Design of a Hierarchical Control Architecture for Fully-Driven Multi-Fingered Dexterous Hand

Abstract

1. Introduction

- Informed by the modular design principles applicable to both hardware and software, a layered control system architecture is presented to develop a four-channel high-precision digital-to-analog converter (DAC) driver module, utilizing a field-programmable gate array (FPGA) as the real-time master control unit. This system is integrated with a multiplexed signal acquisition module to facilitate the control and sensing capabilities of a fully-driven multi-fingered dexterous hand, while simultaneously ensuring the real-time performance of the system.

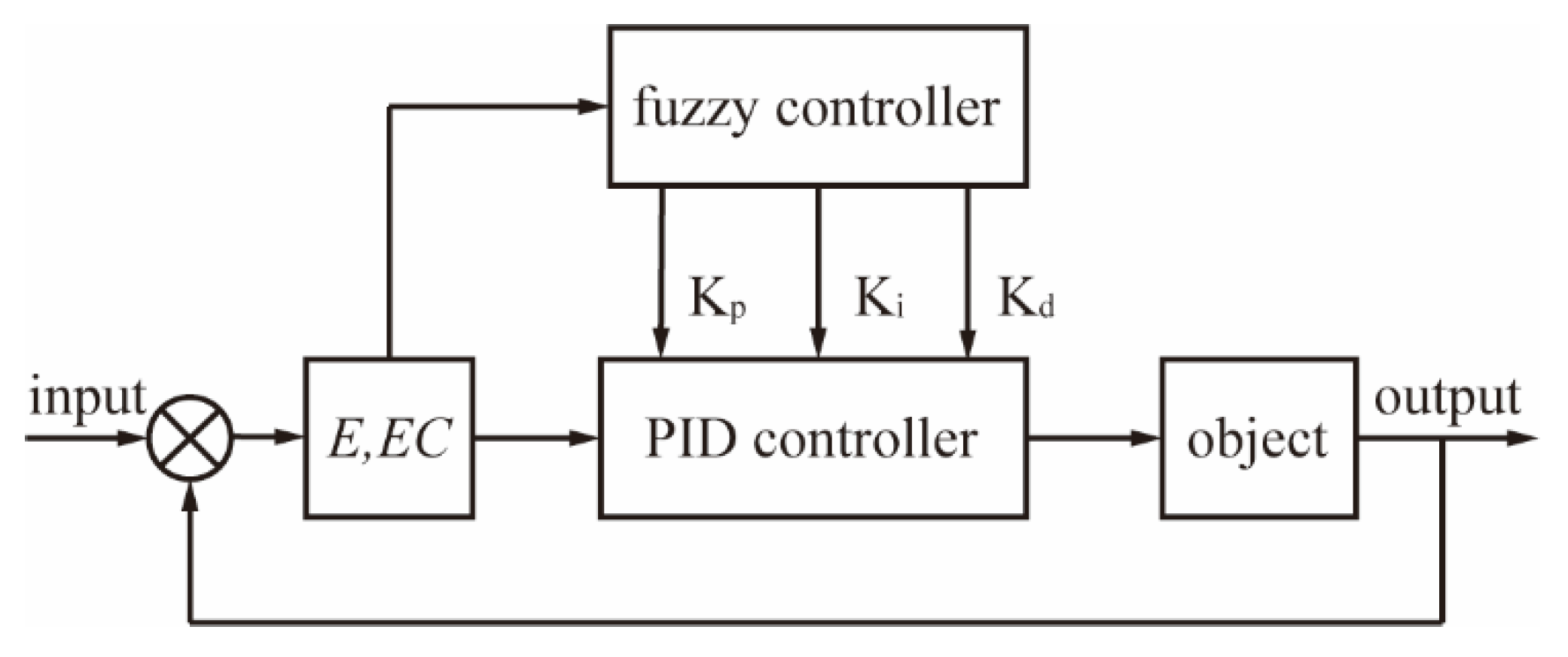

- In addressing the hysteresis nonlinear characteristics of the PAM, we employ a fuzzy PID control strategy. This approach utilizes fuzzy control rules alongside an offline table checking method to swiftly adjust the PID parameters. Consequently, it enhances the time-varying adaptive capacity of the PAM driving system, thereby improving both the real-time performance and robustness of the system. In contrast to traditional fuzzy PID control, predominantly utilized in single-degree-of-freedom systems or simulation platforms, this study, for the first time, applies a real-time control application aimed at a 20-channel high-degree-of-freedom PAM-driven system. This implementation showcases the practicality and scalability of the method in intricate nonlinear contexts.

- Develop the upper computer control terminal utilizing the Qt framework, integrate the three-dimensional model reconstruction module, and implement multiple operational modes and state monitoring through the visualization interface, facilitated by forward and inverse kinematic algorithms.

2. System Architecture

2.1. Multi-Fingered Dexterous Hand Design

2.2. Hardware Modular Design

- Independent actuation of twenty pneumatic artificial muscles.

- The acquisition of twenty joint angle signals along with five fingertip force sensor signals.

- The real-time transmission of sensor data to the host computer facilitates the visualization of the dexterous hand’s motion state.

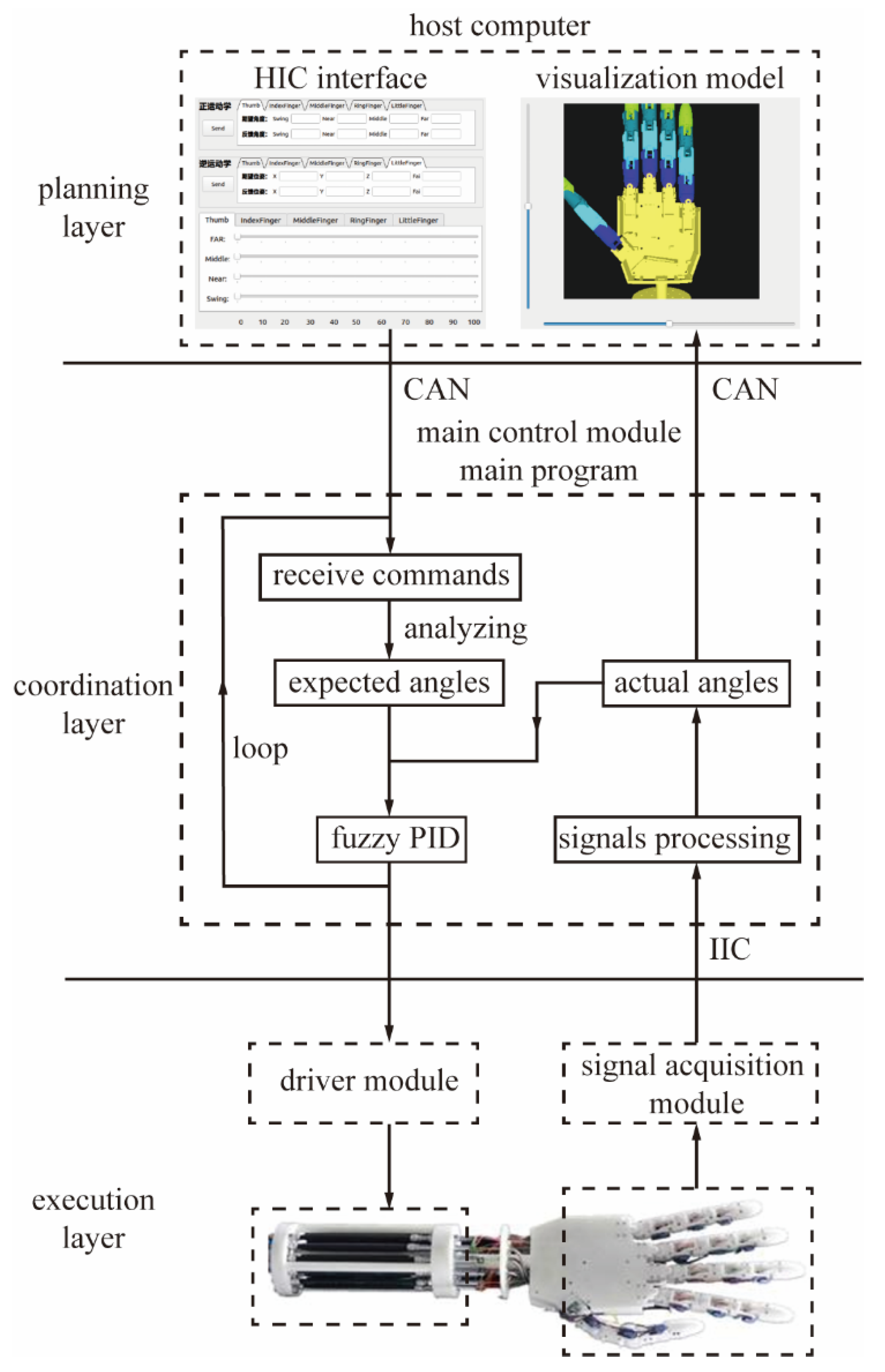

2.3. Hierarchical Control Design

- Top layer—Planning Layer (Host Computer):

- Intermediate Layer—Coordination Layer (Main Control Module):

- Bottom layer—Execution Layer (Driver and Acquisition):

2.4. Main Control Module Design

- The primary program concludes the hardware initialization process, which encompasses the communication interface, sensor, and driver module, following startup. Thereafter, it transitions into standby mode to continuously monitor commands from the host computer in real-time.

- Upon receiving the anticipated angle commands from the host computer, an analysis of the target driver module and the output port address is conducted via the communication protocol to ensure the precise assignment of commands.

- Simultaneously, the actual joint angle signals are acquired and transformed into digital signals by the ADS1115 analog-to-digital converter chip. These digital signals are subsequently processed by the main control module and relayed to the host computer for real-time display.

- The fuzzy PID controller analyzes the anticipated and actual angle data to compute drive signals for accurate joint control.

- The digital drive signals are spliced and transmitted to the driver module, which actuates the electric proportional valve to regulate air pressure and facilitate joint movement.

- The program implements the aforementioned process in a predetermined cycle to ensure the stability of real-time and closed-loop control.

3. Control Strategy

- Rule table generation and quantization: The fuzzy control logic, which encompasses membership functions, linguistic levels, fuzzy inference rules, and the center-of-gravity defuzzification method, was meticulously designed utilizing Fuzzy Logic Toolbox of MATLAB 2022. All parameter increments (ΔKₚ, ΔKᵢ, ΔKd) were represented utilizing 8-bit signed integers (−127 to +127) to facilitate fixed-point arithmetic. Overflow saturation logic was incorporated to avert wraparound, and rounding was executed by truncation to ensure numerical stability and deterministic control timing.

- Address encoding and ROM formatting: The entries of the fuzzy rule table were encoded utilizing 8-bit addressing: the high 4 bits denote the fuzzy level of E, while the low 4 bits indicate that of EC. The quantized rule table was exported in hexadecimal format and subsequently embedded into the FPGA ROM through a Memory Initialization File (MIF).

- Hardware implementation: The control logic was implemented using Verilog HDL and synthesized with the Quartus Prime Lite Edition published by Intel Corporation located at Santa Clara of the USA, specifically targeting the Altera Cyclone IV EP4CE10E22A7 chip developed by the same company. The ROM blocks were initialized with the MIF file during the synthesis process. Within the control cycle, the system performs a direct lookup in the ROM according to the current values of E and EC, retrieving the corresponding parameter increments.

- Control logic execution: The retrieved increments , and are utilized in the incremental PID computation module to facilitate dynamic updates of the PID gains. Overflow protection and rounding logic have been integrated through saturation and truncation methods, ensuring numerical stability and consistent execution within the FPGA environment.

4. Experiments and Results

4.1. Joint-Level Control of Finger

4.2. Bionic Movement of Multi-Fingered Dexterous Hand

4.3. Grasping Performance of Multi-Fingered Dexterous Hand

5. Discussion and Conclusions

- A three-layer hierarchical control architecture has been proposed, which features an FPGA-based core controller alongside four-channel DAC modules that facilitate the independent control of 20 PAMs. This system integrates sensor signal acquisition with host communication and demonstrates commendable scalability and maintainability.

- A fuzzy PID control strategy has been developed to manage the nonlinear and hysteretic characteristics of pneumatic artificial muscles (PAMs). By dynamically adjusting the PID parameters in response to error and its rates of change, the controller adeptly addresses complex dynamic conditions and enhances both the stability and flexibility of the system in multi-task scenarios.

- A fully integrated closed-loop system, encompassing sensing, control computation, actuation, and host interaction, has been developed and validated through three distinct experiments: single-joint angle control, multi-finger collaborative grasping, and biomimetic gesture demonstration. The results substantiate the system’s real-time performance, motion accuracy, and synchronization capabilities.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Salisbury, J.K.; Craig, J.J. Articulated hands: Force control and kinematic issues. Int. J. Robot. Res. 1982, 1, 4–17. [Google Scholar] [CrossRef]

- Loucks, C.; Johnson, V.; Boissiere, P.; Starr, G.; Steele, J. Modeling and control of the Stanford/JPL hand. In Proceedings of the 1987 IEEE International Conference on Robotics and Automation, Raleigh, NC, USA, 31 March–3 April 1987; IEEE: Piscataway, NJ, USA; Volume 4, pp. 573–578. [Google Scholar]

- Speeter, T.H. Control of the Utah/MIT dextrous hand: Hardware and software hierarchy. J. Robot. Syst. 1990, 7, 759–790. [Google Scholar] [CrossRef]

- Jacobsen, S.C.; Wood, J.E.; Knutti, D.; Biggers, K.B. The UTAH/MIT dextrous hand: Work in progress. Int. J. Robot. Res. 1984, 3, 21–50. [Google Scholar] [CrossRef]

- Bridgwater, L.B.; Ihrke, C.A.; Diftler, M.A.; Abdallah, M.E.; Radford, N.A.; Rogers, J.M.; Yayathi, S.; Askew, R.S.; Linn, D.M. The robonaut 2 hand-designed to do work with tools. In Proceedings of the 2012 IEEE International Conference on Robotics and Automation, Saint Paul, MN, USA, 14–18 May 2012; IEEE: Piscataway, NJ, USA; pp. 3425–3430. [Google Scholar]

- Rothling, F.; Haschke, R.; Steil, J.J.; Ritter, H. Platform portable anthropomorphic grasping with the bielefeld 20-DOF shadow and 9-DOF TUM hand. In Proceedings of the 2007 IEEE/RSJ International Conference on Intelligent Robots and Systems, San Diego, CA, USA, 29 October–2 November 2007; IEEE: Piscataway, NJ, USA; pp. 2951–2956. [Google Scholar]

- Eguiluz, A.G.; Rañó, I.; Coleman, S.A.; McGinnity, T.M. Reliable object handover through tactile force sensing and effort control in the shadow robot hand. In Proceedings of the 2017 IEEE International Conference on Robotics and Automation (ICRA), Singapore, 29 May–3 June 2017; IEEE: Piscataway, NJ, USA; pp. 372–377. [Google Scholar]

- Haidacher, S.; Butterfass, J.; Fischer, M.; Grebenstein, M.; Joehl, K.; Kunze, K.; Nickl, M.; Seitz, N.; Hirzinger, G. DLR Hand II: Hard- and Software Architecture for Information Processing. In Proceedings of the IEEE International Conference on Robotics & Automation, Taipei, Taiwan, 14–19 September 2003. [Google Scholar]

- Butterfass, J.; Hirzinger, G.; Knoch, S.; Liu, H. DLR’s multisensory articulated hand. I. Hard- and software architecture. In Proceedings of the 1998 IEEE International Conference on Robotics and Automation (Cat. No.98CH36146), Leuven, Belgium, 20 May 1998; Volume 3, pp. 2081–2086. [Google Scholar]

- Liu, H.; Meusel, P.; Hirzinger, G.; Jin, M.; Xie, Z. The Modular Multisensory DLR-HIT-Hand: Hardware and Software Architecture. IEEE/ASME Trans. Mechatron. 2009, 13, 461–469. [Google Scholar]

- Liu, H.; Wu, K.; Meusel, P.; Seitz, N.; Hirzinger, G.; Jin, M.; Liu, Y.; Fan, S.; Lan, T.; Chen, Z. Multisensory five-finger dexterous hand: The DLR/HIT Hand II. In Proceedings of the 2008 IEEE/RSJ International Conference on Intelligent Robots and Systems, Nice, France, 22–26 September 2008. [Google Scholar]

- Alvarez, D.; Lumbier, A.; Gomez, J.V.; Garrido, S.; Moreno, L. Precision grasp planning with Gifu Hand III based on fast marching square. In Proceedings of the 2013 IEEE/RSJ International Conference on Intelligent Robots and Systems, Tokyo, Japan, 3–7 November 2013; IEEE: Piscataway, NJ, USA; pp. 4549–4554. [Google Scholar]

- Mouri, T.E.T.; Kawasaki, H. Review of Gifu Hand and Its Application. Mech. Based Des. Struct. Mach. 2011, 39, 210–228. [Google Scholar] [CrossRef]

- Chalon, M.; Wedler, A.; Baumann, A.; Bertleff, W.; Beyer, A.; Butterfass, J.; Grebenstein, M.; Gruber, R.; Hacker, F.; Kraemer, E.; et al. Dexhand: A Space qualified multi-fingered robotic hand. In Proceedings of the 2011 IEEE International Conference on Robotics and Automation, Shanghai, China, 9–13 May 2011; IEEE: Piscataway, NJ, USA. [Google Scholar]

- Puhlmann, S.; Harris, J.; Brock, O. RBO hand 3: A platform for soft dexterous manipulation. IEEE Trans. Robot. 2022, 38, 3434–3449. [Google Scholar] [CrossRef]

- Yang, Y.; Li, Y.; Chen, Y.; Li, Y.; Ren, Y. Design and Automatic Fabrication of Novel Bio-inspired Soft Smart Robotic Hands. IEEE Access 2020, 8, 155912–155925. [Google Scholar] [CrossRef]

- Li, Y.; Tian, M.; Wang, X. Fuzzy Self-Tuning PID Control of a Lower Limb Soft Exosuit Based on Pneumatic Artificial Muscles. In Proceedings of the 2019 IEEE 3rd Advanced Information Management, Communicates, Electronic and Automation Control Conference (IMCEC), Chongqing, China, 11–13 October 2019; IEEE: Piscataway, NJ, USA. [Google Scholar]

- Shi, E.; Zhong, X.; Wang, T.; Li, X.; Bu, C.; Zhao, X. Adaptive control for shape memory alloy actuated systems with applications to human–robot interaction. Front. Neurosci. 2024, 18, 1337580. [Google Scholar] [CrossRef]

- Zhou, Z.; Ai, Q.; Li, M.; Meng, W.; Liu, Q.; Xie, S.Q. The Design and Adaptive Control of a Parallel Chambered Pneumatic Muscle-Driven Soft Hand Robot for Grasping Rehabilitation. Biomimetics 2024, 9, 706. [Google Scholar] [CrossRef]

- Azimirad, V. Design of an Adaptive Fixed-Time Fast Terminal Sliding Mode Controller for Multi-Link Robots Actuated by Pneumatic Artificial Muscles. Biomimetics 2025, 10, 37. [Google Scholar]

- Zhao, L.; Peng, M.; Li, Z.; He, M. Integral sliding mode control for an anthropomorphic finger based on nonlinear extended state observer. ISA Trans. 2024, 153, 433–442. [Google Scholar] [CrossRef] [PubMed]

- Pratap, S.; Narayan, J.; Hatta, Y.; Ito, K.; Hazarika, S.M. Robust Non-Singular Terminal Sliding Mode Control for Tendon-driven Hand Exoskeleton: A Numerical Study. In Proceedings of the 2024 10th International Conference on Control, Decision and Information Technologies (CoDIT), Vallette, Malta, 1–4 July 2024. [Google Scholar]

- Liu, Z.; Yang, W.; Cao, Y.; Xie, L. Active Disturbance Rejection Control With Data-Driven Compensation for a Novel Extensible Continuum Robot. IEEE Access 2025, 13, 48202–48211. [Google Scholar] [CrossRef]

- Shang, D.; Xiaopeng, L.; Meng, Y.; Fanjie, L. Dynamic modeling and RBF neural network compensation control for space flexible manipulator with an underactuated hand. Chin. J. Aeronaut. 2024, 37, 417–439. [Google Scholar] [CrossRef]

- Al-Shahrabi, A.; Javid, M.J.; Fahmy, A.A.; Griffiths, C.A.; Li, C. Torque tracking position control of DLR-HIT II robotic hand using a real-time Physics-informed neural network. Appl. Math. Model. 2025, 145, 116110. [Google Scholar] [CrossRef]

- Qi, W.; Fan, H.; Zheng, C.; Su, H.; Alfayad, S. Human-like Dexterous Grasping Through Reinforcement Learning and Multimodal Perception. Biomimetics 2025, 10, 186. [Google Scholar] [CrossRef]

- Huang, H.; Pang, C.; Sun, F.; Dong, M.; Wen, Z.; Zhou, H. Dexterity Operation, Multi-Modal Perception and Tactile Force Interaction of a Bionic Soft Hand. IEEE Trans. Autom. Sci. Eng. 2023, 21, 7219–7229. [Google Scholar] [CrossRef]

- Kappassov, Z.; Corrales, J.A.; Perdereau, V. Tactile sensing in dexterous robot hands—Review. Robot. Auton. Syst. 2015, 74, 195–220. [Google Scholar] [CrossRef]

- Sankar, S.; Cheng, W.-Y.; Zhang, J.; Slepyan, A.; Iskarous, M.M.; Greene, R.J.; DeBrabander, R.; Chen, J.; Gupta, A.; Thakor, N.V. A natural biomimetic prosthetic hand with neuromorphic tactile sensing for precise and compliant grasping. Sci. Adv. 2025, 11, eadr9300. [Google Scholar] [CrossRef]

- Hu, W.; Huang, B.; Lee, W.W.; Yang, S.; Zheng, Y.; Li, Z. Dexterous in-hand manipulation of slender cylindrical objects through deep reinforcement learning with tactile sensing. Robot. Auton. Syst. 2025, 186, 104904. [Google Scholar] [CrossRef]

- Polcz, P.; Schaffer, K.; Koller, M. Posture Estimation for a High Degree of Freedom Anthropomorphic Tendon-Based Hand Model—A Simulation Experiment. In Proceedings of the 2024 European Control Conference (ECC), Stockholm, Sweden, 25–28 June 2024. [Google Scholar]

- Fattepur, G.; Patil, A.Y.; Kumar, P.; Kumar, A.; Hegde, C.; Siddhalingeshwar, I.G.; Kumar, R.; Khan, T.M.Y. Bio-inspired designs: Leveraging biological brilliance in mechanical engineering—An overview. 3 Biotech 2024, 14, 312. [Google Scholar] [CrossRef]

- Dharmdas, A.; Patil, A.Y.; Baig, A.; Hosmani, O.Z.; Mathad, S.N.; Patil, M.B.; Kumar, R.; Kotturshettar, B.B.; Fattah, I.M.R. An Experimental and Simulation Study of the Active Camber Morphing Concept on Airfoils Using Bio-Inspired Structures. Biomimetics 2023, 8, 251. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.; Amraouza, A.; Peng, Y.; Li, D.; Nassour, J.; Cheng, G. Material-Driven Mechanical Programming of Soft Robotic Tentacles. In Proceedings of the 2025 IEEE/SICE International Symposium on System Integration (SII), Munich, Germany, 21–24 January 2025. [Google Scholar]

- Dautov, A.M.; Kopets, E.E.; Karimov, A.I.; Rybin, V.G.; Khafizova, A.M.; Sigaeva, M.S. Development of a Radio-Controlled Tentacle Robot. In Proceedings of the 2021 IV International Conference on Control in Technical Systems (CTS), Saint Petersburg, Russia, 21–23 September 2021; pp. 268–271. [Google Scholar] [CrossRef]

- Han, Z.; Liu, Z.; He, W.; Li, G. Distributed parameter modeling and boundary control of an octopus tentacle-inspired soft robot. IEEE Trans. Control. Syst. Technol. 2021, 30, 1244–1256. [Google Scholar] [CrossRef]

- Zhou, X.; Zhu, Y.; Qian, S.; Ge, H.; Cai, S.; Bao, G. Design of full-drive multi-finger dexterous hand. In Proceedings of the 2022 International Conference on Advanced Robotics and Mechatronics (ICARM), Guilin, China, 9–11 July 2022; IEEE: Piscataway, NJ, USA; pp. 51–56. [Google Scholar]

- Pietrala, D. The characteristics of a pneumatic muscle. EPJ Web Conf. 2017, 143, 02093. [Google Scholar] [CrossRef]

- Donskoj, A.; Kotkas, L.; Salova, T.; Barilovich, V.; Akhmetova, I. Modelling the static and dynamic characteristics of pneumatic muscle. IOP Conf. Ser. Earth Environ. Sci. 2019, 337, 012042. [Google Scholar] [CrossRef]

- Ding, D.K.; Li, L.G.; Xie, C.X.; Zhang, T. A DNA-PID Controller for an Industry Robot. Adv. Mater. Res. 2012, 461, 109–112. [Google Scholar] [CrossRef]

- Hidavat, A.Y.F.; Sendari, S.; Mahandi, Y.D.; Zaeni, I.A.E.; Lestari, D.; Widiyaningtyas, T.; Mustika, S.; Ridhoni, M.S.; Firmansyah, R.R.W.; Purwanto, M.D. Implementation of MPU6050 Module Based On ROS and PID Controller as Stabilization Control and Rotational Motion of SAR Robot. In Proceedings of the 2024 International Conference on Electrical and Information Technology (IEIT), Malang, Indonesia, 12–13 September 2024. [Google Scholar]

- Jaiswal, N.K.; Kumar, V. Comparison between conventional PID and Fuzzy PID supervisor for 3-DOF Scara type robot manipulator. In Proceedings of the 2014 IEEE Students’ Conference on Electrical, Electronics and Computer Science, Bhopal, India, 1–2 March 2014; IEEE: Piscataway, NJ, USA. [Google Scholar]

- Wang, T.Y.; Chang, C.D. Hybrid Fuzzy PID Controller Design for a Mobile Robot. In Proceedings of the 2018 IEEE International Conference on Applied System Invention (ICASI), Chiba, Japan, 13–17 April 2018; pp. 650–653. [Google Scholar]

| NB | NM | NS | ZO | PS | PM | PB | |

|---|---|---|---|---|---|---|---|

| NB | PB | PB | PM | PM | PS | ZO | ZO |

| NM | PB | PB | PM | PS | PS | ZO | NS |

| NS | PM | PM | PM | PS | ZO | NS | NS |

| ZO | PM | PM | PS | ZO | NS | NM | NM |

| PS | PS | PS | ZO | NS | NS | NM | NM |

| PM | PS | ZO | NS | NM | NM | NM | NB |

| PB | ZO | ZO | NM | NM | NM | NB | NB |

| NB | NM | NS | ZO | PS | PM | PB | |

|---|---|---|---|---|---|---|---|

| NB | NB | NB | NM | NM | NS | ZO | ZO |

| NM | NB | NB | NM | NS | NS | ZO | ZO |

| NS | NB | NM | NS | NS | ZO | PS | PS |

| ZO | NM | NM | NS | ZO | PS | PM | PM |

| PS | NM | NS | ZO | PS | PS | PM | PB |

| PM | ZO | ZO | PS | PS | PM | PB | PB |

| PB | ZO | ZO | PS | PM | PM | PB | PB |

| NB | NM | NS | ZO | PS | PM | PB | |

|---|---|---|---|---|---|---|---|

| NB | PS | NS | NB | NB | NB | NM | PS |

| NM | PS | NS | NB | NM | NM | NS | ZO |

| NS | ZO | NS | NM | NM | NS | NS | ZO |

| ZO | ZO | NS | NS | NS | NS | NS | ZO |

| PS | ZO | ZO | ZO | ZO | ZO | ZO | ZO |

| PM | PB | NS | PS | PS | PS | PS | PB |

| PB | PB | PM | PM | PM | PS | PS | PB |

| Joint | Expected Angle (°) | Actual Angle (°) |

|---|---|---|

| DIP | 30 | 29.5 |

| 60 | 60.1 | |

| 80 | 80.4 | |

| MCP | 30 | 30.4 |

| 60 | 60.6 | |

| 80 | 80.1 | |

| PIP | 30 | 29.8 |

| 60 | 59.5 | |

| 80 | 79.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, Y.; Wang, H.; Ge, H.; Bao, G. Design of a Hierarchical Control Architecture for Fully-Driven Multi-Fingered Dexterous Hand. Biomimetics 2025, 10, 422. https://doi.org/10.3390/biomimetics10070422

Jin Y, Wang H, Ge H, Bao G. Design of a Hierarchical Control Architecture for Fully-Driven Multi-Fingered Dexterous Hand. Biomimetics. 2025; 10(7):422. https://doi.org/10.3390/biomimetics10070422

Chicago/Turabian StyleJin, Yinan, Hujiang Wang, Han Ge, and Guanjun Bao. 2025. "Design of a Hierarchical Control Architecture for Fully-Driven Multi-Fingered Dexterous Hand" Biomimetics 10, no. 7: 422. https://doi.org/10.3390/biomimetics10070422

APA StyleJin, Y., Wang, H., Ge, H., & Bao, G. (2025). Design of a Hierarchical Control Architecture for Fully-Driven Multi-Fingered Dexterous Hand. Biomimetics, 10(7), 422. https://doi.org/10.3390/biomimetics10070422