Evolution, Prospects, and Predicaments of Polymers in Marine Applications: A Potential Successor to Traditional Materials

Abstract

1. Introduction

2. The Need for Polymers

3. Marine Sectors

3.1. Marine Environment

3.2. Damage to Marine Structures

3.3. Prerequisites for Marine Applications

- The ability to withstand extreme weather conditions and environmental loads;

- Corrosion-resistant properties;

- Higher resistance to wear and fatigue;

- High strength-to-weight ratio;

- Ease of fabrication;

- Superior noise and vibrational damping behavior;

- Enhanced radar/acoustic transparency;

- Good resistance to impact loads.

3.3.1. Environment-Based Prerequisites

3.3.2. Economy-Based Prerequisites

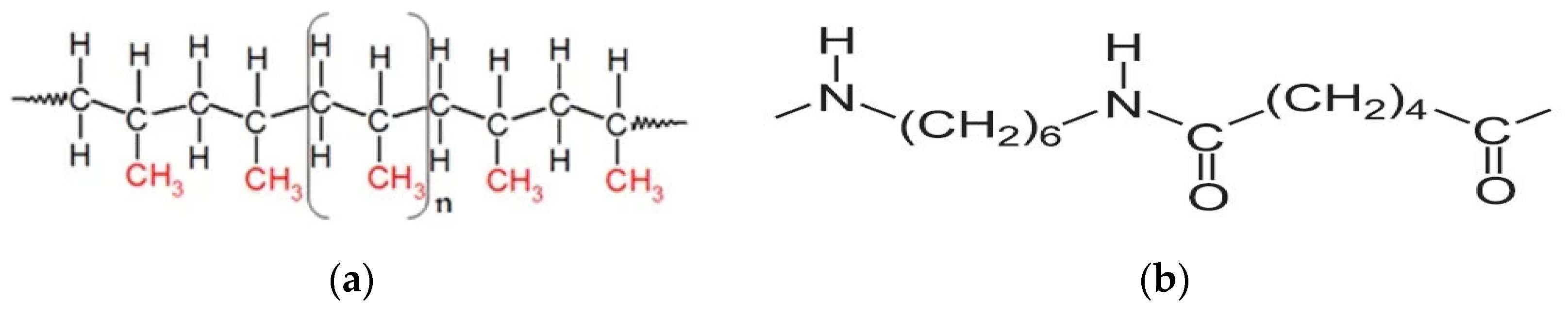

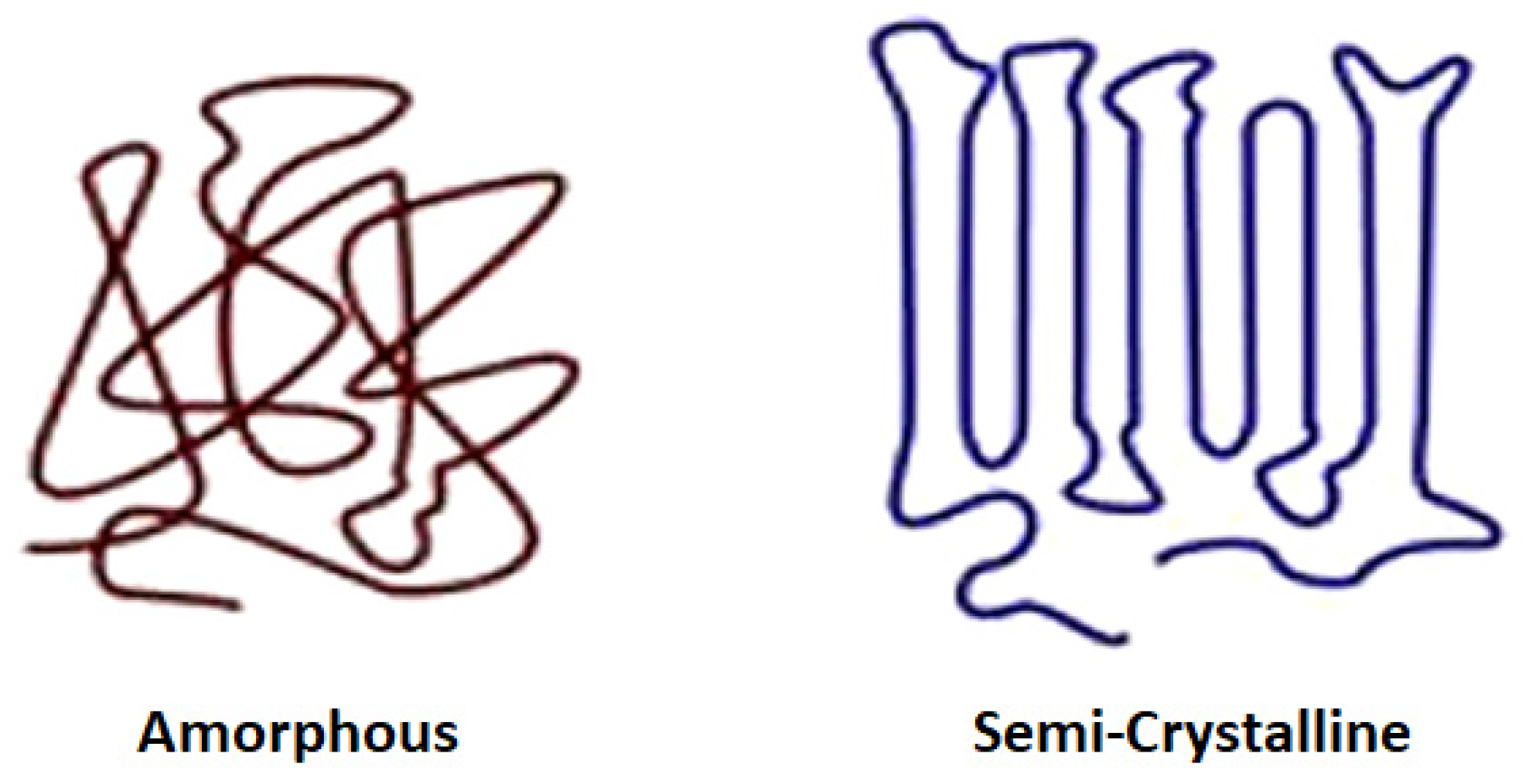

4. Polymers

- Amorphous, where random arrangement exists;

- Crystalline, where an orderly arranged folded chain exists.

4.1. Emergence of Polymers

- The sequence includes ethylene-derived vinyl plastics, homopolymer polyvinyl chloride (PVC), polyethylene, which was followed by low-density polyethylene (LDPE), high-density polyethylene (HDPE), and intermittent linear low-density copolymers of ethylene (LLDP).

- PP, copolymers of ethylene, and a homopolymer of propylene emerged later. Polyolefins refer to polyethylene and PP (and their conventional copolymers). Polymethylmethacrylate (PMMA) and the introduction of nylons happened around the same time, resulting in a material that arguably served the allied war effort.

4.2. Classification of Polymers

- Thermosets are thermosetting engineering plastics that include traditional thermosets and cannot be recycled after being synthesized once. Unreinforced thermosets like epoxies, polyurethanes, and unsaturated polyesters are examples of engineering thermosetting plastics.

- Thermoplastics further include commodity thermoplastics and engineering thermoplastics. Both commodity thermoplastics and engineering thermoplastics can be reprocessed or recycled. Combined, they dominate the polymer market with their high-volume demand. Polyethylene, PP, polyvinyl chloride, polystyrene (PS), polyethylene terephthalate (PET), and related polyesters are examples of commodity thermoplastics. Engineering thermoplastics utilize petroleum products for synthesizing but are in low-volume demand when compared with commodity thermoplastics. Nylon or polyamide, acrylonitrile-butadiene-styrene, and polycarbonate are examples of engineering thermoplastics.

4.3. Advanced Polymers

- Restricted shelf life;

- Low toughness;

- Low strain at failure;

- Processing complexity.

4.4. Common Controversies of Plastics

- Forming a biofilm on the polymer surface results in the colonization of plastics using microorganisms. This induces biodegradation through surface erosion.

- Abiotic hydrolysis of functional groups such as esters, carbonates, and amides results in the reduction in molecular weight. This is influenced by the presence of hydroxide ions.

- Photodegradation due to exposure to UV light and oxygen results in the reduction in molecular weight of the material and causes cracks in them.

5. Structure of Polymer Composites for Marine Applications

5.1. Fiber Reinforcements

- Fiberglass is cheaper, with a low thermal expansion coefficient compared to steel; however, it experiences a decrease in strength and modulus as temperature increases.

- Aramid fibers are in the lower grades of carbon fiber and are human-made by spinning fiber from a chemical blend. They have high specific strengths due to low density, good impact resistance, excellent fatigue, and creep resistance, but face difficulties in bonding with the resin.

- Carbon is expensive, with low thermal expansion coefficients compared to glass and aramid fibers. It has a transverse modulus lower than its longitudinal modulus, high fatigue, and high creep resistance. Tensile strength decreases as the modulus increases, resulting in low strain at rupture. Carbon composites are effective with adhesive bonding, eliminating mechanical fastening. Other fibers like boron, with a higher strength and modulus, are currently chosen due to economic competitiveness.

5.2. Resin Systems

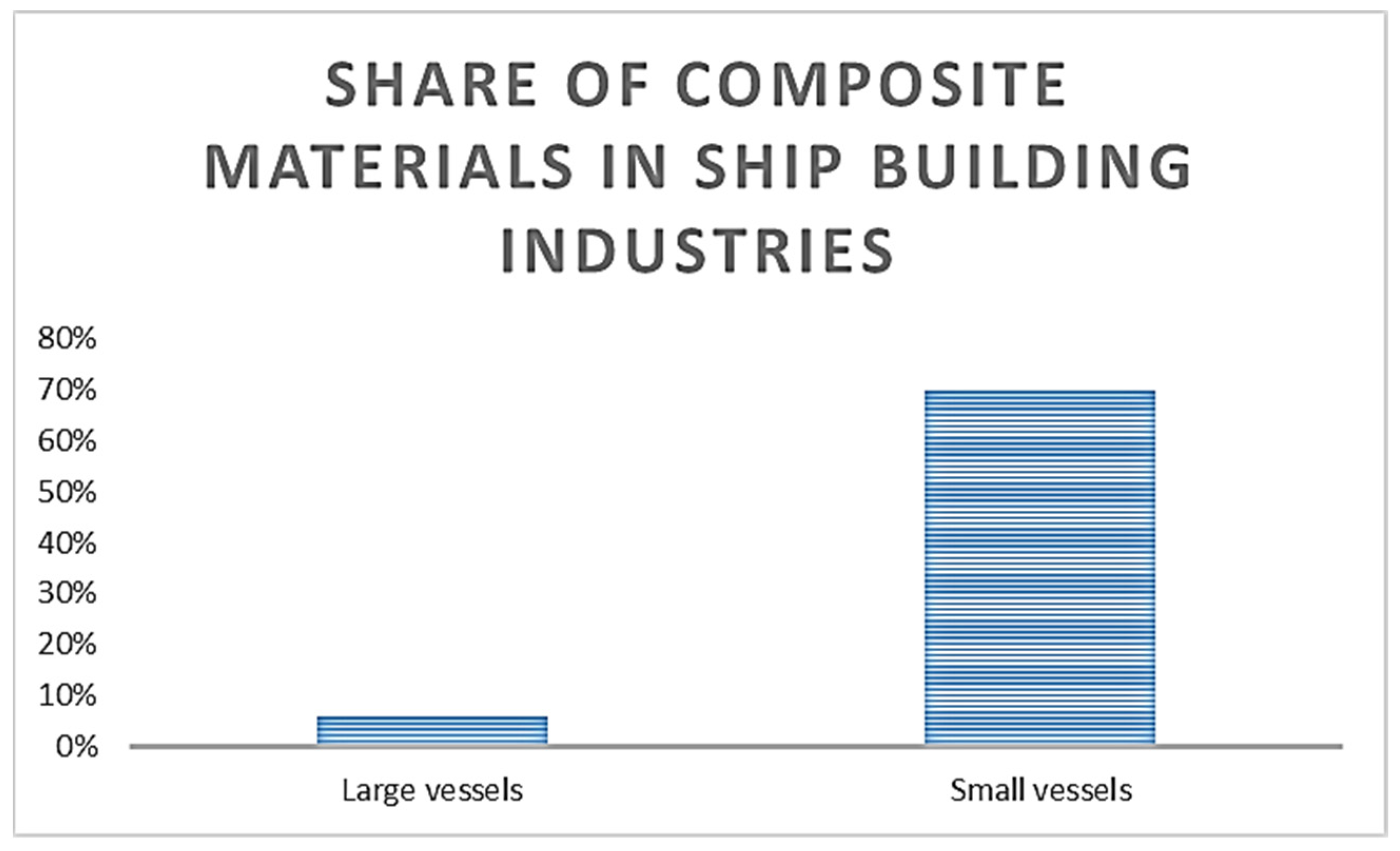

6. Prospects of Polymers in Marine Applications

7. Predicaments Acting as Challenges for Polymers in Marine Applications

- First, from an economic point of view, the CAPEX (capital expenditure) and OPEX (operating costs) of ships are to be made sure, optimized with satisfying material specification leads, including that of boats, and other artifacts.

- Second, from an environmental point of view, the interest in sustainability is ever-increasing.

- An understanding of the fundamental load transfer mechanisms to confirm theoretical capabilities.

- Modeling of concepts for better safety, but this could count as sacrificing both material and structural performance.

- The entire life cycle of composite structures should be analyzed to find better modeling, which could serve meritoriously to better manage the impacts on the environment regarding energy consideration.

- The concept of concurrent engineering being developed could reflect on the interaction of design and production, resulting in a cost-effective optimal choice.

7.1. Plastics, Packing, and Marine Pollution

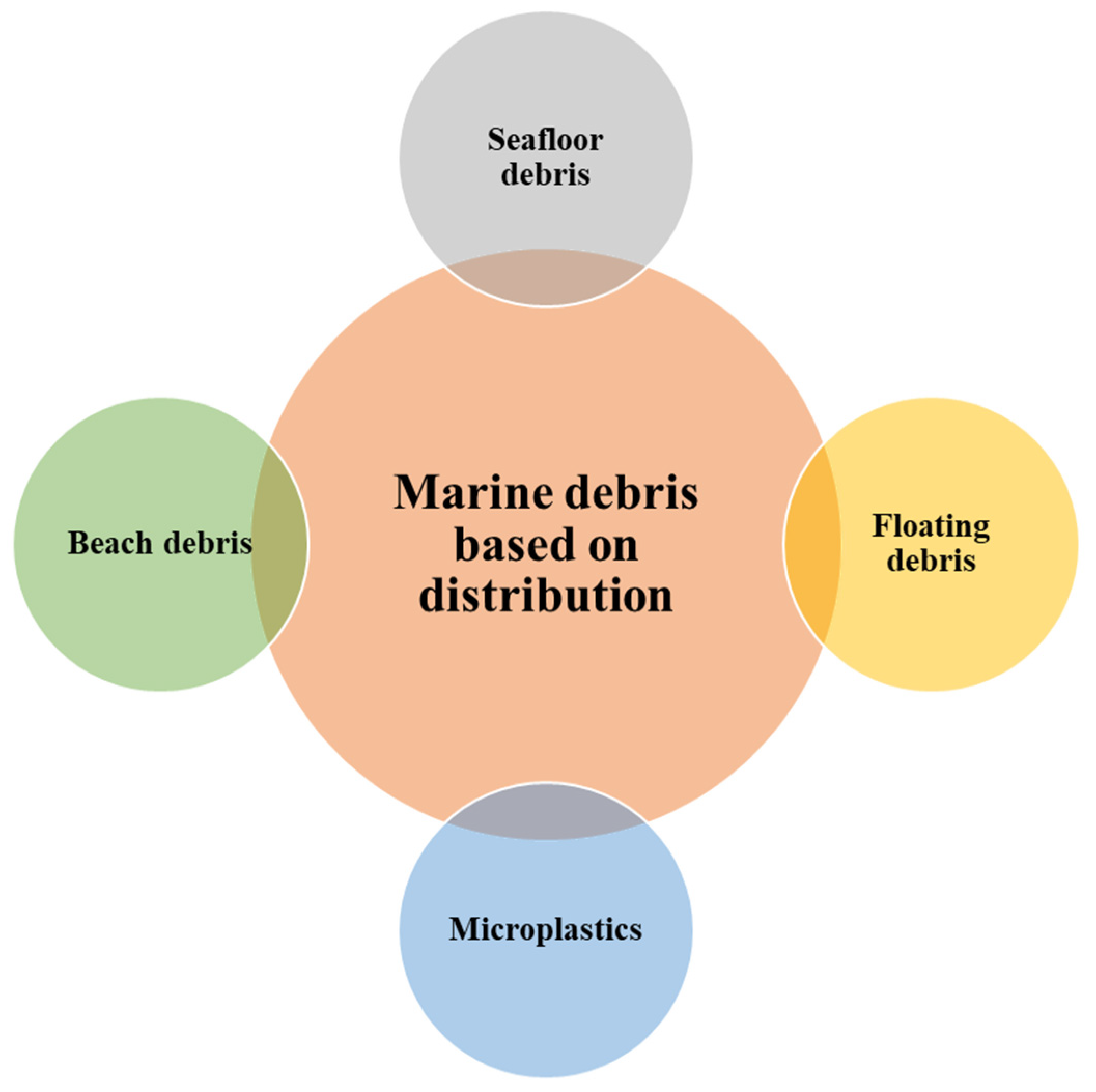

7.2. Marine Debris

- Plastic recycling is the right choice to reduce pollution.

- Adequate litter and recycling bins are mandatory near coastal areas.

- Educational research institutions and industries are working collaboratively on developing biobased plastics; they are also exploring ways to reduce the disposal of microplastics.

- The degradation of plastics should be accelerated by introducing new plastics. This can help restore the natural balance.

8. Recycling and Renewable Plastics as an Effective Solution to Achieve Sustainability

- Preventing debris from entering the marine environment can be achieved through outreach activities supported by governmental efforts at local, state, and national levels. Coordination and education initiatives can help raise awareness about the harmful after-effects of marine debris.

- Improving waste management involves identifying and implementing need-based technological solutions.

- Recycling is a crucial practice to mitigate environmental impacts, as the reuse of materials reduces the need for new production and minimizes energy consumption by avoiding new synthesis. This approach contributes to sustainability. After years of conducting various trials and exclusive research on recycling plastics, three technologies have been identified: mechanical processes, chemical treatment, and thermal processes [62].

- Bioplastics offer a potential long-awaited solution by utilizing plastics of bio-origin or renewable sources. These degradable plastics do not disrupt the marine ecosystem.

- Conversion involves exploring ways to transform marine debris into economically viable and eco-friendly materials.

- Humans need to take responsibility for marine debris, which is a byproduct of human activity. Therefore, it is essential to prioritize the manual clean-up of coastlines and the seafloor, as well as implementing school and public awareness programs on marine ecology and its importance.

9. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Andrady, A.L. Plastics and Environmental Sustainability; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Subramanian, K.; Krishnasamy, S.; Thiagamani, S.M.K.; Pradeepkumar, C.; Dhandapani, A.; Muthukumar, C.; Siengchin, S. Tribo Performance Analysis on Polymer-Based Composites. In Polymer-Based Composites; CRC Press: Boca Raton, FL, USA, 2021; pp. 115–130. [Google Scholar]

- Lambert, S. Environmental Risk of Polymer and Their Degradation Products. No. May, 1–198. 2013. Available online: http://etheses.whiterose.ac.uk/4194/ (accessed on 14 January 2024).

- Ojeda, T. Polymers and the Environment. In Polymer Science; InTech Open: London, UK, 2013; pp. 1–34. [Google Scholar] [CrossRef]

- Stanton, T.; Kay, P.; Johnson, M.; Chan, F.K.S.; Gomes, R.L.; Hughes, J.; Meredith, W.; Orr, H.G.; Snape, C.E.; Taylor, M.; et al. It’s the product not the polymer: Rethinking plastic pollution. Wiley Interdiscip. Rev. Water 2021, 8, e1490. [Google Scholar] [CrossRef]

- Schmaltz, E.; Melvin, E.C.; Diana, Z.; Gunady, E.F.; Rittschof, D.; Somarelli, J.A.; Virdin, J.; Dunphy-Daly, M.M. Plastic pollution solutions: Emerging technologies to prevent and collect marine plastic pollution. Environ. Int. 2020, 144, 106067. [Google Scholar] [CrossRef] [PubMed]

- Scott, G. Plastics packaging and coastal pollution. Int. J. Environ. Stud. 1972, 3, 35–36. [Google Scholar] [CrossRef]

- Scaffaro, R.; Citarrella, M.C.; Catania, A.; Settanni, L. Green composites based on biodegradable polymers and anchovy (Engraulis encrasicolus) waste suitable for 3D printing applications. Compos. Sci. Technol. 2022, 230, 109768. [Google Scholar] [CrossRef]

- Barandiaran, A.; Lascano, D.; Montanes, N.; Balart, R.; Selles, M.A.; Moreno, V. Improvement of the Ductility of Environmentally Friendly Poly(lactide) Composites with Posidonia oceanica Wastes Plasticized with an Ester of Cinnamic Acid. Polymers 2023, 15, 4534. [Google Scholar] [CrossRef] [PubMed]

- Scaffaro, R.; Maio, A.; Gulino, E.F.; Alaimo, G.; Morreale, M. Green composites based on pla and agricultural or marine waste prepared by fdm. Polymers 2021, 13, 1361. [Google Scholar] [CrossRef]

- Mirpoor, S.F.; Giosafatto, C.V.L.; Di Pierro, P.; Di Girolamo, R.; Regalado-González, C.; Porta, R. Valorisation of posidonia oceanica sea balls (Egagropili) as a potential source of reinforcement agents in protein-based biocomposites. Polymers 2020, 12, 2788. [Google Scholar] [CrossRef]

- Bai, Y.; Jin, W.-L. Marine Composite Materials and Structure. In Marine Structural Design; Butterworth-Heinemann: Oxford, UK, 2016; pp. 19–37. [Google Scholar] [CrossRef]

- Zawahid, M. A Conceptual Design of a Fibre Reinforced Plastic Fishing Boat for Traditional Fisheries in Malaysia; UNU-FTP: Reykjavík, Iceland, 2003; pp. 1–53. [Google Scholar]

- Andrady, A.; Fisher, M. Plastics and the Environment|Planète Énergies; John Wiley & Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

- National Oceanic and Atmospheric Administration U.S. Department of Commerce. Ocean Pollution and Marine Debris. Available online: https://www.noaa.gov/education/resource-collections/ocean-coasts/ocean-pollution (accessed on 1 July 2023).

- Kesle, S.E. Mineral supply and demand into the 21st century. In US Geological Survey Circular; Department of Geological Sciences, University of Michigan: Ann Arbor, MI, USA, 2007. [Google Scholar]

- Stein, R.S. Environmental aspects of polymer science and engineering. J. Plast. Film Sheeting 2015, 31, 355–362. [Google Scholar] [CrossRef]

- Dhandapani, A.; Krishnasamy, S.; Muthukumar, C.; Thiagamani, S.M.K.; Nagarajan, R.; Siengchin, S. Plastics in Marine Engineering. Encycl. Mater. Plast. Polym. 2022, 4, 225–236. [Google Scholar] [CrossRef]

- Ghazlan, A.; Ngo, T.D.; Tran, P. Three-dimensional Voronoi model of a nacre-mimetic composite structure under impulsive loading. Compos. Struct. 2016, 153, 278–296. [Google Scholar] [CrossRef]

- Aravind, D.; Senthilkumar, K.; Rajini, N.; Kumar, T.S.M.; Chandrasekar, M.; Ismail, S.O.; Yeetsorn, R.; Parameswaranpillai, J.; Siengchin, S.; Devi, M.I. Feasibility of elastomeric composites as alternative materials for marine applications: A compendious review on their properties and opportunities. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2022, 2022, 839–855. [Google Scholar] [CrossRef]

- Klust, G. Netting Materials for Fishing Gear, 2nd ed.; Wiley: Hoboken, NJ, USA, 1994. [Google Scholar]

- Available online: https://www.globalplasticsheeting.com/our-blog-resource-library/topic/polyethylene-and-polypropylene-101 (accessed on 5 August 2023).

- Polyamides. Available online: https://www.essentialchemicalindustry.org/polymers/polyamides.html (accessed on 5 July 2020).

- focus2.jpg (500 × 283). Available online: https://plasticsdecorating.com/images/022015/focus2.jpg (accessed on 5 July 2020).

- Mallick, P.K. Fiber-Reinforced Composites: Materials, Manufacturing, and Design; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Tolinski, M. Foams Seek Sustainability. Plast. Eng. 2009, 65, 6–8. [Google Scholar] [CrossRef]

- Béland, S. High Performance Thermoplastic Resins and Their Composites; William Andrew Publishing: London, UK, 1990. [Google Scholar] [CrossRef]

- Tolinski, M. Plastics and Sustainability; Scrivener Publishing & Wiley: Beverly, MA, USA, 2012. [Google Scholar]

- Viel, T.; Manfra, L.; Zupo, V.; Libralato, G.; Cocca, M.; Costantini, M. Biodegradation of Plastics Induced by Marine Organisms: Future Perspectives for Bioremediation Approaches. Polymers 2023, 15, 2673. [Google Scholar] [CrossRef] [PubMed]

- Chamas, A.; Moon, H.; Zheng, J.; Qiu, Y.; Tabassum, T.; Jang, J.H.; Abu-Omar, M.; Scott, S.L.; Suh, S. Degradation Rates of Plastics in the Environment. ACS Sustain. Chem. Eng. 2020, 8, 3494–3511. [Google Scholar] [CrossRef]

- Civgin, F. Analysis of Composite Bars in Torsion; Graduate School of Natural and Applied Sciences, Dokuz Eylül University: Konak, Turkey, 2005; p. 141. [Google Scholar]

- Ratwani, M.M. Composite Materials and Sandwich Structures—A Primer. Rto-En-Avt 2010, 156, 1–16. [Google Scholar]

- Mahesh, V.; Joladarashi, S.; Kulkarni, S.M. Damage mechanics and energy absorption capabilities of natural fiber reinforced elastomeric based bio composite for sacrificial structural applications. Def. Technol. 2021, 17, 161–176. [Google Scholar] [CrossRef]

- Dehnavi, F.N.; Safdari, M.; Abrinia, K.; Sheidaei, A.; Baniassadi, M. Numerical study of the conductive liquid metal elastomeric composites. Mater. Today Commun. 2020, 23, 100878. [Google Scholar] [CrossRef]

- Xu, C.; Cao, X.; Jiang, X.; Zeng, X.; Chen, Y. Preparation, structure and properties of dynamically vulcanized polypropylene/acrylonitrile butadiene rubber/zinc dimethacrylate ternary blend composites containing maleic anhydride grafted polypropylene. Polym. Test. 2013, 32, 507–515. [Google Scholar] [CrossRef]

- Ekşi, S.; Genel, K. Comparison of mechanical properties of unidirectional and woven carbon, glass and aramid fiber reinforced epoxy composites. Acta Phys. Pol. A 2017, 132, 879–882. [Google Scholar] [CrossRef]

- Dhandapani, A. Desirability of Tribo-Performance of Natural Based Thermoset and Thermoplastic Composites: A Concise Review. Appl. Sci. Eng. Prog. 2021, 14, 606–613. [Google Scholar] [CrossRef]

- Galanis, K. Hull Construction with Composite Materials for Ships over 100 m in length by. Ocean Eng. 2002, 1987, 1–119. [Google Scholar]

- Chukov, D.I.; Stepashkin, A.A.; Salimon, A.I.; Kaloshkin, S.D. Highly filled elastomeric matrix composites: Structure and property evolution at low temperature carbonization. Mater. Des. 2018, 156, 22–31. [Google Scholar] [CrossRef]

- Afshar, A.; Alkhader, M.; Korach, C.S.; Chiang, F.P. Synergistic effects of fatigue and marine environments on carbon fiber vinyl-ester composites. J. Eng. Mater. Technol. Trans. ASME 2015, 137, 1–8. [Google Scholar] [CrossRef]

- Altunsaray, E.; Neser, G.; Erbil, C.; Gürsel, K.T.; Ünsalan, D. Umweltbedingtes Dauerfestigkeitsverhalten knitterfreier, E-glasfaserverstärkter Polyester-Verbundwerkstoffe für maritime Anwendungen. Materwiss. Werksttech. 2012, 43, 1053–1058. [Google Scholar] [CrossRef]

- Stanier, D.C.; Ciambella, J.; Rahatekar, S.S. Fabrication and characterisation of short fibre reinforced elastomer composites for bending and twisting magnetic actuation. Compos. Part A Appl. Sci. Manuf. 2016, 91, 168–176. [Google Scholar] [CrossRef]

- Cerracchio, P.; Gherlone, M.; Di Sciuva, M.; Tessler, A. A novel approach for displacement and stress monitoring of sandwich structures based on the inverse Finite Element Method. Compos. Struct. 2015, 127, 69–76. [Google Scholar] [CrossRef]

- Marine Composites Market. Available online: https://www.factmr.com/report/marine-composites-market#:~:text=MarineCompositesMarketGrowthOutlook,US%244.8billionin2023 (accessed on 5 November 2023).

- Zini, E.; Scandola, M.; Zimniewska, M. Textile Composites—An Emerging Need of Engineering. Compos. Part B 2003, 6, 113–127. [Google Scholar] [CrossRef]

- Gu, J.; Liang, C.; Zhao, X.; Gan, B.; Qiu, H.; Guo, Y.; Yang, X.; Zhang, Q.; Wang, D.-Y. Highly thermally conductive flame-retardant epoxy nanocomposites with reduced ignitability and excellent electrical conductivities. Compos. Sci. Technol. 2017, 139, 83–89. [Google Scholar] [CrossRef]

- Araby, S.; Li, J.; Shi, G.; Ma, Z.; Ma, J. Graphene for flame-retarding elastomeric composite foams having strong interface. Compos. Part A Appl. Sci. Manuf. 2017, 101, 254–264. [Google Scholar] [CrossRef]

- Araby, S.; Wang, C.-H.; Wu, H.; Meng, Q.; Kuan, H.-C.; Kim, N.K.; Mouritz, A.; Ma, J. Development of flame-retarding elastomeric composites with high mechanical performance. Compos. Part A Appl. Sci. Manuf. 2018, 109, 257–266. [Google Scholar] [CrossRef]

- IUCN. Marine Plastics: What Is the Issue? Why Is This Important? What Can Be Done? International Union for Conservation of Nature. 2018. Available online: https://www.iucn.org/resources/issues-brief/marine-plastic-pollution (accessed on 14 January 2024).

- North, E.J.; Halden, R.U. Plastics and environmental health: The road ahead. Rev. Environ. Health 2013, 28, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Laist, D.W. Impacts of marine debris: Entanglement of marine life in marine debris including a comprehensive list of species with entanglement and ingestion records. In Marine Debris; Springer: Berlin/Heidelberg, Germany, 1997; pp. 99–139. [Google Scholar]

- Wolf, D. Zeehond Met Zwerfvuil. 2008. Available online: https://www.salkodewolf.nl/ (accessed on 30 November 2023).

- Bruin, D. Aanspoelen Bultrug Op De Vliehors; Vlieland, The Netherlands, 2004. [Google Scholar]

- McIlgorm, A.; Campbell, H.F.; Rule, M.J. The economic cost and control of marine debris damage in the Asia-Pacific region. Ocean Coast. Manag. 2011, 54, 643–651. [Google Scholar] [CrossRef]

- Johnson, A.; Salvador, G.; Kenney, J.; Robbins, J.; Kraus, S.; Landry, S.; Clapham, P. Fishing gear involved in entanglements of right and humpback whales. Mar. Mammal Sci. 2005, 21, 635–645. [Google Scholar] [CrossRef]

- Hammer, J.; Kraak, M.H.S.; Parsons, J.R. Plastics in the marine environment: The dark side of a modern gift. In Reviews of Environmental Contamination and Toxicology; Springer: Berlin/Heidelberg, Germany, 2012; pp. 1–44. [Google Scholar]

- Derraik, J.G.B. The pollution of the marine environment by plastic debris: A review. Mar. Pollut. Bull. 2002, 44, 842–852. [Google Scholar] [CrossRef] [PubMed]

- Bergmann, M.; Gutow, L.; Klages, M. Marine Anthropogenic Litter; Springer: Berlin/Heidelberg, Germany, 2015; pp. 1–447. [Google Scholar] [CrossRef]

- Pawar, P.R.; Shirgaonkar, S.S.; Patil, R.B. Plastic marine debris: Sources, distribution and impacts on coastal and ocean biodiversity. Pencil Publ. Biol. Sci. 2016, 3, 40–54. [Google Scholar]

- EPA. Municipal Solid Waste Generation, Recycling, and Disposal in the United States: Facts and Figures for 2012; United States Environmental Protection Agency: Washington, DC, USA, 2014; pp. 1–13. [Google Scholar]

- Hatti-Kaul, R.; Nilsson, L.J.; Zhang, B.; Rehnberg, N.; Lundmark, S. Designing Biobased Recyclable Polymers for Plastics. Trends Biotechnol. 2020, 38, 50–67. [Google Scholar] [CrossRef] [PubMed]

- Neşer, G. Polymer based composites in marine use: History and future trends. Procedia Eng. 2017, 194, 19–24. [Google Scholar] [CrossRef]

- Nair, A.B.; Joseph, R. Eco-Friendly Bio-Composites Using Natural Rubber (NR) Matrices and Natural Fiber Reinforcements; Woodhead Publishing: London, UK, 2014. [Google Scholar]

- Liang, S.L.; Cook, W.D.; Thouas, G.A.; Chen, Q.Z. The mechanical characteristics and in vitro biocompatibility of poly(glycerol sebacate)-Bioglass® elastomeric composites. Biomaterials 2010, 31, 8516–8529. [Google Scholar] [CrossRef]

- Sanetuntikul, J.; Ketpang, K.; Naknaen, P.; Narupai, B.; Petchwattana, N. A circular economy use of waste metalized plastic film as a reinforcing filler in recycled polypropylene packaging for injection molding applications. Clean. Eng. Technol. 2023, 17, 100683. [Google Scholar] [CrossRef]

- Jamnongkan, T.; Intraramongkol, N.; Samoechip, W.; Potiyaraj, P.; Mongkholrattanasit, R.; Jamnongkan, P.; Wongwachirakorn, P.; Sugimoto, M.; Ito, H.; Huang, C.-F. Towards a Circular Economy: Study of the Mechanical, Thermal, and Electrical Properties of Recycled Polypropylene and Their Composite Materials. Polymers 2022, 14, 5482. [Google Scholar] [CrossRef]

- Ugya, Y.A.; Chen, H.; Sheng, Y.; Ajibade, F.O.; Wang, Q. A review of microalgae biofilm as an eco-friendly approach to bioplastics, promoting environmental sustainability. Environ. Res. 2023, 236, 116833. [Google Scholar] [CrossRef] [PubMed]

| Properties | Advantages That Are Specific for Marine Applications |

|---|---|

| Resistance to corrosion | Durability, reduced maintenance, and cost reduction such as the reduction in expenses for achieving anti-corrosion such as painting or treatment. |

| Lightweight | Payload increase, speed, depth, and support for the secure handling of vessels. |

| Complex shape out of monolithic, seamless construction | Easier to achieve complex shapes as it gets draped over smoothly. |

| Good finish and shape | Reduction in material wastage minimizes secondary machining requirements. |

| Esthetic look | Reduction in painting and polishing needs. |

| Tailorability of design properties | Achievement of the expected performance of the component. |

| Non-magnetic | Reduction in signature and galvanic corrosion. |

| Non-magnetic | Reduction in radar cross-section and improves its functioning. |

| Inherently damping | Reduction in radiated noise. |

| Radar/acoustic transparency | Improvement in radar/sonar performance. |

| Low thermal conductivity | Improvement in fire containment. |

| Multiple domestic sources | Easy availability of raw materials. |

| Design cascading effect | Improvement in performance of one component that can substitute, reduce the size of, or eliminate other system components. |

| Properties | Advantages That Are Specific for Marine Applications |

|---|---|

| Impact resistance | Often, lower which makes their applicability questionable during rough sea and other extreme environmental loads. |

| Heat tolerance | Lower for some composites which makes it dangerous to withstand during fire accidents. |

| UV resistance | Lower, which can be extremely risky in a marine environment |

| Initial cost | Higher than some traditional materials which arises the need for optimizing capital expenditure and operating costs using composites |

| Quasi-isotropic elastic modulus | Lower in comparison with than steel and aluminium |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dhandapani, A.; Krishnasamy, S.; Thiagamani, S.M.K.; Periasamy, D.; Muthukumar, C.; Sundaresan, T.K.; Ali, S.; Kurniawan, R. Evolution, Prospects, and Predicaments of Polymers in Marine Applications: A Potential Successor to Traditional Materials. Recycling 2024, 9, 8. https://doi.org/10.3390/recycling9010008

Dhandapani A, Krishnasamy S, Thiagamani SMK, Periasamy D, Muthukumar C, Sundaresan TK, Ali S, Kurniawan R. Evolution, Prospects, and Predicaments of Polymers in Marine Applications: A Potential Successor to Traditional Materials. Recycling. 2024; 9(1):8. https://doi.org/10.3390/recycling9010008

Chicago/Turabian StyleDhandapani, Aravind, Senthilkumar Krishnasamy, Senthil Muthu Kumar Thiagamani, Diwahar Periasamy, Chandrasekar Muthukumar, Thirumalai Kumaran Sundaresan, Saood Ali, and Rendi Kurniawan. 2024. "Evolution, Prospects, and Predicaments of Polymers in Marine Applications: A Potential Successor to Traditional Materials" Recycling 9, no. 1: 8. https://doi.org/10.3390/recycling9010008

APA StyleDhandapani, A., Krishnasamy, S., Thiagamani, S. M. K., Periasamy, D., Muthukumar, C., Sundaresan, T. K., Ali, S., & Kurniawan, R. (2024). Evolution, Prospects, and Predicaments of Polymers in Marine Applications: A Potential Successor to Traditional Materials. Recycling, 9(1), 8. https://doi.org/10.3390/recycling9010008