Occupational Risk Assessment During Carbon Fibre Sizing Using Engineered Nanomaterials

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

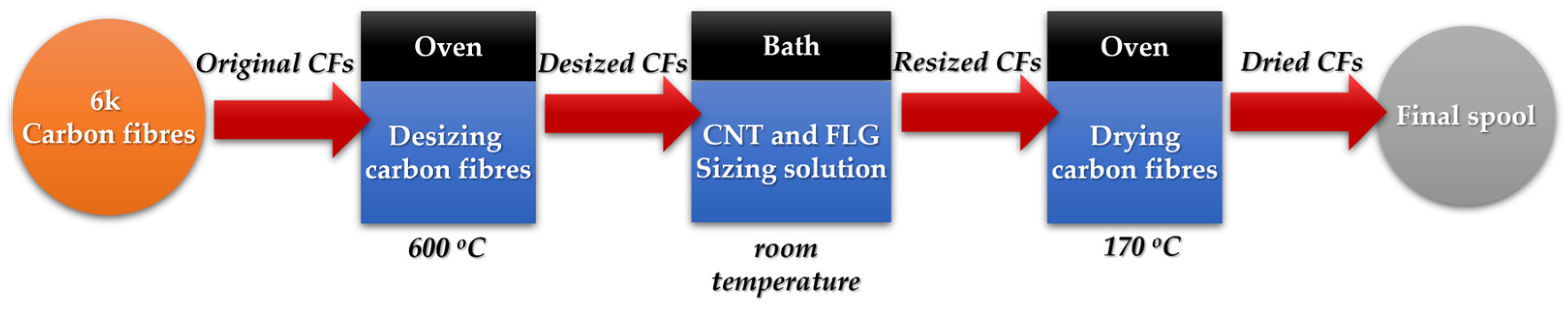

2.2. Carbon Fibre Sizing Pilot Line

2.3. Information Gathering and Hazard Analysis

2.4. ‘What-If’ Process Hazard Analysis

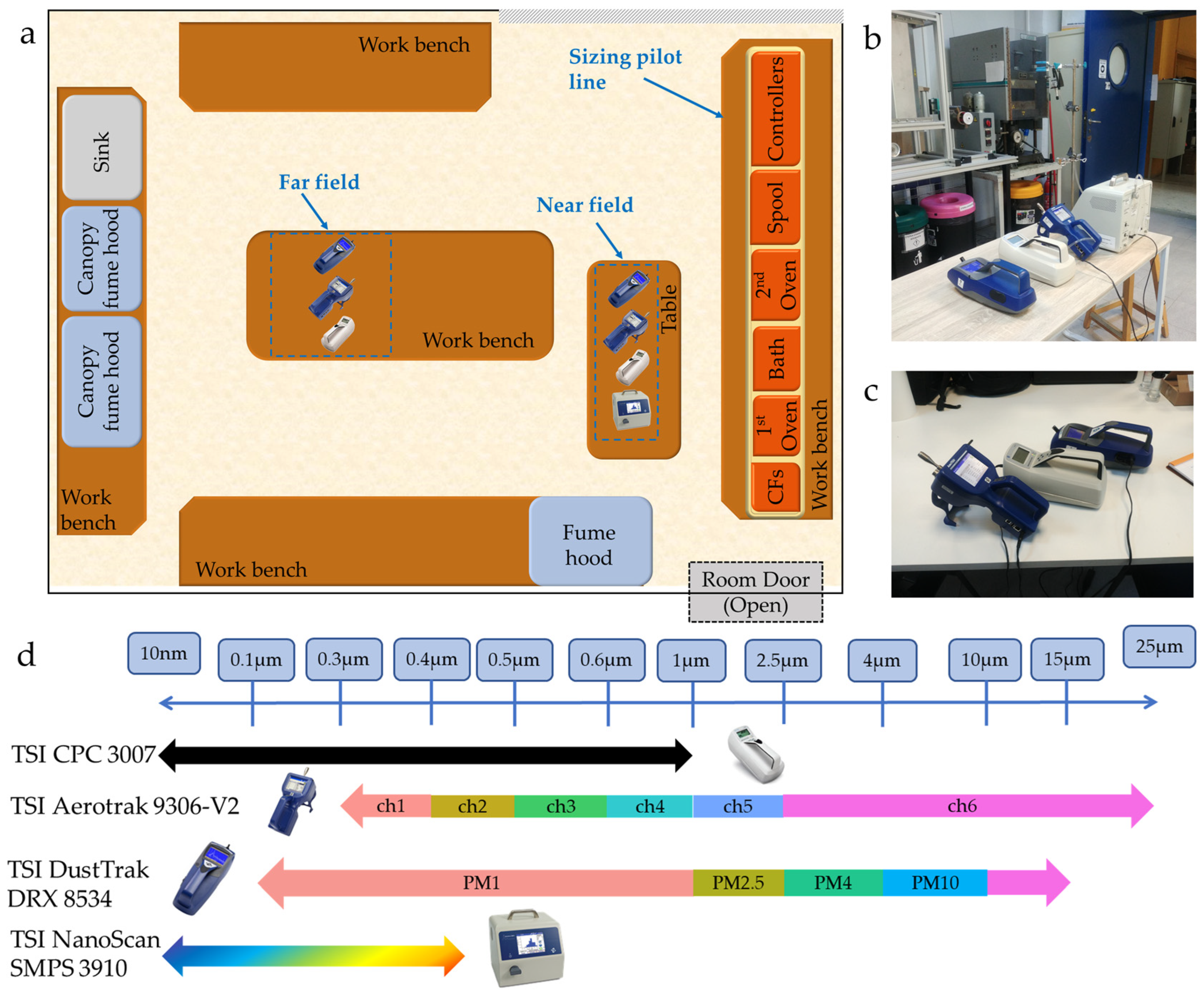

2.5. Occupational Exposure Assessment

2.6. Comprehensive Particle Dosimetry Analysis

3. Results and Discussion

3.1. Preliminary Hazard Assessment

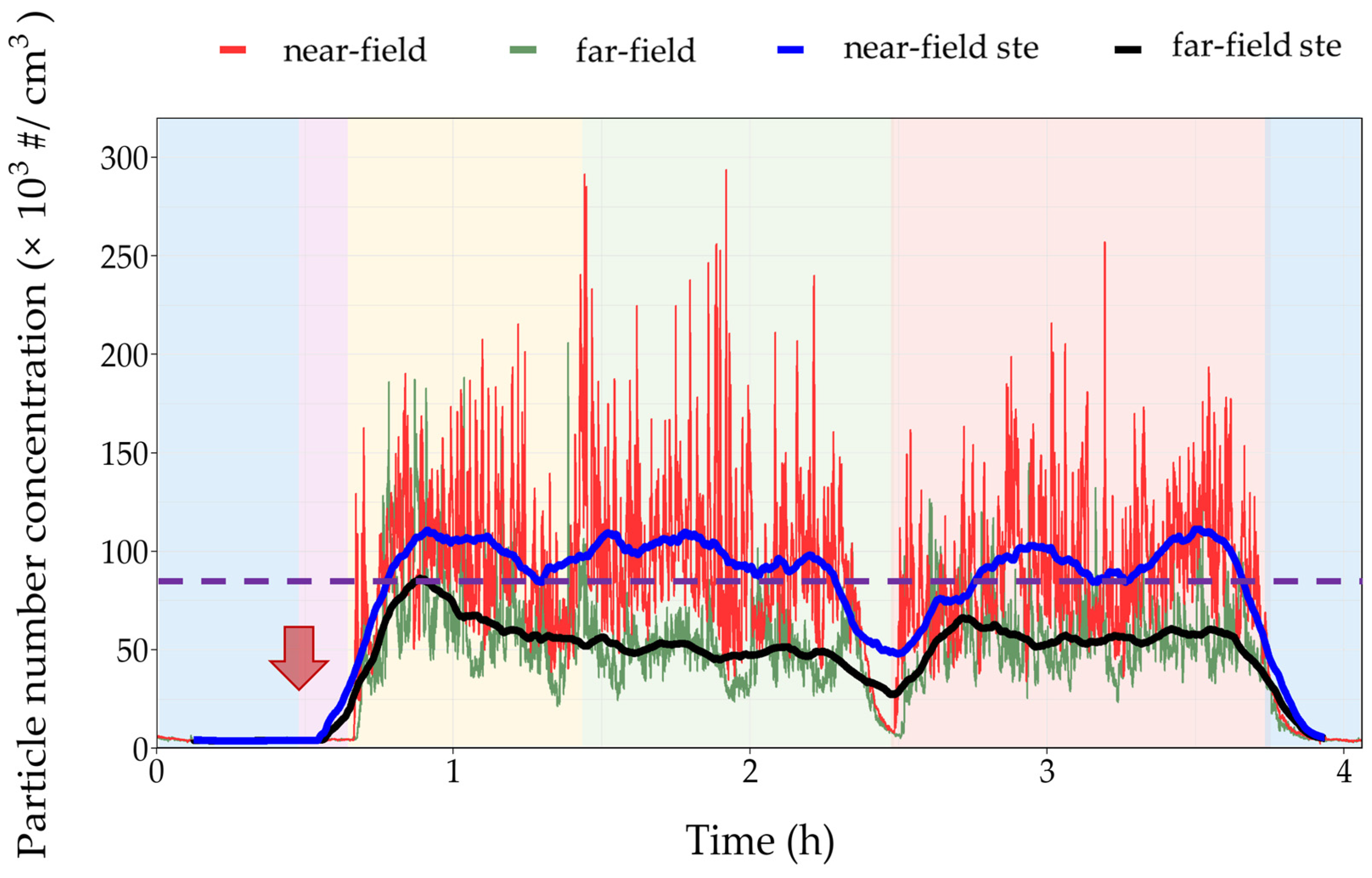

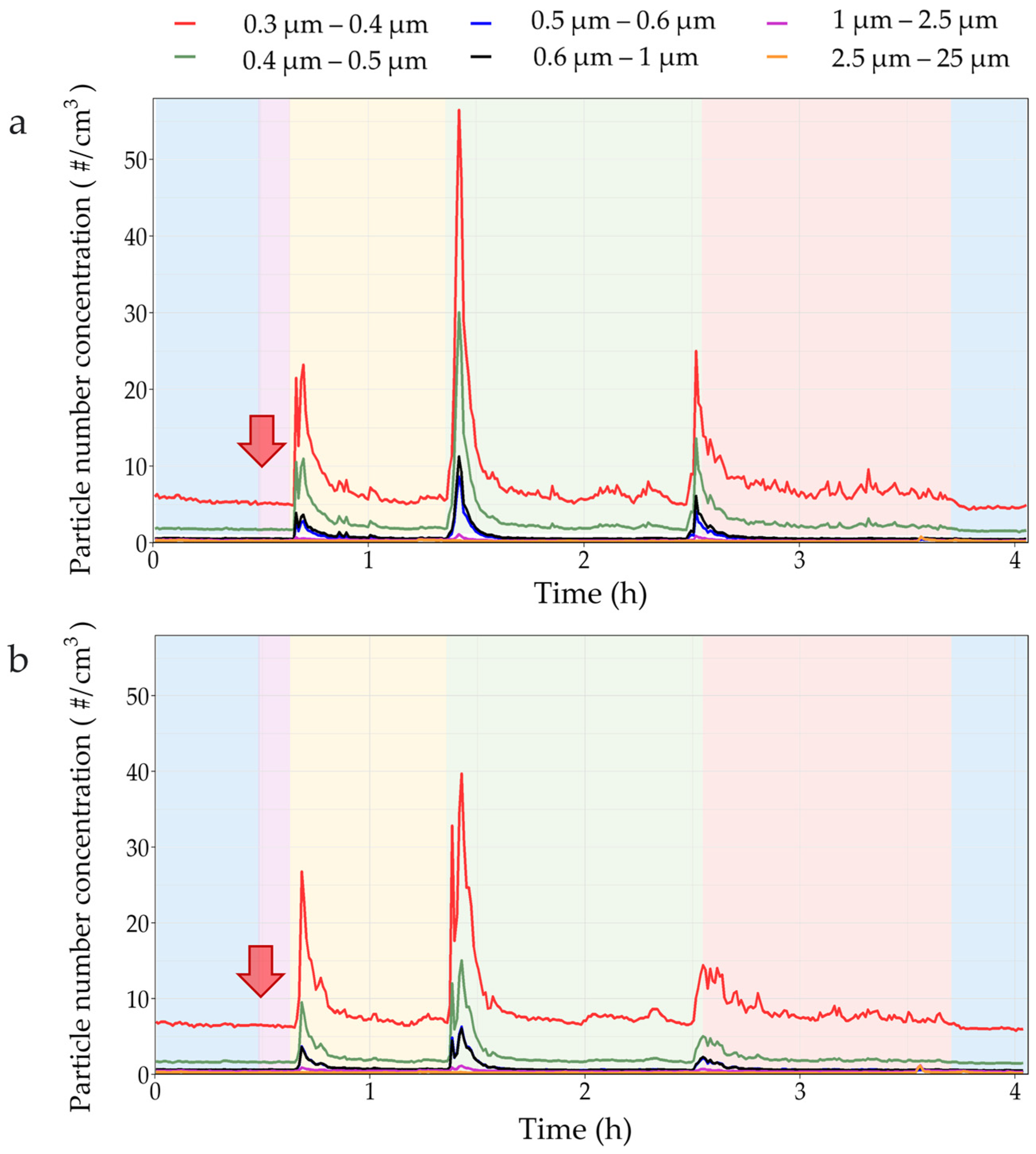

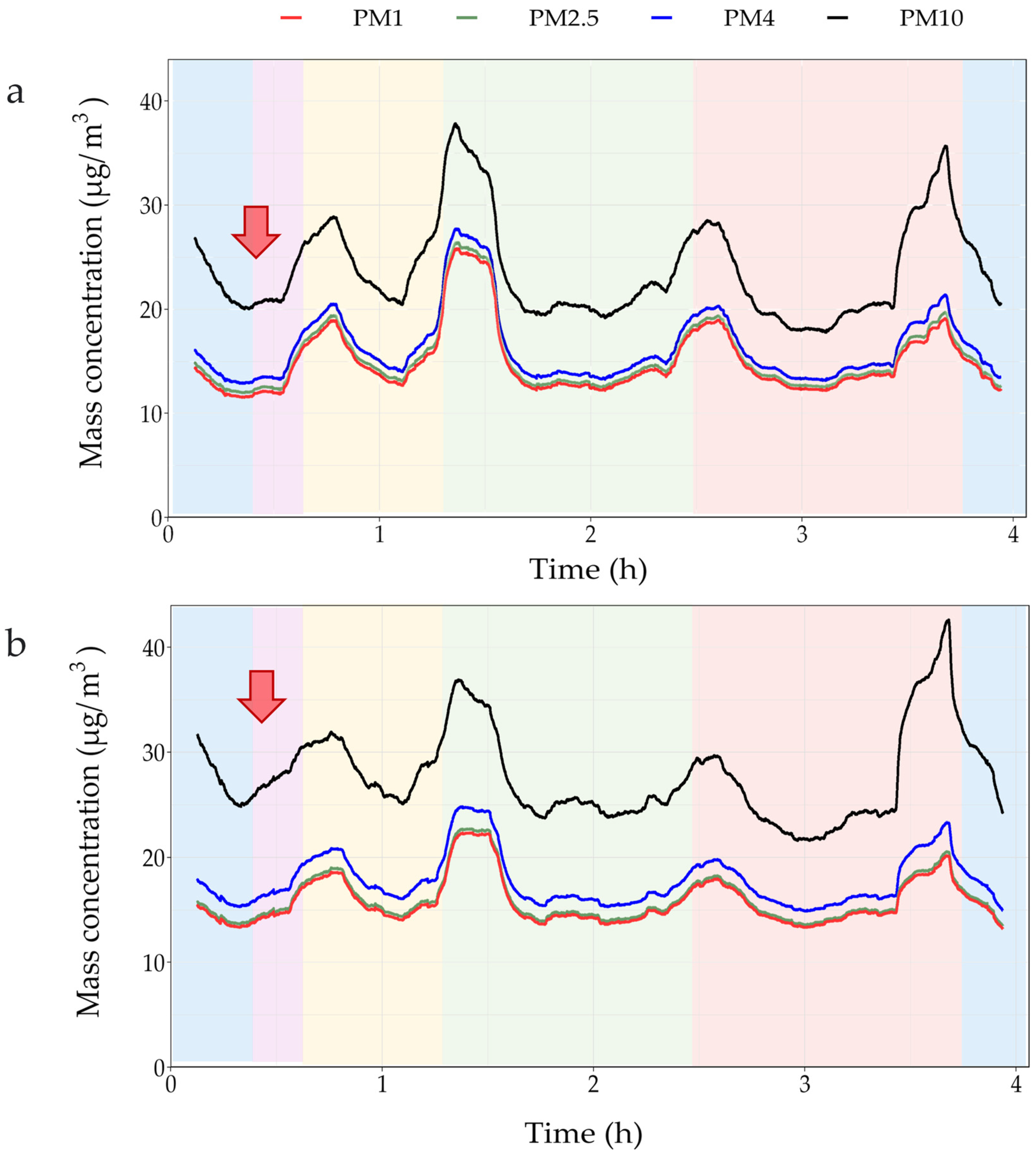

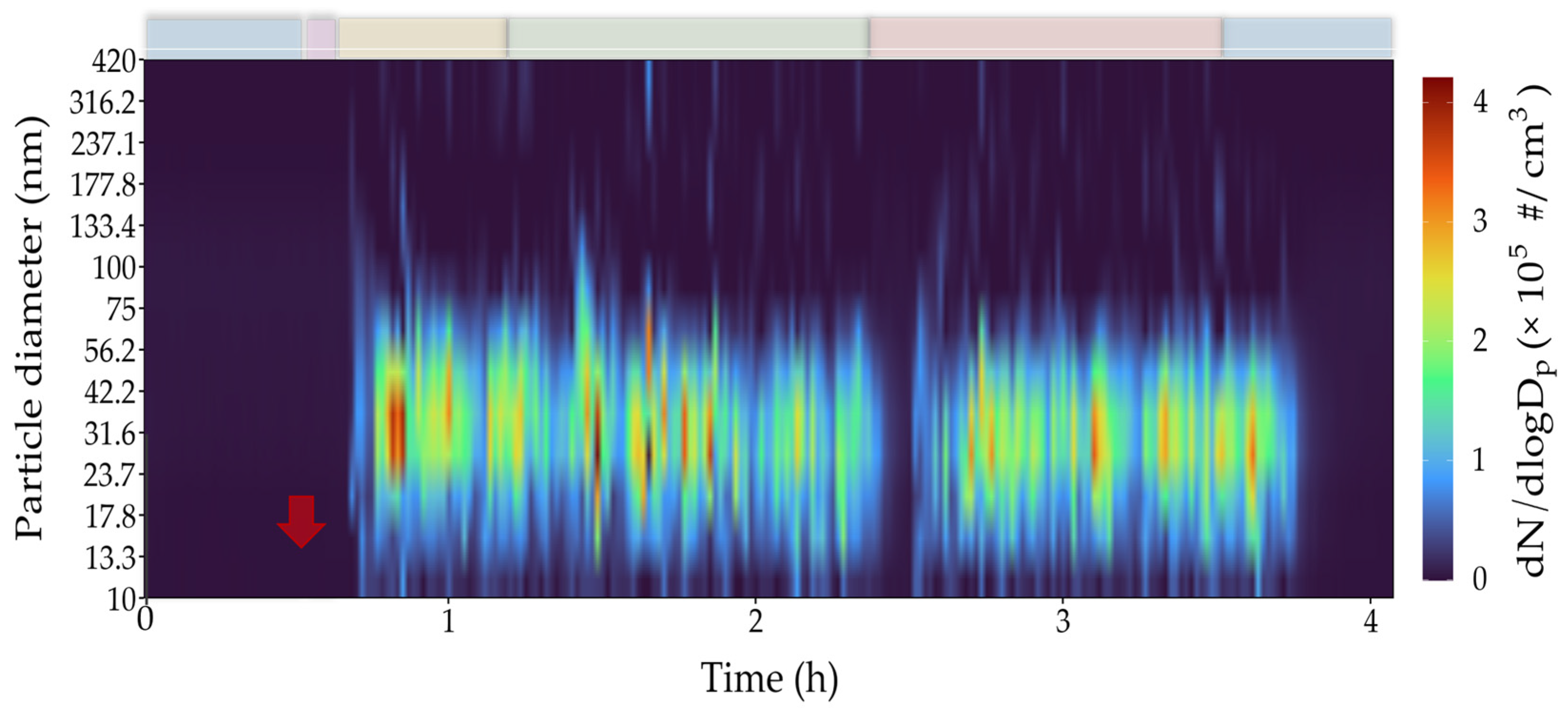

3.2. On-Site Exposure Assessment

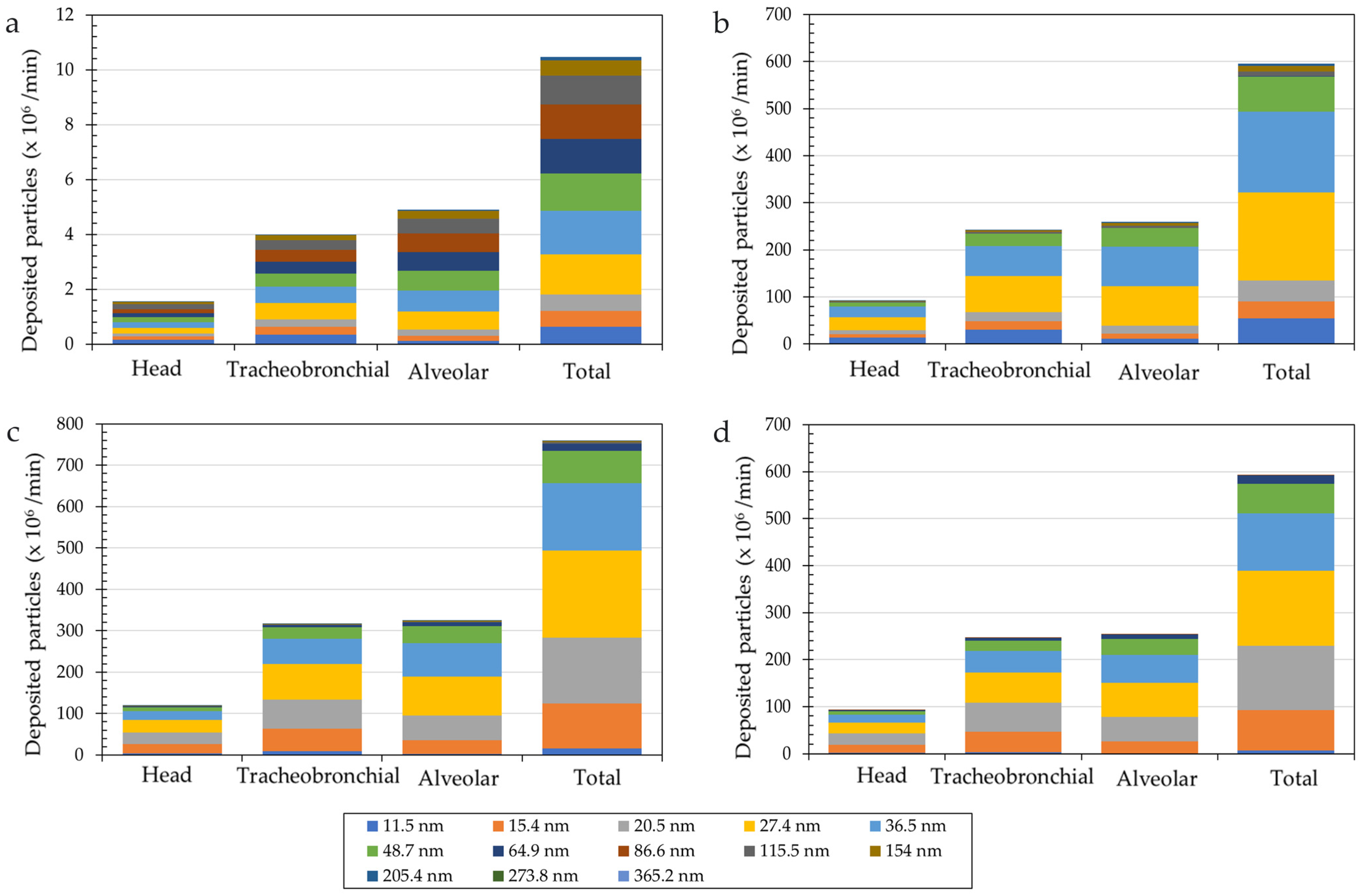

3.3. Respiratory Tract Particle Deposition Analysis

3.4. Study Limitations and Future Research

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ahmad, H.; Markina, A.A.; Porotnikov, M.V.; Ahmad, F. A Review of Carbon Fiber Materials in Automotive Industry—IOPscience. IOP Conf. Ser. Mater. Sci. Eng. 2020, 971, 032011. [Google Scholar] [CrossRef]

- Williams, G.; Trask, R.; Bond, I. A Self-Healing Carbon Fibre Reinforced Polymer for Aerospace Applications. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1525–1532. [Google Scholar] [CrossRef]

- Vijayan, D.S.; Sivasuriyan, A.; Devarajan, P.; Stefańska, A.; Wodzyński, Ł.; Koda, E. Carbon Fibre-Reinforced Polymer (CFRP) Composites in Civil Engineering Application—A Comprehensive Review. Buildings 2023, 13, 1509. [Google Scholar] [CrossRef]

- Harussani, M.M.; Sapuan, S.M.; Nadeem, G.; Rafin, T.; Kirubaanand, W. Recent Applications of Carbon-Based Composites in Defence Industry: A Review. Def. Technol. 2022, 18, 1281–1300. [Google Scholar] [CrossRef]

- Ismail, K.B.M.; Kumar, M.A.; Mahalingam, S.; Raj, B.; Kim, J. Carbon Fiber-Reinforced Polymers for Energy Storage Applications. J. Energy Storage 2024, 84, 110931. [Google Scholar] [CrossRef]

- Teng, H.; Li, S.; Cao, Z.; Li, S.; Li, C.; Ko, T.J. Carbon Fiber Composites for Large-Scale Wind Turbine Blades: Applicability Study and Comprehensive Evaluation in China. J. Mar. Sci. Eng. 2023, 11, 624. [Google Scholar] [CrossRef]

- Gonabadi, H.; Oila, A.; Yadav, A.; Bull, S. Structural Performance of Composite Tidal Turbine Blades. Compos. Struct. 2021, 278, 114679. [Google Scholar] [CrossRef]

- Wang, J.; Schlagenhauf, L.; Setyan, A. Transformation of the Released Asbestos, Carbon Fibers and Carbon Nanotubes from Composite Materials and the Changes of Their Potential Health Impacts. J. Nanobiotechnol. 2017, 15, 15. [Google Scholar] [CrossRef]

- Qiu, J.; Li, J.; Yuan, Z.; Zeng, H.; Chen, X. Surface Modification of Carbon Fibres for Interface Improvement in Textile Composites. Appl. Compos. Mater. 2018, 25, 853–860. [Google Scholar] [CrossRef]

- Fortune Business Insight Carbon Fiber Market Size, Share & Industry Analysis 2024-20232. Available online: https://www.fortunebusinessinsights.com/industry-reports/carbon-fiber-market-101719 (accessed on 28 October 2024).

- Jaber, A.A.; Abbas, S.A.; Farah, A.A.; Kopeć, K.K.; Alsalik, Y.M.; Tayeb, M.A.; Verghese, N. Effect of Fiber Sizing Levels on the Mechanical Properties of Carbon Fiber-Reinforced Thermoset Composites. Polymers 2023, 15, 4678. [Google Scholar] [CrossRef]

- Mamalis, D.; Flanagan, T.; Ó Brádaigh, C.M. Effect of Fibre Straightness and Sizing in Carbon Fibre Reinforced Powder Epoxy Composites. Compos. Part A Appl. Sci. Manuf. 2018, 110, 93–105. [Google Scholar] [CrossRef]

- Matveeva, A.Y.; Lomov, S.V.; Gorbatikh, L. Debonding at the Fiber/Matrix Interface in Carbon Nanotube Reinforced Composites: Modelling Investigation. Comput. Mater. Sci. 2019, 159, 412–419. [Google Scholar] [CrossRef]

- Yang, T.; Zhao, Y.; Liu, H.; Sun, M.; Xiong, S. Effect of Sizing Agents on Surface Properties of Carbon Fibers and Interfacial Adhesion of Carbon Fiber/Bismaleimide Composites. ACS Omega 2021, 6, 23028–23037. [Google Scholar] [CrossRef]

- Aoki, R.; Yamaguchi, A.; Hashimoto, T.; Urushisaki, M.; Sakaguchi, T.; Kawabe, K.; Kondo, K.; Iyo, H. Preparation of Carbon Fibers Coated with Epoxy Sizing Agents Containing Degradable Acetal Linkages and Synthesis of Carbon Fiber-Reinforced Plastics (CFRPs) for Chemical Recycling. Polym. J. 2019, 51, 909–920. [Google Scholar] [CrossRef]

- Bao, J.; Li, Y.; Zhong, X.; Chen, X. The Effect of Sizing Agent of Carbon Fibre on the Interface of Electron Beam Cured Composites. Adv. Compos. Lett. 2011, 20, 096369351102000601. [Google Scholar] [CrossRef]

- Pawar, S.S.; Hutchinson, S.A.; Eyckens, D.J.; Stojcevski, F.; Hayne, D.J.; Gengenbach, T.R.; Razal, J.M.; Henderson, L.C. Carbon Fiber Sizing Agents Based on Renewable Terpenes. Compos. Sci. Technol. 2022, 220, 109280. [Google Scholar] [CrossRef]

- Pozegic, T.R.; Anguita, J.V.; Hamerton, I.; Jayawardena, K.D.G.I.; Chen, J.-S.; Stolojan, V.; Ballocchi, P.; Walsh, R.; Silva, S.R.P. Multi-Functional Carbon Fibre Composites Using Carbon Nanotubes as an Alternative to Polymer Sizing. Sci. Rep. 2016, 6, 37334. [Google Scholar] [CrossRef]

- Jäger, M.; Zabihi, O.; Ahmadi, M.; Li, Q.; Depalmeanar, A.; Naebe, M. Nano-Enhanced Interface in Carbon Fibre Polymer Composite Using Halloysite Nanotubes. Compos. Part A Appl. Sci. Manuf. 2018, 109, 115–123. [Google Scholar] [CrossRef]

- Balaban, A.C.; Toygar, M.E. Usage of Nanomaterials on Carbon Fibre/Epoxy Composites for Improvement of Their Material Properties. Procedia Struct. Integr. 2022, 42, 292–298. [Google Scholar] [CrossRef]

- Semitekolos, D.; Papadopoulos, I.; Anagnou, S.; Dashtbozorg, B.; Li, X.; Dong, H.; Charitidis, C.A. Nanomaterial-Enhanced Sizings: Design and Optimisation of a Pilot-Scale Fibre Sizing Line. Fibers 2024, 12, 16. [Google Scholar] [CrossRef]

- Asmatulu, E.; Alonayni, A.; Alamir, M. Safety Concerns in Composite Manufacturing and Machining. In Proceedings of the Behavior and Mechanics of Multifunctional Materials and Composites XII, Denver, CO, USA, 5–8 March 2018; Naguib, H.E., Ed.; SPIE: Bellingham, WA, USA, 2018; Volume 10596, p. 1059623. [Google Scholar]

- Kehren, D.; Simonow, B.; Bäger, D.; Dziurowitz, N.; Wenzlaff, D.; Thim, C.; Neuhoff, J.; Meyer-Plath, A.; Plitzko, S. Release of Respirable Fibrous Dust from Carbon Fibers Due to Splitting along the Fiber Axis. Aerosol Air Qual. Res. 2019, 19, 2185–2195. [Google Scholar] [CrossRef]

- Tölle, L.; Monsé, C.; Rosenkranz, N.; Haibel, N.; Walter, D.; Bünger, J.; Hopp, M.; Westphal, G.A. Characterization of Fiber Dust Resulting from Recycling of Carbon Fiber-Reinforced Thermoplastics (CFRP) and Their Cell Toxicity. J. Mater. Sci. Chem. Eng. 2022, 10, 1–16. [Google Scholar] [CrossRef]

- Oberdörster, G.; Oberdörster, E.; Oberdörster, J. Nanotoxicology: An Emerging Discipline Evolving from Studies of Ultrafine Particles. Environ. Health Perspect 2005, 113, 823–839. [Google Scholar] [CrossRef]

- Kelly, F.J.; Fussell, J.C. Toxicity of Airborne Particles—Established Evidence, Knowledge Gaps and Emerging Areas of Importance. Philos. Trans. Ser. A Math. Phys. Eng. Sci. 2020, 378, 20190322. [Google Scholar] [CrossRef] [PubMed]

- Marval, J.; Tronville, P. Ultrafine Particles: A Review about Their Health Effects, Presence, Generation, and Measurement in Indoor Environments. Build. Environ. 2022, 216, 108992. [Google Scholar] [CrossRef]

- Ganguly, P.; Breen, A.; Pillai, S.C. Toxicity of Nanomaterials: Exposure, Pathways, Assessment, and Recent Advances. ACS Biomater. Sci. Eng. 2018, 4, 2237–2275. [Google Scholar] [CrossRef] [PubMed]

- McCormick, S.; Niang, M.; Dahm, M.M. Occupational Exposures to Engineered Nanomaterials: A Review of Workplace Exposure Assessment Methods. Curr. Environ. Health Rep. 2021, 8, 223–234. [Google Scholar] [CrossRef]

- Borm, P.J.; Robbins, D.; Haubold, S.; Kuhlbusch, T.; Fissan, H.; Donaldson, K.; Schins, R.; Stone, V.; Kreyling, W.; Lademann, J.; et al. The Potential Risks of Nanomaterials: A Review Carried out for ECETOC. Part. Fibre Toxicol. 2006, 3, 11. [Google Scholar] [CrossRef]

- Ding, Y.; Kuhlbusch, T.A.J.; Van Tongeren, M.; Jiménez, A.S.; Tuinman, I.; Chen, R.; Alvarez, I.L.; Mikolajczyk, U.; Nickel, C.; Meyer, J.; et al. Airborne Engineered Nanomaterials in the Workplace—A Review of Release and Worker Exposure during Nanomaterial Production and Handling Processes. J. Hazard. Mater. 2017, 322, 17–28. [Google Scholar] [CrossRef] [PubMed]

- Heitbrink, W.A.; Lo, L.-M.; Dunn, K.H. Exposure Controls for Nanomaterials at Three Manufacturing Sites. J. Occup. Environ. Hyg. 2015, 12, 16–28. [Google Scholar] [CrossRef]

- Kokkinopoulos, I.; Karayannis, P.; Saliakas, S.; Damilos, S.; Koumoulos, E.P. Employing Nanosafety Standards in a Nanomaterial Research Environment: Lessons Learned and Refinement Potential. Standards 2022, 2, 490–502. [Google Scholar] [CrossRef]

- Zhang, C.; Wu, L.; de Perrot, M.; Zhao, X. Carbon Nanotubes: A Summary of Beneficial and Dangerous Aspects of an Increasingly Popular Group of Nanomaterials. Front. Oncol. 2021, 11, 693814. [Google Scholar] [CrossRef] [PubMed]

- Madannejad, R.; Shoaie, N.; Jahanpeyma, F.; Darvishi, M.H.; Azimzadeh, M.; Javadi, H. Toxicity of Carbon-Based Nanomaterials: Reviewing Recent Reports in Medical and Biological Systems. Chem.-Biol. Interact. 2019, 307, 206–222. [Google Scholar] [CrossRef]

- Ou, L.; Song, B.; Liang, H.; Liu, J.; Feng, X.; Deng, B.; Sun, T.; Shao, L. Toxicity of Graphene-Family Nanoparticles: A General Review of the Origins and Mechanisms. Part. Fibre Toxicol. 2016, 13, 57. [Google Scholar] [CrossRef]

- Kirešová, S.; Guzan, M.; Sobota, B. Using Low-Cost Sensors for Measuring and Monitoring Particulate Matter with a Focus on Fine and Ultrafine Particles. Atmosphere 2023, 14, 324. [Google Scholar] [CrossRef]

- Karayannis, P.; Petrakli, F.; Gkika, A.; Koumoulos, E.P. 3D-Printed Lab-on-a-Chip Diagnostic Systems-Developing a Safe-by-Design Manufacturing Approach. Micromachines 2019, 10, 825. [Google Scholar] [CrossRef] [PubMed]

- Subramanian, V.; Peijnenburg, W.J.G.M.; Vijver, M.G.; Blanco, C.F.; Cucurachi, S.; Guinée, J.B. Approaches to Implement Safe by Design in Early Product Design through Combining Risk Assessment and Life Cycle Assessment. Chemosphere 2023, 311, 137080. [Google Scholar] [CrossRef]

- EN 17058:2018; Workplace Exposure—Assessment of Exposure by Inhalation of Nano-Objects and Their Aggregates and Agglomerates. European Committee for Standardization: Brussels, Belgium, 2018.

- ISO/TS 12901-2:2014; Nanotechnologies—Occupational Risk Management Applied to Engineered Nanomaterials—Part 2: Use of the Control Banding Approach. International Organization for Standardization: Geneva, Switzerland, 2014.

- C&L Inventory—ECHA. Available online: https://echa.europa.eu/information-on-chemicals/cl-inventory-database (accessed on 17 October 2022).

- Kwon, S.-J.; Choi, S.-W.; Lee, E.-B. Hazard Identification and Risk Assessment During Simultaneous Operations in Industrial Plant Maintenance Based on Job Safety Analysis. Sustainability 2024, 16, 9277. [Google Scholar] [CrossRef]

- Lyon, B.K.; Popov, G. The Power of What If: Assessing and Understanding Risk. Prof. Saf. 2020, 65, 36–43. [Google Scholar]

- ISO/TR 12885:2018; Nanotechnologies—Health and Safety Practices in Occupational Settings. European Committee for Standardization: Geneva, Switzerland, 2018.

- Stephens, B.; Azimi, P.; El Orch, Z.; Ramos, T. Ultrafine Particle Emissions from Desktop 3D Printers. Atmos. Environ. 2013, 79, 334–339. [Google Scholar] [CrossRef]

- Saliakas, S.; Karayannis, P.; Kokkinopoulos, I.; Damilos, S.; Gkartzou, E.; Zouboulis, P.; Karatza, A.; Koumoulos, E.P. Fused Filament Fabrication 3D Printing: Quantification of Exposure to Airborne Particles. J. Compos. Sci. 2022, 6, 119. [Google Scholar] [CrossRef]

- Lamon, L.; Asturiol, D.; Vilchez, A.; Cabellos, J.; Damásio, J.; Janer, G.; Richarz, A.; Worth, A. Physiologically Based Mathematical Models of Nanomaterials for Regulatory Toxicology: A Review. Comput. Toxicol. 2019, 9, 133–142. [Google Scholar] [CrossRef] [PubMed]

- Brief Profile—ECHA—Carbon Black. Available online: https://echa.europa.eu/brief-profile/-/briefprofile/100.014.191 (accessed on 30 October 2024).

- Koch, A.; Friederici, L.; Fiala, P.; Springer, A.; Di Bucchianico, S.; Stintz, M.; Frank, M.; Rüger, C.P.; Streibel, T.; Zimmermann, R. Impact of Thermal Stress on Abrasive Dust from a Carbon Fiber-Reinforced Concrete Composite. Fibers 2022, 10, 39. [Google Scholar] [CrossRef]

- American Chemical Society. Identifying and Evaluating Hazards in Research Laboratories; American Chemical Society: Washington, DC, USA, 2015. [Google Scholar]

- Nakanishi, J.; Morimoto, Y.; Ogura, I.; Kobayashi, N.; Naya, M.; Ema, M.; Endoh, S.; Shimada, M.; Ogami, A.; Myojyo, T.; et al. Risk Assessment of the Carbon Nanotube Group. Risk Anal. 2015, 35, 1940. [Google Scholar] [CrossRef] [PubMed]

- C&L Inventory—ECHA—Tangled Multi-Walled Carbon Nanotubes. Available online: https://echa.europa.eu/information-on-chemicals/cl-inventory-database/-/discli/details/256880 (accessed on 29 October 2024).

- van Broekhuizen, P.; van Veelen, W.; Streekstra, W.-H.; Schulte, P.; Reijnders, L. Exposure Limits for Nanoparticles: Report of an International Workshop on Nano Reference Values. Ann. Occup. Hyg. 2012, 56, 515–524. [Google Scholar] [CrossRef] [PubMed]

- American Conference of Governmental Industrial Hygienists. Industrial Ventilation: A Manual of Recommended Practice, 23rd ed.; American Conference of Governmental Industrial Hygienists, Inc.: Cincinnati, OH, USA, 1988; ISBN 1-882417-22-4. [Google Scholar]

- Bello, D.; Wardle, B.L.; Yamamoto, N.; Guzman deVilloria, R.; Garcia, E.J.; Hart, A.J.; Ahn, K.; Ellenbecker, M.J.; Hallock, M. Exposure to Nanoscale Particles and Fibers during Machining of Hybrid Advanced Composites Containing Carbon Nanotubes. J. Nanopart. Res. 2009, 11, 231–249. [Google Scholar] [CrossRef]

- Larese Filon, F.; Mauro, M.; Adami, G.; Bovenzi, M.; Crosera, M. Nanoparticles Skin Absorption: New Aspects for a Safety Profile Evaluation. Regul. Toxicol. Pharmacol. 2015, 72, 310–322. [Google Scholar] [CrossRef] [PubMed]

- Erdely, A.; Dahm, M.; Chen, B.T.; Zeidler-Erdely, P.C.; Fernback, J.E.; Birch, M.E.; Evans, D.E.; Kashon, M.L.; Deddens, J.A.; Hulderman, T.; et al. Carbon Nanotube Dosimetry: From Workplace Exposure Assessment to Inhalation Toxicology. Part. Fibre Toxicol. 2013, 10, 53. [Google Scholar] [CrossRef]

- Dahm, M.M.; Evans, D.E.; Schubauer-Berigan, M.K.; Birch, M.E.; Deddens, J.A. Occupational Exposure Assessment in Carbon Nanotube and Nanofiber Primary and Secondary Manufacturers: Mobile Direct-Reading Sampling. Ann. Occup. Hyg. 2013, 57, 328–344. [Google Scholar] [CrossRef]

- Evans, D.E.; Ku, B.K.; Birch, M.E.; Dunn, K.H. Aerosol Monitoring during Carbon Nanofiber Production: Mobile Direct-Reading Sampling. Ann. Occup. Hyg. 2010, 54, 514–531. [Google Scholar] [CrossRef] [PubMed]

- Damilos, S.; Kokkinopoulos, I.; Semitekolos, D.; Podara, C.V.; Antonaropoulos, G.; Saliakas, S.; Karayannis, P.; Charitidis, C.; Koumoulos, E.P. Occupational Risk Management of Engineered Nanomaterials: A Carbon Fibre Sizing Pilot Line Case Study. In Proceedings of the Conference Proceedings: 2nd International Conference on Polymer Process Innovation, Lavrion, Greece, 15–16 September 2022; ISBN 978-94-6466-761-5. [Google Scholar]

- Thu, H.E.; Haider, M.; Khan, S.; Sohail, M.; Hussain, Z. Nanotoxicity Induced by Nanomaterials: A Review of Factors Affecting Nanotoxicity and Possible Adaptations. OpenNano 2023, 14, 100190. [Google Scholar] [CrossRef]

- Braakhuis, H.M.; Park, M.V.; Gosens, I.; De Jong, W.H.; Cassee, F.R. Physicochemical Characteristics of Nanomaterials That Affect Pulmonary Inflammation. Part. Fibre Toxicol. 2014, 11, 18. [Google Scholar] [CrossRef] [PubMed]

- Heinrich, U.; Fuhst, R.; Rittinghausen, S.; Creutzenberg, O.; Bellmann, B.; Koch, W.; Levsen, K. Chronic Inhalation Exposure of Wistar Rats and Two Different Strains of Mice to Diesel Engine Exhaust, Carbon Black, and Titanium Dioxide. Inhal. Toxicol. 1995, 7, 533–556. [Google Scholar] [CrossRef]

- Raftis, J.B.; Miller, M.R. Nanoparticle Translocation and Multi-Organ Toxicity: A Particularly Small Problem. Nano Today 2019, 26, 8–12. [Google Scholar] [CrossRef]

- Hoshyaripour, G.A.; Bachmann, V.; Förstner, J.; Steiner, A.; Vogel, H.; Wagner, F.; Walter, C.; Vogel, B. Effects of Particle Nonsphericity on Dust Optical Properties in a Forecast System: Implications for Model-Observation Comparison. J. Geophys. Res. Atmos. 2019, 124, 7164–7178. [Google Scholar] [CrossRef]

- Mallios, S.A.; Daskalopoulou, V.; Amiridis, V. Modeling of the Electrical Interaction between Desert Dust Particles and the Earth’s Atmosphere. J. Aerosol Sci. 2022, 165, 106044. [Google Scholar] [CrossRef]

- Federal Institute for Occupational Safety and Health. Sustance Evaluation Report as Required by REACH Article 48 and Evaluation Report for Multi-Walled Carbon Nanotubes (MWCNT), Synthetic Graphite in Tubular Shape and Tangled EC No 936-414-1/701-160-0; Federal Institute for Occupational Safety and Health: Dortmund, Germany, 2020. [Google Scholar]

- Vardharajula, S.; Ali, S.Z.; Tiwari, P.M.; Eroğlu, E.; Vig, K.; Dennis, V.A.; Singh, S.R. Functionalized Carbon Nanotubes: Biomedical Applications. Int. J. Nanomed. 2012, 7, 5361. [Google Scholar] [CrossRef]

- Mohammadi, E.; Zeinali, M.; Mohammadi-Sardoo, M.; Iranpour, M.; Behnam, B.; Mandegary, A. The Effects of Functionalization of Carbon Nanotubes on Toxicological Parameters in Mice. Hum. Exp. Toxicol. 2020, 39, 1147–1167. [Google Scholar] [CrossRef]

- Quang, T.N.; He, C.; Morawska, L.; Knibbs, L.D. Influence of Ventilation and Filtration on Indoor Particle Concentrations in Urban Office Buildings. Atmos. Environ. 2013, 79, 41–52. [Google Scholar] [CrossRef]

- D’Alicandro, A.C.; Mauro, A. Effects of Operating Room Layout and Ventilation System on Ultrafine Particle Transport and Deposition. Atmos. Environ. 2022, 270, 118901. [Google Scholar] [CrossRef]

- Karayannis, P.; Saliakas, S.; Kokkinopoulos, I.; Damilos, S.; Koumoulos, E.P.; Gkartzou, E.; Gomez, J.; Charitidis, C. Facilitating Safe FFF 3D Printing: A Prototype Material Case Study. Sustainability 2022, 14, 3046. [Google Scholar] [CrossRef]

- Saliakas, S.; Damilos, S.; Karamitrou, M.; Trompeta, A.-F.; Milickovic, T.K.; Charitidis, C.; Koumoulos, E.P. Integrating Exposure Assessment and Process Hazard Analysis: The Nano-Enabled 3D Printing Filament Extrusion Case. Polymers 2023, 15, 2836. [Google Scholar] [CrossRef] [PubMed]

- ISO 45001:2018; Occupational Health and Safety Management Systems—Requirements with Guidance for Use. International Organization for Standardization: Geneva, Switzerland, 2018.

- Wang, J.; Pan, Z.; Tang, H.; Guo, W. Assessment of Airborne Viral Transmission Risks in a Large-Scale Building Using Onsite Measurements and CFD Method. J. Build. Eng. 2024, 95, 110222. [Google Scholar] [CrossRef]

- Evans, D. Chapter AD: Quantification of Airborne Dusts from Powders. In NIOSH Manual of Analytical Methods (NMAM), 5th ed.; Centers for Disease Control and Prevention—National Institute for Occupational Safety and Health (NIOSH): Cincinnati, OI, USA, 2016. [Google Scholar]

| Process | Carbon fibre sizing line |

| Release/exposure expected | Emission of particles (ultrafine and microscale) due to partial decomposition and thermal degradation of the polymer resin |

| Workroom characteristics | Volume: ≈212 m3 Temperature: 24–30 °C Relative humidity: 43–48% |

| Secondary processes conducted within the workroom | Preparation of nanomaterial sizing solution |

| Materials used | Carbon fibres: 6k CFs Sizing solution: Epoxy sizing agent, Triton X100 and nanomaterials (MWCNTs or FLG) |

| Process automation | Manual process initiation (print start) and finish (print removal); sizing process is automated and requires only periodic progress monitoring Manual stop and fibre removal in case of critical defects and errors |

| Process containment | The sizing line is not contained in a fume hood The sub-process of nanomaterial sizing solution preparation takes place under a fume hood |

| Process duration | Carbon fibre sizing requires 15 h of operation per week Preparation of nanomaterial sizing solution takes place once per week and requires 2 h per week |

| Employees associated with the process | Two employees directly involved |

| Work patterns | Operators enter the sizing pilot line room for start/stop and periodic inspection during the process Cleaning is compulsory at the end of each batch of production Periodic inspections take place for repair and maintenance purposes |

| Maintenance | Cleaning the line rollers, removing carbon fibres, disposing of the bath solution and cleaning the bath equipment |

| Primary particle emission source | Carbon fibre sizing line |

| Incidental particle emission sources | No other instruments that can lead to particle generation are used within the specific workroom during the sizing operations; no apparent sources of significant incidental ultrafine particle emissions; general workplace dust particles may be present; disturbance of settled/deposited particles on work surfaces may occur (e.g., due to air condition airflow, open windows) |

| Current controls applied | General ventilation Full-face masks with P3 filters available in the workplace |

| ID | What-If… | Causes | Consequences | Controls | Recommendations |

|---|---|---|---|---|---|

| 1 | Carbon fibre is entangled in line/roller. | Improper placement of carbon fibre. | (i) Halting of operation. (ii) Increased residence time of CF in the oven leading to the elevated release of airborne (nano)particles. | Standard operating procedures in place. | Training operators and using a checklist to ensure proper placement of the carbon fibre. |

| 2 | Rollers stop working. | Motor malfunctions and stops working. | (i) Halting of operation. (ii) Increased residence time of CF in the oven leading to the elevated release of airborne (nano)particles. | Inspection before sizing operation. | Periodic maintenance. |

| 3 | Oven thermostats malfunction. | Dirt and particulate matter accumulate. | In case of increased temperature, elevated release of airborne (nano)particles. | Standard operating procedures in place. | Periodic maintenance and risk assessment/standard operating procedures in place for immediate action. |

| 4 | Sizing bath solution agitator stops working. | Damaged shaft damaged wires. | Unevenly dispersed engineered nanomaterials in the sizing solution, requiring the process to restart, thus increasing potential exposure to airborne (nano)particles. | Standard operating procedures in place. | Periodic maintenance and risk assessment/standard operating procedures in place for immediate action. |

| 5 | Sizing bath solution agitator rotates at extreme speeds. | Rotation controller malfunctions. | Spillage of engineered nanomaterials resulting in an emission source. | Standard operating procedures in place. | Periodic maintenance and risk assessment/standard operating procedures in place for immediate action. Guards on the bath to prevent spillage. |

| Material | Hazard Band |

|---|---|

| Commercial sizing solution | HB-A (No significant hazard) |

| Surfactant | HB-C (Moderate hazard) |

| MWCNTs | |

| FLG |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Damilos, S.; Semitekolos, D.; Saliakas, S.; Kostapanou, A.; Charitidis, C.; Koumoulos, E.P. Occupational Risk Assessment During Carbon Fibre Sizing Using Engineered Nanomaterials. Safety 2025, 11, 11. https://doi.org/10.3390/safety11010011

Damilos S, Semitekolos D, Saliakas S, Kostapanou A, Charitidis C, Koumoulos EP. Occupational Risk Assessment During Carbon Fibre Sizing Using Engineered Nanomaterials. Safety. 2025; 11(1):11. https://doi.org/10.3390/safety11010011

Chicago/Turabian StyleDamilos, Spyridon, Dionisis Semitekolos, Stratos Saliakas, Adamantia Kostapanou, Costas Charitidis, and Elias P. Koumoulos. 2025. "Occupational Risk Assessment During Carbon Fibre Sizing Using Engineered Nanomaterials" Safety 11, no. 1: 11. https://doi.org/10.3390/safety11010011

APA StyleDamilos, S., Semitekolos, D., Saliakas, S., Kostapanou, A., Charitidis, C., & Koumoulos, E. P. (2025). Occupational Risk Assessment During Carbon Fibre Sizing Using Engineered Nanomaterials. Safety, 11(1), 11. https://doi.org/10.3390/safety11010011