A Cost-Effective System for Aerial 3D Thermography of Buildings

Abstract

1. Introduction

2. Materials and Methods

2.1. A Cost-Effective System

- Thermal and geometric data should be recorded by the same device and in a single measurement process.

- This device should be commercially available and cost-effective.

- The reconstruction software should not require images taken by more than one recording device.

- The reconstruction software should be as simple as possible without many parameters to tune.

2.2. Choice of Recording Device

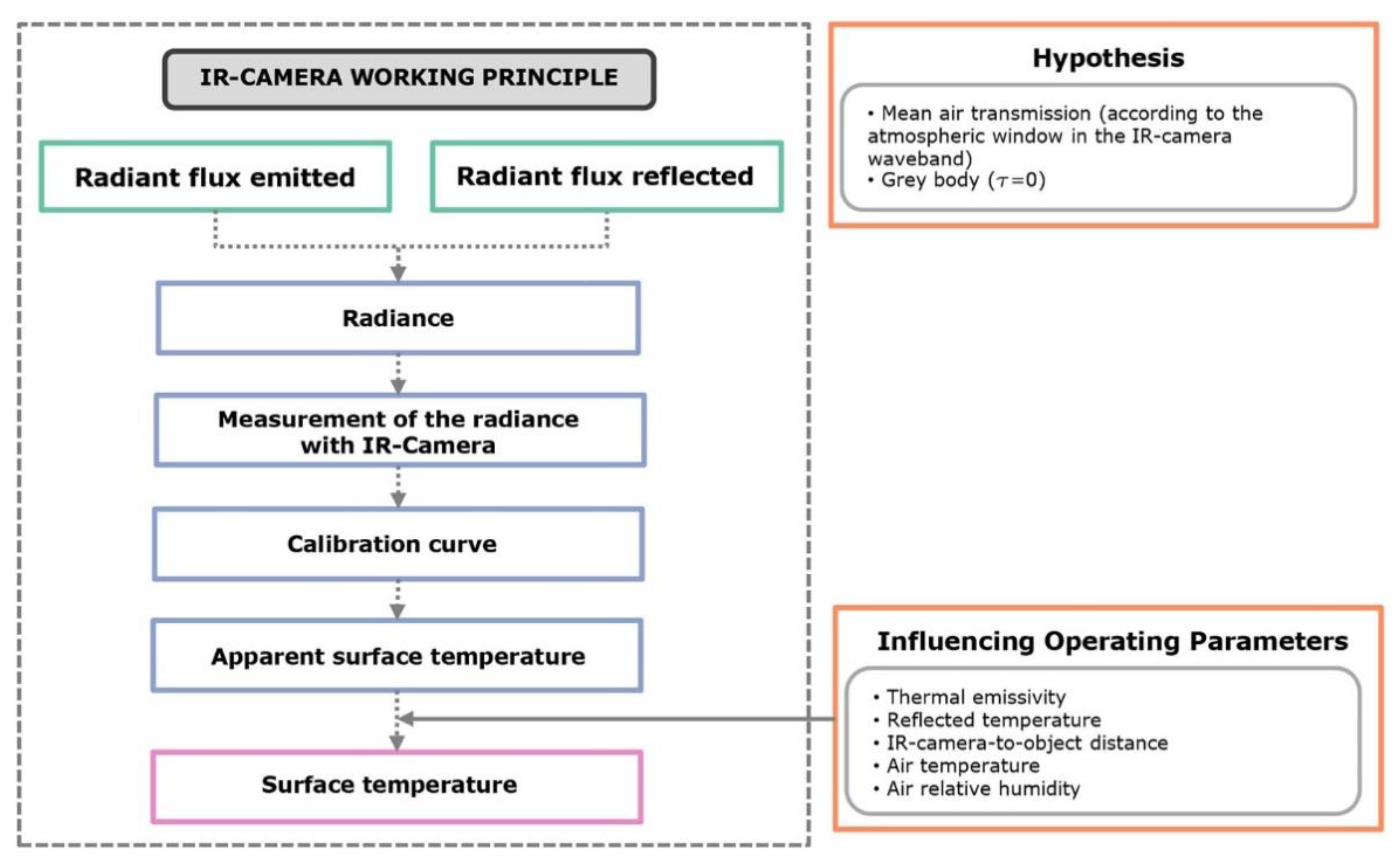

2.3. Calibration Procedure of Visible-Thermal Sensors

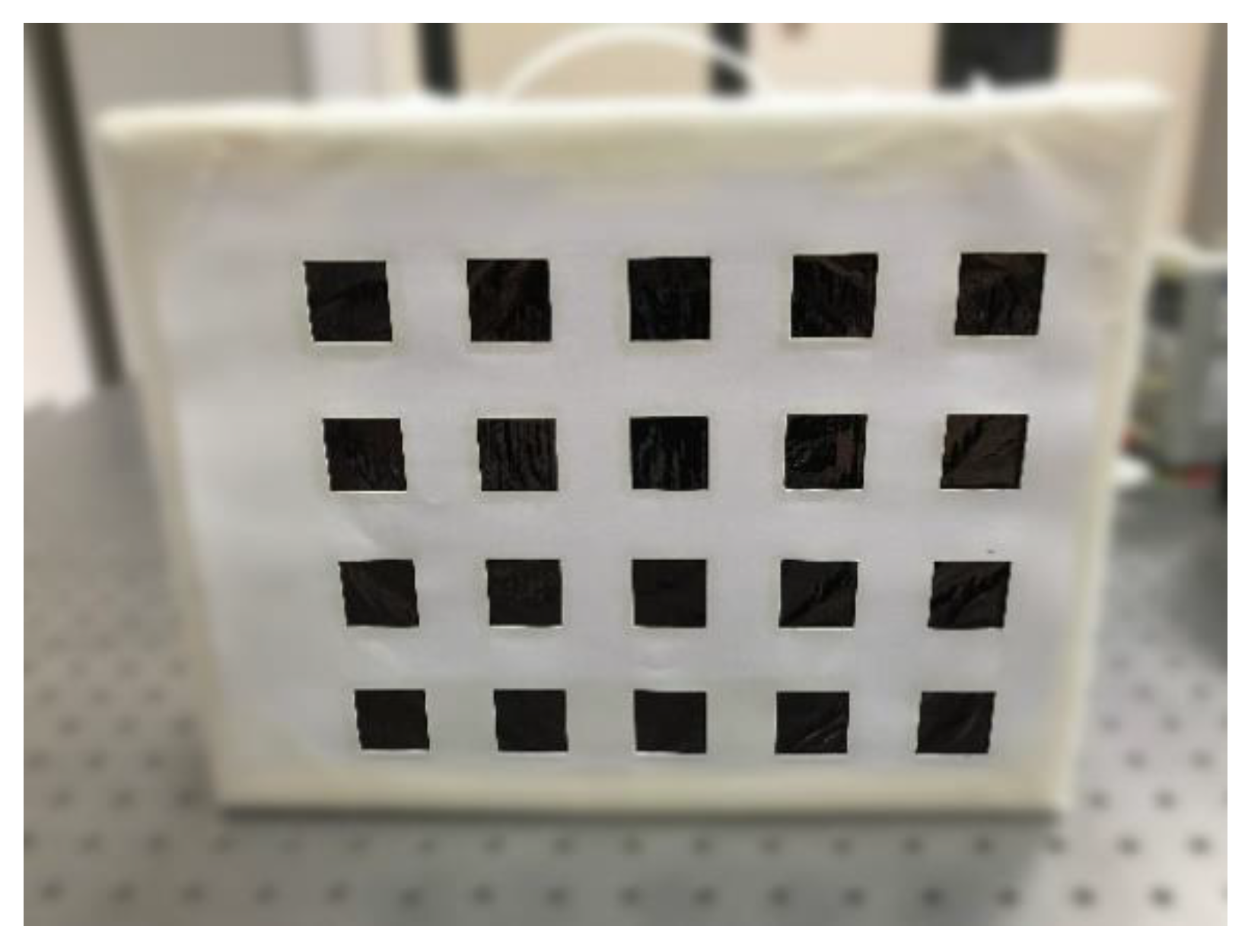

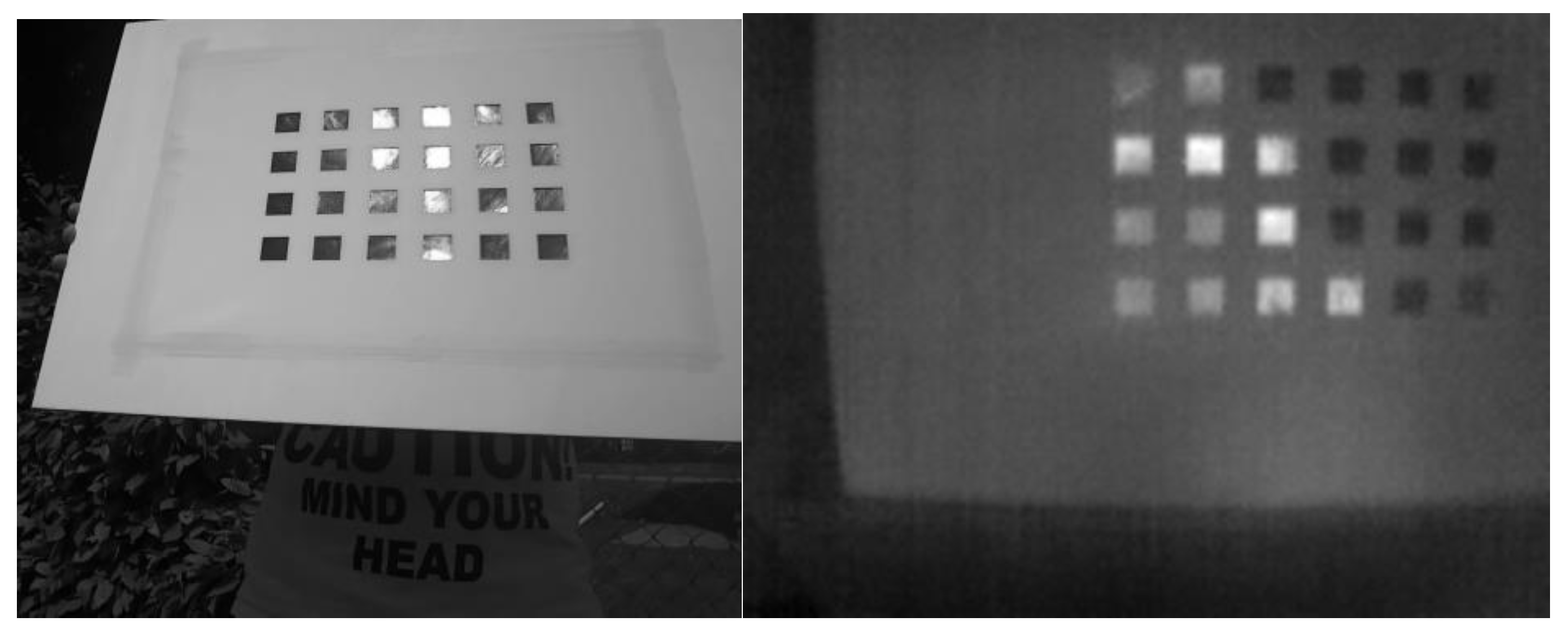

2.3.1. The Calibration Passive Target

2.3.2. The Calibration Algorithm

2.4. Validation on Virtual Environment

2.5. 3D Reconstruction Pipeline

2.6. Mission Planning and Drone Control

3. Results and Discussion

3.1. Experimental Setup

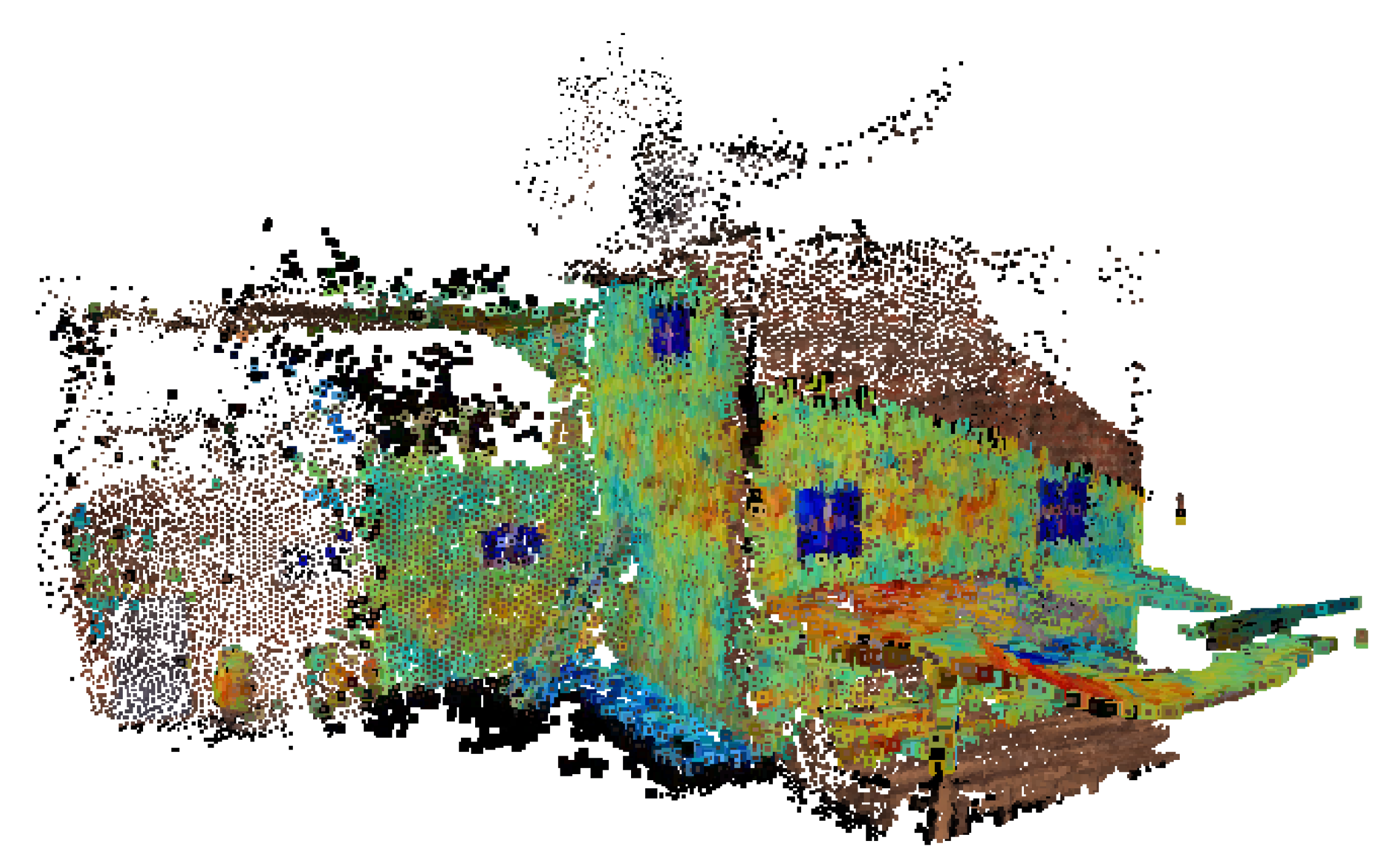

3.2. 3D Reconstruction

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Song, Z. Handbook of 3D machine vision: Optical metrology and imaging. In Optics and Optoelectronics; CRC Press: Boca Raton, FL, USA, 2013; ISBN 9781439872192. [Google Scholar]

- Vollmer, M.; Möllmann, K.-P. Infrared Thermal Imaging: Fundamentals, Research and Applications, 2nd ed.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2018; ISBN 9783527693320. [Google Scholar]

- Rakha, T.; Gorodetsky, A. Review of Unmanned Aerial System (UAS) applications in the built environment: Towards automated building inspection procedures using drones. Autom. Constr. 2018, 93, 252–264. [Google Scholar] [CrossRef]

- Garrido, I.; Lagüela, S.; Otero, R.; Arias, P. Thermographic methodologies used in infrastructure inspection: A review—Post-processing procedures. Appl. Energy 2020, 266, 114857. [Google Scholar] [CrossRef]

- Huang, Y.; Shih, P.; Hsu, K.-T.; Chiang, C.-H. To identify the defects illustrated on building facades by employing infrared thermography under shadow. NDT E Int. 2020, 111, 102240. [Google Scholar] [CrossRef]

- Teni, M.; Krstić, H.; Kosiński, P. Review and comparison of current experimental approaches for in-situ measurements of building walls thermal transmittance. Energy Build. 2019, 203, 109417. [Google Scholar] [CrossRef]

- Bienvenido-Huertas, D.; Moyano, J.; Marín, D.; Fresco-Contreras, R. Review of in situ methods for assessing the thermal transmittance of walls. Renew. Sustain. Energy Rev. 2019, 102, 356–371. [Google Scholar] [CrossRef]

- Soares, N.; Martins, C.; Gonçalves, M.; Santos, P.; da Silva, L.S.; Costa, J.J. Laboratory and in-situ non-destructive methods to evaluate the thermal transmittance and behavior of walls, windows, and construction elements with innovative materials: A review. Energy Build. 2019, 182, 88–110. [Google Scholar] [CrossRef]

- Glavaš, H.; Hadzima-Nyarko, M.; Buljan, I.H.; Barić, T. Locating Hidden Elements in Walls of Cultural Heritage Buildings by Using Infrared Thermography. Buildings 2019, 9, 32. [Google Scholar] [CrossRef]

- Royuela-del-Val, A.; Padilla-Marcos, M.Á.; Meiss, A.; Casaseca-de-la-Higuera, P.; Feijó-Muñoz, J. Air infiltration monitoring using thermography and neural networks. Energy Build. 2019, 191, 187–199. [Google Scholar] [CrossRef]

- Nardi, I.; Lucchi, E.; de Rubeis, T.; Ambrosini, D. Quantification of heat energy losses through the building envelope: A state-of-the-art analysis with critical and comprehensive review on infrared thermography. Build. Environ. 2018, 146, 190–205. [Google Scholar] [CrossRef]

- Kirimtat, A.; Krejcar, O. A review of infrared thermography for the investigation of building envelopes: Advances and prospects. Energy Build. 2018, 176, 390–406. [Google Scholar] [CrossRef]

- Baldinelli, G.; Bianchi, F.; Rotili, A.; Costarelli, D.; Seracini, M.; Vinti, G.; Asdrubali, F.; Evangelisti, L. A model for the improvement of thermal bridges quantitative assessment by infrared thermography. Appl. Energy 2018, 211, 854–864. [Google Scholar] [CrossRef]

- Lucchi, E. Applications of the infrared thermography in the energy audit of buildings: A review. Renew. Sust. Energy Rev. 2018, 82, 3077–3090. [Google Scholar] [CrossRef]

- Lerma, C.; Barreira, E.; Almeida, R.M.S.F. A discussion concerning active infrared thermography in the evaluation of buildings air infiltration. Energy Build. 2018, 168, 56–66. [Google Scholar] [CrossRef]

- O’Grady, M.; Lechowska, A.A.; Harte, A.M. Quantification of heat losses through building envelope thermal bridges influenced by wind velocity using the outdoor infrared thermography technique. Appl. Energy 2017, 208, 1038–1052. [Google Scholar] [CrossRef]

- Barreira, E.; Almeida, R.M.S.F.; Moreira, M. An infrared thermography passive approach to assess the effect of leakage points in buildings. Energy Build. 2017, 140, 224–235. [Google Scholar] [CrossRef]

- Fox, M.; Goodhew, S.; De Wilde, P. Building defect detection: External versus internal thermography. Build. Environ. 2016, 105, 317–331. [Google Scholar] [CrossRef]

- Nardi, I.; Paoletti, D.; Ambrosini, D.; de Rubeis, T.; Sfarra, S. U-value assessment by infrared thermography: A comparison of different calculation methods in a Guarded Hot Box. Energy Build. 2016, 122, 211–221. [Google Scholar] [CrossRef]

- Djupkep Dizeu, F.; Maldague, X.; Bendada, A. Mapping of the Indoor Conditions by Infrared Thermography. J. Imaging 2016, 2, 10. [Google Scholar] [CrossRef]

- Barreira, E.; Almeida, R.M.S.F.; Delgado, J.M.P.Q. Infrared thermography for assessing moisture related phenomena in building components. Constr. Build. Mater. 2016, 110, 251–269. [Google Scholar] [CrossRef]

- Sfarra, S.; Marcucci, E.; Ambrosini, D.; Paoletti, D. Infrared exploration of the architectural heritage: From passive infrared thermography to hybrid infrared thermography (HIRT) approach. Mater. Constr. 2016, 66, e094. [Google Scholar] [CrossRef]

- Fox, M.; Coley, D.; Goodhew, S.; De Wilde, P. Time-lapse thermography for building defect detection. Energy Build. 2015, 92, 95–106. [Google Scholar] [CrossRef]

- Albatici, R.; Tonelli, A.M.; Chiogna, M. A comprehensive experimental approach for the validation of quantitative infrared thermography in the evaluation of building thermal transmittance. Appl. Energy 2015, 141, 218–228. [Google Scholar] [CrossRef]

- Kylili, A.; Fokaides, P.A.; Christou, P.; Kalogirou, S.A. Infrared thermography (IRT) applications for building diagnostics: A review. Appl. Energy 2014, 134, 531–549. [Google Scholar] [CrossRef]

- Nardi, I.; Sfarra, S.; Ambrosini, D. Quantitative thermography for the estimation of the U-value: State of the art and a case study. J. Phys. Conf. Ser. 2014, 547, 012016. [Google Scholar] [CrossRef]

- Krankenhagen, R.; Maierhofer, C. Pulse phase thermography for characterising large historical building façades after solar heating and shadow cast—A case study. Quant. Infrared Thermogr. J. 2014, 11, 10–28. [Google Scholar] [CrossRef]

- Paoletti, D.; Ambrosini, D.; Sfarra, S.; Bisegna, F. Preventive thermographic diagnosis of historical buildings for consolidation. J. Cult. Herit. 2013, 14, 116–121. [Google Scholar] [CrossRef]

- Dall’O’, G.; Sarto, L.; Panza, A. Infrared Screening of Residential Buildings for Energy Audit Purposes: Results of a Field Test. Energies 2013, 6, 3859–3878. [Google Scholar] [CrossRef]

- Martínez-Corral, M.; Javidi, B. Fundamentals of 3D imaging and displays: A tutorial on integral imaging, light-field, and plenoptic systems. Adv. Opt. Photonics 2018, 10, 512. [Google Scholar] [CrossRef]

- Remondino, F.; El-Hakim, S. Image-based 3D modelling: A review. Photogramm. Rec. 2006, 21, 269–291. [Google Scholar] [CrossRef]

- Santos, P.; Ritz, M.; Fuhrmann, C.; Fellner, D. 3D mass digitization: A milestone for archaeological documentation. Virtual Archaeol. Rev. 2017, 8, 1. [Google Scholar] [CrossRef]

- Aicardi, I.; Chiabrando, F.; Maria Lingua, A.; Noardo, F. Recent trends in cultural heritage 3D survey: The photogrammetric computer vision approach. J. Cult. Herit. 2018, 32, 257–266. [Google Scholar] [CrossRef]

- Markiewicz, J.; Tobiasz, A.; Kot, P.; Muradov, M.; Shaw, A.; Al-Shammaa, A. Review of Surveying Devices for Structural Health Monitoring of Cultural Heritage Buildings. In Proceedings of the 2019 12th International Conference on Developments in eSystems Engineering (DeSE), Kazan, Russia, 7–10 October 2019; pp. 597–601. [Google Scholar]

- Chernov, G.; Chernov, V.; Barboza Flores, M. 3D dynamic thermography system for biomedical applications. In Application of Infrared to Biomedical Sciences; Ng, E.Y.K., Etehadtavakol, M., Eds.; Springer: Singapore, 2017; pp. 517–545. [Google Scholar]

- Nardi, I.; Sfarra, S.; Ambrosini, D.; Dominici, D.; Rosciano, E. Complementarity of terrestrial laser scanning and IR thermography for the diagnosis of cultural heritage: The case of Pacentro Castle. In Proceedings of the 13th International Workshop on Advanced Infrared Technology & Applications, Pisa, Italy, 29 Semptember–2 October 2015; pp. 263–266, ISBN 9788879580250. [Google Scholar]

- Wang, C.; Cho, Y.K.; Gai, M. As-Is 3D Thermal Modeling for Existing Building Envelopes Using a Hybrid LIDAR System. J. Comput. Civ. Eng. 2013, 27, 645–656. [Google Scholar] [CrossRef]

- González-Aguilera, D.; Rodriguez-Gonzalvez, P.; Armesto, J.; Lagüela, S. Novel approach to 3D thermography and energy efficiency evaluation. Energy Build. 2012, 54, 436–443. [Google Scholar] [CrossRef]

- Natephra, W.; Motamedi, A.; Yabuki, N.; Fukuda, T. Integrating 4D thermal information with BIM for building envelope thermal performance analysis and thermal comfort evaluation in naturally ventilated environments. Build. Environ. 2017, 124, 194–208. [Google Scholar] [CrossRef]

- Ceccarelli, S.; Guarneri, M.; Ferri de Collibus, M.; Francucci, M.; Ciaffi, M.; Danielis, A. Laser Scanners for High-Quality 3D and IR Imaging in Cultural Heritage Monitoring and Documentation. J. Imaging 2018, 4, 130. [Google Scholar] [CrossRef]

- Kirimtat, A.; Krejcar, O.; Selamat, A.; Herrera-Viedma, E. FLIR vs SEEK thermal cameras in biomedicine: Comparative diagnosis through infrared thermography. BMC Bioinform. 2020, 21, 88. [Google Scholar] [CrossRef]

- Jaspers, M.E.H.; Carrière, M.E.; Meij-de Vries, A.; Klaessens, J.H.G.M.; van Zuijlen, P.P.M. The FLIR ONE thermal imager for the assessment of burn wounds: Reliability and validity study. Burns 2017, 43, 1516–1523. [Google Scholar] [CrossRef]

- García-Tejero, I.; Ortega-Arévalo, C.; Iglesias-Contreras, M.; Moreno, J.; Souza, L.; Tavira, S.; Durán-Zuazo, V. Assessing the Crop-Water Status in Almond (Prunus dulcis Mill.) Trees via Thermal Imaging Camera Connected to Smartphone. Sensors 2018, 18, 1050. [Google Scholar] [CrossRef]

- Yang, M.-D.; Su, T.-C.; Lin, H.-Y. Fusion of Infrared Thermal Image and Visible Image for 3D Thermal Model Reconstruction Using Smartphone Sensors. Sensors 2018, 18, 2003. [Google Scholar] [CrossRef]

- Daffara, C.; Marchioro, G.; Ambrosini, D. Smartphone diagnostics for cultural heritage. In SPIE 11058, Optics for Arts, Architecture, and Archaeology VII.; Liang, H., Groves, R., Targowski, P., Eds.; SPIE: Munich, Germany, 2019; pp. 260–270. [Google Scholar] [CrossRef]

- Somboonkaew, A.; Vuttivong, S.; Prempree, P.; Amarit, R.; Chanhorm, S.; Chaitavon, K.; Porntheeraphat, S.; Sumriddetchkajorn, S. Temperature-compensated infrared-based low-cost mobile platform module for mass human temperature screening. Appl. Opt. 2020, 59, E112. [Google Scholar] [CrossRef]

- FLIR C2 Datasheet. Available online: https://flir.netx.net/file/asset/7595/original (accessed on 20 June 2020).

- FLIR Duo R Datasheet. Available online: https://flir.netx.net/file/asset/10905/original (accessed on 22 June 2020).

- Rangel, J.; Soldan, S.; Kroll, A. 3D Thermal Imaging: Fusion of Thermography and Depth Cameras. In Proceedings of the 2014 International Conference on Quantitative InfraRed Thermograph, QIRT Council, Bordeaux, France, 7–11 July 2014. [Google Scholar]

- Matas, J.; Chum, O.; Urban, M.; Pajdla, T. Robust wide-baseline stereo from maximally stable extremal regions. Image Vis. Comput. 2004, 22, 761–767. [Google Scholar] [CrossRef]

- Zhang, Z. Flexible camera calibration by viewing a plane from unknown orientations. In Proceedings of the 7th IEEE international conference on computer vision, Kerkyra, Greece, 20–27 September 1999; Volume 1, pp. 666–673. [Google Scholar]

- Bolles, R.C.; Baker, H.H.; Marimont, D.H. Epipolar-plane image analysis: An approach to determining structure from motion. Int. J. Comput. Vis. 1987, 1, 7–55. [Google Scholar] [CrossRef]

- Ullman, S. The interpretation of structure from motion. Proc. R. Soc. Lond. B 1979, 203, 405–426. [Google Scholar] [CrossRef] [PubMed]

- Koenderink, J.J.; van Doorn, A.J. Affine structure from motion. J. Opt. Soc. Am. A 1991, 8, 377. [Google Scholar] [CrossRef] [PubMed]

- Westoby, M.J.; Brasington, J.; Glasser, N.F.; Hambrey, M.J.; Reynolds, J.M. ‘Structure-from-Motion’ photogrammetry: A low-cost, effective tool for geoscience applications. Geomorphology 2012, 179, 300–314. [Google Scholar] [CrossRef]

- Schonberger, J.L.; Frahm, J.-M. Structure-from-Motion Revisited. In Proceedings of the 2016 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Las Vegas, NV, USA, 27–30 June 2016; pp. 4104–4113. [Google Scholar]

- Özyeşil, O.; Voroninski, V.; Basri, R.; Singer, A. A survey of structure from motion. Acta Numer. 2017, 26, 305–364. [Google Scholar] [CrossRef]

- Saputra, M.R.U.; Markham, A.; Trigoni, N. Visual SLAM and Structure from Motion in Dynamic Environments: A Survey. ACM Comput. Surv. 2018, 51, 1–36. [Google Scholar] [CrossRef]

- Hartley, R.; Zisserman, A. Multiple View Geometry in Computer Vision, 2nd ed.; Cambridge University Press: Cambridge, UK, 2004; ISBN 9780521540513. [Google Scholar]

- Moulon, P.; Monasse, P.; Perrot, R.; Marlet, R. Openmvg: Open multiple view geometry. In International Workshop on Reproducible Research in Pattern Recognition; Springer: Cham, Switzerland, 2016; pp. 60–74. [Google Scholar]

- Alcantarilla, P.F.; Nuevo, J.; Bartoli, A. Fast explicit diffusion for accelerated features in nonlinear scale spaces. IEEE Trans. Patt. Anal. Mach. Intell. 2011, 34, 1281–1298. [Google Scholar]

| Authors | Year | Main Topic | Notes |

|---|---|---|---|

| Garrido et al. [4] | 2020 | Post-processing | Review |

| Huang et al. [5] | 2020 | Facades diagnostics | |

| Teni et al. [6] | 2019 | Thermal transmittance | Review |

| Bienvenido-Huertas et al. [7] | 2019 | Thermal transmittance | Review |

| Soares et al. [8] | 2019 | Thermal transmittance | Review |

| Glavaš et al. [9] | 2019 | Cultural heritage | |

| Royuela-del-Val et al. [10] | 2019 | Air infiltration | Neural network |

| Nardi et al. [11] | 2018 | Heat losses | Review |

| Kirimtat et al. [12] | 2018 | Thermal performance | Review |

| Baldinelli et al. [13] | 2018 | Thermal bridges | |

| Lucchi [14] | 2018 | Energy audit | Review |

| Lerma et al. [15] | 2018 | Air infiltration | |

| O’Grady et al. [16] | 2017 | Heat losses | |

| Barreira et al. [17] | 2017 | Air leakage | |

| Fox et al. [18] | 2016 | Diagnostics | |

| Nardi et al. [19] | 2016 | Thermal transmittance | |

| Djupkep Dizeu et al. [20] | 2016 | Indoor conditions | |

| Barreira et al. [21] | 2016 | Moisture | |

| Sfarra et al. [22] | 2016 | Cultural heritage | Solar heating |

| Fox et al. [23] | 2015 | Diagnostics | |

| Albatici et al. [24] | 2015 | Thermal transmittance | |

| Kylili et al. [25] | 2014 | Diagnostics | Review |

| Nardi et al. [26] | 2014 | Thermal transmittance | |

| Krankenhagen et al. [27] | 2014 | Cultural heritage | Solar heating |

| Paoletti et al. [28] | 2013 | Cultural heritage | |

| Dall’O’ et al. [29] | 2013 | Energy audit |

| Imaging Specifications | FLIR C2 | FLIR Duo R |

|---|---|---|

| IR sensor | 80 × 60 pixels | 160 × 120 pixels |

| Thermal sensitivity | <0.10 °C | <0.050 °C (*) |

| Field of view | 41° × 31° | 57° × 44° |

| Spectral range | 7.5–14 μm | 7.5–13.5 μm |

| Accuracy | ±2 °C | ±5 °C |

| Digital camera | 640 × 480 pixels | 1920 × 1080 pixels |

| Operating temp. range | −10 to +50 °C | 0 to +50 °C |

| Weight (incl. battery) | 0.13 kg | 0.084 kg |

| Size | 125 × 80 × 24 mm3 | 59 × 41 × 29.6 mm3 |

| UAV Commands | Parameters | Description |

|---|---|---|

| HOME | (latitude, longitude, altitude) | Define the home position for the UAV controller |

| WAYPOINT | (latitude, longitude, altitude) | Define a new waypoint to the current flight plan |

| CAMROT | (yaw, pitch, rool) | Set a camera rotation relative to the forward direction |

| SHOT | none | Trigger the shot command to the FLIR Duo R |

| CYAW | (yaw, pitch, rool) | Define the forward direction of the camera with respect to the initial rotation |

| LOITER | (latitude, longitude, altitude) | Keep the UAV in the commanded position |

| LAND | none | Start the landing procedure |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Daffara, C.; Muradore, R.; Piccinelli, N.; Gaburro, N.; de Rubeis, T.; Ambrosini, D. A Cost-Effective System for Aerial 3D Thermography of Buildings. J. Imaging 2020, 6, 76. https://doi.org/10.3390/jimaging6080076

Daffara C, Muradore R, Piccinelli N, Gaburro N, de Rubeis T, Ambrosini D. A Cost-Effective System for Aerial 3D Thermography of Buildings. Journal of Imaging. 2020; 6(8):76. https://doi.org/10.3390/jimaging6080076

Chicago/Turabian StyleDaffara, Claudia, Riccardo Muradore, Nicola Piccinelli, Nicola Gaburro, Tullio de Rubeis, and Dario Ambrosini. 2020. "A Cost-Effective System for Aerial 3D Thermography of Buildings" Journal of Imaging 6, no. 8: 76. https://doi.org/10.3390/jimaging6080076

APA StyleDaffara, C., Muradore, R., Piccinelli, N., Gaburro, N., de Rubeis, T., & Ambrosini, D. (2020). A Cost-Effective System for Aerial 3D Thermography of Buildings. Journal of Imaging, 6(8), 76. https://doi.org/10.3390/jimaging6080076