Double-Acting Soft Actuator for Soft Robotic Hand: A Bellow Pumping and Contraction Approach

Abstract

1. Introduction

2. Materials and Methods

2.1. Design and Modeling of the Double-Acting Soft Actuator

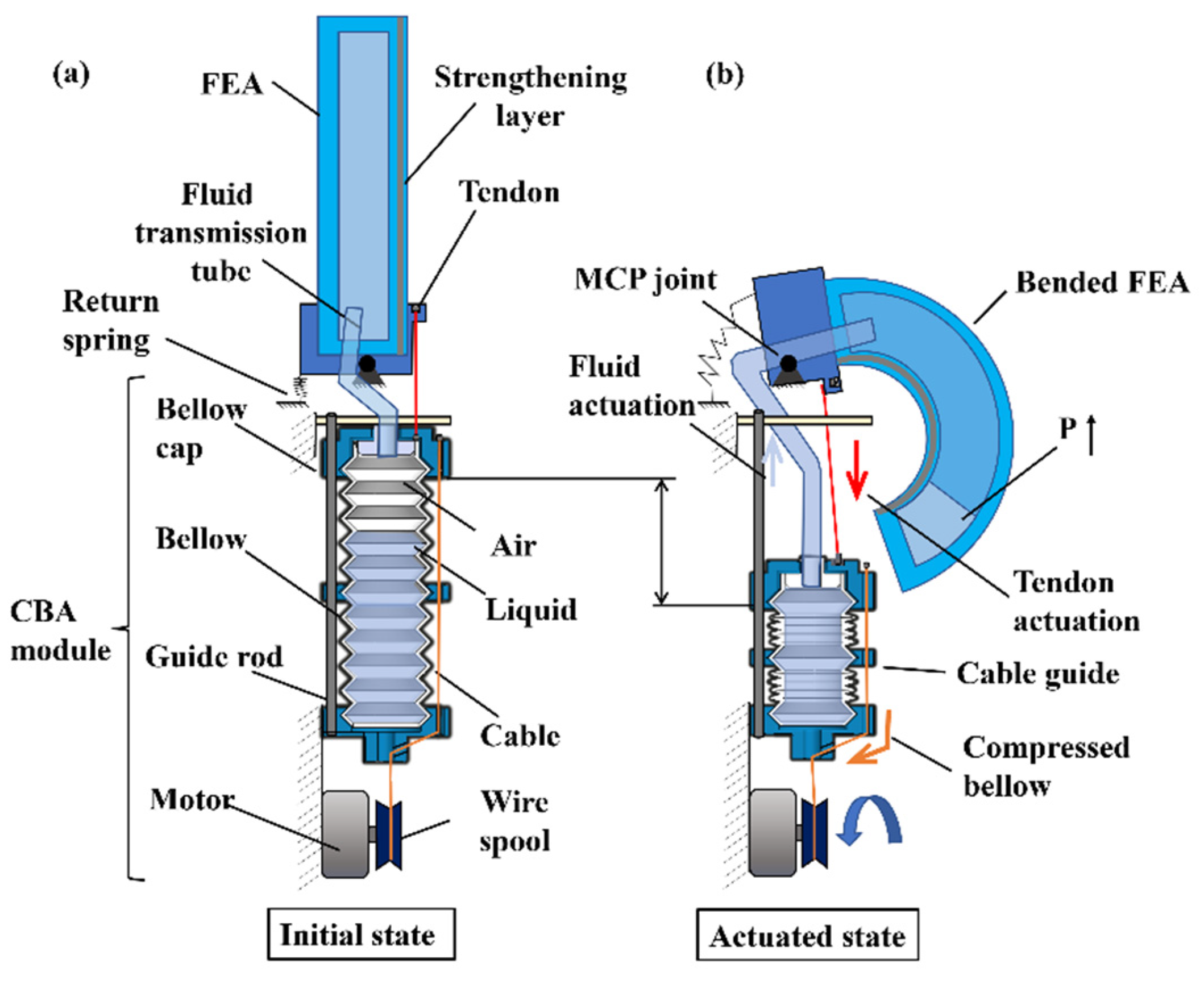

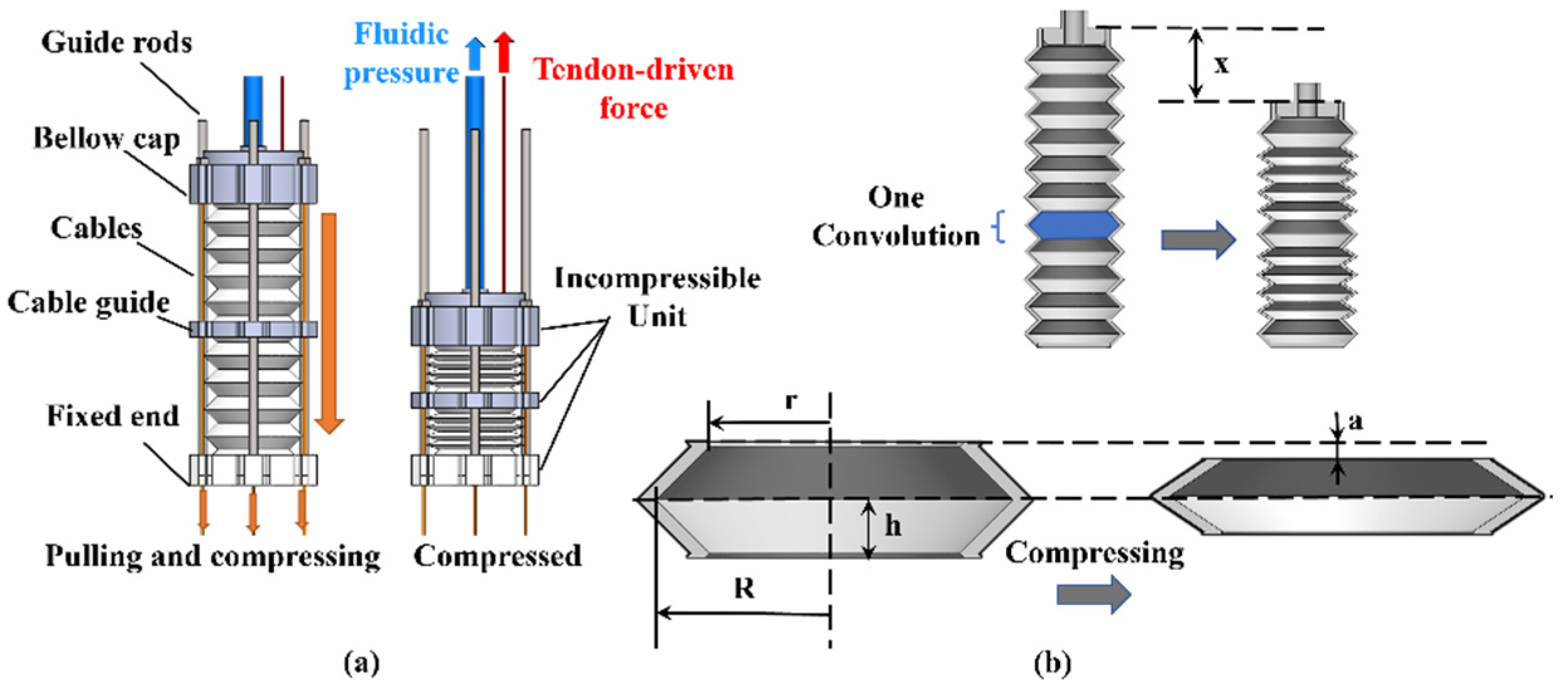

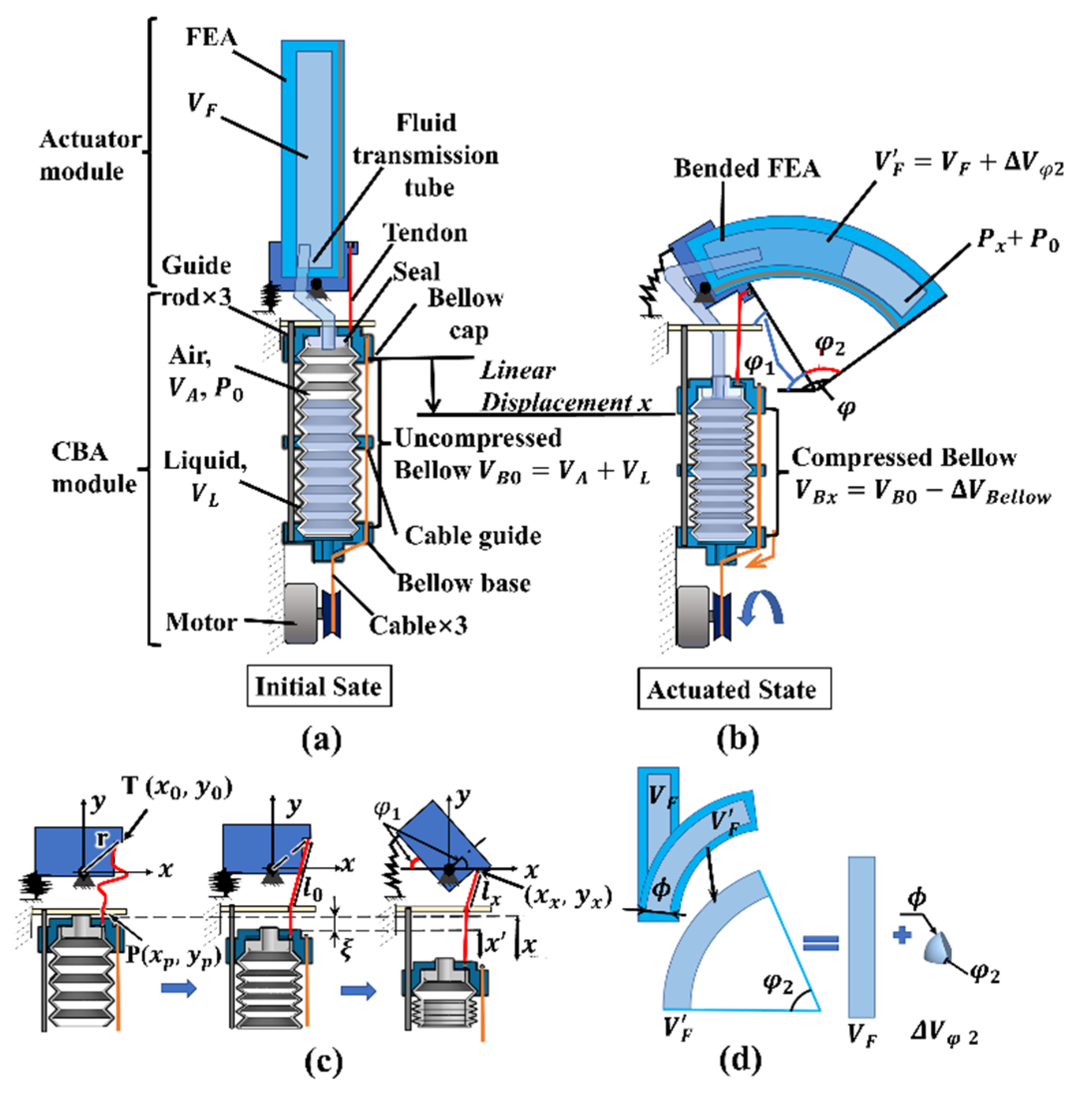

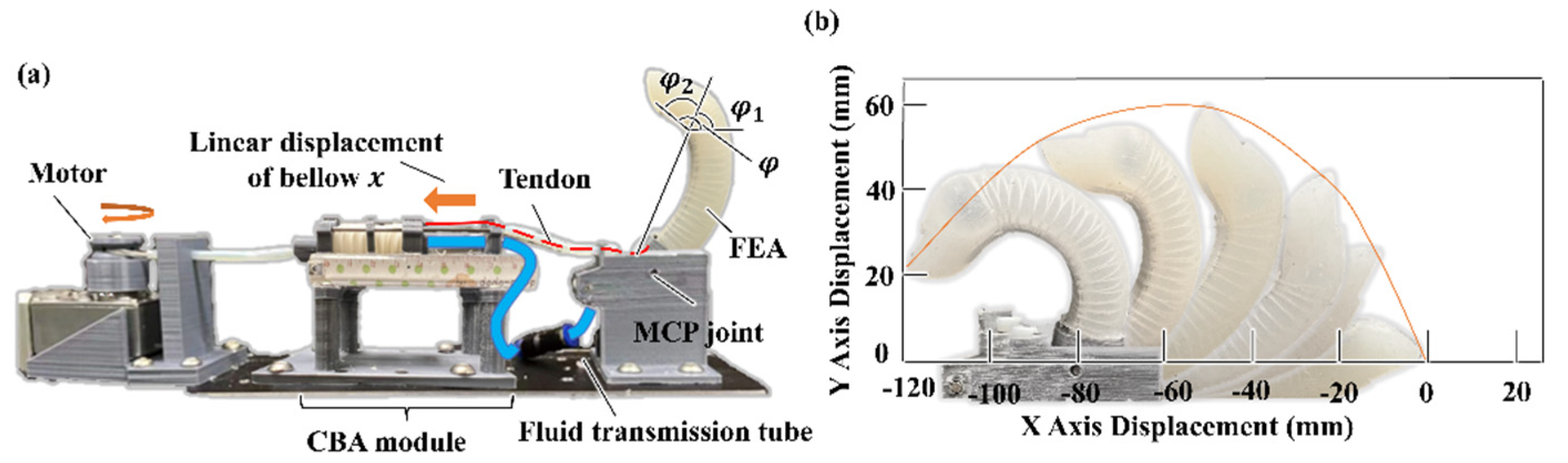

2.1.1. Working Principle and Modeling of the Compressing Bellow Actuation

2.1.2. Design and Modeling of the Double-Acting Soft Actuator

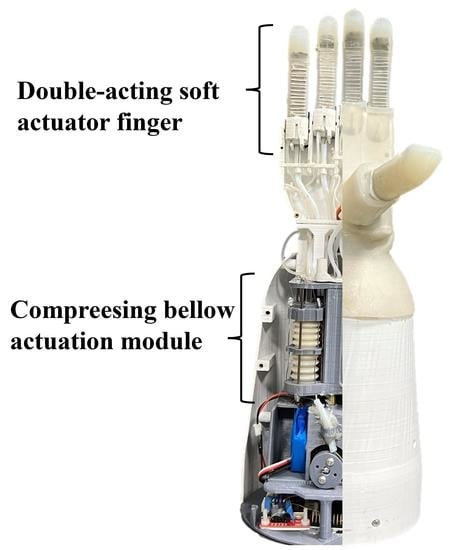

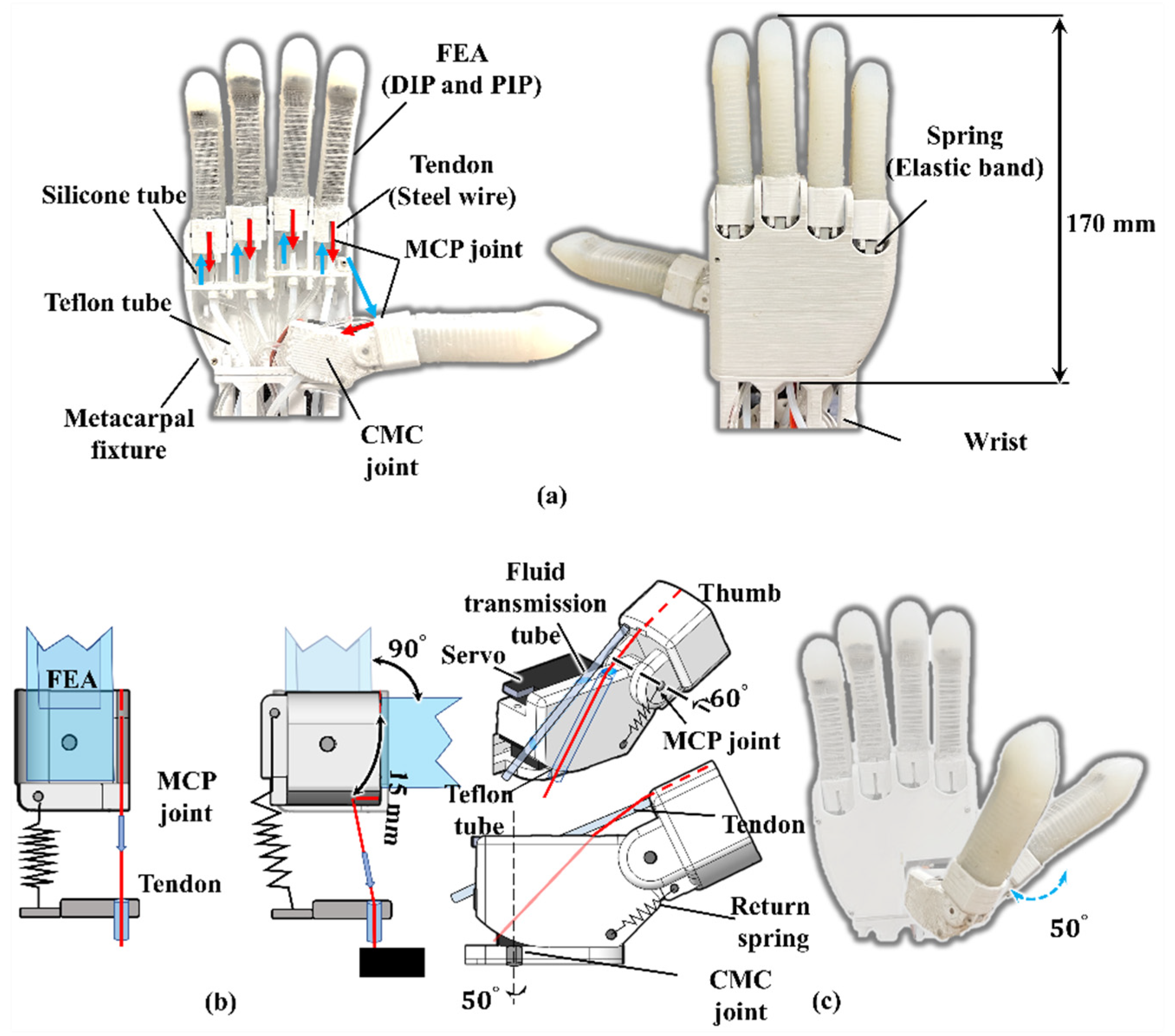

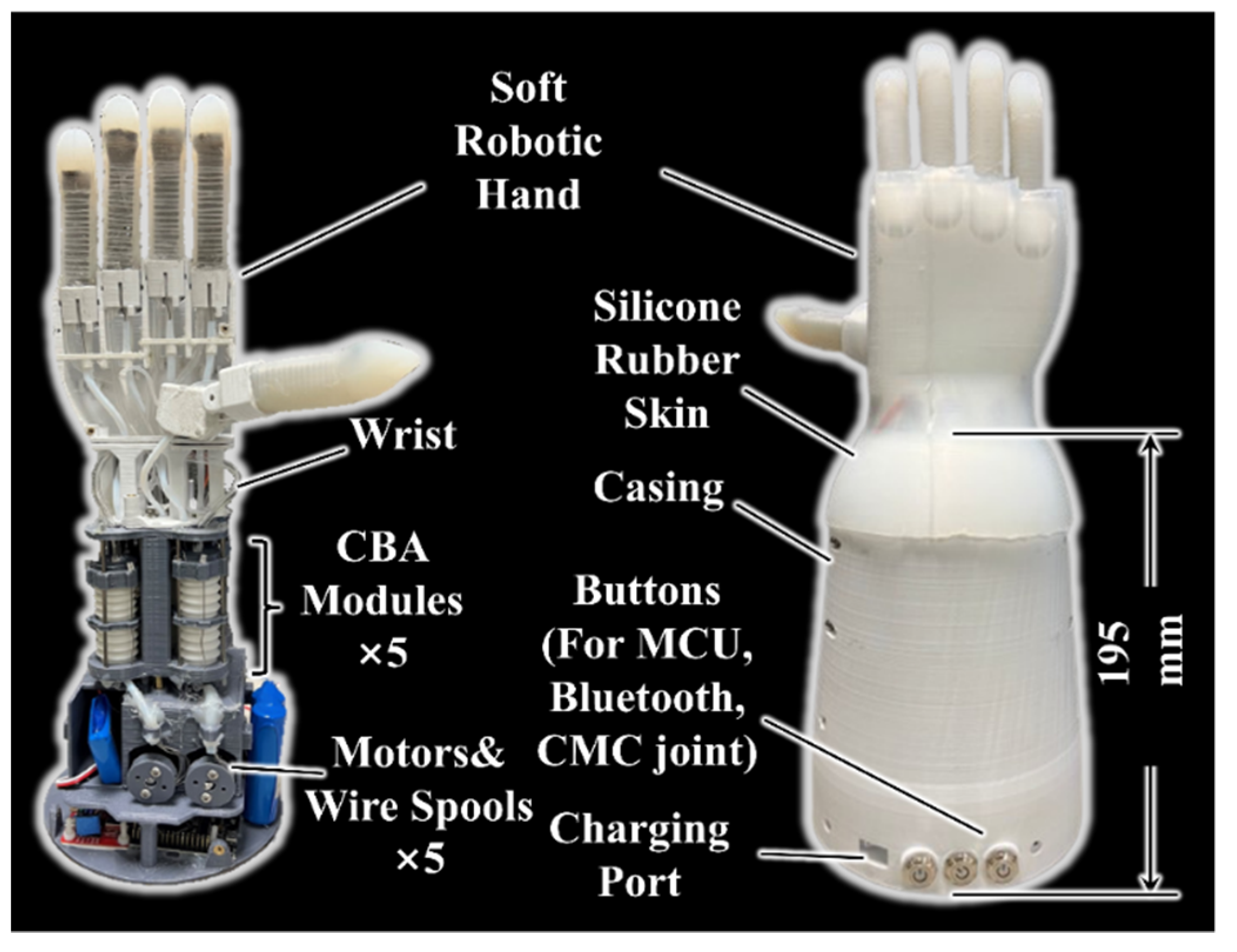

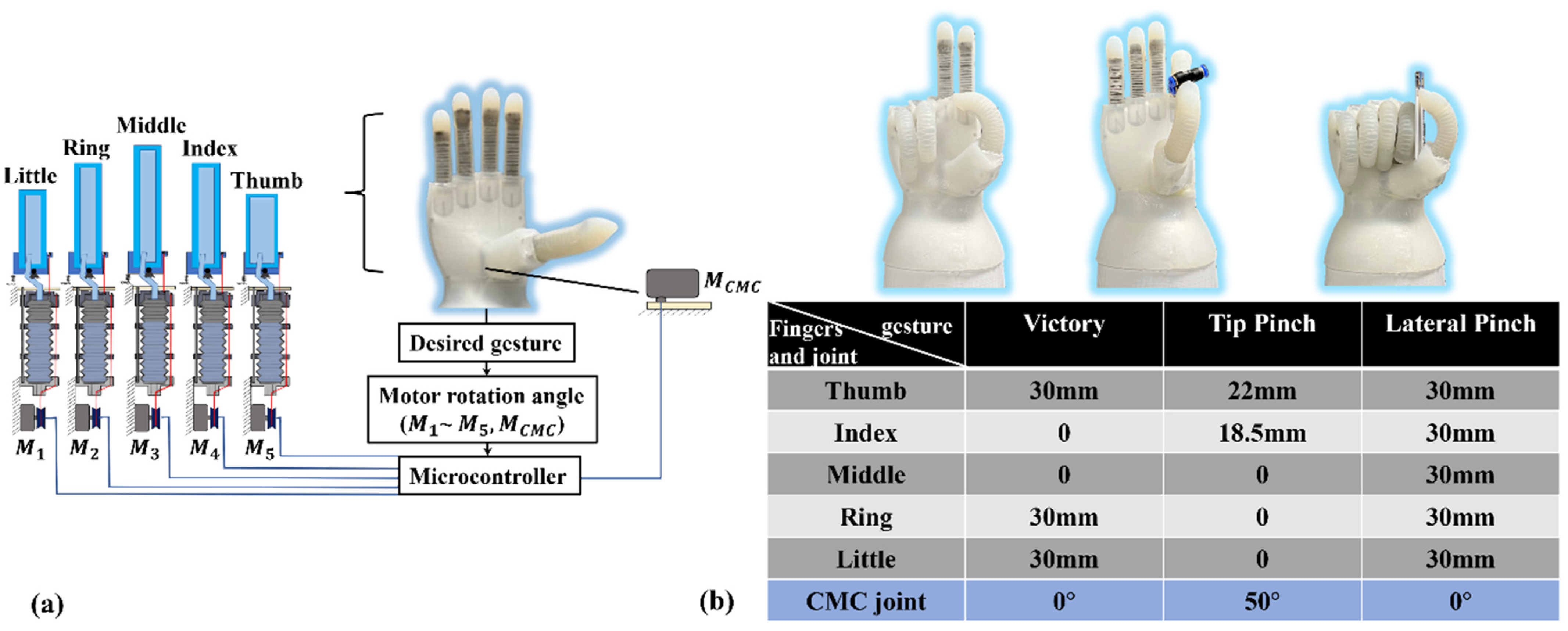

2.2. The Soft Robotic Hand with Five Double-Acting Soft Actuator Fingers

3. Results and Discussion

3.1. Experimental Characterization of the Double-Acting Soft Actuator

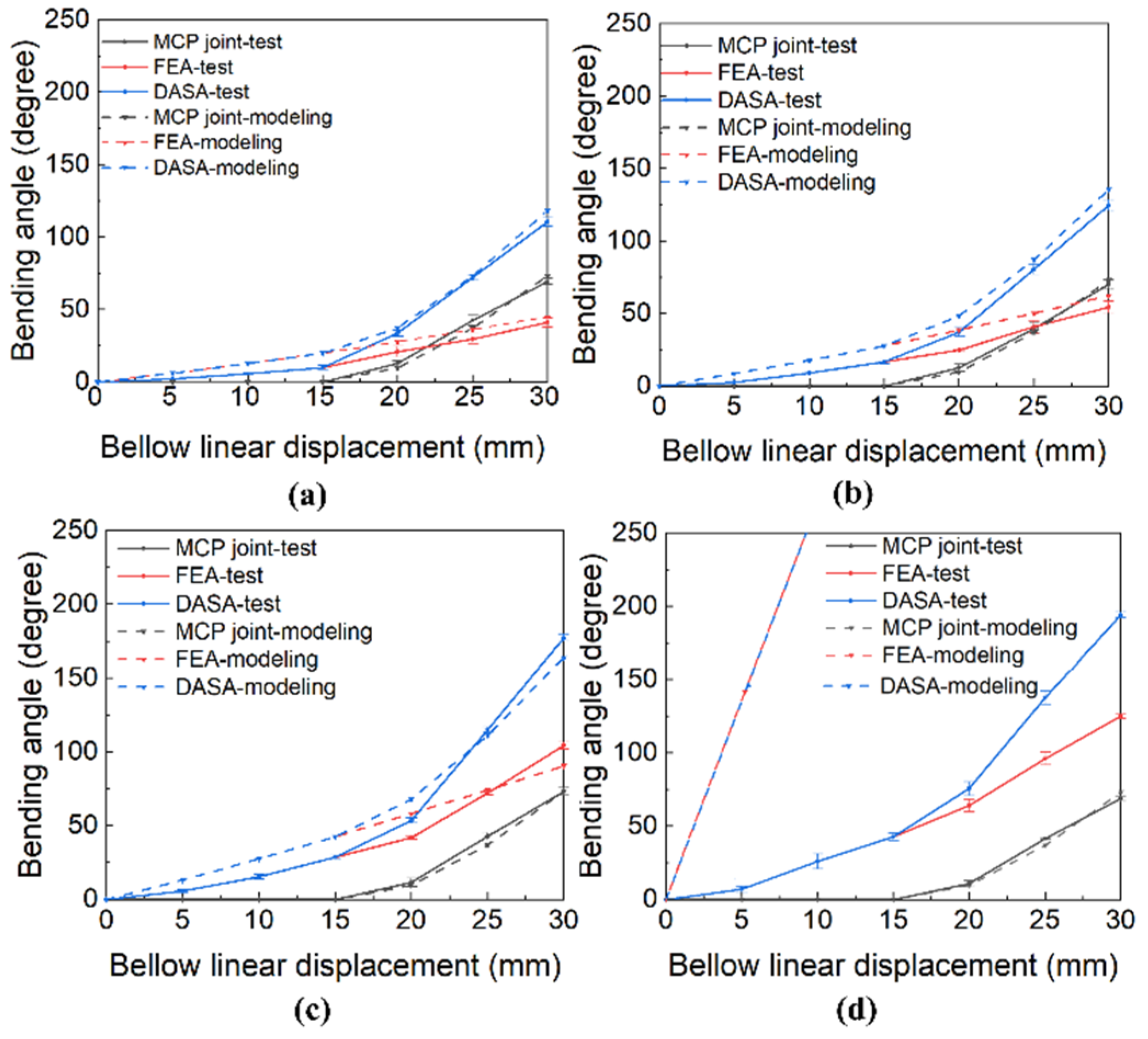

3.1.1. Bending Angle Test

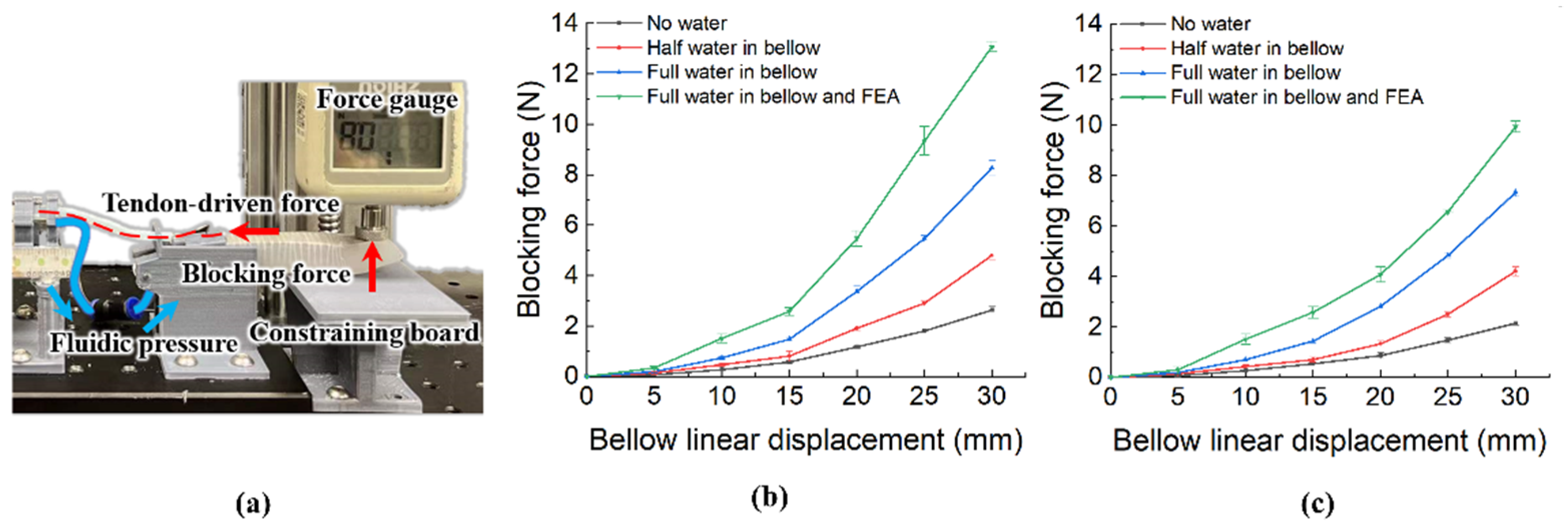

3.1.2. Blocking Force Test

3.1.3. Comparison of the Void Volume in Bending

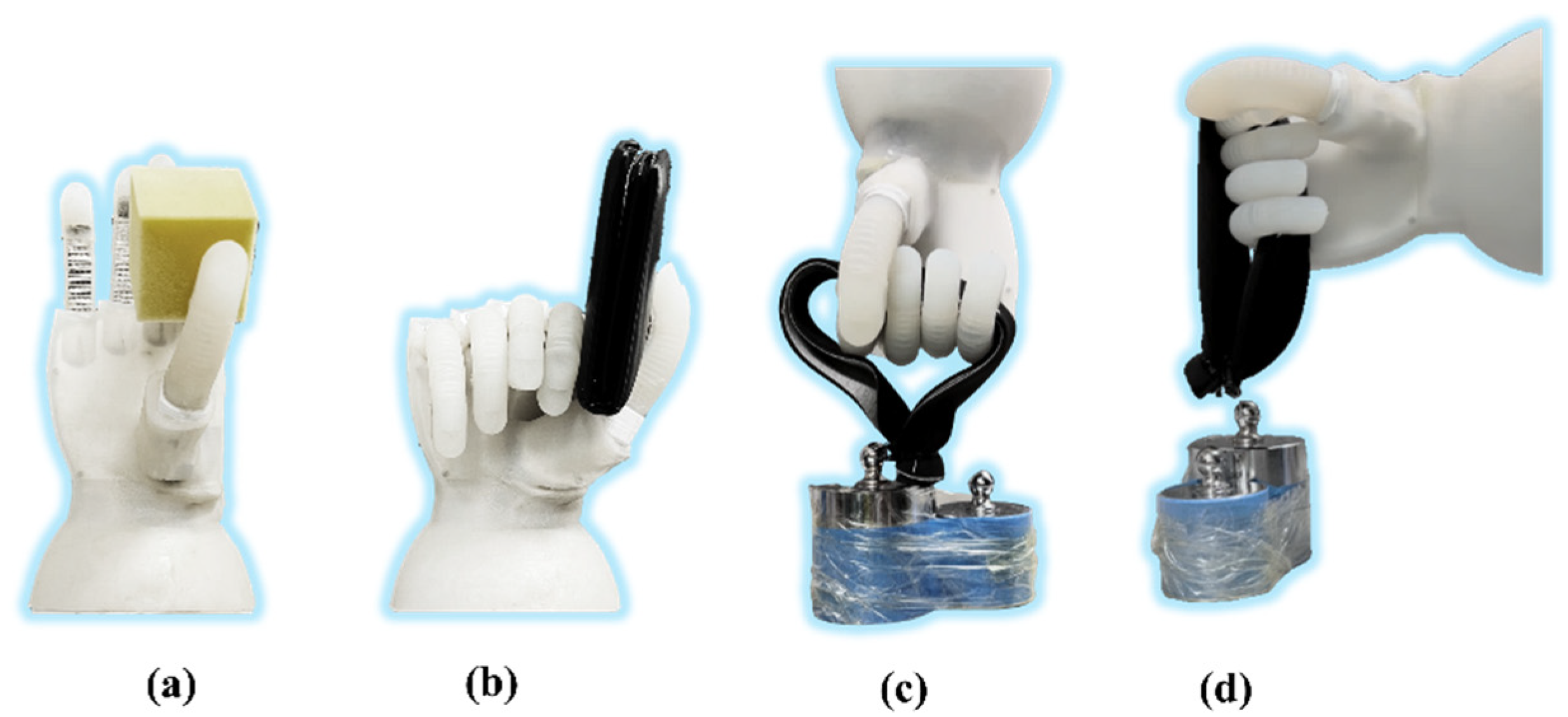

3.2. Experimental Characterization of the Untethered Soft Robotic Hand

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Siciliano, B.; Khatib, O. Robot Hands. In Springer Handbook of Robotics; Springer: New York, NY, USA, 2008; Chapter 15; pp. 391–392. [Google Scholar]

- Loai, A.T.; Nefti-Meziani, A.T.S.; Davis, S. Design of a variable stiffness soft dexterous gripper. Soft Robot. 2017, 4, 274–284. [Google Scholar]

- Shintake, J.; Cacucciolo, V.; Floreano, D.; Shea, H. Soft robotic grippers. Adv. Mater. 2018, 30, 1707035. [Google Scholar] [CrossRef] [PubMed]

- Fras, J.; Althoefer, K. Soft Biomimetic Prosthetic Hand: Design, Manufacturing and Preliminary Examination. In Proceedings of the 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Ilievski, F.; Mazzeo, A.D.; Shepherd, R.; Chen, X.; Whitesides, G.M. Soft Robotics for Chemists. Angew. Chem. Int. Ed. 2011, 50, 1890–1895. [Google Scholar] [CrossRef] [PubMed]

- Xu, Z.; Todorov, E. Design of a highly biomimetic anthropomorphic robotic hand towards artificial limb regeneration. In Proceedings of the 2016 IEEE International Conference on Robotics and Automation (ICRA), Stockholm, Sweden, 16–21 May 2016; pp. 3485–3492. [Google Scholar]

- Wei, Y.; Chen, Y.; Ren, T.; Chen, Q.; Yan, C.; Yang, Y.; Li, Y. A Novel, Variable Stiffness Robotic Gripper Based on Integrated Soft Actuating and Particle Jamming. Soft Robot. 2016, 3, 134–143. [Google Scholar] [CrossRef]

- Shintake, J.; Rosset, S.; Schubert, B.; Floreano, D.; Shea, H. Polymer actuators: Versatile soft grippers with intrinsic electroadhesion based on multifunctional polymer actuators. Adv. Mater. 2016, 28, 205. [Google Scholar] [CrossRef]

- Lan, C.-C.; Lin, C.-M.; Fan, C.-H. A Self-Sensing Microgripper Module With Wide Handling Ranges. IEEE/ASME Trans. Mechatron. 2010, 16, 141–150. [Google Scholar] [CrossRef]

- Behl, M.; Kratz, K.; Zotzmann, J.; Nöchel, U.; Lendlein, A. Reversible Bidirectional Shape-Memory Polymers. Adv. Mater. 2013, 25, 4466–4469. [Google Scholar] [CrossRef]

- Lau, G.-K.; Heng, K.-R.; Ahmed, A.S.; Shrestha, M. Dielectric elastomer fingers for versatile grasping and nimble pinching. Appl. Phys. Lett. 2017, 110, 182906. [Google Scholar] [CrossRef]

- Wang, Z.; Or, K.; Hirai, S. A dual-mode soft gripper for food packaging. Robot. Auton. Syst. 2020, 125, 103427. [Google Scholar] [CrossRef]

- Hirose, S.; Umetani, Y. The development of soft gripper for the versatile robot hand. Mech. Mach. Theory 1978, 13, 351–359. [Google Scholar] [CrossRef]

- Ma, R.; Dollar, A. Yale OpenHand Project: Optimizing Open-Source Hand Designs for Ease of Fabrication and Adoption. IEEE Robot. Autom. Mag. 2017, 24, 32–40. [Google Scholar] [CrossRef]

- Polygerinos, P.; Wang, Z.; Overvelde, J.T.B.; Galloway, K.C.; Wood, R.J.; Bertoldi, K.; Walsh, C.J. Modeling of Soft Fiber-Reinforced Bending Actuators. IEEE Trans. Robot. 2015, 31, 778–789. [Google Scholar] [CrossRef]

- Connolly, F.; Walsh, C.J.; Bertoldi, K. Automatic design of fiber-reinforced soft actuators for trajectory matching. Proc. Natl. Acad. Sci. USA 2017, 114, 51–56. [Google Scholar] [CrossRef] [PubMed]

- Zhu, T.; Yang, H.; Zhang, W. A Spherical Self-Adaptive Gripper with shrinking of an elastic membrane. In Proceedings of the 2016 International Conference on Advanced Robotics and Mechatronics (ICARM), Macau, China, 18–20 August 2016; pp. 512–517. [Google Scholar] [CrossRef]

- Tawk, C.; Gillett, A.; Panhuis, M.I.H.; Spinks, G.M.; Alici, G. A 3D-Printed Omni-Purpose Soft Gripper. IEEE Trans. Robot. 2019, 35, 1268–1275. [Google Scholar] [CrossRef]

- Li, Y.; Ren, T.; Chen, Y.; Zhou, J.; Hu, Y.; Wang, Z.; Sun, W.; Xiong, C. Untethered Multimode Fluidic Actuation: A New Approach to Soft and Compliant Robotics. Soft Robot. 2021, 8, 71–84. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Chen, Y.; Ren, T.; Hu, Y.; Liu, H.; Lin, S.; Yang, Y.; Li, Y.; Zhou, J. A Dual-Mode Actuator for Soft Robotic Hand. IEEE Robot. Autom. Lett. 2021, 6, 1144–1151. [Google Scholar] [CrossRef]

- Guo, N.; Sun, Z.; Wang, X.; Yeung, E.H.K.; To, M.K.T.; Li, X.; Hu, Y. Simulation analysis for optimal design of pneumatic bellow actuators for soft-robotic glove. Biocybern. Biomed. Eng. 2020, 40, 1359–1368. [Google Scholar] [CrossRef]

- Prithvirajan, R.; Sugavaneswaran, M.; Sathishkumar, N.; Arumaikkannu, G. Metal bellow hydroforming using additive manufactured die: A case study. Rapid Prototyp. J. 2019, 25, 765–774. [Google Scholar] [CrossRef]

- Kang, B.H.; Lee, M.Y.; Shon, S.M.; Moon, Y.H. Forming various shapes of tubular bellows using a single-step hydro-forming process. J. Mater. Process. Technol. 2007, 194, 1–6. [Google Scholar] [CrossRef]

- Zhou, J.; Chen, Y.; Chen, X.; Wang, Z.; Li, Y.; Liu, Y. A Proprioceptive Bellows (PB) Actuator With Position Feedback and Force Estimation. IEEE Robot. Autom. Lett. 2020, 5, 1867–1874. [Google Scholar] [CrossRef]

- Zaghloul, A.; Bone, G.M. 3D Shrinking for Rapid Fabrication of Origami-Inspired Semi-Soft Pneumatic Actuators. IEEE Access 2020, 8, 191330–191340. [Google Scholar] [CrossRef]

- Soft Robotics Toolkit. 1 October 2017. Available online: https://softroboticstoolkit.com/ (accessed on 17 March 2022).

- Zhou, J.; Chen, X.; Chang, U.; Lu, J.-T.; Leung, C.C.Y.; Chen, Y.; Hu, Y.; Wang, Z. A Soft-Robotic Approach to Anthropomorphic Robotic Hand Dexterity. IEEE Access 2019, 7, 101483–101495. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Wu, C.; Lin, S.; Li, Y.; Chen, Y. Double-Acting Soft Actuator for Soft Robotic Hand: A Bellow Pumping and Contraction Approach. Biomimetics 2022, 7, 171. https://doi.org/10.3390/biomimetics7040171

Liu H, Wu C, Lin S, Li Y, Chen Y. Double-Acting Soft Actuator for Soft Robotic Hand: A Bellow Pumping and Contraction Approach. Biomimetics. 2022; 7(4):171. https://doi.org/10.3390/biomimetics7040171

Chicago/Turabian StyleLiu, Hao, Changchun Wu, Senyuan Lin, Yunquan Li, and Yonghua Chen. 2022. "Double-Acting Soft Actuator for Soft Robotic Hand: A Bellow Pumping and Contraction Approach" Biomimetics 7, no. 4: 171. https://doi.org/10.3390/biomimetics7040171

APA StyleLiu, H., Wu, C., Lin, S., Li, Y., & Chen, Y. (2022). Double-Acting Soft Actuator for Soft Robotic Hand: A Bellow Pumping and Contraction Approach. Biomimetics, 7(4), 171. https://doi.org/10.3390/biomimetics7040171