Abstract

This article investigates the hygrothermal properties of earth-based materials by analyzing experimental data from 88 articles spanning 32 countries worldwide. The focus is determining effective techniques for leveraging the use of excavated soil in construction, particularly emphasizing enhancement of hygrothermal comfort in specific climates. Based on statistical analysis, the study presents a comprehensive classification of earth production techniques, incorporating additives, and examines their impacts on hygrothermal properties of excavated soils. Additionally, it explores the intricate relationship between the climatic conditions of a region and the chosen earth-material production techniques. The analysis aims to propose standard parameters for earthen materials and identify gaps in both methods and experimental studies. Therefore, this study will provide valuable insights by proposing new design tools (ternary diagrams) to maximize the use of excavated soils in construction practices. The proposed diagrams illustrate the intricate relation linking either hygrothermal properties, the climate zone, and manufacturing techniques, or the relation between the most studied manufacturing techniques (compaction, fibered, and stabilization) and expected dry thermal conductivity. Thereby, results from this meta-analysis and critical review will contribute to advancing sustainable construction practices.

1. Introduction

As the construction industry confronts the pressing need to mitigate its carbon footprint, a shift towards materials with minimal environmental impacts and suitability to local climates has gained momentum. Among these rekindled interests in ancient building materials, earth-based materials emerge prominently, boasting a millennia-old history in architecture and widespread availability, notably sourced from excavation sites. However, unlike quarried earth, excavated soils exhibit significant heterogeneity, often relegated to mere construction waste or primary embankment material, unlike other materials such as demolished concrete.

In France, the construction and public works sector generated, in 2020, 213 million tons of waste annually out of 315 million tons [1]. Approximately 80% of this waste came from construction sites in the form of inert waste such as soil, concrete, and gravel [1]. Roughly three-quarters of this debris was reused on-site by public works companies, primarily for road construction and other related activities. This indicates that the construction sector could reuse about 57 million tons of waste annually [1].

The growth in development across all regions in France has led to a substantial increase in waste production. For instance, in areas like Réunion, around 1.5 million tons [2] of excavated soil from construction sites could be repurposed for other uses. Large-scale projects such as the Grand Paris Express or the 2024 Olympic Games are projected to generate 30 to 40 million tons of excavated soil [3] in the Île-de-France region. Moreover, based on the data provided by the ELGIP Working Group on excavated soil backfilling across Europe, Norway produced 3 million tons of excavated soil in 2017. The quantities in Portugal were 339,000 tons in 2017 and 707,810 in 2016. Slovenia reported 2 million tonnes of excavated soil in 2017 and 3.8 million in 2018. In Sweden, the production of excavated soil amounted to 5.4 million tons in 2016 [4].

In the context of environmental commitments such as COP 21, the Grenelle Environmental Roundtable, and the Energy Transition Law, it has become imperative to reuse this excavated soil efficiently to meet the material needs of the construction sector. Consequently, a study has been initiated to explore solutions for recycling excavated soil in France [3]. Furthermore, several initiatives, like the MATARUN project in Réunion and the NEXTERRE project in Nouvelle-Aquitaine, are underway to investigate recycling methods suitable for these materials.

The allure of earth materials lies in their unique capacity as humidity and heat regulators, offering promising potential for enhancing construction hygrometry and thermal comfort. Structures constructed from this geological resource have the potential to stabilize indoor humidity levels, thereby mitigating sources of hygrometric and thermal discomfort. However, the diversity in earth valorization techniques and geographic variability in conducted studies call for reevaluating current scientific analyses seeking to characterize these hygrothermal properties experimentally.

Hence, this article offers a comprehensive and critical review of experimental analyses concerning earth materials, regardless of their manufacturing methods. The primary objective is establishing characteristic value ranges for hygrothermal properties influencing building thermal comfort and providing insights into expected properties based on various earthen material-use techniques. Additionally, this paper aims to explore correlations between desired hygrothermal properties and earthen material use; we present documented earthen materials using techniques, specifying the various biobased additives or binders and indicating the geographical origin of the earth used. By investigating the impact of additives on modifying the properties of earth materials independently of the origin of the soil, we propose techniques for reusing excavated soil, characterized by its high heterogeneity, as building earthen materials. Moreover, this analysis will shed light on underexplored characterization methods and earth production techniques, guiding future research directions. Drawing from our comprehensive meta-analysis of the entire dataset and leveraging advanced statistical tools, we present three innovative design tools that link hygrothermal properties to formulation, climate, or technique. These tools take the form of ternary diagrams, offering new insights into studying the hygrothermal properties of earth-based materials.

The literature presents documented earth valorization methods and explores relevant hygrothermal properties crucial for construction in tropical climates. Subsequently, we outline our bibliographic analysis methodology, providing an overview of the breadth of our state-of-the-art review. We then compile comprehensive tables that categorize targeted properties based on technique types and specify geographic measurement locations. Finally, we analyze the correlations between these parameters to propose an innovative graphical representation constructed using statistical tools: the “MATARUN” diagrams.

2. Materials and Methods

2.1. Methodology and Bibliometric Analysis

Drafting a comprehensive and precise state-of-the-art review involves gathering, selecting, compiling, and analyzing a vast corpus of scientific articles. For this literature review, the exploration of academic databases was essential. We chose to use the Crossref database due to its user-friendly interface, accessibility, and the selection criteria it offers. Although paid databases might provide greater comprehensiveness, our goal was to gather a substantial yet relevant sample that was easily accessible within our research domain.

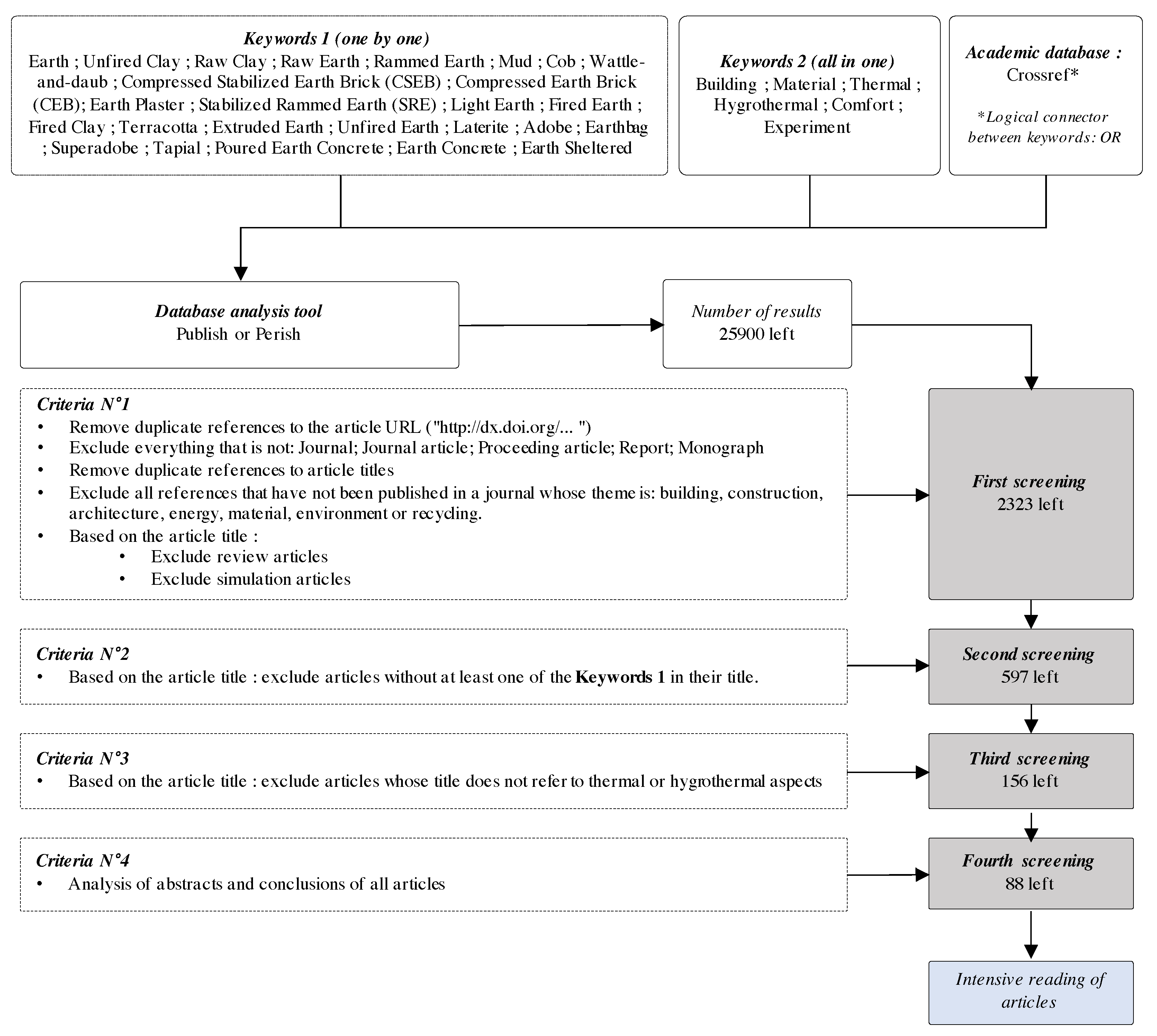

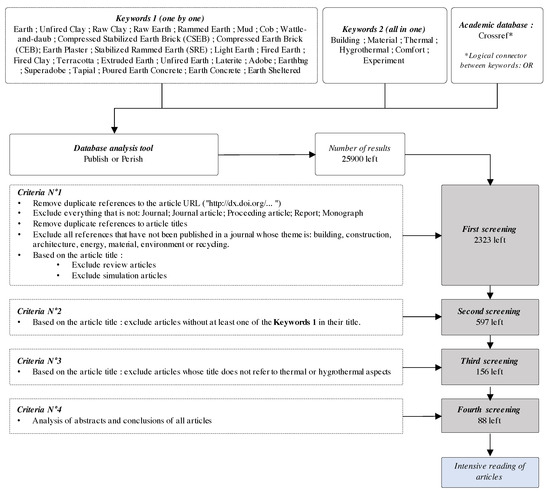

To filter the most-cited studies, we utilized the software “Publish or Perish” [5]. The article selection was conducted exhaustively. Keywords were deliberately chosen to encompass various studies without limiting them to a specific field. “Publish or Perish” enabled us to extract citations via Crossref Metadata Search and subsequently calculate citation metrics, presented in the results. Each search had a limit of 1000 references, with terms in the “Keywords” fields treated as a combination of “Keywords 1” and “Keywords 2” using the logical connector “OR”, as described in Figure 1.

Figure 1.

Methodology applied.

As a result, we collected no fewer than 25,900 references, inevitably including a significant proportion of duplicates. Notably, “Keywords 1” were compiled after an extensive search into terminology specific to earthen construction.

This substantial database eliminated duplicates based on a distinct element from each reference, the URL-DOI of the article. We also excluded references other than articles from scientific journals, conference papers, research reports, or monographs. To maintain relevance in earthen construction, we excluded references unrelated to the building sector, architecture, energy, materials, recycling, and the environment. State-of-the-art articles summarizing information from other scientific articles were also excluded to avoid redundancies. Finally, simulation articles were excluded to focus solely on experimental data. This initial screening resulted in a database reduced to 2323 references.

A more in-depth analysis occurred during a second screening, focusing on article titles. This process eliminated articles that did not contain at least one of the keywords from the “Keywords 1” list. We assume that articles not explicitly mentioning a method of using earth in their title do not address the sought-after subject. This filtering identified a database containing multiphysical experimental analyses on earth material usage methods.

Lastly, a third filtering was performed to refine the selection based on specific criteria related to our study, again based on reference titles, excluding articles not addressing thermal or hygrothermal aspects. This identified 156 references meeting these criteria.

These references were then carefully examined based on their abstracts and conclusions. This helped exclude articles that, despite meeting previous criteria, did not align with the desired content. For instance, we excluded articles that described no physical experiments but used numerical simulations to infer optimal hygrothermals. This final filtering retained 88 references ideally suited for our state-of-the-art analysis. These 88 references were thoroughly analyzed to extract relevant information and analyses for the work presented in our paper.

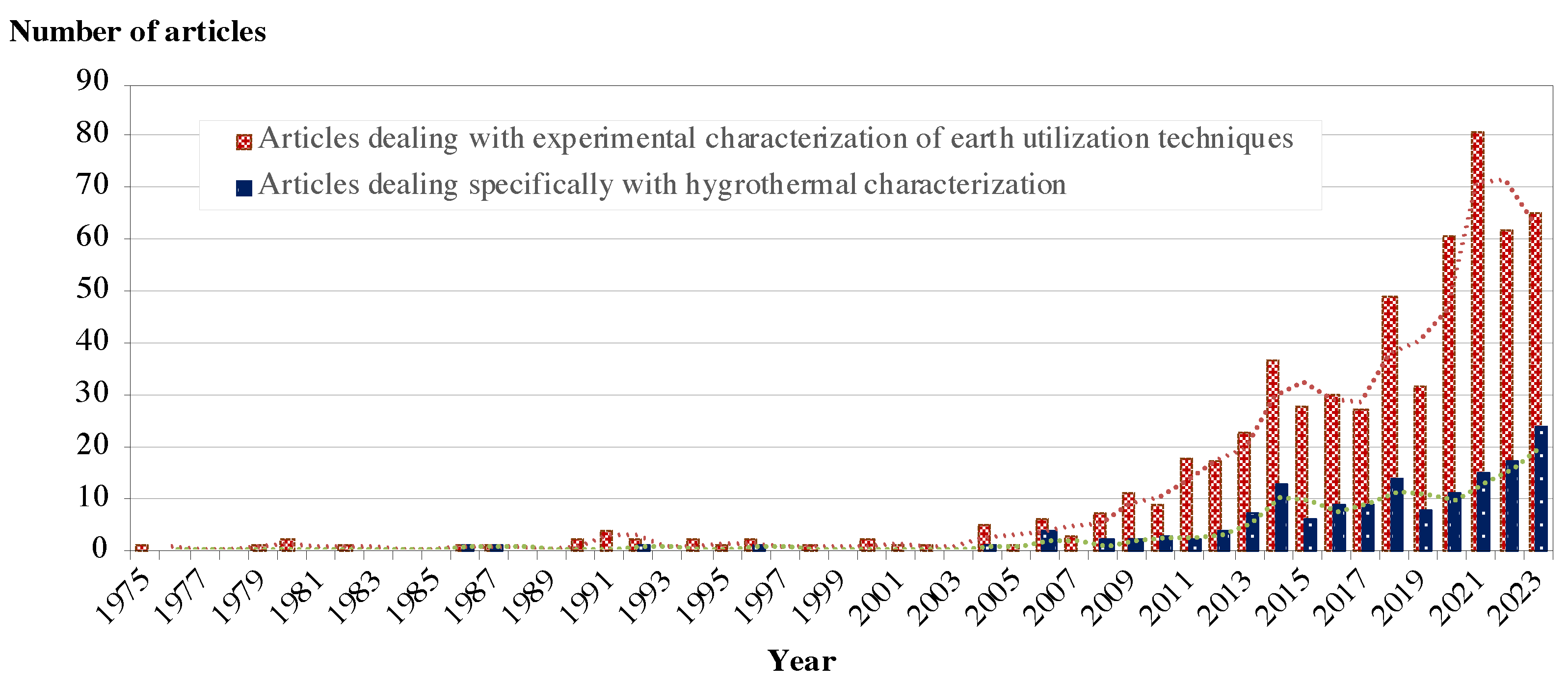

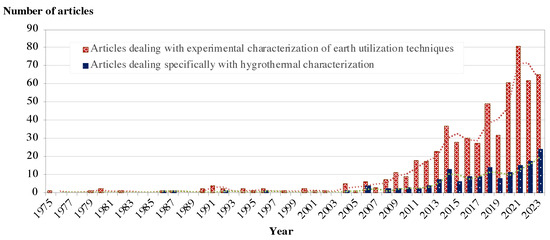

Furthermore, a comparative analysis of trends was conducted using the results from PoP (Publish or Perish). Figure 2 illustrates the annual publication count for studies generally addressing the multiphysical characterization of earth utilization techniques (derived from the database of the second screening, in red) and for articles explicitly focusing on thermal and hygrothermal aspects (derived from the third screening, in blue). We observed that scientific articles aiming to characterize earth utilization techniques experimentally date back to 1975 and primarily centered on mechanical studies. It was not until eleven years later, in 1986, that the first study explicitly delving into the hygrothermal characterization of an adobe structure was conducted and published in Solar Energy by researchers in the United States. While this article lacked precision regarding intrinsic hygrothermal properties, as targeted in our work, it already addressed concepts of thermal comfort induced by the “earth” material. Overall, the surge in scientific studies examining the multiphysical properties of earthen construction began in 2004, coinciding with the launch year of the second version of the LEED (Leadership in Energy and Environmental Design) rating system, marking a significant milestone in promoting sustainable buildings by establishing standards for energy efficiency, sustainability, and environmental impact in constructions. Since then, the number of studies has exponentially increased until showing signs of fatigue between 2015 and 2017, notably aligned with the COP21 in Paris, emphasizing reducing carbon emissions in the construction sector. Considering the lag between content creation and its validation and dissemination within the scientific community, synchronizing historical events with scientific productions may not be fully representative. Interestingly, multiphysical studies have again shown signs of a slowdown since 2021, despite a significant increase in exploring purely thermal or hygrothermal properties of earth techniques since 2019. We note that these studies align with the modulation of indoor environments and the community’s aspiration to identify frugal, durable, and economically viable materials.

Figure 2.

Trend in the number of publications on the characterization of earth use methods since 1975.

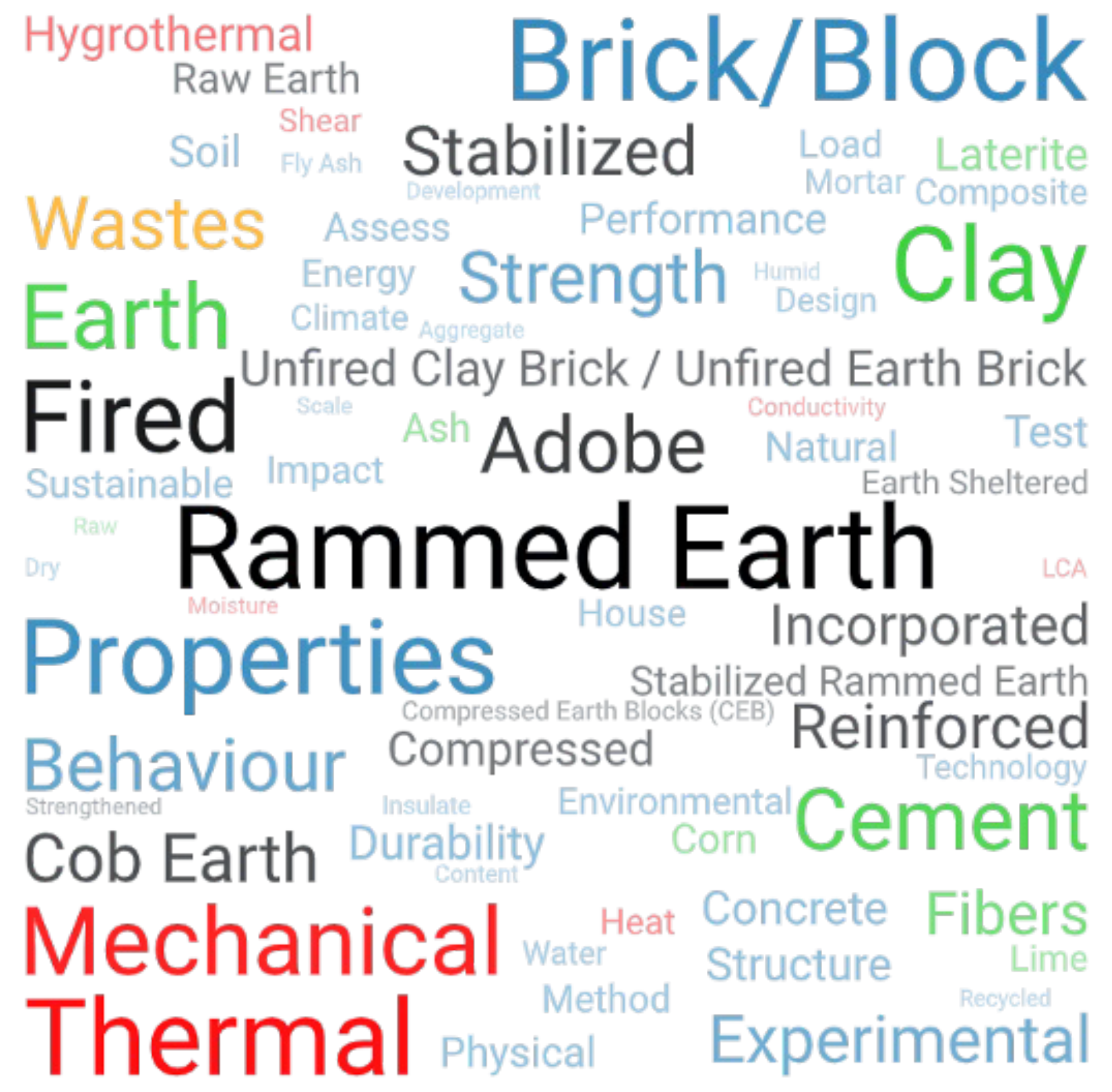

Finally, we constructed a word cloud from the database of reference titles resulting from the second screening (see Figure 3). A word cloud is a visual representation of the most frequently used keywords, word groups, or phrases in a text, in our case, within article titles. Words used most frequently are displayed in a larger font, while less commonly appearing words are depicted in a smaller font.

Figure 3.

Word cloud on the database of article titles in the second screening.

This word cloud allowed us to analyze and comprehend the content of the second screening’s database (597 references, see Figure 1). Words in red tended to represent areas of analysis or types of experiments. In green, elements that seem more oriented towards materials stand out. Lastly, in black were the methods of earth utilization.

The analysis revealed that rammed earth was the most cited and studied method, followed by fired clay and adobe. Surprisingly, raw earth, historically applied, was not among the most cited/studied methods.

Regarding materials, logically, “earth” is the most cited material, followed by “clay”, an essential component of earth. The third material to appear prominently is cement, frequently used as a stabilizer in reinforcing specific earth techniques.

In red, we notice that studies citing the term “thermal” are nearly as numerous as those indicating “mechanical”. However, it is worth noting that some references include both terms in their titles without genuinely addressing the intrinsic characterization of techniques using earth. Additionally, the recurring term “wastes” demonstrates the community’s interest in studies aiming to combine earth with materials qualified as waste or excavated earth, currently considered waste in Europe.

2.2. Methods for Recycling Excavated Soil

We present herein a categorization of various approaches and formulations applicable to the revalorization of excavated soils. These elements are divided into three sections:

- Different typologies of earthen construction suitable for revalorizing excavated soils.

- Various technical processes associated with these typologies of earthen construction.

- Different additives associated with soil to enhance specific properties.

2.2.1. Earth-Based Materials in the Literature

Earth is a material with many uses. The scientific literature confirms its ability to function independently under certain conditions and its capacity to be combined with additives or specific techniques to impart various properties. We propose a brief description of these approaches to present the existing methods comprehensively. This summary aims to clarify the different techniques and provide precise explanations. Our in-depth research revealed a tendency among various authors to mix specific approaches, except for the relatively popular soil enhancement techniques.

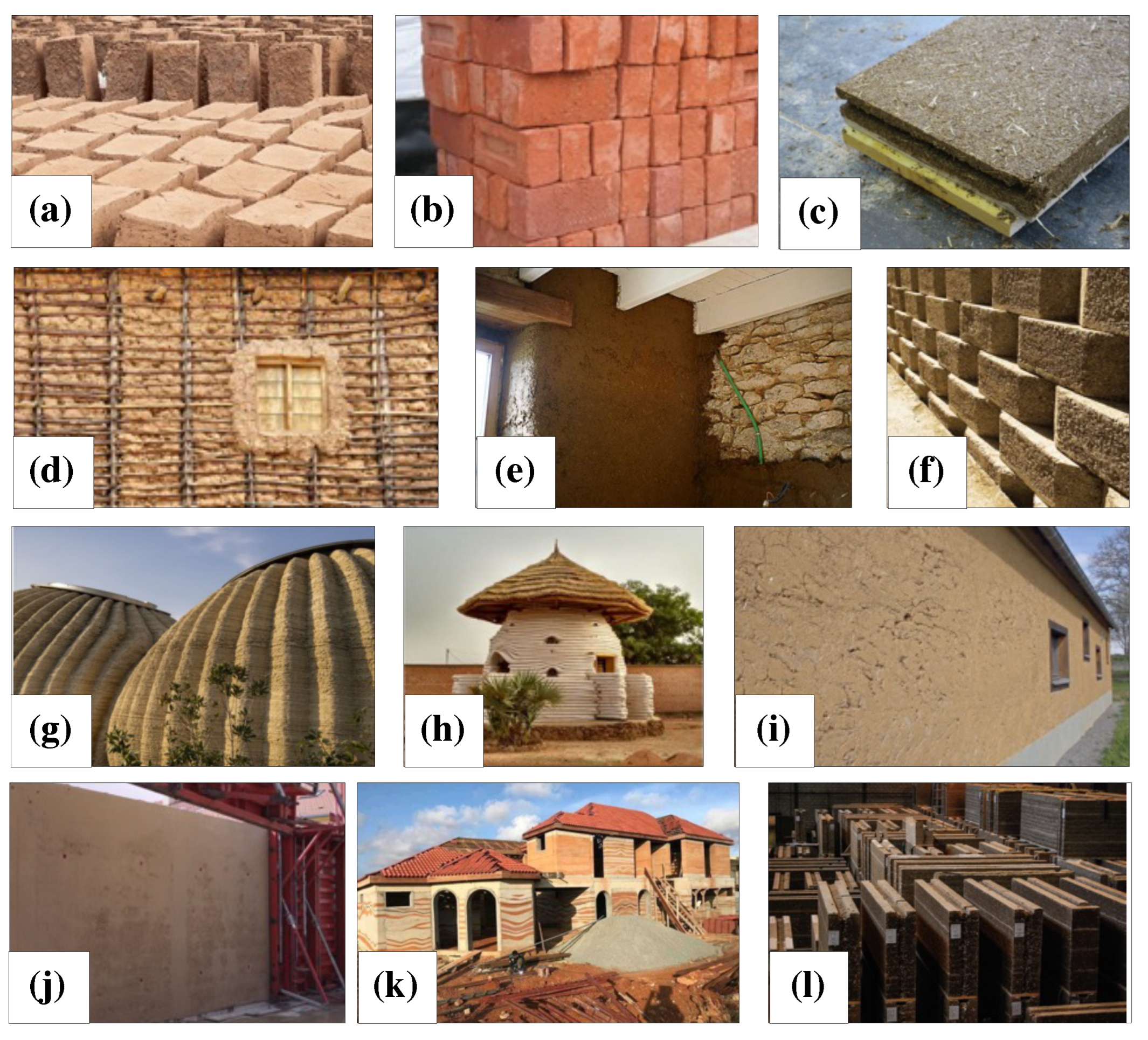

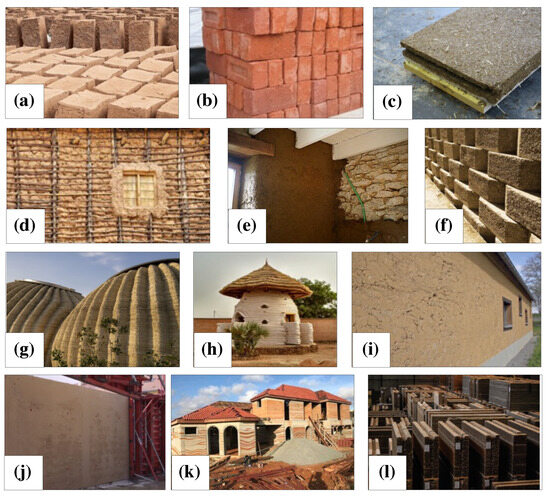

Adobe, invented in Mesopotamia in the 4th millennium BC, is a testament to enduring architectural techniques (see Figure 4a). It has created some of the world’s most enduring human habitats, such as those found in North America, which have stood for 900 years and remain in active use. This process involves shaping mud bricks using wooden or metal molds placed directly on the ground, followed by natural drying in the sun and air. Vegetal fibers, generally straw, are often added to the soil to limit shrinkage and cracking observed during drying. The adobe technique allows the use of a wide range of soils, particularly those with a higher clay content.

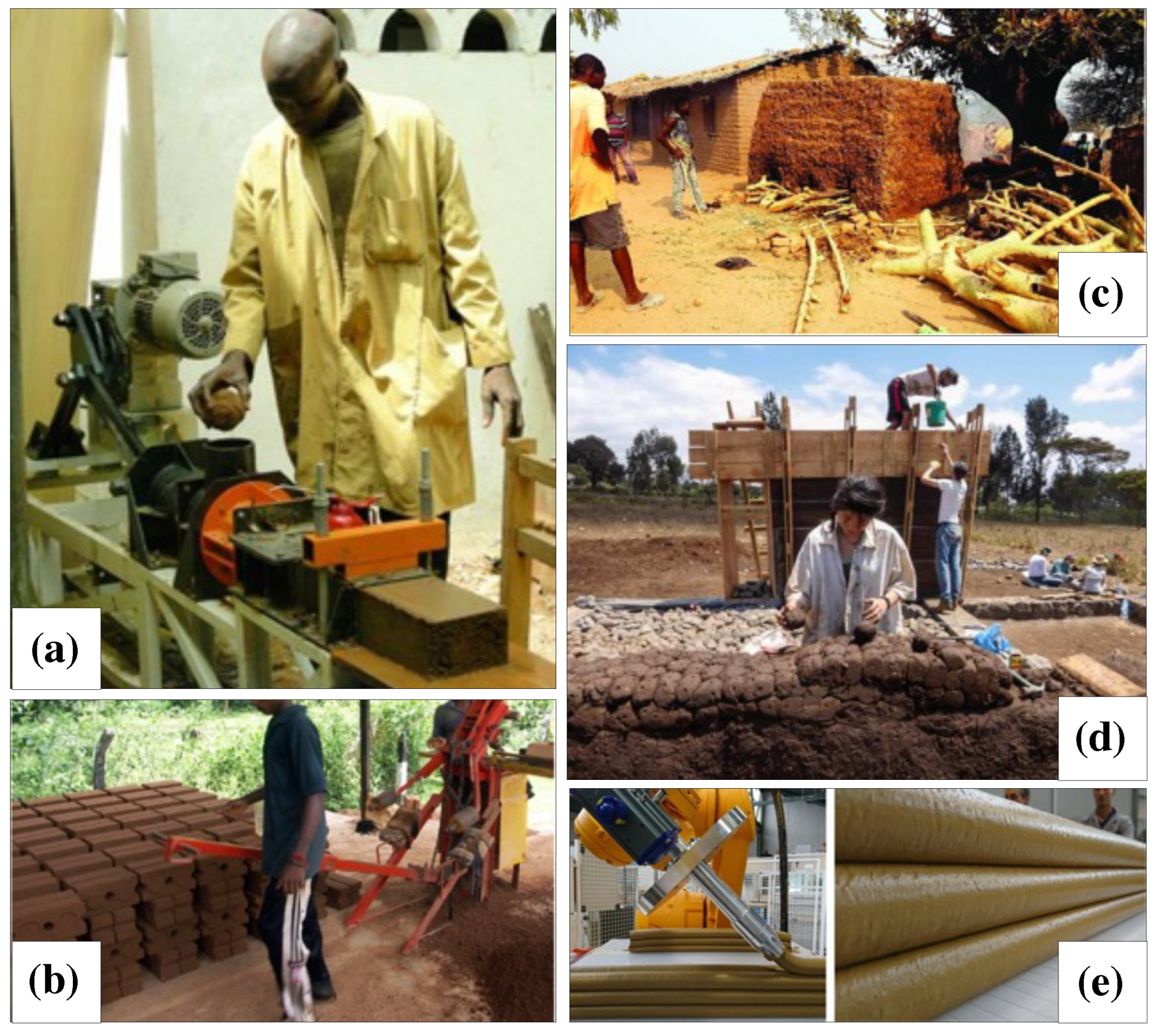

Figure 4.

Methods for recycling excavated soil. (a) Adobe, picture by ©LaMaisonSaintGobain. (b) Fired earth brick, Terracotta, picture by ©Fruggo (CC BY-SA 1.0). (c) Light Earth Method (LEM), picture by ©Amàco. (d) Wattle and daub, picture by ©Rod Waddington (CC BY-SA 2.0). (e) Earth Plasters, picture by ©Esprit Cabane. (f) Pressed earth, picture by ©EESC Glossaries. (g) Printed earth, picture by ©Lago Corazza. (h) Superadobe (earthbag) [6]. (i) Cob (bauge), picture by ©Amàco. (j) Poured earth, picture by ©Amàco. (k) Rammed earth, picture by ©Messibat International. (l) Prefabrication, picture by Ricola Herzog & De Meuron ©Daniel Lüthi.

Light Earth Method (LEM) finds its roots in the enduring European tradition of incorporating lower-density straw and clay into construction practices, notably for filling voids in half-timbered and wattle and daub structures (see Figure 4b). Operating as an infill technique, LEM does not bear the direct load of the roof but functions as semi-structural insulation. It involves a moist blend of natural fibers or lightweight minerals coated in a clay slip binder, compacted within a structural frame and situated within temporary formwork between structural wall framing elements. This approach yields walls up to 300 mm thick, showcasing remarkable insulation capabilities influenced by tamping density and the ratio of clay to fiber. Beyond insulation, the interest of LEM in low density is its ability to offer good thermal resistance accompanied by efficient inertia. It offers more density increases, fewer mixtures are insulating, and they present better inertia. In summary, low densities allow very good winter and summer comfort. Mean densities give a good winter comfort and an excellent summer comfort.

Wattle and daub, also known as torchis in French, represent a construction method used in crafting walls and buildings. It encompasses the weaving of a lattice made of wooden strips, known as wattle, which is then coated with a sticky mixture typically comprised of wet soil, clay, sand, animal dung, and straw (see Figure 4c).

Earth plasters are blended clay, fine aggregate, and fiber, often enriched with additives like pigments, lime, casein, prickly pear cactus juice (Opuntia), manure, and linseed oil. Primarily utilized as a finishing layer for walls and ceilings on surfaces such as masonry, cob, or straw bale, or even on backing boards like gypsum, this plaster serves the dual purpose of safeguarding structural elements and enhancing hygrothermal comfort while introducing a diverse range of textures and hues (see Figure 4d).

Compressed Earth Blocks, a relatively recent advancement in earth-based construction, emerged in the past century and has garnered widespread global acclaim. Typically sized at 295 × 140 × 95 mm, these bricks are crafted manually or mechanically from a dry mixture, often containing up to 10% cement or other binders to enhance mechanical properties. This process produces dense, consistently shaped bricks through compression, offering the potential for diverse shapes and performed features (see Figure 4e). While on-site manual compression or procurement from manufacturers is viable, transporting earth bricks rich in cement might contradict energy conservation principles. Noteworthy for their durability, solidity, and uniformity, compressed earth blocks enable precise alignment for geometric patterns or a more adaptable arrangement to suit desired aesthetics. In terms of design, these blocks are similar to fired bricks while avoiding the cooking step.

Printed earth refers to a subset of construction 3D printing, which encompasses a range of technologies utilizing 3D printing as a foundational method for creating buildings or construction components (see Figure 4f).

Superadobe, also known as earthbag construction, pioneered by Iranian architect Nader Khalili, presents a unique approach to earth-based building practices. This method employs elongated fabric tubes or bags filled with adobe to create a compression structure (see Figure 4g). The resulting edifices, frequently resembling beehives, leverage corbelled arches, corbelled domes, and vaults to fashion resilient, single-, and double-curved shells. Over the last couple of decades, Superadobe has gained significant traction within the natural building and sustainability movements.

Cob, also known as “bauge” in French, stands as an ancient building method renowned for its capacity to sculpt artistic and visually captivating wall formations (see Figure 4h). The endurance of numerous well-preserved cob cottages on the South Island of New Zealand, dating back to the last century, attests to its enduring strength. Cob is a traditional technique based on clay soil mixed with water and vegetal fibers, generally straw. This mixture is often shaped into balls in a plastic state. To raise a wall, they are accumulated in successive layers of 40 to 60 cm in height, then adjusted and smoothed. While the resulting surface is typically rough, it can be refined through trimming and rendering to achieve a more refined appearance. Cob allows for the construction of sturdy, thick, or gracefully curved walls, often tapering toward the top. However, the technique is notably susceptible to shrinkage [7], requiring meticulous soil selection, continually adding fiber, and a long construction time related to slow drying kinetics [8].

Poured Earth revolves around blending water, earth, and additives to achieve a consistency akin to cake batter, facilitating its pouring into formworks directly onto the wall (see Figure 4i). Once the mix sets, the formworks are removed. Unlike rammed earth, this technique employs a mixture in a liquid state, potentially resulting in greater shrinkage. Precise management of the soil mix becomes crucial to avert unwanted cracks during the drying process.

Rammed earth, an age-old building technique traced back to 7000 BC in Pakistan, continues to find relevance worldwide, notably in segments of the Great Wall of China. The process entails compacting soil within formworks, employing manual or pneumatic rammers (see Figure 4j). The mixture must achieve a wet state that permits the immediate removal of the formwork upon completion of a wall panel.

Fire bricks, or terracotta bricks, with their warm hues and timeless appeal, have been an integral part of architectural heritage for centuries. Crafted from natural clay and fired to perfection, these bricks embody a rich tradition of craftsmanship that seamlessly blends aesthetics with functionality. Creating terracotta bricks begins with carefully selecting clay and molding it into shape before undergoing a meticulous firing process. The firing not only strengthens the bricks but also imparts a distinct earthy color, ranging from warm reds to subtle browns, enhancing the visual allure of any structure they grace. Beyond their aesthetic charm, terracotta bricks boast remarkable durability and weather resistance. Their natural composition and firing process make them resilient to the elements, ensuring that buildings constructed with these bricks withstand the test of time. Additionally, the porous nature of terracotta contributes to effective moisture regulation, preventing damage caused by humidity and providing a comfortable indoor environment.

Prefabrication, encompassing distinct processes for brick creation and assembly, streamlines on-site construction schedules and circumvents issues tied to drying. This method harmonizes rapidity with design adaptability, facilitating gradual assembly and the convenient integration of utilities as construction advances (see Figure 4k). Recognized prefabrication forms include compressed earth blocks and straw bales. Yet, the advantages emerge in “wet” techniques like LEM and hempcrete, where pre-dried panels or blocks drastically reduce construction timelines compared to traditional in situ drying. Challenges arise with transporting and placing large precast panels due to their weight requiring lifting equipment.

2.2.2. Earth-Based Material Production Techniques

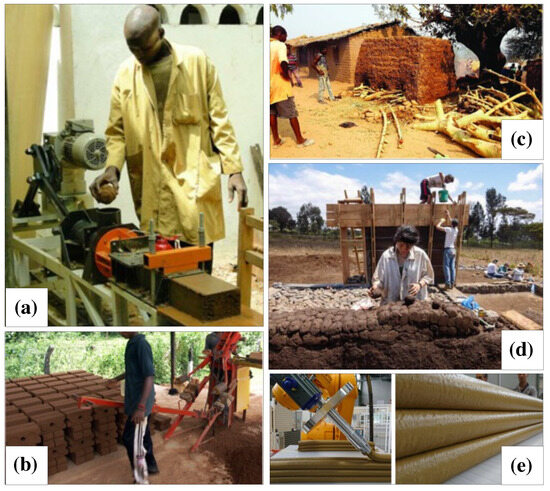

The methodologies employed in fabricating the materials showcased below can be categorized into four distinct groups:

- Non-mechanical or manual techniques involve utilizing the earth as a construction material without applying mechanical means; instead, it involves solely manual methods (see Figure 5d for example). This approach revolves around shaping the material by hand, either with or without molds or formworks, to create bricks or sections of a wall. Earth plaster, cob, and adobe are prime materials crafted using these techniques.

Figure 5. Example of production techniques: (a) Extrusion press prototype developed in Cameroon [11]; (b) Compressing earth with a press [12]; (c) Bricks being fired in Chembe [13]; (d) Manual technique used to build cob walls [14]; (e) Earth printing performed [15].

Figure 5. Example of production techniques: (a) Extrusion press prototype developed in Cameroon [11]; (b) Compressing earth with a press [12]; (c) Bricks being fired in Chembe [13]; (d) Manual technique used to build cob walls [14]; (e) Earth printing performed [15]. - Compaction or compression refers to compacting earth within a mold or formwork, utilizing either mechanical machinery or manual effort to create bricks or entire walls. Compression forces span from 0.39 MPa [9] to 62 MPa (or 100 kN) [10]. Examples of earth-based materials produced through this method include rammed earth, Compressed Earth Blocks (CEB), and Compressed Stabilized Earth Blocks (CSEB), see Figure 5b).

- Extrusion or pulverization encompasses the production of materials through extrusion processes, notably employed in 3D-printing methodologies (see Figure 5a,e).

- The fired method involves the production of bricks through the process of firing (see Figure 5c). Fired bricks serve as an exemplar of this material.

2.2.3. Earth-Based Material Additives

Enhancing the performance of earth materials frequently involves the incorporation of bio- or mineral-sourced materials, as well as the addition of chemicals or polymers by the producer. We distinguish these different additives into three categories:

- Bioadditives encompass various types sourced from plants (leaves, fibers, and cores) or animals (manure, wool, and blood), each offering distinct properties to the material.

- Mineral additives primarily originate from the cement industry and include natural geosourced additions like lime and sand, contributing unique characteristics to the mix.

- Other additives may comprise polymers, phase change materials, waste from mining industries, and ash from power plants (from incineration processes), diversifying the material’s composition and functionalities.

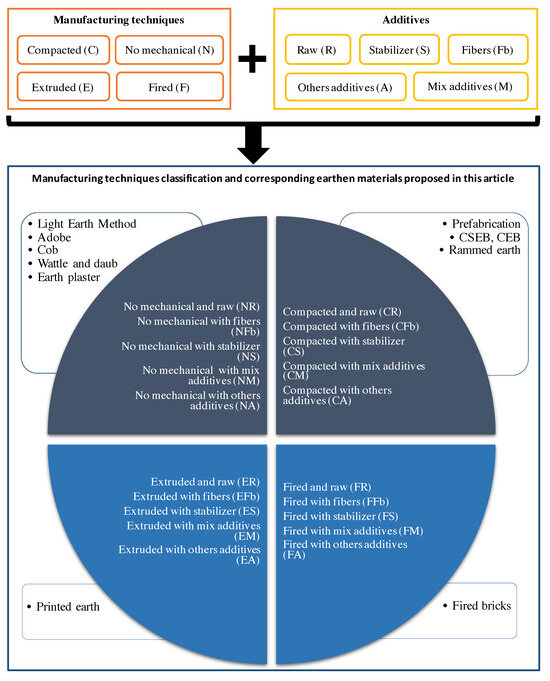

2.2.4. Soil-Excavated Valorization Techniques Nomenclature

In this article, for the sake of clarity and ease of comprehension regarding the subsequent results, we introduce the following terminology:

- N: Represents materials produced without mechanical intervention.

- C: Denotes materials formed through compaction or compression methods.

- E: Signifies materials produced through extrusion techniques.

- F: Represents materials created via firing processes.

- R: Refers to materials without any additives.

- Fb: Indicates materials with fiber additions.

- S: Stands for stabilized materials with mineral-sourced additives.

- M: Represents materials with a mixed composition (mineral-sourced, bio-, and other additives).

- A: Denotes materials with other specific additions.

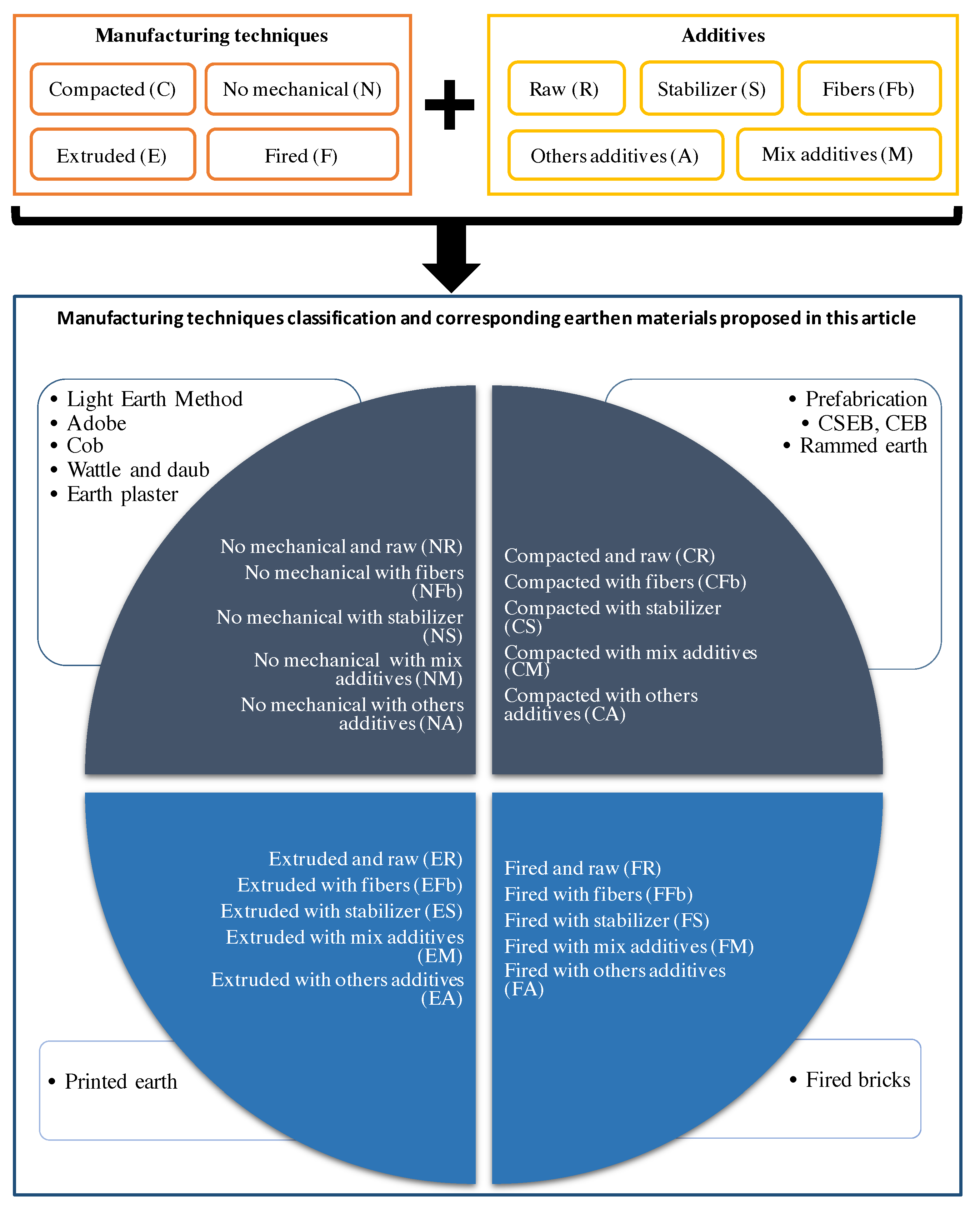

Figure 6 aims to establish a classification of techniques for valorizing excavated soil.

Figure 6.

Excavated soil valorization techniques classification.

2.3. Earth-Based Material Hygrothermal Properties

Our article focuses on the hygrothermal properties relevant to the material “earth”. Through our survey, we’ve identified the most commonly measured hygrothermal properties by various authors. These properties delineate the mass and heat transfers within different formulations. As such, we catalog:

- Dry Density: This parameter represents the mass per unit volume of soil when utterly devoid of moisture, providing insight into the soil’s compactness and structural composition.

- Thermal Conductivity (Dry): Thermal conductivity refers to the material’s ability to conduct heat and is essential in understanding how efficiently heat is transferred through the material when devoid of moisture.

- Dry Specific Heat: Specific heat is the amount of heat required to raise the temperature of a unit mass of material by one degree Celsius when dry, indicating its heat storage capacity.

- Thermal Diffusivity: This property quantifies how quickly a material responds to changes in temperature, indicating its ability to conduct heat relative to its capacity to store thermal energy.

- Thermal Effusivity: It signifies a material’s ability to exchange thermal energy with its surroundings, influenced by thermal conductivity and specific heat.

- Water Vapor Permeability: This parameter measures the rate of water vapor transmission through a unit area of material of a specified thickness, influenced by temperature, humidity, and vapor pressure differences.

- Water Vapor Resistance Factor: It evaluates a material’s resistance to water vapor passage, comparing it to the resistance offered by air.

- Moisture Buffer Value: This value directly measures a material’s capacity to absorb and release moisture in response to changing environmental conditions.

- Moisture Effusivity: It characterizes the rate of moisture absorption by a material when subjected to a sudden increase in surface humidity.

- Water Absorption Coefficient: This coefficient illustrates the rate at which porous building materials absorb liquid water through capillary action.

- Moisture Content: The quantity of water in a material, reflecting its moisture state under specific environmental conditions.

- Sorption Isotherms (Moisture Content per RH): Graphical representations indicating the relationship between a substance’s moisture content and the relative humidity of the surrounding air at a given temperature, essential for understanding moisture equilibrium in materials.

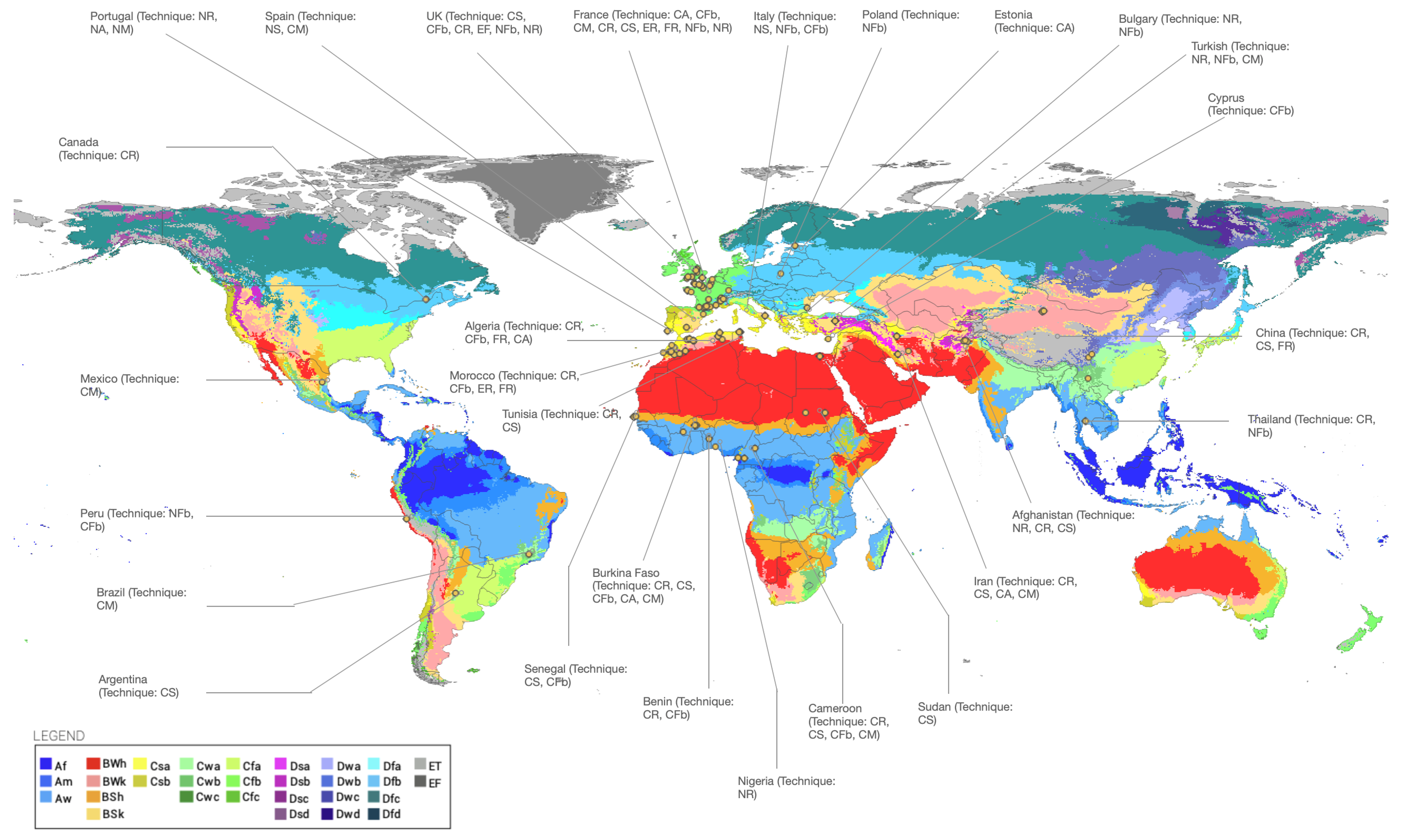

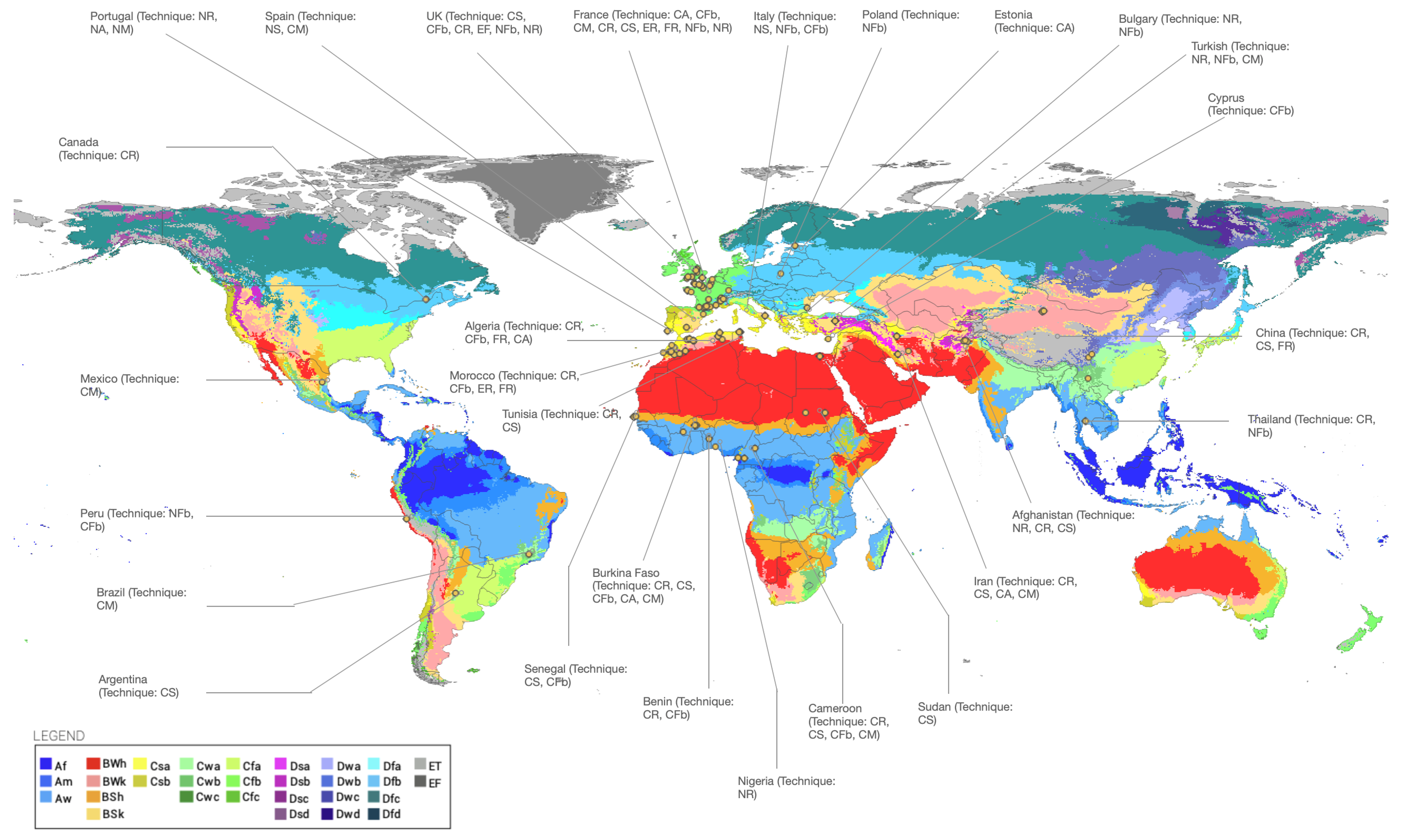

2.4. Climate Classification (Köppen Climate Classification)

The diversity of earth resources and construction methods across the globe is remarkable. Understanding how these materials interact with local climates is significant in tailoring each region’s most fitting earth construction methods. This comprehension also unveils correlations between climate, the essential traits of earth-based formulations, and soil characteristics.

The Köppen climate classification, originating from the work of German–Russian climatologist Wladimir Köppen in 1884 and further refined by Köppen himself in 1918 and 1936, stands as a preeminent system for classifying climates. Subsequent adaptations by German climatologist Rudolf Geiger in 1954 and 1961 resulted in occasional references to the Köppen-–Geiger climate classification [16,17].

This classification system categorizes the world’s climates into five major groups. The following descriptions provide an overview, and a classification table (see Table 1) is provided for reference. Additionally, the map presented in Figure 7) illustrates the distribution of these climate groups described:

Table 1.

Köppen climate classification.

- Group A: Tropical/Megathermal Climates: These climates are characterized by consistently high temperatures, usually above 18 °C (64.4 °F) throughout the year, particularly at sea level and low elevations. They are accompanied by significant annual precipitation.

- Group B: Arid (Desert and Semi-arid) Climates: Arid climates are identified by annual precipitation levels significantly lower than the potential evapotranspiration.

- Group C: Temperate/Mesothermal Climates: Temperate climates in the Köppen system maintain temperatures above 0 °C (32 °F) (or −3 °C (26.6 °F) in previous references) during their coldest month but remain below 18 °C (64.4 °F). The −3 °C (26.6 °F) average temperature aligns with the equatorward limit of frozen ground and sustained snow cover for a month or more.

- Group D: Continental/Microthermal Climates: These climates exhibit average temperatures in the warmest month surpassing 10 °C (50 °F) and average temperatures in the coldest month dropping below 0 °C (or −3 °C (27 °F) in previous mentions). Found predominantly in continental interiors and upper east coasts, particularly above 40° N, these climates are rarer in the Southern Hemisphere’s mid-latitudes due to smaller land masses and limited land between 40 and 60° S. They occur primarily in select highland locations.

- Group E: Polar Climates: Within the Köppen system, Polar climates maintain the warmest monthly temperatures below 10 °C (50 °F). They can be categorized into two main types: tundra and icecap climates.

3. Results

3.1. Comprehensive Analysis of Studies Investigating the Hygrothermal Properties of Earth-Based Materials

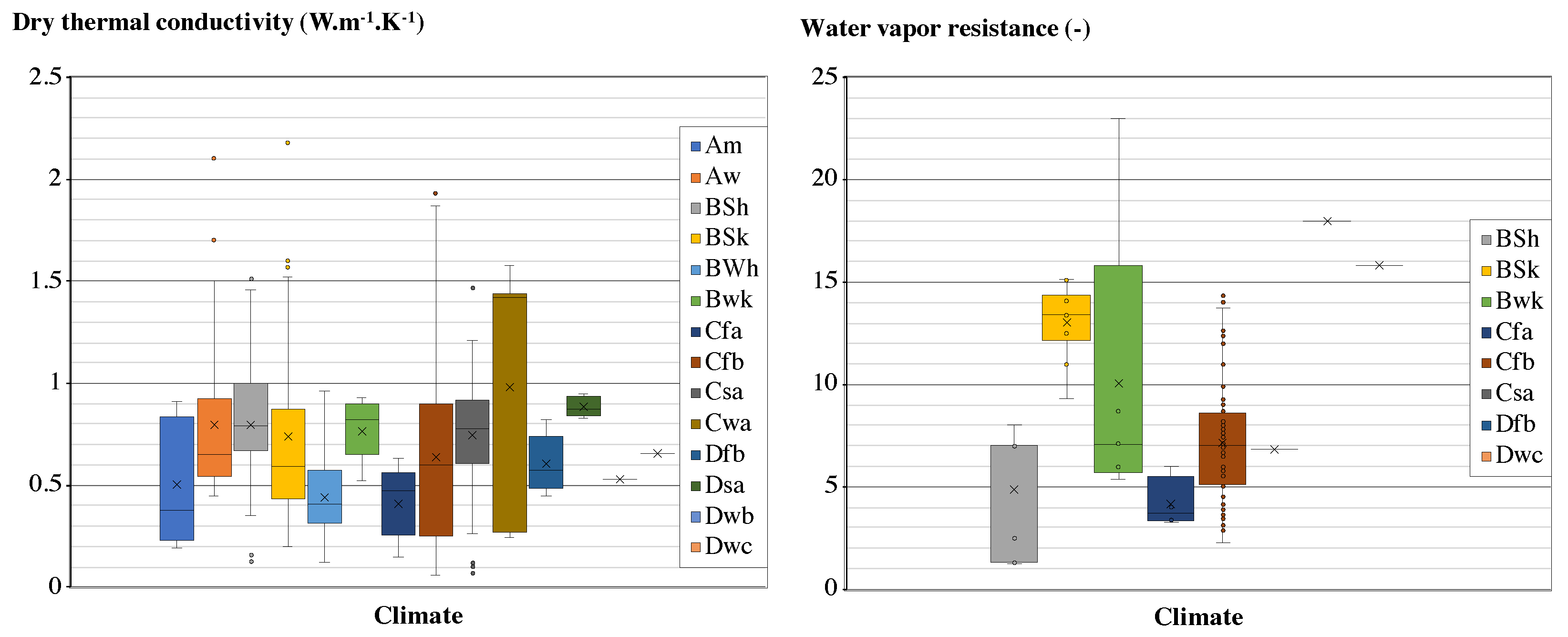

Our analysis will primarily concentrate on the dry thermal conductivity and the water vapor resistance factor, as these attributes represent the most extensively researched hygrothermal properties in the literature. These parameters serve to delineate the insulating capacity of earth-based materials. A comprehensive listing of all reviewed articles can be found in Table A1, Table A2, Table A3, Table A4 and Table A5, categorized by the nature of additives used and the manufacturing techniques applied.

From the pool of 477 samples under consideration, the predominant techniques explored revolve around compacted or compressed earth materials, categorized as CS (compressed/compacted stabilized), CF (compressed/compacted with fiber), CR (compressed/compacted raw), and CM (compressed/compacted mixed).

Cement, documented in numerous studies [18,19,20,21,22,23,24,25,26,27,28,29,30,31,32], is a prevalent stabilizer commonly employed, typically incorporated at rates ranging between 5% and 15% depending on the country of application. Additionally, alternative stabilizers such as lime [19,24,26,33,34,35,36], pozzolan [32], sodium hydroxide (NaOH) [26], fiberglass [32], and calcium carbide residue [32] have been explored for stabilizing earth-based materials in various studies.

The prevalent bioadditives commonly employed include hemp [37,38,39,40,41,42,43,44], wheat [10,41,45,46,47,48,49], and barley [10,35,50,51,52]. Additionally, alternative bioadditives encountered in various studies encompass reed [37,41,53,54,55], olive [56,57,58], rice [53,59], straw [37,60,61,62,63], flax [31,47,54,64], bagasse [59], corn [51], alfa [65,66], hibiscus cannabinus [67], kenaf [68], lavender [50], palm [69], pennisetum setaceum [70], pumice [43], sawdust [65], seaweed [31], thatch [71], typha australis [72,73], fonio [74], grass [53], cocos nucifera [28], canarium schweinfurthii [28], and oat [75]. Fiber sizes vary from 0.63 cm to 6 cm, and the incorporation rates range widely from 0.4% to 67% across these materials.

Additional categories of additives commonly encountered encompass geopolymers. In one study [27], tannin and a geopolymer binder, synthesized from a blend of local clay (metakaolin) calcined at 700 °C and an alkaline solution of NaOH (12 M) in a mass ratio (alkaline solution/solid material) of 0.8, were utilized. Furthermore, phase change materials (PCMs) such as Micronal DS 5038X [64,75] or Nextek 24D [55], as well as commercially available micro-encapsulated PCMs [30,32], animal wool (e.g., sheep wool [76]), biomass ashes resulting from domestic wood heating or tree pruning [77], rice husk ash [23], mining waste [78], gypsum [10], alginate (e.g., CIMALGIN HS4 [79]), agave [80], dung (such as cow dung [46]), glycerol carbonate [81], paper [82], guargum (HydroxyPropyl Guar [32]), among others, have been investigated. These bio-sourced or mineral-sourced additives are often combined. Common combinations include cement or lime mixed with fibers [10,22,31,32,78], phase-change materials with fibers [55,64], or alginate with organic fibers [79].

Moreover, these studies are prevalent across various climates (refer to Figure 7). The highest concentration of studies exists in temperate or dry climates, whereas comparatively fewer studies are conducted in tropical and continental climates. Among the countries contributing to these studies, France leads in Europe, followed closely by Morocco in Africa.

All the data discussed in this article are detailed in Table A6, Table A7, and Table A9 in Appendix A and Table 2.

Figure 7.

Localisation of study and earth-based material technique production around the world: Afghanistan [29], Algeria [48,77,83], Argentina [21], Benin [68], Brazil [78], Bulgaria [49], Burkina Faso [23,27,74,84], Cameroon [22,28,71], Canada [85], China [34,86,87,88,89,90], Cyprus [61], Egypt [10], Estonia [82], France [26,27,31,37,38,39,40,50,52,54,55,64,67,76,91,92,93,94,95] [31,41,42,44,47,63,81], Iran [30,32,96], Italy [35,56,58], Mexico [80], Morocco [45,57,65,66,69,70,97,98,99,100], Nigeria [101], Peru [53], Poland [62], Portugal [75], Senegal [18,72,73], Spain [6,79,102,103], Sudan [19], Thailand [59], Tunisia [9,24], Turkey [46], and the UK [20,25,26,33,37,43,51].

Figure 7.

Localisation of study and earth-based material technique production around the world: Afghanistan [29], Algeria [48,77,83], Argentina [21], Benin [68], Brazil [78], Bulgaria [49], Burkina Faso [23,27,74,84], Cameroon [22,28,71], Canada [85], China [34,86,87,88,89,90], Cyprus [61], Egypt [10], Estonia [82], France [26,27,31,37,38,39,40,50,52,54,55,64,67,76,91,92,93,94,95] [31,41,42,44,47,63,81], Iran [30,32,96], Italy [35,56,58], Mexico [80], Morocco [45,57,65,66,69,70,97,98,99,100], Nigeria [101], Peru [53], Poland [62], Portugal [75], Senegal [18,72,73], Spain [6,79,102,103], Sudan [19], Thailand [59], Tunisia [9,24], Turkey [46], and the UK [20,25,26,33,37,43,51].

Table 2.

Geographical distribution of presented techniques in correspondence with climate.

3.2. Influence of Incorporation and Production Techniques on the Hygrothermal Properties of Earth-Based Materials

Initially, statistical data analysis unveils insights into the influence of techniques and additives within global practices. Subsequent investigations will investigate the correlation between production parameters and hygrothermal properties. Finally, the relationship between utilized techniques and the corresponding climatic zones of application will be explored.

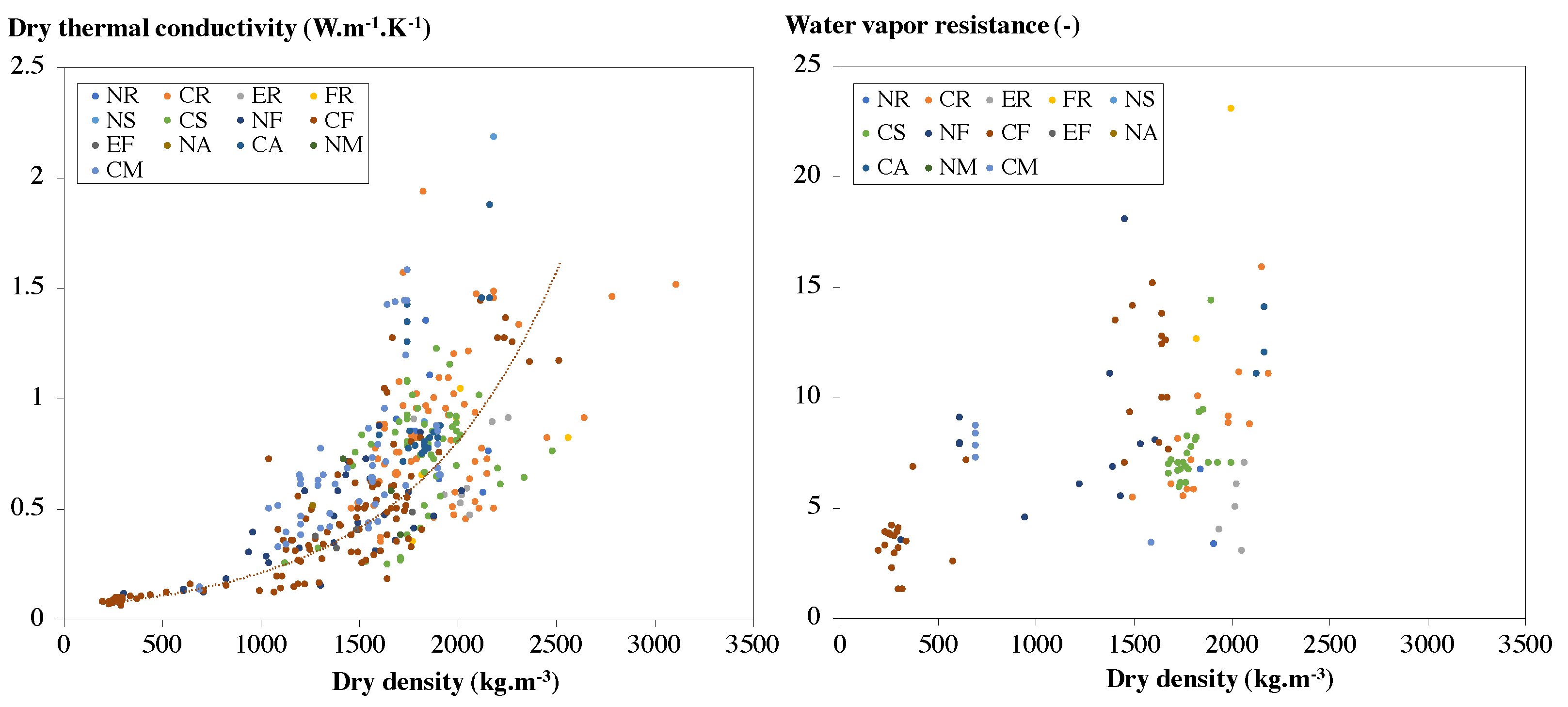

3.2.1. Global Influence

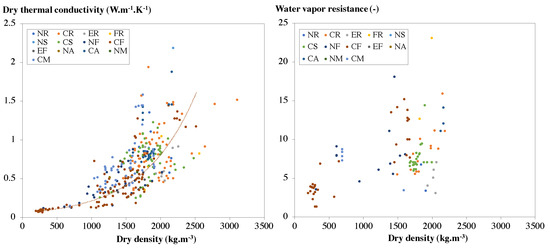

Overall, a global trend indicates that dry thermal conductivity and water vapor resistance factor rise in tandem with dry density. Notably, there appears to be both an exponential and linear correlation between dry thermal conductivity and dry density (refer to Figure 8). Among the techniques studied, none of the mechanical or compressed with fibers (NFb and CFb) exhibited the highest coefficient of determination: and (where y = dry thermal conductivity, and x = dry density). Conversely, while there is an increasing tendency, the water vapor resistance factor demonstrates no significant correlation.

Figure 8.

Relation between dry thermal conductivity and density according to earth-based materials.

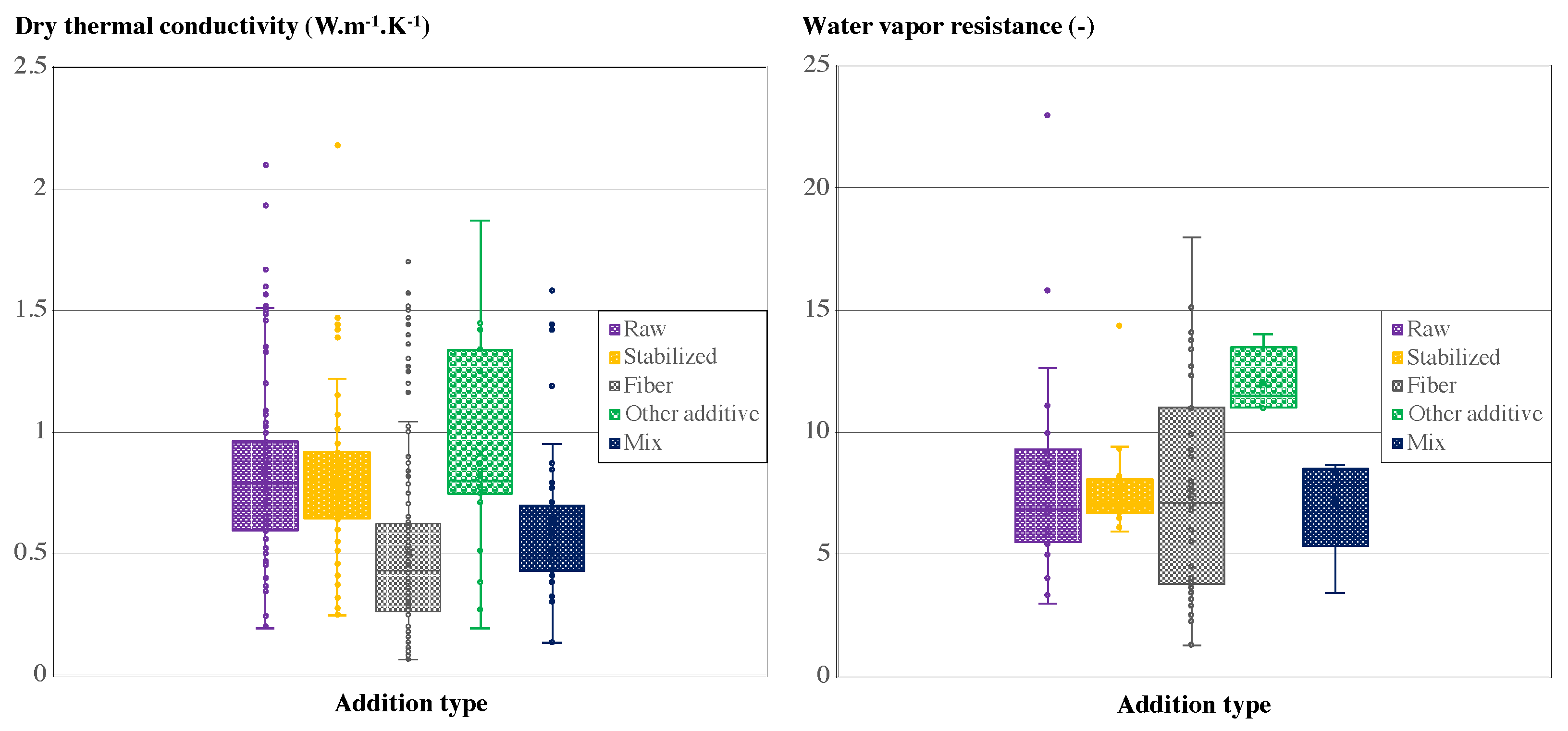

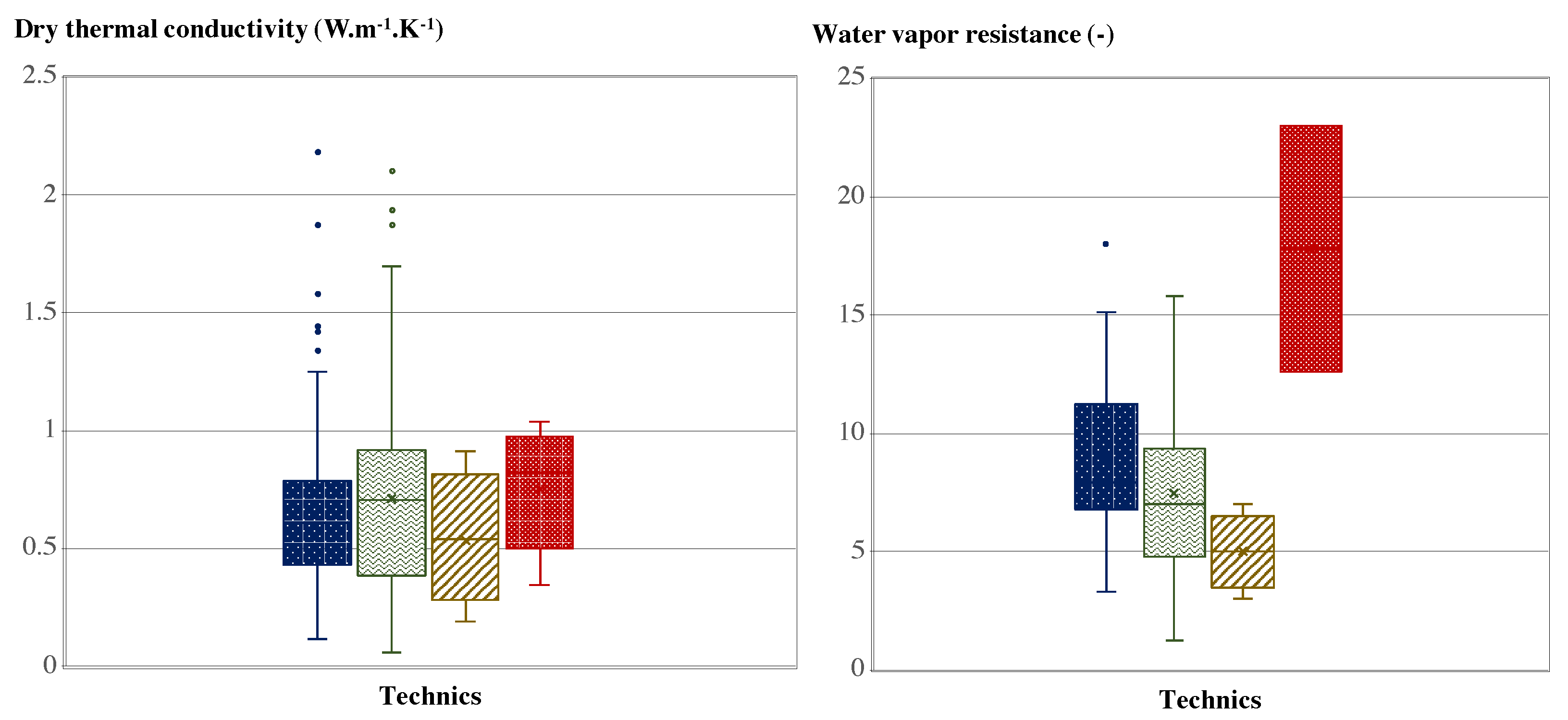

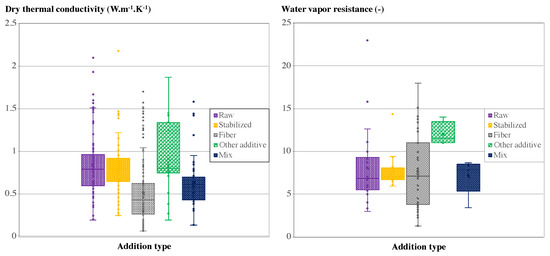

Additive effects on hygrothermal properties are diverse. While fiber incorporation tends to decrease dry thermal conductivity, adding substances like lignin sulfonate, tannin, or sheep wool demonstrates an opposite trend, increasing the water vapor resistance factor and dry thermal conductivity. Moreover, stabilizing agents, such as cement or other additives, significantly reduce the heterogeneity observed in hygrothermal properties (refer to Figure 9). These findings underscore the nuanced impact of different additives on the performance characteristics of earth-based materials.

Figure 9.

Effects of additives on hygrothermal properties.

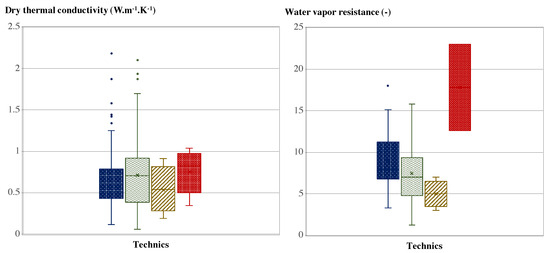

Production techniques subtly influence dry thermal conductivity, although properties vary notably among compressed and mechanically manufactured techniques. Compression and extrusion techniques tend to decrease the water vapor resistance factor, whereas the cooking technique demonstrates an increase in this parameter (refer to Figure 10). This disparity highlights the nuanced impact of different production methodologies on hygrothermal properties.

Figure 10.

Effects of production techniques on hygrothermal properties.

3.2.2. Influence of Fiber Additives on Hygrothermal Properties

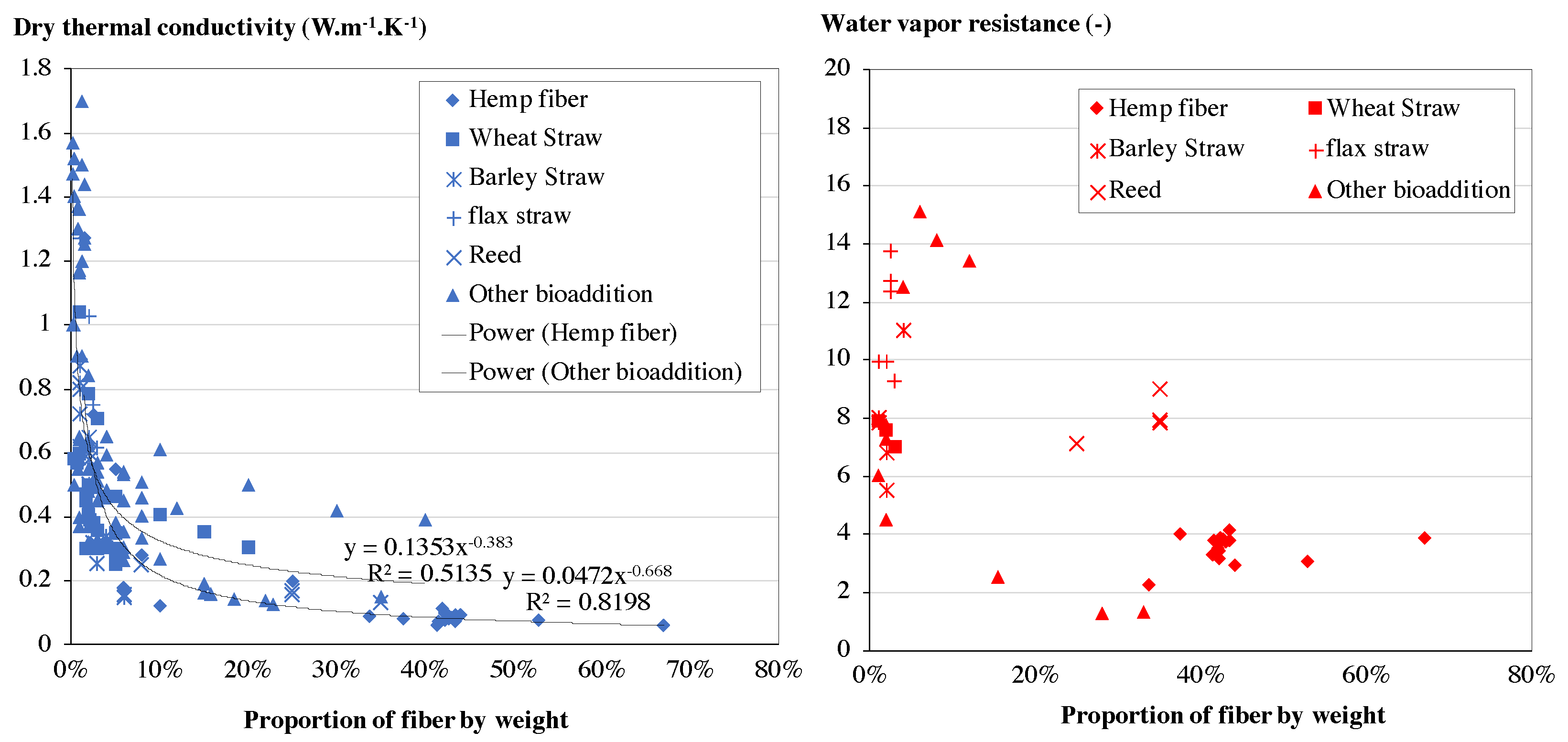

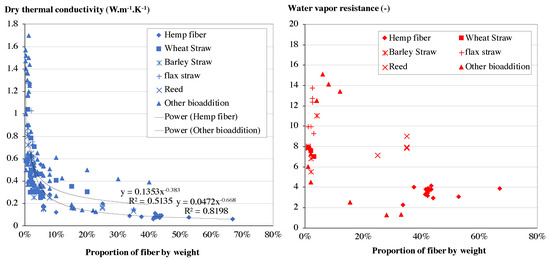

The impact of fiber additives on hygrothermal properties is noteworthy. Incorporating fibers reduces dry thermal conductivity and the water vapor resistance factor. There appears to be a correlation (power function) between the percentage of fiber incorporation and dry thermal conductivity (refer to Figure 11). Table 3 presents equations indicating the highest correlations observed. Notably, olive fiber demonstrates comparatively inferior thermal properties with a minimum dry thermal conductivity of 0.4, whereas hemp and other fibers reach values lower than 0.3. Optimal thermal performance seems to require a minimum fiber incorporation of 10%.

Figure 11.

Correlation between fiber incorporation rate and hygrothermal properties of earth-based materials.

Table 3.

Correlation between fiber incorporation rate and dry thermal conductivity ().

In Table 3, various correlation rates for fiber incorporation are presented.

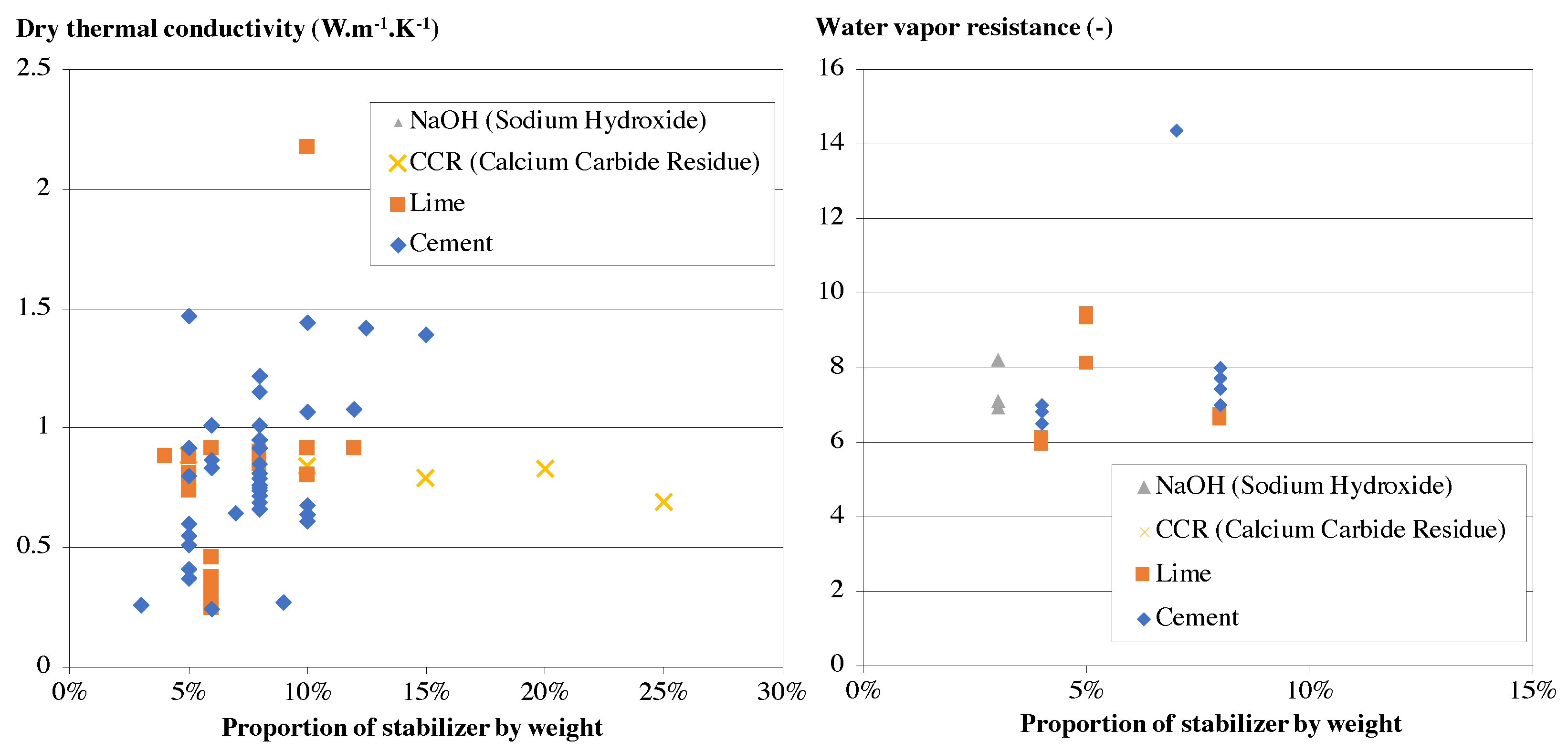

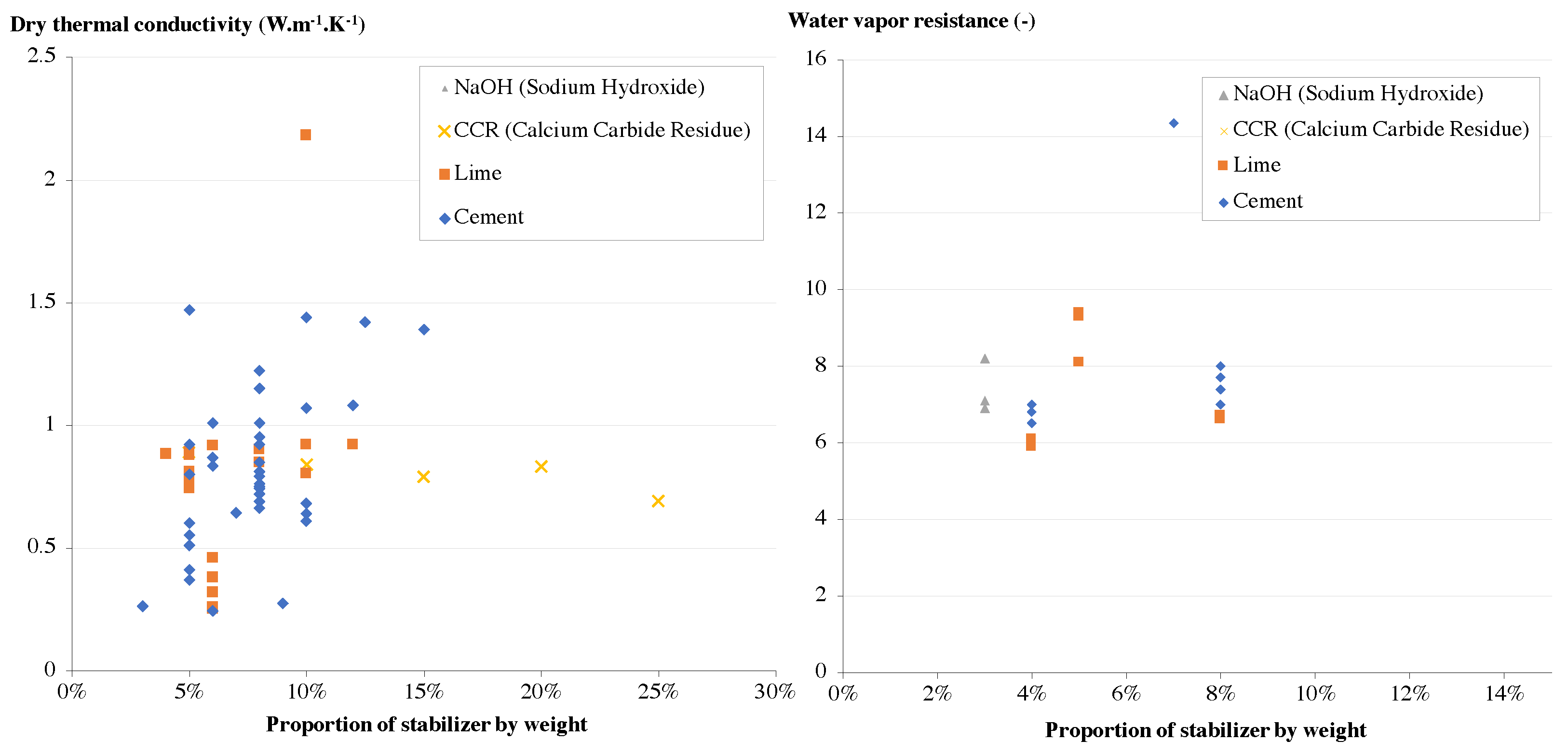

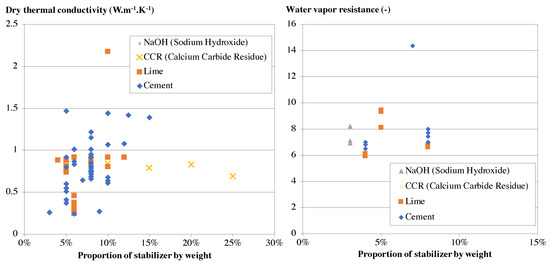

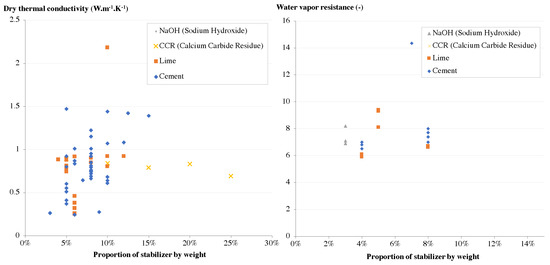

3.2.3. Stabilizer Additive Influence

Except for Calcium Carbide Residue (CCR), adding cement or lime generally increases dry thermal conductivity and water vapor resistance. To maintain optimal thermal performance, limiting the addition of cement or lime to a maximum of 8% is advisable (see Figure 12).

Figure 12.

Correlation between stabilizer incorporation rate and hygrothermal properties of earth-based materials.

3.2.4. Influence of Other Additives and Mixtures

Incorporating a reed fiber mixture with a PCM (Phase Change Material) yields intriguing outcomes, showcasing low dry thermal conductivity alongside an average water vapor resistance factor. Conversely, incorporating a flax fiber mixture with PCM results in less compelling thermal insulating characteristics.

3.2.5. Influence of Compression Techniques

No correlation between stress rates and dry thermal conductivity or water vapor resistance factor is observed (see Figure 13). Within a given compression setting, the thermal conductivity tends to be the lowest for fiber materials, followed by stabilized materials. Regardless of the stress applied, the dry thermal conductivity of raw earth materials never falls below 0.5 W/(m.K). However, optimal thermal conductivity is achieved either with compression of 2.5 MPa for materials with fiber or of 10 MPa for stabilized materials, or 3.47 MPa for mixed fibered/stabilized materials. This compression requirement can be efficiently met using a manually operated hydraulic press, such as the calibrated M&O brand [28].

Figure 13.

Comparative analysis of earth-based materials based on compression production techniques.

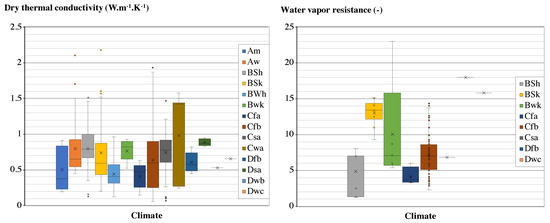

3.3. Correlating Hygrothermal Properties, Production Techniques, and Climate Conditions

A statistical analysis of hygrothermal parameters (summarized in Table 4) highlights that the techniques exhibit optimal thermal insulation performance in tropical, dry, and temperate climates, especially Monsoon (Am), Arid desert hot (Bwh), and not dry season hot summer (Cfa) seasons. Conversely, these techniques demonstrate superior hygroscopic insulation performance in cold arid or semi-arid dry climates (Bsk and Bwk) or continental climates (dry winter cold summer (Dwc) or no dry season warm summer continental climate (Dfb)).

Table 4.

Mean hygrothermal properties across various techniques.

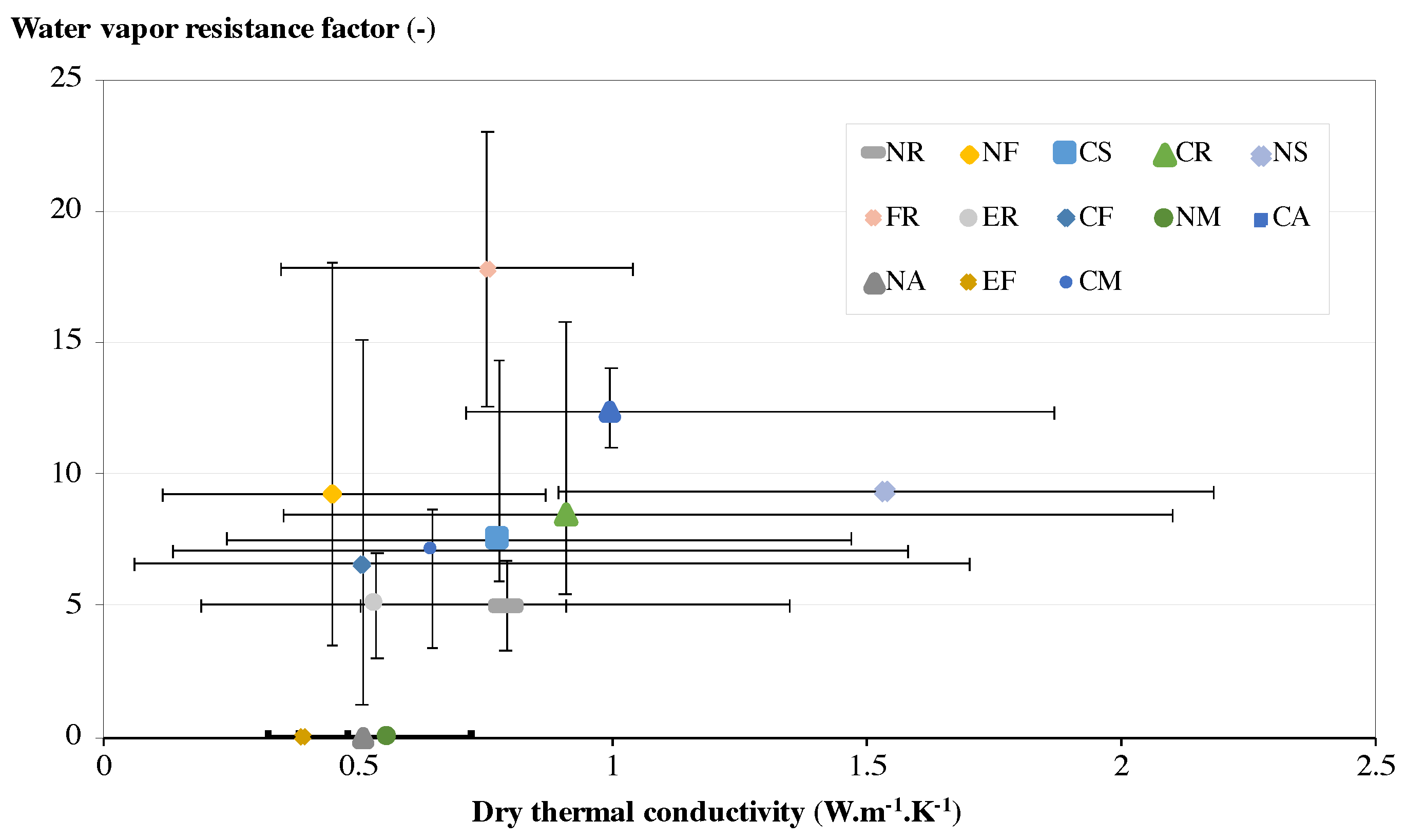

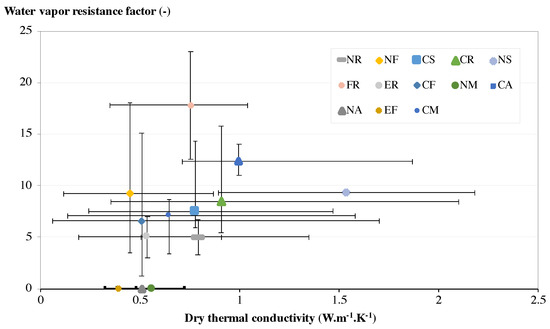

Based on the graphic analysis (see Figure 14), techniques such as no mechanical (with fiber (NFb), mixed stabilizer/fiber (NM) or other additives (NA)), compressed with fiber (Nfb), and extruded (with fiber (EFb) or without fiber (ER)) exhibit superior thermal insulation properties on average. On the other hand, techniques like FR (fired material) or CA (compressed with other additives) tend to excel in providing effective hygroscopic insulation.

Figure 14.

Comparative analysis of terrestrial materials according to climatic distribution of studies.

This suggests the potential for recommending earth manufacturing techniques tailored to specific climate needs and end uses. For instance, an optimal technique for insulation in tropical climates would prioritize hygrothermal coupling, characterized by low thermal conductivity and, depending on the use, high water vapor resistance factor. Techniques such as NFb (no mechanical with fibers standing for wattle and daub or earth plaster) align well with this specific climatic requirement (see Figure 15).

Figure 15.

Comparison of earth-based materials according to production technics.

4. Discussions

4.1. Literature Gap Analysis

Over the past decade, an increasing focus has been placed on studying the hygrothermal properties of earthen materials. Our research targeted these properties to assess their insulating or regulating capacity, emphasizing dry thermal conductivity and water vapor resistance factor. Despite abundant existing literature, there remains a substantial gap in articles that delve deeper into the intricate interplay between the buffering properties of earth materials and their hygrothermal characteristics. An essential aspect for further investigation concerns the relationship between water buffering capacity, measured by the moisture buffering value, and thermal buffering capacity, indicated by thermal effusivity. These parameters are decisive in achieving hygrothermal comfort, particularly in constructions under tropical climates.

Moreover, most studies have been conducted in temperate with warm summer (Cfb) and hot semi-arid dry (BWh) climates. Despite the significance of earth constructions in tropical zones, a notable research gap persists in these regions, heavily affected by hygrothermal comfort concerns in buildings. Areas such as East Africa, Central America, and South Asia, classified under Group A in the Köppen climate classification, stand as examples of tropical climatic zones requiring further exploration on this subject.

It is also noteworthy that earth materials could potentially add considerable value in polar regions due to their thermal masses. This is evident in the vernacular architecture of Icelandic farms, where substantial masses of peat protect and insulate long walls of these constructions, particularly when not utilizing other forms of earth use, such as cave dwellings.

Regarding earth-based material production techniques, methods like extrusion and firing, specifically EF (extruded/fiber—for 3D printing), NF (raw with fibers), or FR (fired bricks), remain among the least studied in terms of hygrothermal properties. However, they could prove critical for specific climates, such as the tropical climate, offering low dry thermal conductivity or high resistance to humidity. The lack of studies on these techniques might be attributed to their substantial financial investment requirements for implementation, a significant barrier in economically less favored countries.

4.2. Critical Analysis of Study Repartition and Earth-Based Material-Manufactured Techniques around the World

The study of earthen architecture has predominantly thrived in Europe, notably France, which is emerging as the epicenter of research in this field. This predominance is partly explained by the correlation between the concentration of studies and regional climatic characteristics, as well as political goals aimed at reducing the environmental impacts of construction.

However, it is crucial to highlight that the history of earthen architecture dates back to ancient times and spans numerous cultures worldwide. The earliest expressions of this architectural form originated in regions where local resources were primarily composed of earth, such as the Middle East, North Africa, Central Asia, and South America. Despite this historical richness, the significant absence of studies in these geographical areas, often tropical climates, raises questions. Development constraints within nations could be an explanatory factor, with experiments being costly and universities in these regions facing challenges related to funding and resources to conduct such research.

Another surprising observation is the lack of studies in the United States. Several hypotheses could be proposed, including a potential lack of comprehensiveness in our research database or a disinterest in studying the hygrothermal properties of earthen materials, thus favoring more complex and scientifically notable technologies.

A notable finding is the substantial concentration of studies in Western Europe, indicating the sustained commitment of the European scientific community to explore sustainable materials. Conversely, in Central Africa, the scientific community has engaged in studying the hygrothermal potential of the earth, signaling a growing interest in earth-based architecture research in this region. Notably, scientific interest in this issue is steadily increasing, and it would not be surprising for Central African countries to inspire in-depth studies on the characterization and optimization of earth usage methods. This is especially plausible given the multiple initiatives emerging on this continent, such as promoting the earth associated with typha in Senegal, aiming to foster enthusiasm for more frugal construction methods.

Finally, it is worth noting that compressed materials are studied across all continents. These materials, often bricks, play a pivotal role in construction, enhancing thermal comfort and providing structural functionality.

In examining additive use, a distinct trend emerges: in Africa, cement or fibers are frequently employed, whereas, in Europe, a broader spectrum of additives like polymers and phase-changing materials is observed. This disparity arises from utilizing locally available resources, often in economically disadvantaged or remote areas.

The choice of additives reflects regional resource accessibility and technological considerations. In African contexts, where cement and fibers are prevalent additives, this could be attributed to their widespread availability and established use within construction practices. Conversely, in more developed regions like Europe, the diversification of additives toward polymers and phase-changing materials might stem from research-driven advancements seeking improved thermal and structural performance. This disparity underscores the influence of local context and technological evolution on material choices in construction practices worldwide.

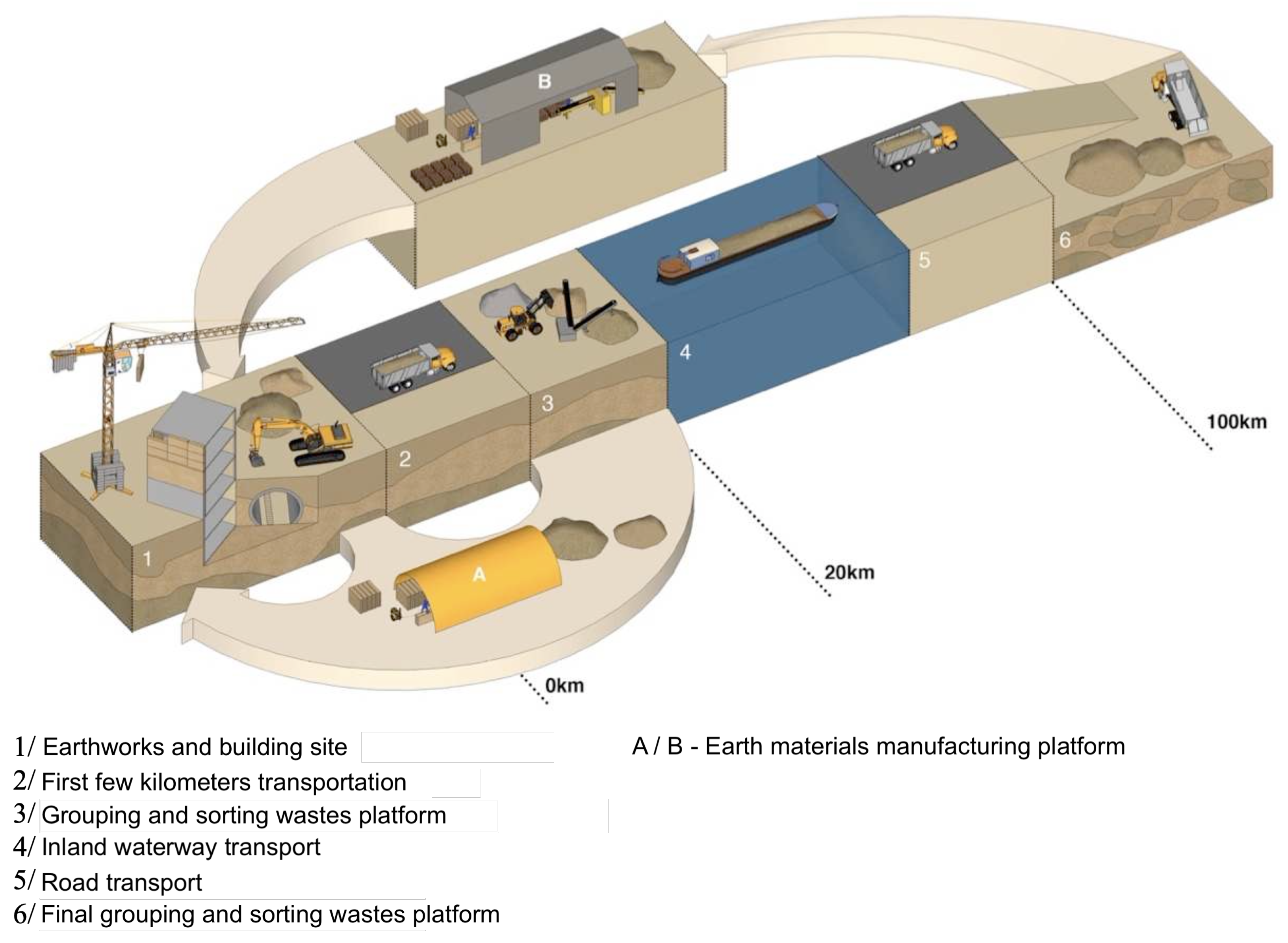

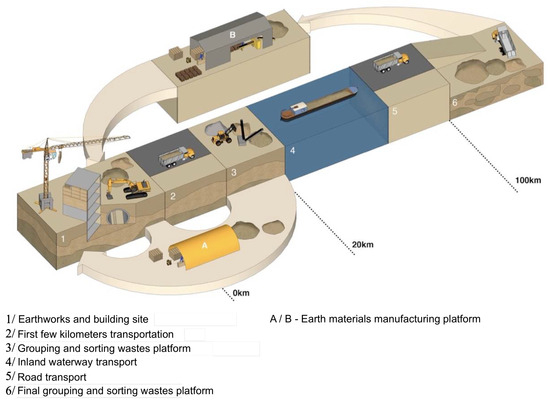

In France, the study by Gasnier [3] introduced a strategy for recovering excavated soil. This approach leverages existing processes utilized in construction sites linked to significant projects in Paris (refer to Figure 16).

Figure 16.

Excavated soil valorization strategy (adapted from [3]).

4.3. Proposal of New Decision-Support Tools: Development of MATARUN Ternary Diagrams

Ternary diagrams are precious tools for visualizing and understanding the intricate relationships among multiple variables. They serve as decision guides to identify formulations or techniques that may achieve specific performance goals. In earthen architecture, two ternary diagrams, the Augustinik and Winkler diagrams, are commonly used as references.

Our research framework utilized this graphical method by creating ternary diagrams based on our extensive database. This statistical approach allowed us to provide crucial insights into the hygrothermal properties of earth-based methods.

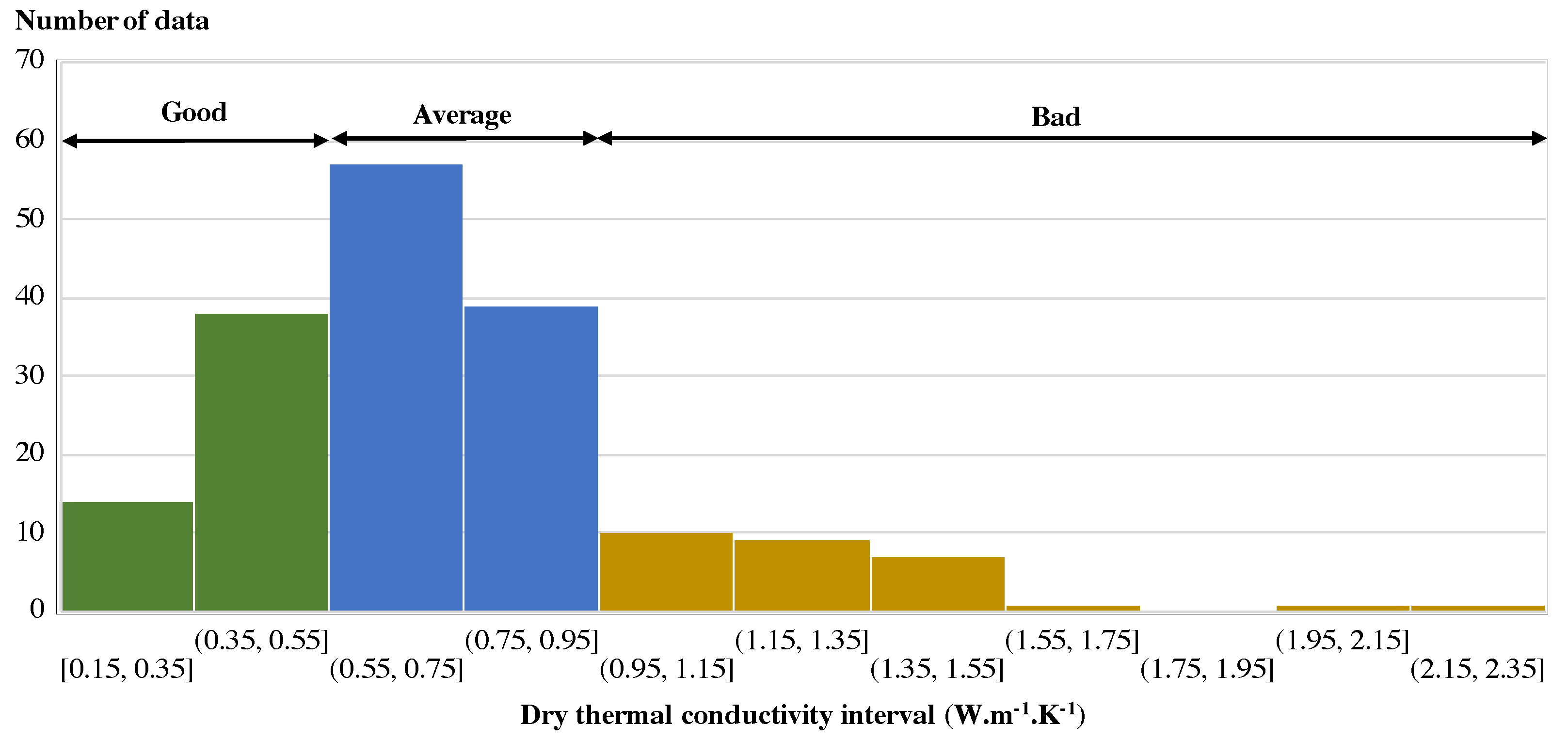

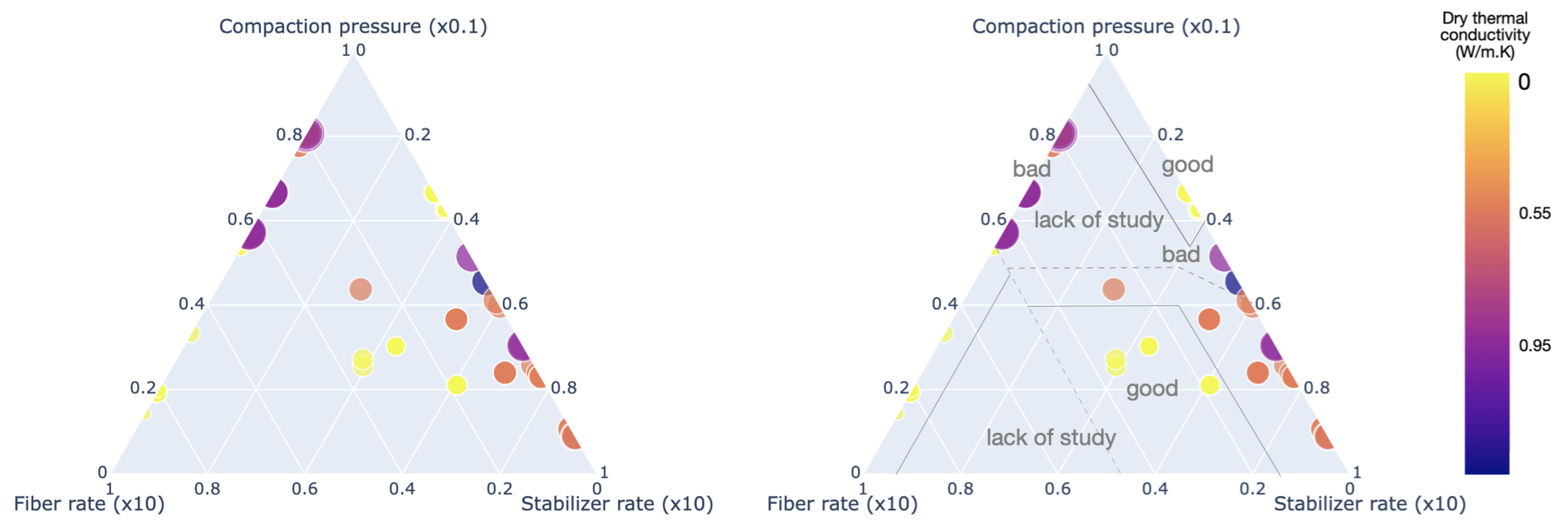

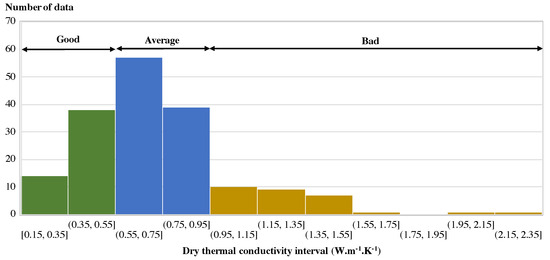

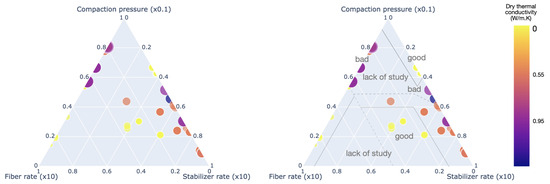

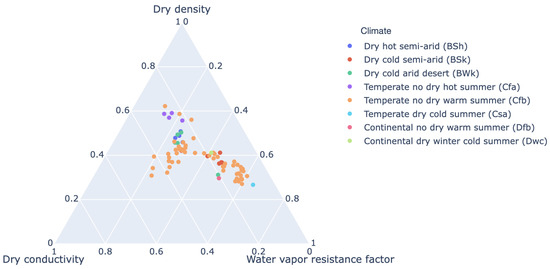

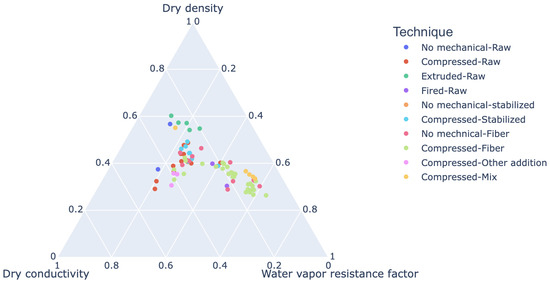

To construct these diagrams, for the first diagram, we selected samples with a compaction pressure of less than 10 MPa and samples manufactured with compaction and fiber or stabilizer addition. We have shown that compaction pressures of more than 10 MPa are not conducive to dry thermal conductivity of less than 0.55 (W/m.K). So, the validity domain of the first diagram is a maximum 15% of fiber, 10% of stabilizer (cement or lime), and 10 MPa of compaction pressure. For the second diagram, we initially normalized the data concerning the maximum values observed in our study. The maximum values of dry thermal conductivity were 2.18 (W/m.K), maximum dry density was 3120 kg/m3, and maximum water vapor resistance factor reached 23. These values served as benchmarks for constructing our ternary diagrams using the Python library "scatter ternary” by Plotly. Based on the dry thermal conductivity data statistical analysis (see Figure 17), we divided the first diagram into three zones, corresponding to good (<0.55 W/m.K), average (<0.95 W/m.K), and bad dry thermal conductivity (>0.95 W/m.K).

Figure 17.

Statistical analysis of dry thermal conductivity.

The first diagram, depicted in Figure 18, provides an in-depth analysis of the thermal insulating properties of earthen materials according to techniques much studied (compressed with fiber (CFb), compressed with stabilizer (CS), compressed mix fibered/stabilizer (CM) standing for prefabrication, compressed earth blocks, or rammed earth). It illustrates the relationship and allows anticipation of the insulating properties of materials based on the balance between the compression rate, fiber content, stabilizer content, and the dry thermal conductivity expected. For example, if we consider earthen materials made with 12% fiber, 0% stabilizer, and 10 MPa compaction pressure, this means that, on our diagram, we will have the equilibrium fiber–stabilizer–compaction of 55%-0%-45%. Therefore, we observe that this material belongs to the zone with good dry thermal conductivity (<0.55 W/m.K). It is the same if we take a material made with 1% fiber, 5% stabilizer, and 3.47 MPa compaction pressure; on the diagram, we have 11%-53%-36%, and it belongs to the zone with average dry thermal conductivity (<0.95 W/m.K). The opposite reasoning could be applied. Supposedly, if we’re looking for materials with good or average dry thermal conductivity, the diagram will determine the appropriate balance and, therefore, the proportions of fiber, stabilizer, and compaction pressure to be applied. Analysis of this diagram also reveals three promising prospects for a fiber–stabilizer–compaction balance. The first is with a high fiber rate and low compaction pressure, the second with low fiber, high stabilizer, and average compaction pressure, and, finally, with average stabilizer rate and high compaction. However, a notable lack of studies exists for formulations with a balance of high fiber rate, low stabilizer rate, and low compaction pressure. This diagram confirms previous analyses by highlighting the significance of fibers in harnessing the insulating capacity of earthen materials.

Figure 18.

MATARUN Diagram No1: ternary representation of the relationship between compression, fiber, and stabilizer balance ratio and dry thermal conductivity expected.

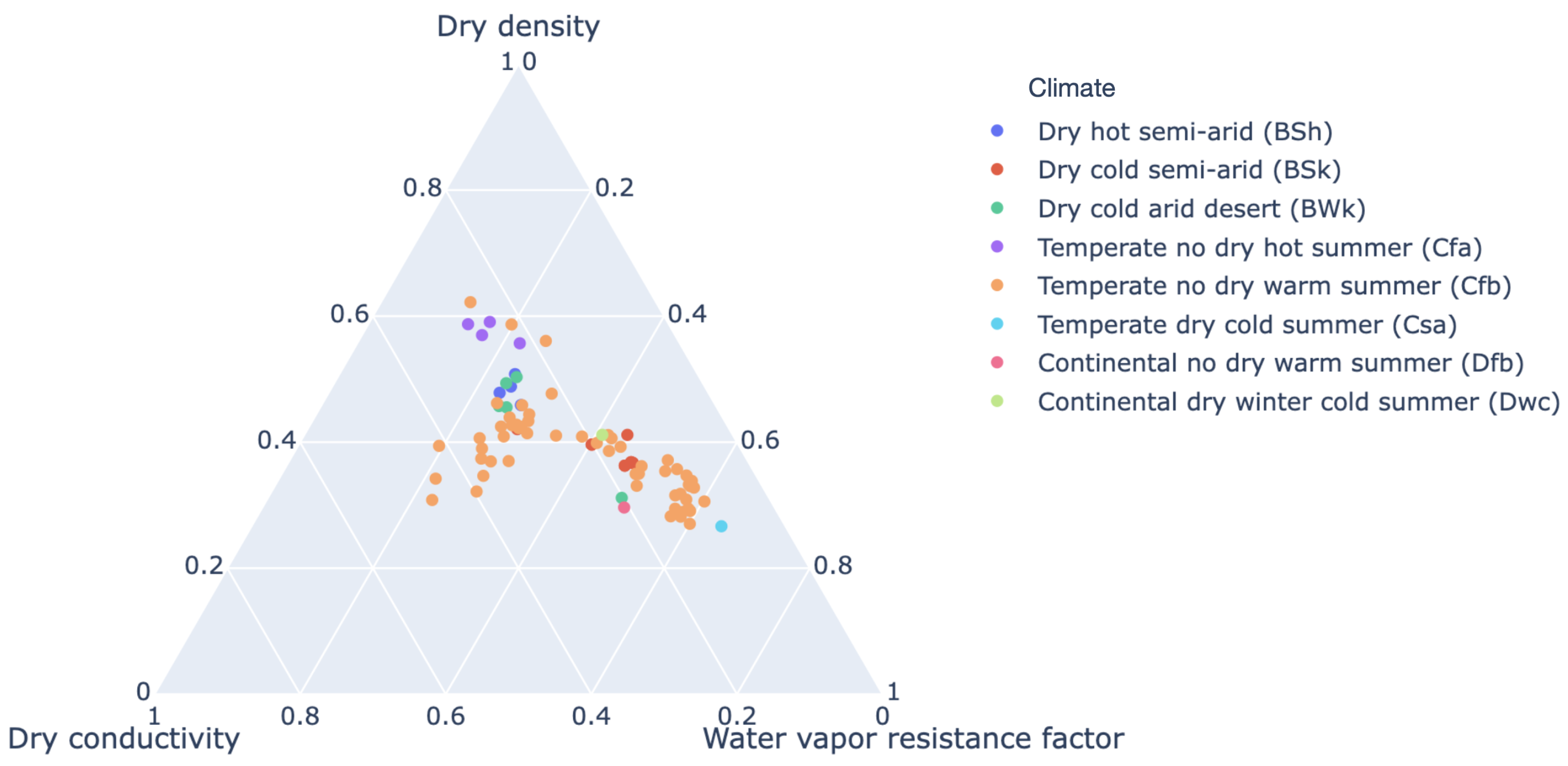

The second diagram presented in Figure 19 offers promising insights for more efficient and suitable use of earth-based construction materials, considering their hygrothermal properties and specific requirements of various climates. Among these, the temperate climate, characterizing a no dry warm summer (Cfb), stands out as the most studied, reflecting the prevalence of research in this climatic zone. Apart from the substantial number of studies, this predominance also reveals the diversity of associated properties and techniques, as indicated by the extensive scatter of data points in the diagram.

Figure 19.

MATARUN Diagram No2: ternary diagram of relationship between hygrothermal and physical properties balances and study climate zones.

Notably, this diagram underscores a deficiency in climate diversity, which is crucial given the close correlation between global climate and geology. Long-term geological processes such as plate tectonics, mountain formation, erosion, and soil composition are vital in planetary climate regulation. Therefore, a comprehensive approach to hygrothermal studies must integrate a holistic properties analysis to comprehend climate’s impact on earthen materials’ final characteristics.

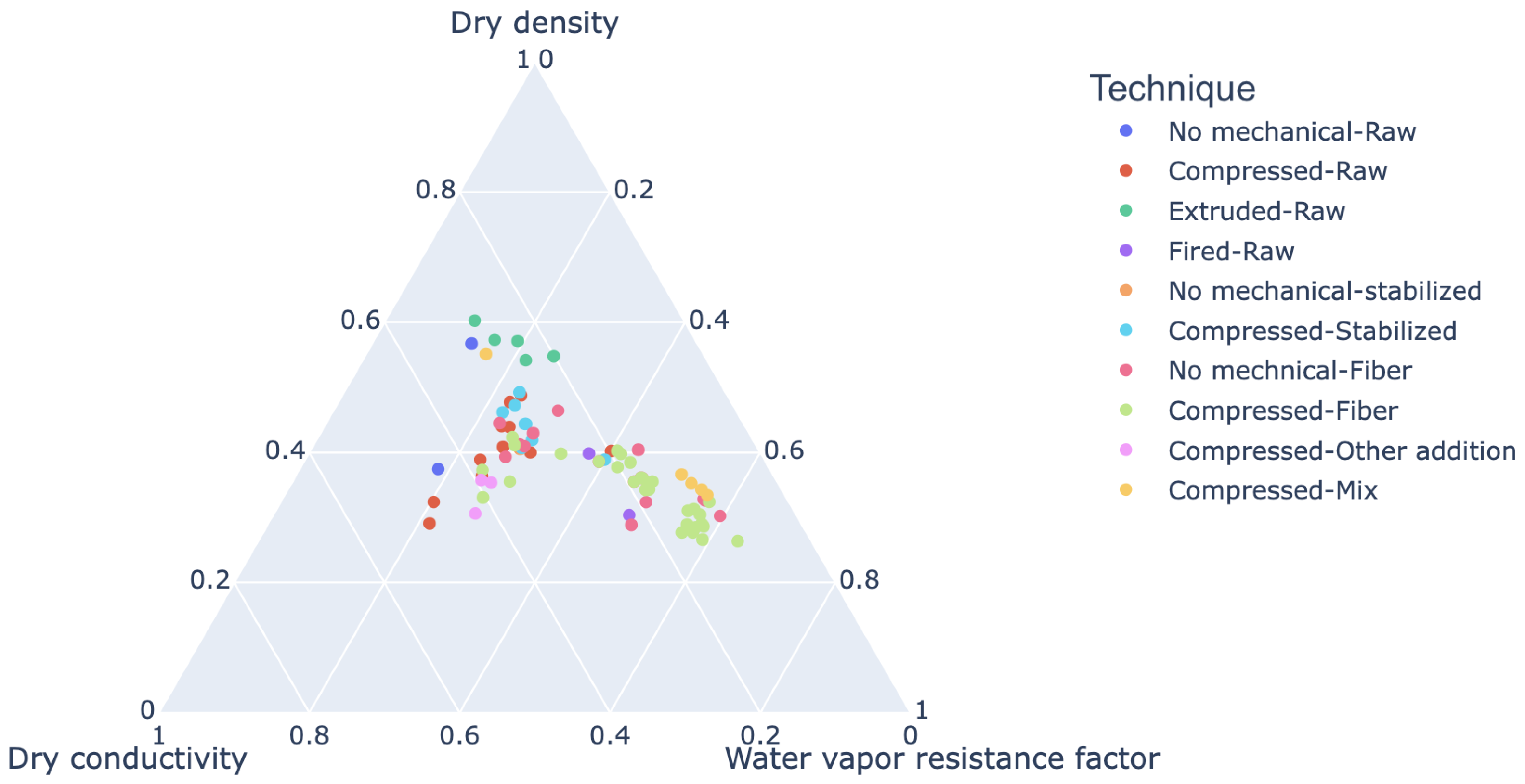

The third diagram, represented in Figure 20, offers a fascinating perspective by associating hygrothermal performances with specific construction techniques, facilitating technique selection based on desired performances for a given construction project. Research on compressed and fibrous earth highlights their potential as hygroscopic regulators, providing intriguing characteristics in this domain. Conversely, according to trends in this diagram, extruded raw earth appears less adept at ensuring an effective role as a thermal insulator.

Figure 20.

MATARUN Diagram No3: ternary diagram of relationship between balance of hygrothermal and physical properties and various techniques.

However, a critical observation emerges from this diagram: the lack of dedicated studies for optimizing hygrothermal performances comprehensively. Despite advances in understanding specific characteristics of certain earth construction techniques, a crucial need remains for more integrated approaches to combine these techniques to achieve optimal hygrothermal performances in earthen constructions.

This diagram not only highlights the relative strengths and weaknesses of different earth construction techniques in terms of hygrothermal performances but also emphasizes the necessity for deeper and more holistic research to maximize the advantages of these materials in sustainable construction.

5. Conclusions and Perspectives

The main objective of this study was to analyze an extensive database compiled within the scope of our research. This allowed us to investigate the existing correlations among various methods for valorizing excavated earth, their formulations, and their climatic origins to explore the potential of these solutions to enhance the hygrothermal comfort of buildings. We meticulously analyzed experimental data from 477 samples from 88 research articles from 32 countries worldwide.

Several significant conclusions emerged from this in-depth analysis. We observed that the addition of fibers generally showed a marked interest in improving dry thermal conductivity. However, the incorporation of cement did not consistently demonstrate benefits for the hydrothermal properties of the materials under study. Thus our findings indicate that a minimum of 8% in weight of fiber content and a maximum of 8% in weight of cement content are necessary to achieve satisfactory thermal performance. Additionally, it is crucial to note that not all fibers are equivalent. For instance, using olive fibers does not seem to lead to optimal hygrothermal properties.

Moreover, we identified correlations between different parameters. For instance, a significant relationship was observed between material density and their dry thermal conductivity, as well as among varying fiber quantities used. By exploring various additives such as geopolymers, tannins, or blends, it is possible to enhance the compatibility between thermal and hygroscopic properties of materials. Additionally, we found that using fired materials can result in high hygroscopic insulation capacity.

Lastly, we developed three ternary diagrams to visualize these intricate relationships better and understand the correlations among hygrothermal properties, climates, and earth manufacturing techniques. One of these ternary diagrams enabled a better understanding of the general properties of dry thermal conductivity based on compression rates, fiber content, and stabilizers, offering a valuable tool for the community to comprehend their formulations.

In the perspective of future studies, the improvement and validation of MATARUN diagrams emerge as critical objectives. Exploring new approaches to optimize hygrothermal insulation properties through alternative additives or combinations thereafter represents a promising avenue to address the complex heterogeneity of excavated soil management. In addition, in this article, the main bioadditive encountered was biofiber. The scientific community should carry out more studies on other bioadditives like biopolymers or biomineralisations, which are available in several regions and have good properties for stabilizing and improving the mechanical and hygrothermal properties of earth materials.

Furthermore, our in-depth investigations have identified optimal parameters for creating earth-based materials, regardless of the specific nature of the soil. These parameters allow for valorizing the diversity of excavated land use methods.

Considering the integration of the hygrothermal parameters identified in our study into a dynamic thermal simulation software, it becomes conceivable to numerically optimize methods for valorizing excavated soil based on diverse climatic conditions. This approach would guide analysis through DTS and help identify the best experimental formulations, therefore reducing costs associated with future experiments.

Author Contributions

Y.I.F.D.: Investigation, Data Curation, Writing—Original draft, and Visualisation. M.G.: Writing—Review and Editing. B.M.-D.: Conceptualisation, Investigation, Methodology, Writing—Review and Editing, Validation, and Project Administration. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by the Action Logement’s overseas innovation plan as part of the PIV OM MATARUN project.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Acknowledgments

The authors express their gratitude to the University of Reunion Island and the PIMENT laboratory for providing an excellent administrative framework and a conducive working environment that nurtures research and innovation. We extend our deepest gratitude to the Action Logement Group for their invaluable financial support, which made this research possible.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| CSEB | Compressed Stabilized Earth Blocks | CEB | Compressed Earth Blocks |

| N | No mechanical | DTS | Dynamic Thermal Simulation |

| C | Compression/compaction | E | Extrusion |

| F | Firing | R | No additives |

| Fb | Fibers additions | S | Stablized |

| M | Mixed composition | A | With others additions |

| LEM | Light Earth Method | PoP | Publish or Perish |

| LEED | Leadership in Energy and Environmental Design |

Appendix A

Appendix A.1. References of Research Presented on This Article

Table A1.

Reference of raw earth material.

Table A1.

Reference of raw earth material.

| Technics | References |

|---|---|

| No mechanical | [29,37,43,46,49,51,75,81] |

| Compressed | [9,10,23,26,27,28,29,30,32,33,34,40,45,47,48,50,51,52,57,59,65,66,67,68,69,70,71,76,77,84,85,86,87,88,89,90,91,95,96,98,99,100] |

| Extruded | [57,91,93,94] |

| Fired | [40,83,87,92,97,103] |

Table A2.

Reference of mineral additive data. Fired technics are not studied for hydrothermal properties.

Table A2.

Reference of mineral additive data. Fired technics are not studied for hydrothermal properties.

| Mineral Additive | No Mechanical | Compressed | Extruded |

|---|---|---|---|

| Lime | [35,36] | [19,21,26,34] | - |

| Cement | - | [18,19,20,21,23,24,26,28,30,31,32,50] | - |

| NaOH | - | [26] | - |

| Fiberglass | - | [32] | - |

| Pozzolan | - | [32] | - |

| Calcium Carbide Residue | - | [23] | - |

Table A3.

Reference of bioadditive data. Fired techniques are not studied for hydrothermal properties.

Table A3.

Reference of bioadditive data. Fired techniques are not studied for hydrothermal properties.

| Bioadditive | No Mechanical | Compressed | Extruded |

|---|---|---|---|

| Hemp | [22,37] | [38,39,40,41,42,43] | - |

| Wheat | [46,49] | [10,41,45,47,48] | - |

| Barley | [35,51,52] | [10,50,51] | - |

| Reed | [41,53,55] | [37,54] | - |

| Olive | [56] | [57,58] | - |

| Rice | [53,59] | [53] | - |

| Straw | [61,63] | [26,37,62] | [37] |

| Bagasse | [59] | - | - |

| Corn | [51] | - | - |

| Alfa | - | [65,66] | - |

| Hibiscus cannabinus | - | [67] | - |

| Kenaf | - | [68] | - |

| Lavender | - | [50] | - |

| Palm | - | [69] | - |

| Pennisetum Setaceum | - | [70] | - |

| Pumice | - | [43] | - |

| Sawdust | - | [65] | - |

| Seaweed | - | [43] | - |

| Thatch | - | [71] | - |

| Typha Australis | - | [71] | - |

| Fonio | - | [74] | - |

| Grass | [53] | [53] | - |

| Cocos Nucifera, Canarium Schweinfurthii | - | [28] | - |

| Flax | - | [31,41,47,54,64] | - |

| Typha australis | - | [72] | - |

Table A4.

Reference of other additional data. Fired and extruded technics are not studied for hydrothermal properties.

Table A4.

Reference of other additional data. Fired and extruded technics are not studied for hydrothermal properties.

| Other Additive | No Mechanical | Compressed |

|---|---|---|

| PCM | [75] | [30,32] |

| Geopolymer (NaOH-activated MK) | - | [27] |

| Wood biomass ash (domestic wood heating, wood from tree pruning) | - | [77] |

| Lignin sulfonate | - | [76] |

| Tannin | - | [76] |

| Sheep Wool | - | [76,102] |

| Guar gum (HydroxyPropyl Guar) | - | [32] |

| Paper | - | [82] |

| Oat fiber | - | [75] |

Table A5.

Reference of mixed additive data. Fired and extruded technics are not studied for hydrothermal properties.

Table A5.

Reference of mixed additive data. Fired and extruded technics are not studied for hydrothermal properties.

| Mix of Additive | No Mechanical | Compressed |

|---|---|---|

| Cement/Pozzolan | - | [22] |

| Cement/sawdust | - | [22] |

| Cement/Agave/cactus mucilage and xanthan gum | - | [80] |

| Cement/Agave | - | [80] |

| Cement/wheat straw | - | [10] |

| Cement/Barley straw | - | [10] |

| Cement/mining waste | - | [78] |

| Gypsum/wheat straw | - | [10] |

| Gypsum/Barley straw | - | [10] |

| Cement/Hemp fiber | - | [31] |

| Natural polymer (Alginate)/Organic fiber (Sheep wool) | - | [79] |

| PCM/Flax Straw | - | [64] |

| PCM/Reed | - | [55] |

| River sand/wheat straw | - | [46] |

| River sand/wheat straw/cow dung | - | [46] |

| Flax fiber/Glycerol Carbonate | - | [81] |

| Pozzolan/Microsilica | - | [32] |

| Calcium Carbide Residue/Rice Husk Ash | - | [23] |

| Lime/PCM | [75] | - |

| Lime/oat fiver | [75] | - |

Appendix A.2. Hydrothermal Properties Presented on This Article

Table A6.

Hygrothermal properties of raw data.

Table A6.

Hygrothermal properties of raw data.

| No Mechanical | Compressed | |||||

|---|---|---|---|---|---|---|

| Properties | Mean | Min | Max | Mean | Min | Max |

| Dry density | 1912.38 | 1699.00 | 2239.00 | 1906.19 | 1470.00 | 3120.00 |

| Water vapor permeability factor | 5.00 | 3.30 | 6.70 | 8.44 | 5.40 | 15.83 |

| Dry thermal conductivity | 0.79 | 0.51 | 1.35 | 0.91 | 0.35 | 2.10 |

| Extruded | Fired | |||||

| Properties | Mean | Min | Max | Mean | Min | Max |

| Dry density | 2045.25 | 1788.00 | 2268.00 | 2039.12 | 1777.00 | 2567.60 |

| Water vapor permeability factor | 5.00 | 3.00 | 7.00 | 17.80 | 12.60 | 23.00 |

| Dry thermal conductivity | 0.54 | 0.19 | 0.91 | 0.75 | 0.35 | 1.04 |

Table A7.

Dry density data.

Table A7.

Dry density data.

| Additive | Proportion | No Mechanical (Min/Mean/Max) | Compressed (Min/Mean/Max) | Extruded (Min/Mean/Max) |

|---|---|---|---|---|

| Bioadditive | ||||

| Hemp | 1.5–67% | 316/1016.25/1503.8 | 205/480.26/2244 | -/-/- |

| Wheat | 0.3–20% | 971.21/1636.9/2028.4 | 1462/1605.39/1827.58 | -/-/- |

| Barley | 1–6% | 1315/1458.71/1613 | 1139.9/1545.49/1818 | -/-/- |

| Reed | 3–35% | 620/726.9/1047.6 | 650/1002.5/1355 | -/-/- |

| Olive | 4–40% | 1409/1543.5/1669 | 1344.3/1509.15/1669 | -/-/- |

| Rice | 1–6% | 836/836/836 | -/-/- | -/-/- |

| Straw | 0.4–2% | 1456/1614.6/1823.3 | 1211/1355.5/1500 | 1283.7/1489.13/1780.3 |

| Bagasse | 1–6% | -/-/- | -/-/- | -/-/- |

| Corn | 1–2% | 948/1088.5/1229 | -/-/- | -/-/- |

| Alfa | 1–8% | -/-/- | 1512/2182.67/2520 | -/-/- |

| Hibiscus cannabinus | 0.2–0.8% | -/-/- | -/-/- | -/-/- |

| Kenaf | 1.20% | -/-/- | -/-/- | -/-/- |

| Lavender | 3–6% | -/-/- | 1585/1678.5/1772 | -/-/- |

| Palm | 3–6% | -/-/- | 1122.3/1214.71/1285.6 | -/-/- |

| Pennisetum Setaceum | 8% | -/-/- | 1330/1330/1330 | -/-/- |

| Pumice | 3.50% | -/-/- | 831/831/831 | -/-/- |

| Sawdust | 8% | -/-/- | 1542/1542/1542 | -/-/- |

| Seaweed | 1–4% | -/-/- | 1100/1233.33/1400 | -/-/- |

| Thatch | 1–4% | -/-/- | 1741.66/1752.53/1770.61 | -/-/- |

| Typha Australis | 15.10–23% | -/-/- | 1000/1164.58/1304.5 | -/-/- |

| Fonio | 0.20–1% | -/-/- | -/-/- | -/-/- |

| Grass | -/-/- | -/-/- | 616/684/721 | -/-/- |

| Cocos Nucifera. Canarium Schweinfurthii | 5–15% | -/-/- | 1120/1363.33/1650 | -/-/- |

| Flax | 1–3% | -/-/- | 1050/1591.19/1912.5 | -/-/- |

| Typha australis | 16–33% | -/-/- | 304.3/404.27/585.5 | -/-/- |

| -/-/- | -/-/- | -/-/- | -/-/- | |

| Mineral additive | ||||

| Lime | 5–15% | 1843/2016.5/2190 | 1130/1777.25/2190 | -/-/- |

| Cement | 3–15% | -/-/- | 1491/1886.44/2490 | -/-/- |

| NaOH | 3% | -/-/- | -/-/- | -/-/- |

| Fiberglass | 1–2% | -/-/- | -/-/- | -/-/- |

| Pozzolan | 10% | -/-/- | -/-/- | -/-/- |

| Calcium Carbide Residue | 5–25% | -/-/- | 1477/1594.4/1711 | -/-/- |

| -/-/- | -/-/- | -/-/- | -/-/- | |

| Other additive | ||||

| PCM | 5–29% | 1270/1270/1270 | 1750/1754.5/1768 | -/-/- |

| Geopolymer (NaOH-activated MK) | 5–20% | -/-/- | 1730/1780/1840 | -/-/- |

| wood biomass ash (domestic wood heating. wood from tree pruning) | 5–20% | -/-/- | 1830/1869.375/1920 | -/-/- |

| Lignin sulfonate | 1% | -/-/- | 2170/2170/2170 | -/-/- |

| tannin | 1% | -/-/- | 2130/2130/2130 | -/-/- |

| sheep Wool | 0.25% | -/-/- | 2170/2170/2170 | -/-/- |

| Guar gum (HydroxyPropyl Guar) | 2.50% | -/-/- | 1611/1611/1611 | -/-/- |

| Paper | -/-/- | -/-/- | -/-/- | -/-/- |

| Oat fiber | 0.20% | 1670/1670/1670 | -/-/- | -/-/- |

| Mix of additive | ||||

| Cement/Pozzolan | 10%/45% | -/-/- | 1329/1516/1643 | -/-/- |

| Cement/sawdust | 10%/9% | -/-/- | 1050/1118.33/1207 | -/-/- |

| Cement/Agave/cactus mucilage and xanthan gum | 16%/1%/ | -/-/- | 1910/1910/1910 | -/-/- |

| Cement/Agave | 16%/1% | -/-/- | 1910/1910/1910 | -/-/- |

| Cement/wheat straw | 5–10%/1–3% | -/-/- | 1100/1188.18/1301.8 | -/-/- |

| Cement/Barley straw | 5–10%/1–3% | -/-/- | 1139.9/1215.93/1301.8 | -/-/- |

| Cement/mining waste | 10%/0–40% | -/-/- | 1650/1716/1750 | -/-/- |

| Gypsum/wheat straw | 5–10%/1–3% | -/-/- | 1211/1429.98/1575.6 | -/-/- |

| Gypsum/Barley straw | 5–10%/1–3% | -/-/- | 1211/1428.58/1575.6 | -/-/- |

| Cement/Hemp fiber | 5–9%/0.8% | -/-/- | -/-/- | -/-/- |

| Natural polymer (Alginate)/ Organic fiber (Sheep wool) | 3%/0.25% | -/-/- | 1390/1450/1510 | -/-/- |

| PCM/Flax Straw | 2–10%/2.5% | -/-/- | 1910.1/1915.67/1922.6 | -/-/- |

| PCM/Reed | 2–20%/25% | -/-/- | 700/700/700 | -/-/- |

| River sand/wheat straw | 80%/0–3.10% | -/-/- | 1313.8/1572.08/1748.2 | -/-/- |

| River sand/wheat straw/cow dung | 80%/0.7–1.60%/6–11% | -/-/- | 1312.8/1572.04/1748.9 | -/-/- |

| Flax fiber/Glycerol Carbonate | 0.75%/1% | -/-/- | 1593/1593/1593 | -/-/- |

| Pozzolan/Microsilica | 10%/1.5% | -/-/- | 1904/1904/1904 | -/-/- |

| Calcium Carbide Residue/Rice Husk Ash | 12–18%/2–8% | -/-/- | 1555/1571.25/1578 | -/-/- |

| Lime/PCM | 1.6%/17% | 1430/1430/1430 | -/-/- | -/-/- |

| Lime/oat fiver | 2%/0.20% | 1720/1720/1720 | -/-/- | -/-/- |

Table A8.

Water vapor permeability factor data.

Table A8.

Water vapor permeability factor data.

| Additive | Proportion | No Mechanical (Min/Mean/Max) | Compressed (Min/Mean/Max) |

|---|---|---|---|

| Bioadditive | |||

| Hemp | 1.5–67% | 3.5/3.5/3.5 | 2.24/3.71/6.8 |

| Wheat | 0.3–20% | -/-/- | 7.01/7.49/7.88 |

| Barley | 1–6% | 5.5/7.82/11 | -/-/- |

| Reed | 3–35% | 7.8/8.23/9 | 7.101/7.1/7.101 |

| Olive | 4–40% | 12.5/13.78/15.1 | 12.5/13.78/15.1 |

| Rice | 1–6% | -/-/- | -/-/- |

| Straw | 0.4–2% | 7.27/11/18 | -/-/- |

| Bagasse | 1–6% | -/-/- | -/-/- |

| Corn | 1–2% | 4.5/5.25/6 | -/-/- |

| Alfa | 1–8% | -/-/- | -/-/- |

| Cocos Nucifera, Canarium Schweinfurthii | 5–15% | -/-/- | -/-/- |

| Flax | 1–3% | -/-/- | 9.25/11.32/13.75 |

| Typha australis | 16–33% | -/-/- | 1.28/1.69/2.5 |

| Mineral additive | |||

| Lime | 5–15% | -/-/- | 5.9/7.42/9.4 |

| Cement | 3–15% | -/-/- | 6.5/7.79/14.34 |

| Other additive | |||

| Lignin sulfonate | 1% | -/-/- | 14/14/14 |

| Tannin | 1% | -/-/- | 11/11/11 |

| Sheep Wool | 0.25% | -/-/- | 12/12/12 |

| Mix of additive | |||

| PCM/Reed | 2–20%/25% | -/-/- | 7.217/7.99/8.673 |

| Flax fiber/Glycerol Carbonate | 0.75%/1% | -/-/- | 3.4/3.4/3.4 |

Table A9.

Dry thermal conductivity data.

Table A9.

Dry thermal conductivity data.

| Additive | Proportion | No Mechanical (Min/Mean/Max) | Compressed (Min/Mean/Max) | Extruded (Min/Mean/Max) |

|---|---|---|---|---|

| Bioadditive | ||||

| Hemp | 1.5–67% | 0.115/0.29/0.43 | 0.06/0.18/1.27 | -/-/- |

| Wheat | 0.3–20% | 0.3032/0.44/0.58 | 0.25/0.44/1.041 | -/-/- |

| Barley | 1–6% | 0.15/0.55/0.87 | 0.155/0.51/0.82 | -/-/- |

| Reed | 3–35% | 0.13/0.16/0.25 | 0.156/0.22/0.32 | -/-/- |

| Olive | 4–40% | 0.428/0.5/0.593 | 0.39/0.49/0.61 | -/-/- |

| Rice | 1–6% | 0.178/0.52/0.65 | 0.19/0.19/0.19 | -/-/- |

| Straw | 0.4–2% | 0.63/0.73/0.84 | 0.26/0.38/0.5 | 0.32/0.39/0.48 |

| Bagasse | 1–6% | 0.45/0.57/0.65 | -/-/- | -/-/- |

| Corn | 1–2% | 0.3/0.44/0.58 | -/-/- | -/-/- |

| Alfa | 1–8% | -/-/- | 0.401/1.15/1.44 | -/-/- |

| Hibiscus cannabinus | 0.2–0.8% | -/-/- | 1.3/1.44/1.57 | -/-/- |

| Kenaf | 1.20% | -/-/- | 0.9/1.33/1.7 | -/-/- |

| Lavender | 3–6% | -/-/- | 0.289/0.31/0.325 | -/-/- |

| Palm | 3–6% | -/-/- | 0.265/0.36/0.49 | -/-/- |

| Pennisetum Setaceum | 8% | -/-/- | 0.333/0.33/0.333 | -/-/- |

| Pumice | 3.50% | -/-/- | 0.15/0.15/0.15 | -/-/- |

| Sawdust | 8% | -/-/- | 0.509/0.51/0.509 | -/-/- |

| Seaweed | 1–4% | -/-/- | 0.4/0.53/0.65 | -/-/- |

| Thatch | 1–4% | -/-/- | 0.485/0.55/0.642 | -/-/- |

| Typha Australis | 15.10–23% | -/-/- | 0.127/0.15/0.163 | -/-/- |

| Fonio | 0.20–1% | -/-/- | 0.37/0.76/1 | -/-/- |

| Grass | -/-/- | -/-/- | 0.121/0.12/0.124 | -/-/- |

| Cocos Nucifera. Canarium Schweinfurthii | 5–15% | -/-/- | 0.19/0.28/0.38 | -/-/- |

| Flax | 1–3% | -/-/- | 0.4/0.69/1.27 | -/-/- |

| Typha australis | 16–33% | -/-/- | -/-/- | -/-/- |

| Geoadditive | ||||

| Lime | 5–15% | 0.892/1.54/2.18 | 0.25/0.79/2.18 | -/-/- |

| Cement | 3–15% | -/-/- | 0.243/0.81/1.47 | -/-/- |

| NaOH | 3% | -/-/- | -/-/- | -/-/- |

| Fiberglass | 1–2% | -/-/- | -/-/- | -/-/- |

| Pozzolan | 10% | -/-/- | -/-/- | -/-/- |

| Calcium Carbide Residue | 5–25% | -/-/- | 0.69/0.81/0.89 | -/-/- |

| Other additive | ||||

| PCM | 5–29% | 0.51/0.51/0.51 | 0.85/1.22/1.42 | -/-/- |

| Geopolymer (NaOH-activated MK) | 5–20% | -/-/- | 0.71/0.77/0.8 | -/-/- |

| Wood biomass ash (domestic wood heating. wood from tree pruning) | 5–20% | -/-/- | 0.748/0.8/0.87 | -/-/- |

| Lignin sulfonate | 1% | -/-/- | 1.87/1.87/1.87 | -/-/- |

| Tannin | 1% | -/-/- | 1.45/1.45/1.45 | -/-/- |

| Sheep Wool | 0.25% | -/-/- | 1.45/1.45/1.45 | -/-/- |

| Guar gum (HydroxyPropyl Guar) | 2.50% | -/-/- | 0.83/0.83/0.83 | -/-/- |

| Paper | -/-/- | -/-/- | -/-/- | -/-/- |

| Oat fiber | 0.20% | 0.58/0.58/0.58 | -/-/- | -/-/- |

| Mix of additive | ||||

| Cement/Pozzolan | 10%/45% | -/-/- | 0.65/0.68/0.71 | -/-/- |

| Cement/sawdust | 10%/9% | -/-/- | 0.5/0.55/0.65 | -/-/- |

| Cement/Agave/cactus mucilage and xanthan gum | 16%/1%/ | -/-/- | 0.846/0.85/0.846 | -/-/- |

| Cement/Agave | 16%/1% | -/-/- | 0.786/0.79/0.786 | -/-/- |

| Cement/wheat straw | 5–10%/1–3% | -/-/- | 0.325/0.47/0.608 | -/-/- |

| Cement/Barley straw | 5–10%/1–3% | -/-/- | 0.38/0.51/0.632 | -/-/- |

| Cement/mining waste | 10%/0–40% | -/-/- | 1.42/1.46/1.58 | -/-/- |

| Gypsum/wheat straw | 5–10%/1–3% | -/-/- | 0.415/0.53/0.64 | -/-/- |

| Gypsum/Barley straw | 5–10%/1–3% | -/-/- | 0.424/0.54/0.64 | -/-/- |

| Cement/Hemp fiber | 5–9%/0.8% | -/-/- | 0.3/0.5/0.58 | -/-/- |

| Natural polymer (Alginate)/ Organic fiber (Sheep wool) | 3%/0.25% | -/-/- | 0.53/0.61/0.68 | -/-/- |

| PCM/Flax Straw | 2–10%/2.5% | -/-/- | 0.65/0.66/0.68 | -/-/- |

| PCM/Reed | 2–20%/25% | -/-/- | 0.134/0.14/0.144 | -/-/- |

| River sand/wheat straw | 80%/0–3.10% | -/-/- | 0.41/0.48/0.6 | -/-/- |

| River sand/wheat straw/cow dung | 80%/0.7–1.60%/6–11% | -/-/- | 0.43/0.83/1.19 | -/-/- |

| Flax fiber/Glycerol Carbonate | 0.75%/1% | -/-/- | 0.518/0.52/0.518 | -/-/- |

| Pozzolan/Microsilica | 10%/1.5% | -/-/- | 0.87/0.87/0.87 | -/-/- |

| Calcium Carbide Residue/Rice Husk Ash | 12–18%/2–8% | -/-/- | 0.64/0.73/0.86 | -/-/- |

| Lime/PCM | 1.6%/17% | 0.72/0.72/0.72 | -/-/- | -/-/- |

| Lime/oat fiver | 2%/0.20% | 0.38/0.38/0.38 | -/-/- | -/-/- |

References

- ADEME. Déchets Chiffres clés, Édition 2023. Annual Report. 2023. Available online: https://librairie.ademe.fr/dechets-economie-circulaire/6108-dechets-chiffres-cles-edition-2023.html (accessed on 1 October 2023).