A Hierarchical Control Strategy for a Rigid–Flexible Coupled Hexapod Bio-Robot

Abstract

:1. Introduction

- (1)

- Feedforward compensation for robot flexible deformation is proposed, predicting the center of gravity and foot-end force for feedforward compensation of flexible deformation.

- (2)

- A coordinated control strategy is proposed involving hydraulic drive unit force control and leg impedance control, along with a controller based on the rigid-body trunk and flexible-leg models. The desired drive force/moment is obtained by a quadratic programming algorithm using the CAM, CLM, and torso trajectories as objective functions.

2. Related Work

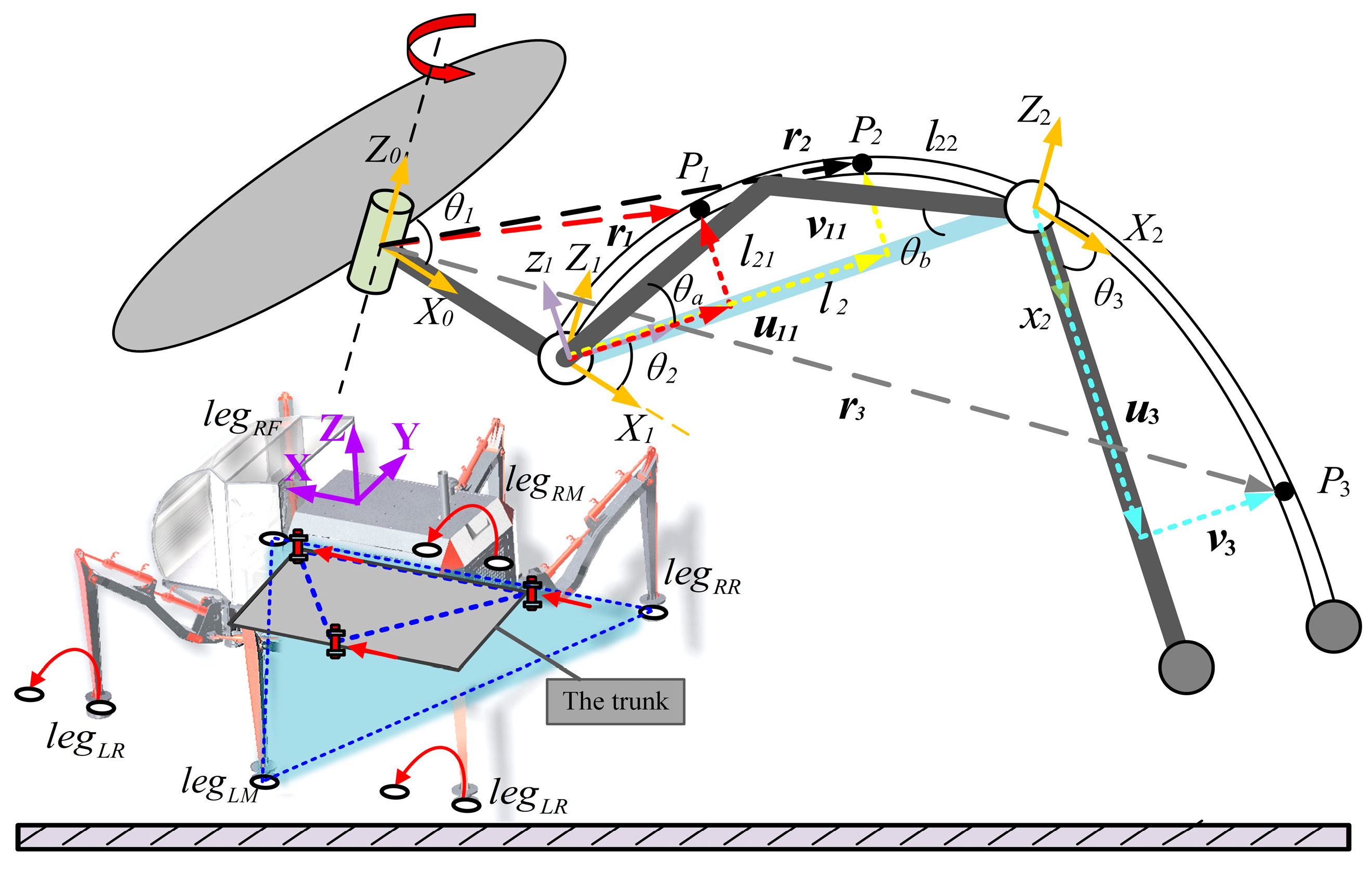

3. Layered Control of Rigid–Flexible Coupling Characteristics

3.1. Feedforward Compensation

3.2. Torque Control for Rigid–Flexible Coupled Robots

4. Results and Discussion

4.1. Simulation

4.2. Experiments

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Appendix A

Appendix B

Appendix C

Appendix D

References

- Fahmi, S.; Barasuol, V.; Esteban, D.; Villarreal, O.; Semini, C. ViTAL: Vision-Based Terrain-Aware Locomotion for Legged Robots. IEEE Trans. Robot. 2023, 39, 885–904. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Z.; Wu, C.; Mao, H.; Sun, P. A Hierarchical Framework for Quadruped Robots Gait Planning Based on DDPG. Biomimetics 2023, 8, 382. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Chen, X.; Yu, Z.; Yu, H.; Meng, L.; Yokoi, H. High-Precision Dynamic Torque Control of High Stiffness Actuator for Humanoids. ISA Trans. 2023, 141, 401–413. [Google Scholar] [CrossRef]

- Ma, J.; Qiu, G.; Guo, W.; Li, P.; Ma, G. Design, Analysis and Experiments of Hexapod Robot with Six-Link Legs for High Dynamic Locomotion. Micromachines 2022, 13, 1404. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Q.; Zhang, J.; Li, X.; Zong, H.; Yu, B.; Ba, K.; Kong, X. An Adaptive Composite Control for a Hydraulic Actuator Impedance System of Legged Robots. Mechatronics 2023, 91, 102951. [Google Scholar] [CrossRef]

- Chen, G.; Wei, N.; Lu, H.; Yan, L.; Li, J. Optimization and Evaluation of Swing Leg Retraction for a Hydraulic Biped Robot. J. Field Robot. 2023, 40, 1525–1542. [Google Scholar] [CrossRef]

- Xing, J.; Jin, W.; Yang, K.; Howard, I. A Bionic Piezoelectric Robotic Jellyfish with a Large Deformation Flexure Hinge. IEEE Trans. Ind. Electron. 2023, 70, 12596–12605. [Google Scholar] [CrossRef]

- Ackerman, J.; Seipel, J. Energy Efficiency of Legged Robot Locomotion with Elastically Suspended Loads. IEEE Trans. Robot. 2013, 29, 321–330. [Google Scholar] [CrossRef]

- Tang, J.; Zhu, Y.; Gan, W.; Mou, H.; Leng, J.; Li, Q.; Yu, Z.; Zhang, J. Design, Control, and Validation of a Symmetrical Hip and Straight-Legged Vertically-Compliant Bipedal Robot. Biomimetics 2023, 8, 340. [Google Scholar] [CrossRef]

- Wang, J.; Fei, Y. Design and Modelling of Flex-Rigid Soft Robot for Flipping Locomotion. J. Intell. Robot. Syst. 2018, 95, 379–388. [Google Scholar] [CrossRef]

- Xu, K.; Liu, H. Design of a Flexure-Jointed Linkage in a Quadruped Walking Robot. IEEE/ASME Trans. Mechatron. 2022, 27, 4022–4032. [Google Scholar] [CrossRef]

- Zhang, T.; Lin, K.; Zhang, A. Research on Flexible Dynamics of a 6-DOF Industrial Robot and Residual Vibration Control with a Pre-Adaptive Input Shaper. J. Mech. Sci. Technol. 2019, 33, 1875–1889. [Google Scholar] [CrossRef]

- Chen, T.; Wang, Y.; Wen, H.; Kang, J. Autonomous Assembly of Multiple Flexible Spacecraft Using RRT* Algorithm and Input Shaping Technique. Nonlinear Dyn. 2023, 111, 11223–11241. [Google Scholar] [CrossRef]

- Zheng, K.; Zhang, Q.; Zeng, S. Trajectory Control and Vibration Suppression of Rigid-flexible Parallel Robot Based on Singular Perturbation Method. Asian J. Control 2022, 24, 3006–3021. [Google Scholar] [CrossRef]

- Xun, M.; Yu, H.; Liu, Y.; Deng, J.; Zhang, S.; Li, K. A Precise Rotary Piezoelectric Actuator Based on the Spatial Screw Compliant Mechanism. IEEE/ASME Trans. Mechatron. 2023, 28, 223–232. [Google Scholar] [CrossRef]

- Pan, T.; Shen, X.; Chen, Y. Active Vibration Control of Thin-Walled Structure with Inertial Piezoelectric Actuator Based on Fuzzy Adaptive PID Algorithm. J. Vib. Eng. Technol. 2023. [Google Scholar] [CrossRef]

- Zhong, R.; Zhao, Y.; Wang, H. Rigid-Flexible Coupling Identification and Attitude Control Based on Deep Neural Networks. Adv. Space Res. 2022, 69, 1538–1549. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, C.; Ma, S.; Pan, J.; Sui, X.; Lin, B.; Shi, M. Rigid–Flexible Coupled System Attitude–Orbit Integration Fixed-Time Control. Electronics 2023, 12, 3329. [Google Scholar] [CrossRef]

- Ye, D.; Xiao, Y. Robust Output Feedback Attitude Tracking Control for Rigid-Flexible Coupling Spacecraft. J. Frankl. Inst. 2018, 355, 9209–9223. [Google Scholar] [CrossRef]

- Kim, S.H. Feedforward Compensation of Contour Errors in Robotic Machining System Using Compliance Model. J. Manuf. Process. 2023, 89, 142–149. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, Q.; Sun, Y. Non-Kinematic Calibration of Industrial Robots Using a Rigid–Flexible Coupling Error Model and a Full Pose Measurement Method. Robot. Comput.-Integr. Manuf. 2019, 57, 46–58. [Google Scholar] [CrossRef]

- Deng, K.; Gao, D.; Ma, S.; Zhao, C.; Lu, Y. Elasto-Geometrical Error and Gravity Model Calibration of an Industrial Robot Using the Same Optimized Configuration Set. Robot. Comput.-Integr. Manuf. 2023, 83, 102558. [Google Scholar] [CrossRef]

- Ding, H.; Wang, Q.; Hu, W.; Yin, X. Spatial Rigid-Flexible-Liquid Coupling Dynamics of Towed System Analyzed by a Hamiltonian Finite Element Method. J. Mar. Sci. Eng. 2021, 9, 1157. [Google Scholar] [CrossRef]

- Wang, B.; Liu, Z.; Zheng, P. Rigid-Flexible Coupling Dynamic Modeling and Analysis of Dumbbell-Shaped Spacecraft. Aerosp. Sci. Technol. 2022, 126, 107641. [Google Scholar] [CrossRef]

- Xiao, L.; Yan, F.; Chen, T.; Zhang, S.; Jiang, S. Study on Nonlinear Dynamics of Rigid-Flexible Coupling Multi-Link Mechanism Considering Various Kinds of Clearances. Nonlinear Dyn. 2022, 111, 3279–3306. [Google Scholar] [CrossRef]

- Safartoobi, M.; Dardel, M.; Daniali, H.M. Gait Cycles of Passive Walking Biped Robot Model with Flexible Legs. Mech. Mach. Theory 2021, 159, 104292. [Google Scholar] [CrossRef]

- Yi, C.; Chen, X.; Zhang, Y.; Yu, Z.; Qi, H.; Liu, Y.; Huang, Q. Simulating the GRF of Humanoid Robot Vertical Jumping Using a Simplified Model with a Foot Structure for Foot Design. J. Bionic Eng. 2023. [Google Scholar] [CrossRef]

- Ren, H.; Zhang, L.; Su, C. Dynamic Analysis and Decoupled Control of a Heavy-Duty Walking Robot with Flexible Feet Based on Super Twisting Algorithm. Meas. Control 2020, 54, 55–64. [Google Scholar] [CrossRef]

- Zamzami, Z.; Amar, F.B. Dynamic Coupling Map: Acceleration Space Analysis for Underactuated Robots. In Proceedings of the 13th International Conference on Informatics in Control, Automation and Robotics, Lisbon, Portugal, 29–31 July 2016; SCITEPRESS—Science and and Technology Publications: Montreal, QC, Canada, 2016. [Google Scholar]

- Spyrakos-Papastavridis, E.; Dai, J.S. Stable Flexible-Joint Floating-Base Robot Balancing and Locomotion via Variable Impedance Control. IEEE Trans. Ind. Electron. 2023, 70, 2748–2758. [Google Scholar] [CrossRef]

- Li, Z.; Ge, Q.; Ye, W.; Yuan, P. Dynamic Balance Optimization and Control of Quadruped Robot Systems with Flexible Joints. IEEE Trans. Syst. Man Cybern. Syst. 2016, 46, 1338–1351. [Google Scholar] [CrossRef]

- Kronander, K.; Billard, A. Stability Considerations for Variable Impedance Control. IEEE Trans. Robot. 2016, 32, 1298–1305. [Google Scholar] [CrossRef]

- Qi, H.; Chen, X.; Yu, Z.; Huang, G.; Liu, Y.; Meng, L.; Huang, Q. Vertical Jump of a Humanoid Robot with CoP-Guided Angular Momentum Control and Impact Absorption. IEEE Trans. Robot. 2023, 39, 3154–3166. [Google Scholar] [CrossRef]

- Yue, Y.; Cao, L.; Chen, H.; Chen, Y.; Su, Z. Towards an Optimal KELM Using the PSO-BOA Optimization Strategy with Applications in Data Classification. Biomimetics 2023, 8, 306. [Google Scholar] [CrossRef] [PubMed]

- Sharma, S.; Majumdar, A.; Elvira, V.; Chouzenoux, E. Blind Kalman Filtering for Short-Term Load Forecasting. IEEE Trans. Power Syst. 2020, 35, 4916–4919. [Google Scholar] [CrossRef]

| Leg Section | Li | di | αi | θi |

|---|---|---|---|---|

| Hip joint | 1.5 m | 0 | π/2 | θ1 |

| Thigh | 1.5 m | 0 | 0 | θ2 |

| Shin | 0.33 m | 0 | 0 | θ3 |

| Level Road | Roll Angle = 10° | Pitch Angle = 10° | ||||

|---|---|---|---|---|---|---|

| OC | LCRFC | OC | LCRFC | OC | LCRFC | |

| Gx_Error (mm) | 38.3 | 6.6 | 41.6 | 6.9 | 53.6 | 8.3 |

| Gy_Error (mm) | 11.6 | 1.4 | 14.3 | 1.6 | 12.3 | 1.4 |

| Gz_Error (mm) | 4.8 | 0.9 | 5.1 | 0.9 | 6.7 | 1.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, K.; Liu, X.; Liu, C.; Tan, X. A Hierarchical Control Strategy for a Rigid–Flexible Coupled Hexapod Bio-Robot. Biomimetics 2023, 8, 561. https://doi.org/10.3390/biomimetics8080561

Yang K, Liu X, Liu C, Tan X. A Hierarchical Control Strategy for a Rigid–Flexible Coupled Hexapod Bio-Robot. Biomimetics. 2023; 8(8):561. https://doi.org/10.3390/biomimetics8080561

Chicago/Turabian StyleYang, Kuo, Xinhui Liu, Changyi Liu, and Xurui Tan. 2023. "A Hierarchical Control Strategy for a Rigid–Flexible Coupled Hexapod Bio-Robot" Biomimetics 8, no. 8: 561. https://doi.org/10.3390/biomimetics8080561

APA StyleYang, K., Liu, X., Liu, C., & Tan, X. (2023). A Hierarchical Control Strategy for a Rigid–Flexible Coupled Hexapod Bio-Robot. Biomimetics, 8(8), 561. https://doi.org/10.3390/biomimetics8080561