1. Introduction

Tanzania’s construction sector is expanding steadily and is the second biggest driver of the country’s real GDP growth, behind agriculture. Agriculture contributed around 26.9 percent of the total; buildings contributed about 14.4 percent; lodging and restaurants 10 percent; and trade and repair 8.4 percent [

1]. Like many others globally, the construction industry in Tanzania faces a challenge in ensuring worker safety. Despite safety rules and regulations, acts (Occupational Health and Safety Act, 2003), and policy (National Occupational Health and Safety Policy, 2010) established by the Occupational Safety and Health Authority (OSHA), increasing construction activities, predominantly building construction projects, continue to experience a high incidence of accidents [

2,

3,

4,

5]. Tanzania’s construction industry is experiencing growth, but there is constantly the possibility of events that take lives, entail disruptions in projects, and limit economic growth. The fatality rate in Tanzania’s construction industry is two times higher than that of the manufacturing industry [

6], while falling and being struck are, worldwide, the most common accidents in projects [

7]. These incidents undermine project budgets, productivity, and the country’s development goals, and have a devastating human cost [

8]. To address this challenge, more is required beyond regular compliance inspections [

9].

The complex framework of construction safety is linked by various factors, including organisational culture, worker training, safety regulations, and even financial limitations. Each link interacts with others to establish a complex structure that ultimately impacts the extent of accidents [

10,

11,

12,

13]. Traditional methods usually struggle to capture this dynamic interaction [

14,

15]. There is a need for a better understanding of how these variables interact and change over time. Understanding these complex interactions is important to implement safer measures and prevent disasters.

This study attempts to quantify the issue and fully understand its complex origins [

16]. It makes it perfectly apparent that a safety climate is more complex than just compliance but a dynamic fabric made up of many components. A complicated network of interrelated elements affects the general frequency of accidents, such as worker training, safety regulations, organisational culture, and even economic constraints [

17].

To unravel this interaction, a powerful tool, system dynamics (SD), was introduced [

18]. In many different domains, system dynamics modelling (SDM) has been shown to be highly valuable in assisting decision makers in comprehending and forecasting the dynamic behaviour of intricate systems, which is crucial for the creation of successful policy initiatives [

19].

Using system dynamics (SD), a virtual replica of Tanzanian construction is created, simulating how the various factors interact to influence accident rates. Visualising this hidden network provides valuable insight into the “why” behind safety performance. By locating critical leverage points within the system, effective interventions are identified to create change. By simulating various scenarios, the model identifies leverage points that are critical areas where targeted interventions can produce the most significant safety improvements.

On the other hand, this research presents the analysis and findings of a system dynamics model simulation aimed at understanding the dynamics of safety climate maturity in construction projects in Tanzania. Moreover, it presents the findings and analysis of a sensitivity analysis conducted on a system dynamics model aimed at understanding safety performance in construction projects in Tanzania.

The sensitivity analysis focuses on evaluating the impact of changes in safety leading factors and safety management process-related factors on safety performance metrics including the frequency, extent, and cost of safety performance parameters. Additionally, this research includes details on model validation and the software used for model development.

The objectives of the simulation study are as follows:

To identify key variables and relationships that influence safety performance;

To develop a system dynamics model simulation for safety performance in construction projects in Tanzania;

To analyse the impact of the safety management process and safety leading factors on safety performance;

To assess the sensitivity analysis of safety key performance indicators (frequency, extent, and cost of safety performance indicators) to changes in project management-related factors, worker-related factors, site environment-related factors, external-related factors, and safety management process-related factors;

To provide insights for decision making and prioritisation of interventions to improve safety performance.

2. Literature Review

In the construction industry, safety is of utmost importance due to the inherent risks and hazards associated with the unique, dynamic, and temporary nature of construction projects. It is crucial to understand the factors that influence safety performance in construction projects to mitigate risks and improve safety outcomes [

20,

21]. According to the reviewed literature, several factors have been identified as influential in improving safety performance in construction projects [

22,

23,

24].

These factors include management commitment, safety training, enforcement of safety rules and regulations, stakeholder collaboration, implementation of a safe working environment, and implementation of a safe plant and equipment. Additionally, the literature emphasises the importance of integrated safety and quality management in construction projects. The literature review also highlights some barriers to successful quality management in construction projects, including poor implementation, the nature of construction work, and the industry itself [

25].

Overall, the literature review suggests that a comprehensive approach to safety management, which includes factors such as management commitment, training, collaboration, and a focus on worker behaviour and safety climate, can greatly improve safety performance in construction projects [

24]. This research established three categories of factors used in determining the safety climate factors at construction sites in Tanzania. These are safety leading factors, safety management process factors, and safety lagging factors (safety performance) [

26,

27,

28,

29,

30,

31,

32].

Safety leading factors are the factors that influence the safety climate of a construction site. These factors can be grouped into three categories [

31].

Table 1,

Table 2 and

Table 3 represent safety categories as defined by different studies.

Table 1.

Safety leading factors.

Table 1.

Safety leading factors.

Factors

Origin | Description | Sources |

|---|

| Project management-related factors | These are factors obtained from five basic functions, namely, planning, organising, staffing, leading, and controlling safety issues within a project. | [33] Brazil, [34] Australia, [35]

Qatar, [36] Brazil |

| Worker-related factors (individual factors) | These are personal attitudes, abilities, habits, and personalities that individual workers bring to their work, which can be strengths or weaknesses depending on the demands of the task. | [37] USA, [38] Indonesia, [39] Sweden, [40] USA |

Site-related factors

(workplace factors) | These are elements of the workplace that can have a positive or negative impact on a worker’s ability to perform their job effectively. | [41] Korea, [42] India, [43] Iran, [44] Greece |

| External related factors | These are external safety factors that have an impact on the construction project’s safety performance. | [45] Nigeria, [46] Nigeria, [47] Spain, [48] South Africa, [49] Australia |

The safety leading factors are important because they can have a significant impact on the safety climate of a project and organisation. By understanding these factors, organisations can take steps to improve their safety climate and reduce the risk of accidents and injuries. The safety management process factors are the safety processes that organisations undertake to implement a safe work environment [

50,

51,

52,

53].

This research applies the Deming cycle (plan–do–check–act (PDCA)) to measure the whole safety climate process of the model. PDCA is a four-step process for continuous improvement. It is a cyclical process that can improve any process or system.

The PDCA cycle is conducted repeatedly until the goal is achieved or until it is determined that the goal is not achievable. The PDCA cycle is a simple but powerful tool that can be used to improve any process or system. It is a cyclical process, which means that it can be repeated as needed to continuously improve the process or system. The PDCA cycle is often used in quality management, but it can be used in any field where improvement is desired. It is a versatile tool that can be used to improve a wide variety of processes, from manufacturing to customer service.

Table 2.

Safety management process factors.

Table 2.

Safety management process factors.

| Process | Denotes | Description | Sources |

|---|

| Plan | Safety process design | An improvement’s purpose is established and a strategy is created to meet it. | [54] USA, [41] Korea, [55] USA |

| Do | Safety process implementation | During the doing stage, the plan is carried out. This entails carrying out the actions that were determined during the planning stage. | [56] Saudi Arabia, [57] Brazil |

| Check | Safety process evaluation | The outcomes of the implementation are assessed at the evaluation stage. This entails gathering information to determine whether the objective was accomplished and to spot any issues that arose during implementation. | [58] UK, [59] Canada, [60] Taiwan |

| Act | Safety process improvement | The plan is improved with the help of the checking phase’s findings. This could entail updating the strategy, putting new protocols into place, or offering more training. | [61] USA, [62] USA |

On the other hand, safety lagging factors are the factors that measure how well an organisation is managing its safety risks in a project. It is typically measured by many features, such as several accidents and injuries that occur. Still, it can also be measured by other factors, such as the number of near misses, safety violations, and cost of accidents and injuries [

27].

Table 3.

Safety lagging factors.

Table 3.

Safety lagging factors.

Items

Origin | Description | Sources |

|---|

| Incidents | An uncommon isolated, random, and sudden instance or event that can disturb a person’s daily routine (good or bad/pleasant or unpleasant/big or small/loss or even profit). | [63] China, [64] USA, [65] Brazil |

| Injuries | Harm caused by accidents, falls, hits, weapons, and more. | [66] China, [67] France, [68] USA, [69] Iran |

| Accidents | An unfortunate event that occurs suddenly and unexpectedly that often results in damage, injury, or loss. | [70] Turkey, [71] Sri Lanka, [72] UK |

| Near misses | An unplanned event that has the potential to cause, but does not result in, human injury, environmental or equipment damage, or an interruption to normal operation. | [73] Israel, [74] China, [75] USA |

| Fatalities | An accident or disaster resulting in death. | [76] USA, [77] USA, [78] USA |

| Damages of property | Destruction of real or tangible personal property, caused by negligence, willful destruction, or an act of nature. | [79] Czech Republic, |

| Financial loss | A disparity in a company between the money they are bringing in and the money going out, leaving them with a net deficit. | [80] Malaysia, [81] Ukraine, [82] Czech Republic |

| Compensation due to accidents. | An award to somebody who has been involved in an accident that was not their fault. | [83] Taiwan, [84] Hong Kong, [85] Taiwan |

| Overtime is associated with slow operation | Overtime refers to any hours worked by a worker that exceed their normally scheduled working hours. | [86] Korea, [87] USA, [88] Canada |

| Production time lost | Production lost time refers to the time during which a production process or operation is not running or is operating at reduced capacity due to various reasons such as equipment breakdowns, maintenance, shortages of raw materials, or other disruptions. | [89] Nigeria, [90] Iran, [91] India |

| Slowdown in operation | A reduction in speed, activity, or the rate that things are produced. | [92] Nigeria, [93] India |

| Decrease in morale | When workers feel poorly about their work and the project. | [94] China, [95] Spain, [96] New Zealand |

| Loss of client | This is when the client does not want to continue their contract with the project. | [97] Turkey, [98] New Zealand |

| Equipment breakdown due to unsafe practice | The condition in which a piece of equipment fails to operate as intended due to mistakes, parts getting old, etc. | [99] Nigeria, [100] India, [101] India |

3. Materials and Methods

3.1. Data Collection

The population samples collected from the Contractors Registration Board (CRB) registry show a total of 757 registered building projects within Classes 1–4, which makes 757 respondents. Although contractors in Tanzania are categorised in Classes 1–7, Classes 1–4 contractors’ projects were chosen as the population size because they are the most affected by the impact on safety performance due to risks subject to project design and cost. It should be noted that the impact on project safety performance increases as the complexity of the project increases [

1,

102]. The sample size formula for the small and finite population is provided by [

103] and is given as

where

| Z | Z value which is 95 percent or 1.96. |

| N | Population size (757 respondents). |

| p | Sample proportion = 0.5, q = 1 − p = 0.5. |

| Margin error = 5, percent = 0.05. |

The sample size for this research was 255 respondents, of which 26 were from Class 1, 50 were from Class 2, 74 were from Class 3, and 105 were from Class 4 contractor companies. To identify the factors affecting safety climate in construction sites, an in-depth literature review was carried out. From this, 143 factors that affect safety climate in construction sites were compiled. Then, these factors were examined by preparing a survey questionnaire in which various construction safety professionals (including owners, managers, engineers, supervisors, etc.) in five Tanzanian regions, namely, Dar es Salaam, Dodoma, Arusha, Mwanza, and Mbeya, participated; the respondent demographics are shown in

Table 4.

The purpose of this questionnaire was to identify the most important factors that affect the safety climate of construction projects in Tanzania. Data on safety climate including safety leading factors, the safety management process, safety performance, and other relevant factors from construction projects were collected and analysed. Smart PLS (version 4) was used to identify key variables using factor reduction, and 19 variables were determined as key factors due to their high loading values and were selected to be used in this study. Then STELLA software Version 3.5 (3121) used them to develop system dynamics modelling. The variables formed the basis for developing the simulation model and are indicated in

Table 5,

Table 6 and

Table 7.

3.2. Model Development

3.2.1. Variable Identification

The first step in the model formulation was to identify the key variables that influence safety climate maturity in construction projects. These variables were categorised into three main groups: safety leading factors, safety management process, and safety performance.

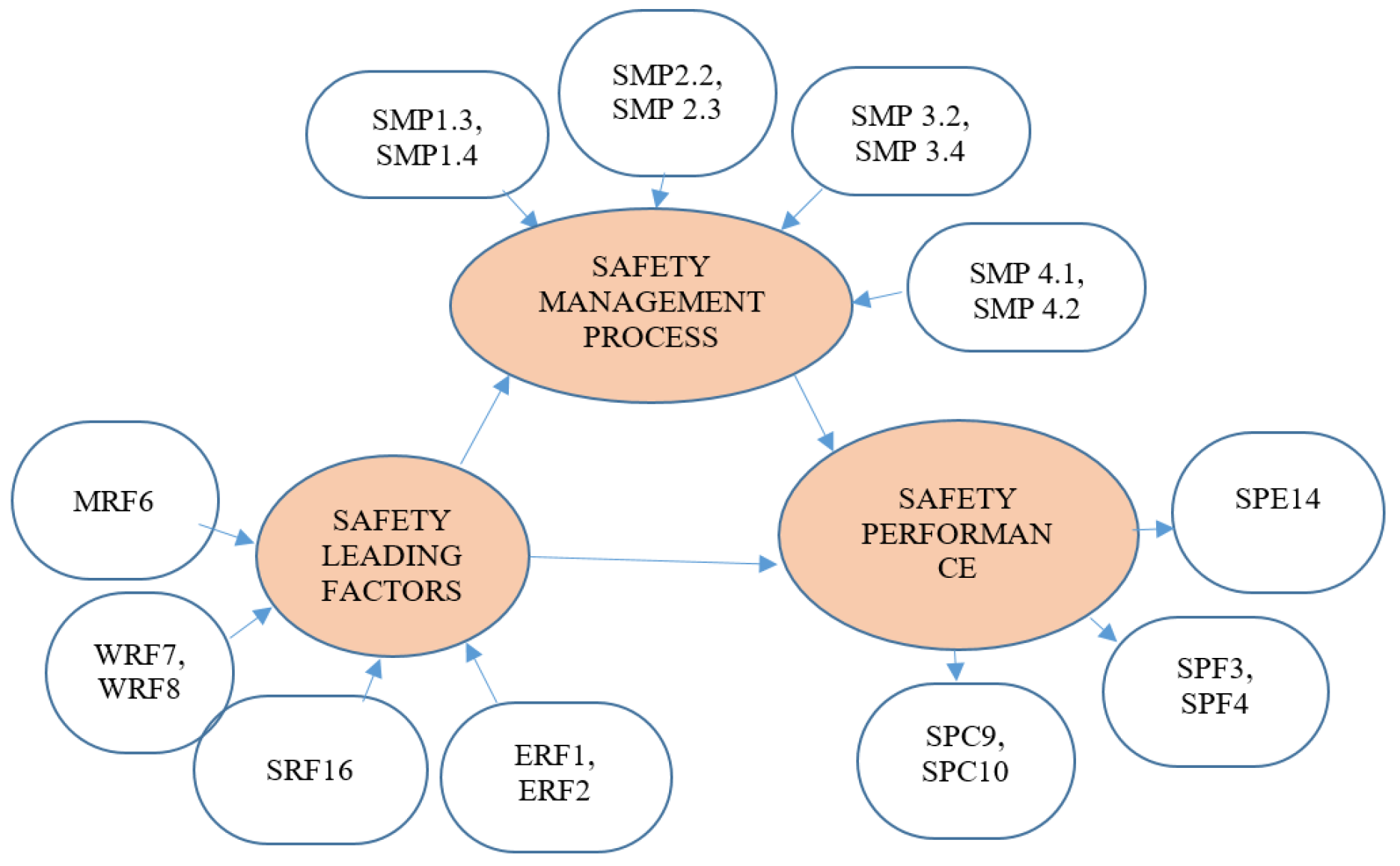

Figure 1 represents variables used to develop an SDM model.

3.2.2. Hypothesis (Causal Loop) SDM Diagram

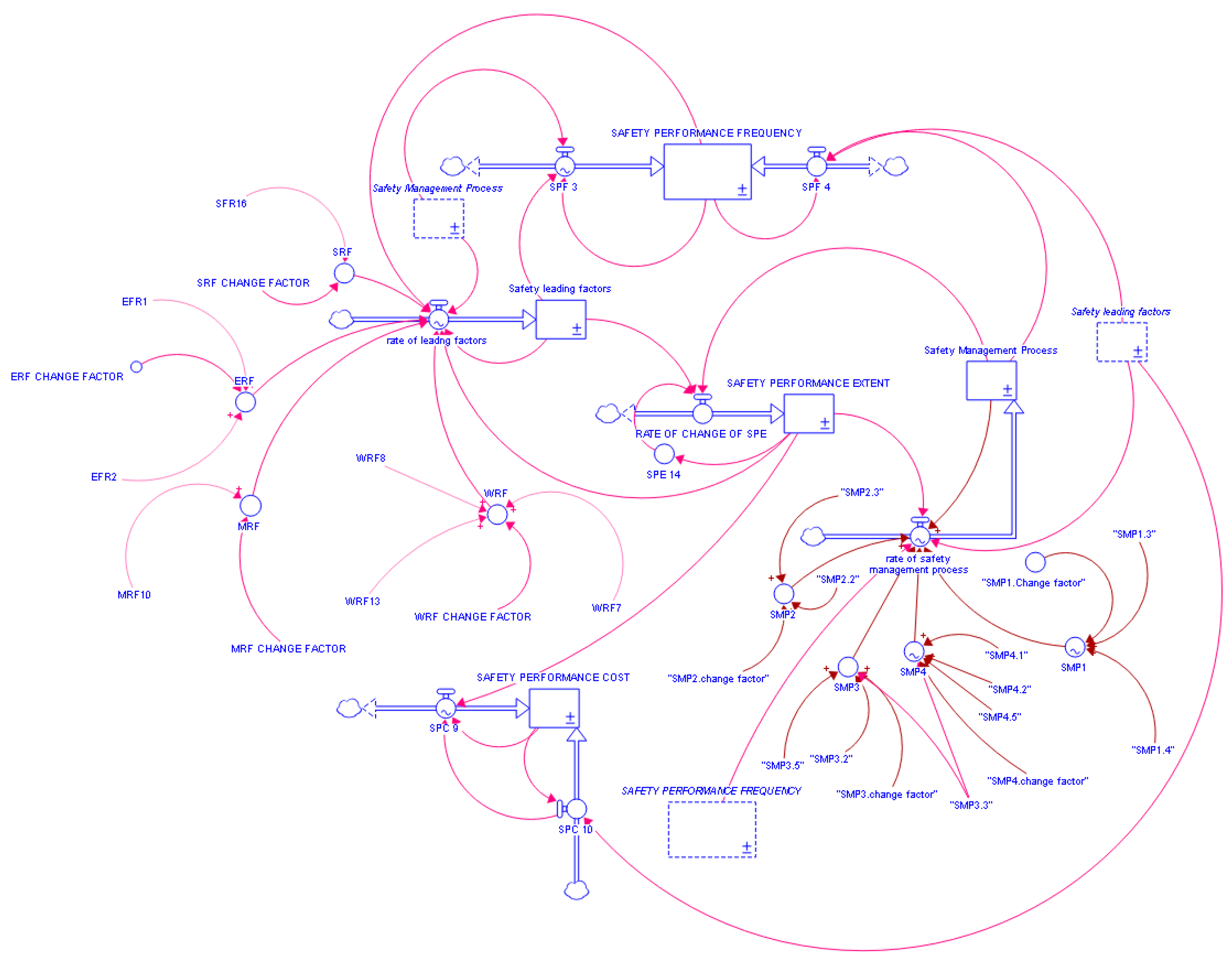

The second step was to develop a hypothesis where the (causal loop) SDM diagram was developed. This involved developing a conceptual model of the system, which includes the relationships between the key variables. The conceptual model is usually represented using causal loop diagrams (hypothesis SDM diagram) as represented in

Figure 2.

Next, a causal loop diagram was developed to illustrate the relationships between the key variables [

104]. These diagrams helped identify feedback loops and dynamic interactions that influence safety climate maturity over time. For example, a reinforcing loop might exist between the safety process design and the safety management process, where increased safety process design leads to a higher safety management process, which in turn reinforces safety performance. The feedback loop is indicated by an arrow with the (+) sign, which shows the reinforced feedback loop.

Mathematical equations were then formulated to describe the dynamics of the system. These equations represented the rates of change of the endogenous variables over time, taking into account the influences of exogenous variables and feedback loops as shown in

Table 8. For example, the rate of change in safety incident rates might be influenced by factors such as safety-related factors effectiveness, project management-related factors, and safety process improvement.

The model equations also involved probabilistic distributions such as Weibull and normal distributions to capture the variability and uncertainty in safety performance metrics. For example, the frequency of safety incidents may be modelled using a Weibull distribution to account for the time-to-failure characteristics of safety systems, while the cost of safety incidents may be modelled using a normal distribution to capture the variability in financial impacts.

The equations in the table above represent the dynamic interactions between various factors influencing safety climate maturity in construction projects and serve as the foundation for the system dynamics model. The equations can be implemented using software such as Stella, which provides tools for building, simulating, and analysing system dynamics models.

4. Results

4.1. Model Implementation

The process of identifying the physical parts of the system so that they can be better understood and managed was conducted [

66]. The formulated equations were implemented using the system dynamics software STELLA. This involved translating the mathematical equations into computational algorithms that could be simulated over time. STELLA Version 3.5 (3121 is a powerful system dynamics modelling software used for developing dynamic simulation models. It provides a user-friendly interface for building complex models that capture the dynamic behaviour of systems over time. The model run specifications are listed in

Table 9.

The model was then calibrated using real-world data to ensure that it accurately represented the dynamics of safety performance in construction projects in Tanzania. Sensitivity analysis was conducted to assess the robustness of the model and identify key parameters that had a significant impact on the simulation results.

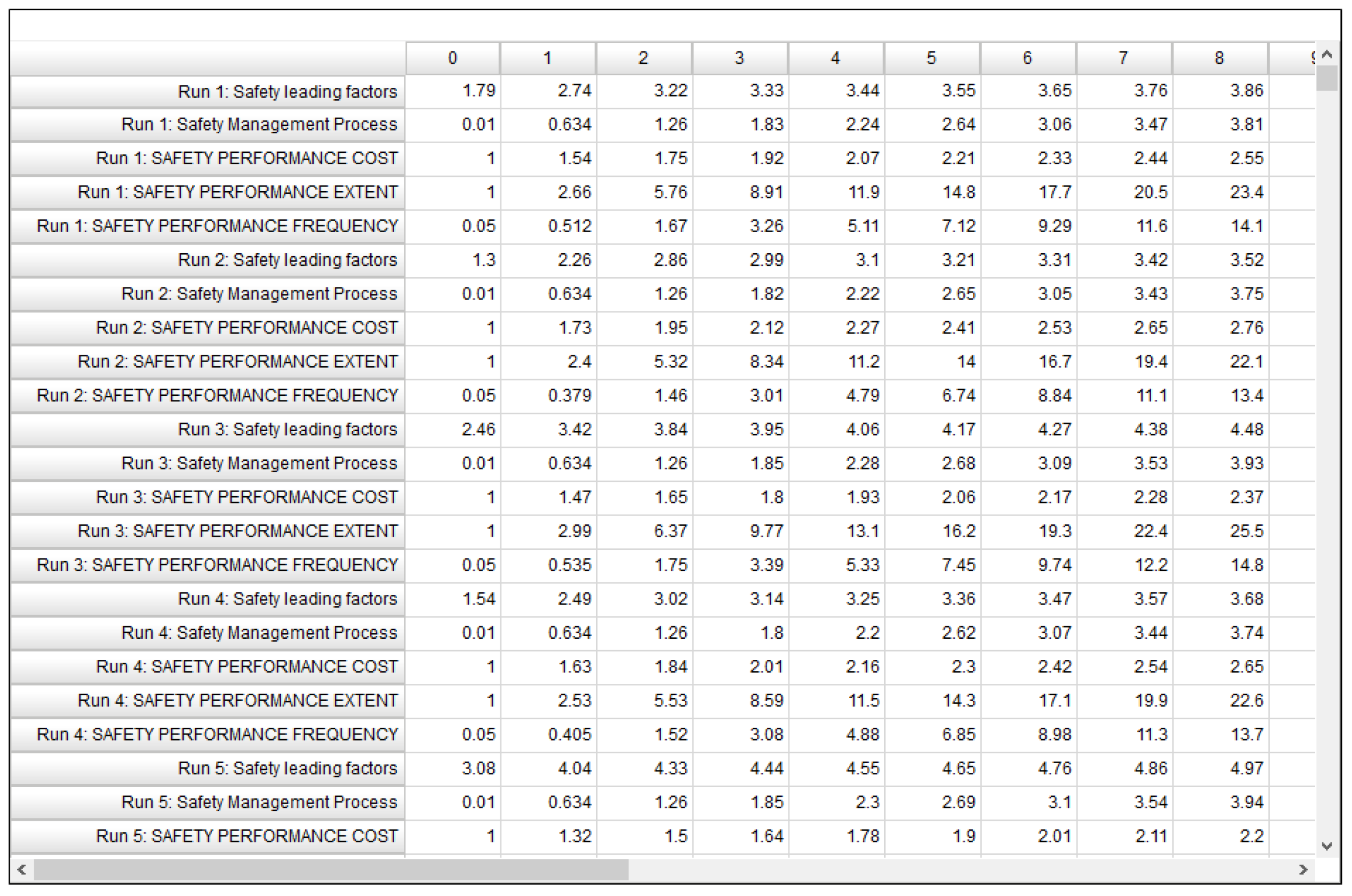

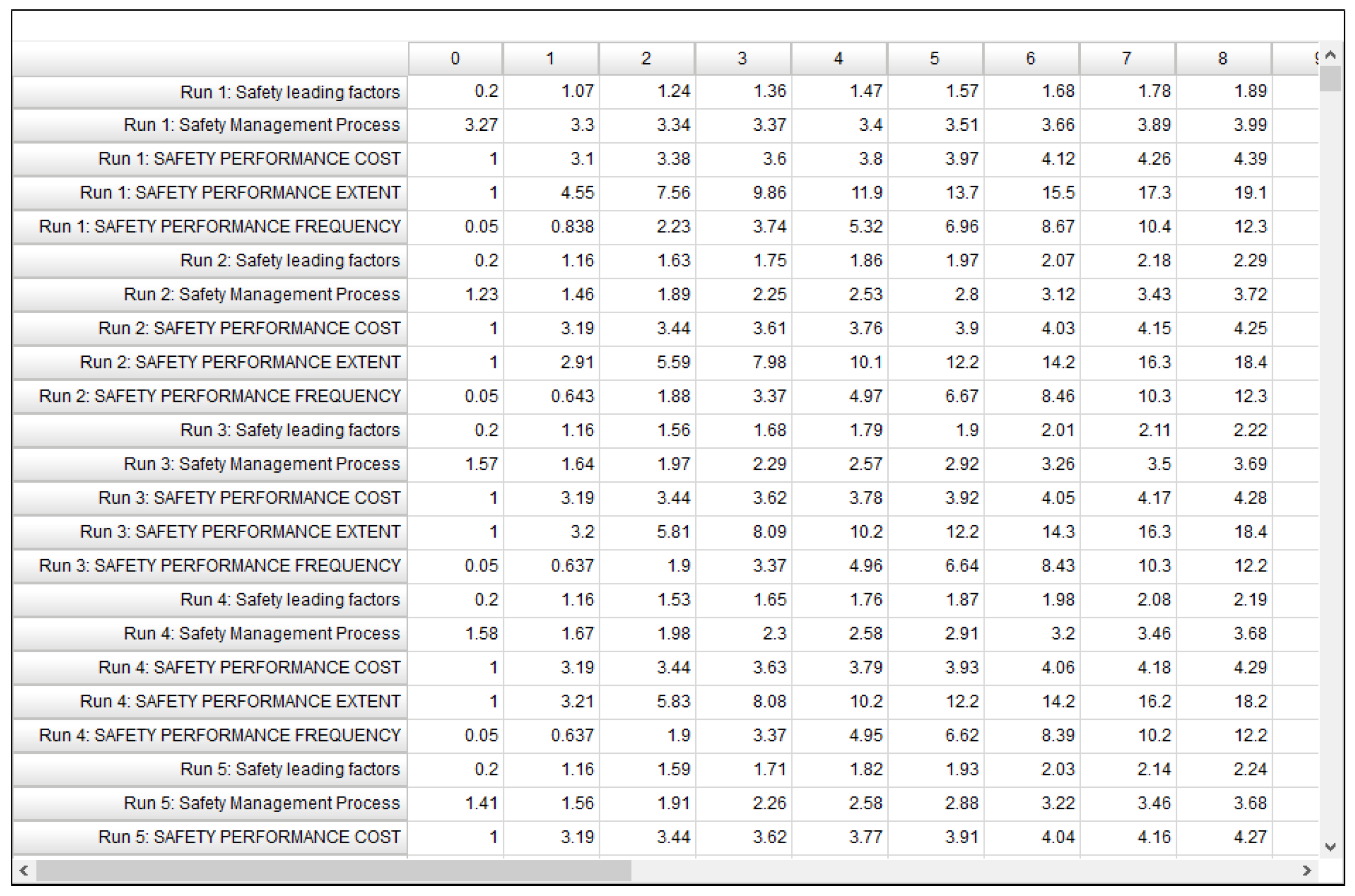

Table 10 represents a summary of the model during the simulation process.

4.2. Model Validation

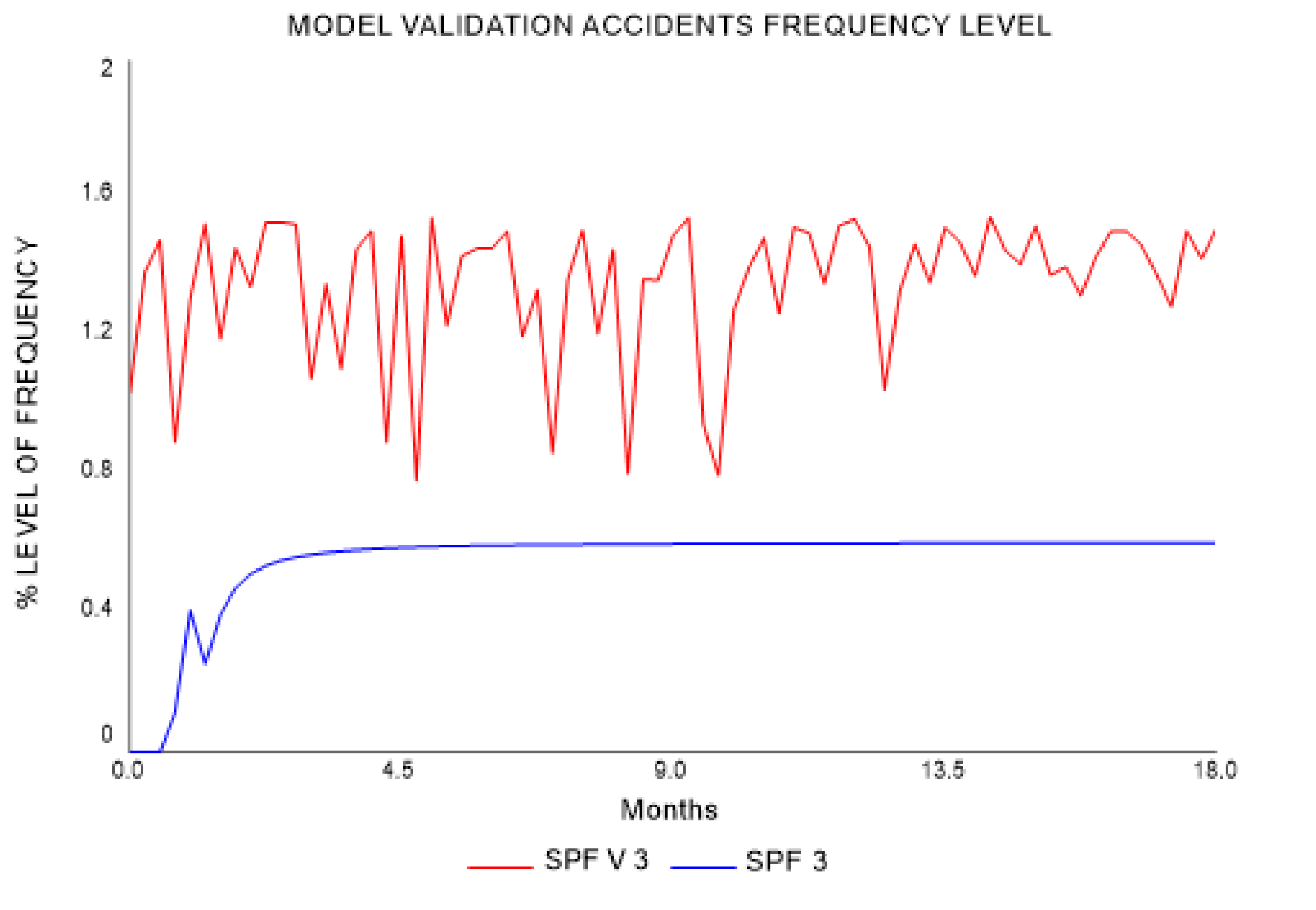

The model was validated by comparing its outputs with data from the “Proposed seven-story commercial residential building on plot Nos. 623 and 624, block L in Temeke Municipality, Dar Es Salaam” project, which had a high safety key performance index. A sensitivity analysis was also performed to assess the robustness of the model. The model performance was measured by comparing the two variables of safety performance frequency, one variable of safety performance extent, and two variables of safety performance cost level. The results achieved are shown in

Figure 3.

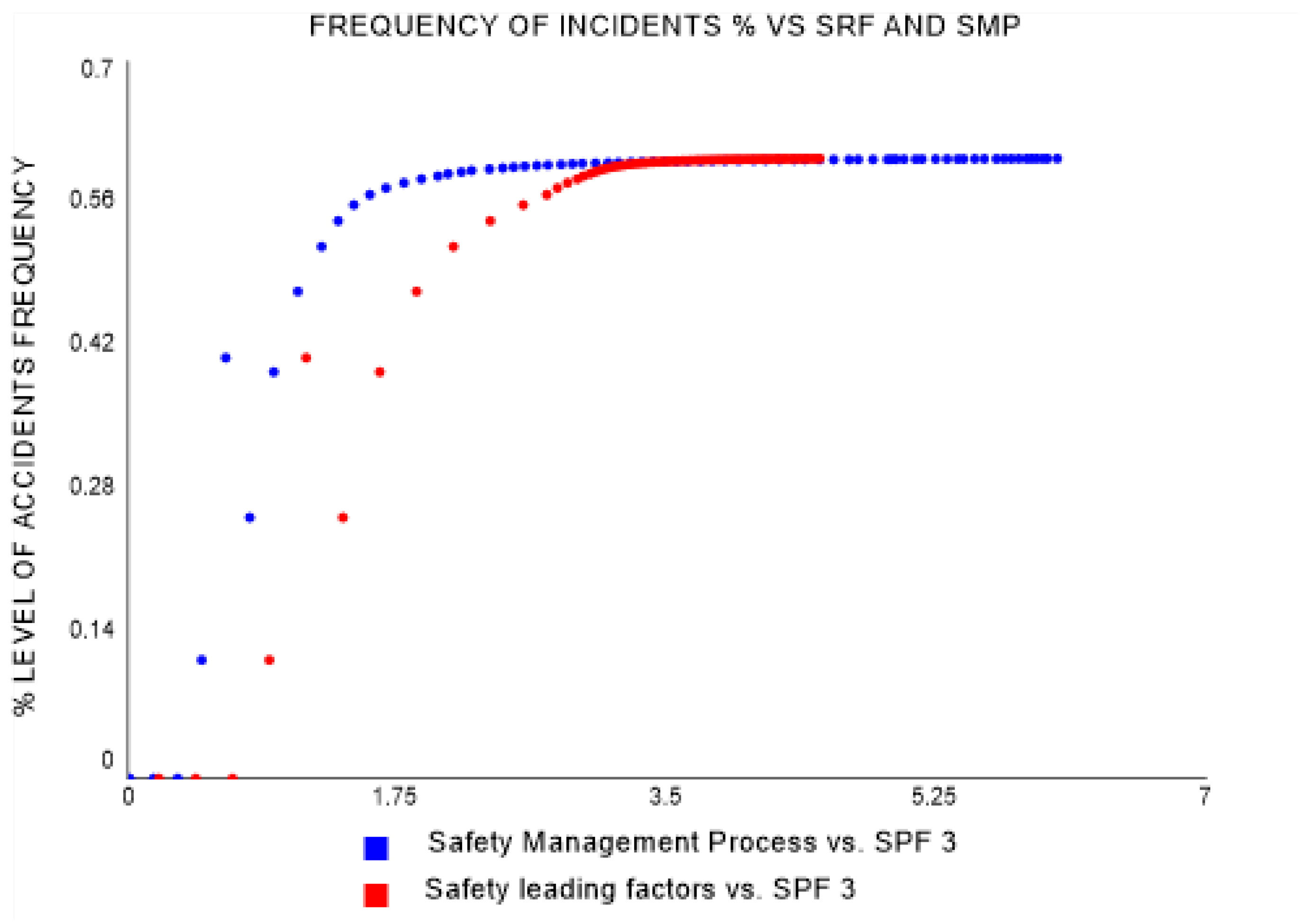

SPF, SPE, and SPC in

Table 11 signify the model results, and SPF V, SPE V, and SPC V signify validation data. The model validation accident frequency level for SPF V3 is significantly higher than the model validation accident frequency level for SPF 3. The y axis in

Figure 4 shows the level of frequency, and the x axis shows months. The data for SPF V3 are represented by the red line, and the data for SPF 3 are represented by the blue line. The red line starts at a level of 1 and increases to a level of around 1.4 over the months. The blue line starts at a level of 0 and increases to a level of around 0.6 over the months, as shown in

Figure 4. Regarding the percentage level of frequency of accidents throughout the 18 months of the project execution, the model variable SPF 3 performed much better than validation data SPF V 3, as was expected; when there is a safety climate during project execution, frequency of accidents will be as low as possible, close to 0. From the results, the deviation of SPF 3 from SPF V 3 is below 0, which is a −0.82 average.

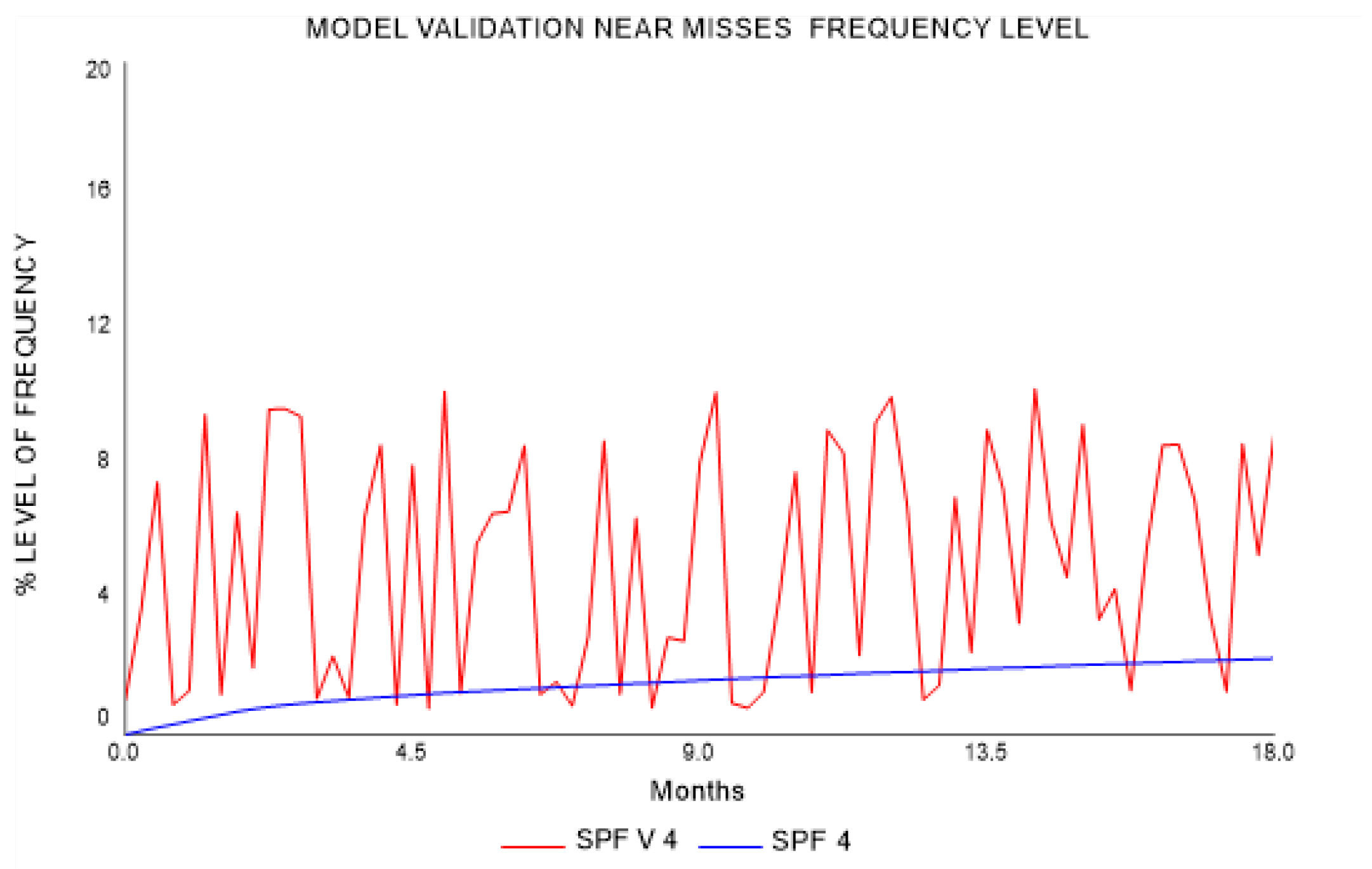

On the other hand,

Figure 5 shows the results of the validation results that predict the frequency of near misses in 18 months at the construction sites. The red line represents the predicted frequency of near misses, while the blue line represents the actual frequency. The two lines appear to track one another very closely, which suggests that the model is successful at predicting the frequency of near misses (SPF 4) at construction sites from the beginning to the end of projects.

At the same time,

Figure 6 and

Table 12 show the results of the validation that predict the extent of equipment breakdown due to unsafe practices in 18 months. The red line labelled “SPE V 14” represents the predicted percentage of equipment breakdown, while the blue line labelled “SPE 14” represents the actual percentage. Overall, the predicted equipment breakdowns (red line) are consistently lower than the actual equipment breakdowns (blue line). This could indicate that the model does not fully capture the extent of equipment breakdown due to unsafe practices. The difference between the red and blue lines seems to shrink over time. This could be due to the model being refined over time to better reflect reality and indicate how the situation will be improved within 18 months.

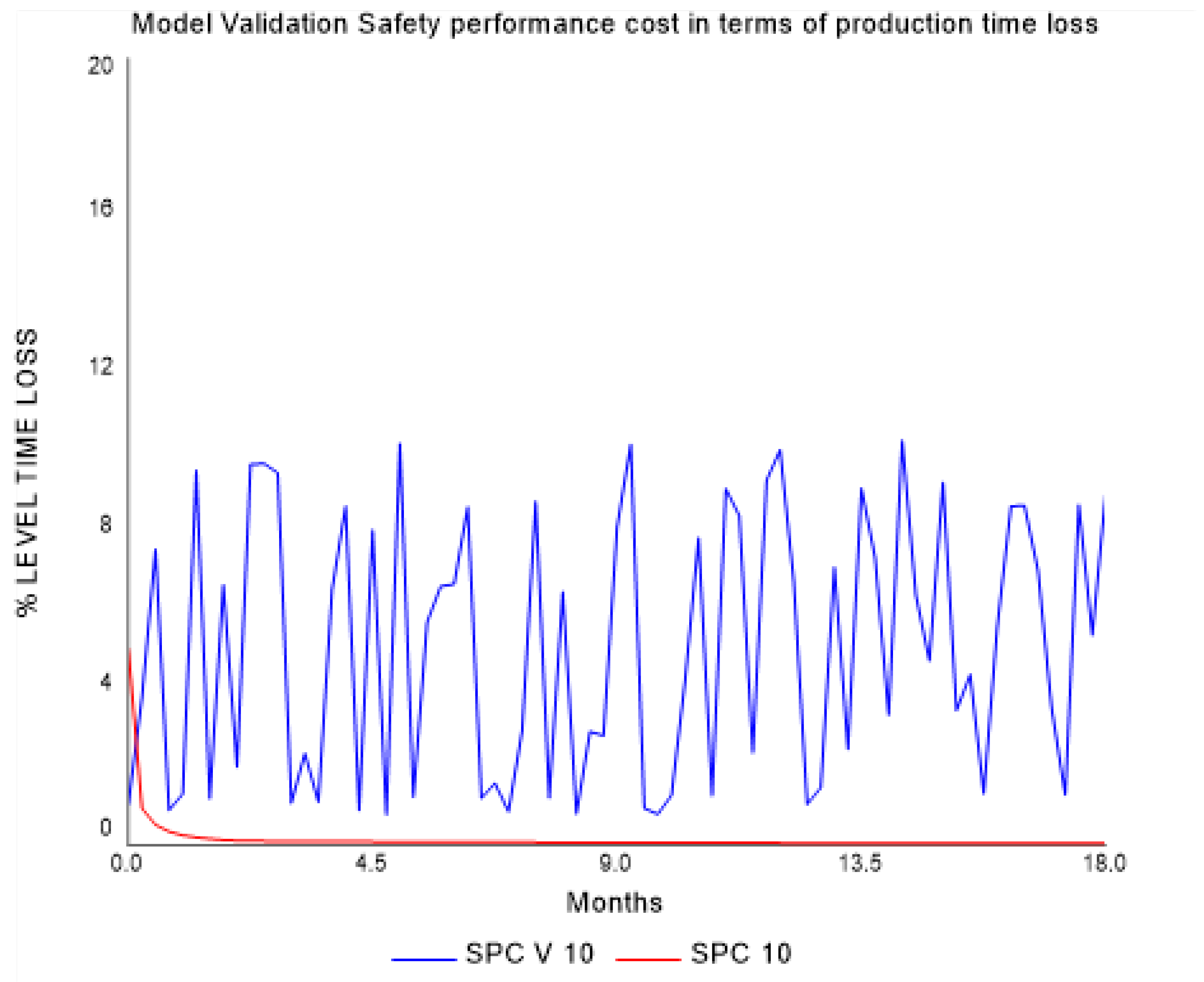

Also, the model seems to accurately predict the trend in the cost of loss of production time because both the predicted cost of loss of production time (SPC V10) and the actual cost of loss of production time (SPC 10) show a similar increasing trend over the period depicted in the graph, as indicated in

Figure 7 and

Table 13. Despite that, the predicted cost of loss of production time (SPC V10) is consistently lower than the actual cost of loss of production time (SPC 10), which indicates that the model may be underestimating the overall cost of loss of production time over 18 months. This could also indicate that the model does not fully capture the cost of loss of production time variable.

4.3. Sensitivity Analysis

A sensitivity analysis was conducted to assess the impact of different interventions and variables on safety climate maturity and performance. Various scenarios were simulated to explore the effects of changes in key variables and parameters. Changes were made to selected variables and parameters within the model, including project management-related factors (MRF), worker-related factors (WRF), site environment-related factors (SRF), external-related factors (ERF), and safety management process-related factors (SMP). These changes were systematically applied across a range of values to assess their impact on safety performance metrics.

4.3.1. Sensitivity Analysis when SP Changed

Hypothesis 1. Safety-Related Factors (SRF) are influenced by the Safety Management process. Changes were made to selected variables and parameters related to safety-related factors and safety management processes. These changes were systematically applied across a range of values to assess their impact on safety performance metrics. For example, a proactive safety management approach may allocate resources towards improving safety-related factors, which in turn enhances safety performance. This forms a reinforcing loop where improvements in safety management lead to better safety-related factors, which further enhance safety performance.

Table 14 represent model distribution for hypothesis one.

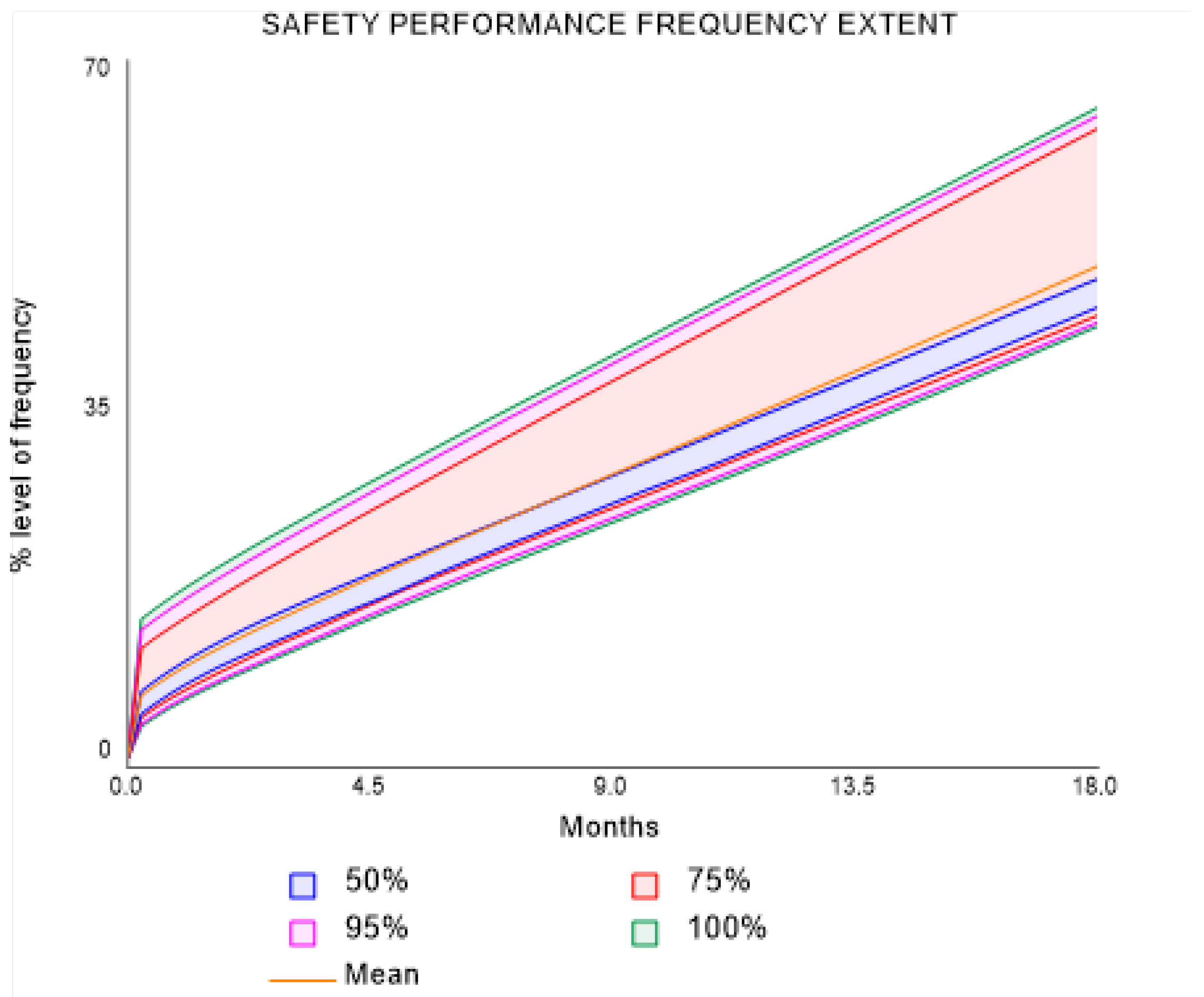

The safety performance extent (SPE) in

Figure 8 appears to be trending significantly over time, as the graph suggests. This indicates that over 18 months, it will become more expensive to maintain a given degree of safety climate.

This can be determined from the fact that the percentile lines (which could be the 50th, 75th, 95th, and 100th) appear to be growing over the months-based x axis. The variation in safety performance extent throughout the 25 scenario analysis runs is shown by the shaded area. The darkened area’s width indicates that this variability rises with time. This implies that the further you look, the more unclear the future extent of preserving safety in a project is.

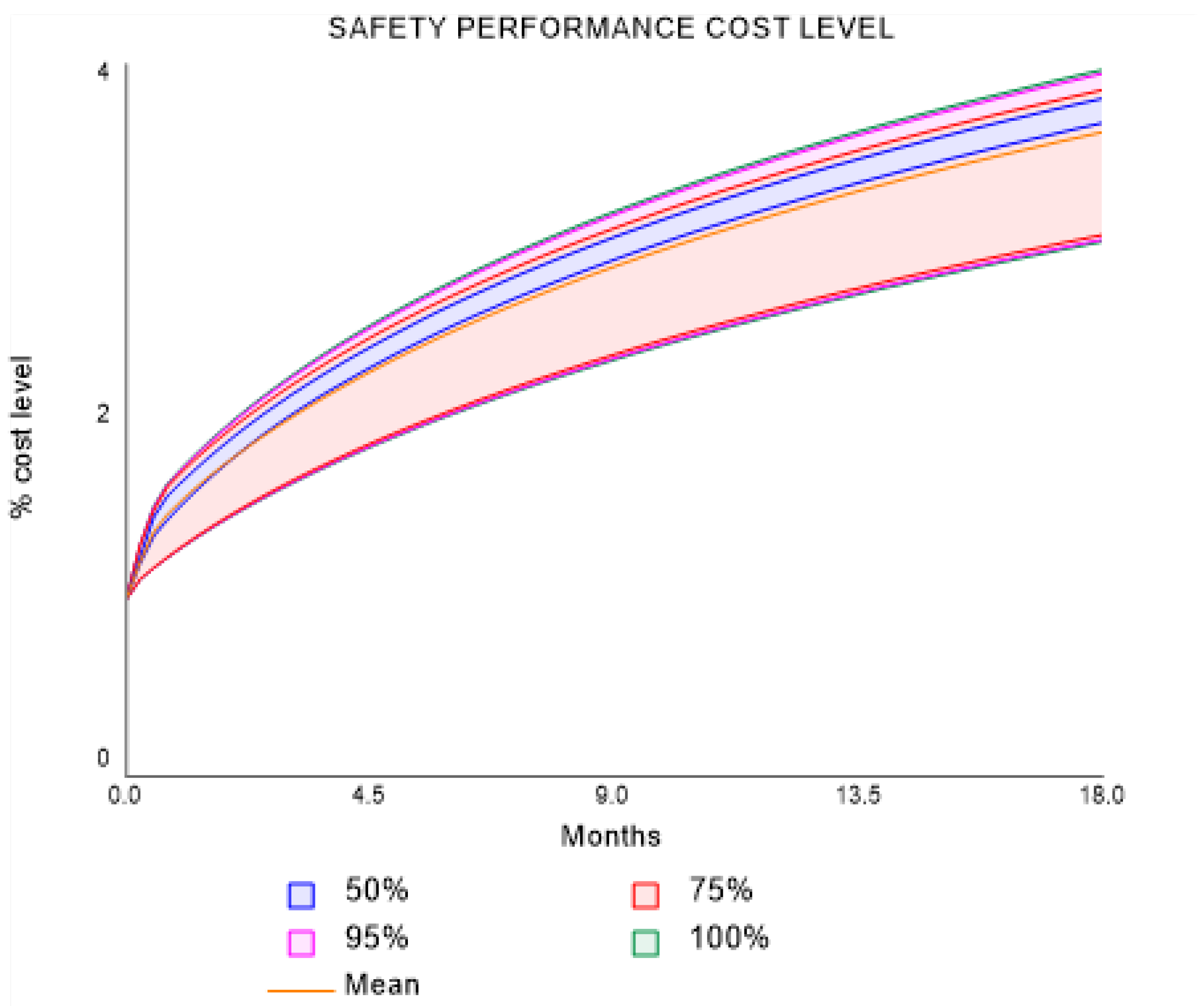

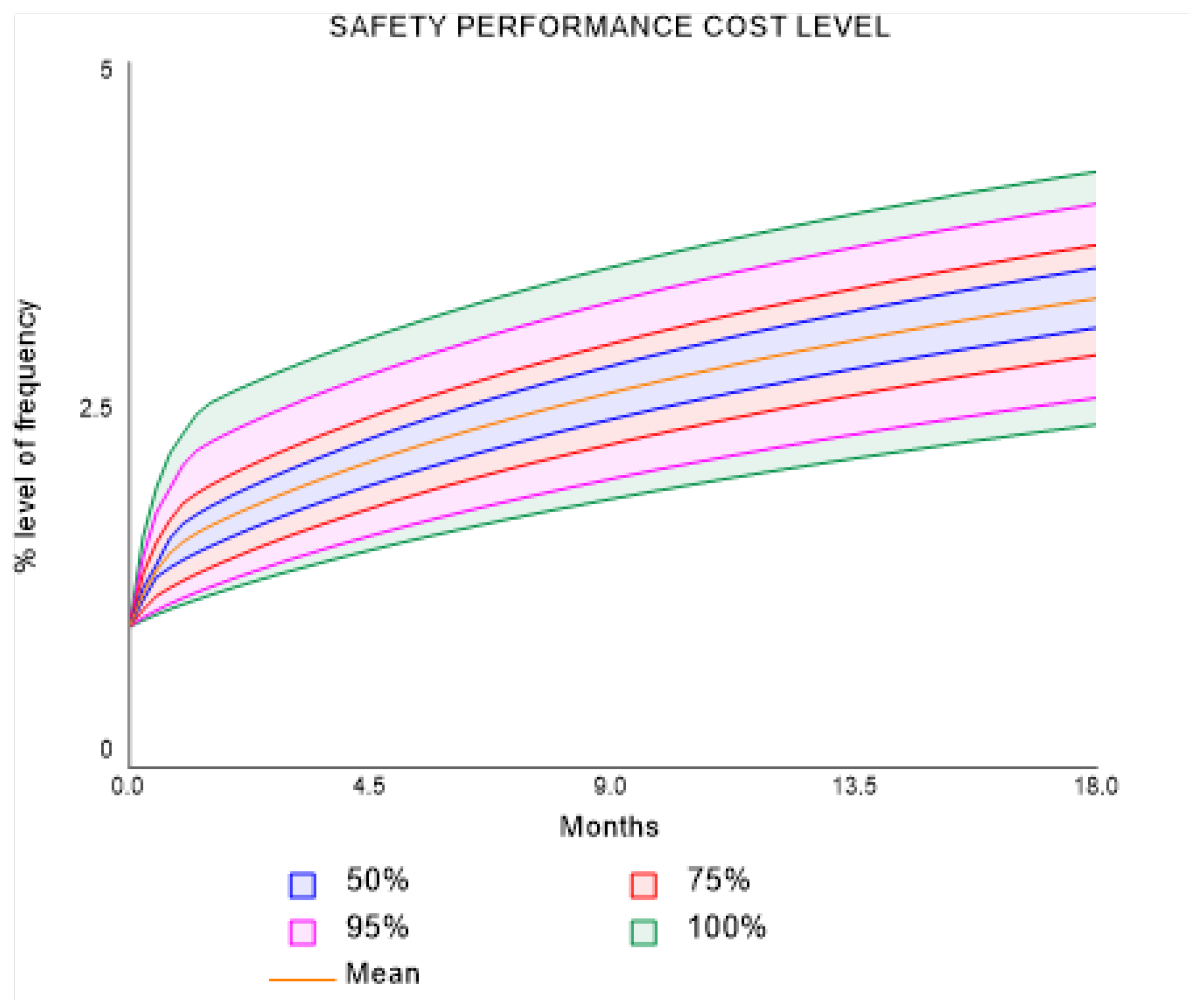

On the other hand, according to the scenario analysis shown in

Figure 9, cost level and safety performance are positively correlated. Both the cost level and safety performance seem to be trending upward throughout the 25 simulations. Over time, it seems that the safety performance cost level rises in all percentiles (50th, 75th, 95th, and 100th). This implies that as time passes, the system’s cost of safe operation will probably increase. The variation in the cost level between the various runs is indicated by the breadth of the darkened area. The spread seems to widen with time, indicating that the farther out you go, the less clear it may be how much it will cost to operate the system safely in the future.

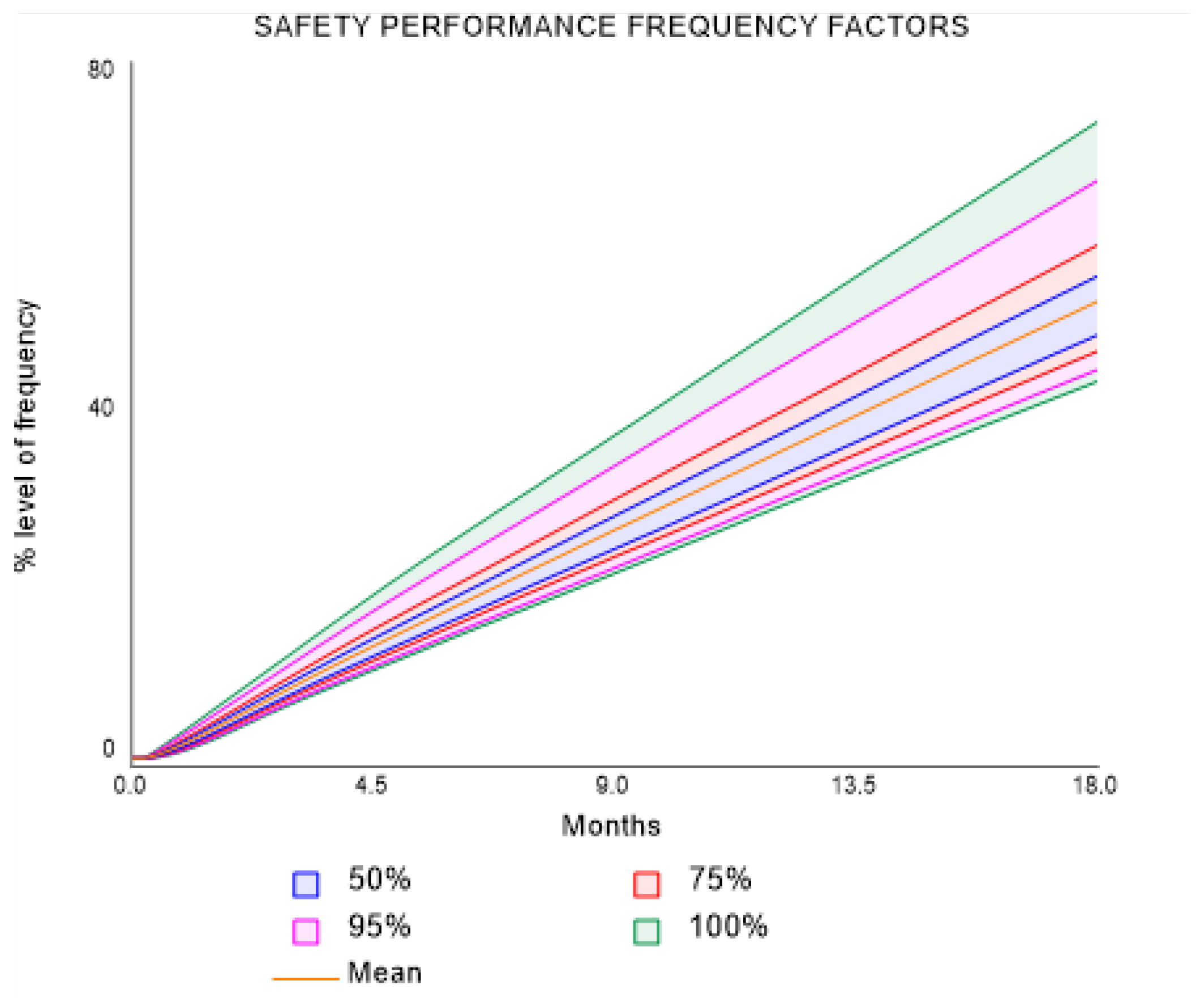

The scenario analysis in

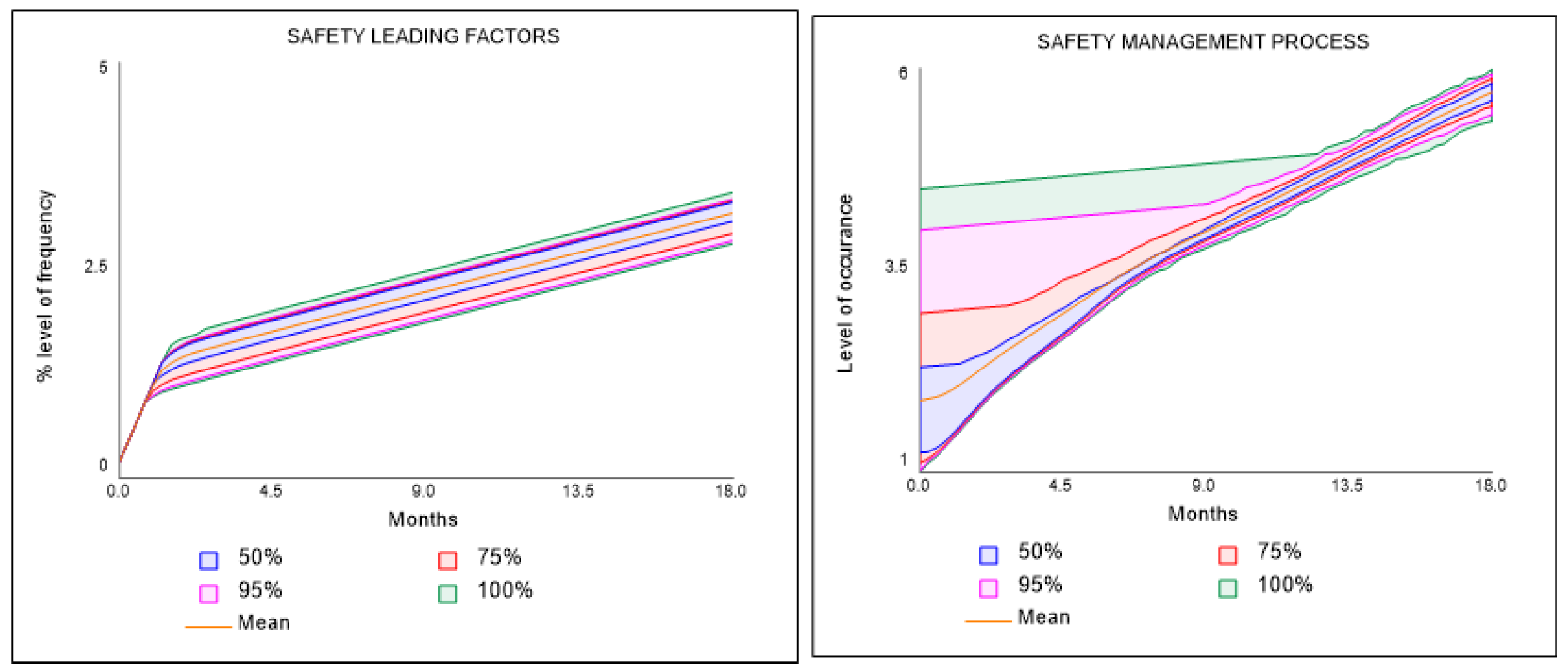

Figure 10 compares safety leading factors with the safety management process to assess their impact on safety outcomes. Both safety leading factors and the safety management process are depicted on separate graphs. The graphs likely show lines representing percentiles (possibly 50th, 75th, 95th, and 100th). It appears the safety leading factors have a higher overall level of occurrence compared to the safety management process (policies, procedures, etc.). This is because the lines for safety leading factors are higher on the graph compared to the safety management process lines. Both graphs show an upward trend over time. This would indicate that both safety leading factors and safety management processes are becoming more effective at preventing accidents over the months. All 25 runs of scenario one are represented in

Table 15.

4.3.2. Sensitivity Analysis when SMP Changed

Hypothesis 2. The safety management process (SMP) is influenced by safety performance (SPF): Positive safety performance outcomes, such as a decrease in accidents or injuries, can enhance the perception and commitment to safety management within the organisation. For example, when safety performance improves, management may be more inclined to allocate resources towards safety initiatives or reinforce safety policies. This forms a reinforcing loop where improvements in safety performance lead to stronger safety management practices.

Table 16 represents its model distribution.

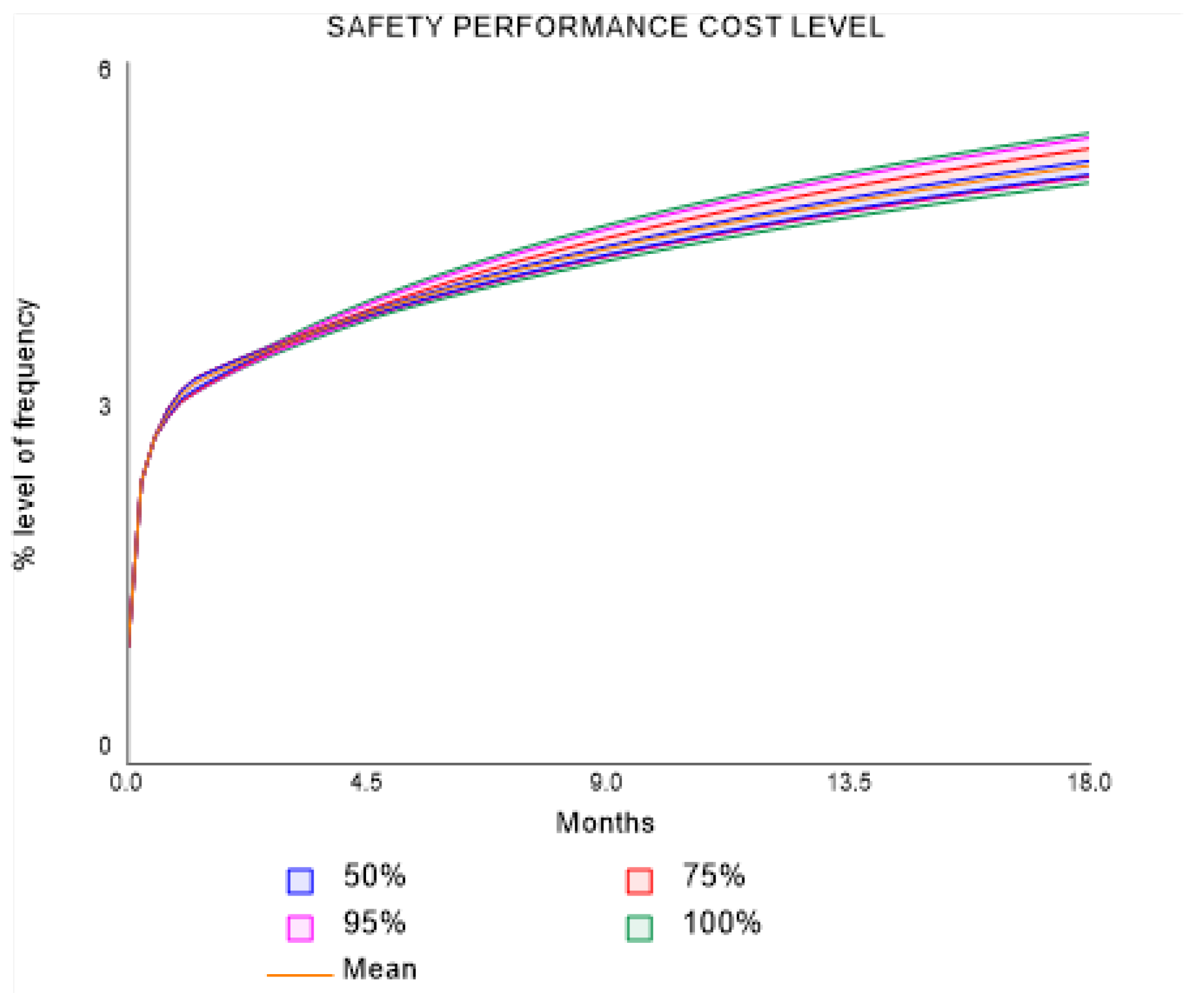

The safety performance frequency appears to be trending upward with time, as indicated by the graph in

Figure 11. This indicates that the probability of safety incidents seems to be increasing over several months. The reason for this is that all of the percentile lines (the 50th, 75th, 95th, and 100th) appear to be advancing along the x axis, which represents months. The range of safety performance frequency throughout the 25 simulations is displayed in the shaded area. The darkened area’s width indicates that this variability rises with time. The same applies to

Figure 11,

Figure 12,

Figure 13 and

Figure 14.

4.3.3. Sensitivity Analysis when SP Changed

Hypothesis 3. Safety Management Process (SMP) influences Safety Performance (SPF): Effective safety management processes, such as clear safety process design or strong leadership commitment to safety, contribute to a safer work environment and fewer accidents, thereby improving safety performance. This is another reinforcing loop where improvements in safety management lead to better safety performance, reinforcing the importance of effective safety management.

Table 17 represents a model distribution when SP changed.

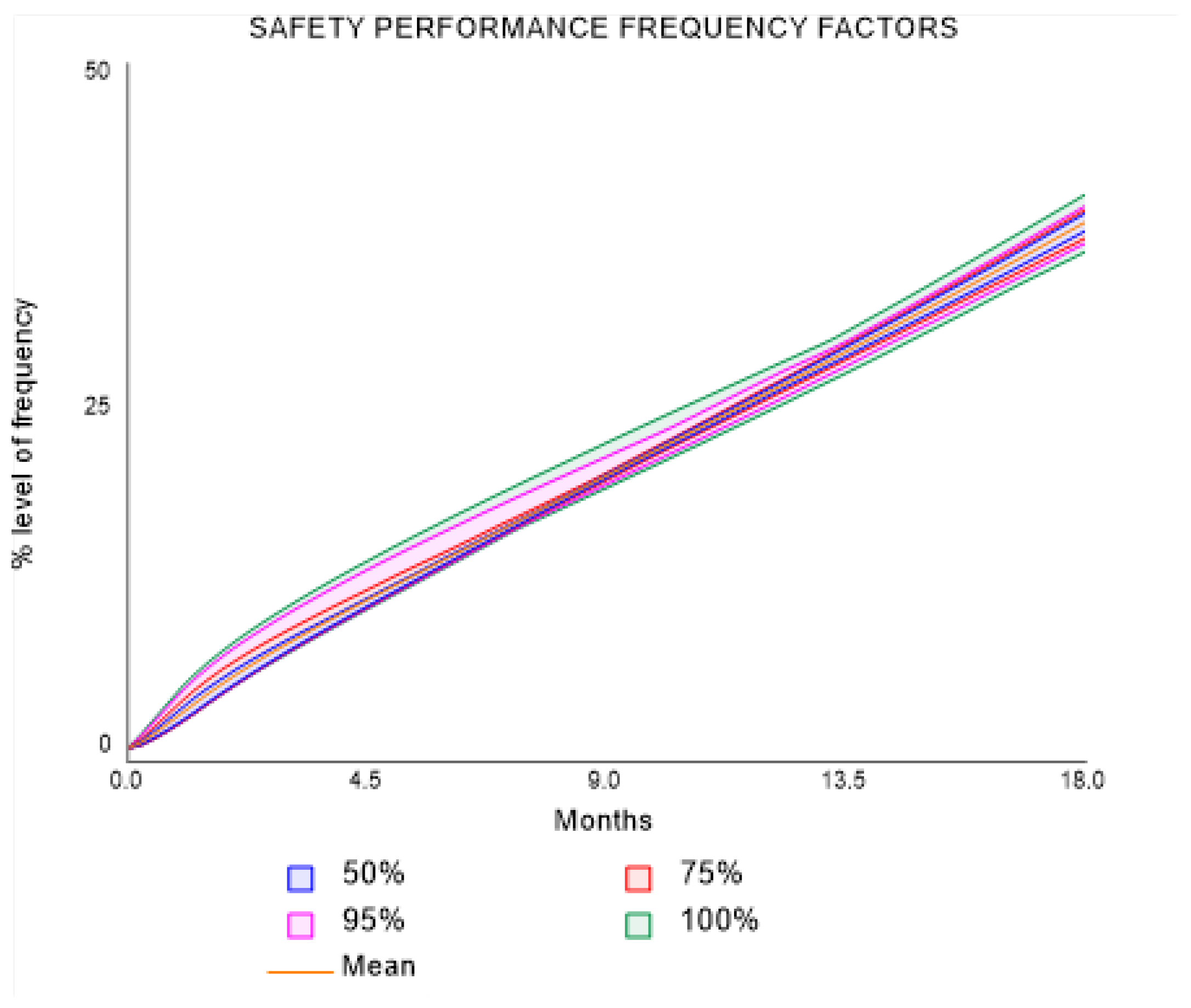

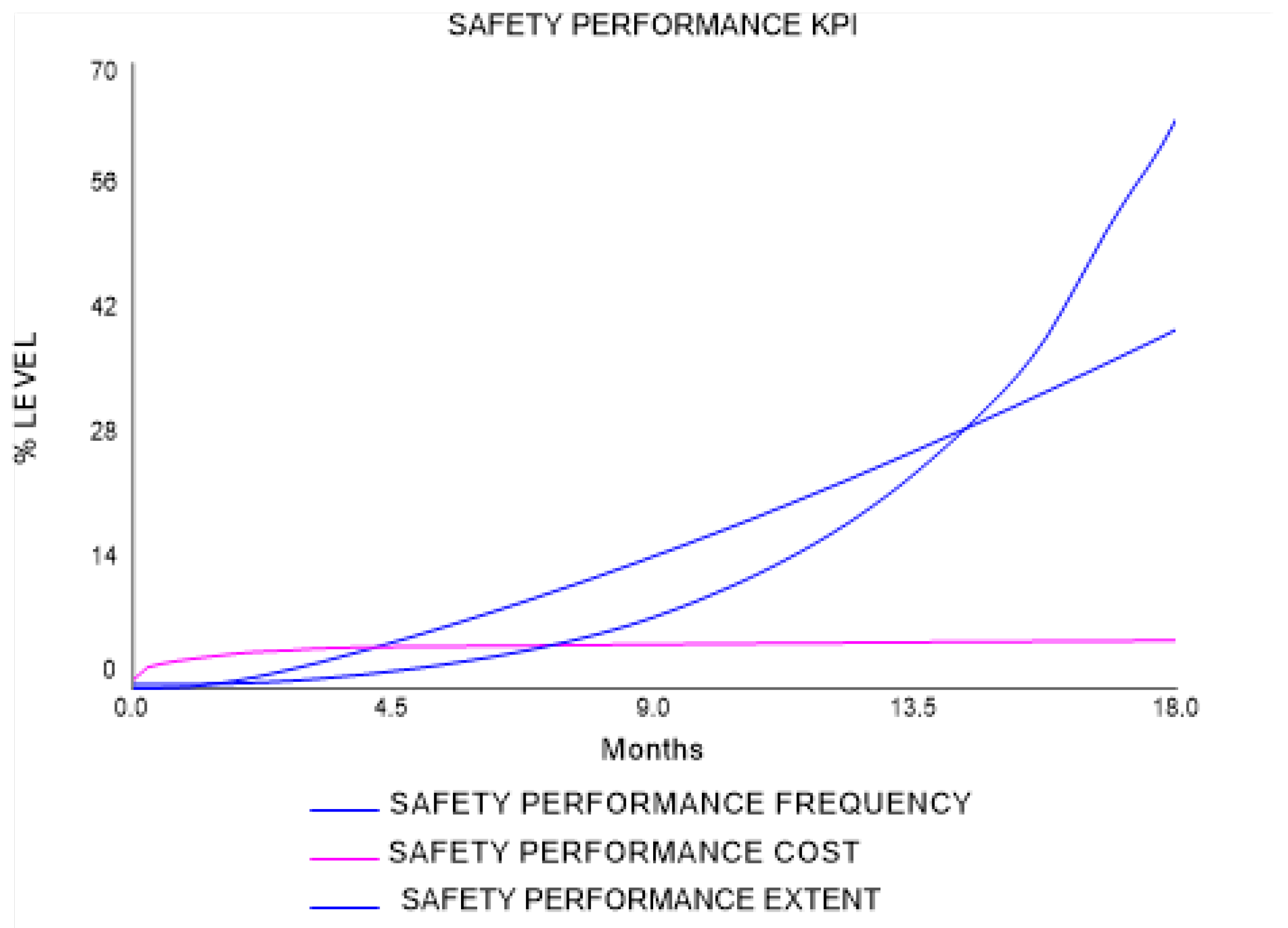

Figure 15,

Figure 16,

Figure 17 and

Figure 18 are the outputs after conducting the sensitivity analysis.

Safety performance metrics including the frequency, extent, and cost of safety incidents were monitored throughout the sensitivity analysis. The model was run for each set of parameter values, and the resulting metrics were recorded and analysed.

The sensitivity analysis revealed several key findings regarding the impact of changes in safety-related factors and safety management processes on safety performance metrics: Frequency of safety incidents: Changes in safety-related factors such as safety training effectiveness and hazard identification had a significant impact on the frequency of safety incidents. Improvements in these factors resulted in lower incident frequencies, while decreases led to higher frequencies.

Extent of safety incidents: Similar trends were observed for the extent of safety incidents. Enhanced safety-related factors and management processes were associated with reduced incident extents, while deterioration led to larger incident extents.

Cost of safety incidents: Changes in safety-related factors and management processes also influenced the cost of safety incidents. Investments in safety training, equipment, and management practices were found to reduce overall safety incident costs, while neglecting these factors led to higher costs due to increased incidents and severity.

Project management-related factors (MRF): Changes in management providing opportunities for feedback and reporting on safety issues to workers were found to have a significant impact on safety performance metrics. Improved management practices led to reductions in the frequency, extent, and cost of safety incidents.

Worker-related factors (WRF): Increases in worker comfort in reporting safety concerns and participating in safety activities such as meetings, training, and inspections were associated with improved safety performance metrics. Enhanced worker engagement resulted in fewer safety incidents and lower associated costs.

Site environment-related factors (SRF): Adequate safety practices to prevent slips, trips, and falls were found to be critical for maintaining safety performance metrics. Investments in site safety infrastructure and practices led to reductions in the frequency, extent, and cost of safety incidents.

External-related factors (ERF): Compliance with industry safety regulations and government inspections were identified as important external factors influencing safety performance metrics. Projects that maintained high levels of compliance and underwent regular inspections demonstrated better safety performance outcomes.

Safety management process-related factors (SMP): The design, implementation, evaluation, and improvement of safety processes and systems were found to have a significant impact on safety performance metrics. Projects that effectively managed safety processes and systems experienced lower frequencies, extents, and costs of safety incidents.

The sensitivity analysis results have important implications for decision making and prioritisation of interventions to improve safety climate maturity in construction projects:

Investment in safety training and equipment: The analysis highlights the importance of investing in safety training programs and equipment to reduce the frequency, extent, and cost of safety incidents. Resources allocated to these areas are likely to yield significant returns in terms of improved safety performance.

Enhanced management commitment: Management commitment to safety emerged as a critical factor influencing safety performance metrics. Organisations should prioritise initiatives aimed at fostering a culture of safety and leadership commitment to ensure positive safety outcomes.

Continuous monitoring and improvement: The findings underscore the need for ongoing monitoring and evaluation of safety-related factors and management processes.

5. Discussion

The simulation results provided valuable insights into the factors influencing safety performance in construction projects in Tanzania. First, safety performance for construction projects is not stagnant but grows exponentially [

105] with time from the beginning of the project to the end of the project, and the performance parameters decline while safety performance grows, as seen in

Figure 19. This differs from the research conducted by Mahmoud, who presented the concept that safety performance in construction projects does not grow exponentially [

106].

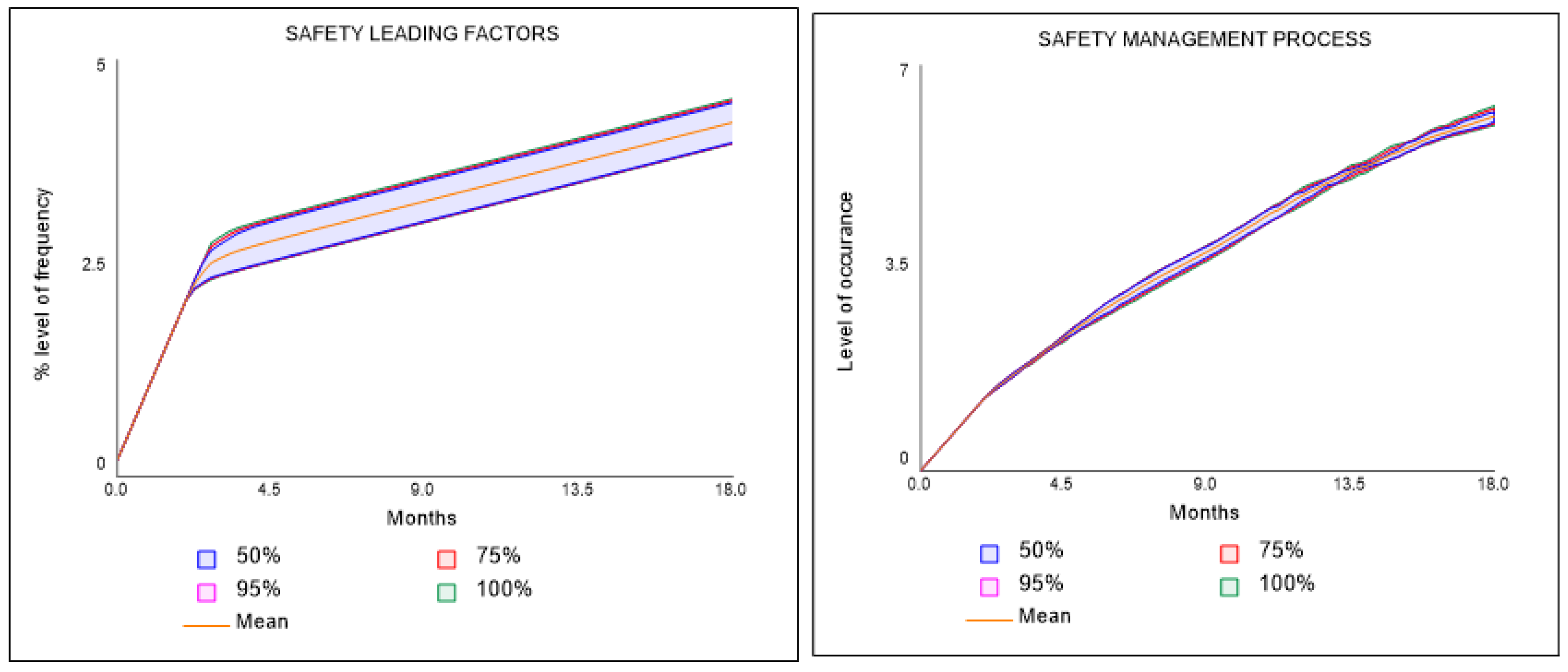

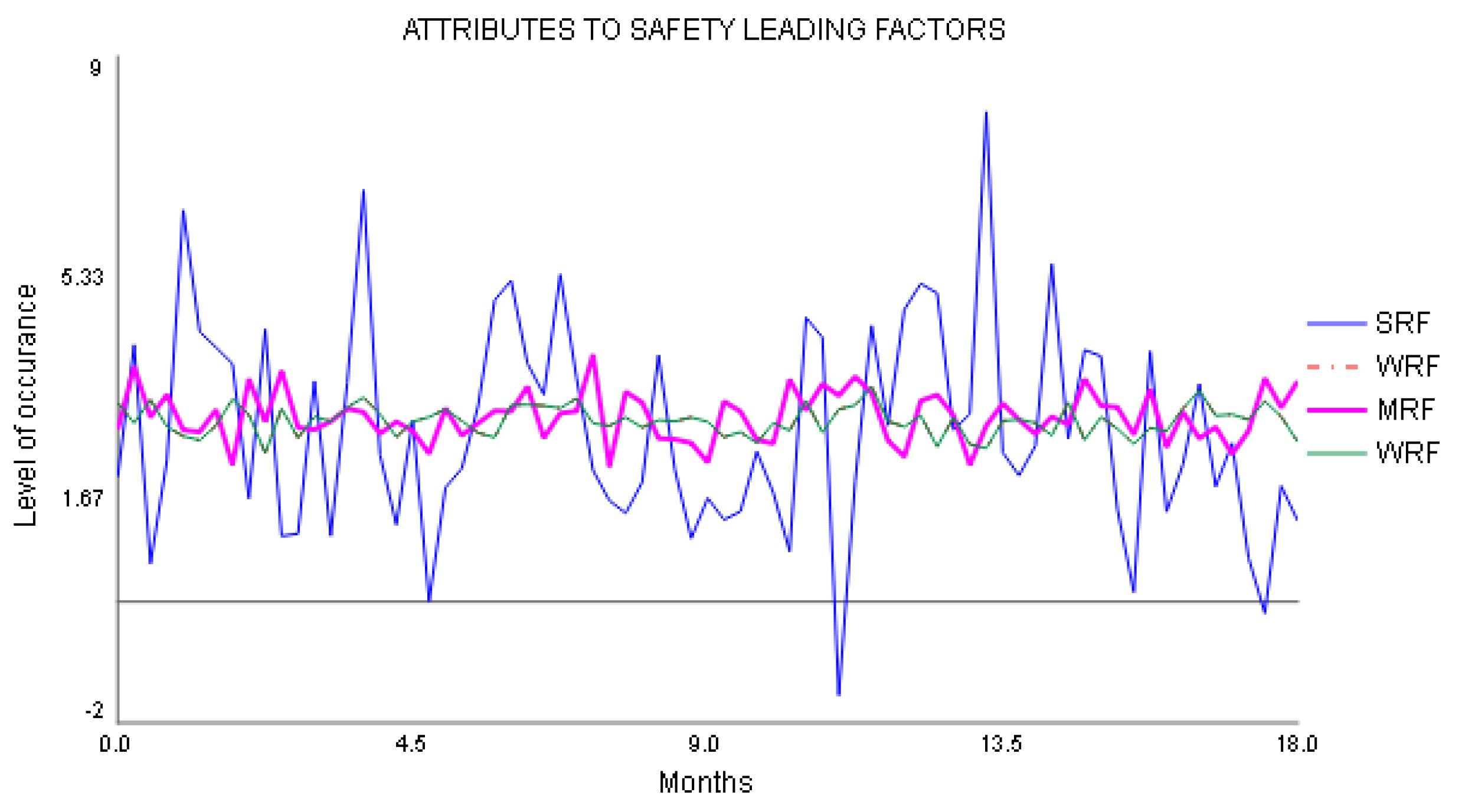

Second, the safety management process, including commitment to safety as a driving force behind safety climate maturity, is important; therefore, the safety management process is expected to rise exponentially at the beginning of the project [

107,

108] and to grow steadily as the project execution approaches its end. This strongly signifies that for an effective safety management process, the project will attain a safety maturity climate at the beginning phase of the project because the safety management process will be implemented at a high rate. About monitoring and controlling, safety leading factors and safety initiatives were found to have a significant positive impact on safety performance. This differs totally from the findings established about the safety management process, and they may not rise exponentially at the project’s start, which may be caused by engineers’ obtrusive habits and lack of integrated tools for safety-critical systems.

The patterns or trends in the relationship between SLF, SMP, and the frequency of accidents as shown in

Figure 20 and

Figure 21 indicate a strong correlation between these factors. This is because of an upward trend in the data points, suggesting that as the SMP and SRF ratings increase, the frequency of incidents might also increase [

105,

109].

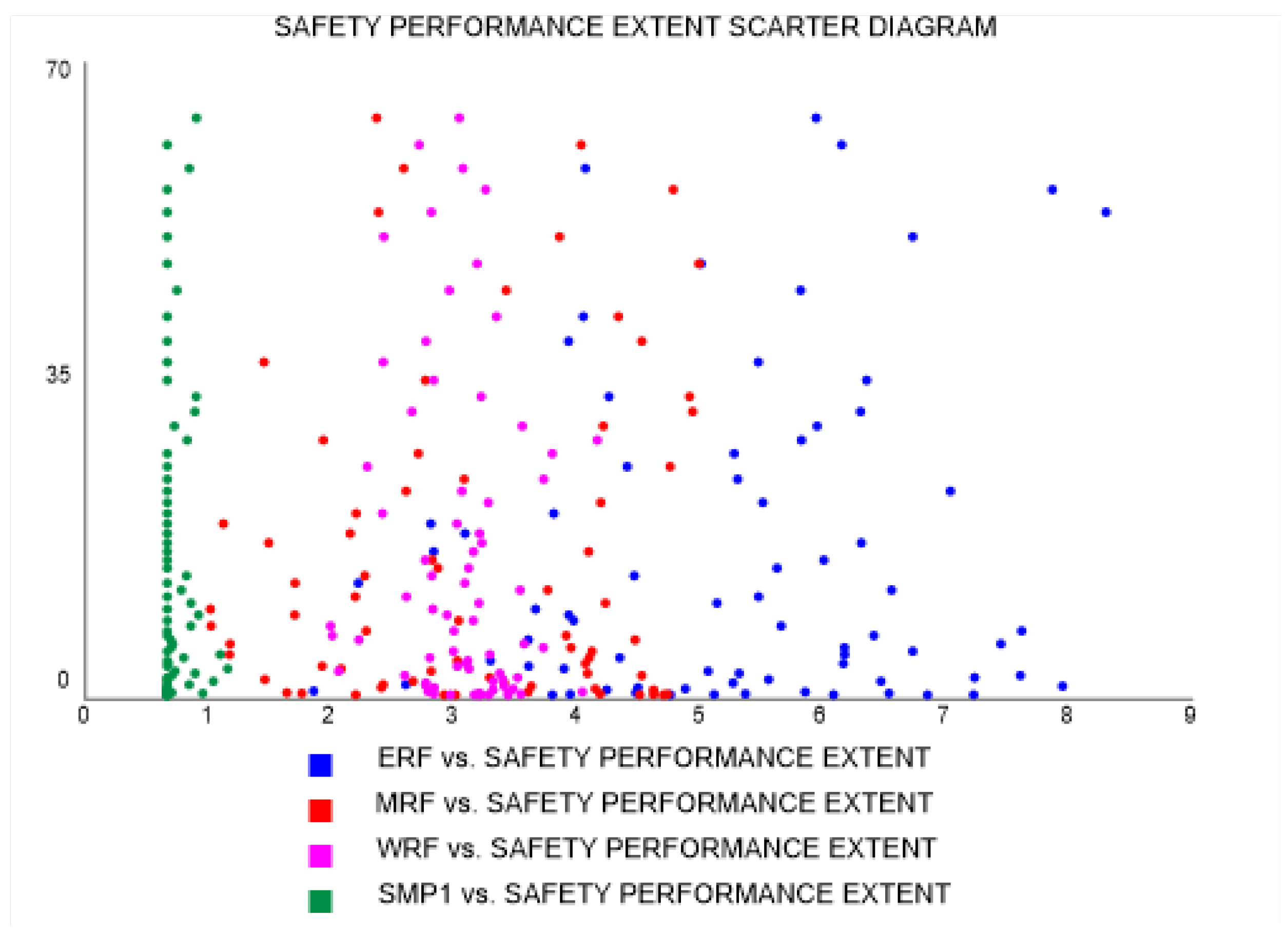

By observing the position of the data points in

Figure 22, it can be inferred that there are some potential relationships between the four factors (ERF, MRF, WRF, SMP1) and the extent of the safety performance. The data points for each factor are somewhat scattered, which means there might not be a strong linear correlation between each factor and the safety performance extent. However, there could be some underlying patterns. There might be a few data points that appear farther away from the main cluster for each factor. These could be outliers, representing unique cases where a factor has a significantly different impact on safety performance extent compared to other cases.

Thirdly, the role of the safety management process in safety performance highlights the importance of fostering a culture of safety awareness and participation among workers. Also, the impact of safety leading factors, including site-related factors, work-related factors, management-related factors, and environmental-related factors, on safety climate maturity is demonstrated, with adherence to safety regulations contributing to improved safety performance.

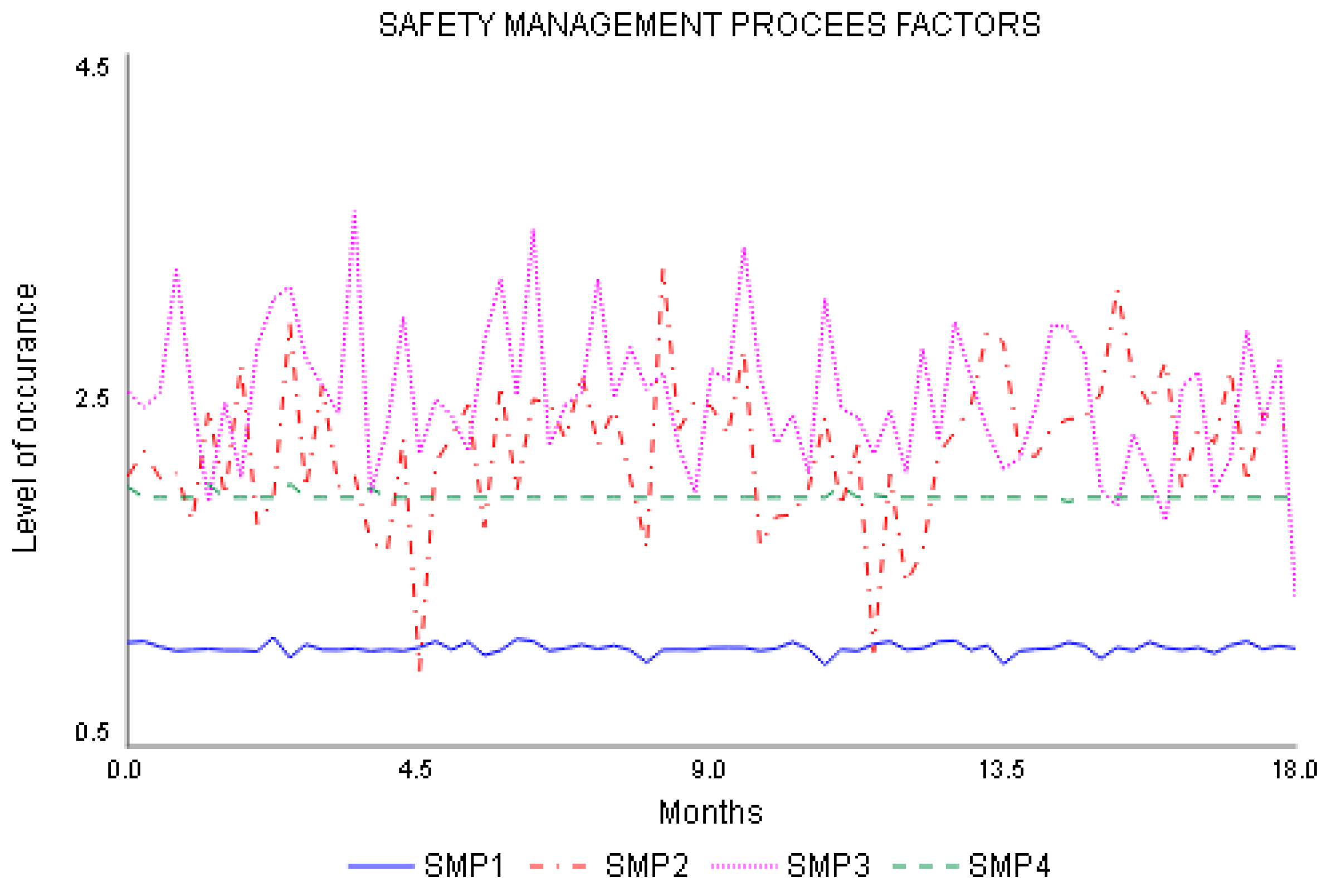

A comparison of SMP2 and SMP4 to SMP1 and SMP3 in

Figure 23 indicates that they tend to occur at higher rates. This is because compared to SMP1 and SMP3, the data points for SMP2 and SMP4 are generally located higher on the y axis. It is possible to see some variations in the incidence levels of each SMP factor. For instance, it appears that SMP3 occurs at a reasonably high level throughout months 6 and 12, whereas SMP1 occurs at a lesser level during the same months. The data points’ scatter indicates that there are differences in the occurrence levels between the SMP components. Throughout the entire duration, no single SMP factor has the highest or lowest amount of occurrences continuously.

However, the complex interplay between safety climate and safety performance emphasises the need for cultural alignment with safety goals and values [

110]. The scenario analysis revealed the potential benefits of interventions such as enhanced safety training programs, improved communication channels, and increased resource allocation to safety initiatives [

111]. These interventions, shown in

Figure 24, were found to lead to improvements in safety climate and performance, with reductions in safety incidents, accidents, injuries, fatalities, financial losses, and production time loss and with enhanced worker morale.

6. Conclusions

In conclusion, the sensitivity analysis conducted on the system dynamics model provided valuable insights into the factors influencing safety performance metrics in construction projects. By assessing the impact of changes in project management-related factors, worker-related factors, site environment-related factors, external-related factors, and safety management process-related factors, the analysis offers important insights for decision making and intervention prioritisation to improve safety performance.

This research journey, guided by the powerful lens of system dynamics, revealed the complicated relationships that shape the safety climate in Tanzania’s construction industry. It went beyond static snapshots and simulated a dynamic web of factors such as worker comfort, worker involvement in safety activities, inspection by government safety agencies, presence of risk assessment, regular safety reviews, provision of safety feedback, and changes in safety communications by tailoring our model to the Tanzanian context and capturing the unique challenges and opportunities that exist in the East African country’s construction landscape.

The system dynamics model simulation provided valuable insights into the dynamics of safety climate maturity in construction projects in Tanzania. By integrating data-driven insights with dynamic feedback mechanisms, the simulation model offers a powerful tool for understanding and improving safety performance in the construction industry. The findings and recommendations from this study can inform policy decisions and interventions aimed at enhancing safety climate maturity and fostering a culture of safety in construction projects. Based on the findings of the simulation study, the following recommendations are suggested for improving safety performance in construction projects in Tanzania:

Strengthen management commitment to safety through clear policies, leadership support, and resource allocation;

Enhance workers’ engagement with safety practices through training programs, communication channels, and participatory initiatives;

Ensure compliance with safety regulations and standards through regular audits, inspections, and enforcement measures;

Foster a positive safety climate that values safety, promotes open communication, and encourages continuous improvement.

This study contributes facts on the status of safety climate according to the established SDM model, it introduced a new definition of safety climate (as a product of safety leading factors, safety management process factors, and safety performance factors), and it introduced the SDM model from another analysis method (SmartPLS to Stella) for building construction projects in Tanzania.

This study has several limitations. During simulation, complex, spatially distributed physical processes were difficult for the SDM model to accurately represent. To overcome this constraint, system dynamics can be combined with additional modelling techniques such as the analytical hierarchy process (AHP).

Occasionally, the SD model did not produce quantitative predictions with sufficient accuracy, particularly when describing intricate safety performance categories. A significant amount of data must be calibrated and verified, which can demand a lot of resources.

Conversely, the SDM model aggregates and oversimplifies system representations. High levels of aggregation may not be sufficient to capture important safety management processes, which frequently take place at finer spatial and temporal scales. This restriction can be lessened by beginning with a broad aggregate model and progressively adding more specifics.

However, spatial variability or system elements such as those established by safety lading factors and safety management processes within the modelled system are not explicitly represented by SD models. Although attempts have been made, it is still difficult to include spatial elements in system dynamics modelling. Furthermore, the SDM does not permit the simultaneous examination of multiple scenarios, even though it captures the diversity of changing variable values as has been observed during the simulation of various sensitivity analysis scenarios.

The practical utility of data was limited and depended on another system of collecting and other program/software analysing it (Smart PLS 4 version 4.0.9.6), which may affect the simulation results.

Conclusively, while system dynamics modelling offers significant perspectives on intricate systems, scholars and professionals must acknowledge these constraints and take them into account when utilising this approach in diverse domains.

Author Contributions

Conceptualization, K.K. and J.M.; methodology, K.K.; software, K.K.; validation, K.K., J.M. and F.M.; formal analysis, K.K.; investigation, K.K.; resources, K.K.; data curation, K.K.; writing—original draft preparation, K.K.; writing—review and editing, J.M.; visualization, F.M.; supervision, J.M. and F.M.; project administration, K.K.; funding acquisition, K.K., J.M. and F.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

The study was conducted according to the Declaration of Helsinki and approved by the Institutional Review Board (or Ethics Committee) of the University of Dar es Salaam (protocol code 17 of 10 March 2020.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

Data are available upon personal request.

Acknowledgments

The authors are very grateful to Adam Mwangaila for his kind and helpful discussion of the paper.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Kajumulo, K.; Matindana, J.; Mohamed, F. Exploring Current and future Research trends on safety climate in construction projects. Tanzan. J. Eng. Technol. 2023, 42, 113–134. [Google Scholar] [CrossRef]

- Kikwasi, G.J. An evaluation of construction skills in Tanzania. Eng. Constr. Archit. Manag. 2011, 18, 127–139. [Google Scholar] [CrossRef]

- Mbilinyi, J.M. Analysis of Occupational Health and Safety in Construction Industry in Tanzania. Ph.D. Thesis, The Open University Of Tanzania, Dar es Salaam, Tanzania, 2015. [Google Scholar]

- Mwemezi, B.R.; Kikwasi, G.J.; Phoya, S. The Paradox of Health and Safety Risks: A Disclose of Handling Strategies in Informal Construction Sites in Tanzania. Indones. J. Occup. Saf. Health 2023, 12, 372–381. [Google Scholar] [CrossRef]

- Wangwe, S.; Mmari, D.; Aikaeli, J.; Rutatina, N.; Mboghoina, T.; Kinyondo, A. The Performance of the Manufacturing Sector in Tanzania: Challenges and the Way Forward; Technical report, WIDER Working Paper; The United Nations University World Institute for Development Economics Research (UNU-WIDER): Helsinki, Finland, 2014. [Google Scholar]

- Mrema, E.J.; Ngowi, A.V.; Mamuya, S.H. Status of occupational health and safety and related challenges in expanding economy of Tanzania. Ann. Glob. Health 2015, 81, 538–547. [Google Scholar] [CrossRef]

- Chan, A.P.; Yang, Y.; Choi, T.N.; Nwaogu, J.M. Characteristics and causes of construction accidents in a large-scale development project. Sustainability 2022, 14, 4449. [Google Scholar] [CrossRef]

- Folkard, S.; Tucker, P. Shift work, safety and productivity. Occup. Med. 2003, 53, 95–101. [Google Scholar] [CrossRef]

- Nyabioge, B.M.; Wachira-Towey, I.N.; Ralwala, A.O. Safety in Building Construction Works: A Review of the Causes of Accidents and Safety Regulations Requirements in Kenya. J. Kenya Natl. Comm. UNESCO 2022, 2, 2958–7999. [Google Scholar]

- Nabi, M.A.; El-adaway, I.H.; Dagli, C. A system dynamics model for construction safety behavior. Procedia Comput. Sci. 2020, 168, 249–256. [Google Scholar] [CrossRef]

- Guo, B.H.; Goh, Y.M.; Wong, K.L.X. A system dynamics view of a behavior-based safety program in the construction industry. Saf. Sci. 2018, 104, 202–215. [Google Scholar] [CrossRef]

- Trinh, M.T.; Feng, Y. Impact of project complexity on construction safety performance: Moderating role of resilient safety culture. J. Constr. Eng. Manag. 2020, 146, 04019103. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, X.; Luo, X.; Zhao, T. Reliability model and critical factors identification of construction safety management based on system thinking. J. Civ. Eng. Manag. 2019, 25, 362–379. [Google Scholar] [CrossRef]

- Gao, Y.; Gonzalez, V.A.; Yiu, T.W. The effectiveness of traditional tools and computer-aided technologies for health and safety training in the construction sector: A systematic review. Comput. Educ. 2019, 138, 101–115. [Google Scholar] [CrossRef]

- Guo, H.; Yiu, T.W. How traditional construction safety performance indicators fail to capture the reality of safety. In Proceedings of the 38th Australasian Universities Building Education Association Conference, Auckland, New Zealand, 20–22 November 2013. [Google Scholar]

- Ryu, H.; Ha, S.; Son, K.; Son, S. Development of a quantification model for human accidents on construction sites in South Korea. J. Asian Archit. Build. Eng. 2021, 20, 760–767. [Google Scholar] [CrossRef]

- Mohammadi, A.; Tavakolan, M.; Khosravi, Y. Developing safety archetypes of construction industry at project level using system dynamics. J. Saf. Res. 2018, 67, 17–26. [Google Scholar] [CrossRef]

- Thompson, B.P.; Bank, L.C. Use of system dynamics as a decision-making tool in building design and operation. Build. Environ. 2010, 45, 1006–1015. [Google Scholar] [CrossRef]

- Karnopp, D.C.; Margolis, D.L.; Rosenberg, R.C. System Dynamics: Modeling, Simulation, and Control of Mechatronic Systems; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Pinion, C.; Klyza, J., Jr.; Brewer, S.; Douphrate, D. North American engineering, procurement, fabrication and construction worker safety climate perception affected by job position. Safety 2018, 4, 14. [Google Scholar] [CrossRef]

- Abas, N.; Yusuf, N.; Suhaini, N.; Kariya, N.; Mohammad, H.; Hasmori, M. Factors affecting safety performance of construction projects: A literature review. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: The 2nd Global Congress on Construction, Material and Structural Engineering 26–27 August 2019; IOP Publishing: Melaka, Malaysia, 2020; Volume 713, p. 012036. [Google Scholar]

- Al-Bayati, A.J. Impact of construction safety culture and construction safety climate on safety behavior and safety motivation. Safety 2021, 7, 41. [Google Scholar] [CrossRef]

- Lestari, F.; Modjo, R.; Wibowo, A.; Sunindijo, R.Y. Influence of safety climate on safety performance in gas stations in Indonesia. Safety 2023, 9, 44. [Google Scholar] [CrossRef]

- Zhou, Z.; Goh, Y.M.; Li, Q. Overview and analysis of safety management studies in the construction industry. Saf. Sci. 2015, 72, 337–350. [Google Scholar] [CrossRef]

- Mohammadi, A.; Tavakolan, M.; Khosravi, Y. Factors influencing safety performance on construction projects: A review. Saf. Sci. 2018, 109, 382–397. [Google Scholar] [CrossRef]

- Lingard, H.; Hallowell, M.; Salas, R.; Pirzadeh, P. Leading or lagging? Temporal analysis of safety indicators on a large infrastructure construction project. Saf. Sci. 2017, 91, 206–220. [Google Scholar] [CrossRef]

- Neamat, S.D.S. A comparative study of safety leading and lagging indicators measuring project safety performance. Indicators 2019, 1, 29. [Google Scholar] [CrossRef]

- Pawłowska, Z. Using lagging and leading indicators for the evaluation of occupational safety and health performance in industry. Int. J. Occup. Saf. Ergon. 2015, 21, 284–290. [Google Scholar] [CrossRef]

- Payne, S.C.; Bergman, M.E.; Beus, J.M.; Rodríguez, J.M.; Henning, J.B. Safety climate: Leading or lagging indicator of safety outcomes? J. Loss Prev. Process. Ind. 2009, 22, 735–739. [Google Scholar] [CrossRef]

- Sheehan, C.; Donohue, R.; Shea, T.; Cooper, B.; De Cieri, H. Leading and lagging indicators of occupational health and safety: The moderating role of safety leadership. Accid. Anal. Prev. 2016, 92, 130–138. [Google Scholar] [CrossRef] [PubMed]

- Tang, D.K.H.; Dawal, S.Z.M.; Olugu, E.U. Actual safety performance of the Malaysian offshore oil platforms: Correlations between the leading and lagging indicators. J. Saf. Res. 2018, 66, 9–19. [Google Scholar] [CrossRef]

- Versteeg, K.; Bigelow, P.; Dale, A.M.; Chaurasia, A. Utilizing construction safety leading and lagging indicators to measure project safety performance: A case study. Saf. Sci. 2019, 120, 411–421. [Google Scholar] [CrossRef]

- Besteiro, É.N.C.; de Souza Pinto, J.; Novaski, O. Success factors in project management. Bus. Manag. Dyn. 2015, 4, 19–34. [Google Scholar]

- D’Antoine, E.; Jansz, J.; Barifcani, A.; Shaw-Mills, S.; Harris, M.; Lagat, C. Psychosocial Safety and Health Hazards and Their Impacts on Offshore Oil and Gas Workers. Safety 2023, 9, 56. [Google Scholar] [CrossRef]

- Gunduz, M.; Almuajebh, M. Critical success factors for sustainable construction project management. Sustainability 2020, 12, 1990. [Google Scholar] [CrossRef]

- Martens, M.L.; Carvalho, M.M. Key factors of sustainability in project management context: A survey exploring the project managers’ perspective. Int. J. Proj. Manag. 2017, 35, 1084–1102. [Google Scholar] [CrossRef]

- Dong, X.S.; Wang, X.; Largay, J.A. Occupational and non-occupational factors associated with work-related injuries among construction workers in the USA. Int. J. Occup. Environ. Health 2015, 21, 142–150. [Google Scholar] [CrossRef] [PubMed]

- Hertanto, A.; Erwandi, D.; Widanarko, B.; Tejamaya, M. Relationship between safety climate and safety behavior in company X in Indonesia. Safety 2023, 9, 89. [Google Scholar] [CrossRef]

- Spangenberg, S.; Baarts, C.; Dyreborg, J.; Jensen, L.; Kines, P.; Mikkelsen, K.L. Factors contributing to the differences in work related injury rates between Danish and Swedish construction workers. Saf. Sci. 2003, 41, 517–530. [Google Scholar] [CrossRef]

- Dennerlein, J.T.; Eyllon, M.; Garverich, S.; Weinstein, D.; Manjourides, J.; Vallas, S.P.; Lincoln, A.K. Associations between work-related factors and psychological distress among construction workers. J. Occup. Environ. Med. 2021, 63, 1052–1057. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.S.; Kim, H.; Park, M.; Ai Lin Teo, E.; Lee, K.P. Construction risk assessment using site influence factors. J. Comput. Civ. Eng. 2012, 26, 319–330. [Google Scholar] [CrossRef]

- Vipin, V.; Rahima Shabeen, S. Factors affecting material management in construction industry. Int. J. Recent Technol. Eng. 2019, 8, 8445–8448. [Google Scholar]

- Khosravi, Y.; Asilian-Mahabadi, H.; Hajizadeh, E.; Hassanzadeh-Rangi, N.; Bastani, H.; Behzadan, A.H. Factors influencing unsafe behaviors and accidents on construction sites: A review. Int. J. Occup. Saf. Ergon. 2014, 20, 111–125. [Google Scholar] [CrossRef]

- Vrouva, S.; Sopidou, V.; Sifakis, E.; Ntoulaveris, I.; Papamarkos, G.; Tse, G.; Chanopoulos, K.; Koumantakis, G. Chronic Sufferers and Environmental Conditions. Safety 2023, 9, 85. [Google Scholar] [CrossRef]

- Adeleke, A.; Bahaudin, A.Y.; Kamaruddeen, A.; Bamgbade, J.; Salimon, M.G.; Khan, M.W.A.; Sorooshian, S. The influence of organizational external factors on construction risk management among Nigerian construction companies. Saf. Health Work. 2018, 9, 115–124. [Google Scholar] [CrossRef]

- Adeleke, A.; Bahaudin, A.; Kamaruddeen, A.; Bamgbade, J.; Ali, M.W. An empirical analysis of organizational external factors on construction risk management. Int. J. Supply Chain. Manag. 2019, 8, 932–940. [Google Scholar]

- Muñoz-La Rivera, F.; Mora-Serrano, J.; Oñate, E. Factors influencing safety on construction projects (Fscps): Types and categories. Int. J. Environ. Res. Public Health 2021, 18, 10884. [Google Scholar] [CrossRef]

- Salem, A.; Simpeh, E.; Fapohunda, J. Construction stakeholder’s perspective on external related risk factors influencing construction project performance. J. Constr. Proj. Manag. Innov. 2020, 10, 70–85. [Google Scholar]

- Selleck, R.; Cattani, M.; Hassall, M. How did COVID-19 pandemic impact safety performance on a construction project? A case study comparing pre and post COVID-19 influence on safety at an Australian construction site. Safety 2022, 8, 77. [Google Scholar] [CrossRef]

- Ismail, Z.; Doostdar, S.; Harun, Z. Factors influencing the implementation of a safety management system for construction sites. Saf. Sci. 2012, 50, 418–423. [Google Scholar] [CrossRef]

- Kunodzia, R.; Bikitsha, L.S.; Haldenwang, R. Perceived factors affecting the implementation of occupational health and safety management systems in the South African construction industry. Safety 2024, 10, 5. [Google Scholar] [CrossRef]

- Men, J. Application of safety management system in building construction based on BIM and PDCA theory. Acad. J. Archit. Geotech. Eng. 2022, 4, 16–21. [Google Scholar]

- Sutanto, F.P.; Setiawan, B.; Mauludin, A.; Zuraida, R. Deming Cycle Utilization In Construction Project For Modular Building Construction For Oil And Gas Industry. J. Tekno 2023, 20, 1–14. [Google Scholar] [CrossRef]

- Cooper, M.D. Behavioral safety interventions a review of process design factors. Prof. Saf. 2009, 54, 36–45. [Google Scholar]

- Roy, N.; Eljack, F.; Jiménez-Gutiérrez, A.; Zhang, B.; Thiruvenkataswamy, P.; El-Halwagi, M.; Mannan, M.S. A review of safety indices for process design. Curr. Opin. Chem. Eng. 2016, 14, 42–48. [Google Scholar] [CrossRef]

- Al Haadir, S.; Panuwatwanich, K. Critical success factors for safety program implementation among construction companies in Saudi Arabia. Procedia Eng. 2011, 14, 148–155. [Google Scholar] [CrossRef]

- Carvalho, K.M.; Picchi, F.; Camarini, G.; Edna, M. Benefits in the implementation of safety, health, environmental and quality integrated system. Int. J. Eng. Technol. 2015, 7, 333. [Google Scholar] [CrossRef][Green Version]

- Bridges, J.; May, C.; Fuller, A.; Griffiths, P.; Wigley, W.; Gould, L.; Barker, H.; Libberton, P. Optimising impact and sustainability: A qualitative process evaluation of a complex intervention targeted at compassionate care. BMJ Qual. Saf. 2017, 26, 970–977. [Google Scholar] [CrossRef] [PubMed]

- Khan, F.; Rathnayaka, S.; Ahmed, S. Methods and models in process safety and risk management: Past, present and future. Process. Saf. Environ. Prot. 2015, 98, 116–147. [Google Scholar] [CrossRef]

- Chang, J.I.; Liang, C.L. Performance evaluation of process safety management systems of paint manufacturing facilities. J. Loss Prev. Process. Ind. 2009, 22, 398–402. [Google Scholar] [CrossRef]

- Van Scyoc, K. Process safety improvement—Quality and target zero. J. Hazard. Mater. 2008, 159, 42–48. [Google Scholar] [CrossRef] [PubMed]

- Johnson, C.D.; Miranda, R.; Aakre, K.T.; Roberts, C.C.; Patel, M.D.; Krecke, K.N. Process improvement: What is it, why is it important, and how is it done? Am. J. Roentgenol. 2010, 194, 461–468. [Google Scholar] [CrossRef] [PubMed]

- Chan, A.P.; Guan, J.; Choi, T.N.; Yang, Y.; Wu, G.; Lam, E. Improving safety performance of construction workers through learning from incidents. Int. J. Environ. Res. Public Health 2023, 20, 4570. [Google Scholar] [CrossRef] [PubMed]

- Memarian, B.; Mitropoulos, P. Safety incidents and high-risk activities of masonry construction. In Proceedings of the Construction Research Congress 2012: Construction Challenges in a Flat World, West Lafayette, IN, USA, 21–23 May 2012; pp. 2510–2519. [Google Scholar]

- Saurin, T.A.; Formoso, C.T.; Reck, R.; Beck da Silva Etges, B.M.; Ribeiro, J.L.D. Findings from the analysis of incident-reporting systems of construction companies. J. Constr. Eng. Manag. 2015, 141, 05015007. [Google Scholar] [CrossRef]

- Birhane, G.E.; Yang, L.; Geng, J.; Zhu, J. Causes of construction injuries: A review. Int. J. Occup. Saf. Ergon. 2022, 28, 343–353. [Google Scholar] [CrossRef]

- Chau, N.; Gauchard, G.C.; Siegfried, C.; Benamghar, L.; Dangelzer, J.L.; Français, M.; Jacquin, R.; Sourdot, A.; Perrin, P.P.; Mur, J.M. Relationships of job, age, and life conditions with the causes and severity of occupational injuries in construction workers. Int. Arch. Occup. Environ. Health 2004, 77, 60–66. [Google Scholar] [CrossRef]

- Waehrer, G.M.; Dong, X.S.; Miller, T.; Haile, E.; Men, Y. Costs of occupational injuries in construction in the United States. Accid. Anal. Prev. 2007, 39, 1258–1266. [Google Scholar] [CrossRef]

- Ahmad, S.; Iraj, M.; Abbas, M.; Mahdi, A. Analysis of occupational accidents induced human injuries: A case study in construction industries and sites. J. Civ. Eng. Constr. Technol. 2016, 7, 1–7. [Google Scholar]

- Yilmaz, F.; Çelebi, U.B. The importance of safety in construction sector: Costs of occupational accidents in construction sites. Bus. Econ. Res. J. 2015, 6, 25. [Google Scholar]

- Asanka, W.; Ranasinghe, M. Study on the impact of accidents on construction projects. In Proceedings of the 6th International Conference on Structural Engineering and Construction Management, Kandy, Sri Lanka, 11–13 December 2015; Voume 4, pp. 58–67. [Google Scholar]

- Haslam, R.A.; Hide, S.A.; Gibb, A.G.; Gyi, D.E.; Pavitt, T.; Atkinson, S.; Duff, A.R. Contributing factors in construction accidents. Appl. Ergon. 2005, 36, 401–415. [Google Scholar] [CrossRef] [PubMed]

- Raviv, G.; Shapira, A. Systematic approach to crane-related near-miss analysis in the construction industry. Int. J. Constr. Manag. 2018, 18, 310–320. [Google Scholar] [CrossRef]

- Zhou, Z.; Li, C.; Mi, C.; Qian, L. Exploring the potential use of near-miss information to improve construction safety performance. Sustainability 2019, 11, 1264. [Google Scholar] [CrossRef]

- Wu, W.; Gibb, A.G.; Li, Q. Accident precursors and near misses on construction sites: An investigative tool to derive information from accident databases. Saf. Sci. 2010, 48, 845–858. [Google Scholar] [CrossRef]

- Albert, A.; Pandit, B.; Patil, Y. Focus on the fatal-four: Implications for construction hazard recognition. Saf. Sci. 2020, 128, 104774. [Google Scholar] [CrossRef]

- Janicak, C.A. Occupational fatalities due to electrocutions in the construction industry. J. Saf. Res. 2008, 39, 617–621. [Google Scholar] [CrossRef]

- Zhao, D.; Thabet, W.; McCoy, A.; Kleiner, B. Electrical deaths in the US construction: An analysis of fatality investigations. Int. J. Inj. Control. Saf. Promot. 2014, 21, 278–288. [Google Scholar] [CrossRef] [PubMed]

- Hanák, T.; Korytárová, J. Estimating large-scale damages to real property. Procedia-Soc. Behav. Sci. 2014, 119, 829–836. [Google Scholar] [CrossRef][Green Version]

- Abdul-Rahman, H.; Takim, R.; Min, W.S. Financial-related causes contributing to project delays. J. Retail. Leis. Prop. 2009, 8, 225–238. [Google Scholar] [CrossRef]

- Bielienkova, O. Factor analysis of profitability (losses) construction enterprises in 1999–2019. Econ. Financ. Manag. Rev. 2020, 4–16. [Google Scholar] [CrossRef]

- Spicka, J. The financial condition of the construction companies before bankruptcy. Eur. J. Bus. Manag. 2013, 5, 160–169. [Google Scholar]

- Jou, R.C.; Chen, T.Y. The willingness to pay of parties to traffic accidents for loss of productivity and consolation compensation. Accid. Anal. Prev. 2015, 85, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Li, R.Y.M.; Poon, S.W. Workers’ compensation for non-fatal accidents: Review of Hong Kong court cases. Asian Social Science 2009, 5, 15–24. [Google Scholar] [CrossRef]

- Liao, C.W.; Chiang, T.L. Accident compensation of occupational fatalities in the construction industry. Adv. Mater. Res. 2014, 838, 3167–3170. [Google Scholar] [CrossRef]

- Chang, C.K.; Woo, S. Critical review of previous studies on labor productivity loss due to overtime. KSCE J. Civ. Eng. 2017, 21, 2551–2557. [Google Scholar] [CrossRef]

- Hanna, A.S.; Sullivan, K.T. Impact of overtime on construction labor productivity. Cost Eng. 2004, 46, 20. [Google Scholar] [CrossRef]

- Sonmez, R. Impact of occasional overtime on construction labor productivity: Quantitative analysis. Can. J. Civ. Eng. 2007, 34, 803–808. [Google Scholar] [CrossRef]

- Ameh, O.J.; Osegbo, E.E. Study of relationship between time overrun and productivity on construction sites. Int. J. Constr. Supply Chain. Manag. 2011, 1, 56–67. [Google Scholar]

- Ghoddousi, P.; Hosseini, M.R. A survey of the factors affecting the productivity of construction projects in Iran. Technol. Econ. Dev. Econ. 2012, 18, 99–116. [Google Scholar] [CrossRef]

- Santosh, V.; Apte, M. Productivity in building construction. IOSR J. Mech. Civ. Eng. 2014, 10, 64–71. [Google Scholar] [CrossRef]

- Alintah, A.; Nnadi, E.; Onoh, F. Relationship between workplace accidents and project success in construction industry in Enugu State. IOSR J. Mech. Civ. Eng 2021, 18, 28–34. [Google Scholar]

- Bajpai, A.; Misra, S.C. Identifying critical risk factors for use of digitalization in construction industry: A case study. In Proceedings of the 2020 IEEE India Council International Subsections Conference (INDISCON), Visakhapatnam, India, 3–4 October 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 124–128. [Google Scholar]

- Yang, J.; Liu, A.; Fellows, R. Team morale and leadership styles of project managers in China construction projects. In Proceedings of the CIB World Building Congress, Salford, UK, 10–13 May 2010. [Google Scholar]

- María-Dolores, R.; Alarcón, G.; Garre, M.E. Tax morale in Spain: A study into some of its principal determinants. J. Econ. Issues 2010, 44, 855–876. [Google Scholar] [CrossRef]

- Rotimi, F.E.; Brauner, M.; Burfoot, M.; Naismith, N.; Silva, C.C.; Mohaghegh, M. Work environment challenge and the wellbeing of women in construction industry in New Zealand–The mediating role of work morale. Eng. Constr. Archit. Manag. 2023. [Google Scholar] [CrossRef]

- Aydin, D.; Mihlayanlar, E. Causes and Effects of Construction Project Delays: A Local Case Study in Edirne City Centre. In Proceedings of the 5th International Project and Construction Management Conference (IPCMC 2018), Nicosia, North Cyprus, 16–18 November 2018; Available online: https://www.researchgate.net/publication/329415192_Causes_and_Effects_of_Construction_Project_Delays_A_Local_Case_Study_in_Edirne_City_Centre (accessed on 17 June 2024).

- Aliakbarlou, S.; Wilkinson, S.; Costello, S.B. Rethinking client value within construction contracting services. Int. J. Manag. Proj. Bus. 2018, 11, 1007–1025. [Google Scholar] [CrossRef]

- Tsado, T.Y.; Tsado, T.Y. Equipment maintenance: An effective aspect of enhancing construction project profitability. Int. J. Eng. Sci. Invent. 2014, 3, 34–41. [Google Scholar]

- Manikandan, M.; Adhiyaman, M.; Pazhani, K. A study and analysis of construction equipment management used in construction projects for improving productivity. Int. Res. J. Eng. Technol. 2018, 5, 1297–1303. [Google Scholar]

- Kumar, K.P.; Mouli, T.C. Impact of construction equipment downtime in Indian construction sector. Int. J. Res. Eng. Sci. Manag. 2019, 2, 2581. [Google Scholar]

- Andrews, T.D. Using Project Complexity Determinations to Establish Required Levels of Project Rigor; Technical report; Nevada Test Site (NTS): Mercury, NV, USA, 2015. [Google Scholar]

- Kothari, C.R. Research Methodology: Methods and Techniques; New Age International: New Delhi, India, 2004. [Google Scholar]

- Slim, H.; Nadeau, S. A proposition for combining rough sets, fuzzy logic and FRAM to address methodological challenges in safety management: A discussion paper. Safety 2020, 6, 50. [Google Scholar] [CrossRef]

- Ghosh, S.; Nourihamedani, M.; Reyes, M.; Snyder, L. Association between leading indicators of safety performance in construction projects. Int. J. Constr. Educ. Res. 2024, 20, 121–135. [Google Scholar] [CrossRef]

- Mahmoud, A.; Ahmad, M.H.; Yatim, Y.M. Overview of safety performance in the construction industry. In Proceedings of the 3rd European and Mediterranean Structural Engineering and Construction Conference 2020, Euro-Med-Sec 2020, Limassol, Cyprus, 3–8 August 2020. [Google Scholar]

- Lingard, H.; Rowlinson, S. Occupational Health and Safety in Construction Project Management, 1st ed.; Routledge: London, UK, 2005. [Google Scholar] [CrossRef]

- Lu, Y.; Zhang, D.; Chen, D. Safety Management Model of Construction Project Based on the Cooperation Between Owner and Contractor. In Proceedings of the 25th International Symposium on Advancement of Construction Management and Real Estate; Springer: Singapore, 2021; pp. 921–930. [Google Scholar]

- Fang, D.; Wang, Y.; Lim, H.W.; Ma, L.; Gu, B.; Huang, Y. Construction of a Bayesian network based on leadership-culture-behavior model to improve owner safety management behavior. J. Constr. Eng. Manag. 2023, 149, 04022177. [Google Scholar] [CrossRef]

- Griffin, M.A.; Neal, A. Perceptions of safety at work: A framework for linking safety climate to safety performance, knowledge, and motivation. J. Occup. Health Psychol. 2000, 5, 347. [Google Scholar] [CrossRef]

- Nuñez, I.; Villanueva, M. Safety capital: The management of organizational knowledge on occupational health and safety. J. Workplace Learn. 2011, 23, 56–71. [Google Scholar] [CrossRef]

Figure 1.

Variable identification.

Figure 1.

Variable identification.

Figure 2.

Causal loop diagram.

Figure 2.

Causal loop diagram.

Figure 3.

Stock and flow diagram.

Figure 3.

Stock and flow diagram.

Figure 4.

Model validation level of frequency of accidents (SPF 3).

Figure 4.

Model validation level of frequency of accidents (SPF 3).

Figure 5.

Model validation safety performance frequency.

Figure 5.

Model validation safety performance frequency.

Figure 6.

Model validation level of safety performance extent (SPE 14).

Figure 6.

Model validation level of safety performance extent (SPE 14).

Figure 7.

Model validation level for safety performance cost (SPF 10).

Figure 7.

Model validation level for safety performance cost (SPF 10).

Figure 8.

Scenario analysis for SPE.

Figure 8.

Scenario analysis for SPE.

Figure 9.

Scenario analysis for SPC.

Figure 9.

Scenario analysis for SPC.

Figure 10.

Scenario analysis for SLF and SMP.

Figure 10.

Scenario analysis for SLF and SMP.

Figure 11.

Sensitivity analysis for SPF.

Figure 11.

Sensitivity analysis for SPF.

Figure 12.

Scenario analysis for SPC.

Figure 12.

Scenario analysis for SPC.

Figure 13.

Sensitivity Eight simulations as part of 25 simulations for SLF, SPC, and SMPF.

Figure 13.

Sensitivity Eight simulations as part of 25 simulations for SLF, SPC, and SMPF.

Figure 14.

Sensitivity analysis for SLF and SMP.

Figure 14.

Sensitivity analysis for SLF and SMP.

Figure 15.

Scenario analysis for SPC.

Figure 15.

Scenario analysis for SPC.

Figure 16.

Sensitivity analysis for SPF when SP is changed.

Figure 16.

Sensitivity analysis for SPF when SP is changed.

Figure 17.

Sensitivity analysis for third scenario.

Figure 17.

Sensitivity analysis for third scenario.

Figure 18.

Safety performance KPI.

Figure 18.

Safety performance KPI.

Figure 19.

Safety climate growth.

Figure 19.

Safety climate growth.

Figure 20.

SLF and SMP trend.

Figure 20.

SLF and SMP trend.

Figure 21.

Comparative scatter diagram.

Figure 21.

Comparative scatter diagram.

Figure 22.

SMP factors performance.

Figure 22.

SMP factors performance.

Figure 23.

SMPF attributes.

Figure 23.

SMPF attributes.

Figure 24.

SLF attributes.

Figure 24.

SLF attributes.

Table 4.

Demographics of the respondents.

Table 4.

Demographics of the respondents.

| Region | Frequency | Percent | Cumulative Percent |

|---|

| Dar es Salaam | 123 | 48.2 | 48.2 |

| Arusha | 45 | 17.6 | 65.9 |

| Mbeya | 20 | 7.8 | 73.7 |

| Mwanza | 15 | 7.9 | 79.6 |

| Dodoma | 52 | 20.4 | 100.0 |

| Total | 255 | 100 | |

Table 5.

Safety leading factor loadings.

Table 5.

Safety leading factor loadings.

| Factors | Denotes | Variables | Factor Loadings |

|---|

| Project management-related factors (MRF) | MRF6 | Management takes corrective actions promptly about safety. | 1 |

| Worker-related factors (WRF) | WRF7 | Workers feel comfortable reporting safety concerns and unsafe conditions. | |

| | WRF8 | Workers participate in safety activities, such as safety meetings, training, and inspections. | |

| Site environment-related factors (SRF) | SRF16 | The safety practices are adequate to prevent slips, trips, and falls. | 1 |

| External-related factors ERF | ERF1 | The project safety practices comply with all applicable industry safety regulations. | 0.888 |

| | ERF2 | The project has been inspected by government safety agencies | 0.837 |

Table 6.

Safety management process factor loadings.

Table 6.

Safety management process factor loadings.

| Factors | Denotes | Variables | Factor Loadings |

|---|

| Safety process design—SMP1 | SMP1.3 | The project has a process for risks assessment. | 0.998 |

| | SMP1.4 | There is a risk management plan for handling safety issues. | 0.998 |

| Safety process implementation—SMP2 | SMP2.2 | Safety inspections are conducted regularly. | 0.779 |

| | SMP2.3 | Workers feel comfortable reporting safety concerns. | 0.914 |

| Safety process evaluation—SMP3 | SMP3.2 | The project conducts regular safety audits to assess the effectiveness of its safety processes and systems. | 0.892 |

| | SMP3.3 | Workers feel comfortable providing feedback on safety processes and systems. | 0.897 |

| Safety process improvement—SMP4 | SMP4.1 | The project makes changes to its safety processes and systems based on the results of its safety process reviews. | 0.87 |

| | SMP4.2 | The project communicates changes to its safety processes and systems to workers in a timely and effective manner. | 0.849 |

Table 7.

Safety performance factor loadings.

Table 7.

Safety performance factor loadings.

| Factors | Denotes | Variables | Factor Loadings |

|---|

| Safety performance extent (SPE) | SPE14 | Extent of equipment breakdown due to unsafe practice. | 1 |

| Safety performance frequency (SPF) | SPF3 | Frequency of accidents. | 0.977 |

| | SPF4 | Frequency of near misses. | 0.985 |

| Safety performance costs (SPC) | SPC9 | Costs of overtime associated with slowdown in operation. | 0.721 |

| | SPC10 | Costs of production time loss. | 0.785 |

Table 8.

Equations deployed in the model.

Table 8.

Equations deployed in the model.

| Variable | Equation |

|---|

| Top-level model | |

| Safety leading factors(t) | Safety leading factors(t − dt) + (rate of leading factors) * dt |

| Safety management process(t) | Safety Management Process(t − dt) + (rate of safety management process) * dt |

| SAFETY_PERFORMANCE_COST(t) | SAFETY_PERFORMANCE_COST(t − dt) + (SPC_10 + SPC_9) * dt |

| SAFETY_PERFORMANCE_EXTENT(t) | SAFETY_PERFORMANCE_EXTENT(t − dt) + (RATE_OF_CHANGE_OF_SPE) * dt |

| SAFETY_PERFORMANCE_FREQUENCY(t) | SAFETY_PERFORMANCE_FREQUENCY(t − dt) + (SPF_4 + SPF_3) * dt |

| RATE_OF_CHANGE_OF_SPE | (Safety Management Process * Safety leading factors)/SPE_14 |

| Rate of leading factors | GRAPH((ERF + SRF + WRF + MRF) * (1/(Safety_lead-ing_factors * Safety_Management_Process * SAFETY_PERFORMANCE_EXTENT * SAFETY_PERFORMANCE_FREQUENCY))) Points: (0.000, 0.105), (0.500, 0.127), (1.000, 0.253), (1.500, 0.262), (2.000, 0.310), (2.500, 0.445), (3.000, 0.541), (3.500, 0.620), (4.000, 0.773), (4.500, 0.917), (5.000, 0.956) |

| Rate of safety management process | GRAPH((Safety_Management_Process * LN(Safe-ty_Management_Process)/(GROWTH(PERCENT(MEAN(SMP1, SMP2, SMP3, SMP4))))) * (1/SAFETY_PERFORMANCE_EXTENT + 1/Safety_leading_factors + 1/

SAFETY_PERFORMANCE_FREQUENCY)) Points: (0.000, 0.624), (0.500, 0.616), (1.000, 0.371), (1.500, 0.472), (2.000, 0.253), (2.500, 0.406), (3.000, 0.100), (3.500, 0.332), (4.000, 0.035), (4.500, 0.031), (5.000, 0.035) |

| SPC_10 | NORMAL(1/(Safety leading factors * SAFETY_PERFORMANCE_COST)) |

| SPC_9 | NOR-MAL(SAFETY_PERFORMANCE_EXTENT/(SAFETY_PERFORMANCE_COST * SPC_10)) |

| SPF_3 | (1/(SAFETY_PERFORMANCE_FREQUENCY * (Safety_leading_factors + Safety_Management_Process))) * f(x;,k) |

| SPF_4 | SAFE-TY_PERFORMANCE_FREQUENCY/(SAFETY_PERFORMANCE_FREQUENCY * (1/Safety_Management_Process + 1/Safety_leading_factors)) |

| “SMP1.3” | RANDOM (1, 5) |

| “SMP1.4” | RANDOM (1, 5) |

| “SMP1.Change_factor” | 0.15 |

| “SMP2.2” | RANDOM (1, 5) |

| “SMP2.3” | RANDOM (1, 5) |

| “SMP2.change_factor” | 0.13 |

| “SMP3.2” | RANDOM (1, 5) |

| “SMP3.3” | RANDOM (1, 4) |

| “SMP3.5” | RANDOM (1, 5) |

| “SMP3.change_factor” | 0.14 |

| “SMP4.1” | TRIANGULAR (1, 2, 5) |

| “SMP4.2” | TRIANGULAR (2, 3, 4) |

| “SMP4.5” | TRIANGULAR (1, 3, 5) |

| “SMP4.change_factor” | 0.15 |

| EFR1 | RANDOM (1, 5) |

| EFR2 | RANDOM (1, 5) |

| ERF | (EFR1 + EFR2) * ERF_CHANGE_FACTOR |

| ERF_CHANGE_FACTOR | MEAN (0.837, 0.888) |

| MRF | MRF6 + MRF6 * MRF_CHANGE_FACTOR |

| MRF_CHANGE_FACTOR | 0 * 9 |

| MRF6 | RANDOM (1, 5) |

| Project time frame | 18 |

| SFR16 | RANDOM (1, 5) |

| SMP1 | GRAPH((“SMP1.3” + “SMP1.4”) * “SMP1.Change_factor”) Points: (1.000, 0.664), (1.400, 1.170), (1.800, 1.100), (2.200, 1.109), (2.600, 1.066), (3.000, 1.048), (3.400, 1.074), (3.800, 0.961), (4.200, 1.022), (4.600, 1.345), (5.000, 1.563) |

| SMP2 | (“SMP2.2”+“SMP2.3”) * “SMP2.change_factor” |

| SMP3 | NORMAL(MEAN(“SMP3.2”, “SMP3.5”,“SMP3.3”, “SMP3.change_factor”), “SMP3.change_factor”) |

| SMP4 | GRAPH(NORMAL(MEAN(“SMP4.1”, “SMP4.2”, “SMP4.5”, “SMP3.3”, “SMP4.change_factor”), “SMP4.change_factor”)) Points: (0.000, 2.341), (0.200, 1.869), (0.400, 1.869), (0.600, 1.607), (0.800, 1.520), (1.000, 1.502), (1.200, 1.537), (1.400, 1.712), (1.600, 1.380), (1.800, 2.026), (2.000, 1.939) |

| SPE_14 | SAFETY_PERFORMANCE_EXTENT/4.5 |

| SRF | NORMAL(SFR16, SRF_CHANGE_FACTOR, 1, 5) |

| SRF_CHANGE_FACTOR | 1 |

| WRF | NOR-MAL(MEAN(WRF8,WRF7,WRF13),WRF_CHANGE_FACTOR) |

| WRF_CHANGE_FACTOR | 0.13 |

| WRF13 | TRIANGULAR (1, 3, 5) |

| WRF7 | TRIANGULAR (1, 3, 5) |

| WRF8 | TRIANGULAR (1, 3, 5) |

Table 9.

Model simulation run specifications.

Table 9.

Model simulation run specifications.

| Run Specs | |

|---|

| Start time | 0 |

| Stop time | project time frame (18 months set) |

| DT | 0.25 |

| Fractional DT | False |

| Save interval | 0.25 |

| Sim duration | 20 |

| Time units | Months |

| Pause interval | 0 |

| Integration method | Euler |

| Keep all variable results | True |

| Run by | Run |

| Calculate loop dominance information | True |

| Exhaustive search threshold | 1000 |

| Entry 1 | Data |

| Entry 2 | Data 1 |

Table 10.

Summary of the model.

Table 10.

Summary of the model.

| Total | Count | Including Array Elements |

|---|

| Variables | 19 | 19 |

| Stocks | 5 | 5 |

| Flows | 7 | 7 |

| Converters | 47 | 47 |

| Constants | 8 | 8 |

| Equations | 46 | 46 |

| Graphics | 18 | 18 |

Table 11.

Model validation for accidents.

Table 11.

Model validation for accidents.

| Project Run Time | Spf v 3 | Spf 3 | Spf 3 Deviation (spf-spv) | Spf v 4 | Spf 4 | Spf 4 Deviation (spf-spv) |

|---|

| 0 | 1.0395 | 0.0000 | −1.0395 | 1.0395 | 0.0095 | −1.0300 |

| 1 | 1.3130 | 0.4107 | -0.9023 | 1.3130 | 0.4094 | −0.9036 |

| 2 | 1.3462 | 0.5157 | −0.8304 | 1.9960 | 0.7688 | −1.2273 |

| 3 | 1.0796 | 0.5720 | −0.5076 | 1.0796 | 0.9732 | −0.1064 |

| 4 | 1.5068 | 0.5875 | −0.9192 | 8.6176 | 1.1158 | −7.5018 |

| 5 | 1.5455 | 0.5944 | -0.9511 | 10.2141 | 1.2510 | −8.9631 |

| 6 | 1.4589 | 0.5979 | −0.8610 | 6.6436 | 1.3442 | −5.2994 |

| 7 | 0.8649 | 0.6000 | −0.2650 | 0.8649 | 1.4379 | 0.5730 |

| 8 | 1.4541 | 0.6013 | −0.8527 | 6.4452 | 1.5294 | −4.9158 |

| 9 | 1.4939 | 0.6023 | −0.8916 | 8.0882 | 1.6235 | −6.4647 |

| 10 | 1.2782 | 0.6030 | −0.6752 | 1.2782 | 1.7081 | 0.4299 |

| 11 | 1.5175 | 0.6035 | −0.9141 | 9.0619 | 1.7802 | −7.2817 |

| 12 | 1.5415 | 0.6039 | −0.9376 | 10.0494 | 1.8607 | −8.1887 |

| 13 | 1.4692 | 0.6042 | −0.8650 | 7.0677 | 1.9325 | −5.1351 |

| 14 | 1.3782 | 0.6044 | −0.7738 | 3.3186 | 2.0064 | −1.3122 |