Valorizing Fruit and Vegetable Waste: The Untapped Potential for Entrepreneurship in Sub-Saharan Africa—A Systematic Review

Abstract

1. Introduction

Definitions of Food Waste

2. Literature Review

2.1. Global Perspectives of FW: Quantities and Challenges

2.2. Sources of FW

2.3. An Overview of the Waste Valorizing Concept

3. Conceptualizing the Potential Benefits of Valorizing FW in SSA

Study Objectives

- To investigate global practices by exploring and analyzing laboratory studies and international endeavours focused on valorizing FW into value-added products, particularly on successful examples from diverse geographical contexts.

- To evaluate the feasibility of FW valorization in sub-Saharan Africa, considering resources and infrastructure.

- To outline actionable pathways for sustainable economic development and job creation in the region.

4. Methodology

5. Results and Analysis

6. Valorizing FW into Value-Added Products

6.1. FW Value-Added Products from Diverse Geographical Regions Relevant to the SSA Context

6.1.1. Green Energy Production

6.1.2. Nutraceuticals

6.1.3. Livestock Feed Formulation

6.1.4. Heavy Metal Adsorbents

6.1.5. Biomaterials

6.1.6. Soil Amendments

6.2. Unlocking Entrepreneurial Opportunities in SSA’s Agricultural Sector through Valorizing FW

6.2.1. Challenges

6.2.2. Opportunities

7. Conclusions and Future Perspectives

Funding

Acknowledgments

Conflicts of Interest

References

- Bhat, R. Valorization of Agri-Food Wastes and By-Products: Recent Trends, Innovations and Sustainability Challenges; Academic Press: Cambridge, MA, USA, 2021. [Google Scholar]

- Lau, K.Q.; Sabran, M.R.; Shafie, S.R. Utilization of vegetable and fruit by-products as functional ingredient and food. Front. Nutr. 2021, 8, 261. [Google Scholar] [CrossRef] [PubMed]

- Xue, L.; Liu, X.; Lu, S.; Cheng, G.; Hu, Y.; Liu, J.; Dou, Z.; Cheng, S.; Liu, G. China’s food loss and waste embodies increasing environmental impacts. Nat. Food 2021, 2, 519–528. [Google Scholar] [CrossRef] [PubMed]

- Janus, A. More Than Half of All Food Produced in Canada is Lost or Wasted, Report Says. CBC News. 2019. Available online: https://www.cbc.ca/news/canada/toronto/food-waste-report-second-harvest-1.49817282019 (accessed on 6 January 2022).

- Girotto, F.; Piazza, L. Food waste bioconversion into new food: A mini-review on nutrients circularity in the production of mushrooms, microalgae and insects. Waste Manag. Res. 2022, 40, 47–53. [Google Scholar] [CrossRef] [PubMed]

- Mu’azu, N.D.; Blaisi, N.I.; Naji, A.A.; Abdel-Magid, I.M.; AlQahtany, A. Food waste management current practices and sustainable future approaches: A Saudi Arabian perspectives. J. Mater. Cycles Waste Manag. 2019, 21, 678–690. [Google Scholar] [CrossRef]

- Machate, M. The Conundrums of the Estimated Magnitude of Food Waste Generated in South Africa. Planning 2020, 15, 893–899. [Google Scholar] [CrossRef]

- Panigrahi, S.; Dubey, B.K. A critical review on operating parameters and strategies to improve the biogas yield from anaerobic digestion of organic fraction of municipal solid waste. Renew. Energy 2019, 143, 779–797. [Google Scholar] [CrossRef]

- Cheng, J.Y.; Lo, I.M. Investigation of the available technologies and their feasibility for the conversion of food waste into fish feed in Hong Kong. Environ. Sci. Pollut. Res. 2016, 23, 7169–7177. [Google Scholar] [CrossRef] [PubMed]

- FAO, Fruits and Vegetables-Your Dietary Essentials. The International Year of Fruits and Vegetables; FAO: Rome, Italy, 2021. [Google Scholar]

- Kibler, K.M.; Reinhart, D.; Hawkins, C.; Motlagh, A.M.; Wright, J. Food waste and the food-energy-water nexus: A review of food waste management alternatives. Waste Manag. 2018, 74, 52–62. [Google Scholar] [CrossRef] [PubMed]

- Mason-D’Croz, D.; Sulser, T.B.; Wiebe, K.; Rosegrant, M.W.; Lowder, S.K.; Nin-Pratt, A.; Willenbockel, D.; Robinson, S.; Zhu, T.; Cenacchi, N. Agricultural investments and hunger in Africa modeling potential contributions to SDG2–Zero Hunger. World Dev. 2019, 116, 38–53. [Google Scholar] [CrossRef] [PubMed]

- McGuire, S. FAO, IFAD, and WFP. The state of food insecurity in the world 2015: Meeting the 2015 international hunger targets: Taking stock of uneven progress. Rome: FAO, 2015. Adv. Nutr. 2015, 6, 623–624. [Google Scholar] [CrossRef]

- Food and Agriculture Organization (FAO); International Fund for Agricultural Development (IFAD); The United Nations Children’s Fund (UNICEF); World Food Programme (WFP); World Health Organization (WHO). The State of Food Security and Nutrition in the World 2022. Repurposing Food and Agricultural Policies to Make Healthy Diets More Affordable; Food and Agriculture Organization (FAO): Rome, Italy, 2022. [Google Scholar]

- Caldeira, C.; Vlysidis, A.; Fiore, G.; De Laurentiis, V.; Vignali, G.; Sala, S. Sustainability of food waste biorefinery: A review on valorisation pathways, techno-economic constraints, and environmental assessment. Bioresour. Technol. 2020, 312, 123575. [Google Scholar] [CrossRef] [PubMed]

- Mintah, B.; Eliason, A.; Nsiah, M.; Baah, E.; Hagan, E.; Ofosu, D. Consumption of fruits among students: A case of a Public University in Ghana. Afr. J. Food Agric. Nutr. Dev. 2012, 12, 5978–5993. [Google Scholar] [CrossRef]

- Hanssen, O.J.; Syversen, F.; Stø, E. Edible food waste from Norwegian households—Detailed food waste composition analysis among households in two different regions in Norway. Resour. Conserv. Recycl. 2016, 109, 146–154. [Google Scholar] [CrossRef]

- Östergren, K.; Holtz, E. Food Waste Prevention Strategies in Global Food Chains. 2016. Available online: https://www.siani.se/wp-content/uploads/2017/03/Food-waste-prevetion-in-global-food-chainsver-2016_11_30.pdf (accessed on 6 January 2022).

- Buzby, J.C.; Farah-Wells, H.; Hyman, J. The Estimated Amount, Value, and Calories of Postharvest Food Losses at the Retail and Consumer Levels in the United States; United States Department of Agriculture: Washington, DC, USA, 2014. [Google Scholar]

- HLPE. Food Security and Nutrition: Building a Global Narrative Towards 2030; High Level Panel of Experts on Food Security and Nutrition: Rome, Italy, 2020. [Google Scholar]

- Hanson, C.; Dias, D.; Fonseca, J.; Timmermans, T.; Lomax, J.; Dawe, A.; Berger, V. Food Loss and Waste Accounting and Reporting Standard. 2016. Available online: https://flwprotocol.org/wp-content/uploads/2017/05/FLW_Standard_final_2016.pdf (accessed on 6 January 2022).

- Benucci, I.; Lombardelli, C.; Mazzocchi, C.; Esti, M. Natural colorants from vegetable food waste: Recovery, regulatory aspects, and stability—A review. Compr. Rev. Food Sci. Food Saf. 2022, 21, 2715–2737. [Google Scholar] [CrossRef] [PubMed]

- Abdelradi, F. Food waste behaviour at the household level: A conceptual framework. Waste Manag. 2018, 71, 485–493. [Google Scholar] [CrossRef]

- Bellemare, M.F.; Çakir, M.; Peterson, H.H.; Novak, L.; Rudi, J. On the measurement of food waste. Am. J. Agric. Econ. 2017, 99, 1148–1158. [Google Scholar] [CrossRef]

- Negri, C.; Ricci, M.; Zilio, M.; D’Imporzano, G.; Qiao, W.; Dong, R.; Adani, F. Anaerobic digestion of food waste for bio-energy production in China and Southeast Asia: A review. Renew. Sustain. Energy Rev. 2020, 133, 110138. [Google Scholar] [CrossRef]

- Teigiserova, D.A.; Hamelin, L.; Thomsen, M. Towards transparent valorization of food surplus, waste and loss: Clarifying definitions, food waste hierarchy, and role in the circular economy. Sci. Total Environ. 2020, 706, 136033. [Google Scholar] [CrossRef]

- Gustafsson, J.; Cederberg, C.; Sonesson, U.; Emanuelsson, A. The Methodology of the FAO Study: Global Food Losses and Food Waste-Extent; Causes and Prevention-FAO: Rome, Italy, 2011. [Google Scholar]

- Sagar, N.A.; Pareek, S.; Sharma, S.; Yahia, E.M.; Lobo, M.G. Fruit and vegetable waste: Bioactive compounds, their extraction, and possible utilization. Compr. Rev. Food Sci. Food Saf. 2018, 17, 512–531. [Google Scholar] [CrossRef]

- Sánchez, M.; Laca, A.; Laca, A.; Díaz, M. Value-Added Products from Fruit and Vegetable Wastes: A Review. CLEAN–Soil Air Water 2021, 49, 2000376. [Google Scholar] [CrossRef]

- Calzadilla, A.; Zhu, T.; Rehdanz, K.; Tol, R.S.; Ringler, C. Climate change and agriculture: Impacts and adaptation options in South Africa. Water Resour. Econ. 2014, 5, 24–48. [Google Scholar] [CrossRef]

- Sethi, G.; Bedregal, L.; Cassou, E.; Constantino, L.; Hou, X.; Jain, S.; Messent, F.; Morales, X.; Mostafa, I.; Pascual, J. Addressing Food Loss and Waste: A Global Problem with Local Solutions; World Bank Group: Washington, DC, USA, 2020. [Google Scholar]

- Adhikari, B.K.; Barrington, S.; Martinez, J. Predicted growth of world urban food waste and methane production. Waste Manag. Res. 2006, 24, 421–433. [Google Scholar] [CrossRef] [PubMed]

- Bhat, S.A.; Huang, N.-F.; Sofi, I.B.; Sultan, M. Agriculture-food supply chain management based on blockchain and IoT: A narrative on enterprise blockchain interoperability. Agriculture 2021, 12, 40. [Google Scholar] [CrossRef]

- Bhatt, S.; Lee, J.; Deutsch, J.; Ayaz, H.; Fulton, B.; Suri, R. From food waste to value-added surplus products (VASP): Consumer acceptance of a novel food product category. J. Consum. Behav. 2018, 17, 57–63. [Google Scholar] [CrossRef]

- Raak, N.; Symmank, C.; Zahn, S.; Aschemann-Witzel, J.; Rohm, H. Processing-and product-related causes for food waste and implications for the food supply chain. Waste Manag. 2017, 61, 461–472. [Google Scholar] [CrossRef] [PubMed]

- Xue, L.; Liu, G.; Parfitt, J.; Liu, X.; Van Herpen, E.; Stenmarck, Å.; O’Connor, C.; Ostergren, K.; Cheng, S. Missing food, missing data? A critical review of global food losses and food waste data. Environ. Sci. Technol. 2017, 51, 6618–6633. [Google Scholar] [CrossRef] [PubMed]

- Tai, J.; Zhang, W.; Che, Y.; Feng, D. Municipal solid waste source-separated collection in China: A comparative analysis. Waste Manag. 2011, 31, 1673–1682. [Google Scholar] [CrossRef] [PubMed]

- Affognon, H.; Mutungi, C.; Sanginga, P.; Borgemeister, C. Unpacking postharvest losses in sub-Saharan Africa: A meta-analysis. World Dev. 2015, 66, 49–68. [Google Scholar] [CrossRef]

- Gustavsson, J.; Cederberg, C.; Sonesson, U.; Van Otterdijk, R.; Meybeck, A. Global Food Losses and Food Waste; FAO: Rome, Italy, 2011. [Google Scholar]

- Gustavsson, J.; Stage, J. Retail waste of horticultural products in Sweden. Resour. Conserv. Recycl. 2011, 55, 554–556. [Google Scholar]

- Oelofse, S.; Polasi, T.; Haywood, L.; Musvoto, C. Increasing Reliable, Scientific Data and Information on Food Losses and Waste in South Africa; CSIR: Pretoria, South Africa, 2021. [Google Scholar]

- FAO (Food and Agriculture Organization of the United Nations). Key Facts on Food Loss and Waste You Should Know! Food and Agriculture Organization of the United Nations. 2018. Available online: http://www.fao.org/save-food/resources/keyfindings/en/ (accessed on 12 May 2023).

- Mbow, C.; Rosenzweig, C.; Barioni, L.G.; Benton, T.G.; Herrero, M.; Krishnapillai, M.; Liwenga, E.; Pradhan, P.; Rivera-Ferre, M.-G.; Sapkota, T. Food Security; IPCC: Geneva, Switzerland, 2019. [Google Scholar]

- Olavarria-Key, N.; Ding, A.; Legendre, T.S.; Min, J. Communication of food waste messages: The effects of communication modality, presentation order, and mindfulness on food waste reduction intention. Int. J. Hosp. Manag. 2021, 96, 102962. [Google Scholar]

- Nishida, J. Reducing Food Waste and Promoting Food Recovery Globally, EPA Connect. The Official Blog of the EPA Leadership. Off. Blog EPA Leader. 2014. Available online: https://blog.epa.gov/blog/2014/10/reducing-food-waste-and-promoting-food-recovery-globally/ (accessed on 6 January 2022).

- Morone, P.; Koutinas, A.; Gathergood, N.; Arshadi, M.; Matharu, A. Food waste: Challenges and opportunities for enhancing the emerging bio-economy. J. Clean. Prod. 2019, 221, 10–16. [Google Scholar] [CrossRef]

- Bond, M.; Meacham, T.; Bhunnoo, R.; Benton, T. Food Waste within Global Food Systems; Global Food Security: Swindon, UK, 2013. [Google Scholar]

- Lipinski, B.; Hanson, C.; Waite, R.; Searchinger, T.; Lomax, J. Reducing Food Loss and Waste; Working Paper, Instalment 2 of “Creating a Sustainable Food Future”; World Resources Institute: Washington, DC, USA, 2013. [Google Scholar]

- Sheahan, M.; Barrett, C.B. Food loss and waste in Sub-Saharan Africa: A critical review. Food Policy 2017, 70, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Hoehn, D.; Vázquez-Rowe, I.; Kahhat, R.; Margallo, M.; Laso, J.; Fernández-Ríos, A.; Ruiz-Salmón, I.; Aldaco, R. A critical review on food loss and waste quantification approaches: Is there a need to develop alternatives beyond the currently widespread pathways? Resour. Conserv. Recycl. 2023, 188, 106671. [Google Scholar] [CrossRef]

- Plazzotta, S.; Manzocco, L.; Nicoli, M.C. Fruit and vegetable waste management and the challenge of fresh-cut salad. Trends Food Sci. Technol. 2017, 63, 51–59. [Google Scholar] [CrossRef]

- UNEP. Food Waste Index Report 2021; UNEP: Nairobi, Kenya, 2021. [Google Scholar]

- Capanoglu, E.; Nemli, E.; Tomas-Barberan, F. Novel Approaches in the Valorization of Agricultural Wastes and Their Applications. J. Agric. Food Chem. 2022, 70, 6787–6804. [Google Scholar] [CrossRef]

- Esparza, I.; Jiménez-Moreno, N.; Bimbela, F.; Ancín-Azpilicueta, C.; Gandía, L.M. Fruit and vegetable waste management: Conventional and emerging approaches. J. Environ. Manag. 2020, 265, 110510. [Google Scholar] [CrossRef] [PubMed]

- Jiménez-Moreno, N.; Esparza, I.; Bimbela, F.; Gandía, L.M.; Ancín-Azpilicueta, C. Valorization of selected fruit and vegetable wastes as bioactive compounds: Opportunities and challenges. Crit. Rev. Environ. Sci. Technol. 2020, 50, 2061–2108. [Google Scholar] [CrossRef]

- Arancon, R.A.D.; Lin, C.S.K.; Chan, K.M.; Kwan, T.H.; Luque, R. Advances on waste valorization: New horizons for a more sustainable society. In Waste Management and Valorization; Apple Academic Press: Williston, VT, USA, 2017; pp. 23–66. [Google Scholar]

- Kiran, E.U.; Trzcinski, A.P.; Ng, W.J.; Liu, Y. Bioconversion of food waste to energy: A review. Fuel 2014, 134, 389–399. [Google Scholar] [CrossRef]

- Lin, K. CS et al. Food waste as a valuable resource for the production of chemicals, materials and fuels. Curr. Situat. Glob. Perspect. Energy Environ. Sci 2013, 6, 426–464. [Google Scholar] [CrossRef]

- Liu, Z.; de Souza, T.S.P.; Holland, B.; Dunshea, F.; Barrow, C.; Suleria, H.A.R. Valorization of Food Waste to Produce Value-Added Products Based on Its Bioactive Compounds. Processes 2023, 11, 840. [Google Scholar] [CrossRef]

- Aidoo, R.; Kwofie, E.M.; Adewale, P.; Lam, E.; Ngadi, M. Designing Sustainable Circular Bioeconomy Solutions for the Pulse Industry: The Case of Pea-Starch Based Single Cell Protein. Sci. Total Environ. 2024, 912, 169029. [Google Scholar] [CrossRef] [PubMed]

- Figge, F.; Thorpe, A.S. Circular economy, operational eco-efficiency, and sufficiency. An integrated view. Ecol. Econ. 2023, 204, 107692. [Google Scholar] [CrossRef]

- Homrich, A.S.; Galvao, G.; Abadia, L.G.; Carvalho, M.M. The circular economy umbrella: Trends and gaps on integrating pathways. J. Clean. Prod. 2018, 175, 525–543. [Google Scholar] [CrossRef]

- Brandão, M. Do bioenergy, bioeconomy and circular economy systems mitigate climate change? insights from life cycle assessment. In Handbook of the Circular Economy; Edward Elgar Publishing: Cheltenham, UK, 2020; pp. 396–409. [Google Scholar]

- Matousek, R.; Tzeremes, N.G. The asymmetric impact of human capital on economic growth. Empir. Econ. 2021, 60, 1309–1334. [Google Scholar] [CrossRef]

- Chaboud, G.; Daviron, B. Food losses and waste: Navigating the inconsistencies. Glob. Food Secur. 2017, 12, 1–7. [Google Scholar] [CrossRef]

- Strotmann, C.; Baur, V.; Börnert, N.; Gerwin, P. Generation and prevention of food waste in the German food service sector in the COVID-19 pandemic–Digital approaches to encounter the pandemic related crisis. Socio-Econ. Plan. Sci. 2022, 82, 101104. [Google Scholar] [CrossRef]

- Do, Q.; Ramudhin, A.; Colicchia, C.; Creazza, A.; Li, D. A systematic review of research on food loss and waste prevention and management for the circular economy. Int. J. Prod. Econ. 2021, 239, 108209. [Google Scholar] [CrossRef]

- Nobre, G.C.; Tavares, E. Scientific literature analysis on big data and internet of things applications on circular economy: A bibliometric study. Scientometrics 2017, 111, 463–492. [Google Scholar] [CrossRef]

- Almeida, P.; Rodrigues, R.; Gaspar, M.; Braga, M.; Quina, M. Integrated management of residues from tomato production: Recovery of value-added compounds and biogas production in the biorefinery context. J. Environ. Manag. 2021, 299, 113505. [Google Scholar] [CrossRef]

- Bas-Bellver, C.; Barrera, C.; Betoret, N.; Seguí, L. Turning agri-food cooperative vegetable residues into functional powdered ingredients for the food industry. Sustainability 2020, 12, 1284. [Google Scholar] [CrossRef]

- Merino, D.; Bertolacci, L.; Paul, U.C.; Simonutti, R.; Athanassiou, A. Avocado Peels and Seeds: Processing Strategies for the Development of Highly Antioxidant Bioplastic Films. ACS Appl. Mater. Interfaces 2021, 13, 38688–38699. [Google Scholar] [CrossRef] [PubMed]

- Sánchez, M.; Laca, A.; Laca, A.; Díaz, M. Towards food circular economy: Hydrothermal treatment of mixed vegetable and fruit wastes to obtain fermentable sugars and bioactive compounds. Environ. Sci. Pollut. Res. 2022, 30, 3901–3917. [Google Scholar] [CrossRef]

- Črnivec, I.G.O.; Skrt, M.; Šeremet, D.; Sterniša, M.; Farčnik, D.; Štrumbelj, E.; Poljanšek, A.; Cebin, N.; Pogačnik, L.; Možina, S.S. Waste streams in onion production: Bioactive compounds, quercetin and use of antimicrobial and antioxidative properties. Waste Manag. 2021, 126, 476–486. [Google Scholar] [CrossRef] [PubMed]

- Esposito, T.; Paolucci, M.; Sansone, F.; Mencherini, T.; Pacifico, S.; Volpe, M.G. Exploitation and Valorization of Agro-Food Wastes from Grape Harvesting: Production, Characterization of MAE-Extracts from Vitis vinifera Leaves and Stabilization in Microparticulate Powder Form. Appl. Sci. 2021, 11, 5827. [Google Scholar] [CrossRef]

- Dyjakon, A.; Sobol, Ł.; Noszczyk, T.; Mitręga, J. The Impact of Torrefaction Temperature on the Physical-Chemical Properties of Residual Exotic Fruit (Avocado, Mango, Lychee) Seeds. Energies 2022, 15, 612. [Google Scholar] [CrossRef]

- Giordano, M.; Pinela, J.; Dias, M.I.; Calhelha, R.C.; Stojković, D.; Soković, M.; Tavares, D.; Cánepa, A.L.; Ferreira, I.C.; Caleja, C. Ultrasound-assisted extraction of flavonoids from kiwi peel: Process optimization and bioactivity assessment. Appl. Sci. 2021, 11, 6416. [Google Scholar] [CrossRef]

- Gosset-Erard, C.; Zhao, M.; Lordel-Madeleine, S.; Ennahar, S. Identification of punicalagin as the bioactive compound behind the antimicrobial activity of pomegranate (Punica granatum L.) peels. Food Chem. 2021, 352, 129396. [Google Scholar] [CrossRef] [PubMed]

- Krivokapić, S.; Vlaović, M.; Damjanović Vratnica, B.; Perović, A.; Perović, S. Biowaste as a Potential Source of Bioactive Compounds—A Case Study of Raspberry Fruit Pomace. Foods 2021, 10, 706. [Google Scholar] [CrossRef]

- Mastrogiovanni, F.; Mukhopadhya, A.; Lacetera, N.; Ryan, M.T.; Romani, A.; Bernini, R.; Sweeney, T. Anti-inflammatory effects of pomegranate peel extracts on in vitro human intestinal caco-2 cells and ex vivo porcine colonic tissue explants. Nutrients 2019, 11, 548. [Google Scholar] [CrossRef]

- Muchagato Maurício, E.; Rosado, C.; Duarte, M.P.; Fernando, A.L.; Díaz-Lanza, A.M. Evaluation of industrial sour cherry liquor wastes as an ecofriendly source of added value chemical compounds and energy. Waste Biomass Valorization 2020, 11, 201–210. [Google Scholar] [CrossRef]

- Metzner Ungureanu, C.-R.; Lupitu, A.I.; Moisa, C.; Rivis, A.; Copolovici, L.O.; Poiana, M.-A. Investigation on high-value bioactive compounds and antioxidant properties of blackberries and their fractions obtained by home-scale juice processing. Sustainability 2020, 12, 5681. [Google Scholar] [CrossRef]

- Negroiu, M.; Țurcanu, A.A.; Matei, E.; Râpă, M.; Covaliu, C.I.; Predescu, A.M.; Pantilimon, C.M.; Coman, G.; Predescu, C. Novel adsorbent based on banana peel waste for removal of heavy metal ions from synthetic solutions. Materials 2021, 14, 3946. [Google Scholar] [CrossRef] [PubMed]

- Rico, X.; Nuutinen, E.-M.; Gullón, B.; Pihlajaniemi, V.; Yáñez, R. Application of an eco-friendly sodium acetate/urea deep eutectic solvent in the valorization of melon by-products. Food Bioprod. Process. 2021, 130, 216–228. [Google Scholar] [CrossRef]

- Gil, L.S.; Maupoey, P.F. An integrated approach for pineapple waste valorisation. Bioethanol production and bromelain extraction from pineapple residues. J. Clean. Prod. 2018, 172, 1224–1231. [Google Scholar]

- Tedesco, D.E.A.; Scarioni, S.; Tava, A.; Panseri, S.; Zuorro, A. Fruit and Vegetable Wholesale Market Waste: Safety and Nutritional Characterisation for Their Potential Re-Use in Livestock Nutrition. Sustainability 2021, 13, 9478. [Google Scholar] [CrossRef]

- Jayesree, N.; Hang, P.K.; Priyangaa, A.; Krishnamurthy, N.P.; Ramanan, R.N.; Turki, M.A.; Charis, M.G.; Ooi, C.W. Valorisation of carrot peel waste by water-induced hydrocolloidal complexation for extraction of carotene and pectin. Chemosphere 2021, 272, 129919. [Google Scholar] [CrossRef] [PubMed]

- Banerjee, R.; Chintagunta, A.D.; Ray, S. A cleaner and eco-friendly bioprocess for enhancing reducing sugar production from pineapple leaf waste. J. Clean. Prod. 2017, 149, 387–395. [Google Scholar] [CrossRef]

- Castro, L.A.d.; Lizi, J.M.; Chagas, E.G.L.d.; Carvalho, R.A.d.; Vanin, F.M. From orange juice by-product in the food industry to a functional ingredient: Application in the circular economy. Foods 2020, 9, 593. [Google Scholar] [CrossRef] [PubMed]

- Diéguez-Santana, K.; Sarduy-Pereira, L.B.; Sablón-Cossío, N.; Bautista-Santos, H.; Sánchez-Galván, F.; Ruíz Cedeño, S.d.M. Evaluation of the Circular Economy in a Pitahaya Agri-Food Chain. Sustainability 2022, 14, 2950. [Google Scholar] [CrossRef]

- Gómez-García, R.; Vilas-Boas, A.A.; Machado, M.; Campos, D.A.; Aguilar, C.N.; Madureira, A.R.; Pintado, M. Impact of simulated in vitro gastrointestinal digestion on bioactive compounds, bioactivity and cytotoxicity of melon (Cucumis melo L. inodorus) peel juice powder. Food Biosci. 2022, 47, 101726. [Google Scholar]

- Ledesma, B.; Beltramone, A. Revalorization of agro-industrial waste as a catalyst source for production of biofuels. Renew. Energy 2021, 174, 747–757. [Google Scholar] [CrossRef]

- Martinez-Fernandez, J.S.; Seker, A.; Davaritouchaee, M.; Gu, X.; Chen, S. Recovering valuable bioactive compounds from potato peels with sequential hydrothermal extraction. Waste Biomass Valorization 2021, 12, 1465–1481. [Google Scholar] [CrossRef]

- Martinez-Fernandez, J.S.; Gu, X.; Chen, S. Techno-economic assessment of bioactive compound recovery from potato peels with sequential hydrothermal extraction. J. Clean. Prod. 2021, 282, 124356. [Google Scholar] [CrossRef]

- Zhang, Y.; Cheng, X.; Wang, Z.; Tahir, M.H.; Wang, Z.; Wang, X.; Wang, C. Full recycling of high-value resources from cabbage waste by multi-stage utilization. Sci. Total Environ. 2022, 804, 149951. [Google Scholar] [CrossRef] [PubMed]

- Ahmadi, F.; Lee, W.H.; Oh, Y.-K.; Park, K.; Kwak, W.S. Microbial, nutritional, and antioxidant stability of fruit and vegetables discards treated with sodium metabisulfite during aerobic and anaerobic storage. Waste Biomass Valorization 2021, 12, 347–357. [Google Scholar] [CrossRef]

- Casabar, J.T.; Ramaraj, R.; Tipnee, S.; Unpaprom, Y. Enhancement of hydrolysis with Trichoderma harzianum for bioethanol production of sonicated pineapple fruit peel. Fuel 2020, 279, 118437. [Google Scholar] [CrossRef]

- Angadam, J.O. Tertiary Biovalorisation of Grape Pomace. Ph.D. Thesis, Cape Peninsula University of Technology, Cape Town, South Africa, 2018. [Google Scholar]

- Nassar, H.N.; Ali, H.R.; El-Gendy, N.S. Waste prosperity: Mandarin (Citrus reticulata) peels inspired SPION for enhancing diesel oil biodesulfurization efficiency by Rhodococcus erythropolis HN2. Fuel 2021, 294, 120534. [Google Scholar] [CrossRef]

- Nasser, N.A. Converting Post-Consumer Food Waste into Fish Feed. Ph.D. Thesis, American University of Beirut, Beirut, Lebanon, 2019. [Google Scholar]

- Kumar, A.; Kumar, B.; Singh, S.K.; Kaur, B.; Singh, S. A review on phytosomes: Novel approach for herbal phytochemicals. Asian J. Pharm. Clin. Res. 2017, 10, 41–47. [Google Scholar] [CrossRef]

- Burò, I.; Consoli, V.; Castellano, A.; Vanella, L.; Sorrenti, V. Beneficial Effects of Standardized Extracts from Wastes of Red Oranges and Olive Leaves. Antioxidants 2022, 11, 1496. [Google Scholar] [CrossRef]

- Lombardelli, C.; Liburdi, K.; Benucci, I.; Esti, M. Tailored and synergistic enzyme-assisted extraction of carotenoid-containing chromoplasts from tomatoes. Food Bioprod. Process. 2020, 121, 43–53. [Google Scholar] [CrossRef]

- Mathew, S. Entrepreneurial Opportunities in Nutraceuticals Developed from Fish and Fish Wastes; ICAR-Central Institute of Fisheries Technology: Kerala, India, 2020. [Google Scholar]

- Tedesco, D.E.A.; Conti, C.; Lovarelli, D.; Biazzi, E.; Bacenetti, J. Bioconversion of fruit and vegetable waste into earthworms as a new protein source: The environmental impact of earthworm meal production. Sci. Total Environ. 2019, 683, 690–698. [Google Scholar] [CrossRef] [PubMed]

- Kihara, J.; Nziguheba, G.; Zingore, S.; Coulibaly, A.; Esilaba, A.; Kabambe, V.; Njoroge, S.; Palm, C.; Huising, J. Understanding variability in crop response to fertilizer and amendments in sub-Saharan Africa. Agric. Ecosyst. Environ. 2016, 229, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Heger, M.; Zens, G.; Bangalore, M. Does the Environment Matter for Poverty Reduction? World Bank Group: Washington, DC, USA, 2018. [Google Scholar]

| European Unuion (EU) | |||||||

|---|---|---|---|---|---|---|---|

| Title of Paper | Fruit and Vegetable (FV) Waste Source | FV Residue | Value Added Component/Bioactive Compounds | Recovery Method | By-Product | Author(s) | |

| 1 | Integrated management of residues from tomato production: Recovery of value-added compounds and biogas production in the biorefinery context | Tomatoes (Solanum lycopersicum) | Tomato residues (rotten, green and immature stems, branches and leaves) | β-carotene and lycopene, carotenoids, fiber, phenolic compounds, pigments, carbohydrates, volatile compounds, and phenolics: gallic acid; carotenoids: lycopene | Physical and chemical | Biogas Nutraceuticals Cosmetic industry Textile industry Pharmaceutical industry | [69] |

| 2 | Turning Agri-Food Cooperative Vegetable Residues into Functional Powdered Ingredients for the Food Industry | Cabbage and leek | Antioxidant properties, phenolic compounds, carotenoids, and fiber | Physical and chemical | Food industry Health products | [70] | |

| Carrot and celery sticks | Sticks | ||||||

| Olive leaves | |||||||

| 3 | Avocado Peels and Seeds: Processing Strategies for the Development of Highly Antioxidant Bioplastic Films | Avocado (Persea americana) | Peel and seeds | Pectin, cellulose, hemicellulose, and starch | Physical Chemical | Biomaterials, Food industry Cosmetic and pharmaceutical industries | [71] |

| 4 | Towards food circular economy: hydrothermal treatment of mixed vegetable and fruit wastes to obtain fermentable sugars and bioactive compounds | (Orange, apple, pear, banana, and kiwi) + (potato, tomato, lettuce, onion, and red pepper) | A mixture of fruits and vegetables | Polyphenols antioxidants | Hydrothermal treatment | Biotechnology Food industry Pharmaceutical industry | [72] |

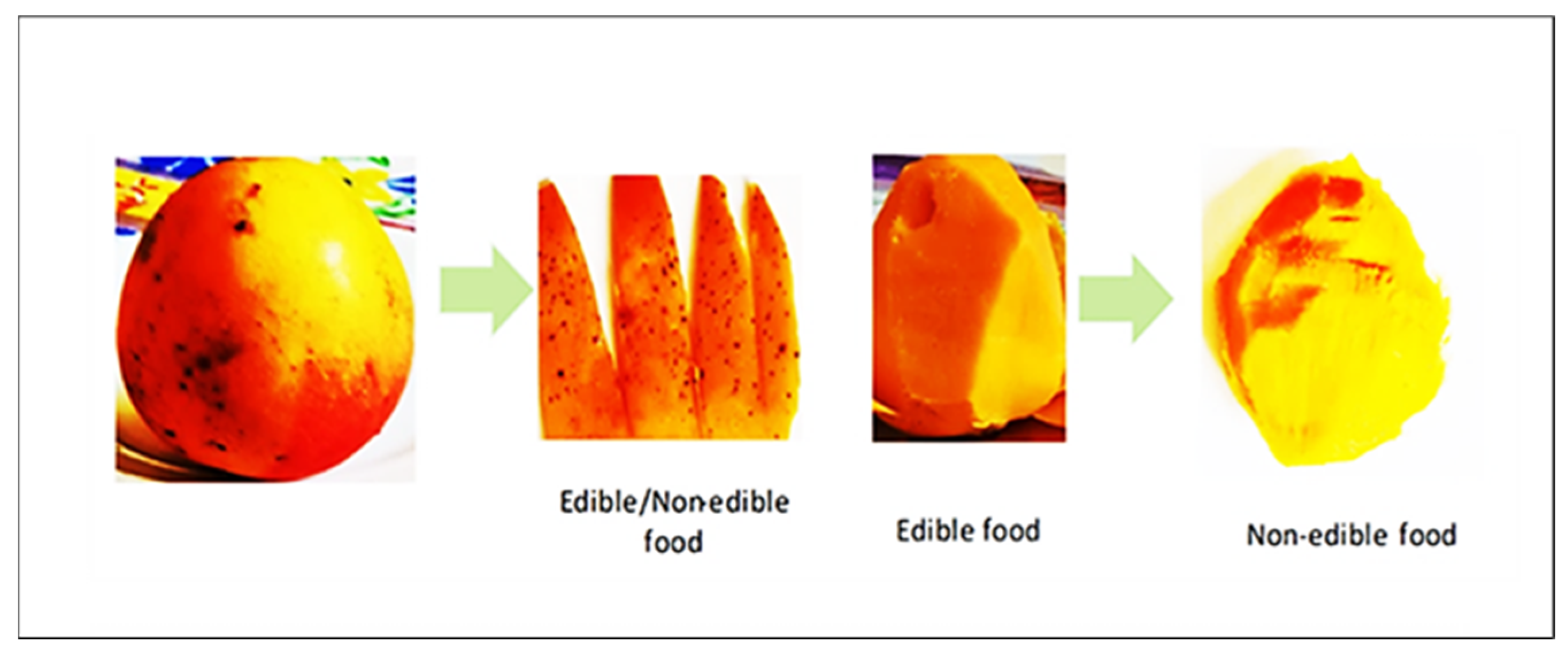

| 5 | Waste streams in onion production: Bioactive compounds, quercetin and use of antimicrobial and antioxidative properties | Onion (Allium cepa) Red onion | Edible parts | Quercetin | Chemical | Nutraceuticals | [73] |

| Inedible parts | |||||||

| Yellow onion | Edible parts | ||||||

| Inedible parts | |||||||

| White onion | Edible parts | No quercetin | |||||

| Inedible parts | |||||||

| Shallots (Allium cepa gr) | Edible parts | Quercetin | |||||

| Inedible parts | |||||||

| 6 | Exploitation and Valorization of Agro-Food Wastes from Grape Harvesting: Production, Characterization of MAE-Extracts from Vitis vinifera Leaves and Stabilization in Microparticulate Powder Form | Grapes (Vitis vinifera) | Leaf extracts from two cultivars of Vitis vinifera Aglianico (Agl) and Greco di Tufo (Gre) | Phenolic compounds (quercetin and kaempferol) | Physical: Chemical | Health industry | [74] |

| 7 | The Impact of Torrefaction Temperature on the Physical-Chemical Properties of Residual Exotic Fruit (Avocado, Mango, Lychee) Seeds | Mango (Mangifera indica), lychee (Litchi chinensis), avocado (Persea americana) | Seeds | (Polyphenols and essential nutrients) | Physical: Chemical | Green energy | [75] |

| 8 | Ultrasound-Assisted Extraction of Flavonoids from Kiwi Peel: Process Optimization and Bioactivity Assessment | Kiwi (Actinidia deliciosa) | Peel | Phenolic compounds, antioxidant and antimicrobial capacities | Physical: Chemical | Food industry Health industry | [76] |

| 9 | Identification of punicalagin as the bioactive compound behind the antimicrobial activity of pomegranate (Punica granatum L.) peels | Pomegranate (Punica granatum L.) | Peels | Phenolics: ellagic acid, gallic acid, punicalin, punicalagin; carotenoids, antimicrobial activity | Physical: Chemical | Food industry Pharmaceutical industry | [77] |

| 10 | Biowaste as a Potential Source of Bioactive Compounds-A Case Study of Raspberry Fruit Pomace | Raspberry (Rubus idaeus) | Pomace | Antioxidant compounds | Physical: Chemical | Food industry Pharmaceutical industry | [78] |

| 11 | Anti-Inflammatory Effects of Pomegranate Peel Extracts on In Vitro Human Intestinal Caco-2 Cells and Ex Vivo Porcine Colonic Tissue Explants | Pomegranate (Punica granatum L.) | Peel extracts | Polyphenols; phenolics: ellagic acid, gallic acid, punicalin, punicalagin; carotenoids, antimicrobial activity | Physical: Chemical | Pharmaceutical industry | [79] |

| 12 | Evaluation of Industrial Sour Cherry Liquor Wastes as an Ecofriendly Source of Added Value Chemical Compounds and Energy | Cherry (Prunus avium) | Pomace sour cherry liquor | Polyphenolic content and antioxidant activity, cyanidin-3-O-glucoside, (+) catechin and (−)Epicatechin, and phenolic acids | Physical: Chemical | Nutraceutical formulations | [80] |

| 13 | Investigation on High-Value Bioactive Compounds and Antioxidant Properties of Blackberries and Their Fractions Obtained by Home-Scale Juice Processing | Blackberries (Rubus) | Pomace | Polyphenolic compounds antioxidants | Physical: Chemical | Food industry | [81] |

| 14 | Novel Adsorbent Based on Banana Peel Waste for Removal of Heavy Metal Ions from Synthetic Solutions | Banana (Musa) | Peel | Banana peel ash | Physical: Chemical | Environmental management (ecological adsorbents) | [82] |

| 15 | Application of an eco-friendly sodium acetate/urea deep eutectic solvent in the valorisation of melon by-products | Melon (Cucumis melo) | Peels | Pectin and polyphenols, oligosaccharides, protein, and antioxidants | Physical: Chemical | Industrial applications | [83] |

| 16 | An integrated approach for pineapple waste valorisation. Bioethanol production and bromelain extraction from pineapple residues | Pineapple (Ananas comosus) | Core and peel | Bromelain, proteolytic enzymes | Chemical method | Bioethanol | [84] |

| 17 | Fruit and Vegetable Wholesale Market Waste: Safety and Nutritional Characterization for Their Potential Re-Use in Livestock Nutrition | Fruit and vegetable | Mixed | Sugars Vitamins | Physical: | Animal feed | [85] |

| India | |||||||

| 18 | Valorization of carrot peel waste by water-induced hydrocolloidal complexation for extraction of carotene and pectin | Carrots (Daucus carota) | Peels | β-carotene Pectin | Physical: Chemical | Food processing and biomedical applications | [86] |

| 19 | A cleaner and eco-friendly bioprocess for enhancing reducing sugar production from pineapple leaf waste | Pineapple (Ananas comosus) | Leaf | Holocellulose | Physical Chemical | Bioethanol | [87] |

| South and Central America | |||||||

| 20 | From Orange Juice By-Product in the Food Industry to a Functional Ingredient: Application in the Circular Economy | Orange (Citrus sinensis) | Orange juice by-product | Phenolic compounds/dietary fiber | Physical: Chemical | Food industry | [88] |

| 21 | Evaluation of the Circular Economy in a Pitahaya Agri-Food Chain | Pitahaya–fruit (Selenicereus megalanthus, K. Schum. Ex Vaupel, Moran/(Dragon fruit) | Seeds | Natural fatty linoleic, oleic, and palmitic acids | Biomedical | [89] | |

| Peel and pulp | Betalains, bioflavonoids derived from quercetin | ||||||

| Stem | Proteins | ||||||

| 22 | Impact of simulated in vitro gastrointestinal digestion on bioactive compounds, bioactivity, and cytotoxicity of melon (Cucumis melo L. inodorus) peel juice powder | Melon (Cucumis melo L. inodorus | Peel | Phenolic compounds | Chemical | Food industry Nutraceutical and pharmaceutical industry | [90] |

| 23 | Revalorization of agro-industrial waste as a catalyst source for the production of biofuels | Oranges (Citrus sinensis) | Peels | Active carbon | Physical Chemical | Biofuels | [91] |

| Other Regions * | |||||||

| 24 | Valorization of carrot peel waste by water-induced hydrocolloidal complexation for extraction of carotene and pectin | Carrots (Daucus carota) | Peels | Carotene and pectin | Chemical method | Nutraceuticals | [86] |

| 25 | Recovery of value bioactive compounds from potato peels with sequential hydrothermal extraction | Potato (Solanum tuberosum) | Peels | Glycoalkaloids antioxidants polysaccharides nutrients, phenolics: chlorogenic, gallic, protocatechuic and caffeic acids; flavonoids | Improving texture, water retention, and emulsion stabilization | [92,93] | |

| 26 | Full recycling of high-value resources from cabbage waste by multi-stage utilization | Cabbage (Brassica oleracea) | Cabbage waste | Fatty acids, phytosterols, aldehydes | Thermochemical conversion and extraction | Agricultural application (botanical pesticides, insect repellent, and pest avoidance) | [94] |

| 27 | Microbial, nutritional, and antioxidant stability of fruit and vegetables discards treated with sodium metabisulfite during aerobic and anaerobic storage | Fruit and vegetables | Fruit and vegetable discards | Antioxidants | Feed ingredients for animals | [95] | |

| 28 | Enhancement of hydrolysis with Trichoderma harzianum for bioethanol production of sonicated pineapple fruit peel | Pineapple (Ananas comosus) | peel | Bromelain, polyphenols, biohydrogen, and biogas cellulose, hemicellulose, and lignin | Chemical | Biofuel | [96] |

| Africa | |||||||

| 29 | Tertiary bipolarization of grape pomace | Grape (Vitis vinifera) | Pomace | Lignin, holocellulose, and ash total reducible sugars (TRS), | Physical/chemical | [97] | |

| 30 | Waste prosperity: Mandarin (Citrus reticulata) peels inspired SPION for enhancing diesel oil biodesulfurization efficiency by Rhodococcus erythropolis HN2 | Mandarin (Citrus reticulata) | Peels | Phenolic acids, saturated fatty acids, and sugar derivative compounds | Chemical | Petroleum refinery | [98] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Okuthe, G. Valorizing Fruit and Vegetable Waste: The Untapped Potential for Entrepreneurship in Sub-Saharan Africa—A Systematic Review. Recycling 2024, 9, 40. https://doi.org/10.3390/recycling9030040

Okuthe G. Valorizing Fruit and Vegetable Waste: The Untapped Potential for Entrepreneurship in Sub-Saharan Africa—A Systematic Review. Recycling. 2024; 9(3):40. https://doi.org/10.3390/recycling9030040

Chicago/Turabian StyleOkuthe, Grace. 2024. "Valorizing Fruit and Vegetable Waste: The Untapped Potential for Entrepreneurship in Sub-Saharan Africa—A Systematic Review" Recycling 9, no. 3: 40. https://doi.org/10.3390/recycling9030040

APA StyleOkuthe, G. (2024). Valorizing Fruit and Vegetable Waste: The Untapped Potential for Entrepreneurship in Sub-Saharan Africa—A Systematic Review. Recycling, 9(3), 40. https://doi.org/10.3390/recycling9030040