A Study on the Calculation of the Standard Recycling Cost of PVC Profiles and Flooring Waste in Korea

Abstract

1. Introduction

2. Results and Discussion

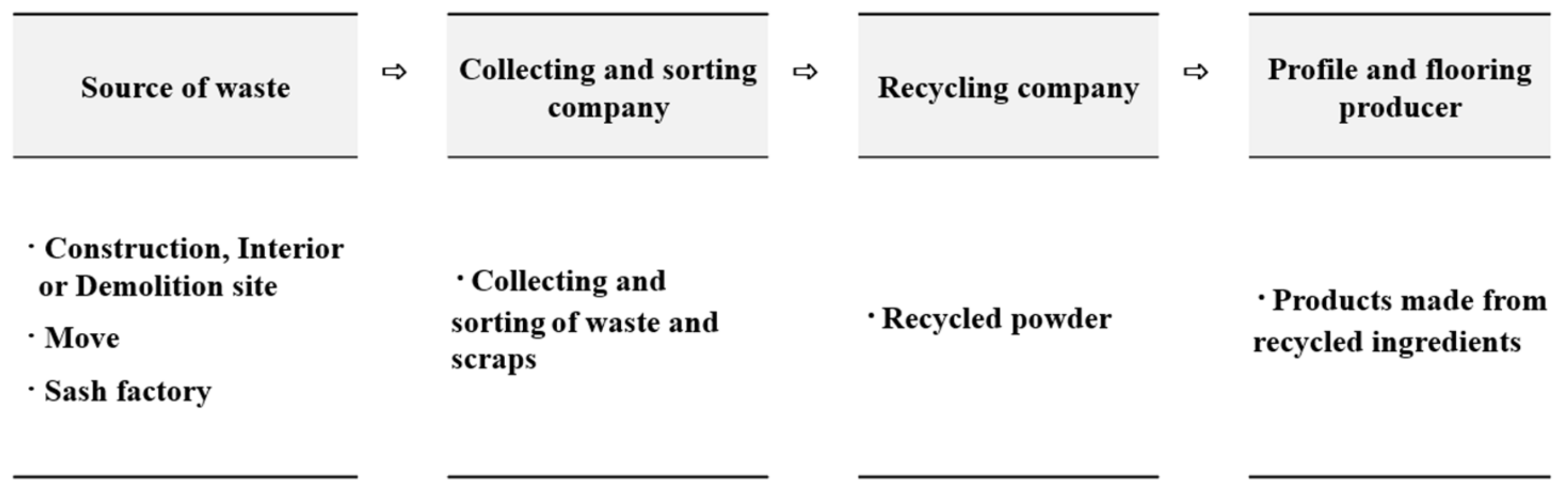

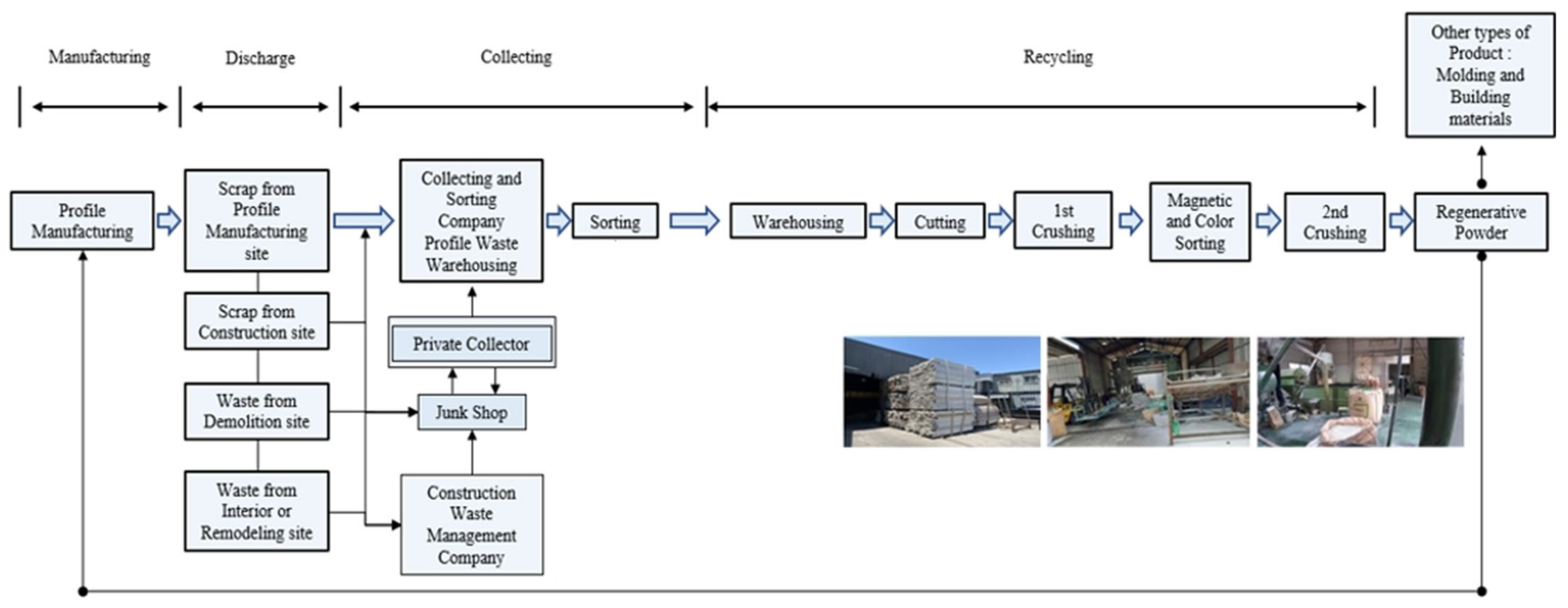

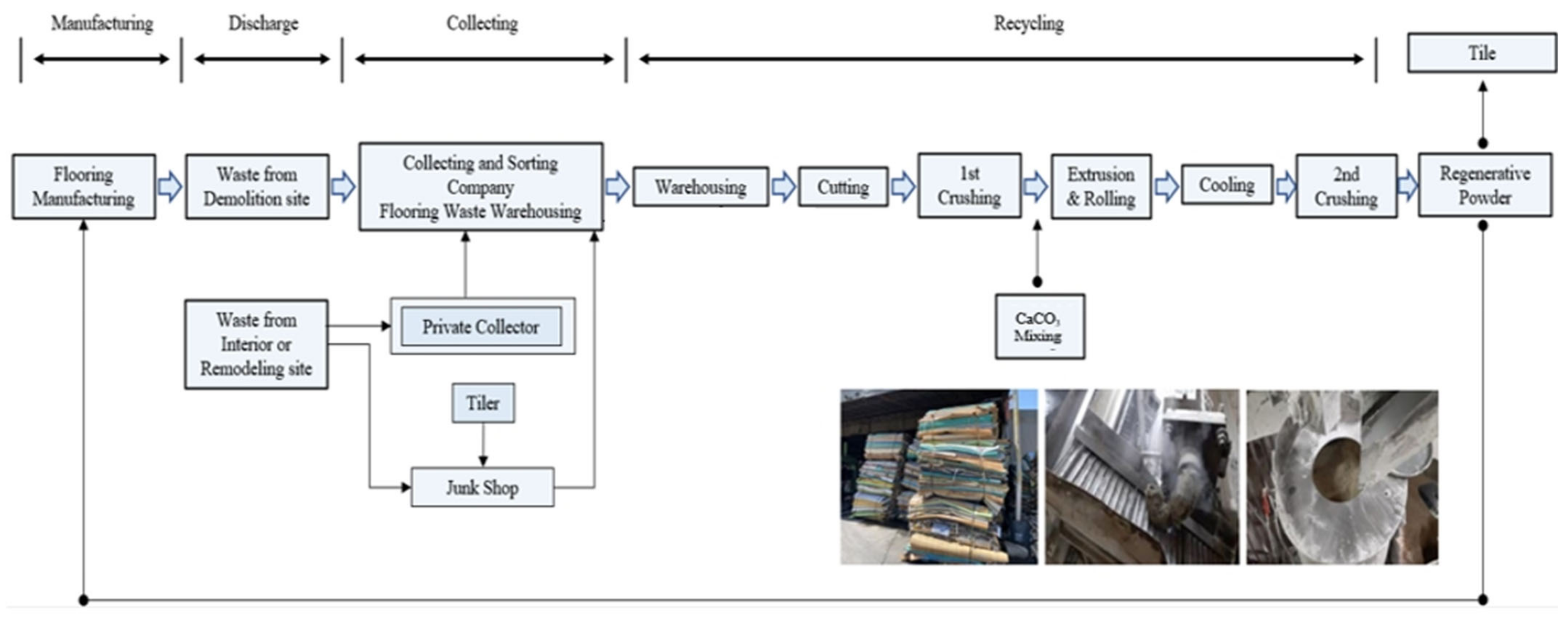

2.1. Recycling System for Profiles and Flooring

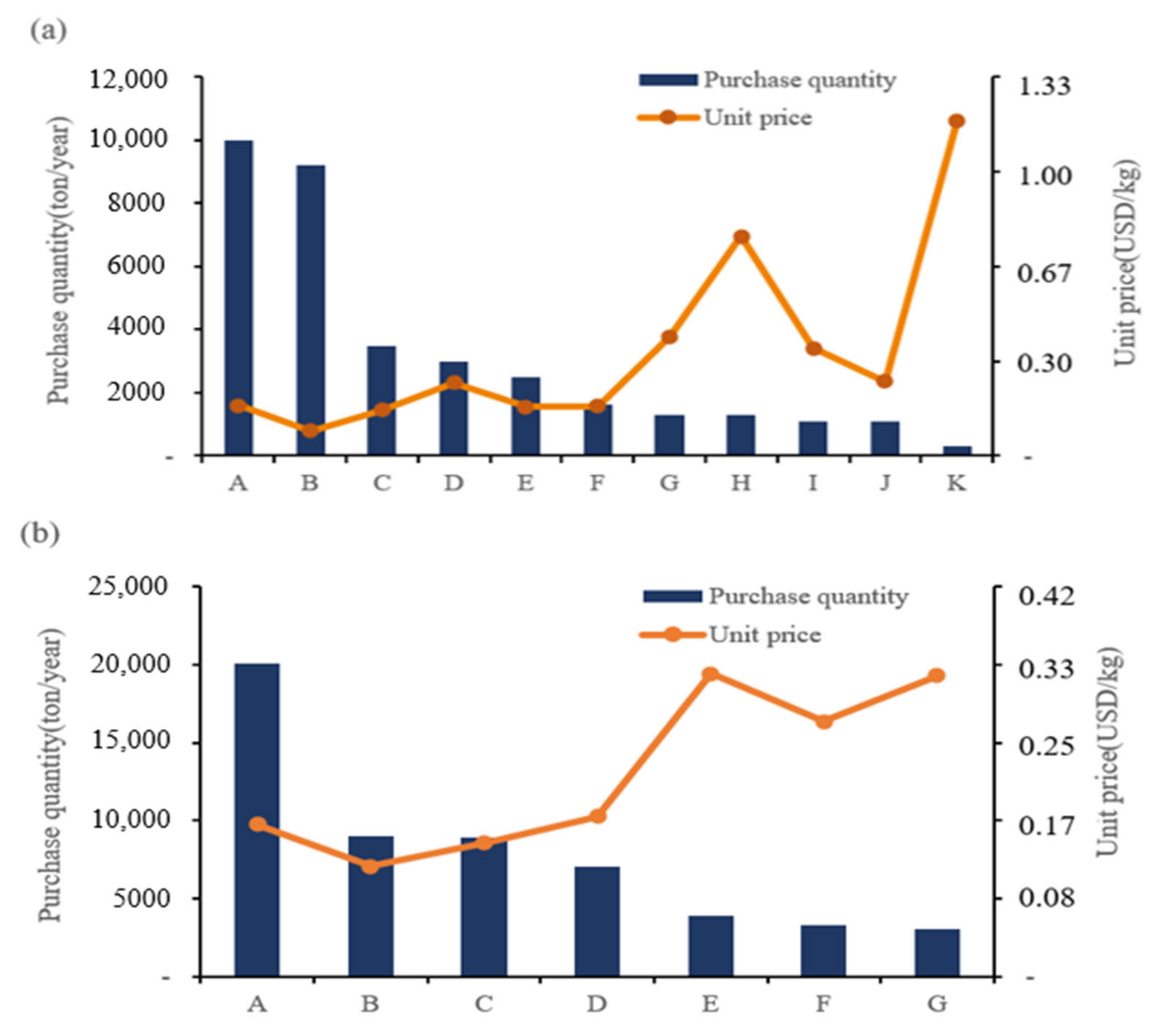

2.2. Cost Analysis to Calculate Recycling Standard Cost

2.3. Results of Total Recovery and Recycling Market Size Estimation

3. Materials and Methods

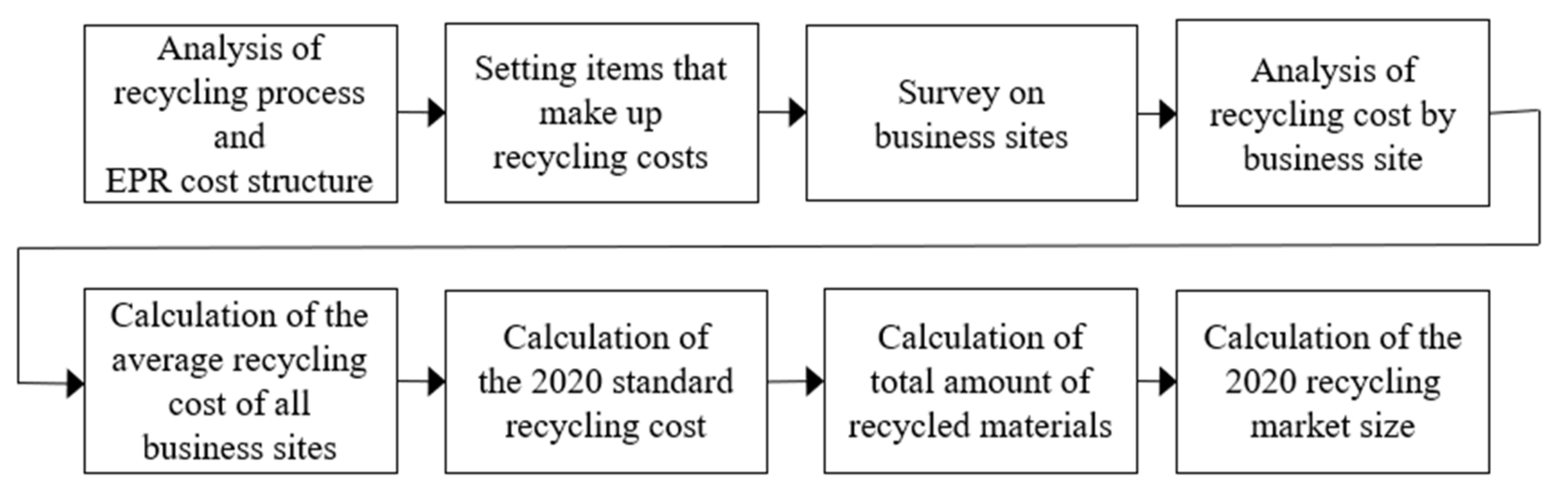

3.1. Research Procedures and Methods

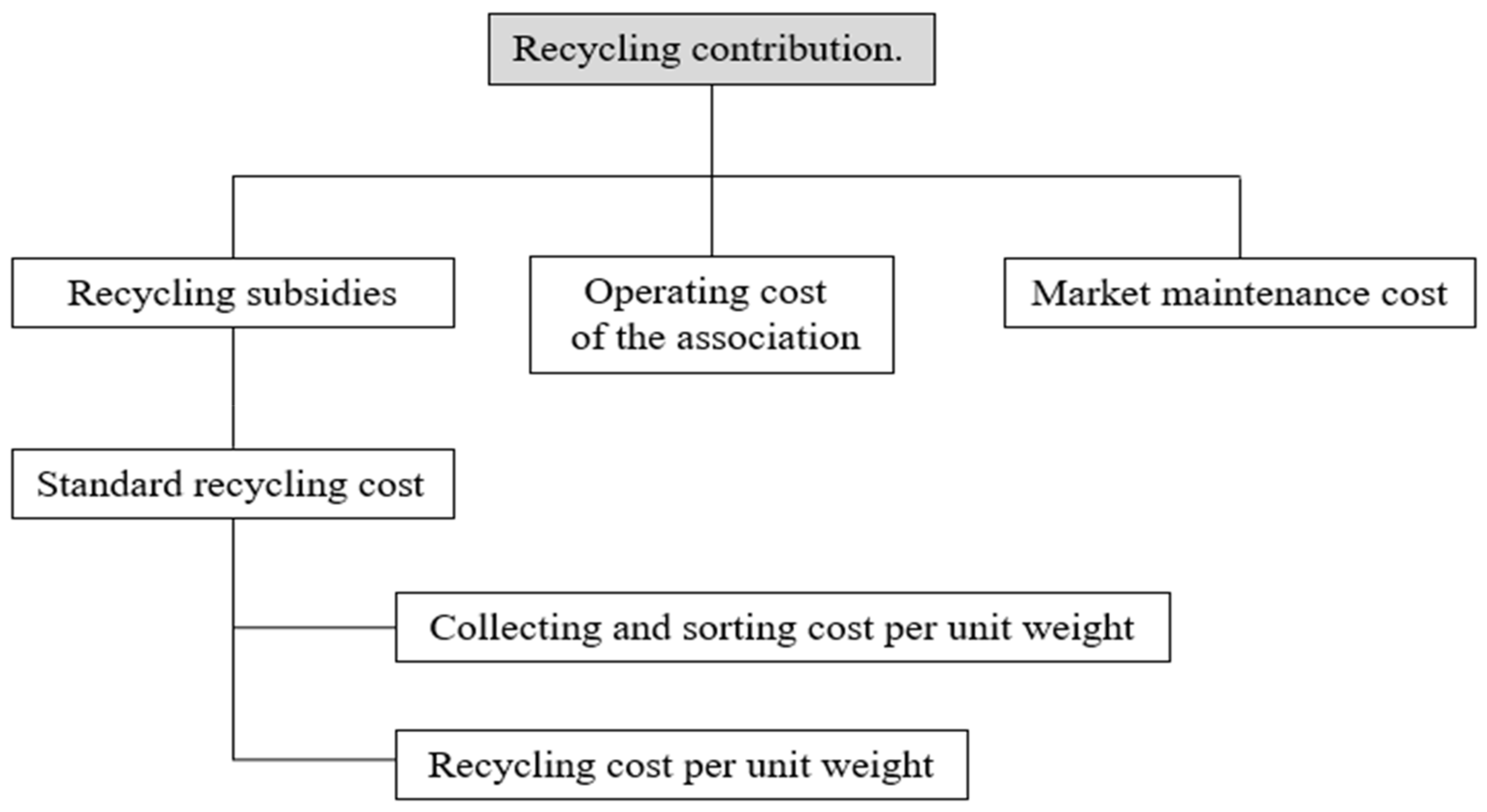

3.2. Analysis of the Cost Structure of the EPR System

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- PlasticsEurope. Plastics—The Facts 2017. An Analysis of European Plastics Production, Demand and Waste Data, (2017); PlasticsEurope: Brussels, Belgium, 2018. [Google Scholar]

- PVC Applications. Available online: https://pvc.org/pvc-applications/pvc-in-building-and-construction/ (accessed on 21 June 2021).

- Article 12, The Act on the Promotion of Saving and Recycling of Resources. Available online: https://www.law.go.kr/%EB%B2%95%EB%A0%B9/%EC%9E%90%EC%9B%90%EC%9D%98%EC%A0%88%EC%95%BD%EA%B3%BC%EC%9E%AC%ED%99%9C%EC%9A%A9%EC%B4%89%EC%A7%84%EC%97%90%EA%B4%80%ED%95%9C%EB%B2%95%EB%A5%A0 (accessed on 21 June 2021).

- Korea Petrochemical Industry Association, Statistics of Synthetic Resin Production and Sales. Available online: https://www.kpia.or.kr/ (accessed on 13 June 2021).

- Enforcement Decree, The Act on the Promotion of Saving and Recycling of Resources. Available online: https://www.law.go.kr/LSW//lsBylInfoP.do?bylSeq=14591017&lsiSeq=236855&efYd=20230101, (accessed on 14 June 2022).

- KS M 3802, Floorcovering—PVC. Available online: https://standard.go.kr/KSCI/standardIntro/getStandardSearchView.do?pageIndex=1&pageUnit=10&ksNo=KSM3802&tmprKsNo=KSM3802&reformNo=19&menuId=919&topMenuId=502&upperMenuId=503 (accessed on 14 June 2022).

- Cho, Y.A.; Kim, W.I.; Kim, M.S.; Kang, Y.Y.; Shin, S.K. Exposure characteristics of VOCs from living spaces regarding floor materials. J. Korea Soc. Waste Manag. 2016, 33, 558–564. [Google Scholar] [CrossRef]

- Miliute-Plepiene, J.; Fråne, A.; Almasi, A. Overview of polyvinyl chloride (PVC) waste management practices in the Nordic countries. Clean. Eng. Technol. 2021, 4, 100246. [Google Scholar] [CrossRef]

- Kim, M.S.; Park, S.A.; Kim, S.H. A Comparative Analysis on the Internal and External Characteristics of Power Cord Plugs Using New PVC and Regenerated PVC. In Proceedings of the Korean Society of Production and Manufacturing Autumn Conference Paper Collection, 2018. p. 41. Available online: https://www.dbpia.co.kr/pdf/pdfView.do?nodeId=NODE07542895&googleIPSandBox=false&mark=0&ipRange=false&accessgl=Y&language=ko_KR&hasTopBanner=true (accessed on 13 March 2021).

- Zhao, Y.; Liang, H.; Wu, D.; Bian, J.; Hao, Y.; Zhang, G.; Liu, S.; Zhang, H.; Dong, L. Poly (1,2-propylene glycol adipate) as an environmentally friendly plasticizer for poly(vinyl chloride). Polymer 2015, 39, 247–255. [Google Scholar]

- Chun, I.S.; Kim, Y.J. Effect of Plasticizer on Automobile Plastic Materials. In Proceedings of the Spring Conference of the Korea Automotive Engineering Association, 2013. pp. 2110–2115. Available online: https://www.dbpia.co.kr/pdf/pdfView.do?nodeId=NODE02175167&googleIPSandBox=false&mark=0&ipRange=false&accessgl=Y&language=ko_KR&hasTopBanner=true (accessed on 14 June 2022).

- Shin, S.M.; Jeon, H.S. Chemical structure, and PVC shape after dehydrochlorination of PVC. J. Korean Inst. Res. Recycl. 2014, 13, 37–42. [Google Scholar]

- Chantreux, M.; Ricard, D.; Asia, L.; Rossignol, S.; Wong-Wah-Chung, P. Additives as a Major Source of Radiolytic Organic Byproducts of Polyvinyl Chloride (PVC). Radiat. Phys. Chem. 2021, 188, 109671. [Google Scholar] [CrossRef]

- Park, C.H.; Jeon, H.S.; Yu, H.S.; Han, O.H.; Park, J.K. Application of Electrostatic separation to the recycling of plastic wastes: Separation of PVC, PET, and ABS. Environ. Sci. Technol. 2008, 42, 249–255. [Google Scholar] [CrossRef] [PubMed]

- Min, D.K.; Jung, O.J. A Study on the transboundary movement of PVC scrap. Korea Soc. Environ. Admin. 2013, 1, 39–43. [Google Scholar]

- Phae, C.G.; Jung, O.J. Investigation on material flow diagram for PVC (poly vinyl Chloride) profile based production, Generation, Recycling and Treatment. Elastom. Compos. 2012, 47, 129–140. [Google Scholar] [CrossRef]

- Jamialahmadi, N. Recycling of mixed plastic wastes containing PVC. In Proceedings of the 7th International Conference on Compasites: Characterization, Fabrication and Application (CCFA-7), Tabriz, Iran, 23 December 2020. [Google Scholar]

- Seike, T.; Isobe, T.; Harada, Y.; Kim, Y.; Shimura, M. Analysis of the efficacy and feasibility of recycling PVC sashes in Japan. Resour. Conserv. Recycle 2018, 131, 41–53. [Google Scholar] [CrossRef]

- Lee, J.H.; Won, J.C.; Lee, Y.H.; Choi, G.Y. The technic of PVC recycling. Polym. Sci. Technol. 2002, 13, 332–341. [Google Scholar]

- Koyama, A.; Yamaguchi, K. Study on the properties of the recycled sheet with multiple kinds of the PVC construction waste. J. Struct. Constr. Eng. 2016, 81, 211–218. [Google Scholar]

- Kim, W.; Lee, S.B.; Gyoung, J.H.; Lim, J.H.; Kwon, H.M. A Study on the Improvement of Fluidity and Heat Resistance of PVC Compound with Eco-Plasticizer. In Proceedings of the Autumn Conference of the Korean Society of Manufacturing Technology Engineers, 2018. p. 42. Available online: https://www.dbpia.co.kr/pdf/pdfView.do?nodeId=NODE07542896&googleIPSandBox=false&mark=0&ipRange=false&accessgl=Y&language=ko_KR&hasTopBanner=true (accessed on 13 March 2021).

- Bonadies, I.; Avella, M.; Avolio, R.; Carfagna, C. PVC/CaCO3 Nanocom- posites: Influence of nanoparticle surface treatment on properties. In AIP Conference Proceedings; American Institute of Physics: University Park, PA, USA, 2010; Volume 1255, pp. 162–164. [Google Scholar]

- Seike, T.; Kim, Y.; Isobe, T.; Murakami, N.; Shimoyama, H.; Ono, S.; Kigawa, M. Study on constructing of recycling system of PVC sash: Verification of the possibility of used PVC window recycling. AIJ J. Technol. Des. 2015, 21, 423–427. [Google Scholar] [CrossRef]

- Available online: https://www.law.go.kr/%ED%96%89%EC%A0%95%EA%B7%9C%EC%B9%99/(%EA%B3%84%EC%95%BD%EC%98%88%EA%B7%9C)%EC%98%88%EC%A0%95%EA%B0%80%EA%B2%A9%EC%9E%91%EC%84%B1%EA%B8%B0%EC%A4%80 (accessed on 13 June 2021).

- Tailor, A.; Solanki, B.; Padariya, N.; Patel, P.; Thanki, S. Implementation of material flow cost Accounting (MFCA) in Manufacturing SME: A case study. Productivity 2017, 58, 53–63. [Google Scholar]

- Available online: https://www.law.go.kr/LSW/lsBylInfoPLinkR.do?lsiSeq=249113&lsNm=%EB%B2%95%EC%9D%B8%EC%84%B8%EB%B2%95+%EC%8B%9C%ED%96%89%EA%B7%9C%EC%B9%99&bylNo=0006&bylBrNo=00&bylCls=BE&bylEfYd=20230320&bylEfYdYn=Y (accessed on 13 June 2021).

- Available online: https://ecos.bok.or.kr/mobile/#/StatisticsByTheme/KoreanStat100/K402 (accessed on 10 June 2021).

| Category | Amount and Cost | Comment | ||

|---|---|---|---|---|

| Profile | Flooring | |||

| Purchase volume | 10,500 tons | 21,105 tons | Additional correction of process loss rate of 5% to total sales volume | |

| Purchase price | 0.17 | 0.17 | Cost of purchasing from junk shops, collecting individuals, and agencies. | |

| Collecting cost | 1,750,000 | 3,517,500 | ||

| The 1st sorting | 438,161 | 20 people (based on overseas workers) | Profile | |

| Reinforcement; wheel removal | ||||

| Flooring | ||||

| Silicone, tape, and edge removal | ||||

| The 2nd sorting | 328,621 | 15 people (based on overseas workers) | Profile | |

| Plastic film; other substances removal and cutting | ||||

| Total sorting cost | 766,782 | 766,782 | ||

| Total cost | 2,516,782 | 4,284,282 | ||

| The unit cost | 0.24 | 0.20 | ||

| Profile Company | Amount of Raw Materials Purchased (Ton/Year) | Ratio | Unit Cost (USD/kg) | Flooring Company | Amount of Raw Materials Purchased (Ton/Year) | Ratio | Unit Cost (USD/kg) |

|---|---|---|---|---|---|---|---|

| A | 10,000 | 28.6% | 0.18 | A | 20,100 | 36.5% | 0.16 |

| B | 9231 | 26.4% | 0.09 | B | 9000 | 16.3% | 0.12 |

| C | 3500 | 10.0% | 0.16 | C | 8900 | 16.1% | 0.14 |

| D | 3000 | 8.6% | 0.26 | D | 7000 | 12.7% | 0.17 |

| E | 2500 | 7.2% | 0.17 | E | 3850 | 7.0% | 0.32 |

| F | 1636 | 4.7% | 0.18 | F | 3270 | 5.9% | 0.27 |

| G | 1290 | 3.7% | 0.42 | G | 3000 | 5.4% | 0.32 |

| H | 1300 | 3.7% | 0.77 | - | - | - | |

| I | 1100 | 3.1% | 0.38 | - | - | - | |

| J | 1100 | 3.1% | 0.26 | - | - | - | |

| K | 300 | 0.9% | 1.16 | - | - | - | |

| The standard cost for recycling profile (USD/kg) | 0.21 | The standard cost for recycling flooring (USD/kg) | 0.18 | ||||

| Items | Collecting and Sorting Unit Cost (A) | Recycling Unit Cost (B) | Standard Recycling Cost (A + B) |

|---|---|---|---|

| Profile | 0.24 | 0.21 | 0.45 |

| Flooring | 0.18 | 0.18 | 0.36 |

| Price and Percentage (Unit: USD) | Quality Level | Weighted Average Price | |||

|---|---|---|---|---|---|

| High | Medium | Low | |||

| Profile | Percentage (%) | 60.2 | 29.7 | 10.1 | - |

| Purchase price | 0.47 | 0.33 | 0.17 | 0.40 | |

| Sale price | 0.85 | 0.55 | 0.36 | 0.71 | |

| Flooring | Percentage (%) | 46.6 | 38.3 | 15.1 | - |

| Purchase price | 0.25 | 0.20 | 0.06 | 0.20 | |

| Sale price | 0.54 | 0.35 | 0.22 | 0.42 | |

| Scope of Market | Collecting Market | Recycled Ingredients Market | Sub-Total | Total | |

|---|---|---|---|---|---|

| Voluntary Agreement participating market | Profile | 20.4 | 35.0 | 55.4 | 102.3 |

| Flooring | 15.6 | 31.4 | 47.0 | ||

| The entire market | Profile | 21.6 | 37.0 | 58.6 | 113.6 |

| Flooring | 18.2 | 36.7 | 54.9 | ||

| Classification of Cost | Formula to Calculate the Cost |

|---|---|

| (1) Standard recycling cost | = Recovery cost (collecting/transport cost + sorting cost) + Recycling cost |

| (2) Recycling subsidies (costs to support recycling companies by reflecting the cost of purchasing and selling valuables) | = Standard recycling cost − Renewable value (Availability of recycled resources) |

| (3) Recycling share cost | = Recycling subsidies + EPR system operating cost (association (a mutual aid association) operating cost) + Recycling promotion cost such as education, publicity, and technology development + Market maintenance cost |

| Comments | ||

|---|---|---|

| Analysis Target Companies | Profile |

|

| Flooring |

| |

| Items | Details |

|---|---|

| Labor costs |

|

| Depreciation costs |

|

| Present value of investment costs |

|

| Use of weighted average in the calculation of the standard recycling cost |

|

| Type of Worker | Personnel Expense (USD/Month) | Comment | |

|---|---|---|---|

| Office worker | 3488 | Office job | |

| Machine Operator | 2838 | Device operation and assembly | |

| Labor workers (Korean) | 1833 | Simple labor | |

| Labor workers (foreigner) | 1519 | The minimum hourly wage standard | |

| Insurance | Rate (%) | ||

| Total Rate | Employee’s Share | Employer’s Share | |

| National pension | 9 | 4.5 | 4.5 |

| health insurance | 6.67 | 3.335 | 3.335 |

| Long-term care insurance | 10.25% of health insurance | 50% | 50% |

| Employment insurance | 1.85 | 0.925 | 0.925 |

| Industrial accident insurance | 2 | 2 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, D.-W.; Kim, K.; Baek, C.-R.; Phae, C.-G. A Study on the Calculation of the Standard Recycling Cost of PVC Profiles and Flooring Waste in Korea. Recycling 2023, 8, 37. https://doi.org/10.3390/recycling8020037

Kim D-W, Kim K, Baek C-R, Phae C-G. A Study on the Calculation of the Standard Recycling Cost of PVC Profiles and Flooring Waste in Korea. Recycling. 2023; 8(2):37. https://doi.org/10.3390/recycling8020037

Chicago/Turabian StyleKim, Do-Wan, Kyung Kim, Choong-Real Baek, and Chae-Gun Phae. 2023. "A Study on the Calculation of the Standard Recycling Cost of PVC Profiles and Flooring Waste in Korea" Recycling 8, no. 2: 37. https://doi.org/10.3390/recycling8020037

APA StyleKim, D.-W., Kim, K., Baek, C.-R., & Phae, C.-G. (2023). A Study on the Calculation of the Standard Recycling Cost of PVC Profiles and Flooring Waste in Korea. Recycling, 8(2), 37. https://doi.org/10.3390/recycling8020037