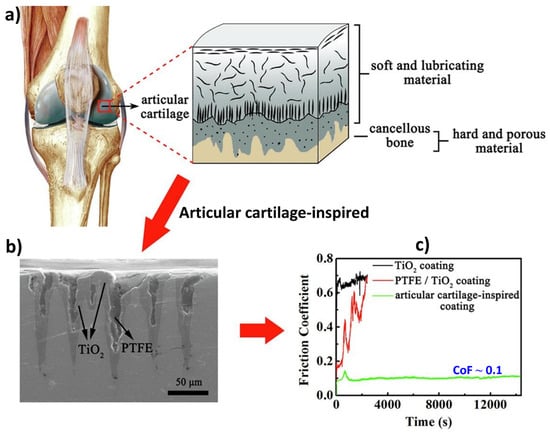

Healthy articular cartilage in joints provides crucial lubrication for smooth movement of human hips or knees [180]. Inadequate lubrication of articular cartilage can lead to degenerative joint diseases, resulting in irreversible degradation of the cartilage. Hence, incorporating stimuli-responsive drug release into lubrication strategies can aid in repairing damaged articular cartilage. In terms of tribological studies, for instance, articular cartilage features a distinctive biphasic structure that incorporates both soft and hard materials to support heavy loads and minimize friction within joints [59,181,182,183,184]. To mimic this structure, Li et al. [59] developed a composite coating consisting of a dual-layer configuration comprising a thin PTFE layer atop a porous TiO2 coating on Ti6Al4V alloy, as shown in Figure 11. The top self-lubricating layer reduces friction, while the underlying TiO2 layer enhances wear resistance. This bioinspired bilayer coating demonstrates low friction (~0.1), exceptionally high load-bearing capacity (3.2 GPa under nanoindentation of 0.19 N, and a penetration depth of 600 nm), prolonged low-friction durability, and superior wear resistance during dry sliding. These remarkable properties are attributed to a self-repair mechanism, where PTFE is continuously replenished from the pores to the surface by frictional forces, effectively repairing scratches and combating abrasive wear. These findings offer insights into designing intelligent biomimetic coatings with enhanced mechanical properties, thus broadening the scope of applications for biomedical coatings in various fields.

Figure 11.

(a) Schematic illustration of cartilage organization in joints; (b) SEM image of the cross-section of the bioinspired bilayer coating; and (c) friction curves of the TiO2, PTFE/TiO2, and bioinspired bilayer coating under a ball-on-plate reciprocating configuration (counterbody 0.006 m dia. GCr15 steel ball, frequency of 1 Hz, stroke of 0.005 m, and a load of 20 N). Adopted with permission from Ref. [59].

5. Bioinspired Surfaces for Erosive Wear Resistance

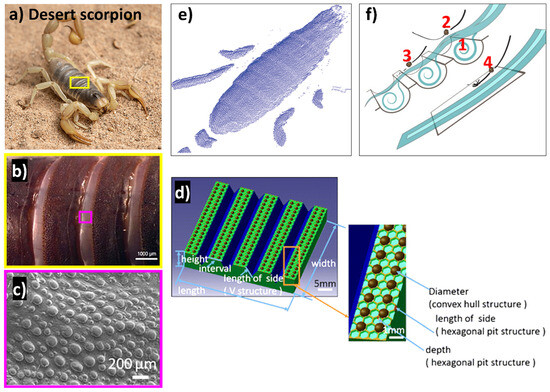

Interest in anti-erosion characteristics and mimicked material design inspired by living creatures inhabiting harsh erosive environments, like desert lizards, sandfish, tamarisk, desert scorpions, and dung beetles, has grown gradually [24]. For instance, despite harsh desert conditions where sand particles travel at velocities over 100 km/h, Androctonus australis, a north African desert scorpion, remains resilient on the surface, enduring sand-laden harsh winds. Researchers have discovered that desert scorpions resist erosion through their body design. A team from Jilin University in China used 3D laser scanning to create a cloud point representation of the scorpion’s back [185] as shown in Figure 12e. Their analysis revealed that the surface’s convex and grooved design aids in erosion resistance. The grooves cause the air striking the scorpion’s surface to rotate, creating a low-speed reverse flow zone. Essentially, this air flow zone acts like an air cushion, allowing some particles like sand to be harmlessly blown away rather than hitting the surface directly. The particles that do manage to pass through strike the surface with significantly lower velocity and impact angle, reducing the rate of erosion (Figure 12f).

Figure 12.

Images showing (a) back of an Androctonus australis (desert scorpion); (b) high-magnification image of desert scorpion back revealing V-groove-like pattern [186]; (c) scanning electron microscope image of scorpion back revealing outward bumps on the grooved surface [186]; (d) schematic of structure sizes of biomimetic samples; (e) point clouds of scorpion back showing bumps on the skin surface, later utilized to model an erosion study [185]; and (f) point 1—the swirling air caught in the grooves creates air cushions that slow down the velocity of the wind. This phenomenon reduces the speed of airborne particles, leading to different outcomes; point 2—some particles bounce away without impact, while point 3—others hit the surface at a much slower velocity and with less impact. Point 4—in contrast, a particle hitting a flat surface where the wind velocity remains unaffected will experience a much higher impact [187]. All images are adopted with permission from respective publishers.

Inspired by the back of the desert scorpion, a few researchers have reported a hexagonal pit structure with excellent anti-erosion properties [186,188,189,190]. The biomimetic samples with microstructures as shown in Figure 12d resulted in reduced erosion wear due to reduced solid particle velocity caused by rotational low velocity (explained in Figure 12f). Similarly, Han et al. [188] explored the erosion resistance of bump and groove shapes inspired by the desert scorpion surface, demonstrating increased erosion resistance compared to smooth structures by approximately 10% and 25%, respectively. Another study by Zhiwu et al. [185] reported that the erosion resistance of the desert scorpion involves a biological coupling approach, combining convex, grooved, and flexible elements. Numerical simulations showed that the grooved surface exhibited superior erosion resistance compared to smooth and convex surfaces, attributed to particle impact velocity, angle, and frequency. Erosion tests confirmed that grooved surfaces performed best at a 30° injection angle. Analysis of groove dimensions revealed that groove distance had the greatest influence on erosion resistance, followed by groove width and height.

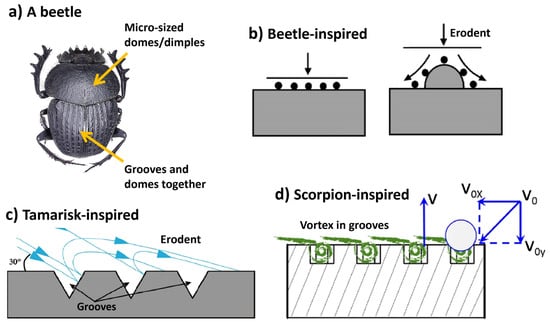

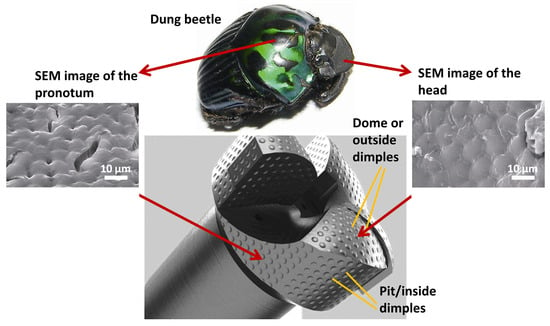

Researchers have replicated snakeskin texture features, demonstrating that snake-like skin samples experience significantly less wear than smooth/untextured samples [24,110,124,125,126]. Effectively mitigating erosion wear depends on optimizing the interaction and interference between contributing factors such as geometry, material, and mechanics. For instance, inspired by the head and pronotum surface of the dung beetle, Yang et al. and others [41,97,191] constructed and optimized a dung beetle-inspired textured drill bit surface, achieving better wear reduction and efficiency. However, the exact size and location of the dome and pit structures on the drill bit demand optimization based on soil environment and dung beetle species as the solid particles hitting these structures change trajectory, reducing wear on other structures. However, the relationship between the position and volume of the domes/outside dimples was overlooked and missing.

Tamarisk-inspired V-shaped grooved solid surfaces have been quantitatively studied for erosion rates under particle impact [55,192,193]. These grooves effectively reduce erosion wear within an impingement angle range of 20–60°. However, these impingement angles (global impingement angle) vary due to the ductility of the eroded substance. Jung et al. [194] successfully explained the dependence of the grooved surface’s erosion rate on the impingement angle by considering the diversification of the local impact angle caused by the presence of the grooves. Other factors, such as multiple impacts of particles and air swirls within grooves, have negligible effects on erosion [194]. This suggests both the promise and limitations of this biologically inspired anti-erosive approach. Grooves aggravate erosion when the ambient flow direction is nearly parallel or perpendicular to the surface, which is eroded in a ductile manner. However, one can benefit from the grooves if the surface direction can be adjusted to align with effective anti-erosion impingement angles (i.e., 20–60°). Cylindrical surfaces with grooves exhibit greater erosion resistance compared to smooth surfaces, regardless of wind direction, as observed in tamarisks [30,195]. Yin et al. [193] tested different bioinspired grooves (square, U-shaped, and V-shaped) and found that the V-shaped groove morphology displayed the lowest erosion rate, as shown in Figure 13. However, over time, the bionic structure on the surface degrades, leading to decreased erosion resistance. Other approaches must be explored to limit erosive wear in bionic surfaces as eddy currents on non-smooth surfaces are reduced, eventually leading to erosion resistance loss.

Figure 13.

(a) Beetle skin surface revealing presence of domes/dimples and grooves [196]; (b) schematic diagram of smooth surface and beetle-inspired surface domes in erosion wear [41]; (c) schematic diagram of the interaction between tamarisk-inspired surface V-grooves and erodent particles [193]; and (d) schematic diagram of the interaction between desert scorpion-inspired grooved surface and erodent particles. Occurrence of rotational flow (vortex) for the impact velocity of particles (Vo), which forms the upward velocity vector perpendicular to the surface (V). The vertical upward velocity V is opposite to the velocity component Voy of the particle in the normal direction, which can slow the normal velocity of the solid particles. Studies show that, even if the rotational flow velocity is small, it still plays a very important role in reducing erosion wear [186]. All images were reproduced with permission.

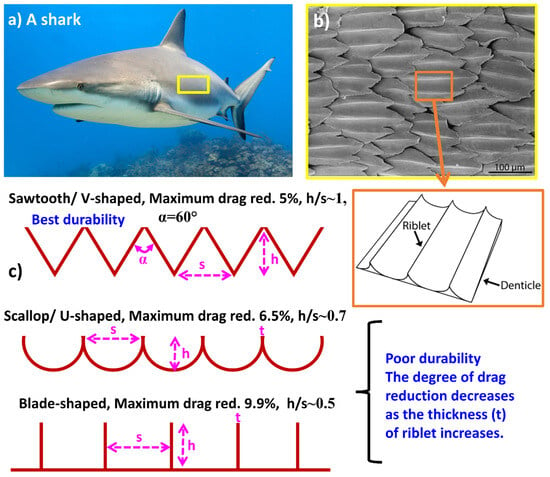

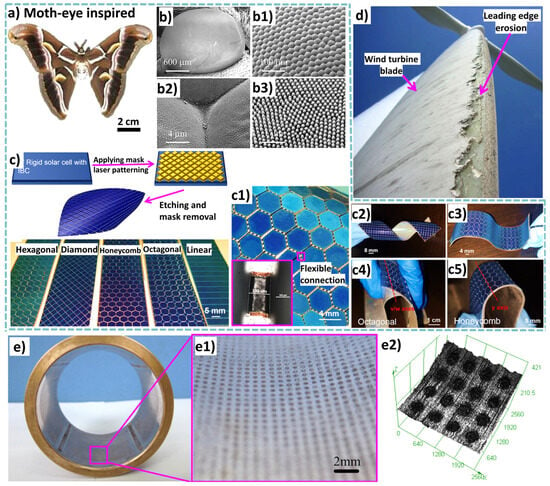

Bionic tribological designs utilize the features of fast-swimming sharks that have skin with scaled structures aligned in the flow direction to minimize friction drag under turbulent conditions [24]. These structures, known as scales or denticles, resemble small dermal teeth and contribute to a 5 to 10% reduction in drag while swimming and are quite widely utilized to develop fluid flow erosive resistance [197]. Luo et al. [48] examined the morphology of shark skin scales and identified factors contributing to frictional drag reduction, including reduced wall friction from microgroove tips protruding into the viscous sublayer, decreased turbulence intensity near the wall due to backflowing microdroplets, a superhydrophobic effect from boundary slipping on the fluid–solid interface, and a nanochain of mucous increasing the thickness of the viscous sublayer to further reduce viscous resistance. Martin et al. [198] studied optimization of riblet geometries inspired by shark skin for minimal frictional drag. Their research emphasized that the reduction in drag was linked to vortices being lifted away from the surface and forming over the riblets, particularly under turbulent flow conditions. This phenomenon contributed to decreased overall shear stress. Fu et al. demonstrated that triangular-shaped riblets offered a more favorable balance between ease of manufacturing and effectiveness in drag reduction [46].

Many studies utilize various models such as V-shaped, U-shaped, I-shaped, scallop-shaped, and blade-shaped structures to replicate the characteristics of shark skin. Airbus applied grooved film to its A320 experimental aircraft, achieving an expected fuel-saving effect of 1% to 2% [199]. Similarly, China’s Y7 aircraft experienced an 8% reduction in drag after being coated with a flow-grooved skin, while applying V-shaped trench film to the surface of the NACA 0012 aircraft resulted in a 6.6% drag reduction [199]. In contrast, the riblet surface exhibited a 9.9% decrease in adhesion resistance compared to the smooth surface [199]. The drag reduction effect was worse as the height of the riblet increased when h > 0.6 μm. Schulz et al. [200] investigated the application of shark skin riblet structures in high-temperature coatings for aerospace blade dynamics optimization. The experimental findings suggested that the zigzag groove spacing (s) should be approximately twice the height (h) of the zigzag groove, with h/s ratios ranging from 0.5 to 0.6 and s values between 15 and 17 μm. These findings offer valuable insights for establishing bionic riblet surface structures for erosive wear resistance. A study by Bechert et al. [201] reported the experimental results on frictional drag-reducing surfaces and their optimization with an adjustable geometry. The results of the study in terms of optimized structural dimensions are shown in Figure 14c.

Figure 14.

(a) Shark skin; (b) SEM image of shark skin showing microriblets structure [202,203]; and (c) proposed models of shark skin riblets’ structures in the form of a sawtooth (V-shaped groove), scallop (U-shaped groove), and blade (I-shaped groove) [199]. Their optimal structural dimensions leading to improved performance are mentioned as per Ref. [201].

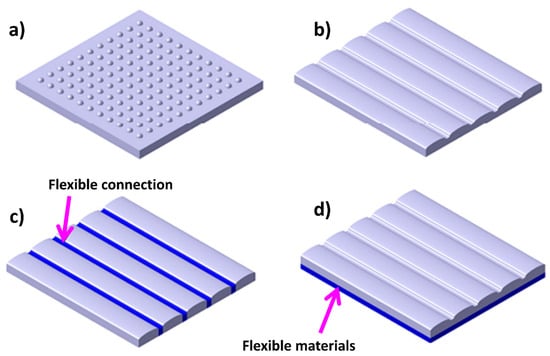

The surface effectiveness of the sharkskin or dorsal of the scorpion in resisting erosion is not solely due to its unique surface morphology but is also influenced by several factors related to coupling function. The protrusions and furrows on the surface serve as morphological coupling elements, while the adaptable linkage acts as a flexible coupling element. The bionic model incorporates these coupling elements, as depicted in Figure 15. By eliminating the adaptable linkage from the model, it was divided into two layers. The upper layer comprises rigid material shaped into a bionic surface morphology, while the lower layer consists of pliable materials. This dual-layered arrangement creates an alternating composite structure of soft and hard materials, which is believed to offer superior erosion resistance, as shown in Figure 15d.

Figure 15.

Bionic model of the desert scorpion’s back with (a) dome pattern; (b) groove pattern; (c) coupling bionic models with flexible connection; (d) coupling bionic models with a composite structure alternating between soft and hard materials. Reproduced with permission from Ref. [204].

Erosive wear results from solid particles flowing along water or gas, impacting solid surfaces and causing repeated deformations [205]. The complexity of this phenomenon depends on various factors such as the size, shape, hardness, and concentration of erodent particles, as well as the elastic properties, surface hardness, and morphology of the eroded substance, and flow conditions like impacting velocity, angle, and location of impact [51,206,207,208,209]. Investigating erosion wear involves considering erosion rate, penetration depth, load spreading, and stress distribution [24,194]. The lack of a clear understanding of the erosion mechanism hinders the development of a simple, reliable, and universally quantitative erosion model. Despite the growing interest in anti-erosion characteristics and biomimicked material design, the current research in this area remains fragmented. Nevertheless, some significant results are documented in Table 4. Bioinspired surfaces offer erosion wear protection through various mechanisms: enhancing fluid turbulence along the wall, disrupting particle motion, reducing the number of particles impacting the eroded substance, and preventing particle sliding and rolling [194,210,211].

Table 4.

Results of different bioinspired structures under erosive wear conditions, as reported in the literature.

6. Bioinspired Structures for Impact or Energy Absorption

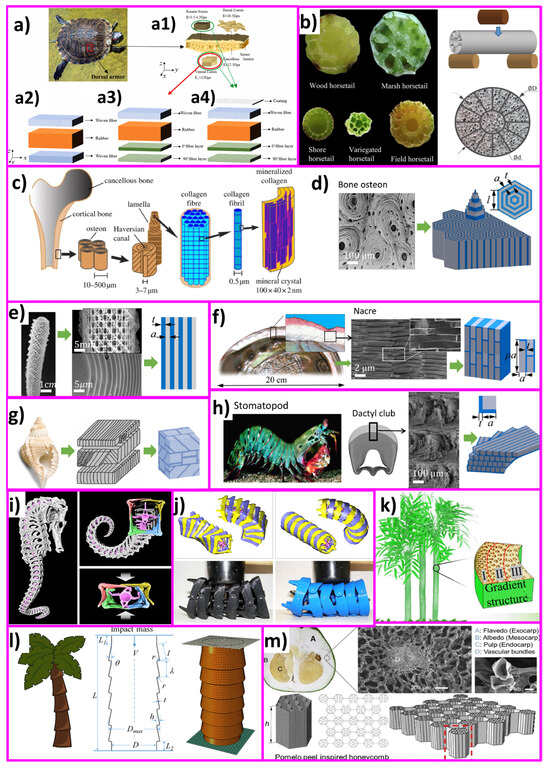

Drawing inspiration from natural organisms such as beetles, woodpeckers, turtles, etc., researchers have explored novel structural designs and materials that exhibit remarkable impacts or energy absorption properties, as shown in Figure 16. By mimicking the unique features and mechanisms found in nature, such as hierarchical microstructures, multilayered compositions, and energy dissipation mechanisms, bioinspired structures offer promising solutions for mitigating impact forces, enhancing structural resilience, and sometimes improved flexibility.

Figure 16.

(a) The macroscopic morphology of the turtle shell is depicted [49]; (a1) illustrates a cross-sectional view of the turtle shell carapace, highlighting its composite layers; (a2) ordinary three-layer sandwich structure. Moving to the bionic sandwich structures, (a3) fine structure of the ventral cortical layer, resulting in a four-layer sandwich structure, and (a4) bionic sandwich structure that mimics the keratin scutes, leading to a five-layer sandwich structure. Reproduced with permission from Ref. [49]; (b) horsetail-inspired foamy structures under lateral loading. Reproduced with permission from Ref. [50]; (c) bone’s architecture exhibits five levels of hierarchy; (d) SEM image illustrates the bone osteon along with a concentric hexagonal unit cell model, (e–h) optical image, SEM image, and microstructures of sea sponge, nacre, conch shell, and stomatopod dactyl club, respectively. Reproduced with permission from Ref. [213]; (i) seahorse skeletons are composed of highly articulated bony plates for flexibility. Reproduced with permission from Ref. [214]; (j) DNA-inspired helical structures and their deformations during compression tests. Reproduced with permission from Ref. [215]; (k) bamboo-inspired functional gradient structure. Reproduced with permission from Ref. [216]; (l) bioinspired conical corrugation tube. Reproduced with permission from Ref. [217]; (m) pomelo peel-inspired honeycomb. Reproduced with permission from Ref. [218].

The turtle shell abaxial armor, comprising lightweight and robust natural composite laminated material, typically consists of three to six layers. Its macro-mechanical properties are influenced not only by its multilayer structural characteristics but also by its intricate multiscale and multilayered microstructure and layering methods. The complex morphology of the turtle shell has been extensively studied by several researchers [49,219,220,221,222,223,224,225] to understand its superior protective capabilities against environmental penetration. Pangolin shells offer similar characteristics to turtle shells and have been studied by several researchers [24,135,149,226].

Beetles’ elytra serve as lightweight yet rigid structures, effectively shielding beetles from external impact loads, capable of withstanding an impact velocity of up to 1 mm/min [227,228]. The superior mechanical properties of the elytra are attributed to the irregular cellular pattern observed in the laminated cross-section, featuring hollow pillars at the wall and intersections. This pattern includes circular cross-section fibers sparsely distributed around the outer edge, transitioning to rectangular structures with a denser distribution towards the middle lamination. Furthermore, the beetle’s forewing is reinforced by trabecular structures between different laminas, significantly enhancing inter-laminar strength, approximately 30 times higher than that of pure chitin fiber laminas [228]. Some studies on beetle inspiration have shown its tremendous benefits regarding the impact-absorbing structure [41,70,97,227,229,230].

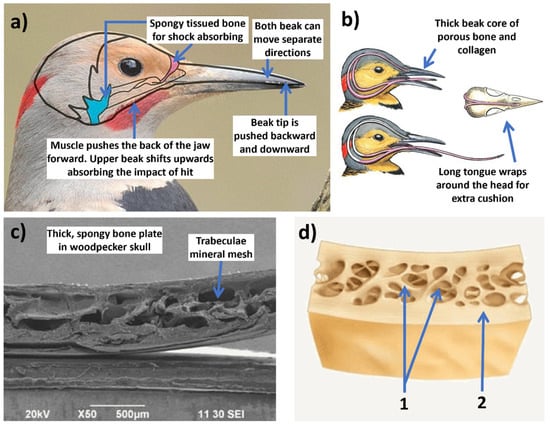

Woodpeckers demonstrate remarkable shock absorption capabilities when they drum rhythmically with their beaks. They can peck at a frequency of 18–22 times per second and around 12,000 times a day on average, with each peck lasting approximately 50 ms. Despite the high impact deceleration and a repeated impact velocity of 6–7 m/s during the pecking process, no head injuries are observed afterward [228,231]. Ha et al. [231] created a woodpeckers’ beak-inspired novel wavy honeycomb sandwich panel and investigated its structural design approach by adjusting wave number and amplitude. This innovative design outperformed the traditional hexagonal honeycomb sandwich panel in energy absorption performance.

The mantis shrimp, known for its powerful raptorial projections, utilizes its sharp dactyl club as a biological hammer for smashing prey and defending against predators. With extreme accelerations facilitated by a unique power amplification mechanism, it can strike both hard-shelled and soft-bodied prey with remarkable force. Particularly, the peacock mantis shrimp can achieve accelerations of over 105 m/s2 and impact velocity exceeding 20 m/s, making it one of nature’s most formidable and fastest impact scenarios [228]. Most of the notable studies on shrimp-inspired energy-absorbing structures include [114,228,232,233,234,235].

Inspirations from various fruits and plants, such as nutshell, pomelo skin, bamboo structure, and horsetail, present promising opportunities for designing impact-absorbing structures. The pericarp, or fruit wall, of all angiosperms consists of three layers: the outermost exocarp, followed by the mesocarp, and the innermost endocarp. In nuts, the pericarp dehydrates entirely, resulting in a highly lignified, mechanically robust compact shell. On the other hand, in drupes, only the endocarp undergoes lignification, forming a resilient protective layer around the seed.

Yang et al. [236] studied pomelo peel and its bionic PEEK structures, finding that different varieties follow similar porosity trends: lowest near the endocarp and exocarp, highest in the mesocarp. The location of maximum porosity varies by pomelo variety. During quasistatic compression, deformation initiates in the highest porosity region, with a near-zero Poisson’s ratio, while the region near the exocarp remains less compressed with a positive Poisson’s ratio. Additively manufactured porous PEEK cubes and numerical simulations confirm the benefits of porous design from pomelo peels for efficient energy absorption, offering clear guidance for designing lightweight materials with high energy absorption.

Chen et al. [237] investigated three bioinspired hierarchical self-similar structures based on basic shapes (curve, circle, and hexagon). They assessed energy absorption rates of unit cells with varying structure ratios through experiments and simulations. Honeycomb and bamboo fractal structures outperformed snake-like fractals in energy absorption. The bamboo fractal structure displayed the highest energy absorption capacity and was used to construct carbon fiber-reinforced composite structures. The numerical findings showed that a seven-cell bamboo fractal structure effectively represents the energy absorption ability of a self-similar structure with an array of cells. Overall, the 3D-printed self-similar composite sandwich structure demonstrates significant potential as a lightweight energy absorption structure.

In terms of aircraft wing’s navigation where energy absorption is as important as other mechanical parameters such as flexure strength, etc., Prakash et al. [238] developed a cashew nut-inspired bionic structure using 3D-printed high-stiffness lignin–ABS core and industrial hemp with aluminized glass fiber epoxy skin. The addition of 30 vol% Al-glass and hemp fiber with lignin-strengthened ABS core (60 vol%) significantly enhanced the mechanical properties of the composite. This composite demonstrated impressive tensile strength, flexural strength, Izod impact resistance, interlaminar shear strength, and compression strength. Table 5 records several bioinspired structures reported in recent literature for their superior impact or energy-absorbing capabilities.

Table 5.

Results of different bioinspired structures under impact-absorbing (wear) conditions, as reported in the literature.

A few promising examples of such inspiration applied to material structuring are described below and systematically compiled in Table 5.

Several features combine to influence the impact resistance of a material and its response to dynamic loading: hierarchical structure (discrete structural elements across multiple length scales); composition (distinct interfaces between a stiff phase for rigidity and strength and a softer phase for ductility); and porosity (gaps filled with air or fluid across all length scales).

Additionally, biological materials demonstrate viscoelastic and/or viscoplastic behaviors, characterized by time-dependent stress and strain responses and time-dependent permanent deformations, respectively [251]. These behaviors are attributed to the polymeric constituents present in biological materials, such as collagen, keratin, cellulose, hemi-cellulose, lignin, and chitin, which determine their ability to absorb and dissipate energy under dynamic conditions. These characteristics are ubiquitous across biological materials. Viscoelastic materials exhibit both elastic and viscous responses, where energy is stored during deformation and dissipated as heat upon loading, respectively. This time-dependent behavior allows viscoelastic materials to attenuate shock and dampen vibration, contributing to impact isolation. For instance, the viscoelastic response of muscle and tissues surrounding the woodpecker’s hyoid apparatus reduces stress waves induced by pecking, while articular cartilage serves as a viscoelastic barrier against high-speed loading, limiting potential damage to surrounding tissues [252,253]. Despite the inherent viscoelasticity of all biological materials, alternative energy absorption mechanisms may prevail at high strain rates, influenced by structural factors such as layering and void distribution, as observed in wood’s impact resistance mechanisms [231].

Furthermore, many biological systems exhibit specific impact-resistant structural elements predominantly on the micro- and mesoscale, including layered, gradient, tubular, sandwich, and sutured structures [251]. These elements, often found in combination, contribute to remarkable properties under dynamic loading conditions. While serving as foundational components for hierarchical impact-resistant structures, individual tests using computer simulations, 3D printing, and composite prepregs have shown that each of these arrangements can enhance a material’s impact resistance independently [217,229,233,249,254].

A very good example is the woodpecker, as shown in Figure 17. When the woodpecker strikes an object with its beak, the immense force at the tip is cushioned by its beak structure and the resilient hyoid bone [255,256]. Consequently, the impact’s stress is significantly diminished from the beak’s tip to where it connects with the skull, reducing the force that reaches the bird’s cranium. The cranial bone, consisting of dense compact bone enveloping layered plate-like structures, forms an efficient shock absorption system [257]. When encountering forces, this deeper bone disperses frequencies in various directions away from the central impact point. Although fragile on its own, the deeper bone, encased in compact bone, maintains flexibility within, absorbing shock during movement. Furthermore, the woodpecker’s brain, proportionally small with a high surface area to weight ratio, further disperses impact force over a larger area, minimizing damage. Computer simulations suggest that only a minute fraction of the impact ultimately reaches the brain, bolstered by the bird’s lengthy tongue, which envelops the brain for added protection [253].

Figure 17.

Images showing (a) a woodpecker’s head and beak; (b) tongue wrapping around the brain to provide extra protection from impact; (c) SEM image of spongy bone situated in between brain and beak that absorbs impact (pink area in part (a)); and (d) schematic of bone showing 1—spongy bone; 2—compact bone. Images adopted CC BY-NC from Science China Press and asknature.org (Accessed on 12 February 2024) [255].

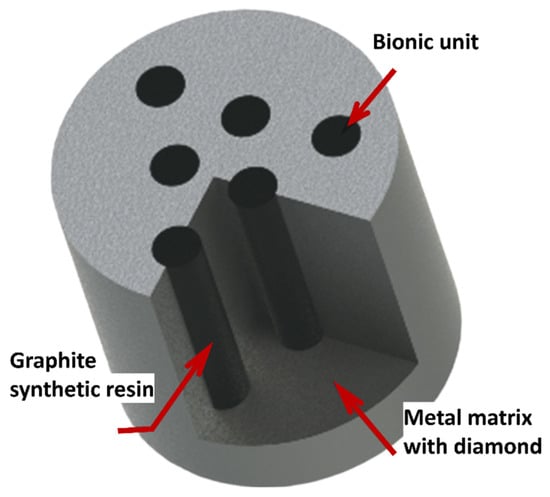

7. Bioinspired Design of Tools for Cutting or Machining

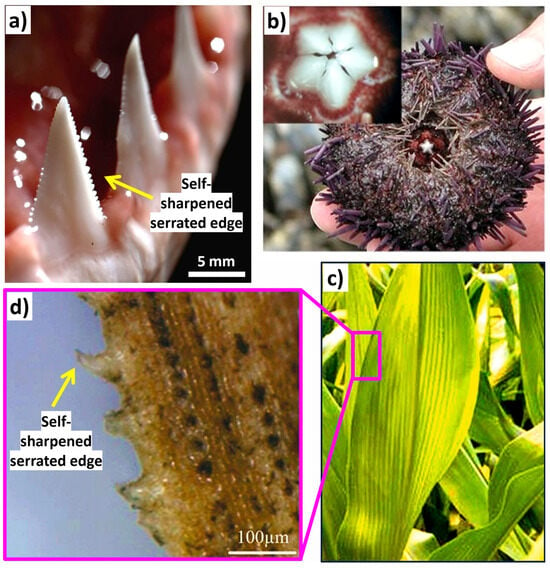

Bionic enhancements of cutting tools (soil, rock, metal, and biological) enhance tool durability, reduce friction, increase heat dissipation, and improve material/surgical removal rates. For example, soil adherence on soil excavation equipment poses a significant technical challenge due to soil characteristics. Metal cutting tools endure significant mechanical and thermal stresses due to the hardness and strength of metals, leading to considerable abrasion and chip adhesion [258]. This wear ultimately diminishes the tools’ lifespan and compromises the quality of the workpiece during processing. This phenomenon elevates traction force by over 30% and concurrently diminishes productivity by the same margin [259]. In such cases, biomimetic designs inspired by the structure of animal teeth or plant leaves have been explored to increase wear resistance and reduce energy consumption during drilling operations. In rock-cutting tools or tunnel-boring machine applications, bioinspired surface modifications based on the properties of animal skins or plant surfaces have been investigated to reduce friction between the cutting tool and the tunnel surface, leading to greater mechanical traction, smoother excavation, and reduced tool wear. Moreover, features like anti-sticking properties for drilling the soft coal or earth [41,260], reducing sticking of drilling-breaks [41,261,262,263,264,265], reducing soil wear and adherence [41,259,266,267,268], self-cleaning [25,73,204,269,270], self-sharpening [271,272,273], self-lubricating [76,138,142,144], self-cooling [274], erosion protection (dry and slurry) [24,211,275,276], increased flexibility [24,277], reducing tool-chip friction [278], decreasing contact length between tool and chip [263,278], changing chip flow direction, improving adhesion resistance [88,266], stabilizing the built-up edge, lowering adhesive wear between tool and chip [105], etc., are shown to be attainable with specific biomimetic surface designs on machining/cutting tools. Additionally, some studies have suggested that a synergistic approach of solid lubricant and the bioinspired textures on tools (turning, etc.) can greatly enhance their performance due to considerable reduction in turning/milling/drilling force and temperature, resulting in major reduction in tool wear [138,270,279]. Some existing examples and nature inspirations reported are derived from python skin [123,274], sea urchin teeth [44,272,273], crab or dung beetle claw and legs [21,41,228,280], mole pelt claw [24,36,268,281,282], pangolin claw [24,52,226,277], wood wasp ovipositors [265,280], earthworm skin [262], seashell [283,284], human teeth [285,286], sunflower seeds [259], corn/maize leaf [287,288,289], badger teeth [36,44,271,273,285], etc. Figure 18 shows the self-sharpened serrated edges in different biological species.

Figure 18.

Images showing self-sharpened serrated edges in (a) shark teeth [290]; (b) rock-eating sea urchin’s teeth [291]; and (c,d) corn leaf [289]. Images were reproduced with permission.

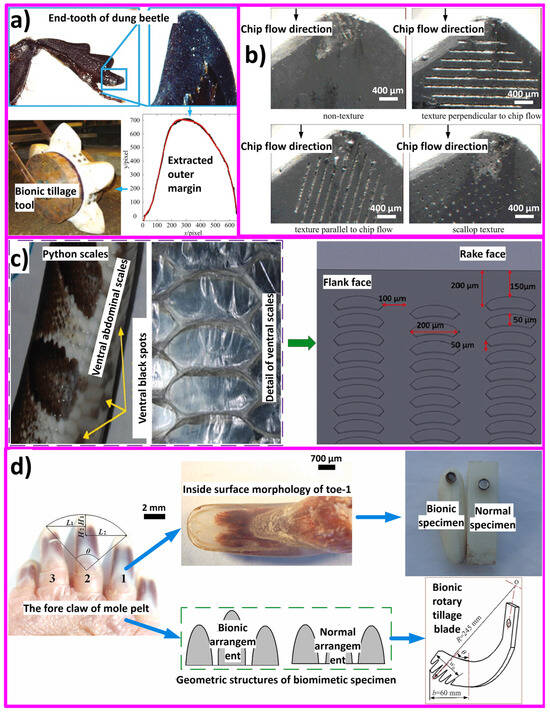

In agricultural and other machining or cutting tools, a certain level of cutting resistance is expected and necessary for the tool to effectively perform its task. However, excessively high cutting resistance and soil adhesion can lead to increased working resistance, increased wear on the tool, and reduced cutting efficiency, significantly reducing service life [292]. Certain soil-burrowing animals, notably dung beetles, ants, and mole pelts, thrive in moist or sticky soil environments yet manage to keep their shells clean and free from soil adhesion. They achieve this anti-adhesive property through the evolution of unique non-smooth surfaces. Moreover, due to their claw’s low soil-cutting resistance (a measure of the difficulty or effort required for the tool to move through the soil medium) and soil adhesion, they can easily dig long tunnels within a short period of time. Hence, the foreleg of the dung beetle and mole pelts serves as an effective bionic prototype for soil-cutting tools as well. For instance, Zhang et al. [35] fabricated a toothed gear inspired by the intricate outer contour curve of the foreleg end-tooth of a dung beetle (Figure 19a). The bionic toothed wheel significantly diminishes draft force by up to 16.5%. Finite element analysis demonstrated that the apex of the bionic peak tooth experiences the highest stress concentration at the contact point with the soil, leading to enhanced cutting tool performance and reduced adhesion and friction between the tool and soil material [35]. Ji et al. [282] created a bionic soil cutting model with ABS polymer, mimicking the foreclaw toes of a mole pelt through reverse engineering and 3D printing. The bionic model exhibited a 12.8% reduction in cutting resistance compared to a standard specimen.

Figure 19.

(a) Dung beetle-inspired design of tillage toothed wheel [35]; (b) various bionic texturing on rake face of a turning tool [259,293]; (c) snakeskin-inspired bionic turning tool [294]; and (d) bionic soil cutting tools inspired by claw toes of mole pelt [282]. All images were reproduced with permission.