Development and Properties of Recycled Biomass Fly Ashes Modified Mortars

Abstract

1. Introduction

- Loss on ignition (EN 196-2): it must not exceed 5% by mass in order to limit the amount of unburnt carbon in the fly ash;

- Chloride content Cl− (EN 196-21): not to exceed 0.1% by mass;

- Sulphuric anhydride content SO3 (EN 196-2): must not exceed 3% by mass;

- Free calcium oxide content (EN 451-1): must not exceed 1% by mass;

- Fineness (EN 451-2): the maximum value of the fineness must not exceed 40%;

- Activity index (EN 196-1): the activity index at 28 days and 90 days must be greater than 75% and 85%, respectively.

- -

- aesthetically acceptable and beautiful;

- -

- protect the interior structure from the penetration of air, water or chemical elements into a masonry assembly;

- -

- help support the weight placed on the wall;

- -

- seal the joints to provide a weather-resistant wall.

- -

- mechanically resistant;

- -

- aesthetically pleasing, as it is visible on part of the wall;

- -

- waterproof but permeable to water vapor.

- -

- incompatibility between the base material and the mortar;

- -

- poor plaster layering;

- -

- poor knowledge of mortar application techniques.

2. Comparison of Fly Ash with Biomass Ash

2.1. Physico-Chemical Characterization of Fly Ash

2.2. Mortars Design and Testing

2.3. Results of the Sensitivity Study on The Substitution Rate

3. Development of Masonry and Rendering Mortars with Biomass Ash

4. Conclusions

- The mineralogy of FA and BA is different, inducing a lower reactivity of BA;

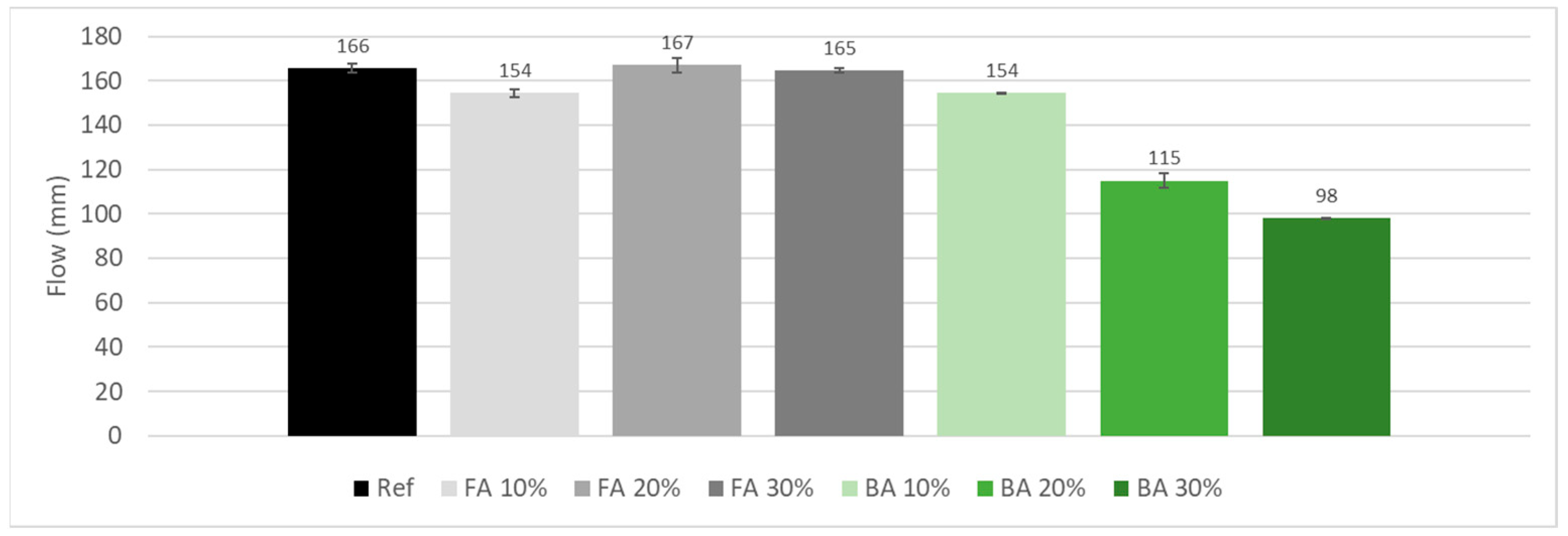

- The workability of fresh mortar is much more affected by the addition of BA than by the addition of FA, which is probably due to the rougher shape of BA;

- Density does not seem to be affected by the addition of FA or of BA, except for the BA 30% mortar for which air bubbles appeared and led to a significant drop in density;

- The mechanical strength of mortars deteriorates more for mortars containing BA than for mortars containing FA, even if it remains higher than 30 MPa for a substitution rate of 20% at 7 days;

- When FA is added to the mortar mix, the long-term mechanical performance (90 days) is generally improved. However, above a 30% substitution, the long-term mechanical performance starts to decrease;

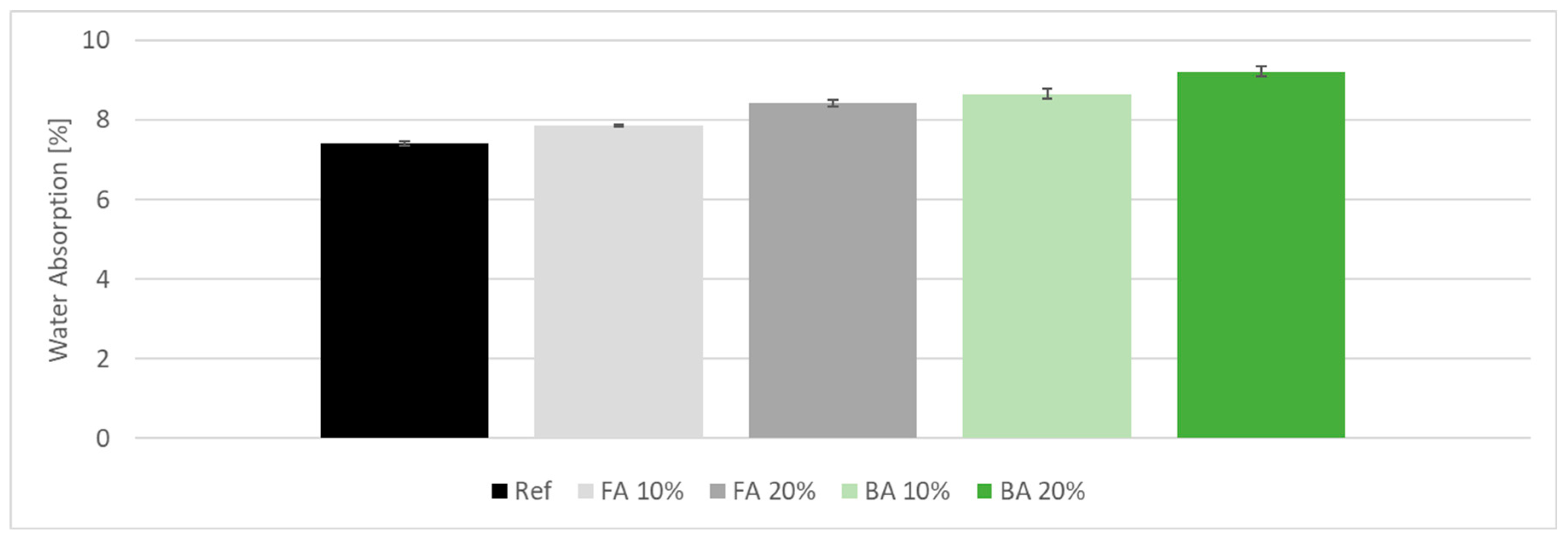

- BA induces a higher water absorption by immersion and porosity than FA.

- BA does not affect the workability of these mortars as the water demand remains almost identical for all substitution rates;

- Density does not seem to be affected by the addition of BA;

- The mechanical strength of mortars is affected by the addition of BA with a significant loss of compressive strength of up to 27% for rendering mortar with 20% BA. Mechanical performances remain, however, higher than the required value for masonry or rendering mortars.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Monteiro, P.; Miller, S.; Horvath, A. Towards sustainable concrete. Nat. Mater. 2017, 16, 698–699. [Google Scholar] [CrossRef] [PubMed]

- Lothenbach, B.; Scrivener, K.; Hooton, R.D. Supplementary cementitious materials. Cem. Concr. Res. 2011, 41, 217–229. [Google Scholar] [CrossRef]

- Kiattikomol, K.; Jaturapitakkul, C.; Songpiriyakij, S.; Chutubtim, S. A study of ground coarse fly ashes with different finenesses from various sources as pozzolanic materials. Cem. Concr. Compos. 2001, 23, 335–343. [Google Scholar] [CrossRef]

- Suraneni, P.; Shaerer, C.R.; Hooton, D.; Burris, L. ASTM C618 fly ash specification: Comparison with other specifications, shortcomings, and solutions. ACI Mater. J. 2021, 118, 157–167. [Google Scholar]

- Garcia-Lodeiro, I.; Carcelen-Taboada, V.; Fernández-Jiménez, A.; Palomo, A. Manufacture of hybrid cements with fly ash and bottom ash from a municipal solid waste incinerator. Constr. Build. Mater. 2016, 105, 218–226. [Google Scholar] [CrossRef]

- Garg, M.; Pundir, A. Comprehensive study of fly ash binder developed with fly ash—Alpha gypsum plaster—Portland cement. Constr. Build. Mater. 2012, 37, 758–765. [Google Scholar] [CrossRef]

- Prochon, P.; Zhao, Z.; Courard, L.; Piotrowski, T.; Michel, F.; Garbacz, A. Influence of activators on mechanical properties of modified fly ash based geopolymer mortars. Materials 2020, 13, 1033. [Google Scholar] [CrossRef] [PubMed]

- Meys, M. Study of the Use of Biomass Fly Ashes for Mortar Production. Master’s Thesis, Université de Liège, Liège, Belgium, 2020; 139p. (In French). [Google Scholar]

- 2009/28-EN-Renewable Energy Directive. Directive 2009/28/EC of the European Parliament and of the Council of 23 April 2009 on the Promotion of the Use of Energy from Renewable Sources and Amending and Subsequently Repealing. Directives 2001/77/EC and 2003/30/EC (Text with EEA Relevance). Available online: http://data.europa.eu/eli/dir/2009/28/oj (accessed on 12 December 2023).

- Zhai, J.; Burke, I.T.; Stewart, D.I. Beneficial management of biomass combustion ashes. Renew. Sustain. Energy Rev. 2021, 151, 111555. [Google Scholar] [CrossRef]

- World Bioenergy Association. Global Bioenergy Statistics 2019; World Bioenergy Association: Stockholm, Sweden, 2019. [Google Scholar]

- Vassilev, S.V.; Vassileva, C.G.; Song, Y.; Li, W.; Feng, J. Ash contents and ash-forming elements of biomass and their significance for solid biofuel combustion. Fuel 2017, 208, 377–409. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Matias, J.C.O.; Catalao, J.P.S. Biomass in the generation of electricity in Portugal: A review. Renew. Sustain. Energy Rev. 2017, 71, 373–378. [Google Scholar] [CrossRef]

- Sustainable Biomass Availability in the EU, to 2050, Imperial College London Consultants. 2021. Available online: https://www.concawe.eu/wp-content/uploads/Sustainable-Biomass-Availability-in-the-EU-Part-I-and-II-final-version.pdf. (accessed on 12 December 2023).

- Available online: https://www.ieabioenergy.com/wp-content/uploads/2021/11/CountryReport2021_Belgium_final.pdf (accessed on 12 December 2023).

- Renewable Energy in Belgium. Biomass Energy Production and Consumption in Belgium 2017–2022. Statistica Research Dep, 23 April 2024. Available online: https://www.statista.com/statistics/799494/solid-biomass-production-consumption-belgium (accessed on 12 December 2023).

- Odzijewicz, J.I.; Wolejko, E.; Wydro, U.; Wasil, M.; Jablonska-Tripuc, A. Utilization of ashes from biomss combustion. Energies 2022, 15, 9653. [Google Scholar] [CrossRef]

- Hubert, J.; Kępniak, M.; Marquis, S.; Zalegowski, K.; Descamps, P.; Garbacz, A.; Courard, L. Biomass fly ash as a substitute to cementitious materials: Overview and perspectives. Resour. Conserv. Recycl. 2024. under revision. [Google Scholar]

- Jala, S.; Goyal, D. Fly ash as a soil ameliorant for improving crop production—A review. Bioresour. Technol. 2006, 97, 1136–1147. [Google Scholar] [CrossRef] [PubMed]

- Berra, M.; Mangialardi, T.; Paolini, A.E. Reuse of woody biomass fly ash in cement-based materials. Constr. Build. Mater. 2015, 76, 286–296. [Google Scholar] [CrossRef]

- Ban, C.C.; Ramli, M. The implementation of wood waste ash as a partial cement replacement material in the production of structural grade concrete and mortar: An overview. Resour. Conserv. Recycl. 2011, 55, 669–685. [Google Scholar] [CrossRef]

- Rajamma, R.; Ball, R.J.; Tarelho, L.A.C.; Allen, G.C.; Labrincha, J.A.; Ferreira, V.M. Characterization and use of biomass fly ash in cement-based materials. J. Hazard. Mater. 2009, 172, 1049–1060. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Z.; Courard, L.; Remond, S.; Damidot, D. Mechanical strength of mortars containing biomass fly ash from combustion of 100% wood pellets as partial replacement of cement. In Proceedings of the 15th International Congress on the Chemistry of Cement (ICCC 2019), Prague, Czech Republic, 16–20 September 2019. [Google Scholar]

- Teixeira, E.R.; Camões, A.; Branco, F.G. Valorisation of wood fly ash on concrete. Resour. Conserv. Recycl. 2019, 145, 292–310. [Google Scholar] [CrossRef]

- Nagrockiene, D.; Dauge, A. Investigation into the properties of concrete modified with biomass combustion fly ash. Constr. Build. Mater. 2018, 174, 369–375. [Google Scholar] [CrossRef]

- Fort, J.; Sal, J.; Sevcik, R. Biomass fly ash as an alternative to coal fly ash in blended cements: Functional aspects. Constr. Build. Mater. 2021, 271, 121544. [Google Scholar] [CrossRef]

- Esteves, T.C.; Rajamma, R.; Soares, D.; Silva, A.S.; Ferreira, V.M.; Labrincha, J.A. Use of biomass fly ash for mitigation of alkali-silica reaction of cement mortars. Constr. Build. Mater. 2012, 26, 687–693. [Google Scholar] [CrossRef]

- Wang, S.; Baxter, L.; Fonseca, F. Biomass fly ash in concrete: SEM, EDX and ESEM analysis. Fuel 2008, 87, 372–379. [Google Scholar] [CrossRef]

- Balakrishnan, B.; Awal, A.S.M.A.; Abdullah, A.H.B.; Hossain, M.Z. Flow properties and strength behaviour of masonry mortar incorporating high volume fly ash. GEOMATE J. 2017, 12, 121–126. [Google Scholar] [CrossRef]

- Chama, F. Composition and Uses of Lime and Mortar. Building Technology Demystified. 2015. Available online: https://buildingtechnology.wordpress.com/2011/01/18/composition-and-uses-of-lime-and-mortar/ (accessed on 12 December 2023).

- Courard, L.; Bissonnette, B.; Garbacz, A. Concrete Surface Engineering; Modern Concrete Technology 18; CRC Press: Boca Raton, FL, USA, 2015; 272p, Available online: http://hdl.handle.net/2268/189200 (accessed on 12 December 2023)ISBN 978-1-4987-0488-5.

- Valean, M.; Manea, D.L.; Aciu, C.; Popa, F.; Plesa, L.M.; Jumate, E.; Furtos, G. Performance Assessments of Plastering Mortars with Partial Replacement of Aggregates with Glass Waste. Buildings 2024, 14, 507. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Buapa, N.; Cao, H.T. Mixed cement containing fly ash for masonry and plastering work. Constr. Build. Mater. 2015, 19, 612–618. [Google Scholar] [CrossRef]

- Prochon, P.; Piotrowski, T.; Courard, L.; Zhao, Z. The effects of calcium and phosphate compounds on the mechanical and microstructural properties of fly ash geopolymer mortars. In Proceedings of the 17th International Congress on Polymers in Concrete ICPIC 2023, Warsaw, Poland, 17–20 September 2023. [Google Scholar]

- Yang, N.; Tran, H.; Scott, A.C.N.; Dhakal, R.; Watson, M.; Shi, C. Properties Of Magnesium Based Cements. In Proceedings of the New Zeland Concrete Industry Conference, Wellington, New Zealand, 12–14 October 2017. [Google Scholar]

- Yang, N.; Shi, C.; Yang, J.; Chang, Y. Research Progresses in Magnesium Phosphate Cement–Based Materials. J. Mater. Civ. Eng. 2014, 26, 4014–4071. [Google Scholar] [CrossRef]

- Rajamma, R.; Senff, L.; Ribeiro, M.J.; Labrincha, J.A.; Ball, R.J.; Allen, G.C. Biomass fly ash effect on fresh and hardened state properties of cement based materials. Compos. Part B Eng. 2015, 77, 1–9. [Google Scholar] [CrossRef]

- Courard, L.; Michel, F.; Martin, M. The evaluation of the surface free energy of liquids and solids in concrete technology. Constr. Build. Mater. 2011, 25, 260–266. [Google Scholar] [CrossRef]

| D10 (µm) | D50 (µm) | D90 (µm) | Specific Surface (m2/g) BET (m2/g) | Specific Surface (m2/g) (Laser Granulometry) (m2/g) | Specific Surface Blaine (m2/g) | Density | |

|---|---|---|---|---|---|---|---|

| FA | 4.63 | 29.04 | 88.65 | 2.1790 | 0.68 | 0.5582 | 2.75 |

| BA | 5.01 | 33.39 | 114.31 | 2.6119 | 0.63 | 0.4984 | 2.61 |

| SiO2 | Al2O3 | Fe2O3 | MnO | MgO | CaO | Na2O | K2O | P2O5 | TiO2 | LOI | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| FA (%) | 49.3 | 27.7 | 7.9 | 0.1 | 1.6 | 1.4 | 0.8 | 4 | 0.3 | 1 | 5.9 |

| BA (%) | 24.7 | 5.3 | 3.2 | 1 | 9.3 | 25.8 | 2.3 | 7.9 | 4.9 | 0.4 | 9.7 |

| CEM I 52.5 N | 20.5 | 4.8 | 3.4 | - | - | 63.6 | 0.83 | - | - | - | 1.5 |

| Mortar | Ref | FA | BA | |||||

|---|---|---|---|---|---|---|---|---|

| Materials | 10% | 20% | 30% | 10% | 20% | 30% | ||

| Standard Sand [kg/m3] | 1350 | 1350 | 1350 | |||||

| CEM I 52.5 N [kg/m3] | 450 | 405 | 360 | 315 | 405 | 360 | 315 | |

| FA [kg/m3] | 0 | 45 | 90 | 135 | 0 | |||

| BA [kg/m3] | 0 | 0 | 45 | 90 | 135 | |||

| Water [kg/m3] | 225 | 225 | 225 | |||||

| Loss of Compressive Strength Compared to the Reference Mortar (%) | ||||||

|---|---|---|---|---|---|---|

| FA | BA | |||||

| 10% | 20% | 30% | 10% | 20% | 30% | |

| 7 days | 10 | 24 | 36 | 11 | 29 | 69 |

| 28 days | 4 | 9 | 15 | 23 | 28 | 42 |

| 90 days | 8 | 14 | 29 | 15 | 25 | 61 |

| Water Absorption (% in Mass) | Porosity (% in Volume) | ||

|---|---|---|---|

| Ref | 7.4 | 15.9 | |

| FA | 10% | 7.9 | 16.6 |

| 20% | 8.4 | 17.5 | |

| 30% | - | - | |

| BA | 10% | 8.7 | 17.8 |

| 20% | 9.2 | 19.1 | |

| 30% | - | - | |

| Mortar | Masonry | Rendering | |||||

|---|---|---|---|---|---|---|---|

| Materials | |||||||

| Substitution Rate [%] | 0% | 10% | 20% | 0% | 10% | 20% | |

| Yellow Rhine Sand [kg/m3] | 1350 | 1350 | |||||

| CEM III 32.5 N [kg/m3] | 369 | 332 | 295 | 246 | 222 | 197 | |

| BA [kg/m3] | 0 | 35 | 70 | 0 | 23 | 47 | |

| Water [kg/m3] | 240 | 257 | 256 | 251 | 250 | 249 | |

| W/B | 0.65 | 0.7 | 0.7 | 1.02 | 1.02 | 1.02 | |

| Loss of Compressive Strength Compared with Reference Mortars (%) | ||||

|---|---|---|---|---|

| Masonry Mortar | Rendering Mortar | |||

| 10% | 20% | 10% | 20% | |

| 28 days | 11 | 17 | 23 | 23 |

| 90 days | 13 | 25 | 20 | 27 |

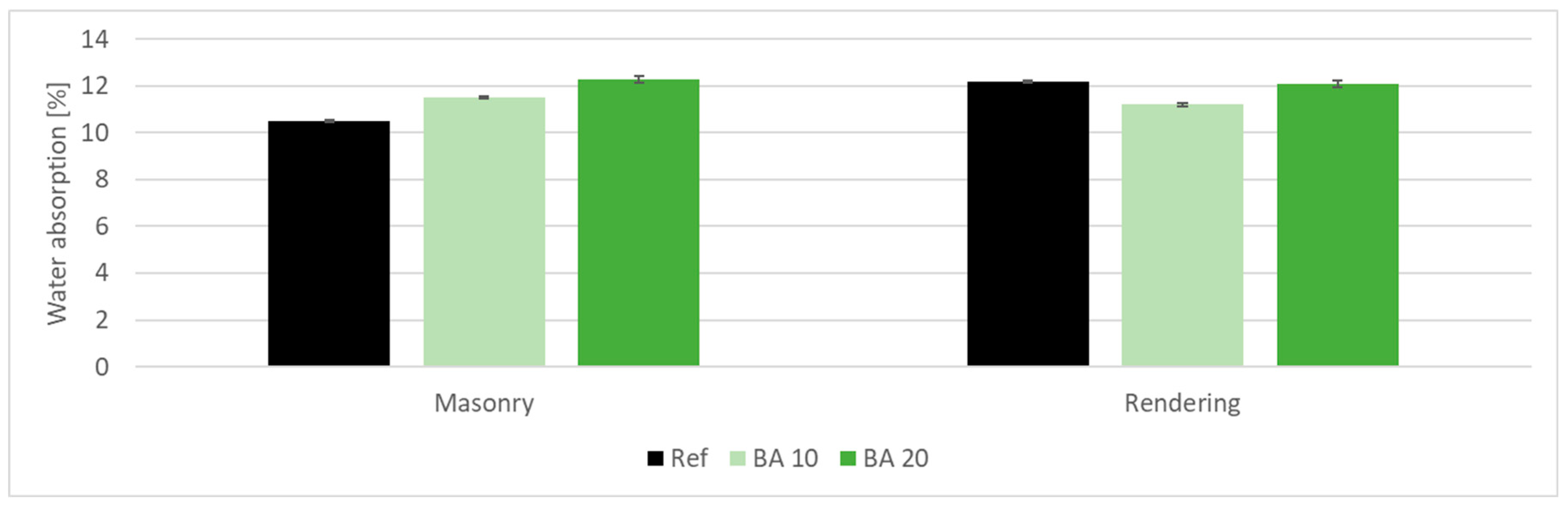

| Water Absorption (% in Mass) | Porosity (% in Volume) | ||

|---|---|---|---|

| Masonry | 0% | 10.5 | 21.3 |

| 10% | 11.5 | 23 | |

| 20% | 12.3 | 24.1 | |

| Rendering | 0% | 12.2 | 24.1 |

| 10% | 11.2 | 22.4 | |

| 20% | 10.5 | 23.7 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hubert, J.; Grigoletto, S.; Michel, F.; Zhao, Z.; Courard, L. Development and Properties of Recycled Biomass Fly Ashes Modified Mortars. Recycling 2024, 9, 46. https://doi.org/10.3390/recycling9030046

Hubert J, Grigoletto S, Michel F, Zhao Z, Courard L. Development and Properties of Recycled Biomass Fly Ashes Modified Mortars. Recycling. 2024; 9(3):46. https://doi.org/10.3390/recycling9030046

Chicago/Turabian StyleHubert, Julien, Sophie Grigoletto, Frédéric Michel, Zengfeng Zhao, and Luc Courard. 2024. "Development and Properties of Recycled Biomass Fly Ashes Modified Mortars" Recycling 9, no. 3: 46. https://doi.org/10.3390/recycling9030046

APA StyleHubert, J., Grigoletto, S., Michel, F., Zhao, Z., & Courard, L. (2024). Development and Properties of Recycled Biomass Fly Ashes Modified Mortars. Recycling, 9(3), 46. https://doi.org/10.3390/recycling9030046