Neutron Imaging with Timepix Coupled Lithium Indium Diselenide

Abstract

:1. Introduction

1.1. Indirect Neutron Detection

1.2. Direct Neutron Detection

1.3. Lithium Indium Diselenide

1.4. High-Resolution Imaging

2. Materials and Methods

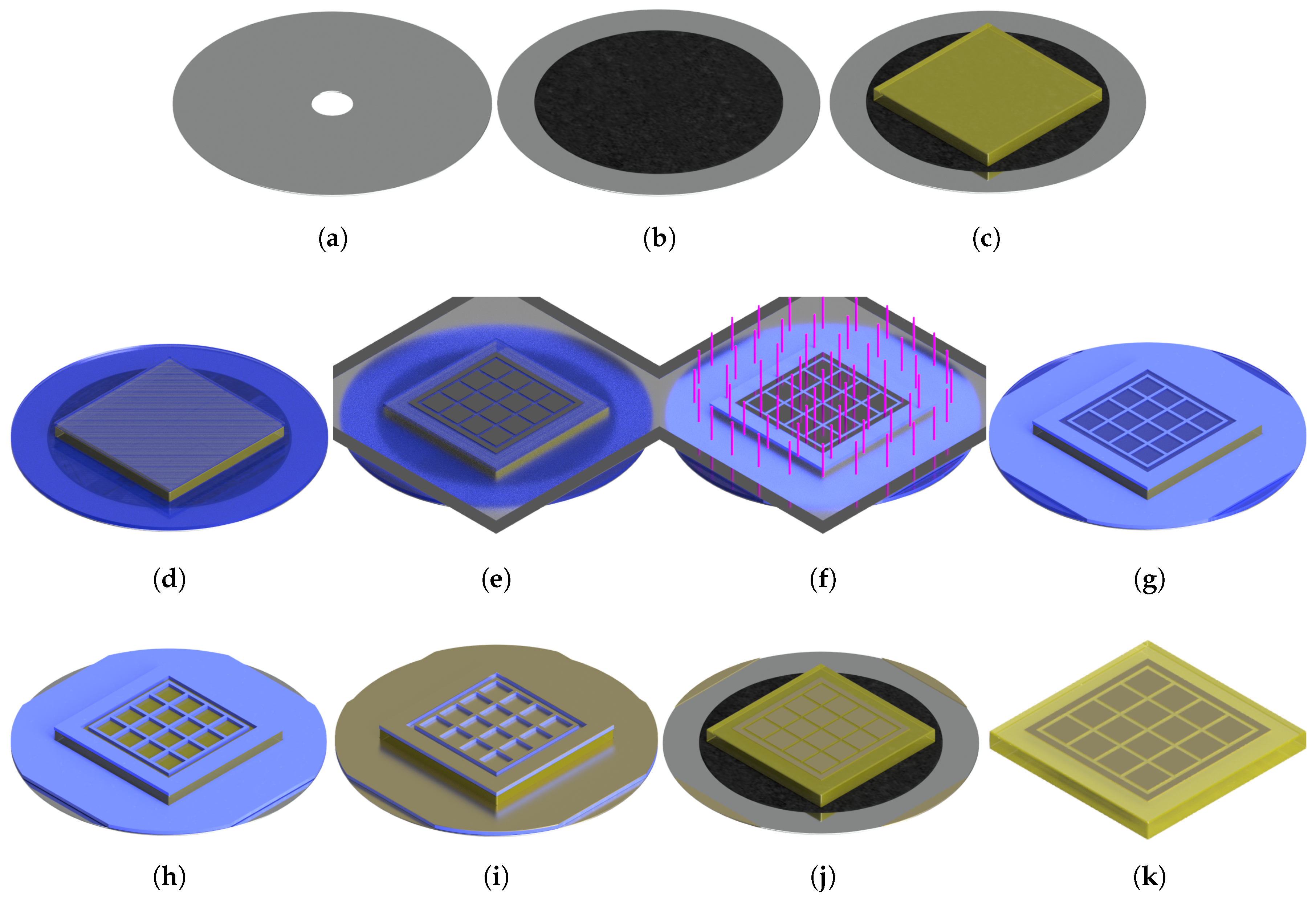

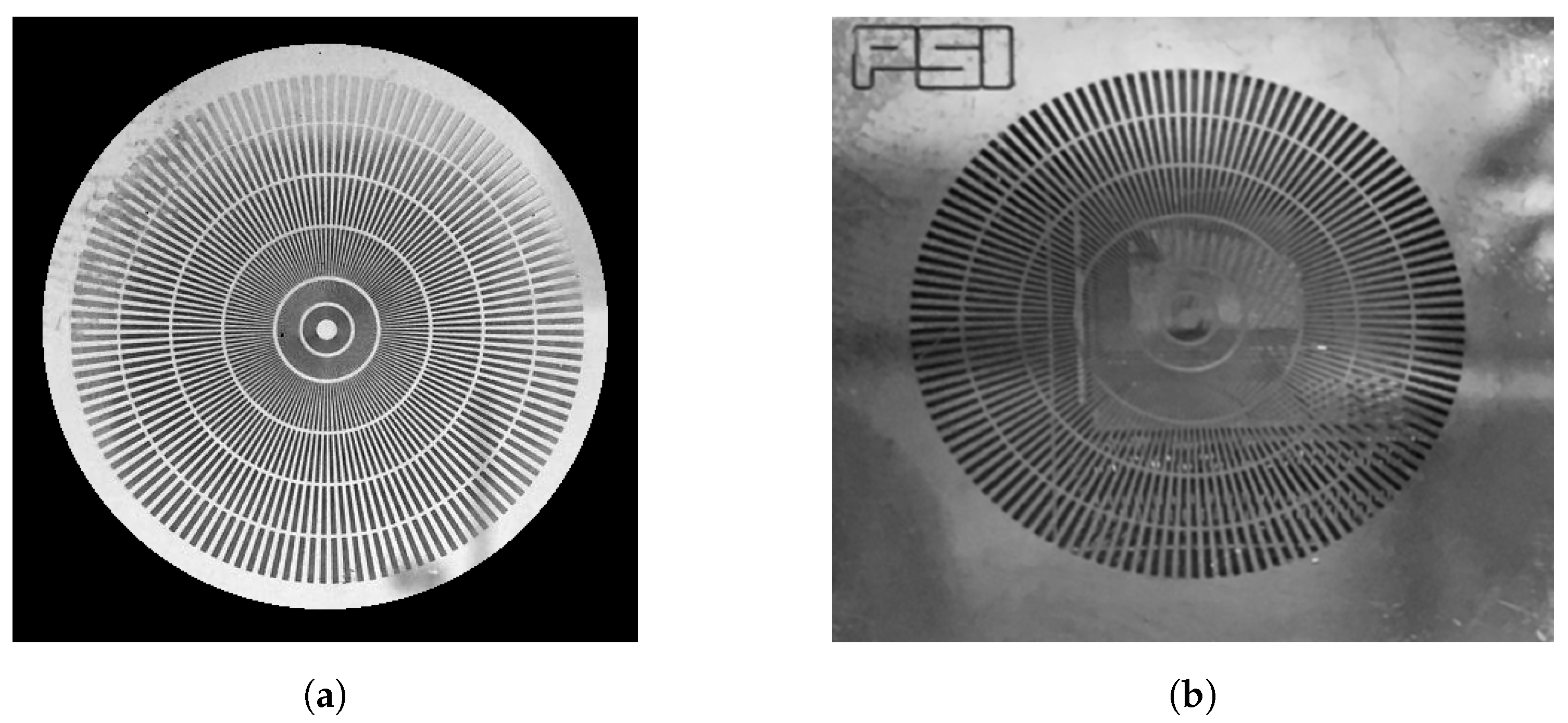

2.1. Sensor Fabrication

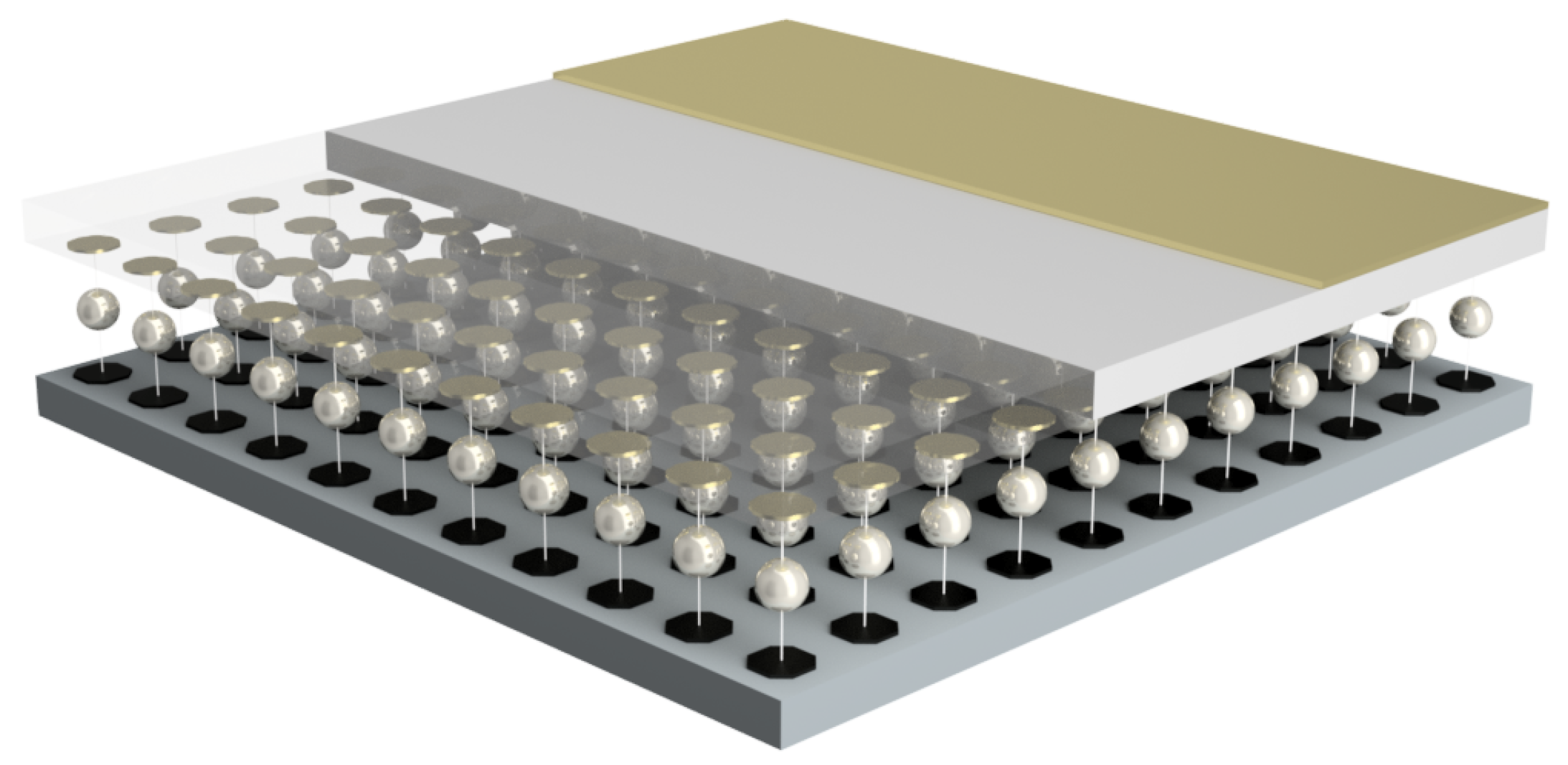

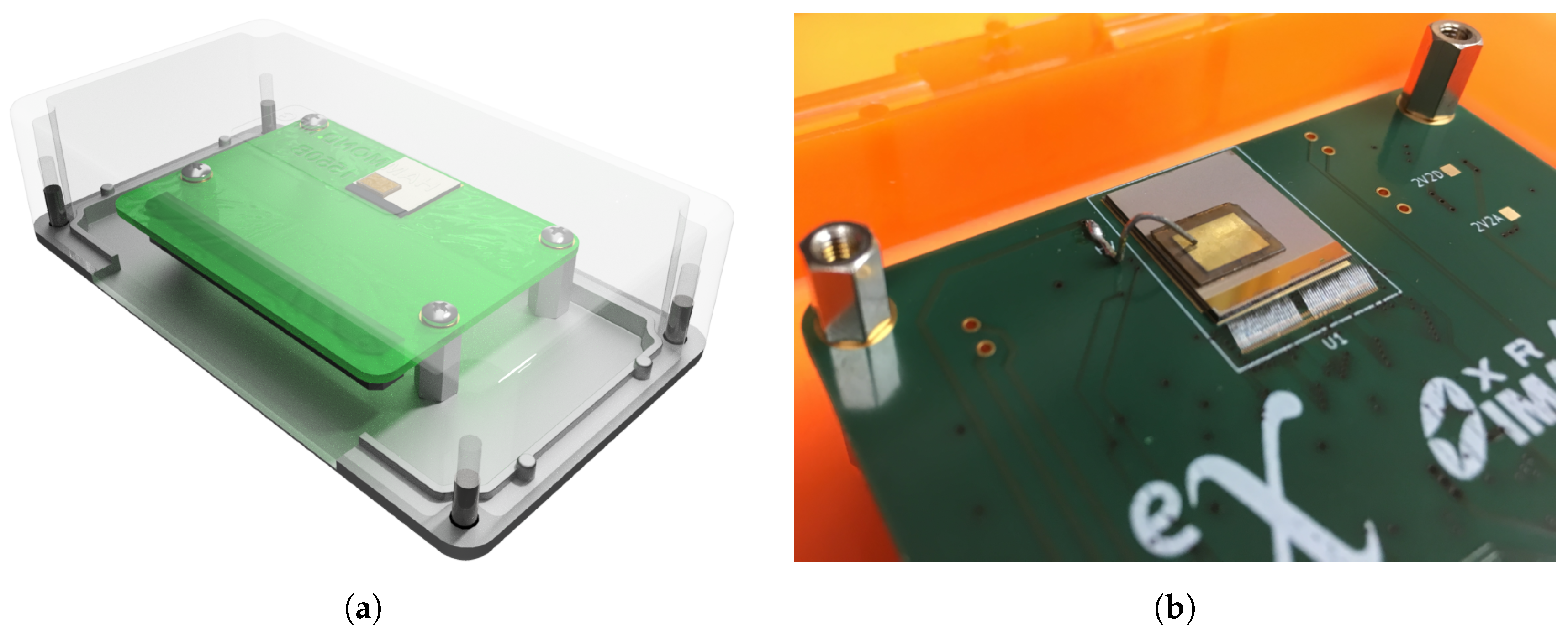

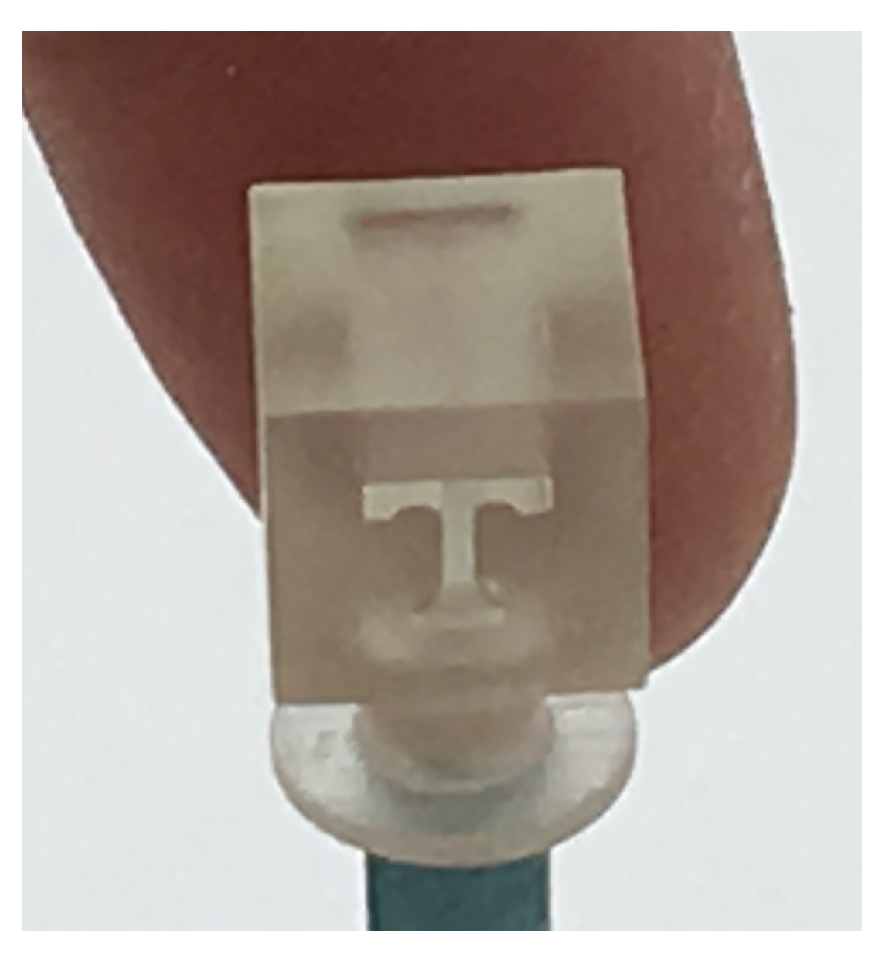

2.2. Imaging Device Construction

2.3. HFIR Beamline Testing

2.4. Image Processing

3. Results

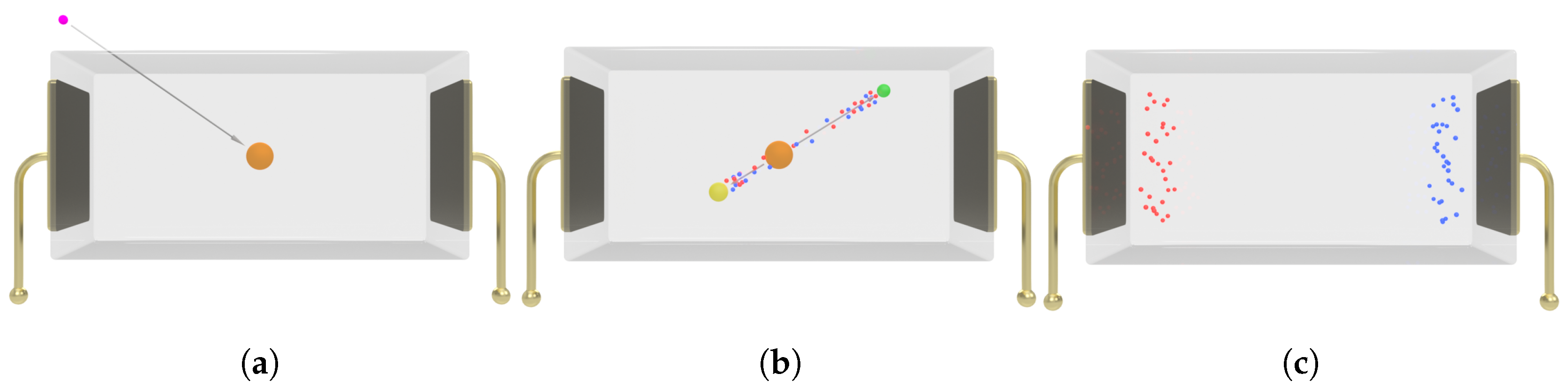

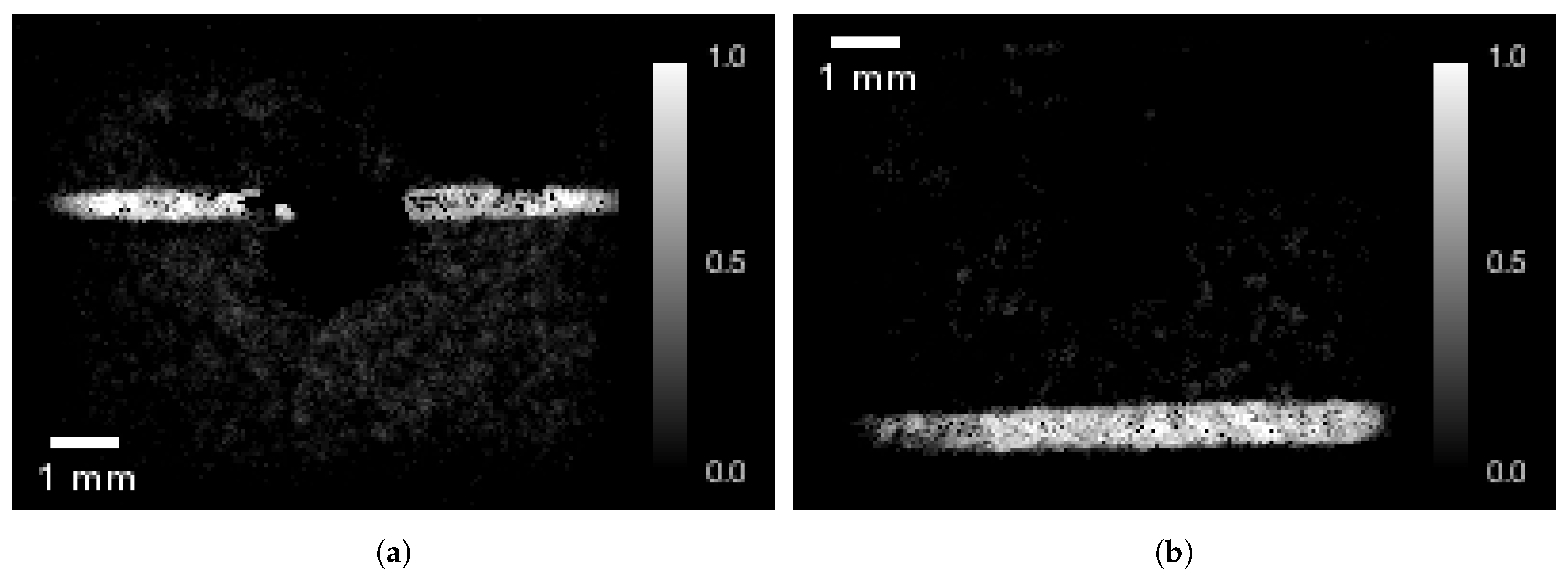

3.1. PuBe Source Response

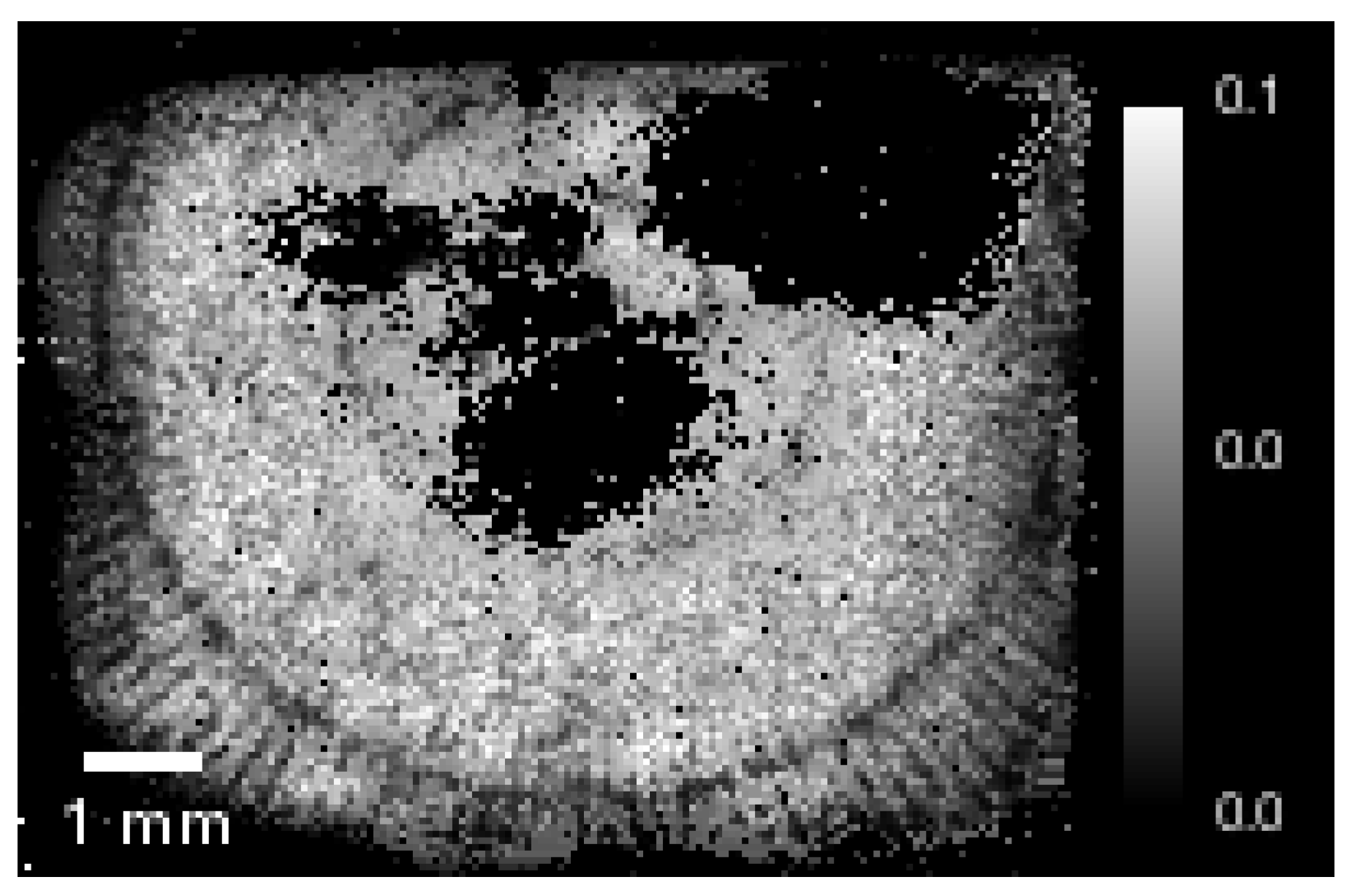

3.2. Open Beam Response

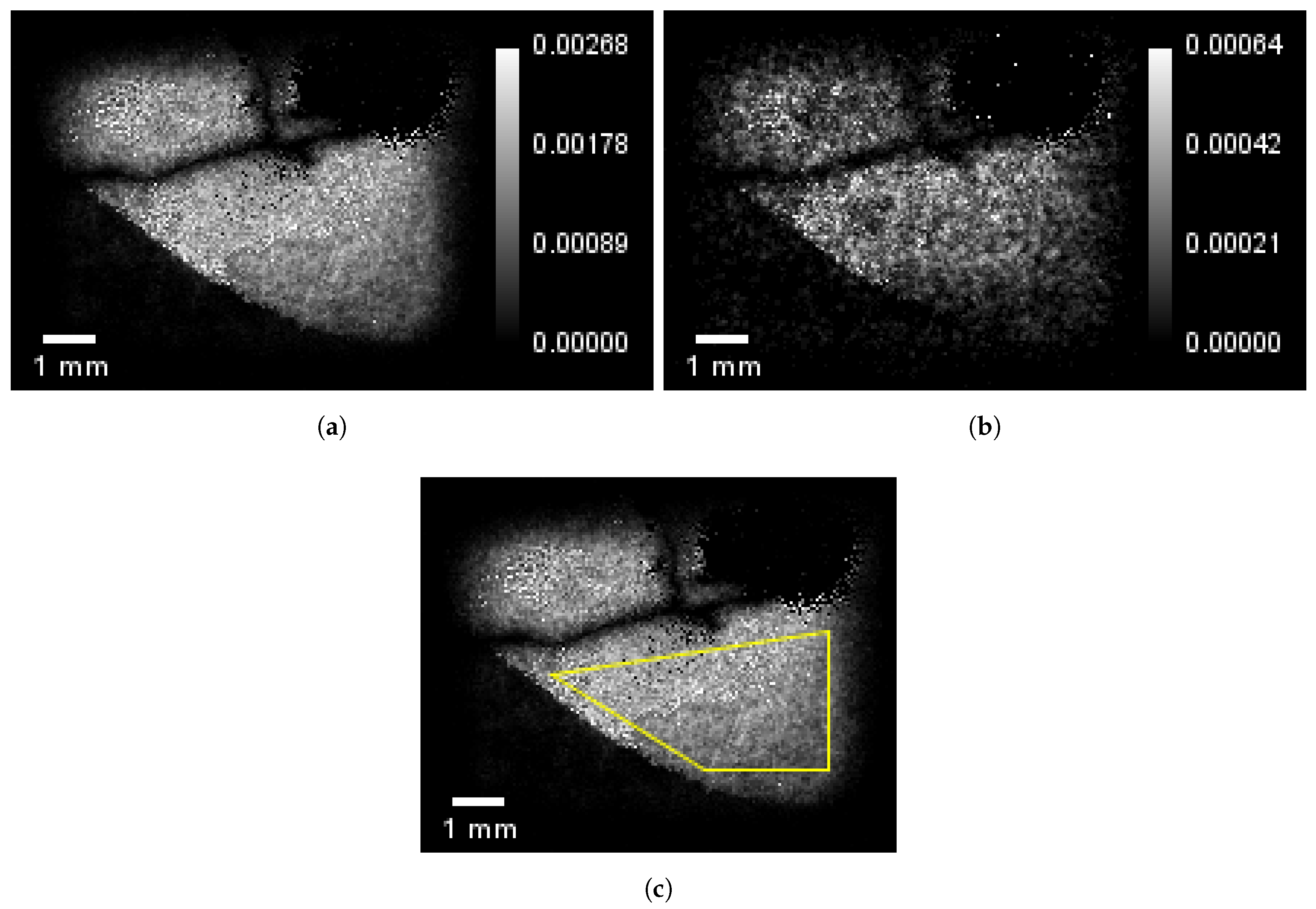

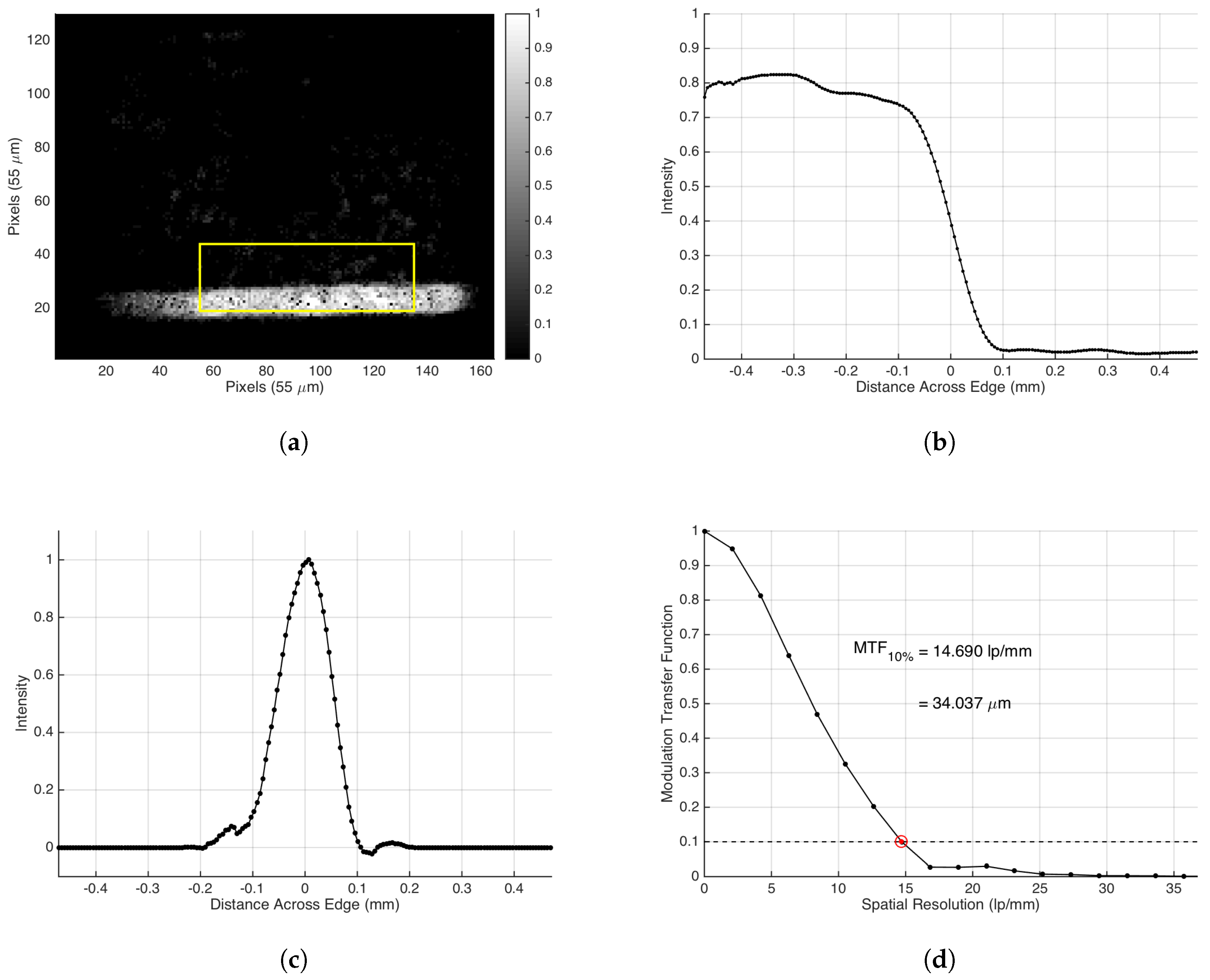

3.3. Knife Edge Test

3.4. Resolution Testing

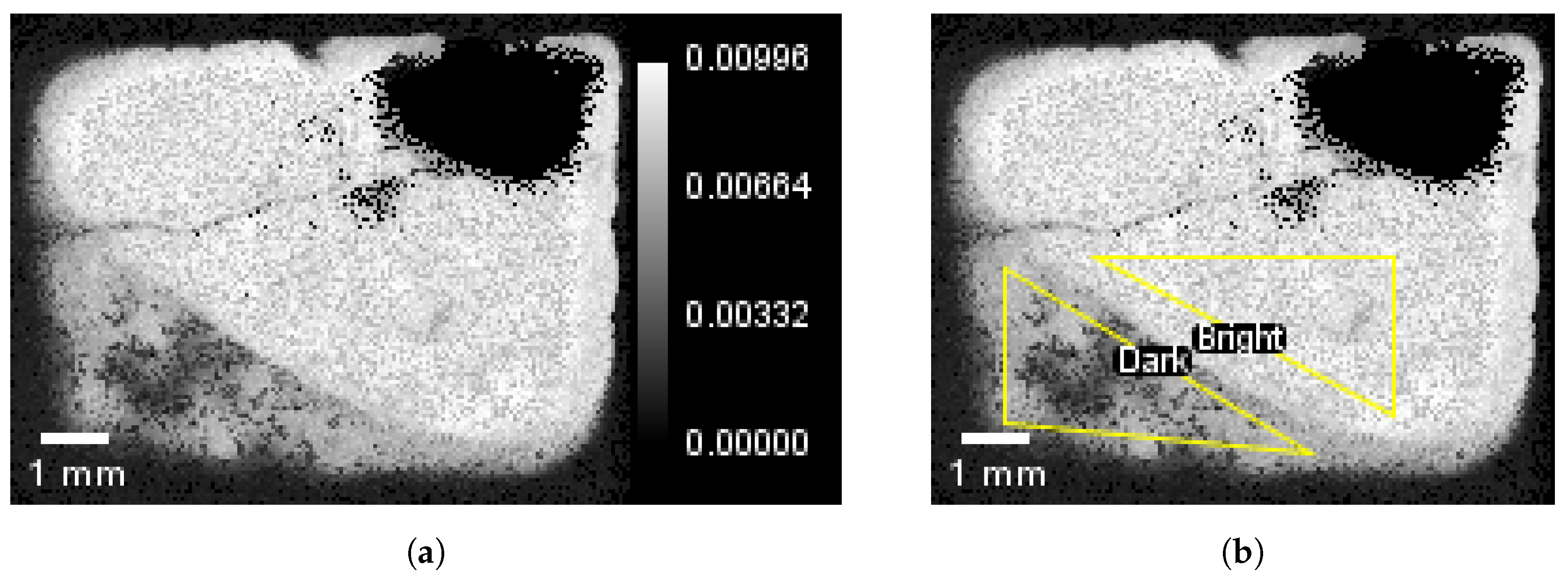

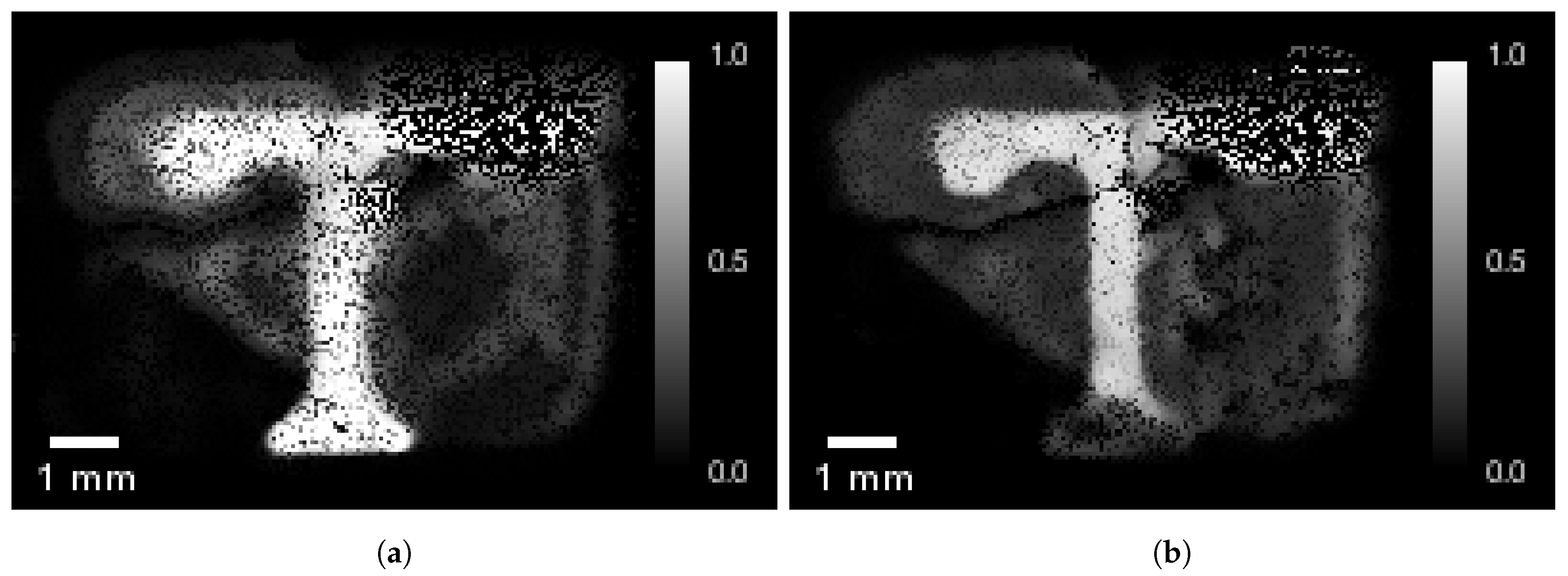

3.5. Object Identification

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| ASIC | Application specific integrated circuit |

| CAD | Computer aided design |

| DOAJ | Directory of open access journals |

| RF | Radio frequency |

| HFIR | High-Flux Isotope Reactor |

| LISe | Lithium indium diselenide |

| MDPI | Multidisciplinary Digital Publishing Institute |

| ORNL | Oak Ridge National Laboratory |

| PCB | Printed circuit board |

| PSI | Paul Scherrer Institute |

| ROI | Region of interest |

| SLA | Stereolithography apparatus |

| UV | Ultraviolet |

References

- Anderson, I.S.; Bilheux, H.Z.; McGreevy, R. (Eds.) Neutron Imaging and Applications; Springe: New York, NY, USA, 2009. [Google Scholar]

- Grünzweig, C.; Mannes, D.; Kaestner, A.; Schmid, F.; Vontobel, P.; Hovind, J.; Hartmann, S.; Peetermans, S.; Lehmann, E. Progress in Industrial Applications using Modern Neutron Imaging Techniques. Phys. Procedia 2013, 43, 231–242. [Google Scholar] [CrossRef]

- Owens, A. Compound Semiconductor Radiation Detectors; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Baker, C.; Green, K.; van der Grinten, M.; Iaydjiev, P.; Ivanov, S.; Al-Ayoubi, S.; Harris, P.; Pendlebury, J.; Shiers, D.; Geltenbort, P. Development of solid-state silicon devices as ultra cold neutron detectors. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 2002, 487, 511–520. [Google Scholar] [CrossRef]

- Santodonato, L.; Bilheux, H.; Bailey, B.; Bilheux, J.; Nguyen, P.; Tremsin, A.; Selby, D.; Walker, L. The CG-1D Neutron Imaging Beamline at the Oak Ridge National Laboratory High Flux Isotope Reactor. Phys. Procedia 2015, 69, 104–108. [Google Scholar] [CrossRef]

- Trtik, P.; Hovind, J.; Grünzweig, C.; Bollhalder, A.; Thominet, V.; David, C.; Kaestner, A.; Lehmann, E.H. Improving the Spatial Resolution of Neutron Imaging at Paul Scherrer Institut—The Neutron Microscope Project. Phys. Procedia 2015, 69, 169–176. [Google Scholar] [CrossRef]

- Trtik, P.; Lehmann, E.H. Progress in High-resolution Neutron Imaging at the Paul Scherrer Institut—The Neutron Microscope Project. J. Phys. Conf. Ser. 2016, 746, 012004. [Google Scholar] [CrossRef]

- Tremsin, A.S.; Feller, W.B.; Downing, R.G. Efficiency optimization of microchannel plate (MCP) neutron imaging detectors. I. Square channels with 10B doping. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 2005, 539, 278–311. [Google Scholar] [CrossRef]

- Tremsin, A.; Morgano, M.; Panzner, T.; Lehmann, E.; Filgers, U.; Vallerga, J.; McPhate, J.; Siegmund, O.; Feller, W. High resolution neutron imaging capabilities at BOA beamline at Paul Scherrer Institut. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 2015, 784, 486–493. [Google Scholar] [CrossRef]

- Tremsin, A.; Vallerga, J.; McPhate, J.; Siegmund, O. Optimization of high count rate event counting detector with Microchannel Plates and quad Timepix readout. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 2015, 787, 20–25. [Google Scholar] [CrossRef]

- Tupitsyn, E.; Bhattacharya, P.; Rowe, E.; Matei, L.; Groza, M.; Wiggins, B.; Burger, A.; Stowe, A. Single crystal of LiInSe2 semiconductor for neutron detector. Appl. Phys. Lett. 2012, 101. [Google Scholar] [CrossRef]

- Stowe, A.; Woodward, J.; Tupitsyn, E.; Rowe, E.; Wiggins, B.; Matei, L.; Bhattacharya, P.; Burger, A. Crystal growth in LiGaSe2 for semiconductor radiation detection applications. J. Cryst. Growth 2013, 379, 111–114. [Google Scholar] [CrossRef]

- Tupitsyn, E.; Bhattacharya, P.; Rowe, E.; Matei, L.; Cui, Y.; Buliga, V.; Groza, M.; Wiggins, B.; Burger, A.; Stowe, A. Lithium containing chalcogenide single crystals for neutron detection. J. Cryst. Growth 2014, 393, 23–27. [Google Scholar] [CrossRef]

- Lukosi, E.; Herrera, E.; Hamm, D.; Lee, K.M.; Wiggins, B.; Trtik, P.; Penumadu, D.; Young, S.; Santodonato, L.; Bilheux, H.; et al. Lithium indium diselenide: A new scintillator for neutron imaging. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 2016, 830, 140–149. [Google Scholar] [CrossRef]

- Lukosi, E.D.; Herrera, E.H.; Hamm, D.S.; Burger, A.; Stowe, A.C. Neutron imaging with lithium indium diselenide: Surface properties, spatial resolution, and computed tomography. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 2017, 872, 181–186. [Google Scholar] [CrossRef]

- Herrera, E.; Hamm, D.; Wiggins, B.; Milburn, R.; Burger, A.; Bilheux, H.; Santodonato, L.; Chvala, O.; Stowe, A.; Lukosi, E. LISe pixel detector for neutron imaging. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 2016, 833, 142–148. [Google Scholar] [CrossRef]

- Knoll, G.F. Radiation Detection and Measurement; John Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- Lukosi, E.; Chvala, O.; Stowe, A. Response functions of semiconducting lithium indium diselenide. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 2016, 822, 9–14. [Google Scholar] [CrossRef]

- Hamm, D.S.; Lukosi, E.D.; Rust, M.R.; Herrera, E.H.; Burger, A.; Wiggins, B.; Stowe, A.C. Characterization of lithium indium diselenide. In Proceedings of the IEEE Nuclear Science Symposium and Medical Imaging Conference (NSS/MIC), San Diego, CA, USA, 31 October–7 November 2015. [Google Scholar]

- Jakubek, J.; Holy, T.; Lehmann, E.; Pospisil, S.; Uher, J.; Vacik, J.; Vavrik, D. Spatial resolution of Medipix-2 device as neutron pixel detector. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 2005, 546, 164–169. [Google Scholar] [CrossRef]

- Jakubek, J.; Schmidt-Wellenburg, P.; Geltenbort, P.; Platkevic, M.; Plonka-Spehr, C.; Solc, J.; Soldner, T. A coated pixel device TimePix with micron spatial resolution for UCN detection. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 2009, 600, 651–656. [Google Scholar] [CrossRef]

- Wiggins, B.; Groza, M.; Tupitsyn, E.; Lukosi, E.; Stassun, K.; Burger, A.; Stowe, A. Scintillation properties of semiconducting 6LiInSe2 crystals to ionizing radiation. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 2015, 801, 73–77. [Google Scholar] [CrossRef]

- Ohring, M. Material Science of Thin Films: Deposition and Structure, 2nd ed.; Academic Press, Inc.: San Diego, CA, USA, 2001. [Google Scholar]

- Grünzweig, C.; Frei, G.; Lehmann, E.; Kühne, G.; David, C. Highly absorbing gadolinium test device to characterize the performance of neutron imaging detector systems. Rev. Sci. Instrum. 2007, 78. [Google Scholar] [CrossRef] [PubMed]

- Formlabs, Inc. ‘High Resolution SLA and SLS 3D Printers for Professionals’. 2017. Available online: https//www.formlabs.com (accessed on 26 September 2017).

- Gibson, I.; Rosen, D.W.; Stucker, B. Additive Manufacturing Technologies; Springer: New York, NY, USA, 2014. [Google Scholar]

- Bilheux, H.Z.; Bilheux, J.C.; Bailey, W.B.; Keener, W.S.; Davis, L.E.; Herwig, K.W.; Cekanova, M. Neutron imaging at the Oak Ridge National Laboratory: Application to biological research. In Proceedings of the 2014 IEEE Biomedical Sciences and Engineering Conference, Oak Ridge, TN, USA, 6–8 May 2014. [Google Scholar]

- Crow, L.; Robertson, L.; Bilheux, H.; Fleenor, M.; Iverson, E.; Tong, X.; Stoica, D.; Lee, W. The CG1 instrument development test station at the high flux isotope reactor. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 2011, 634, S71–S74. [Google Scholar] [CrossRef]

- Rossi, L.; Fischer, P.; Rohe, T.; Wermes, N. Pixel Detectors: From Fundamentals to Applications; Springer: Berlin, Germany, 2006. [Google Scholar]

- Cao, R.L.; Biegalski, S.R. The measurement of the presampled MTF of a high spatial resolution neutron imaging system. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 2007, 582, 621–628. [Google Scholar] [CrossRef]

- Jakubek, J.; Jakubek, M.; Platkevic, M.; Soukup, P.; Turecek, D.; Sykora, V.; Vavrik, D. Large area pixel detector WIDEPIX with full area sensitivity composed of 100 Timepix assemblies with edgeless sensors. J. Instrum. 2014, 9, C04018. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Herrera, E.; Hamm, D.; Stowe, A.; Preston, J.; Wiggins, B.; Burger, A.; Lukosi, E. Neutron Imaging with Timepix Coupled Lithium Indium Diselenide. J. Imaging 2018, 4, 10. https://doi.org/10.3390/jimaging4010010

Herrera E, Hamm D, Stowe A, Preston J, Wiggins B, Burger A, Lukosi E. Neutron Imaging with Timepix Coupled Lithium Indium Diselenide. Journal of Imaging. 2018; 4(1):10. https://doi.org/10.3390/jimaging4010010

Chicago/Turabian StyleHerrera, Elan, Daniel Hamm, Ashley Stowe, Jeffrey Preston, Brenden Wiggins, Arnold Burger, and Eric Lukosi. 2018. "Neutron Imaging with Timepix Coupled Lithium Indium Diselenide" Journal of Imaging 4, no. 1: 10. https://doi.org/10.3390/jimaging4010010

APA StyleHerrera, E., Hamm, D., Stowe, A., Preston, J., Wiggins, B., Burger, A., & Lukosi, E. (2018). Neutron Imaging with Timepix Coupled Lithium Indium Diselenide. Journal of Imaging, 4(1), 10. https://doi.org/10.3390/jimaging4010010