Analysis of Gloss Unevenness and Bidirectional Reflectance Distribution Function in Specular Reflection

Abstract

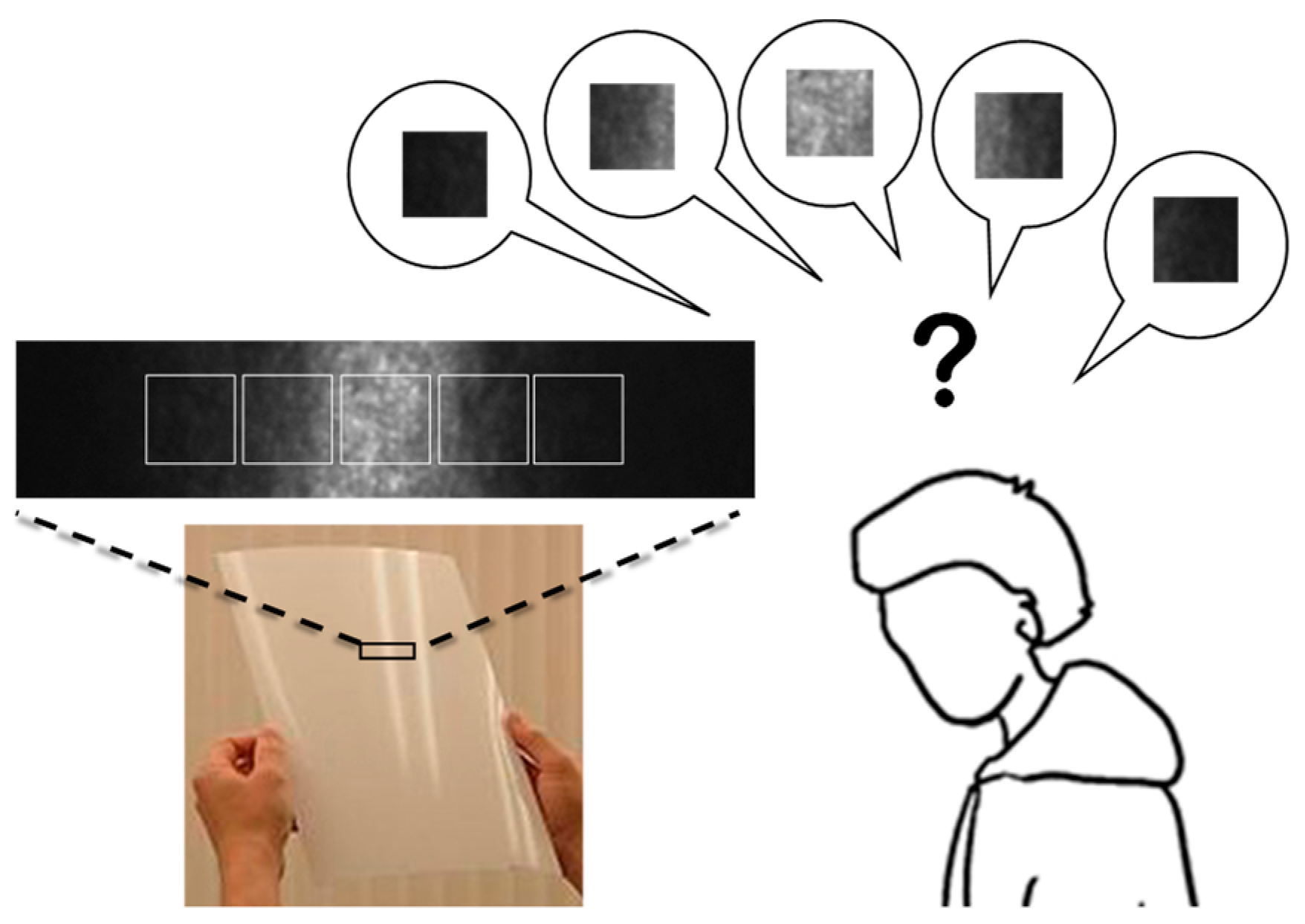

1. Introduction

2. Experiment and Results

2.1. Observation Conditions for Gloss Unevenness

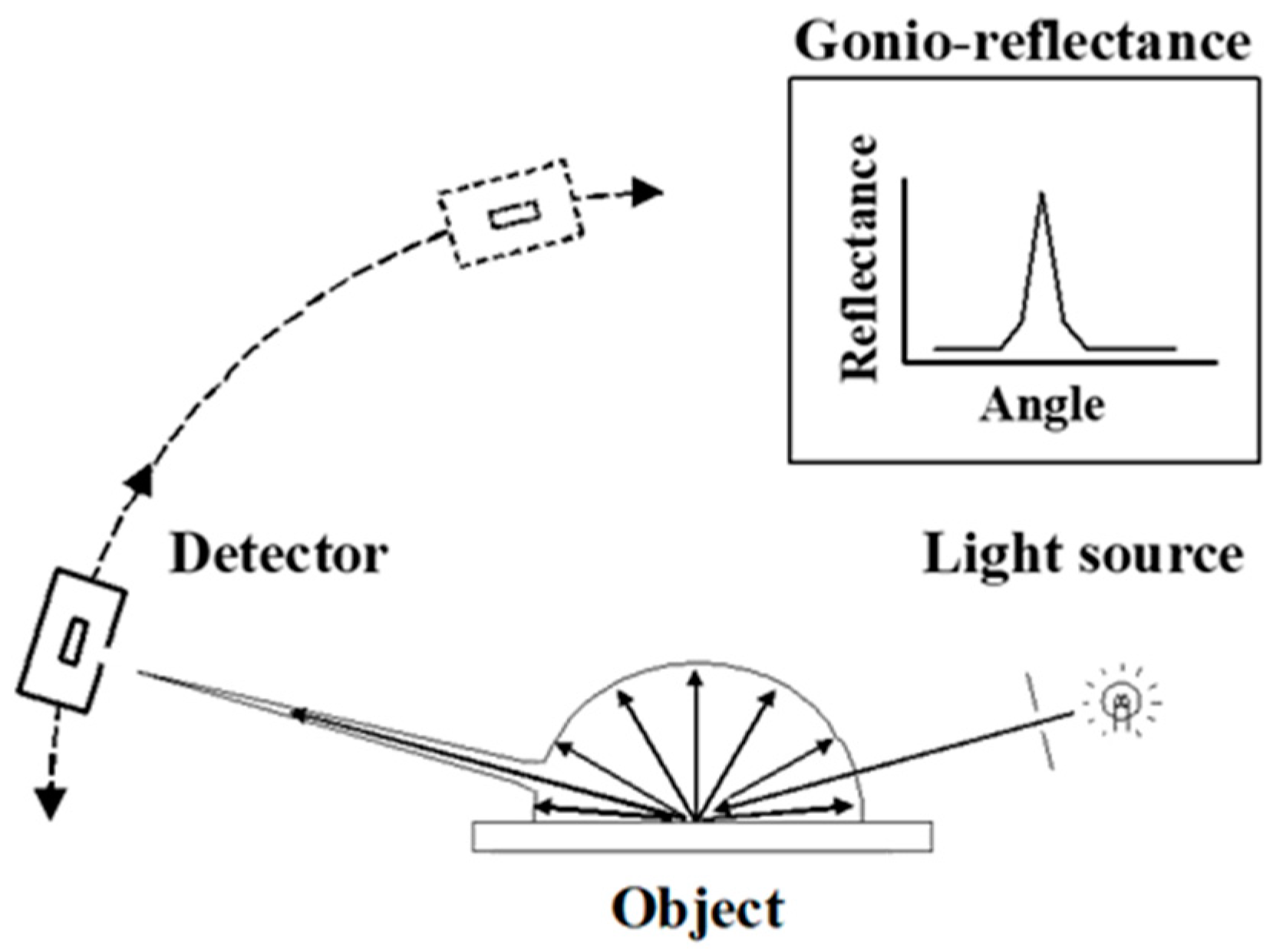

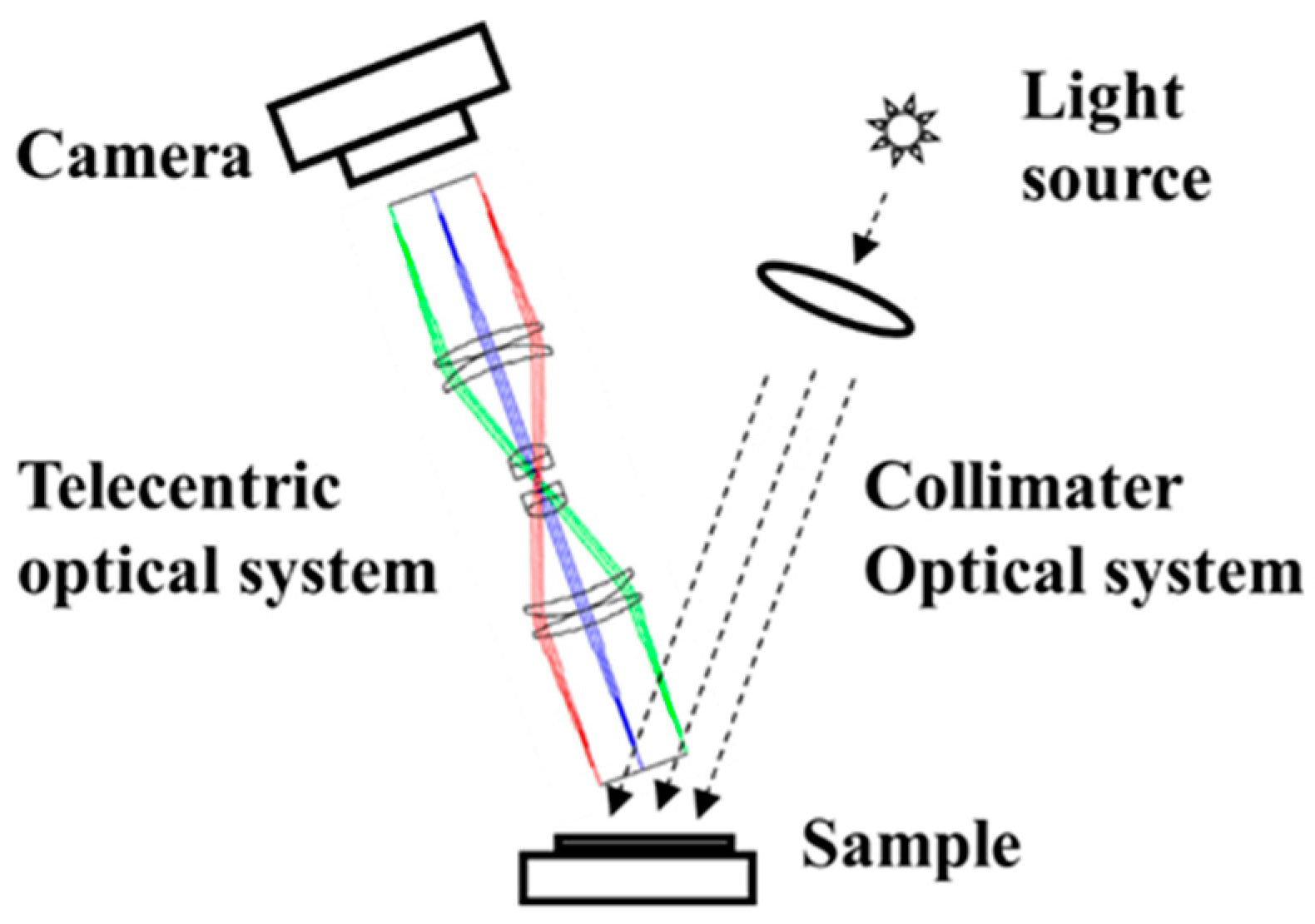

2.2. Developed Apparatus

2.3. Samples

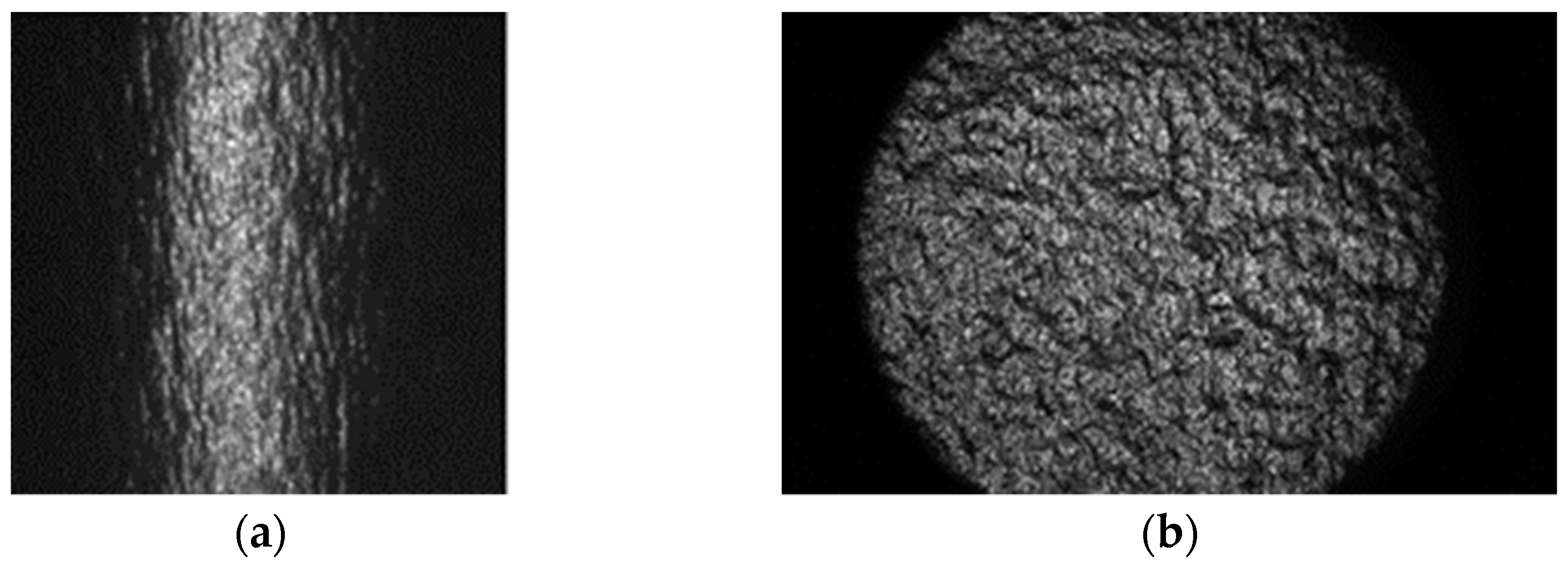

2.4. Measurement Results

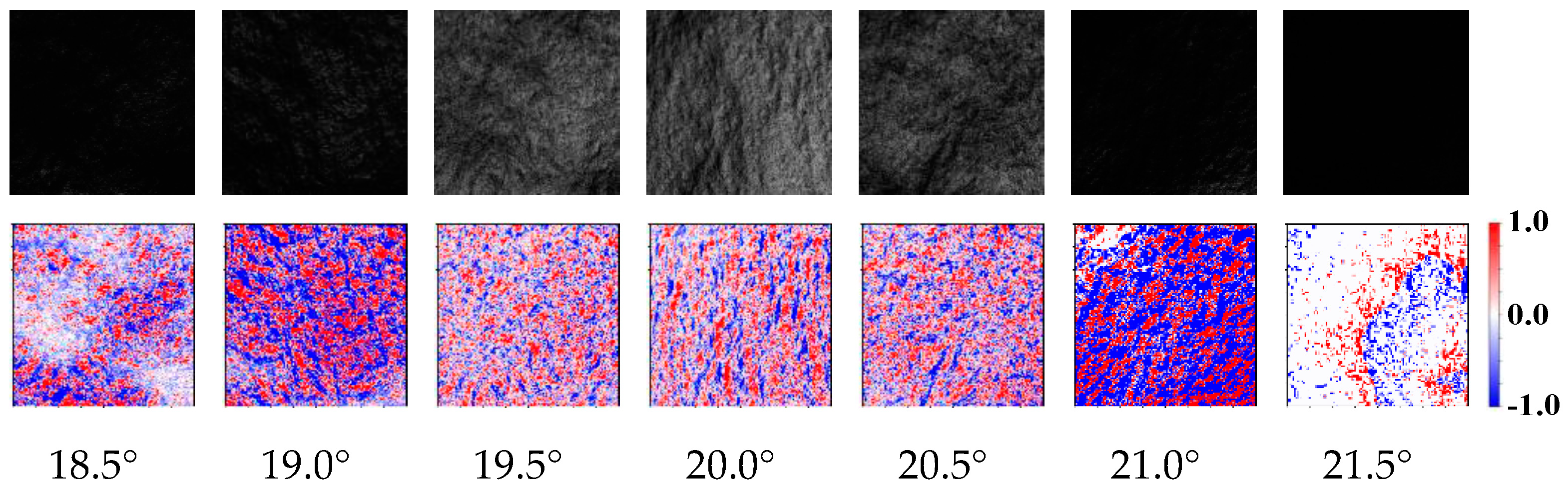

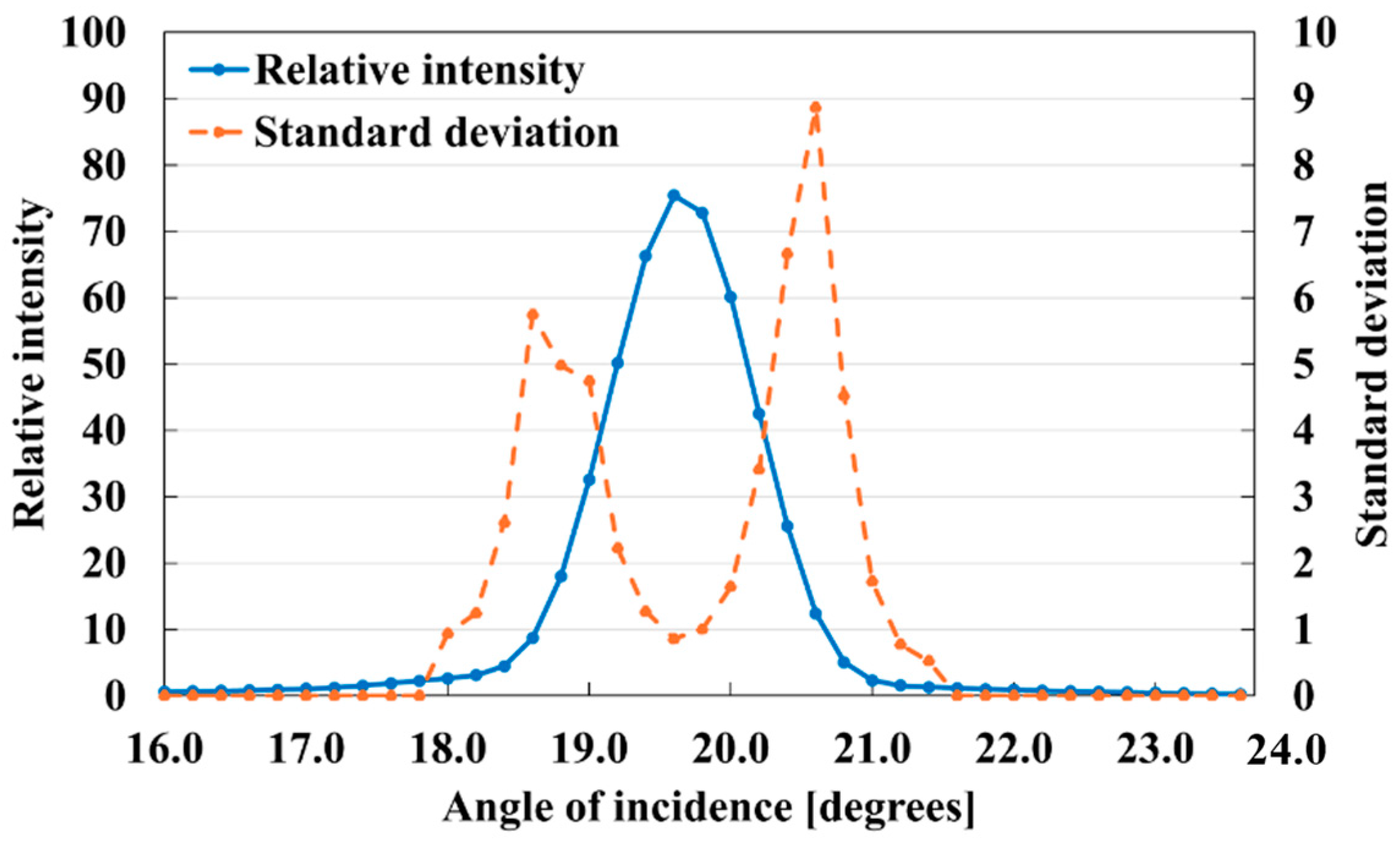

2.4.1. Gloss Unevenness Images with Different Incident Light Angles

2.4.2. Definition of Gloss Unevenness

2.4.3. Analysis of Gloss Unevenness

3. Discussion

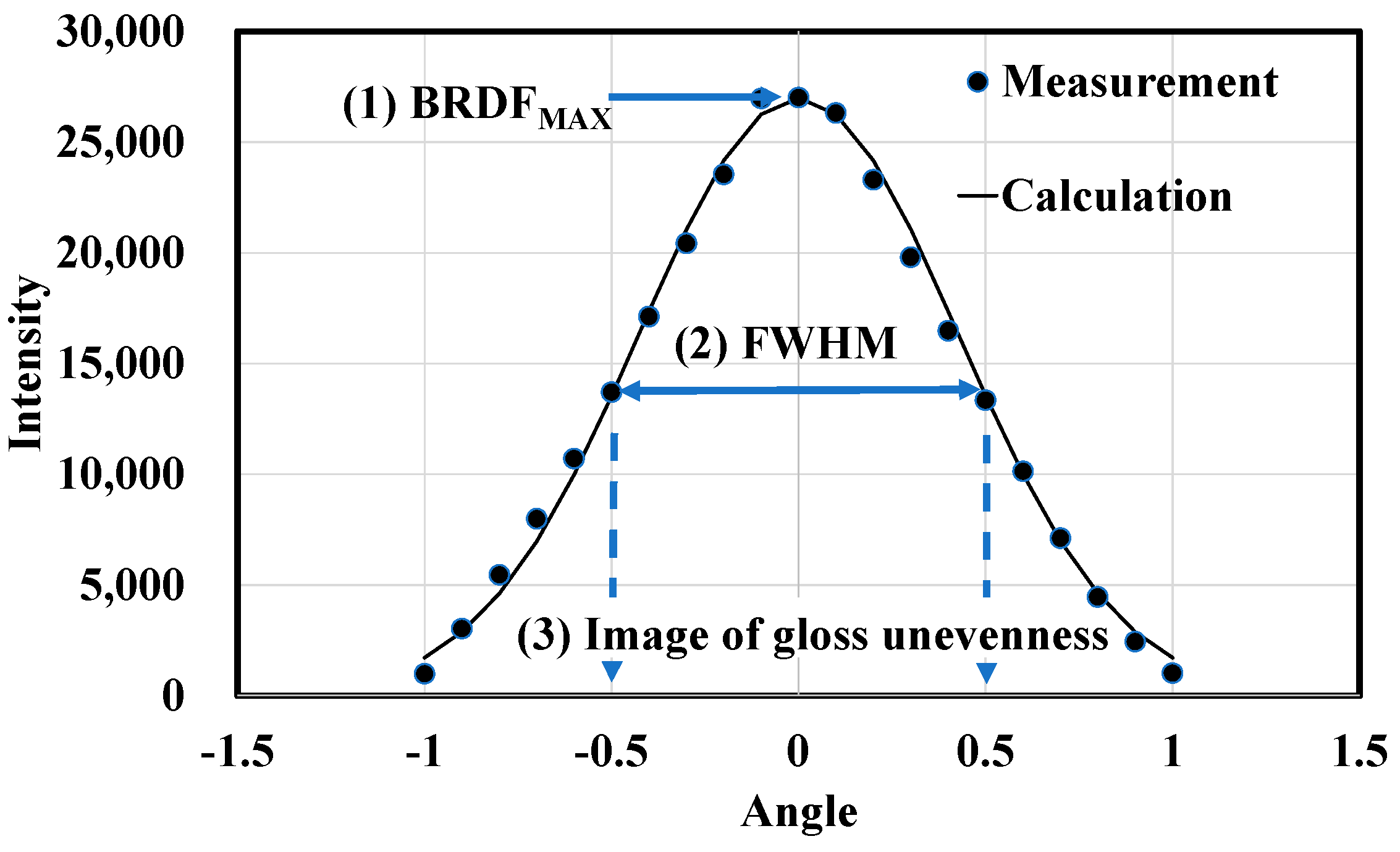

3.1. Gloss Quantification

- (1)

- BRDFMax: The reflection value at the peak of the specular reflection. In this study, we analyzed the phenomenon of specular reflection. Diffuse reflected light components are excluded. This is achieved by subtracting the baseline value of the BRDF curve. This is performed by subtracting the value of the base of the BRDF curve. Because the angle at which the reflected light was measured was fixed at 20.0° in this system, the reflection value was considered when the incident light angle was 20.0°. This value primarily represents the specular reflectance of an object, with high values for mirror-like samples, such as mirrors and plastics, and low values for low-gloss samples, such as paper. When comparing different sample types, one must scale the specular reflectance values.

- (2)

- FWHM: The full width at half maximum (FWHM) of the BRDF. This value indicates the extent to which the gloss intensity decreases as the incident light angle shifts away from the BRDFMax. The FWHM is the full width of the incident light angle at half the BRDFMax. When the gloss of an object is observed using a linear light source, its center (specular reflection) is glossy. The larger the distance from the specular reflection, the weaker the gloss. In general, the higher the reflectance of the object, the more clearly the gloss is observed at the center, and the more significant the decrease in gloss. Although this system uses a collimated light source, the gloss reduction rate can be estimated by scanning the gloss intensity at each incident light angle. Our measurement data show that the BRDF curve of gloss intensity can be fitted to a normal distribution curve. Therefore, by combining the FWHM and BRDFMax, a BRDF mountain-shaped graph of gloss can be obtained.

- (3)

- Image of gloss unevenness at FWHM. This image best represents the texture of the sample. The reason for using FWHM to represent gloss unevenness images is discussed in the next section. Our system can simultaneously obtain the BRDF and a gloss unevenness image at a specific incident light angle.

3.2. Gloss Unevenness Image Selection

3.3. Apparatus Features

3.4. Applications for Flaw Detector

3.5. Limitations of This Study

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Motoyoshi, I.; Nishida, S.Y.; Sharan, L.; Adelson, E.H. Image statistics and the perception of surface qualities. Nature 2007, 447, 206–209. [Google Scholar] [CrossRef] [PubMed]

- Anderson, B.L.; Kim, J. Image statistics do not explain the perception of gloss and lightness. J. Vis. 2009, 9, 10. [Google Scholar] [CrossRef] [PubMed]

- Fleming, R.W. Visual perception of materials and their properties. Vis. Res. 2014, 94, 62–75. [Google Scholar] [CrossRef] [PubMed]

- Chadwick, A.C.; Kentridge, R.W. The perception of gloss: A review. Vis. Res. 2015, 109, 221–235. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Marlow, P.J.; Anderson, B.L. The dark side of gloss. Nat. Neurosci. 2012, 15, 1590–1595. [Google Scholar] [CrossRef] [PubMed]

- Marlow, P.J.; Kim, J.; Anderson, B.L. The perception and misperception of specular surface reflectance. Curr. Biol. 2012, 22, 1909–1913. [Google Scholar] [CrossRef]

- Béland, M.C.; Bennett, J.M. Effect of local microroughness on the gloss uniformity of printed paper surfaces. Appl. Opt. 2000, 39, 2719–2726. [Google Scholar] [CrossRef]

- Zhu, X.; Inoue, S.; Sato, H.; Mizokami, Y. Effect of light source distances and illuminances on the gloss perception of papers. JOSA A 2022, 39, B28–B38. [Google Scholar] [CrossRef] [PubMed]

- Leloup, F.B.; Pointer, M.R.; Dutré, P.; Hanselaer, P. Luminance-based specular gloss characterization. J. Opt. Soc. Am. A 2011, 28, 1322–1330. [Google Scholar] [CrossRef][Green Version]

- Leloup, F.B.; Pointer, M.R.; Dutré, P.; Hanselaer, P. Overall gloss evaluation in the presence of multiple cues to surface glossiness. J. Opt. Soc. Am. A 2012, 29, 1105–1114. [Google Scholar] [CrossRef]

- Pellacini, F.; Ferwerda, J.A.; Greenberg, D.P. Toward a psychophysically-based light reflection model for image synthesis. In Proceedings of the 27th Annual Conference on Computer Graphics and Interactive Techniques, New Orleans, LA, USA, 23–28 July 2000; pp. 55–64. [Google Scholar]

- Guarnera, D.; Guarnera, G.C.; Ghosh, A.; Denk, C.; Glencross, M. BRDF Representation and Acquisition. State Art Rep. 2016, 35, 625–650. [Google Scholar] [CrossRef]

- Ghosh, A.; Heidrich, W.; Achutha, S.; O’Toole, M. A basis illumination approach to BRDF measurement. Int. J. Comput. Vis. 2010, 90, 183–197. [Google Scholar] [CrossRef]

- Faul, F. The influence of Fresnel effects on gloss perception. J. Vis. 2019, 19, 1. [Google Scholar] [CrossRef] [PubMed]

- Leloup, F.B.; Obein, G.; Pointer, M.R.; Hanselaer, P. Toward the soft metrology of surface gloss: A review. Color Res. Appl. 2014, 39, 559–570. [Google Scholar] [CrossRef]

- Marschner, S.R.; Westin, S.H.; Lafortune, E.P.F.; Torrance, K.E. Image-based BRDF measurement. Appl. Opt. 2000, 39, 171–177. [Google Scholar]

- Gardner, A.; Tchou, C.; Hawkins, T.; Debevec, P. Linear light source reflectometry. In Proceedings of the SIGGRAPH ‘03 ACM SIGGRAPH 2003 Papers, San Diego, CA, USA, 27–31 July 2003; pp. 749–758. [Google Scholar]

- Becker, M.E. High-resolution scatter analysis of anti-glare layer reflection. SID Symp. Dig. Tech. Pap. 2016, 47, 368–371. [Google Scholar] [CrossRef]

- Arney, J.S.; Heo, H.; Anderson, P.G. A micro-goniophotometer and the measurement of print gloss. J. Imaging Sci. Technol. 2004, 48, 458–463. [Google Scholar] [CrossRef]

- Inoue, S.; Tsumura, N. Point spread function of specular reflection and gonio-reflectance distribution. J. Imaging Sci. Technol. 2015, 59, 010501-1–010501-10. [Google Scholar] [CrossRef]

- Inoue, S.; Kotori, Y.; Takishiro, M. Paper gloss analysis by specular reflection point spread function part I. Jpn. Tappi J. 2012, 66, 879. [Google Scholar] [CrossRef]

- Inoue, S.; Kotori, Y.; Takishiro, M. Paper gloss analysis by specular reflection point spread function part II. Jpn. Tappi J. 2012, 66, 1416. [Google Scholar] [CrossRef]

- Fujiwara, H.; Kaga, C.; Kano, I. Measurement of gloss profile. Jpn. Tappi J. 1990, 44, 1092–1098. [Google Scholar] [CrossRef]

- Inoue, S.; Tsumura, N. Measuring method for line spread function of specular reflection. OSA Contin. 2020, 3, 864–877. [Google Scholar] [CrossRef]

- Hunter, R. Methods of determining gloss. J. Res. Natl. Bur. Stand. 1937, 18, 19. [Google Scholar] [CrossRef]

- Ferwerda, J.A.; Pellacini, F.; Greenberg, D.P. Psychophysically based model of surface gloss perception. In Proceedings of the Human Vision and Electronic Imaging VI, San Jose, CA, USA, 8 June 2001; Volume 4299. [Google Scholar]

- Ishizuka, K.; Kondo, Y.; Takahashi, K. Study about the evaluation method of gloss unevenness. Jpn. Tappi J. 2016, 70, 1179. [Google Scholar] [CrossRef][Green Version]

- Kitamura, N. A study of sheet gloss part 2. Jpn. Tappi J. 2004, 58, 1047–1053. [Google Scholar] [CrossRef]

- Shiiyama, E. A study of sheet gloss. Jpn. Tappi J. 2003, 57, 850–856. [Google Scholar] [CrossRef]

- Fajita, K.; Matsuda, N.; Matsui, H.; Zama, Y. Application of new evaluation method of sheet appearance to various coated papers. Jpn. Tappi J. 2003, 56, 1302–1307. [Google Scholar] [CrossRef]

- Matsuda, N.; Ichihashi, T.; Zama, Y. Influence of ultra fine surface profile to sheet and print gloss of coated paper. Jpn. Tappi J. 2000, 54, 461–469. [Google Scholar] [CrossRef]

- ASTM Standard D 523-14; Standard Test Method for Specular Gloss. ASTM International: West Conshohocken, PA, USA, 2018.

- Arney, J.S.; Ye, L.; Banach, S. Interpretation of gloss meter measurements. J. Imaging Sci. Technol. 2006, 50, 567–571. [Google Scholar]

- Leloup, F.B.; Audenaert, J.; Hanselaer, P. Development of an image-based gloss measurement instrument. J. Coat. Technol. Res. 2019, 16, 913–921. [Google Scholar] [CrossRef]

| Sample | Specular Gloss (ASTM D523) | Annotation | ||

|---|---|---|---|---|

| 20°/20° | 60°/60° | 85°/85° | ||

| Black glass | 82.0 | 90.5 | 99.0 | Standard for gloss |

| Plastic | 90.2 | 96.5 | 98.2 | White acrytic resin |

| Inkjet paper | 15.3 | 45.3 | 81.9 | Photo-like inkjet paper |

| Coated paper(A) | 7.3 | 36.7 | 84.3 | A2 coated paper for printing |

| Black Glass | Plastic | Inkjet Paper | Coated Paper (A) | |

|---|---|---|---|---|

| BRDFMax | 5.40 × 107 | 4.86 × 107 | 21.1 × 105 | 9.71 × 105 |

| FWHM [°] | 1.0 | 1.0 | 4.0 | 4.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nakamura, S.; Inoue, S.; Igarashi, Y.; Sato, H.; Mizokami, Y. Analysis of Gloss Unevenness and Bidirectional Reflectance Distribution Function in Specular Reflection. J. Imaging 2024, 10, 146. https://doi.org/10.3390/jimaging10060146

Nakamura S, Inoue S, Igarashi Y, Sato H, Mizokami Y. Analysis of Gloss Unevenness and Bidirectional Reflectance Distribution Function in Specular Reflection. Journal of Imaging. 2024; 10(6):146. https://doi.org/10.3390/jimaging10060146

Chicago/Turabian StyleNakamura, So, Shinichi Inoue, Yoshinori Igarashi, Hiromi Sato, and Yoko Mizokami. 2024. "Analysis of Gloss Unevenness and Bidirectional Reflectance Distribution Function in Specular Reflection" Journal of Imaging 10, no. 6: 146. https://doi.org/10.3390/jimaging10060146

APA StyleNakamura, S., Inoue, S., Igarashi, Y., Sato, H., & Mizokami, Y. (2024). Analysis of Gloss Unevenness and Bidirectional Reflectance Distribution Function in Specular Reflection. Journal of Imaging, 10(6), 146. https://doi.org/10.3390/jimaging10060146