1. Introduction

Over the years and due to increasing levels of population growth, there was also an accelerated growth of civil construction and, consequently, an increase in the demand for non-renewable resources, the exploitation of natural resources and the generation of waste, both from the construction and demolition, and from agroindustry.

One of the alternatives for the reuse of agroindustry waste is its use as raw material in agglomerated panels. Particleboard is one of the major wood-based products in global trade. Its global demand and production saw an upward trend in recent years. In 2020, the production quantity of particleboard reached 96.01 million m

3 worldwide [

1].

Medium density particleboard (MDP) are formed by wood particles that are consolidated through pressure and heat when joined with synthetic adhesive. The panels have a versatility of applications in several industries, among others, in the furniture, construction and packaging [

2]. Typically, the MDP panels are produced from a lignocellulosic product that and commands the specific weight and provides the high mechanical, biological and physical resistance. Today, panel industries usually use wood from planted forests, especially from the pine and eucalyptus genres, the pines being the most used [

3].

However, due to the great development presented by civil construction and the growth of the furniture sector, the need for raw material also augmented, which leads to the search for other types of materials, giving rise to the alternative of reusing agro-industry waste. A combination of agro-industrial residues particles and adhesives can presented a high potential for application as an eco-friendly, such as interior applications [

4]. Among the lignocellulosic residues with potential for use in the production of MDP are: sugarcane bagasse, rice husk, peanut husk, among others. Some researches carried out studies with the employment of sugarcane bagasse in the production of MDP panels reported its ability for being utilised [

3,

5,

6,

7,

8],. Furthermore, the use of sugarcane bagasse makes it possible to reduce the large-scale use of wood.

The environmental benefits verified with the use of waste depend on variables, such as: the environmental aspects of the waste life cycle, the amount of waste used in the production of panels, the allocation criterion adopted in the life cycle assessment (LCA), and the distance in the transport route from waste to the panel factory. Therefore, to assert the environmental viability of using waste in the production of wood panels, each case must be analysed [

9], considering that bagasse particleboard is a good candidate to substitute conventional wood particleboard due to its better environmental performance [

1].

To make it possible to reuse the material, it is important to consider its life cycle, considering all the steps from the extraction of material and energy resources to the final disposal in the environment, from the cradle to the gate.

Being aware the impacts on the environment caused using waste, the LCA methodology was shown to be a practice that was increasingly studied and improved. This methodology is based on the study of the environmental contributions of each individual stage of a system or product, through the analysis of the quantitative inputs of energy and necessary inputs and the outputs of waste and emissions to the environment [

10]. To guide better choices of products and materials contributing to sustainability, the LCA methodology plays an important role, as it promotes a broader and more consistent view of the impacts generated in all stages of the production of a product.

Therefore, the goal of the present work is to analyse the environmental impacts resulting from the incorporation of sugarcane bagasse in MDP panels, through the life cycle assessment tool. Two scenarios of environmental effects of the life cycle of MDP panels were compared: (i) considering the production with wood commonly used pine chips, and (ii) the manufacture with incorporation of sugarcane bagasse.

2. Results

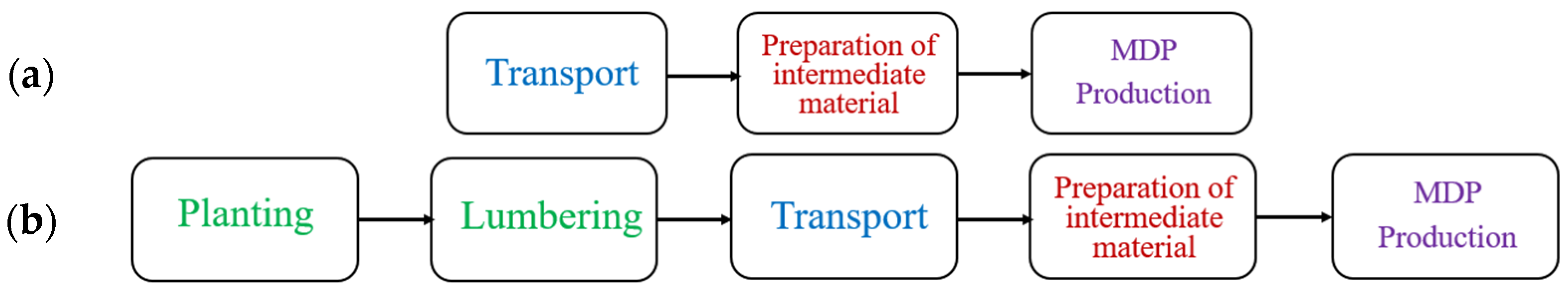

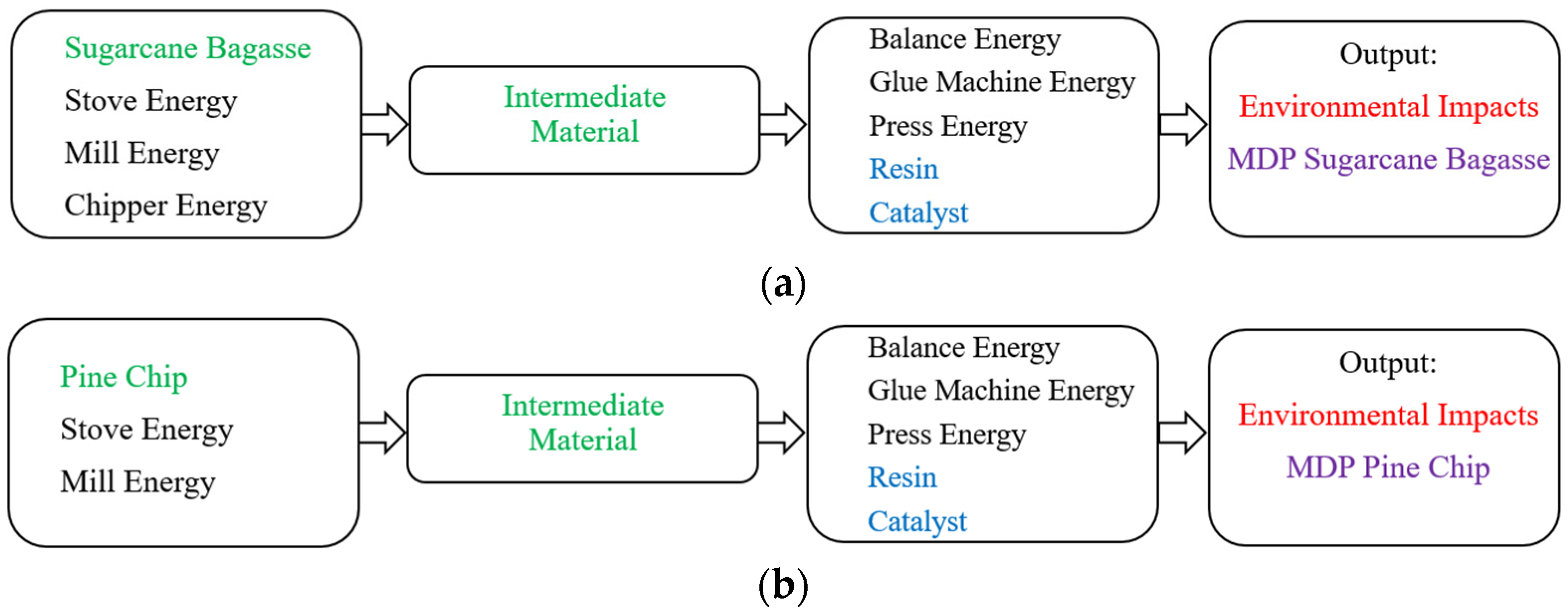

Two scenarios were analysed with the software OpenLCA

® considering the process chain flows of each one as shown in

Figure 1. After obtaining the input data, the flowcharts of each elementary process were arranged, and their respective inputs and outputs were quantified in tables. In the sugarcane bagasse transport process, (Scenario I) is represented in

Figure 2a and the pine chip transport process is represented in

Figure 2b.

For Scenario I, the calculated diesel input was 0.39 L of diesel for the transport of each ton of raw material. The calculation considered 3.4 km per litre of diesel, and the total distance of 8 km, being, therefore, 2.35 L of diesel consumed for the total capacity of 6 tons. As 1 ton was considered for the Functional Unit, the consumption to be considered was 0.39 L of diesel for each ton of sugarcane bagasse transported. The outputs were atmospheric emissions from transport and the amount of sugarcane bagasse transported, as shown in

Table 1.

In the process of transporting the pine chips (Scenario II), the calculated diesel input was 0.98 L of diesel. Considering the same consumption (3.4 km/L of diesel) and capacity (6 tons) of the truck, for the 20 km travelled, 5.88 L diesel will be needed, with 0.98 L of diesel for each ton of raw material. The outputs were the amount of sludge transported and the atmospheric emissions of transport, as shown in

Table 1.

For the production process of the MDP panel the quantities of the input of electric energy and the output of environmental impacts are shown in

Table 2. The software was launched with the numerical data of the stages of the systems analysed, which generated the LCIA report considering the previously specified impact categories.

Table 3 presents the factors for each category in the two scenarios, and considers the outputs from Transportation (Diesel

→ Atmospheric Emissions) and MDP Production Process (Electric Energy

→ CO

2-eq).

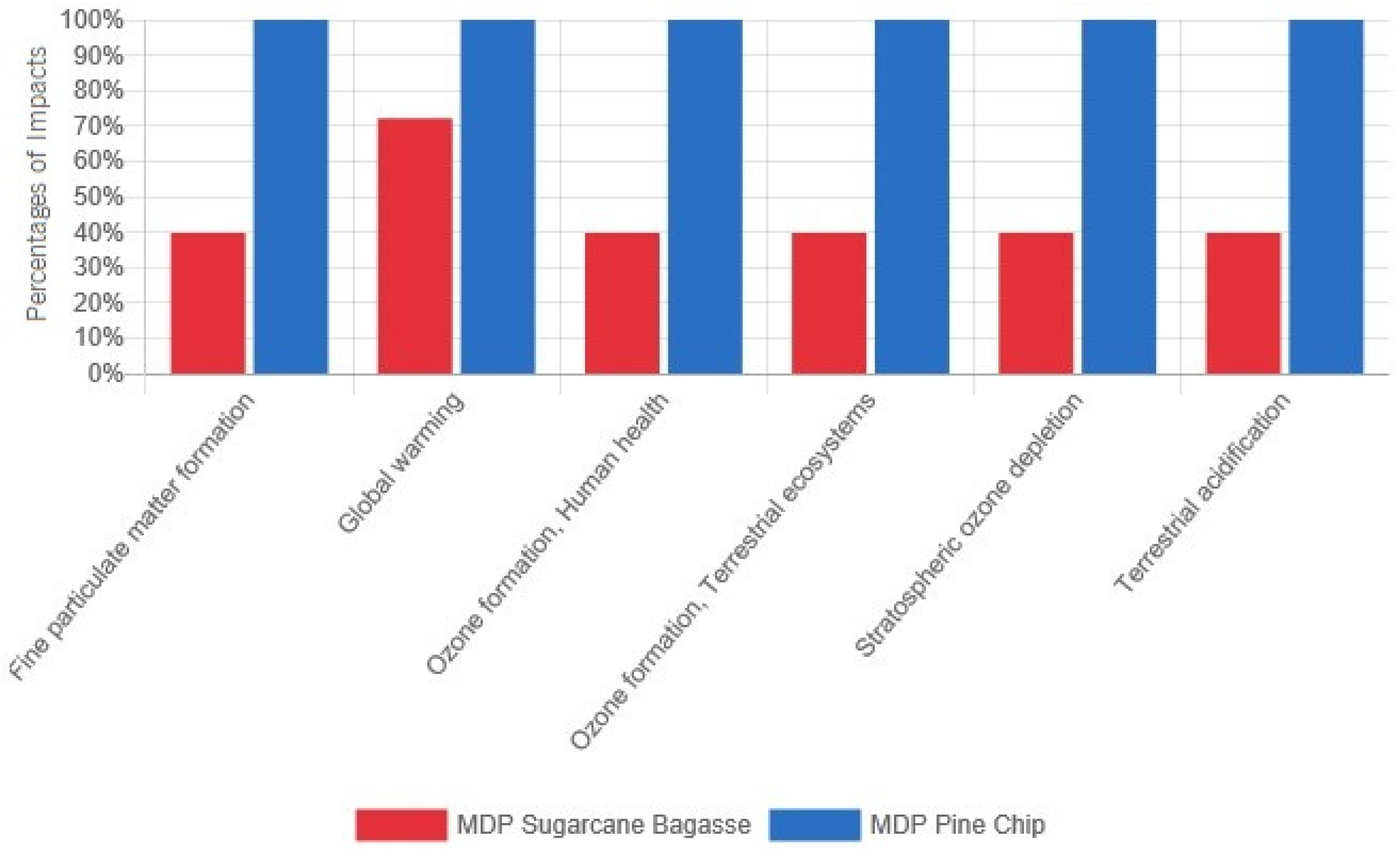

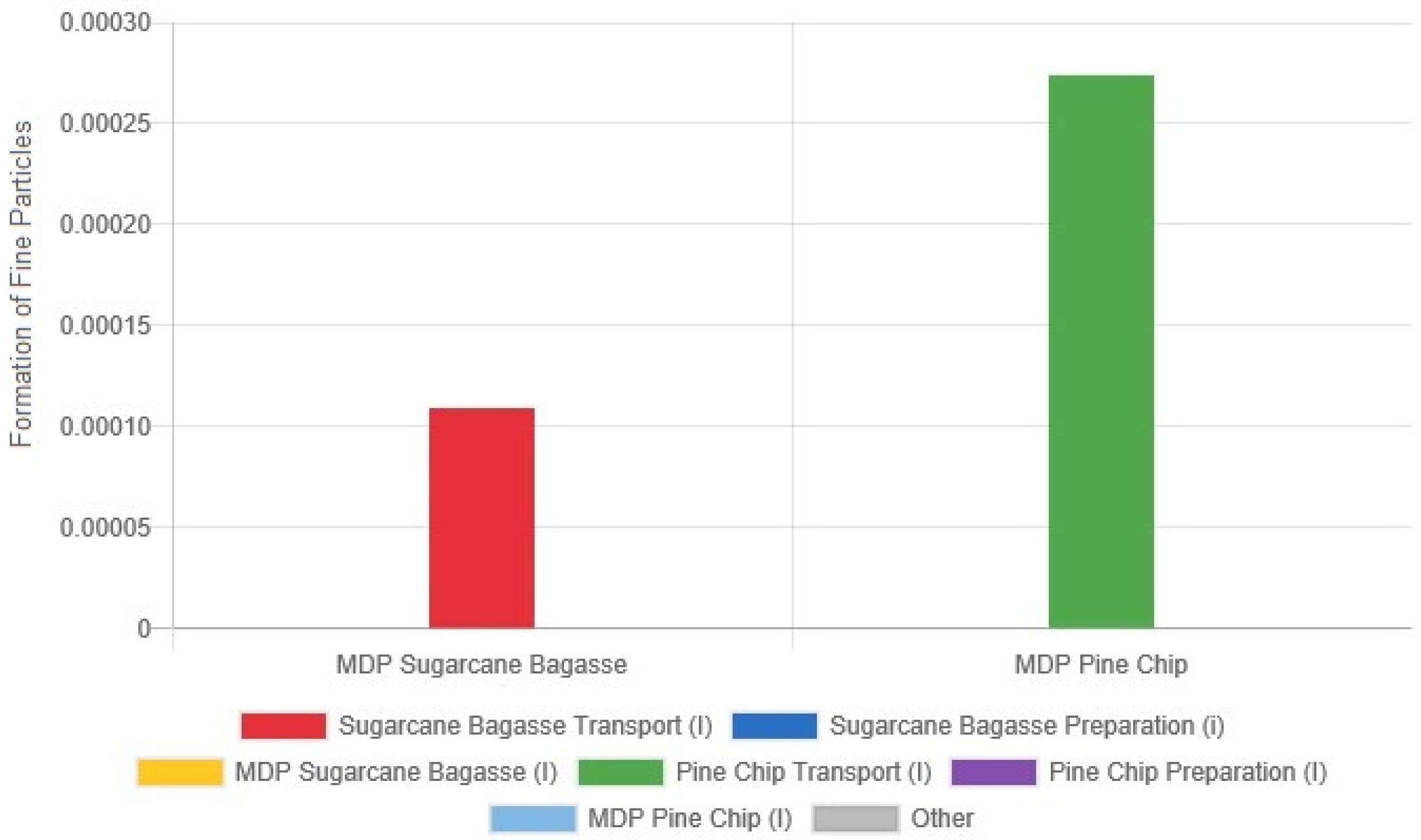

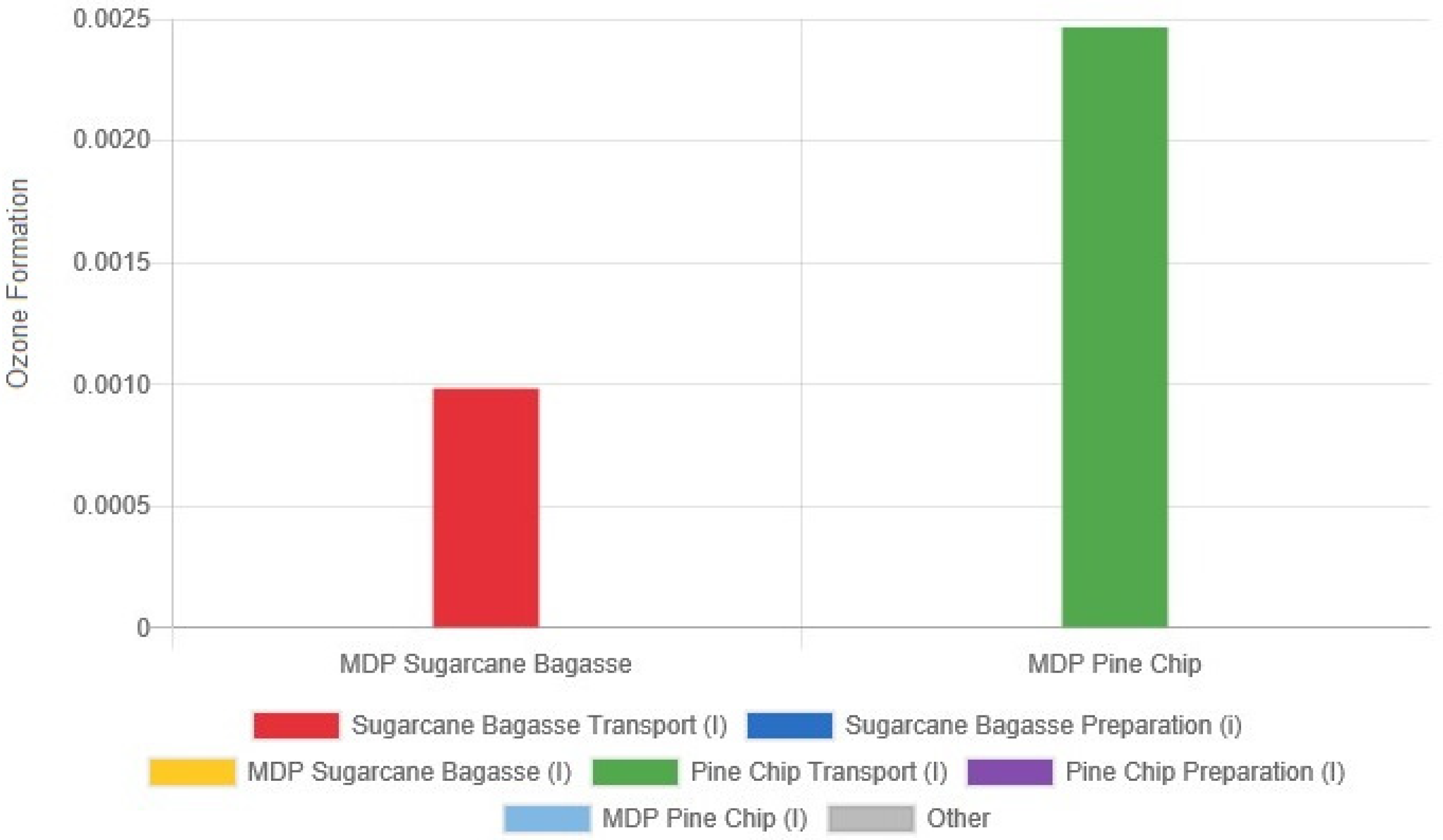

The comparison of the results of each class of impacts generated between Scenario I and Scenario II can be seen in the graph represented in

Figure 3. In

Figure 3, the maximum value in each impact category is defined as being 100%. In the other scenarios, the impacts values are represented as a percentage of the maximum value. In addition, individual graphs of the impact categories were generated, demonstrating the contribution shares of each elementary flow in the resulting value, represented from

Figure 4,

Figure 5,

Figure 6 and

Figure 7.

3. Materials and Methods

Initially, a survey of bibliographic references was carried out on the life cycle of the materials used for the production of MDP panels and the impacts they can generate. A study was also carried out on the LCA methodology and the main methods were applied. During the research, scientific articles, websites, among other sources were consulted.

The construction of the LCA was carried out considering the criteria and recommendations described in the Brazilian standards ABNT-NBR ISO 14040 (2001)—“Environmental management—Life cycle assessment: principles and structure” [

11] and ABNT-NBR ISO 14044 (2014)—“Environmental management—Life cycle assessment: requirements and guidelines” [

12]. They were based on four steps: (i) definition of objective and scope, (ii) inventory analysis, (iii) impact assessment, and (iv) interpretation [

12]. Similar work was proposed by Cangussu; Vasconcelos and Maia (2021) [

13].

In defining the target of the LCA, it was defined that the objective of the research was to evaluate the depletion of natural resources and the environmental impacts associated with atmospheric emissions and the depletion of natural resources in the production chain of the MDP panel, comparing the impacts observed in the system with the incorporation of sugarcane bagasse (Scenario I) and the common production system using pine chips (Scenario II).

In the scope, the limitations of the methodology were defined considering the stages of planting and lumbering (pine—Scenario II); transporting the raw material (sugarcane bagasse and pine chip); preparing the intermediate material to produce MDP; and, finally, the production of the MDP, as shown in

Figure 8. The scope of Scenario I did not consider planting and lumbering, considering that it is a by-product/residue. The flowchart of the production process of the MDP panel, for both scenarios, was prepared taking into consideration the input of electric energy and the output of environmental impacts, reported by

Figure 9.

The analyses of this study were based on obtaining the raw material and production phases. The final distribution of the product was not considered. The study was classified as cradle-to-gate. One ton of respective material—sugarcane bagasse and pine chips—was defined as the Functional Unit (UF). The determination of the UF is important to allow comparing LCA results using a common base [

11]. The UF considered in Scenario I is 1 ton of bagasse, by-product from the extraction of sugarcane juice, obtained after sugarcane milling, obtained in the Municipal Market of the city of Montes Claros-MG. The UF considered in Scenario II, considered 1 ton of pine, arising from planting.

For the analysis and development of the LCA of Scenario II, the elementary flows of diesel oil, grease and lubricating oil from the processes of soil preparation, pre-planting and forest planting of

Pinus sp. were considered, in the period of three years, by author Ribaski et al. [

14]. The author used the calculation method of Impact ReCipe, 2016, Midpoint, and considered as UF the “kg” of input (diesel oil, greases and lubricants) per hectare to produce 1470 seedlings per hectare with the function of preparing soil for forest plantation.

To estimate the environmental emissions related to the lumbering, the methodology proposed in the research of Lorena et al. [

15] was applied. The methodology considers data and equations adapted from Intergovernmental Panel on Climate Change (IPCC) to found CO

2 emissions [

16].

The data referring to the productivity of sheets per ton of raw material were extracted from the work of Ref. [

17]. There was also an addition of resin, responsible for the agglomeration of the particles, and the catalyst, used for the curing process of the adhesive (resin). The content of resin was considered constant in both scenarios. The data were extracted from the research carried out by Santos (2010) in Ref. [

17] wherein the author attested the technical feasibility of its use. For the quantities used in each scenario (1 ton of raw material), the consumption of 152.76 kg of resin and 2.27 kg of catalyst was considered.

The software OpenLCA

® version 1.11 (a free and open access tool) was used for the evaluation of the LCA of the study. The ReCiPe 2016 approach used to assess the impacts. This is a widely used approach and deals with a midpoint approach, characterizing the potential impacts on the environment [

13]. The inventoried data is composed of inputs of energy and of raw material and the outputs are constituted of atmospheric emissions and products. The free library LCIA (Life Cycle Impact Assessment) from OpenLCA

® were used. Other data applied in the research were collected from literary reviews. The environmental analysis proposed in this work was based on the technically viable product documented in Ref. [

5].

To produce the particleboard, the location of the industrial district of the same city was considered. In the transport stage, therefore, from sugarcane bagasse to the industrial district, a distance of 8 km was considered. In the transport flow of the pine chip extraction area, a distance of 20 km was considered, and the collection was carried out from the locality of Campos Eliseos, municipality of the city of Montes Claros-MG, to the industrial district of the same city. The National Inventory of Atmospheric Emissions by Road Vehicles, launched in 2013 by the Ministry of the Environment [

18], was applied to determine in each phase the diesel consumption and the emissions of material transport due to burning the fuel. Transport flows were analysed using a semi-heavy truck, considering a mileage of 3.4 km per litre of diesel consumed to transport 6 tons of freight. The one-way journey of the full truck was considered, given the most favourable condition with return/departure of the full truck for another activity, such as the distribution of finished sheets, not considered in this work.

Table 4 describes the calculations of atmospheric emissions of burning diesel with pre-established factors.

After the sugarcane bagasse is transported, the production process consists of drying the material, using an oven, to eliminate moisture. The bagasse is then crushed, ground and sieved. After the preparation of the intermediate materials, weighing is carried out, the addition of resin and catalyst is carried out. The raw materials are mixed in the glue machine and, finally, the sheet is pressed. To determine the data of this production, the electric energy consumption of the equipment used was calculated. Due to the limitation in carrying out the measurements of each piece of equipment, data from the study were carried out by [

17].

In the study, an electrical magnitude analyser, model “SAGA 4.000”, was considered, which measures voltage, current and power to obtain the electricity consumption from the equipment. For the calculation of atmospheric emissions related to electricity consumption, data were taken from the BEN 2022—Energy Balance 2022 [

19] released by the Ministry of Mines and Energy of Brazil, referring to the year 2021. The report estimates a carbon footprint in the generation of Brazilian electricity of the order of 118.5 kg CO

2-eq/MWh.

In the development of the life cycle impact assessment (LCIA), the categories were selected according to the purpose of the LCA. Moreover, the ones that are typically connected in studies about to the production of particle boards and that are directly affected by atmospheric emissions and depletion of natural resources were considered. The categories of impact were defined, namely: global warming, terrestrial acidification, formation of fine particles, formation of photochemical ozone—effects on human health and ozone formation—terrestrial ecosystems.

Finally, to validate the conclusion of the LCA target and obtain recommendations on the systems analysed, in the interpretation stage, the results of impact assessment and of the data inventory analysis were investigated.

4. Discussion

According to [

20], fine particles increase the density of clouds, making it difficult for sunlight to enter the atmosphere, creating a process known as radiative forcing, which causes a decrease in the frequency of precipitation and acid rain. Considering the formation of fine particles, for Scenario I, a reduction of about 60% was obtained of the generated effects, compared to Scenario II.

Regarding terrestrial acidification, a process that can lead to a decrease in plant nutrients and even soil erosion, Scenario I also showed a decrease of approximately 60% of the generated effects, compared to Scenario II.

In the categories of global warming, a process that causes an increase in the average global surface temperature, and ozone formation (human health and terrestrial ecosystems), there was an average decrease of 49% of the impacts in each one, also from Scenario I in in relation to Scenario II. This difference was due to the transport and production processes. In transport, due to the location of each raw material and, in production, caused by the percentages of emissions from each type of plate manufacturing.

In addition to the environmental impacts generated by transportation and the production process, other stages contribute to environmental degradation. The results shown in

Table 5 adapted from Ref. [

14] demonstrate the impacts for the planting of pine, a step that is spared by the use of sugarcane bagasse residue. In this research, 1470 pine seedlings were planted in one hectare. Considering that the average final production for the species is 40 m

3/ha [

21], and de pinus density ~450 kg/m

3, it can be estimated that the impacts found refer to 18 tons of pine. Since the UF used in this work was 1 ton of raw material, the impacts found for diesel transport in Ref. [

14] were calculated in the order of 1/18 to Scenario II, as an estimate of the impacts generated by the planting of pine in this case.

The calculation to estimate atmospheric emission (CO

2) from the lumbering takes into account the wood biomass (1 ton = 1000 kg), the carbon content (42%) of the biome Cerrado and the stoichiometric constant 3.6667 [

15], resulting in 1541.01 kg of carbon stock for the each 1 ton of cut pine. It is important to mention that when a tree is cut down, in addition to ceasing its absorption of carbon dioxide, through decomposition or burning, the carbon stock stored in it is released into the atmosphere.

The PEVS 2021 (Production of Vegetal Extraction and Silviculture), from the Brazilian Institute of Geography and Statistics (IBGE), reported that the area of planted forests in Brazil is 9.5 million hectares, with the Pinus area corresponding to 1.8 million hectares [

22]. For the cultivation of Pinus, according to Brazilian Agricultural Research Corporation (EMBRAPA) [

21], 40 m

3/ha are produced annually, that is, 72 million cubic meters of pine being produced in Brazil per year. According to PEVS 2021 [

22], of the total amount of pine production, 26.5% is destined to the production of logs for “other purposes” that are not pulp and paper (30.3%), firewood (11.2%), charcoal (27.6%) and non-timber (4.4%), as can be seen in

Figure 10. Then, if it is considered that, of this amount, 1% is used for the manufacture of MDP, it has 190, 800 cubic meters of pine, which means that opting for the replacement of sugarcane bagasse residues would correspond to a saving of 4770 ha of pine.

Considering the UF of 1 ton of pine (10,000 kg), pine density of 450 kg/m3 and forest result corresponding of 40 m3/ha, it can be concluded that for each ton of pine not used with the use of sugarcane bagasse, 555 m2 of pine forest would be saved.

The impacts generated by pine begin in reforestation forests. According to Ref. [

24], studies that were carried out indicated that the cultivation of pine causes beneficial physical changes to the environment. However, chemical changes are not favourable to the soil. In studies carried out by [

25] in the Canela/RS/BR region, it was found that the impacts caused by the planting of extensive reforestation areas include the pollution of water resources, damage to the health of the population, loss of biodiversity, rural exodus, among other socio-environmental damages [

26].

Research carried out by Ref. [

25] found that large areas of native vegetation gave way to pine plantations. The abundant wealth of native vegetation is slowly being replaced by pine cultivation. In many places, where the wood from the crops was removed, the soil was apparently destroyed. Among the negative points, in addition to the areas that present a strong erosive process, are the accumulation of organic matter from the removal of wood; heavily compacted areas, resulting from the use of heavy machinery; large use of agrochemicals; disappearance of native species of flora and fauna; the appearance of “pests” and the visible change in the landscape [

25].

From another perspective, considering the disposal of sugarcane bagasse residue (Scenario I) in a sanitary landfill, the primary factor is the volumetric amount that the amount of bagasse produced would need (space to be packed), since, in addition to environmental risks, such as, methane gas emissions, groundwater pollution, leaching, and soil contamination, there is also the difficulty of finding suitable areas to receive new landfills [

27].

The National Supply Company in Brazil released sugarcane production for the 2021/2022 harvest at ~8.3 million hectares [

28], with an average productivity of ~70.35 ton/ha. Considering that of this total of 583.9 million tons of sugarcane produced, 12% is transformed into bagasse [

29], there was, therefore, the generation of 70 million tons of bagasse in Brazil in 2021. If it considers that 10% corresponds to waste (garbage) that could be transformed into plate, 7 million tons can be considered as savings for the landfill.

For the volumetric amount of sugarcane bagasse, the compacted unit mass of 213.05 kg/m

3 can be considered [

30]. Compaction expels air from empty spaces and leads to a decrease in its volume [

31], considered, thus, the lowest consumption of landfill volume. To calculate the volume of landfill required for the disposal of the bagasse, considering the non-reuse of the residue with the MDP production, the 7 million tons would require approximately 32.85 million m³ for packaging.

5. Conclusions

Applying the life cycle assessment methodology, the results obtained allow us to conclude that the production of MDP panels with sugarcane bagasse has lower environmental impacts in all the impact categories studied than considering MDP panels produced with wood from pine chips. It should be noted that the study was carried out with a focus on atmospheric emissions and consumption of materials in the cradle-to-gate stages, transport, sheet production and MDP production.

The results found by the LCA denote potential impacts. However, they are not accurately representing the actual effects cause because the results obtained are correlated to specific attributes of the impacted regions.

Thus, the production of agglomerated MDP panels with sugarcane bagasse was shown to be an environmentally viable alternative, resulting in environmental gains from the insertion of the material in the production chain. The benefits range from the reduction in waste disposed of in landfills, which increase its useful life, the lower demand for reforestation, with steps that generate atmospheric emissions and degrade the soil, among other environmental impacts.

Considering the area of planted pine forests in Brazil, considering 0.265% of production destination to MDP, the choice of replacing sugarcane bagasse residues would correspond to a saving of 4770 ha of pine. For the considered UF of 1 ton of pinewood, 555 m2 of forest would be saved.

Regarding sugarcane, considering 10% of the annual Brazilian production, it is estimated that 7 million tons of sugarcane bagasse could be considered as savings for the landfill, which corresponds to approximately 32.85 million m3 for packaging.

As a suggestion for future work, it is suggested to study the economic viability of the production of panel produced with sugarcane bagasse.