1. Introduction

An application of lean techniques within a system results to zero bottlenecks, which plays a big role in the accuracy of troubleshooting methods [

1]. Quality assurance is a scientific discipline that plays a big role in monitoring and sustaining a culture of good quality product and services by implementing standardised procedures to assist the manufacturers and service providers to comply with quality standards, hence, quality nonconformance results from the system that lacks quality assurance [

2]. The product or service that is not of good quality is commonly categorised as a nonconformance. There are different levels of nonconformances which are minor nonconformance and the major nonconformance [

3].

The minor nonconformance is the type of nonconformance that has less negative impact within the product, process, or services, which needs to be addressed and prevented to avoid huge negative impact. On the other aspect, the major nonconformance is the type of a nonconformance that results into major negative impact, hence, a need for a feasible solution for both minor and major nonconformance [

4]. Nonconforming products or services are confirmed to be nonconforming by the quality-specific tolerance according to the desired output and specification, the tolerance to confirm the nonconformity of the product and services is mostly guided by a set of rules extracted from a certain quality management system [

5].

To solve the quality nonconformance, one must verify the nonconformance according to the specified tolerance. Once the raised nonconformance is confirmed to be either a minor or a major nonconformance it is then investigated accordingly, and the solution is provided to get rid of the nonconformance. Hence, a good nonconformance closure system could potentially decrease the rate of poor quality [

6].

Quality management system is the management system that focuses on the good practise of carrying out activities that makes up a desired output by customers. A quality management system (QMS) is composed of various pillars that could potentially assist the business to remain competitive by zero defects and good services to customers [

7]. The quality management system can be designed in various ways depending on the nature of the process and the specification of the quality standards of the process. It depends on the organisation’s top management and the business values as well as the business targets on which quality management systems the business should adopt [

8].

Process engineering breakdowns are the faults within a process that decrease the productivity rate. The process engineering breakdowns could result into process malfunctioning, hence, process delays. Processes are maintained through machinery monitoring, process performance monitoring, and quality standards, as well as overall effectiveness of the process [

9]. Process re-engineering serves as a frequent monitoring tool for engineering maintenance systems which involves overall equipment effectiveness (OEE) monitoring, hence, zero rate of process engineering breakdowns. Process re-engineering is a method that is used to define, analyse, and measure processes to find areas of improvements, which results to good functioning of machines, safer processes, and high productivity rate [

10].

Process re-engineering is combined with integrated management systems (IMS) to increase productivity rate, reduce injuries within the processes, eliminate doublehanding, reduce defect rate and to redesign processes to meet the product as well as the service specification [

11]. An integrated management systems (IMS) is a system that has been upgraded in a manner that it combines safety systems, quality systems, environmental systems as well as Good Manufacturing Practices systems (GMP), which involves process re-engineering on each system due to the need of engineering maintenance system and process redesign [

12].

The safety incidents are injuries that results from not following safety protocols when designing Standard Operating Procedures (SOP), Work Instructions (WI), machinery maintenance systems and when performing daily tasks routine. The safety incidents can be categorised according to the severity of an injury which is minor incident, major incident and catastrophic [

13].

The most common safety incident causes results from safety hazards that are not addressed accordingly in terms of Personal Protective Equipment (PPE). The Personal Protective Equipment (PPE) is the equipment that is used as a precaution of a process or any other form of work environment that could potentially result to an injury, illness, and fatality [

14].

Even though the corrective and preventive action reduce safety incidents, defect rate and process engineering breakdowns, there is also a need for checking the deeper cause of the issue and evaluate the opportunity of improvement that arises from that issue which could assist to develop smaller improvement that might build up to future kaizen project [

15]. The project evaluation is a process of actioning the continual improvement opportunity and closing the gap where there are loopholes to fulfil some desired specific end results. Project evaluation does not arise from the purpose of continual improvement only, it also arises from new developments within the organisation when addressing predicted areas of future improvements [

16].

When the problem occurs within a system, the solution should be applied, and prevention measures should be provided. The prevention measures within a problem result to lesser chances of the similar problem occurring in future [

17]. An investigation was conducted in the health sector to understand and eliminate factors that contribute to safety incidents to the patients and hospital staff. The tree-based machine learning algorithm and random forests as well as the gradient booting analysis were adopted for analysis. It was found that human errors due to unsafe acts were the main contributing factor; this study assisted the case study company to improve human safety related factors [

18]. The safety injuries mostly relate to adequate procedures or equipment failure, but the main root cause of the problem could be potentially resulting from the solutions provided for a particular problem or a previous problem occurrence. The evaluation of the solution that was provided during the production breakdowns aids one to provide proper preventive action to avoid future occurrences of the problem, therefore it is essential to evaluate the nonconformity closure and corrective action modelling systems for engineering breakdowns that have been successfully implemented by different industries.

Moon et al., 2022 [

19] evaluated that risks rating validates the accuracy of problem solving. It is an assurance of working according to a certain specification. The project prioritisation can be based on budget where one allocates the projects according to the available funds; it can be based on the availability of resources or any other specific desired output. Below is the review of different risks rating strategies that have been implemented successfully for project prioritisation. A study was conducted to evaluate the proper models that could potentially result into accurate analysis of risks and best prioritization of factors to be attended urgently in any given problem. An artificial-intelligence-driven Bayesian Network model with a combination of physical data for risks analysis was developed and simulated into a blowout accident which resulted to other opportunities of improving the developed model by adding a feature that assists in drafting the emergency plans and prevention methods [

20].

A study was conducted in the mineral industry to analyse the risks associated advancing mineral industries as well as risks associated with the type of mineral industries; A Fuzzy Delphi, the DEMATEL (Decision Making Trial and Evaluation Laboratory) and ANP (Analytical Network Process) procedure for risks evaluation were applied. It was found that the risks associated with investing on mineral sectors were political issues, geological issues, and infrastructure factors. The legal factors were found to be the most dominant risks within mineral sectors. This study resulted into a benchmark for the decision of investing in mineral sectors [

21].

Research was carried out in industrial processes to categorise and measure the impact of the hazards within the industrial processes. A model composed of FMEA (Failure Mode and Effects Analysis) and Fuzzy TOPSIS (Technique for Order of Preference by Similarity to Ideal Solution) for risk analysis was constructed and applied in nodular iron melting and casting process. It was found that some processes were out of specification which results into inadequate procedure, hence, poor-quality product. The study contributed to eliminating risks within the processes of the case study company [

22].

2. Significance and Contribution of the Study

The significance of this study is to add more knowledge to the process enhancement field, total quality management, occupational health, the safety field and the quality management systems field by developing a troubleshooting model that evaluates continual improvement projects and integrates safety incidents investigation, quality nonconformances investigation and engineering-related issues for corrective action.

An interdisciplinary theory is a collaboration of different fields with the same objectives and common target to accomplish desired outcomes. Nowadays, technology requires different researchers with different expertise conducting the same study to build up creative strategies to remain relevant on their own specific fields, hence, the introduction of integrated management systems (IMS) [

23]. This study seeks to add practical problem-solving knowledge in total quality management (TQM) Theory by developing an integrated management troubleshooting system, which is composed of safety, quality and process engineering breakdown phases of problem solving.

The aim of this study is to add more knowledge to the problem-solving method, which also assists the industries to upgrade the old version of ISO standards in terms of problem-solving accuracy and technical innovations by evaluating continual improvement projects within the aid of integrated lean techniques.

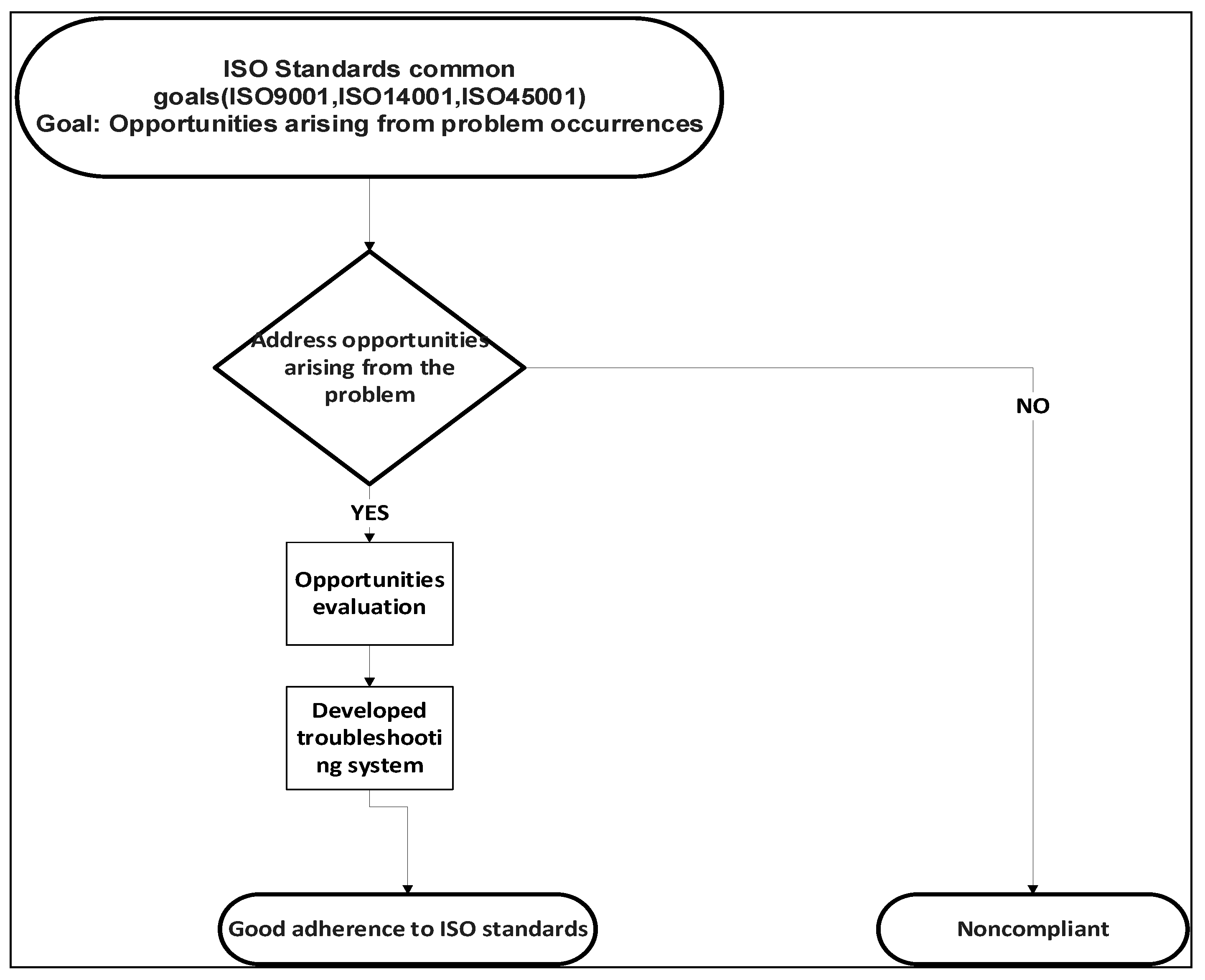

The developed model is composed of 5whys, Ishikawa, 5S, and risk and project prioritization analysis. Below on

Figure 1 is an illustration of the requirements of the international standards in terms of continual improvement, hence, the need of an upgraded troubleshooting system.

The ISO standard common goal for quality, safety and process-engineering-related issues is to evaluate opportunities of the improvement within problem occurrence. If this requirement is not fulfilled, it results to noncompliance due to the missed requirement on the standards [

24].

Even though quality issues, safety incidents and engineering-related breakdowns are mostly guided by the ISO 9001 and ISO 45001, the proposed model can assist the organisation to fully comply with ISO 31000. The ISO 31000 is an international standard that emphasises the risk identification, analysis, and management within a process [

25]. Below on

Figure 2 is an illustration of the steps involved in implementing ISO 31000, which is the communication and consultation, the establishment of the context, risks identification, analysis, evaluation, treatment as well as the review of the risks.

The objective of this study is to close the gap that was identified within nonconformance problem-solving systems. It was found via the review of literature that even though the nonconformance problem-solving models are existing, there remains a need for improving the accuracy of problem solving by developing a model that investigates and evaluates kaizen projects for quality nonconformances, safety incidents, and engineering-maintenance-related breakdowns using lean techniques.

The limitations of the proposed troubleshooting model are that it is designed for quality defects, safety incidents and process-engineering-related problems. A human resource module has not been included, which limits the full utilization of the system especially in human-resource-related problems.

The structure of the following sections of the paper is separated into different parts.

Section 3 explains the methodology and the development of the proposed model.

Section 4 presents the model application and the data used for the study including the results, and

Section 5 contains the conclusion.

3. Materials and Methods

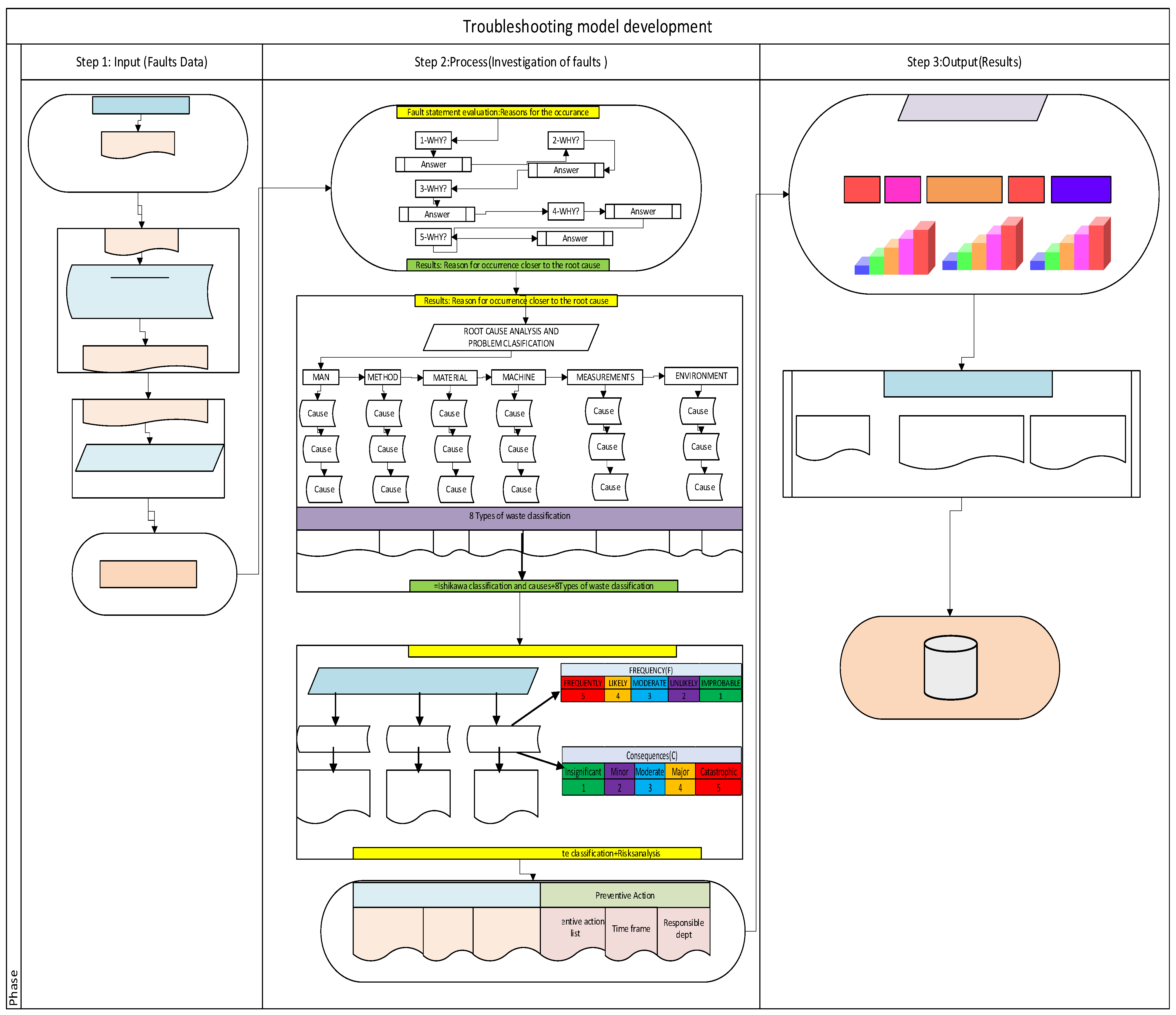

3.1. Development of the New Model

The first step is the inputs where the fault details are logged in and validated. Once the fault is confirmed to be investigated via lab tests or any other validation that suits the nature of the fault, the fault’s details are recorded and allocated to the department responsible for investigation. The second step is the actual process of investigation. The investigation begins with the 5Whys analysis where the reasons for the faults are drilled down to the most possible reason. The next step is problem classification in terms of Ishikawa and eight types of waste. When the problem is classified, the risk analysis is performed by risks rating which is the product of the problem frequency and the problem consequences of the problem using the level risks table as illustrated on the diagram. The opportunities as well as the threats of the problem are also listed for project evaluation purposes. The third step involves the outputs which is the fault’s closure status, the retrievable information which is the project evaluation report, weekly or monthly faults closure status and the tracking of the faults evaluation system holistically. The data is then stored for historical data purposes. Below on

Figure 3 is an illustration of the full details on how the proposed troubleshooting model carries out the investigation of faults and the evaluation of continual improvement through risks analysis.

Extracting kaizen projects from the opportunities for improvements arising from nonconformance occurrences within safety incidents, quality issues as well as process-engineering-related issues can result into drastic improvements, hence, an innovative organisation [

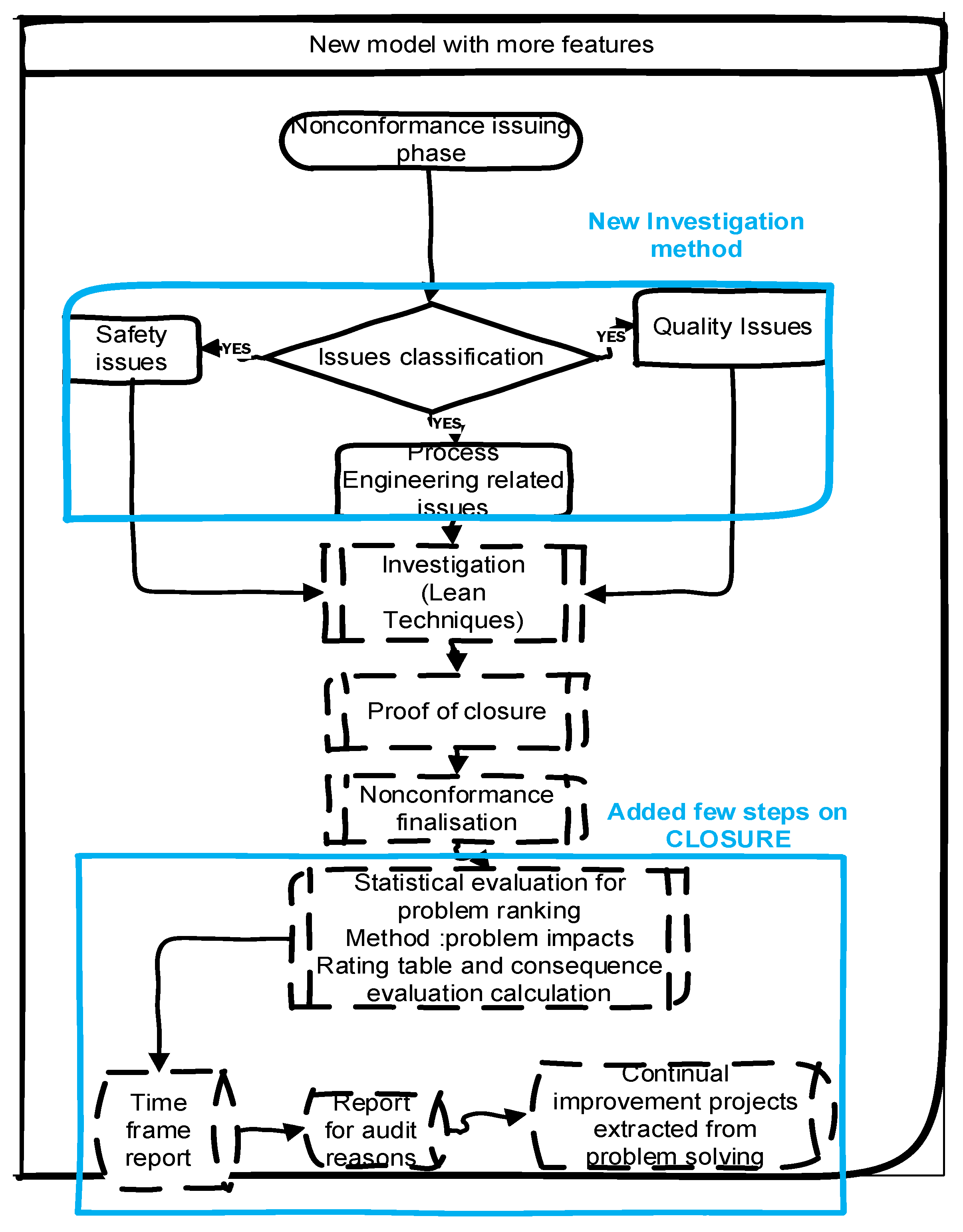

27]. Below on

Figure 4 is an illustration of the added features of the proposed troubleshooting model. The proposed troubleshooting model investigation is made up of the parts of the integrated management system elements which are safety, quality and engineering maintenance systems, including both ISO 9001 and ISO 45001 management systems. The investigation for the proposed model evaluates the problem from the causes using 5WHYS to the problem categorisation using Ishikawa and 8 types of waste. The proposed troubleshooting model nonconformance system is made up of the statistical evaluation for the problem (ranking method: problem impacts rating table and consequence evaluation calculation), reports for status of closure and for audit report reasons as well as continual improvement project evaluation.

3.2. Proposed Model Derivation

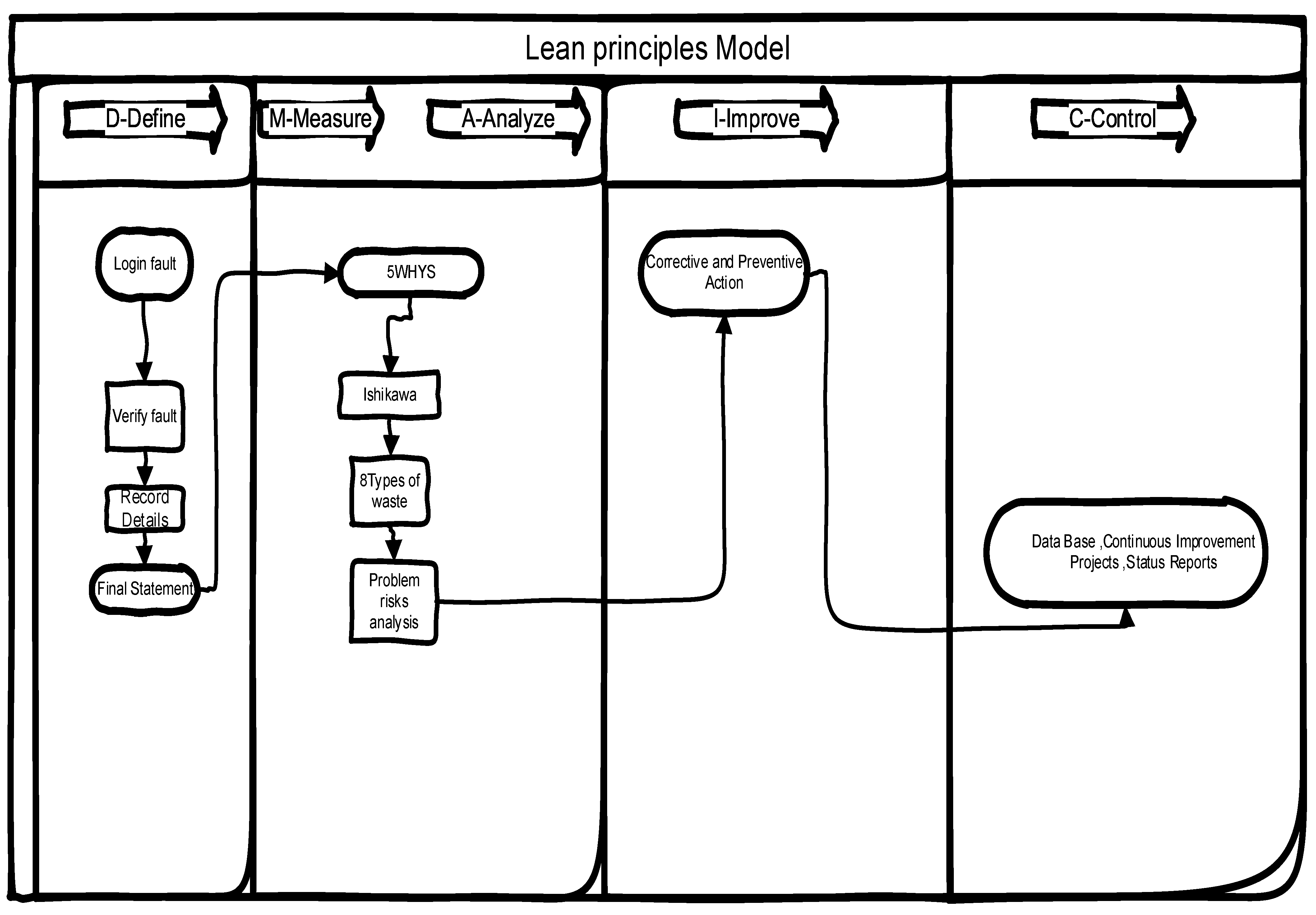

The proposed model is designed into four different steps using a holistic systematic approach with the aid of DMAIC lean technique. Below on

Figure 5 is an illustration of the developed model in different steps and the triangle calculation of the output of the model as well as the formulated equations that build up the proposed model.

The first section of the model is a stage where the problem is defined and allocated for investigation and the second step is where the investigation process takes place. The problem is analysed and measured where necessary and the third step is where the solution is applied, and opportunities for improvement are also identified in this step. The fourth step is the control measures where continuous improvement projects are evaluated through the product of database and status report of nonconformances extracted from the problem raised.

4. Model Application

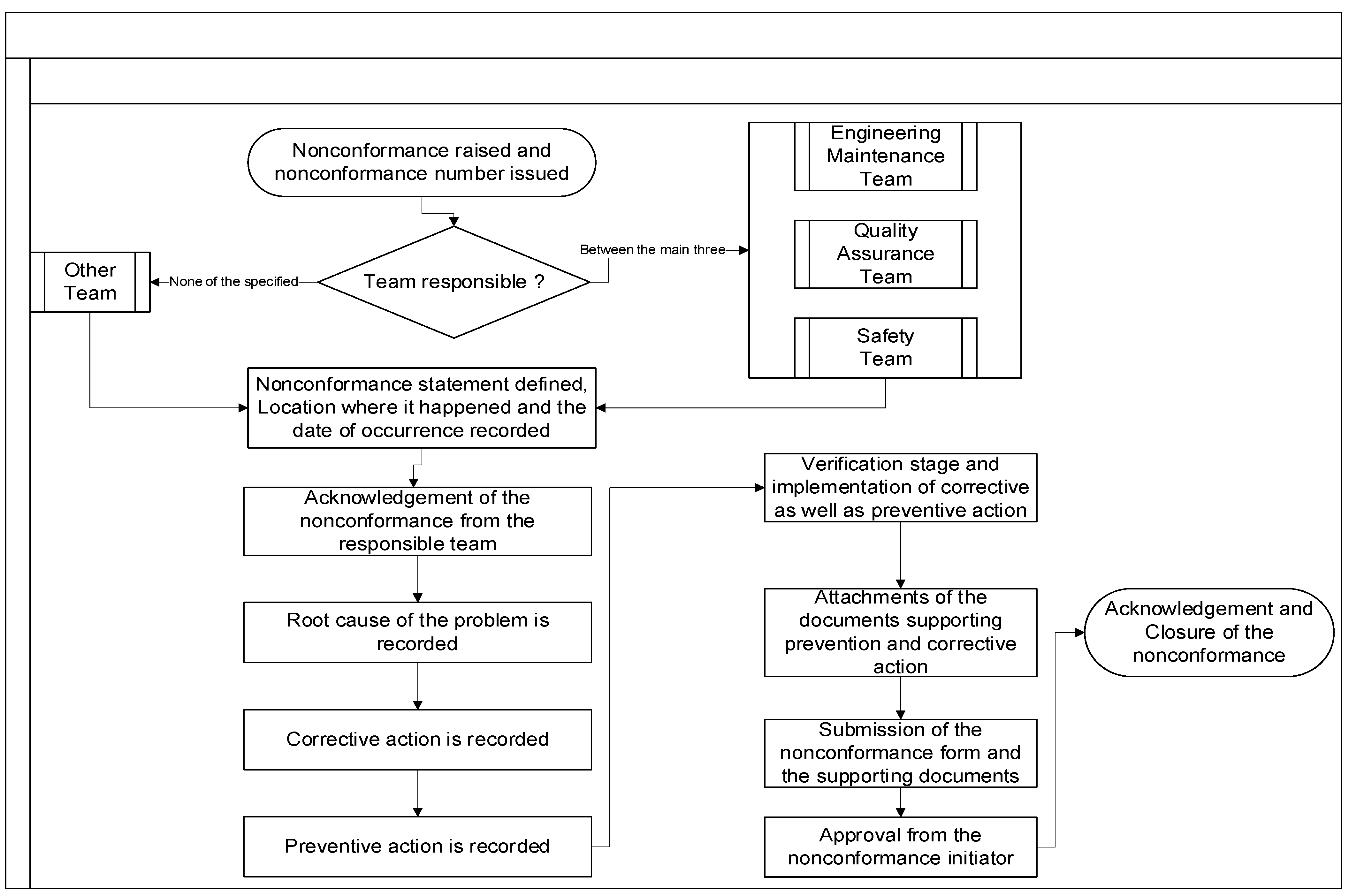

The proposed model was tested in the electrical services industry by collecting the data of the existing quality issues, safety issues and engineering breakdown issues. As a sector that provide services to the community it is important for the case study company to have a smooth flow troubleshooting system. The case study company has a manual troubleshooting system where the nonconformance is raised on an investigation form that is also used for the closure of the non-conformances. For the quality issues, maintenance engineering issues and safety incidents, the case study company uses the same method to address the raised nonconformances. Below on

Figure 6 is the flow chart illustrating the existing troubleshooting for the case study company.

Nonconformance is raised, allocated to the responsible team and the responsible team conducts the investigation by evaluating the root cause of the problem, corrective action as well as preventive action. The solution to the problem is then verified and implemented and the investigation form is then submitted to the initiator to approve together with documents for closure evident. Even though the case study company has existing troubleshooting, they still have not reached a point where the accuracy of nonconformance closure results to drastic improvement of future project, hence, the application of the proposed model seeks to close the continuous improvement project evaluation gap.

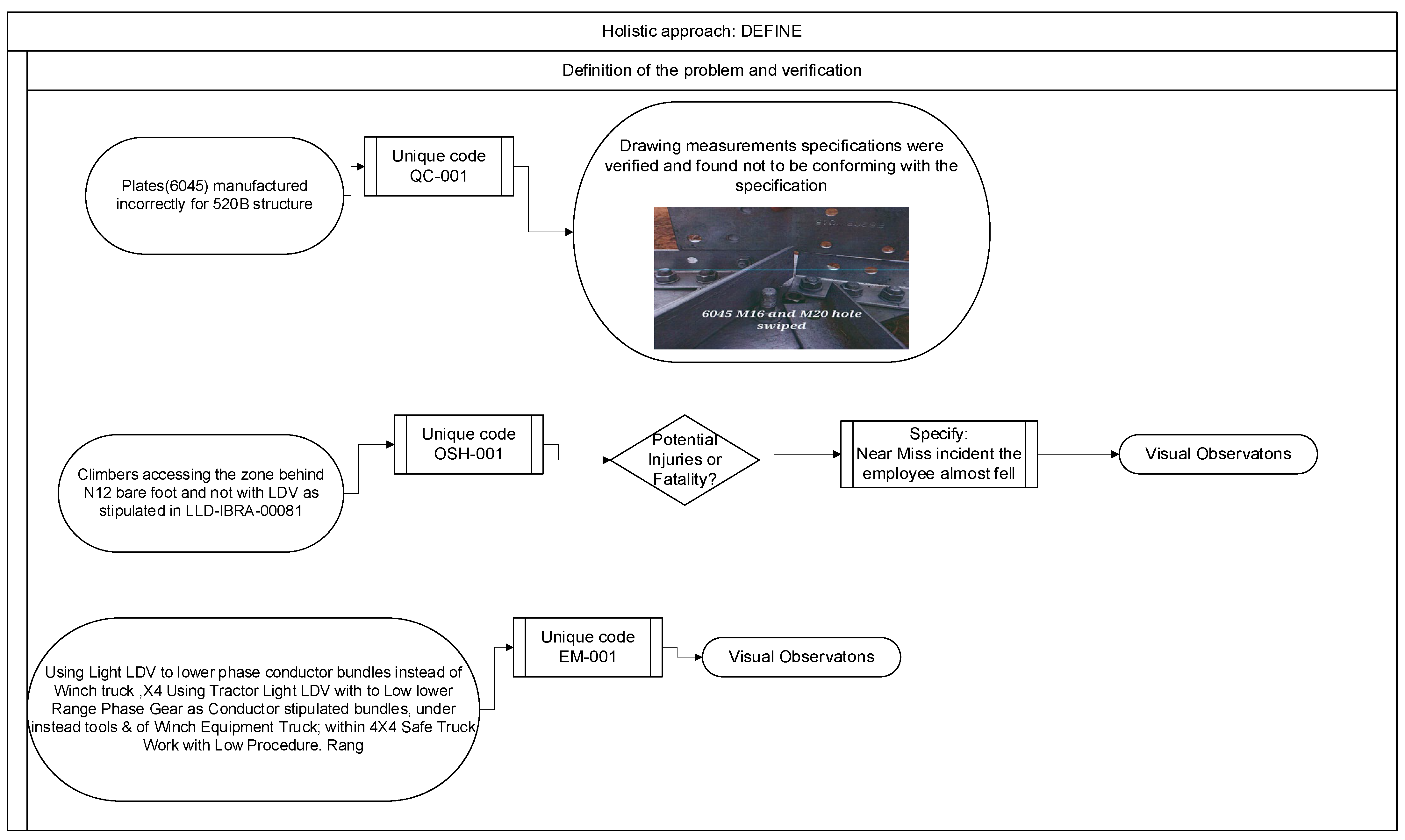

The initial stage of the proposed model ‘Define’ is where the nonconformance is raised, defined, and verified either by observation, specific tool or by means of diagramming and drawing. Once the fault has been verified it is then allocated to a responsible department with a unique code.

The unique code for the fault is formulated using the department abbreviation, the double zeros, and the number according to the total count of nonconformance raised in a particular department within the current year. The abbreviation QC is for quality issues, the abbreviation OSH is for safety incidents, and the EM abbreviation is for engineering maintenance issues.

The first issue was about the parts (plates) that were manufactured incorrectly for a 520B structure which was regarded as a quality issue since the product was not aligning with the specification. The nonconformance was verified by comparing drawing measurements, since it was the first nonconformance under quality issues it was given a number 001, hence, the final unique code was QC-001. The second nonconformance was related to safety issues—the climbers in the site accessing the zone behind N12 by foot instead of wearing the correct personal protective equipment LDV as stipulated in safety protocols. This issue was verified by visual observations and allocated to safety issues. The potential injuries were also evaluated and the final unique code was OSH-001.

The third issue was related to engineering maintenance, which was the incorrect use of tools. They used Light LDV to lower phase conductor instead of using Winch truck. This nonconformance was verified to be nonconforming by the visual observations and the final unique code was EM-001. Below on

Figure 7 is an illustration of the initial stage of the proposed model.

4.1. Results and Discussion

The risks rating normally assist the analyst in evaluating the severity of the problem occurrence, and it also assists by providing the sequence of the list of problems to be resolved by prioritizing the problems according to the specific range of percentages [

28]. On the proposed model a similar methodology of risks rating for results development as well as problem-solving priority has been adopted, where the risks rating is the product of likelihood of the occurrence and consequence if the event occurred. The prioritization which is computed by dividing risk rating with the maximum number of occurrences multiplied by 100% is then ranked according to the specific tolerance. The tolerances proposed on the results are specified and categorised in terms of priorities. The risk rating results are color coded in terms of priority of the problem solving: the red color where RR > 48% or =100% refers to special attention where the process resulting to this type of range should be stopped immediately because if the problem is not solved immediately, there could be moderate or major risk, or even deaths could potentially occur.

The blue color where RR > 20% or =48% refers to an urgent problem that needs to be solved as soon as it has been detected and lastly, the green color where RR < or =20% refers to a day-to-day basis problem that needs to be addressed quickly during work in progress which resembles the daily basis of small 5S activities. Below on

Table 1 and

Table 2 is an illustration of risks analysis.

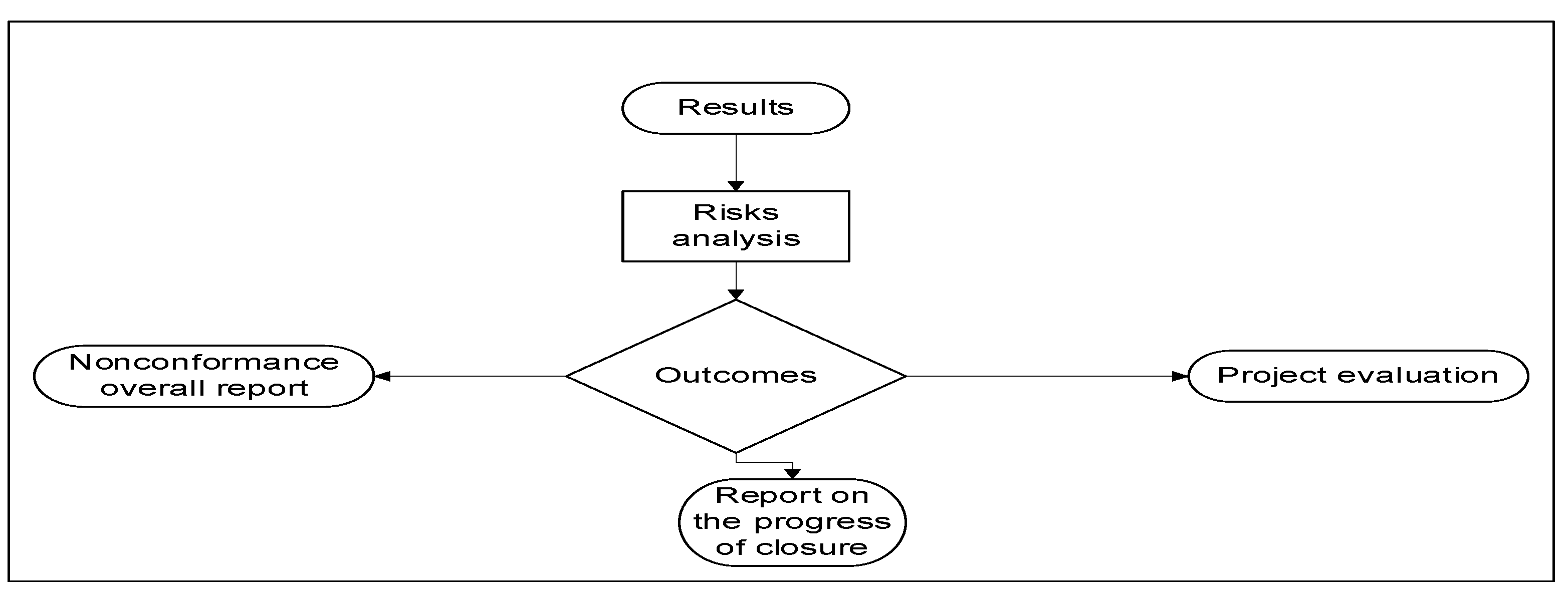

The model has been developed by performing critical analysis on the risks rating factors to rank the project according to the priority. Once the risks have been rated, the analysis of project evaluation are performed which could be either integrated management systems project or process engineering and 5S as well as the status report of closure of nonconformances is also computed. The overall report for nonconformance status is then extracted from the historical data of the outcomes of the proposed model. Below

Figure 8 is an illustration of an overview of possible outcomes from the model where the results are risk rated, then the outcomes are divided into three sections which are the project evaluation, status and nonconformance overall report.

4.2. Project Allocation Development

The project evaluation commonly results from a certain analysis that has been performed according to the specific desired output. On the proposed model, the project allocation has been developed according to Ishikawa analysis results and the Quality, Cost, Delivery, Safety, Moral (QCDSM) category which assist in specifying the project that needs to be conducted to prevent the problem occurrences in future and to provide a feasible solution. The projects are specified into two categories, the integrated management system (IMS) as well as the 5s and re-process engineering project. The IMS project results from any result with Quality, Safety and Moral (Q, S, M) issues which are extracted from Ishikawa analysis eight types of waste.

The 5s and process engineering project results from cost and delay issues which are extracted from Ishikawa analysis and eight types of waste. Below on

Table 3 is an illustration of project allocation development.

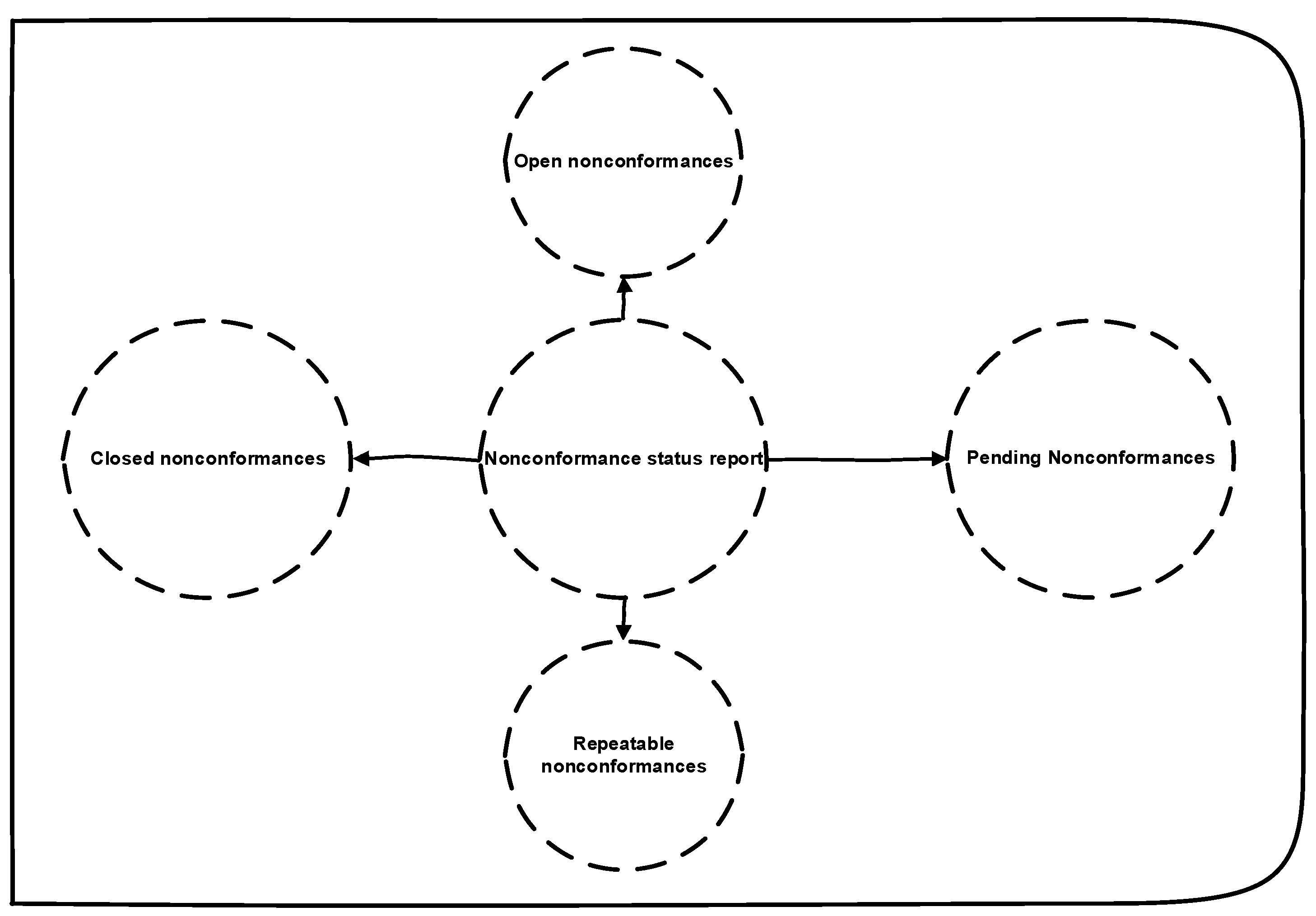

4.3. Nonconformance Status Report Development

The nonconformance status report assists the analyst to evaluate the effectiveness of the nonconformance closure system [

29]. On the proposed model, the nonconformance status report is developed from the data of opened nonconformances, pending nonconformances, closed nonconformances and the repeatable historical data of nonconformances. Below on

Figure 9 is an illustration of how the nonconformance report is developed on the proposed model.

The nonconformance related to quality issues with a unique code QC-001 resulted to the IMS project with a risk rating of 48% and as per status report, the corrective action was provided and the nonconformance was closed. Below on

Table 4 is an illustration of the results for the unique code QC-001.

The nonconformance related to safety issues with a unique code OHSA-001 resulted to the IMS project with a risk rating of 48% and as per status report, the corrective action was provided and the nonconformance was closed. Below

Table 5 is an illustration of results for unique code OSHA-001.

The nonconformance related to engineering maintenance issues with a unique code EM-001 resulted to the 5S and process re-engineering project with a risk rating of 32% and as per status report the corrective action was provided and the nonconformance was closed. Below on

Table 6 is an illustration of the results for the unique code EM-001.

5. Conclusions

Troubleshooting models can be served as a business development tool due to the accuracy of its problem-solving characteristics. If the troubleshooting system is more accurate, the business yields good quality products and good services to customers. The evaluation and upgrade of the existing troubleshooting models for problem solving could result to drastic improvements, hence, the business growth. This research has successfully evaluated the accuracy of the existing nonconformance troubleshooting models, the gap in finding the opportunity of the nonconformance raised and created a kaizen project through problem-solving analysis.

The newly developed model is composed of various lean tools which assisted in analyzing the root cause of the problem. The Ishikawa, 5Whys and eight types of wastes were the lean techniques used to build up the proposed model. For project evaluation, the QCDSM (Quality, Cost, Safety, Moral) total quality management progress-measuring features and lean techniques together with the risks analysis were applied to prioritize the kaizen projects accordingly. The developed model was then trialed as an application to the sampled portion of quality issues, safety incidents and process engineering breakdowns. The simulation of the proposed model resulted in a list of the kaizen projects to the case study company, which was the integrated management systems projects, 5S projects as well as process-engineering-related projects.

6. Future Works

The developed model aids the organisation to be more profitable and unique by evaluating opportunities of continual improvement within the occurrences of a problem related to quality issues, safety incidents as well as process engineering breakdowns. The examination of ergonomical and environmental continual improvement projects has been recommended due to the upgraded integrated management systems, which also includes environmental and process operators’ wellbeing. Integrated management systems have been upgraded into a combination of various fields that catalyse waste elimination and continual improvement within processes. An Integration Management system is integrated with safety and quality as well as the environmental standards which serves as a foundation for continual improvement.

An integration management also includes the environmental standard, hence, an environmental study is significant for good adherence to environmental study. Even though environmental projects can be evaluated through integrated management systems, there is a need for a risks assessment based on the aspect and impacts of environmental issues, hence, a need to improve the proposed model investigation analysis by adding parameters that could indicate the need of environmental aspects and impact risks assessment. The environmental aspects and impact risk analysis is an exercise performed to evaluate possible threats that could lead to noncompliance to the environmental standards.